Page 1

TI01104D/06/EN/04.15

71302410

Products Solutions Services

Technical Information

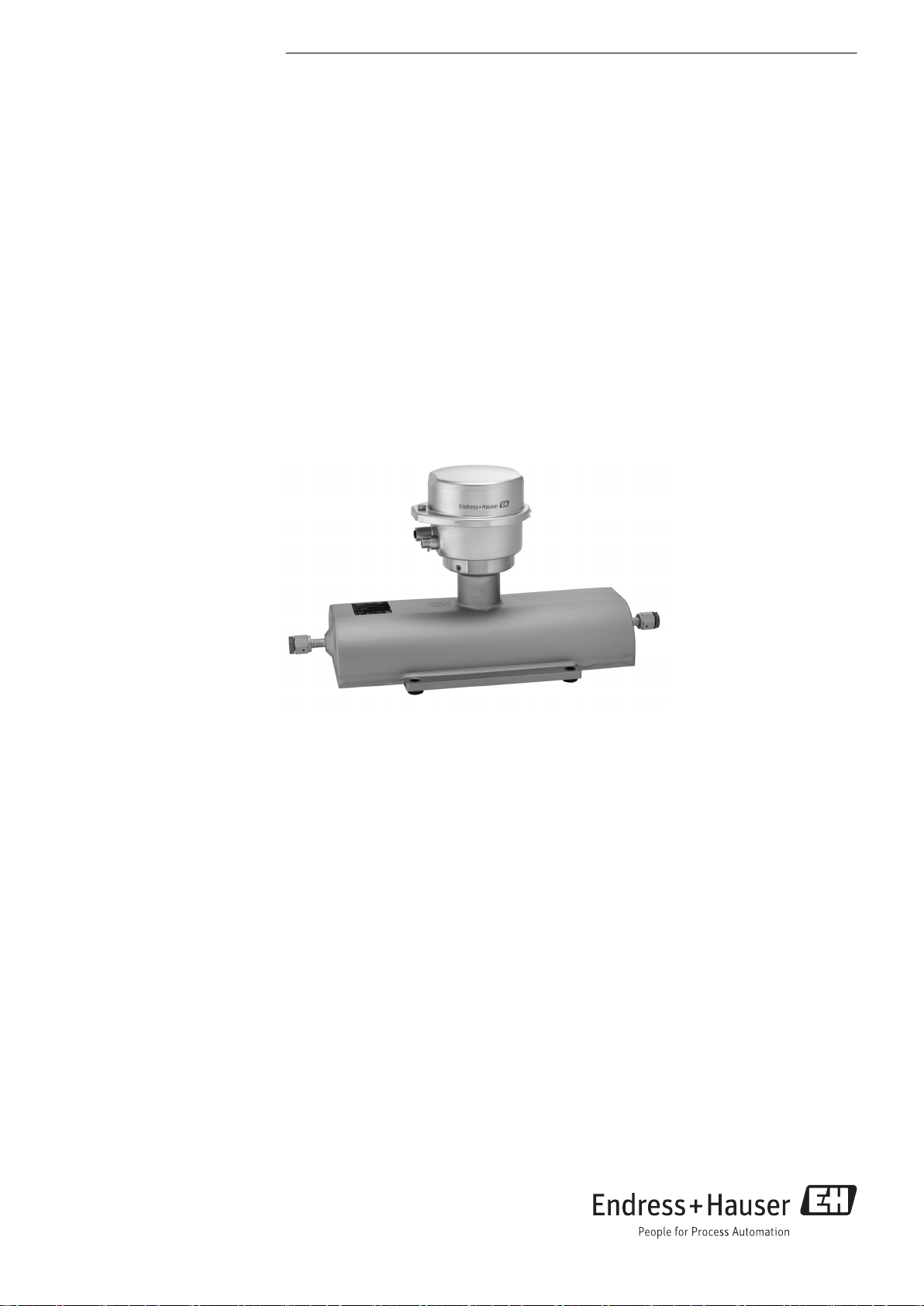

Proline Promass A 100

Coriolis flowmeter

The single-tube flowmeter for smallest flow quantities with an ultra-compact

transmitter

Application

• Measuring principle operates independently of physical fluid

properties such as viscosity or density

• Accurate measurement of smallest quantities of liquids and

gases for continuous process control

Device properties

• Nominal diameter: DN 1 to 4 (¹⁄₂₄ to ¹⁄₈")

• Process pressure up to 400 bar (5 800 psi)

• Medium temperature up to +205 °C (+401 °F)

• Robust, ultra-compact transmitter housing

• Highest degree of protection: IP69K

• Local display available

Your benefits

• Highest process safety – self-drainable measuring tube

design

• Fewer process measuring points – multivariable

measurement (flow, density, temperature)

• Space‐saving installation – no inlet/outlet run needs

• Space‐saving transmitter – full functionality on smallest

footprint

• Time‐saving local operation without additional software and

hardware – integrated web server

• Integrated verification – Heartbeat Technology™

Page 2

Table of contents

Proline Promass A 100

Document information ....................... 4

Symbols used ................................ 4

Function and system design ................... 5

Measuring principle ............................ 5

Measuring system ............................. 5

Equipment architecture ......................... 7

Safety ..................................... 7

Input ..................................... 8

Measured variable ............................. 8

Measuring range .............................. 8

Operable flow range ........................... 8

Input signal ................................. 9

Output ................................... 9

Output signal ................................ 9

Signal on alarm .............................. 11

Ex connection data ........................... 12

Low flow cut off ............................. 13

Galvanic isolation ............................ 13

Protocol-specific data .......................... 13

Power supply ............................. 23

Terminal assignment .......................... 23

Pin assignment, device plug ...................... 30

Supply voltage .............................. 32

Power consumption ........................... 33

Current consumption .......................... 33

Power supply failure .......................... 33

Electrical connection .......................... 34

Potential equalization ......................... 39

Terminals ................................. 39

Cable entries ............................... 39

Cable specification ............................ 39

Performance characteristics .................. 41

Reference operating conditions ................... 41

Maximum measured error ....................... 41

Repeatability ............................... 42

Response time .............................. 43

Influence of ambient temperature ................. 43

Influence of medium temperature .................. 43

Influence of medium pressure .................... 43

Design fundamentals .......................... 43

Degree of protection .......................... 51

Vibration resistance ........................... 51

Shock resistance ............................. 51

Shock resistance ............................. 51

Interior cleaning ............................. 51

Electromagnetic compatibility (EMC) ............... 51

Process .................................. 52

Medium temperature range ...................... 52

Density ................................... 52

Pressure-temperature ratings .................... 52

Secondary containment pressure rating .............. 54

Rupture disk ................................ 54

Flow limit ................................. 54

Pressure loss ............................... 55

System pressure ............................. 55

Thermal insulation ........................... 55

Heating ................................... 56

Vibrations ................................. 56

Mechanical construction .................... 57

Dimensions in SI units ......................... 57

Dimensions in US units ......................... 68

Weight ................................... 76

Materials .................................. 77

Process connections ........................... 78

Surface roughness ........................... 78

Operability ............................... 79

Operating concept ............................ 79

Local display ................................ 79

Remote operation ............................ 79

Service interface ............................. 81

Certificates and approvals ................... 84

CE mark ................................... 84

C-Tick symbol ............................... 84

Ex approval ................................ 84

Sanitary compatibility ......................... 85

HART certification ............................ 85

Certification PROFIBUS ......................... 85

Certification PROFINET ........................ 85

EtherNet/IP certification ........................ 85

Modbus RS485 certification ..................... 85

Other standards and guidelines ................... 85

Installation ............................... 44

Mounting location ............................ 44

Orientation ................................ 45

Inlet and outlet runs .......................... 46

Special mounting instructions .................... 46

Mounting Safety Barrier Promass 100 ............... 48

Ordering information ....................... 86

Application packages ....................... 86

Heartbeat Technology ......................... 87

Concentration ............................... 87

Accessories ............................... 87

Environment .............................. 49

Ambient temperature range ..................... 49

Storage temperature .......................... 51

Climate class ............................... 51

Device-specific accessories ...................... 87

Communication-specific accessories ................ 87

Service-specific accessories ...................... 88

System components ........................... 89

2 Endress+Hauser

Page 3

Proline Promass A 100

Supplementary documentation ............... 89

Standard documentation ........................ 89

Supplementary device-dependent documentation ....... 89

Registered trademarks ...................... 90

Endress+Hauser 3

Page 4

Document information

,…,

-

.

