Page 1

TI00459C/07/EN/15.19

71447514

2019-07-31

Products Solutions Services

Technical Information

Viomax CAS51D

Photometric sensor for SAC or nitrate measurement

Application

SAC measurement

• Organic load in WWTP inlet

• Organic load WWTP outlet

• Discharger monitoring

• Organic load in drinking water

Nitrate measurement

• Nitrate measurement in natural bodies of water

• Monitoring nitrate content in WWTP outlet

• Monitoring nitrate content in aeration basins

• Monitoring and optimizing denitrification phases

Your benefits

• Affordable, environmentally friendly product

• No complicated sampling and treatment

• Chemical-free measurement

• Low-maintenance

• Data conditioning in the sensor

• Minimum sensitivity to interference during signal

transmission

• Short response time

• Early, continuous detection of load peaks without delay

• Ready for use thanks to factory calibration

• Standardized communication (Memosens technology)

enables "plug and play"

• Very long maintenance intervals thanks to compressed air

cleaning

• Customer calibrations with 1 - 5 points (max.) - in the lab or

at place of installation

Page 2

Function and system design

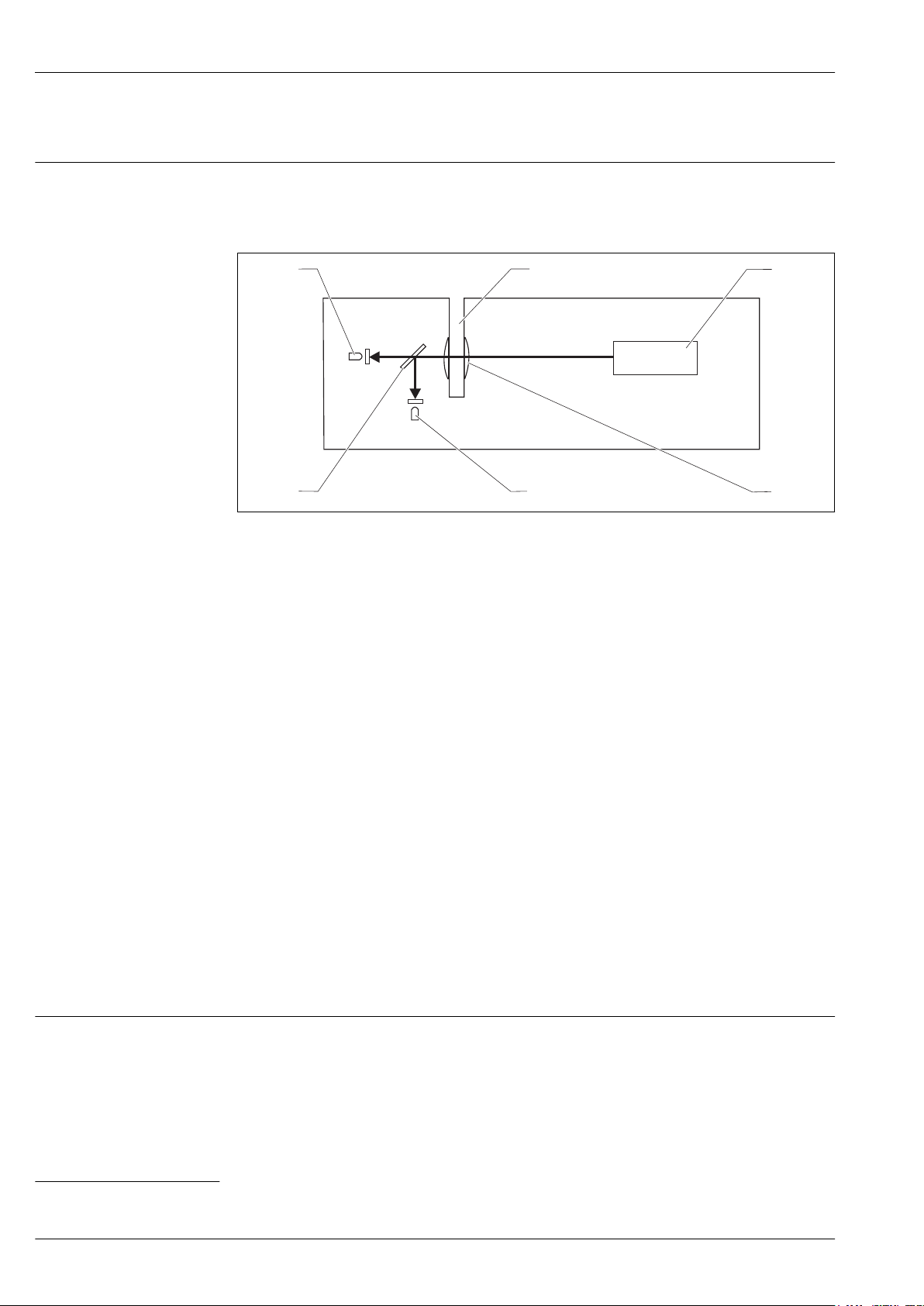

1

2

3

4

56

Viomax CAS51D

Measuring principle

The light from a pulsed, high-stability strobe lamp (item 3) passes through the measuring path

1)

(item 2). A beam splitter (item 6) directs the light beam to the two receivers (items 1 and 5). A filter

upstream from the receivers only lets through light in the measuring wavelength or reference

wavelength.

A0013213

1 Measuring principle of nitrate sensor

1 Measuring receiver with filter

2 Cuvette gap

3 Strobe lamp

4 Lens

5 Reference receiver with filter

6 Beam splitter

Nitrate measurement

Within the measuring path, the medium in the cuvette (water, dissolved substances and particles)

absorbs light across the entire spectrum. In the measuring wavelength range, the measured

component

2)

takes an additional amount of energy from the light.

For the calculation of the measured value, the ratio of the light signal of the measuring wavelength

to the light signal of the reference wavelength is calculated in order to minimize the effect of

turbidity and lamp aging.

This change in the ratio can be converted to determine the nitrate concentration or the SAC value.

This dependency is non-linear.

Conclusion:

• Long measuring paths are required for low concentrations of the measured component.

For clear water measurements, this is achieved with the 8 mm cuvette for nitrate measurement

and the 40 mm cuvette for SAC measurement.

• For high turbidity values, longer measuring paths result in the total absorption of light - the