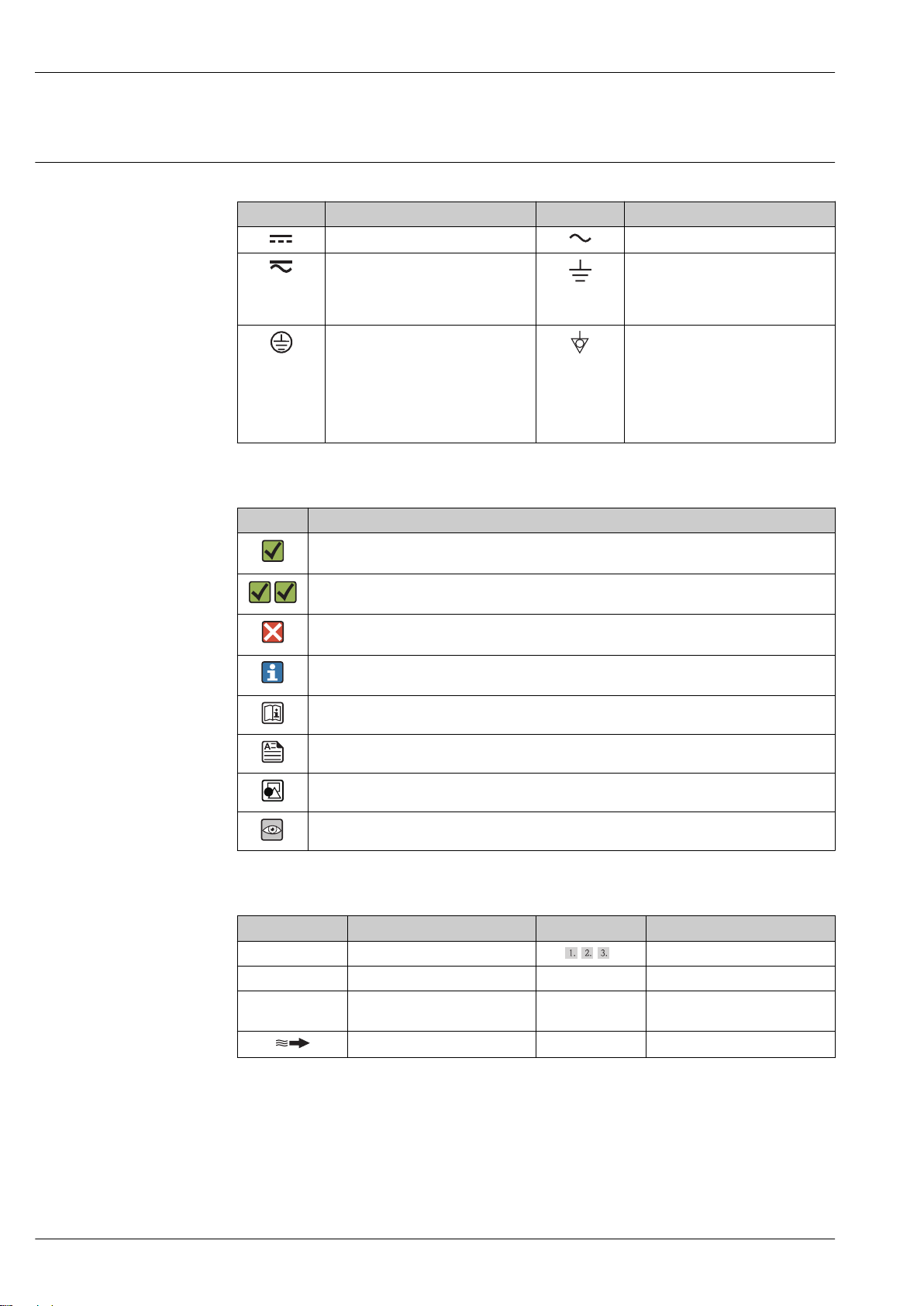

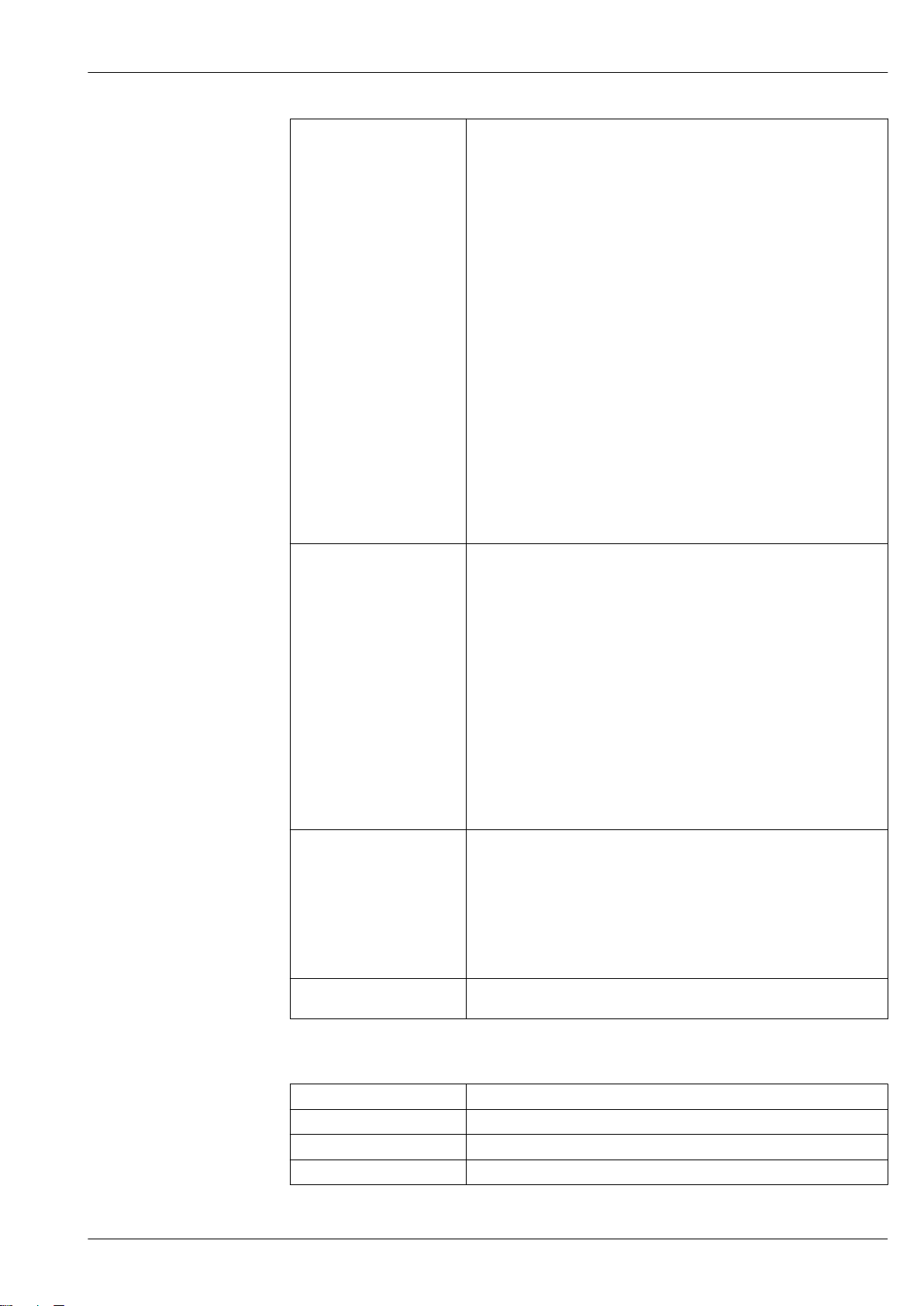

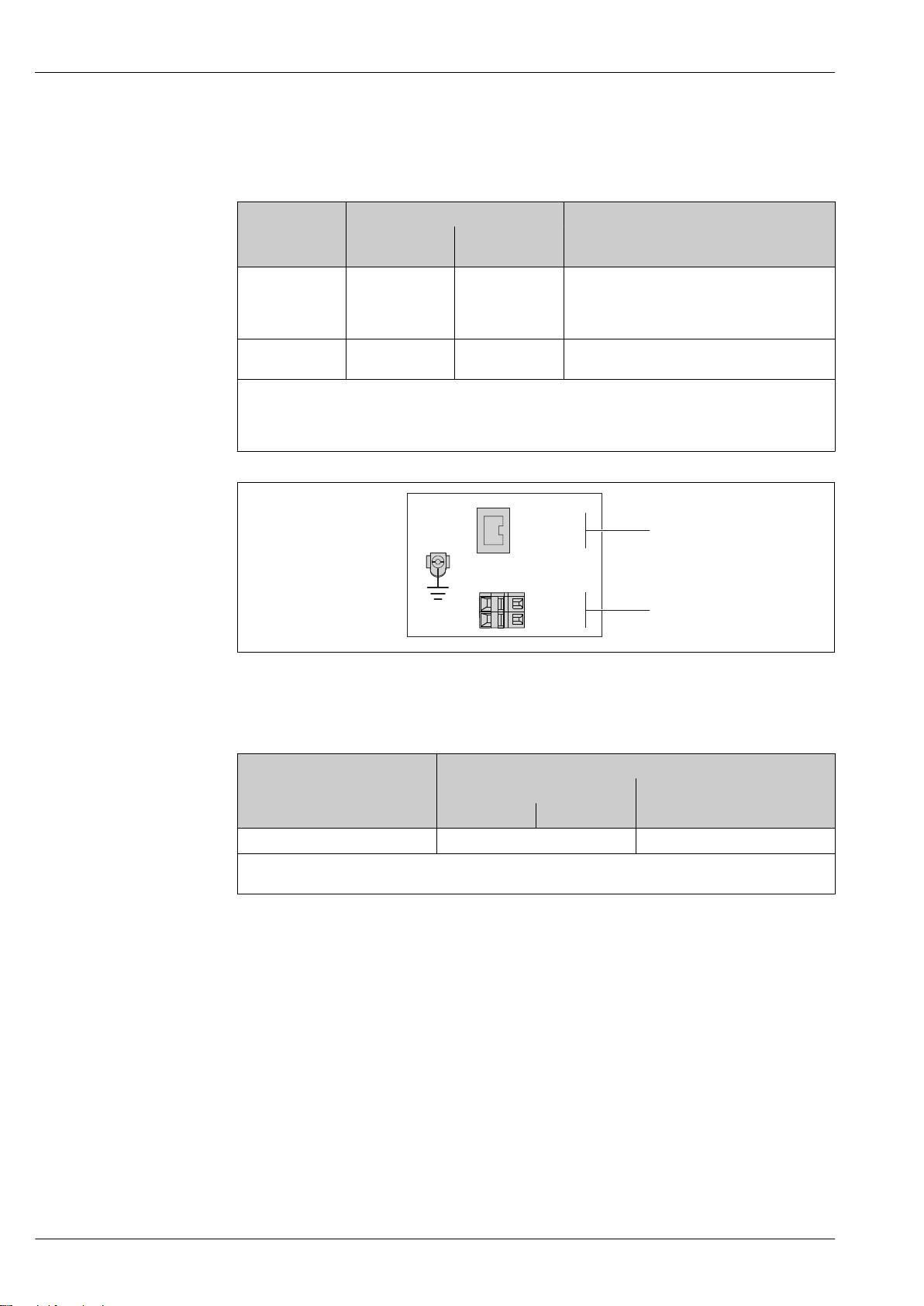

Symbols used Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Symbols for certain types of information

Proline Promass A 100

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Symbols in graphics

Symbol Meaning Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views A-A, B-B, C-C, ... Sections

Hazardous area

Series of steps

Safe area (non-hazardous area)

Flow direction

4 Endress+Hauser

Page 5

Proline Promass A 100

1 2

3

Function and system design

Measuring principle

The measuring principle is based on the controlled generation of Coriolis forces. These forces are

always present in a system when both translational and rotational movements are superimposed.

Fc = 2 · ∆m (ν · ω)

Fc = Coriolis force

∆m = moving mass

ω = rotational velocity

ν = radial velocity in rotating or oscillating system

The amplitude of the Coriolis force depends on the moving mass ∆m, its velocity ν in the system and

thus on the mass flow. Instead of a constant rotational velocity ω, the sensor uses oscillation.

In the sensor, an oscillation is produced in the measuring tube. The Coriolis forces produced at the

measuring tube cause a phase shift in the tube oscillations (see illustration):

• If there is zero flow (i.e. when the fluid stands still), the oscillation measured at points A and B has

the same phase (no phase difference).

• Mass flow causes deceleration of the oscillation at the inlet of the tubes (2) and acceleration at the

outlet (3).

Measuring system

A0016772

The phase difference (A-B) increases with increasing mass flow. Electrodynamic sensors register the

tube oscillations at the inlet and outlet. System balance is created by exciting an eccentrically

arranged swinging mass to antiphase oscillation. The measuring principle operates independently of

temperature, pressure, viscosity, conductivity and flow profile.

Density measurement

The measuring tube is continuously excited at its resonance frequency. A change in the mass and

thus the density of the oscillating system (comprising measuring tube and fluid) results in a

corresponding, automatic adjustment in the oscillation frequency. Resonance frequency is thus a

function of medium density. The microprocessor utilizes this relationship to obtain a density signal.

Volume measurement

Together with the measured mass flow, this is used to calculate the volume flow.

Temperature measurement

The temperature of the measuring tube is determined in order to calculate the compensation factor

due to temperature effects. This signal corresponds to the process temperature and is also available

as an output signal.

The device consists of a transmitter and a sensor. If a device with Modbus RS485 intrinsically safe is

ordered, the Safety Barrier Promass 100 is part of the scope of supply and must be implemented to

operate the device.

The device is available as a compact version:

The transmitter and sensor form a mechanical unit.

Endress+Hauser 5

Page 6

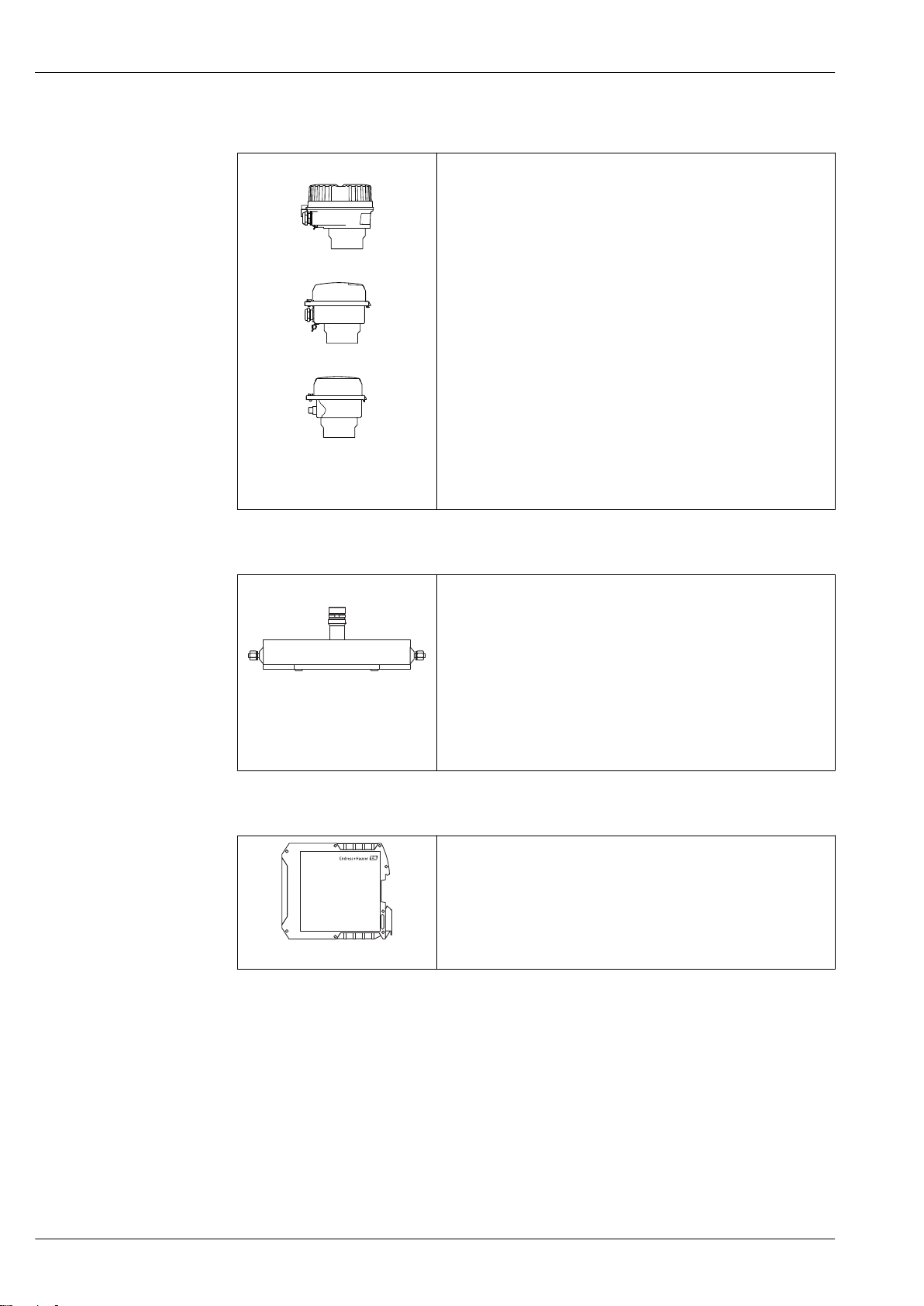

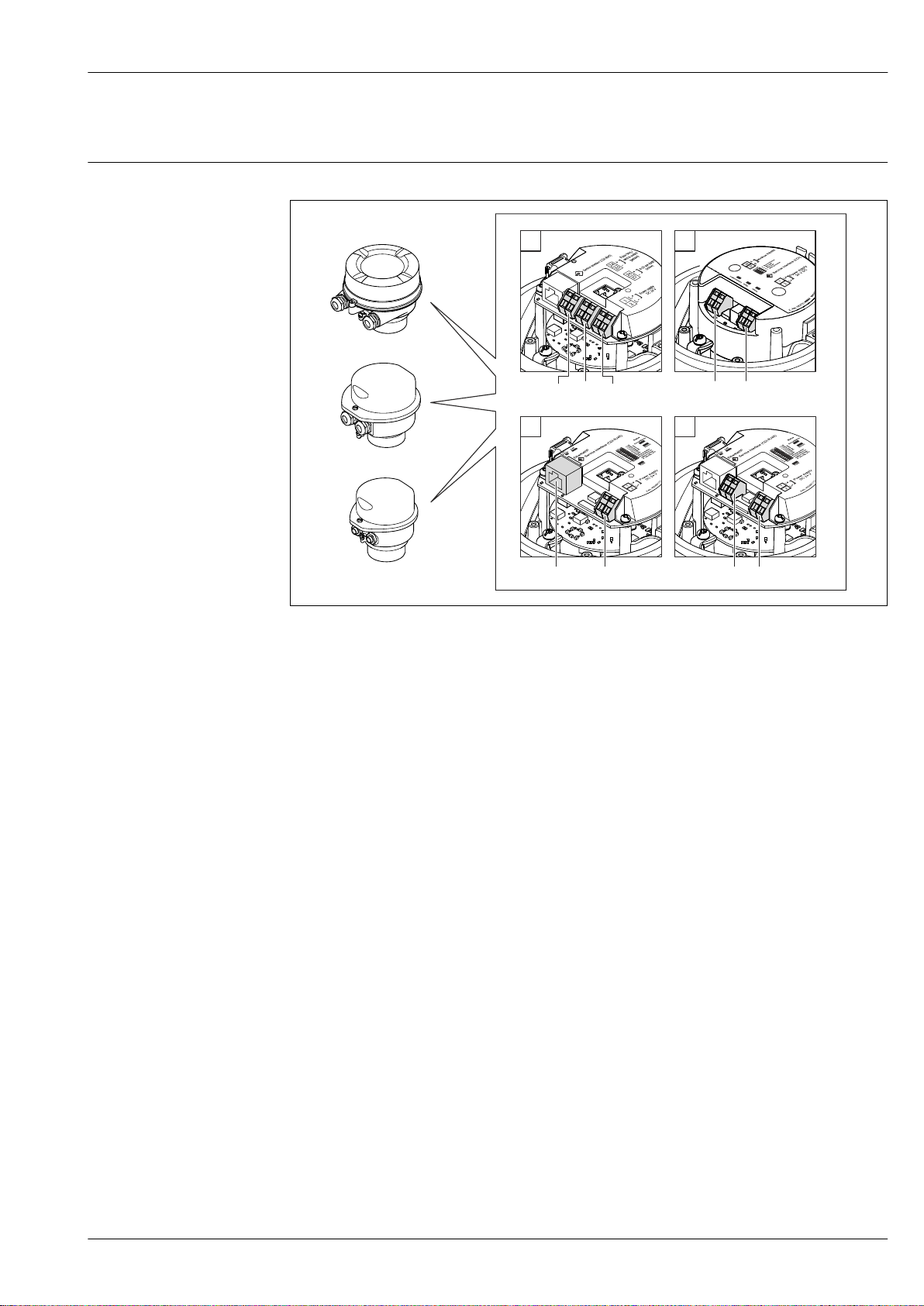

Transmitter

Promass 100 Device versions and materials:

• Compact, aluminum coated:

Aluminum, AlSi10Mg, coated

• Compact, hygienic, stainless:

Hygienic version, stainless steel 1.4301 (304)

• Ultra-compact, hygienic, stainless:

A0016693

A0016694

A0016695

Hygienic version, stainless steel 1.4301 (304)

Configuration:

• Via operating tools (e.g. FieldCare)

• Additionally for device version with local display:

Via Web browser (e.g. Microsoft Internet Explorer)

• Also for device version with 4-20 mA HART, pulse/frequency/switch

output:

Via Web browser (e.g. Microsoft Internet Explorer)

• Also for device version with EtherNet/IP output:

– Via Web browser (e.g. Microsoft Internet Explorer)

– Via Add-on Profile Level 3 for automation system from Rockwell

Automation

– Via Electronic Data Sheet (EDS)

• Also for device version with PROFINET output:

– Via Web browser (e.g. Microsoft Internet Explorer)

– Via device master file (GSD)

Proline Promass A 100

Sensor

Promass A • Single-tube system for high-precision measurement of minimum flow

rates

• Simultaneous measurement of flow, volume flow, density and

temperature (multivariable)

• Immune to process influences

• Nominal diameter range: DN 1 to 4 (¹⁄₂₄ to ¹⁄₈ ")

• Materials:

A0017118

– Sensor: stainless steel, 1.4301 (304)

– Measuring tube: stainless steel, 1.4539 (904L); Alloy C22, 2.4602

(UNS N06022)

– Process connections: stainless steel, 1.4404 (316/316L); stainless

steel, 1.4539 (904L); Alloy C22, 2.4602 (UNS N06022)

Safety Barrier Promass 100

• Dual-channel safety barrier for installation in non-hazardous locations

or zone 2/div. 2:

– Channel 1: DC 24 V power supply

– Channel 2: Modbus RS485

• In addition to current, voltage and power limitation, it offers galvanic

isolation of circuits for explosion protection.