measured values are no longer valid.

The nitrate sensor with the 2 mm cuvette is recommended for media with high turbidity values

(activated sludge application).

The SAC sensor with the 2 mm cuvette is ideal for measuring the organic load in the inlet of

municipal wastewater treatment plants.

The sensor is designed for measuring nitrate. As nitrite is also measured, it could also be regarded as

an NOx sensor.

Nitrate ions absorb UV light in the range of approx. 190 to 230 nm. Nitrite ions have a similar

absorption rate in the same range.

The sensor measures the light intensity of the 214 nm wavelength (measuring channel). At this

wavelength, nitrate and nitrite ions absorb light in proportion to their concentration, while the light

intensity in the reference channel remains virtually unchanged at 254 nm.

1) Measuring path = open path through cuvette

2) Nitrate or substances that contribute to the spectral absorption coefficient (SAC)

2 Endress+Hauser

Page 3

Viomax CAS51D

Interference factors, such as turbidity, fouling or organic hydrocarbons, are minimized.

The signal ratio between the reference wavelength and measurement wavelength constitutes the

measurement result. This ratio is converted to the concentration of nitrate using the calibration

curve programmed into the sensor.

Cross-interference when measuring nitrate

SAC measurement

The following have a direct impact on the measuring range:

• Total solids (TS) and turbidity

• Sludge properties

• Nitrite

Trends:

• A higher proportion of TS or greater turbidity reduces the upper end of the measuring range,

resulting in a smaller measuring range.

• High COD

3)

levels reduce the upper end of the measuring range, resulting in a smaller measuring

range.

• Nitrite is measured as nitrate, thus resulting in a higher measured value.

The following can be deduced from the interdependencies cited above:

• Sludge floc causes scattering in the medium, resulting in the attenuation of both the measuring

and reference signal to varying degrees. This in turn can bring about a change in the nitrate value

due to turbidity.

• High concentrations of oxidizable substances

4)

in the medium may result in an increase in the

measured value.

• Nitrite absorbs light in a similar wavelength range to nitrate and is measured along with nitrate.

The dependency is constant: 1.0 mg/l nitrite is displayed as 0.8 mg/l nitrate.

• An adjustment to the customer process is always worthwhile.

Many organic substances absorb light in the range of 254 nm. In the SAC sensor, absorption on the

measuring wavelength (254 nm) is compared with the largely unaffected reference measurement at

550 nm.

KHP (potassium hydrogen phthalate C8H5KO4) is the established organic reference in SAC

measurement operations. That is why the sensor is calibrated in the factory using KHP.

The SAC value can be regarded as a trend indicator of the organic load in a medium. For this

purpose, it is converted to COD, TOC, BOD and DOC

5)

using predefined, adjustable factors:

c (TOC) = 0.4705 * c (KHP)

c (COD) = 1.176 * c (KHP)

c (BOD) = 1.176 * c (KHP)

c (DOC) = 0.4705 * c (KHP)

The ratio to SAC (based on KHP) is calculated as follows:

1/m = 1.487 mg/l COD = 1.487 mg/l BOD = 0.595 mg/l TOC = 0.595 mg/l DOC

Many components that absorb light at 254 nm deviate significantly from KHP in terms of their

absorption behavior. For this reason, an adjustment to the customer process is worthwhile.

Cross-interference when measuring SAC

The following have a direct impact on the measuring range:

• Turbidity

• Color

Trends:

• Oxidizable substances, absorbing at 550 nm, corrupt the measurement result. In instances of this

nature, a comparison or calibration is necessary.

• Coloration that absorbs in the green spectral range increases the measured value.

• Oxidizable substances with spectral properties that differ to those of KHP (potassium hydrogen

phthalate) provide measurement results that can deviate from the factory calibration. In instances

of this nature, a comparison or adjustment is necessary.

• A higher proportion of TS or greater turbidity reduces the upper end of the measuring range,

resulting in a smaller measuring range.

• Sludge floc causes scattering in the medium, resulting in the attenuation of both the measuring

and reference signal to varying degrees. This in turn can bring about a change in the measured

value due to turbidity.

3) COD = Chemical Oxygen Demand

4) Specified as COD. Corresponds to the quantity of oxygen that would be required to oxidize the substances if oxygen were the oxidizing agent.

5) Chemical Oxygen Demand (COD), Total Organic Carbon (TOC), Biochemical Oxygen Demand (BOD), Dissolved Organic Carbon (DOC)