• Easy top-hat rail mounting (DIN 35 mm) for installation in control

A0016763

cabinets

6 Endress+Hauser

Page 7

Proline Promass A 100

2 3

7

8

6

9

10

11

4

1

5

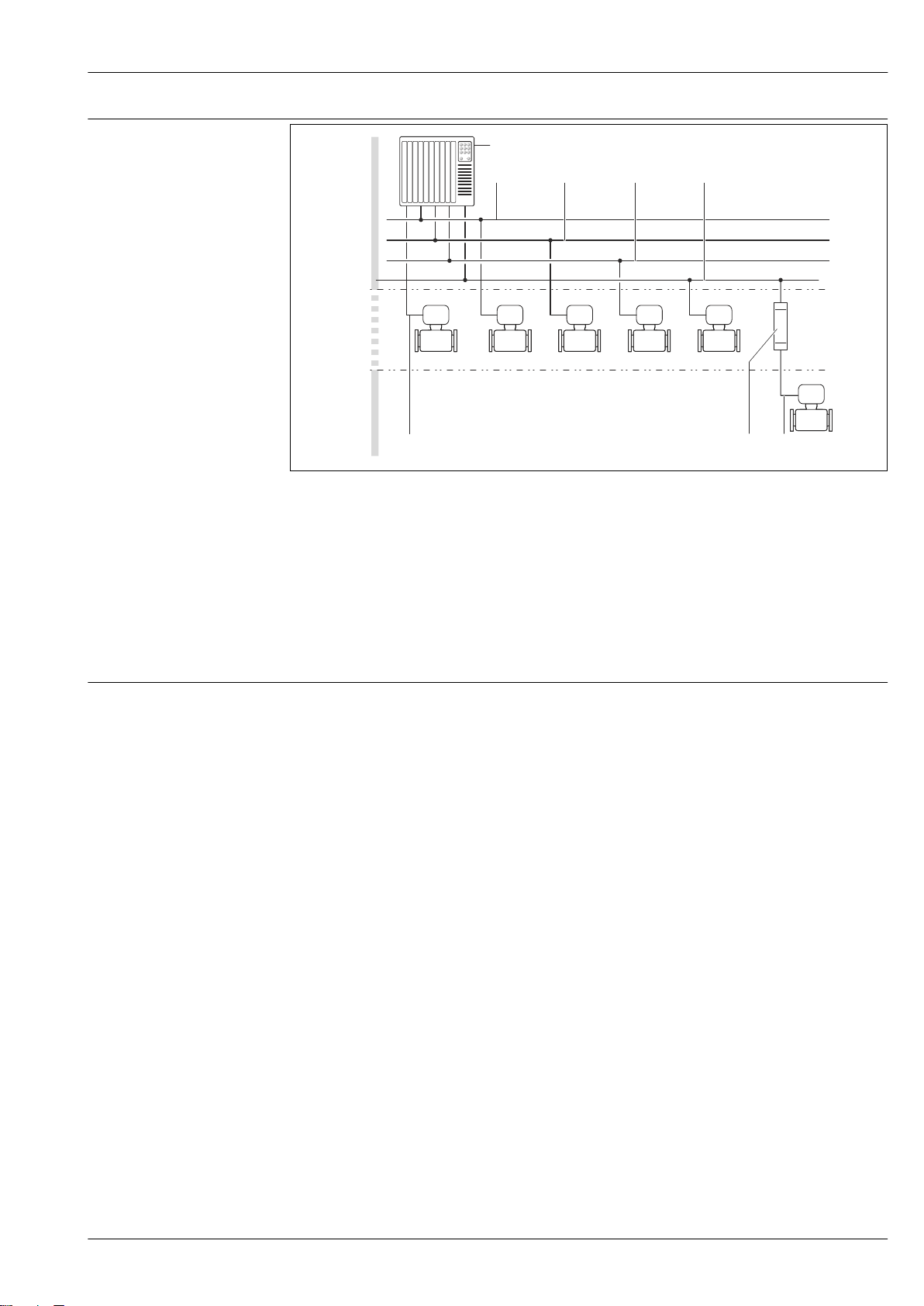

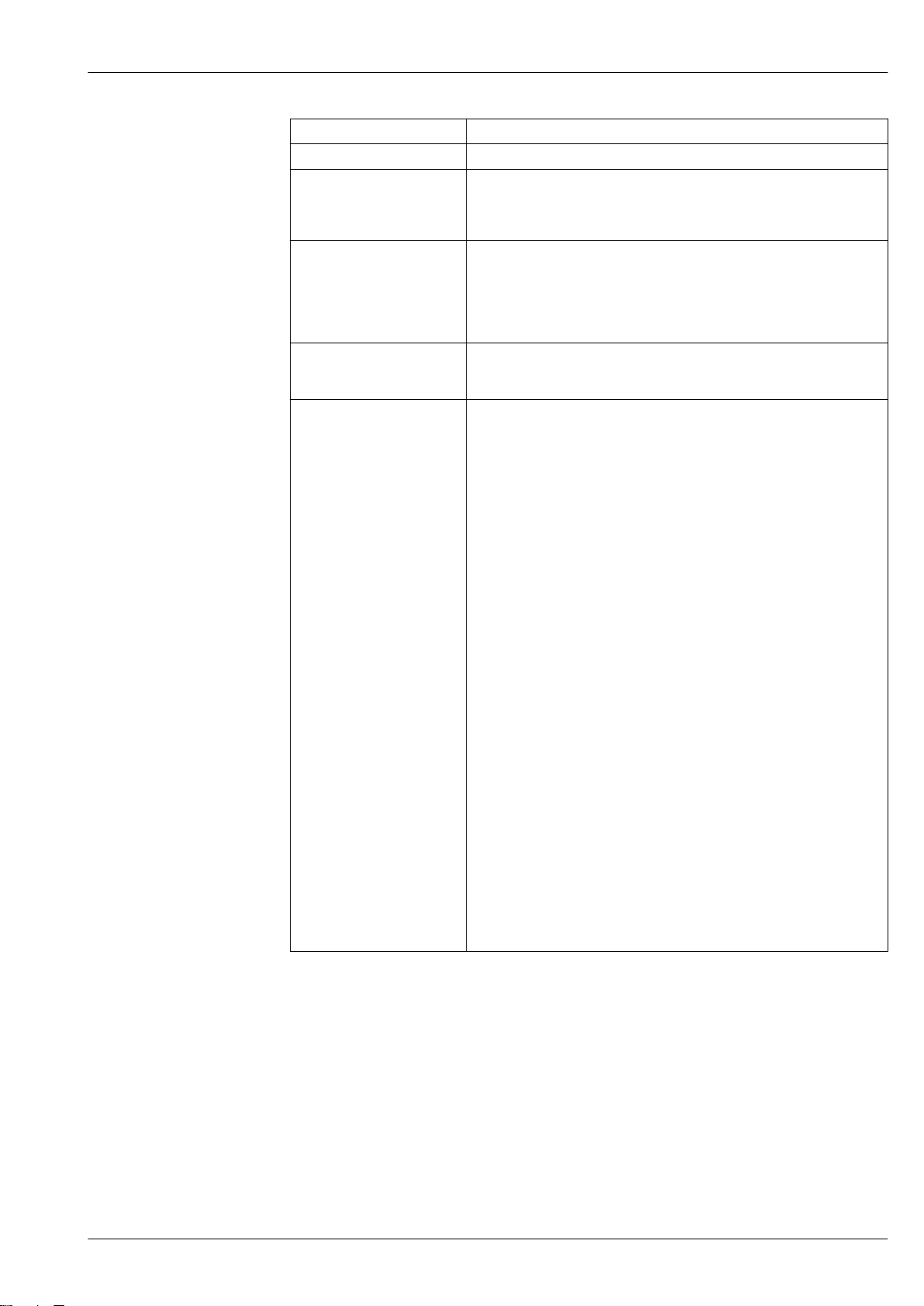

Equipment architecture

A0016779

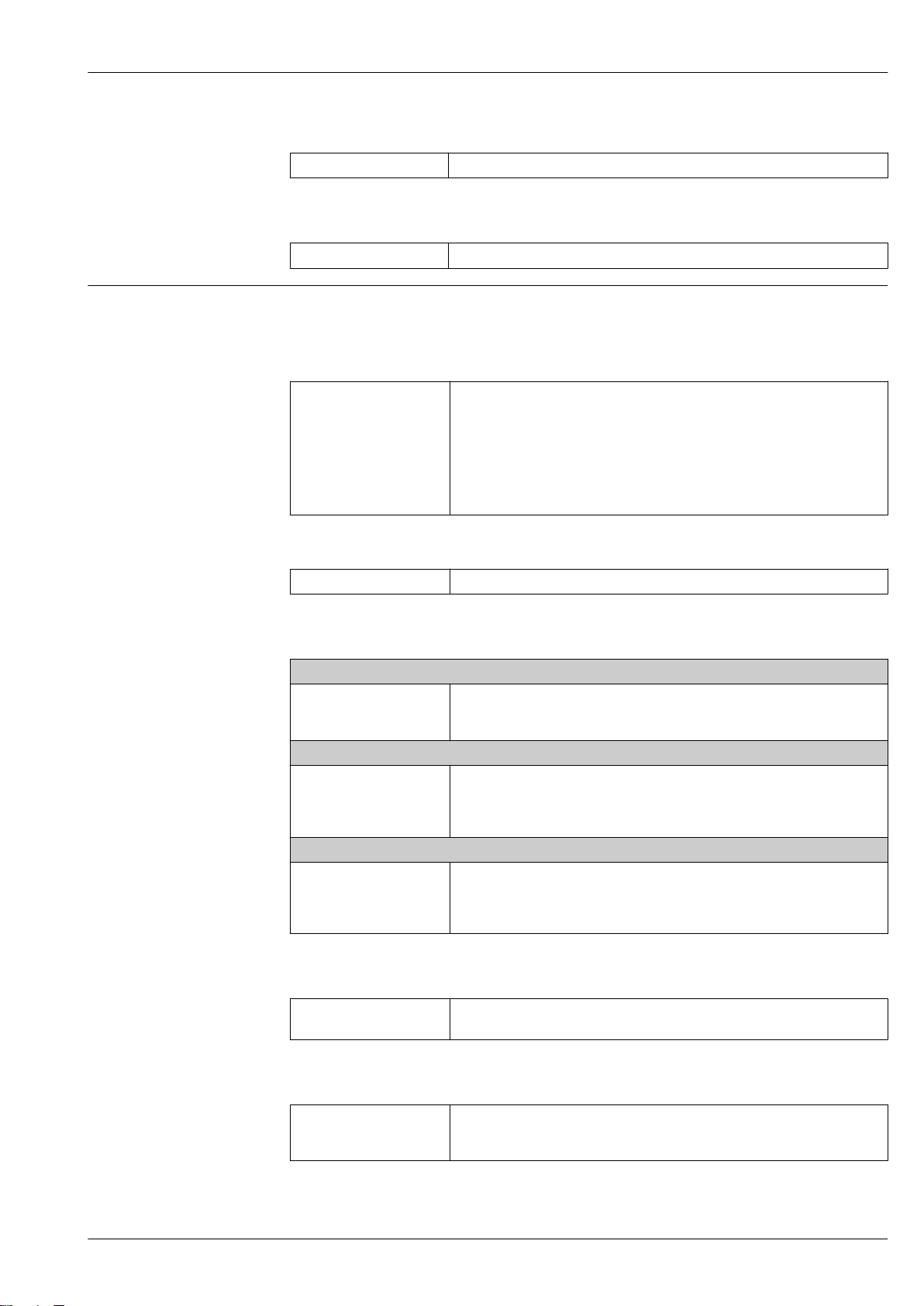

1 Possibilities for integrating measuring devices into a system

1 Automation system (e.g. PLC)

2 EtherNet/IP

3 PROFIBUS DP

4 Modbus RS485

5 4-20 mA HART, pulse/frequency/switch output

6 Safety Barrier Promass 100

7 Modbus RS485 intrinsically safe

8 Non-hazardous area

9 Non-hazardous area and Zone 2/Div. 2

10 Intrinsically safe area and Zone 1/Div. 1

Safety IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Endress+Hauser 7

Page 8

Input

Measured variable Direct measured variables

• Mass flow

• Density

• Temperature

Calculated measured variables

• Volume flow

• Corrected volume flow

• Reference density

Measuring range Measuring ranges for liquids

Proline Promass A 100

DN Measuring range full scale values

[mm] [in] [kg/h] [lb/min]

1 ¹⁄₂₄ 0 to 20 0 to 0.735

2 ¹⁄₁₂ 0 to 100 0 to 3.675

4 ¹⁄₈ 0 to 450 0 to 16.54

min(F)

to

max(F)

Measuring ranges for gases

The full scale values depend on the density of the gas and can be calculated with the formula below:

max(G)

ρ

G

max(G)

max(F)

max(G)

=

<

· ρG : x

max(F)

Maximum full scale value for gas [kg/h]

Maximum full scale value for liquid [kg/h]

max(F)

[mm] [in] [kg/m3]

1 ¹⁄₂₄ 32

2 ¹⁄₁₂ 32

4 ¹⁄₈ 32

can never be greater than

max(G)

Gas density in [kg/m³] at operating conditions

DN x

max(F)

To calculate the measuring range, use the Applicator sizing tool → 88

Calculation example for gas

• Sensor: Promass A, DN 2

• Gas: Air with a density of 11.9 kg/m³ (at 20 °C and 10 bar)

• Measuring range (liquid): 100 kg/h

• x = 32 kg/m³ (for Promass A DN 2)

Maximum possible full scale value:

max(G)

=

· ρG : x = 100 kg/h · 11.9 kg/m³ : 32 kg/m³ = 37.2 kg/h

max(F)

Recommended measuring range

"Flow limit" section → 54