Endress+Hauser 3

Page 4

Viomax CAS51D

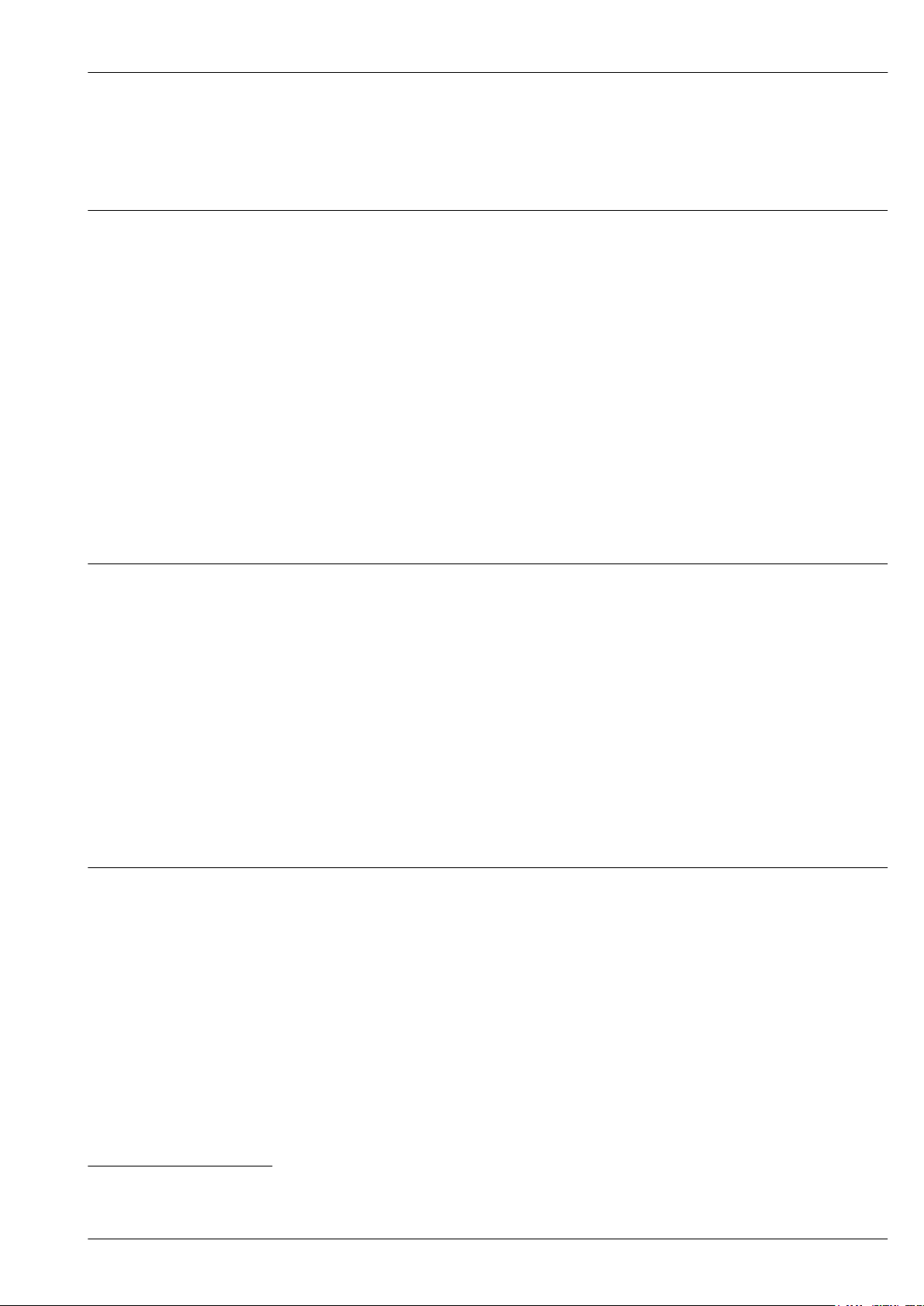

1

2

3

4

Measuring system

A complete measuring system comprises:

• Viomax CAS51D

• Liquiline CM44x multi-channel transmitter

• Universal installation or flow assembly

• Flexdip CYA112 and Flexdip CYH112 holder or

• Flowfit CYA251 or 71110000 (for clear water)

A0034082

2 Example of a measuring system with flow assembly for clear water

1 Transmitter CM44x

2 Sensor Viomax CAS51D

3 Flow assembly

4 Holders (included in the flow assembly delivery)

4 Endress+Hauser

Page 5

Viomax CAS51D

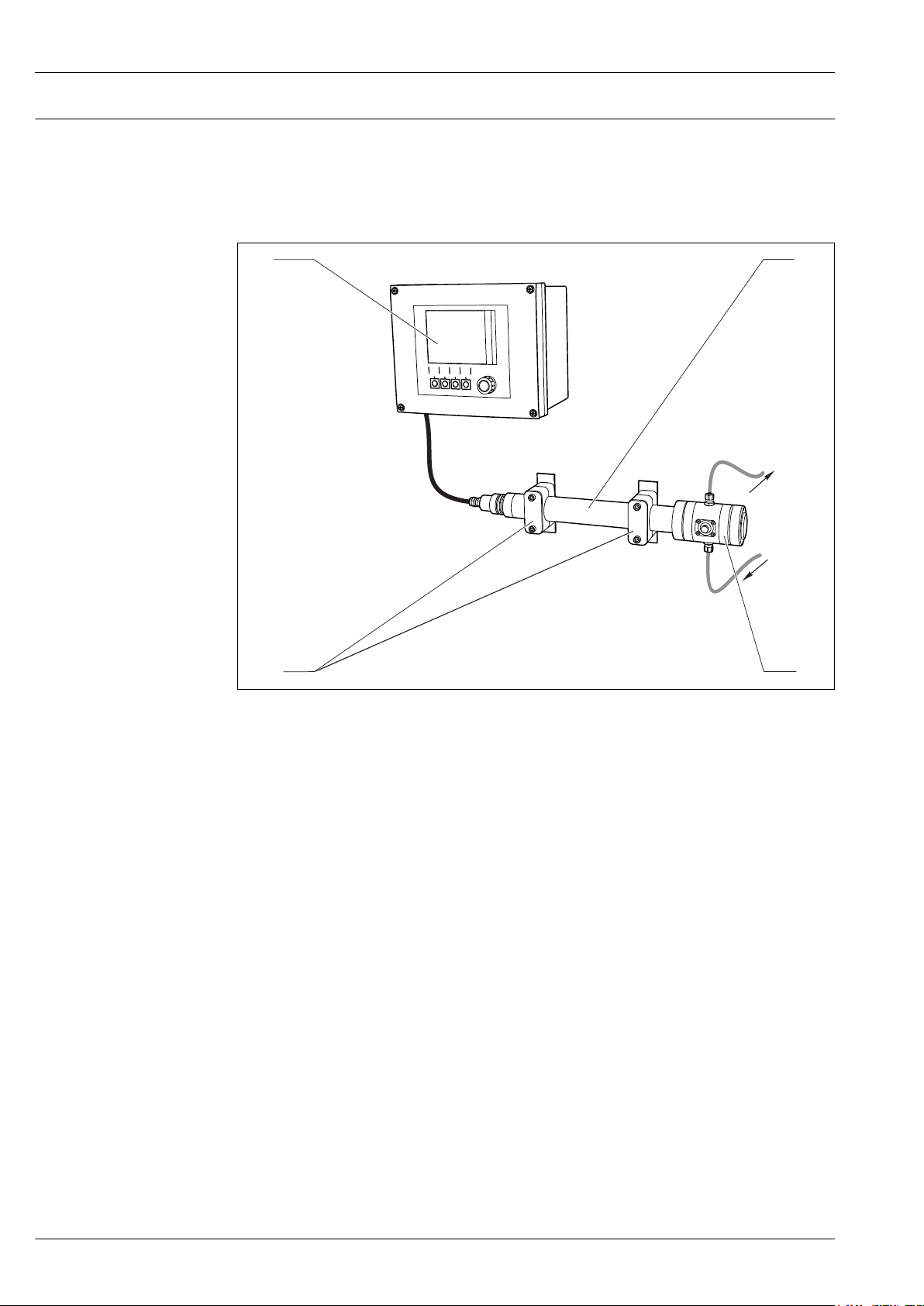

Input

Measured variables

Measuring ranges

Nitrate

NO3-N [mg/l], NO3 [mg/l]

SAC

SAC [1/m], COD [mg/l], TOC [mg/l], BOD [mg/l], DOC [mg/l], transmission [%]

CAS51D-**A2 (2 mm gap) 0.1 to 50 mg/l NO3-N

0.4 to 200 mg/l NO

Clear water and sludge activation

CAS51D-**A1 (8 mm gap) 0.01 to 20 mg/l NO3-N

0.04 to 80 mg/l NO

Clear water (with a COD (KHP) content of up to 125 mg/l and up

to 50 FNU turbidity based on mineral kaolin)

CAS51D-**C1 (40 mm gap) SAC 0 to 50 1/m

CSB/BSB 0 to 75 mg/l

TOC/DOC 0 to 30 mg/l

Clear water, low measuring range, drinking water

CAS51D-**C2 (8 mm gap) SAC 0 to 250 1/m

COD/BOD 0 to 375 mg/l

TOC/DOC 0 to 150 mg/l

Clear water, medium measuring range, drinking water,

wastewater treatment plant outlet, monitoring of bodies of

water

CAS51D-**C3 (2 mm gap) SAC 0 to 1000 1/m

COD/BOD 0 to 1500 mg/l

TOC/DOC 0 to 600 mg/l

Organic load in the inlet, influent control, industrial processes

3

3

1)

1)

1)

1)

1)

1)

1) equivalent KHP

The possible measuring range depends greatly on the properties of the medium.

Empirical values for typical COD measuring ranges

Inlet of municipal wastewater treatment

plant

Influent from milk-processing industry 0 to 10 000 mg/l COD

Influent from chemical industry 0 to 10 000 mg/l COD

0 to 4000 mg/l COD

Power supply

The following connection options are available:

• via M12 connector (version: fixed cable, M12 connector)

• via sensor cable to the plug-in terminals of a sensor input on the transmitter (version: fixed cable,

end sleeves)

Endress+Hauser 5

Page 6

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

Sensor

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

Sensor

3 Sensor connection to sensor input (left) or via M12 connector (right)

1

2

3

4

Viomax CAS51D

A0033092

Reference operating conditions

Connecting the cable shield

Cable sample (does not necessarily correspond to the original cable supplied)

4 Terminated cable

1 Outer shield (exposed)

5 Inserting the cable

4 Grounding clip

2 Cable cores with ferrules

3 Cable sheath (insulation)

The maximum cable length is 100 m (328.1 ft).