Operable flow range

Over 1000 : 1.

Flow rates above the preset full scale value are not overridden by the electronics unit, with the result

that the totalizer values are registered correctly.

8 Endress+Hauser

Page 9

Proline Promass A 100

Input signal External measured values

To increase the accuracy of certain measured variables or to calculate the corrected volume flow for

gases, the automation system can continuously write different measured values to the measuring

device:

• Operating pressure to increase accuracy (Endress+Hauser recommends the use of a pressure

measuring device for absolute pressure, e.g. Cerabar M or Cerabar S)

• Medium temperature to increase accuracy (e.g. iTEMP)

• Reference density for calculating the corrected volume flow for gases

Various pressure transmitters and temperature measuring devices can be ordered from Endress

+Hauser: see "Accessories" section → 89

It is recommended to read in external measured values to calculate the following measured variables:

• Mass flow

• Corrected volume flow

HART protocol

The measured values are written from the automation system to the measuring device via the HART

protocol. The pressure transmitter must support the following protocol-specific functions:

• HART protocol

• Burst mode

Digital communication

The measured values can be written from the automation system to the measuring via:

• PROFIBUS DP

• Modbus RS485

• EtherNet/IP

• PROFINET

Output

Output signal Current output

Current output 4-20 mA HART (active)

Maximum output values • DC 24 V (no flow)

Load 0 to 700 Ω

Resolution 0.38 µA

Damping Adjustable: 0.07 to 999 s

Assignable measured

variables

Pulse/frequency/switch output

Function Can be set to pulse, frequency or switch output

Version Passive, open collector

Maximum input values • DC 30 V

Voltage drop For 25 mA: ≤ DC 2 V

Pulse output

• 22.5 mA

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

The range of options increases if the measuring device has one or more

application packages.