Performance characteristics

20 °C (68 °F), 1013 hPa (15 psi)

6 Tightening the screw

(2 Nm (1.5 lbf ft))

The cable shield is grounded by the

grounding clip

6 Endress+Hauser

Page 7

Viomax CAS51D

Measured error

Repeatability

6)

Detection limits

6)

Nitrate With 0.1 to 50 mg/l NO3-N (2 mm cuvette gap):

2 % of full scale value above 10 mg/l

0.4 % of full scale value below 10 mg/l

With 0.01 to 20 mg/l NO3-N (8 mm cuvette gap):

2 % of full scale value above 2 mg/l

0.2 % below 2 mg/l

SAC 2 % of full scale value for standard measurement with potassium

hydrogen phthalate (KHP)

Nitrate

At least ±0.2 mg/l NO3-N

SAC

0.5 % of end of measuring range (for homogeneous media)

Nitrate

• CAS51D-AAA1

0.003 mg/l NO3-N

• CAS51D-AAA2

0.013 mg/l NO3-N

SAC

In relation to the standard potassium hydrogen phthalate (KHP):

• CAS51D-AAC1

0.045 mg/l COD

• CAS51D-AAC2

0.3 mg/l COD

• CAS51D-AAC3

1.5 mg/l COD

Determination limits

Nitrate

• CAS51D-AAA1

0.01 mg/l NO3-N

• CAS51D-AAA2

0.043 mg/l NO3-N

SAC

In relation to the standard potassium hydrogen phthalate (KHP):

• CAS51D-AAC1

0.15 mg/l COD

• CAS51D-AAC2

1.0 mg/l COD

• CAS51D-AAC3

5.0 mg/l COD

Long-term drift

Nitrate

Better than 0.1 mg/l NO3-N over one week

SAC

Better than 0.2 % of end of measuring range over one week

Mounting

Installation conditions Mounting location

Choose a mounting location that can be easily accessed at a later stage.

‣

Ensure that upright posts and fittings are fully secured and vibration-free.

‣

Select an installation location that produces a typical nitrate concentration / a typical SAC value

‣

for the application in question.

6) The measured error contains all the uncertainties of the sensor and transmitter (electrode system). It does not contain all the uncertainties

caused by the reference material and adjustments that may have been performed.

Endress+Hauser 7

Page 8

Viomax CAS51D

Do not install the sensor above aeration discs. Oxygen bubbles may accumulate at the cuvette gap

‣

and distort the measured value.

Orientation

Align the sensor in such a way that the cuvette gap is rinsed

‣

with the flow of medium and air bubbles are removed.

A0013268

7 Sensor orientation, arrow =

direction of flow

Flexdip CYA112 wastewater assembly and Flexdip CYH112 holder

A0013267

8 Horizontal, fixed installation

The installation angle is 90°.

Align the sensor in such a way that the

‣

cuvette gap is rinsed with the flow of

medium and air bubbles are removed.

9 Suspended vertically from a chain

The installation angle is 0°. Tried and tested

arrangement for operation in aerated zones.

Ensure that the sensor is adequately cleaned.

‣

There must be no buildup on the optical

windows.

A0013270

8 Endress+Hauser

Page 9

Viomax CAS51D

1

2

3

4

5

1 2

3

4

5

6

Flow assembly CAS51D 2-40 mm for small sample volumes

A0013266

10 Horizontally, in flow assembly, arrow points in the direction of flow

1 Sensor

2 Flow assembly

3 Medium outlet

4 Medium inflow

5 Window, required for aligning the sensor

Flowfit CYA251 flow assembly

11 Horizontally, in flow assembly CYA251, arrow points in the direction of flow

1 Sensor

2 Medium outlet

3 Cap

4 Flow assembly

5 Medium inflow

6 Rinse connection

A0032901

Ambient temperature range

Storage temperature

Degree of protection

Endress+Hauser 9

Environment

–20 to 60 °C (–4 to 140 °F)

–20 to 70 °C (–4 to 158 °F)

IP 68 (1 m (3.3 ft) water column, 60 days, 1 mol/l KCl)

Page 10

Process

50

(1.97)

40 (1.57)

388 (15.28)

78 (3.07)

NPT “¾

G1

2 (0.08)

8 (0.31)

12 (0.47)

20 (0.79)

14.5 (0.57)

NPT “¾

G1

78 (3.07)

394 (15.51)

8 (0.31)

40 (1.57)

14 (0.55)

20 (0.79)

12 (0.47)

14.5 (0.57)

Viomax CAS51D

Process temperature

Process pressure (absolute)

Minimum flow

5 to 50 °C (41 to 122 °F)

0.5 to 10 bar (7.3 to 145 psi) (abs.)