• 25 mA

Endress+Hauser 9

Page 10

Pulse width Adjustable: 0.05 to 2 000 ms

Maximum pulse rate 10 000 Impulse/s

Pulse value Adjustable

Assignable measured

variables

Frequency output

Output frequency Adjustable: 0 to 10 000 Hz

Damping Adjustable: 0 to 999 s

Pulse/pause ratio 1:1

Assignable measured

variables

Switch output

Switching behavior Binary, conductive or non-conductive

Switching delay Adjustable: 0 to 100 s

Number of switching

cycles

Assignable functions • Off

• Mass flow

• Volume flow

• Corrected volume flow

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

The range of options increases if the measuring device has one or more

application packages.

Unlimited

• On

• Diagnostic behavior

• Limit value

– Mass flow

– Volume flow

– Corrected volume flow

– Density

– Reference density

– Temperature

– Totalizer 1-3

• Flow direction monitoring

• Status

– Partially filled pipe detection

– Low flow cut off

The range of options increases if the measuring device has one or more

application packages.

Proline Promass A 100

PROFIBUS DP

Signal encoding NRZ code

Data transfer 9.6 kBaud…12 MBaud

Modbus RS485

Physical interface In accordance with EIA/TIA-485-A standard

Terminating resistor • For device version used in non-hazardous areas or Zone 2/Div. 2: integrated

and can be activated via DIP switches on the transmitter electronics module

• For device version used in intrinsically safe areas: integrated and can be

activated via DIP switches on the Safety Barrier Promass 100

10 Endress+Hauser

Page 11

Proline Promass A 100

EtherNet/IP

Standards In accordance with IEEE 802.3

PROFINET

Standards In accordance with IEEE 802.3

Signal on alarm

Depending on the interface, failure information is displayed as follows:

Current output

4-20 mA

Failure mode Choose from:

• 4 to 20 mA in accordance with NAMUR recommendation NE 43

• 4 to 20 mA in accordance with US

• Min. value: 3.59 mA

• Max. value: 22.5 mA

• Freely definable value between: 3.59 to 22.5 mA

• Actual value

• Last valid value

HART

Device diagnostics Device condition can be read out via HART Command 48

Pulse/frequency/switch output

Pulse output

Failure mode Choose from:

• Actual value

• No pulses

Frequency output

Failure mode Choose from:

• Actual value

• 0 Hz

• Defined value: 0 to 12 500 Hz

Switch output

Failure mode Choose from:

• Current status

• Open

• Closed

PROFIBUS DP

Status and alarm

messages

Diagnostics in accordance with PROFIBUS PA Profile 3.02

Modbus RS485

Failure mode Choose from:

• NaN value instead of current value

• Last valid value

Endress+Hauser 11

Page 12

Proline Promass A 100

EtherNet/IP

Device diagnostics Device condition can be read out in Input Assembly

PROFINET

Device diagnostics In accordance with "Application Layer protocol for decentral device periphery and

distributed automation", version 2.3

Local display

Plain text display With information on cause and remedial measures

Backlight Red backlighting indicates a device error.

Status signal as per NAMUR recommendation NE 107

Operating tool

• Via digital communication:

– HART protocol

– PROFIBUS DP

– Modbus RS485

– EtherNet/IP

– PROFINET

• Via service interface

• Via Web server

Ex connection data

Plain text display With information on cause and remedial measures

Additional information on remote operation → 79

Web browser

Plain text display With information on cause and remedial measures

Light emitting diodes (LED)

Status information Status indicated by various light emitting diodes

The following information is displayed depending on the device version:

• Supply voltage active

• Data transmission active

• Device alarm/error has occurred

• EtherNet/IP network available

• EtherNet/IP connection established

• PROFINET network available

• PROFINET connection established

• PROFINET blinking feature

These values only apply for the following device version:

Order code for "Output", option M "Modbus RS485", for use in intrinsically safe areas

12 Endress+Hauser

Page 13

Proline Promass A 100

Safety Barrier Promass 100

Safety-related values

Terminal numbers

Supply voltage Signal transmission

2 (L-) 1 (L+) 26 (A) 27 (B)

U

nom

U

= AC 260 V

max

= DC 24 V

U

nom

U

= AC 260 V

max

= DC 5 V

Intrinsically safe values

Terminal numbers

Supply voltage Signal transmission

20 (L-) 10 (L+) 62 (A) 72 (B)

Uo = 16.24 V

Io = 623 mA

Po = 2.45 W

With IIB

1)

: Lo = 92.8 µH, Co = 0.433 μF, Lo/Ro = 14.6 μH/Ω

1)

: Lo= 372 µH, Co = 2.57 μF, Lo/Ro = 58.3 μH/Ω

With IIC

For an overview and for information on the interdependencies between the gas group - sensor - nominal

diameter, see the "Safety Instructions" (XA) document for the measuring device

Low flow cut off

Galvanic isolation

1) The gas group depends on the sensor and nominal diameter.

Transmitter

Intrinsically safe values

Order code for

"Approval"

• Option BM: ATEX II2G + IECEx Z1 Ex ia, II2D Ex tb

• Option BO: ATEX II1/2G + IECEx Z0/Z1 Ex ia, II2D

• Option BQ: ATEX II1/2G + IECEx Z0/Z1 Ex ia

• Option BU: ATEX II2G + IECEx Z1 Ex ia

• Option C2: CSA C/US IS Cl. I, II, III Div. 1

• Option 85: ATEX II2G + IECEx Z1 Ex ia + CSA C/US

IS Cl. I, II, III Div. 1

For an overview and for information on the interdependencies between the gas group - sensor - nominal

diameter, see the "Safety Instructions" (XA) document for the measuring device

Supply voltage Signal transmission

20 (L-) 10 (L+) 62 (A) 72 (B)

Terminal numbers

Ui = 16.24 V

Ii = 623 mA

Pi = 2.45 W

Li = 0 µH

Ci = 6 nF

The switch points for low flow cut off are user-selectable.

The following connections are galvanically isolated from each other:

• Outputs

• Power supply

Protocol-specific data HART

Manufacturer ID 0x11

Device type ID 0x4A

HART protocol revision 7

Device description files

(DTM, DD)

HART load Min. 250 Ω

Information and files under:

www.endress.com

Endress+Hauser 13

Page 14

Dynamic variables Read out the dynamic variables: HART command 3

The measured variables can be freely assigned to the dynamic variables.

Measured variables for PV (primary dynamic variable)

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

Measured variables for SV, TV, QV (secondary, tertiary and quaternary

dynamic variable)

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

• Totalizer 1

• Totalizer 2

• Totalizer 3

The range of options increases if the measuring device has one or more

application packages.

Heartbeat Technology Application Package

Additional measured variables are available with the Heartbeat Technology

application package:

• Carrier pipe temperature

• Oscillation amplitude 0

Device variables Read out the device variables: HART command 9

The device variables are permanently assigned.