No minimum flow required.

Mechanical construction

Dimensions Sensor

For solids which have a tendency to form deposits, ensure that sufficient mixing is performed.

12 Sensor with 2 mm gap width, dimensions in

mm (inch)

A0013193

13 Sensor with 8 mm gap width, dimensions in

mm (inch)

A0013208

10 Endress+Hauser

Page 11

Viomax CAS51D

20 (0.79)

12 (0.47)

14.5 (0.57)

40 (1.57)

NPT “¾

G1

69 (2.72)

40 (1.57)

46 (1.81)

426 (16.77)

Ø 6.5 (0.26)

86

(3.39)

30 (1.18)

100 (3.94)

70 (2.76)

**

70 (2.76)

60 (2.36)

A0031311

14 Sensor with 40 mm gap width, dimensions in

mm (inch)

Flow assembly

15 Dimensions in mm (inch)

** Variable length

A0013290

Endress+Hauser 11

Page 12

Cleaning unit

20.5

(0.81)

300 (11.81)

1

2

1

2

16 (0.63)

295 (11.6)

A

C

Viomax CAS51D

Weight

Materials

Process connections

EAC version

A0013292

16 Dimensions in mm (inch)

1 Adapter 8 mm with 300 mm hose (only for 8 mm connection)

2 Connection 6 mm or 6.35 mm (¼")

A Sensor (2mm oder 8 mm gap)

C SAC sensor (40 mm gap)

Approx. 1.6 kg (3.53 lbs) (without cable)

Sensor

Optical windows Sapphire

O-rings EPDM

G1 and NPT ¾''

Stainless steel 1.4404 (AISI 316 L)

Certificates and approvals

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011 which

apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the product.

Product page

12 Endress+Hauser

Ordering information

www.endress.com/cas51d

Page 13

Viomax CAS51D

Product Configurator

Scope of delivery

Assemblies

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The delivery comprises:

• Sensor in the version ordered

• Operating Instructions

Accessories

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Holder

Flowfit CYA251

• Connection: See product structure

• Material: PVC-U

• Product Configurator on the product page: www.endress.com/cya251

Technical Information TI00495C

Flow assembly for CAS51D

• For small flow volumes

• Connection: hose, OD 6 mm

• Material: PVC-U

• Two brackets for CAS51D

• Order number: 71110000

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the capstone, on the wall or directly onto railings.

• Plastic or stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

Endress+Hauser 13

Page 14

Viomax CAS51D

1

2

4

A

B

Compressed air cleaning

Compressed air cleaning for CAS51D

• Connection: 6 or 8 mm (metric) or 6.35 mm (¼")

• Order numbers for sensor with 2 mm gap or 8 mm gap:

• 6 mm (with 300 mm hose and 8 mm adapter)

Order No.: 71110787

• 6.35 mm (¼")

Order No.: 71110788

• Order numbers for sensor with 40 mm gap:

• 6 mm (with 300 mm hose and 8 mm adapter)

Order No.: 71126757

• 6.35 mm (¼")

Order No.: 71126758

Standard solutions

A0013263

17 Compressed air cleaning for CAS51D

A Cleaning for sensors with 2 mm and 8 mm gap

B Cleaning for sensors with 40 mm gap

1 Adapter, 8 mm

2 300 mm hose (Ø = 6 mm)

3 Coupling, 6 mm or 6.35 mm (¼") for 2 mm and 8 mm gap

4 Coupling, 6 mm or 6.35 mm (¼") for 40 mm gap

Compressor

• For compressed air cleaning

• 230 V AC order no. 71072583

• 115 V AC order no. 71194623

Nitrate standard solutions, 1 liter

• 5 mg/l NO3-N, order number: CAY342-V10C05AAE

• 10 mg/l NO3-N, order number: CAY342-V10C10AAE

• 15 mg/l NO3-N, order number: CAY342-V10C15AAE

• 20 mg/l NO3-N, order number: CAY342-V20C10AAE

• 30 mg/l NO3-N, order number: CAY342-V20C30AAE

• 40 mg/l NO3-N, order number: CAY342-V20C40AAE

• 50 mg/l NO3-N, order number: CAY342-V20C50AAE

KHP standard solution

CAY451‐V10C01AAE, 1000 ml parent solution 5 000 mg/l TOC

14 Endress+Hauser

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...