A maximum of 8 device variables can be transmitted:

• 0 = mass flow

• 1 = volume flow

• 2 = corrected volume flow

• 3 = density

• 4 = reference density

• 5 = temperature

• 6 = totalizer 1

• 7 = totalizer 2

• 8 = totalizer 3

• 13 = target mass flow

• 14 = carrier mass flow

• 15 = concentration

Proline Promass A 100

PROFIBUS DP

Manufacturer ID 0x11

Ident number 0x1561

Profile version 3.02

Device description files (GSD,

DTM, DD)

Information and files under:

• www.endress.com

On the product page for the device: Documents/Software → Device drivers

• www.profibus.org

14 Endress+Hauser

Page 15

Proline Promass A 100

Output values

(from measuring device to

automation system)

Input values

(from automation system to

measuring device)

Supported functions • Identification & Maintenance

Configuration of the device

address

Analog input 1 to 8

• Mass flow

• Volume flow

• Corrected volume flow

• Target mass flow

• Carrier mass flow

• Density

• Reference density

• Concentration

• Temperature

• Carrier pipe temperature

• Electronic temperature

• Oscillation frequency

• Oscillation amplitude

• Frequency fluctuation

• Oscillation damping

• Tube damping fluctuation

• Signal asymmetry

• Exciter current

Digital input 1 to 2

• Partially filled pipe detection

• Low flow cut off

Totalizer 1 to 3

• Mass flow

• Volume flow

• Corrected volume flow

Analog output 1 to 3 (fixed assignment)

• Pressure

• Temperature

• Reference density

Digital output 1 to 3 (fixed assignment)

• Digital output 1: switch positive zero return on/off

• Digital output 2: perform zero point adjustment

• Digital output 3: switch switch output on/off

Totalizer 1 to 3

• Totalize

• Reset and hold

• Preset and hold

• Stop

• Operating mode configuration:

– Net flow total

– Forward flow total

– Reverse flow total

Simplest device identification on the part of the control system and

nameplate

• PROFIBUS upload/download

Reading and writing parameters is up to ten times faster with PROFIBUS

upload/download

• Condensed status

Simplest and self-explanatory diagnostic information by categorizing

diagnostic messages that occur

• DIP switches on the I/O electronics module

• Via operating tools (e.g. FieldCare)

Modbus RS485

Protocol Modbus Applications Protocol Specification V1.1

Device type Slave

Slave address range 1 to 247

Broadcast address range 0

Endress+Hauser 15

Page 16

Proline Promass A 100

Function codes • 03: Read holding register

• 04: Read input register

• 06: Write single registers

• 08: Diagnostics

• 16: Write multiple registers

• 23: Read/write multiple registers

Broadcast messages Supported by the following function codes:

• 06: Write single registers

• 16: Write multiple registers

• 23: Read/write multiple registers

Supported baud rate • 1 200 BAUD

• 2 400 BAUD

• 4 800 BAUD

• 9 600 BAUD

• 19 200 BAUD

• 38 400 BAUD

• 57 600 BAUD

• 115 200 BAUD

Data transfer mode • ASCII

• RTU

Data access Each device parameter can be accessed via Modbus RS485.

For Modbus register information

EtherNet/IP

Protocol • The CIP Networks Library Volume 1: Common Industrial Protocol

• The CIP Networks Library Volume 2: EtherNet/IP Adaptation of CIP

Communication type • 10Base-T

• 100Base-TX

Device profile Generic device (product type: 0x2B)

Manufacturer ID 0x49E

Device type ID 0x104A

Baud rates Automatic ¹⁰⁄₁₀₀ Mbit with half-duplex and full-duplex detection

Polarity Auto-polarity for automatic correction of crossed TxD and RxD pairs

Supported CIP connections Max. 3 connections

Explicit connections Max. 6 connections

I/O connections Max. 6 connections (scanner)

Configuration options for

measuring device

Configuration of the EtherNet

interface

Configuration of the device

address

Device Level Ring (DLR) No

• DIP switches on the electronics module for IP addressing

• Manufacturer-specific software (FieldCare)

• Add-on Profile Level 3 for Rockwell Automation control systems

• Web browser

• Electronic Data Sheet (EDS) integrated in the measuring device

• Speed: 10 MBit, 100 MBit, auto (factory setting)

• Duplex: half-duplex, full-duplex, auto (factory setting)

• DIP switches on the electronics module for IP addressing (last octet)

• DHCP

• Manufacturer-specific software (FieldCare)

• Add-on Profile Level 3 for Rockwell Automation control systems

• Web browser

• EtherNet/IP tools, e.g. RSLinx (Rockwell Automation)

16 Endress+Hauser

Page 17

Proline Promass A 100

Fix Input

RPI 5 ms to 10 s (factory setting: 20 ms)

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0x66 64

T → O configuration: 0x64 44

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0x66 64

T → O configuration: 0x64 44

Input only Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0xC7 -

T → O configuration: 0x64 44

Input only Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0xC7 -

T → O configuration: 0x64 44

Input Assembly • Current device diagnostics

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

• Totalizer 1

• Totalizer 2

• Totalizer 3

Configurable Input

RPI 5 ms to 10 s (factory setting: 20 ms)

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0x66 64

T → O configuration: 0x65 88

Exclusive Owner Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0x66 64

T → O configuration: 0x65 88

Input only Multicast Instance Size [byte]

Instance configuration: 0x68 398

O → T configuration: 0xC7 -

T → O configuration: 0x65 88

Input only Multicast Instance Size [byte]

Instance configuration: 0x69 -

O → T configuration: 0xC7 -

T → O configuration: 0x65 88

Endress+Hauser 17

Page 18

Proline Promass A 100

Configurable Input Assembly • Current device diagnostics

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

• Totalizer 1

• Totalizer 2

• Totalizer 3

The range of options increases if the measuring device has one or

more application packages.

Fix Output

Output Assembly • Activation of reset totalizers 1-3

• Activation of pressure compensation

• Activation of reference density compensation

• Activation of temperature compensation

• Reset totalizers 1-3

• External pressure value

• Pressure unit

• External reference density

• Reference density unit

• External temperature

• Temperature unit

Configuration

Configuration Assembly Only the most common configurations are listed below.

• Software write protection

• Mass flow unit

• Mass unit

• Volume flow unit

• Volume unit

• Corrected volume flow unit

• Corrected volume unit

• Density unit

• Reference density unit

• Temperature unit

• Pressure unit

• Length

• Totalizer 1-3:

– Assignment

– Unit

– Measuring mode

– Failsafe mode

• Alarm delay

PROFINET

Protocol "Application layer protocol for decentral device periphery and distributed

automation", version 2.3

Conformity class B

Communication type 100 MBit/s

Device profile Application interface identifier 0xF600

Generic device

Manufacturer ID 0x11

Device type ID 0x844A

Device description files (GSD,

DTM)

Baud rates Automatic 100 Mbit/s with full-duplex detection

Information and files under:

• www.endress.com

On the product page for the device: Documents/Software → Device drivers

• www.profibus.org

18 Endress+Hauser

Page 19

Proline Promass A 100

Cycle times From 8 ms

Polarity Auto-polarity for automatic correction of crossed TxD and RxD pairs

Supported connections • 1 x AR (Application Relation)

• 1 x Input CR (Communication Relation)

• 1 x Output CR (Communication Relation)

• 1 x Alarm CR (Communication Relation)

Configuration options for

measuring device

Configuration of the device

name

Output values

(from measuring device to

automation system)

• DIP switches on the electronics module, for device name assignment (last

part)

• Manufacturer-specific software (FieldCare, DeviceCare)

• Web browser

• Device master file (GSD), can be read out via the integrated Web server of

the measuring device

• DIP switches on the electronics module, for device name assignment (last

part)

• DCP protocol

Analog Input module (slot 1 to 14)

• Mass flow

• Volume flow

• Corrected volume flow

• Target mass flow

• Carrier mass flow

• Density

• Reference density

• Concentration

• Temperature

• Carrier pipe temperature

• Electronic temperature

• Oscillation frequency

• Oscillation amplitude

• Frequency fluctuation

• Oscillation damping

• Tube damping fluctuation

• Signal asymmetry

• Exciter current

Discrete Input module (slot 1 to 14)

• Empty pipe detection

• Low flow cut off

Diagnostics Input module (slot 1 to 14)

• Last diagnostics

• Current diagnosis

Totalizer 1 to 3 (slot 15 to 17)

• Mass flow

• Volume flow

• Corrected volume flow

Heartbeat Verification module (fixed assignment)

Verification status (slot 23)

The range of options increases if the measuring device has one or more

application packages.

Endress+Hauser 19

Page 20

Proline Promass A 100

Input values

(from automation system to

measuring device)

Supported functions • Identification & Maintenance

Analog Output module (fixed assignment)

• External pressure (slot 18)

• External temperature (slot 19)

• External reference density (slot 20)

Discrete Output module (fixed assignment)

• Activate/deactivate positive zero return (slot 21)

• Perform zero point adjustment (slot 22)

Totalizer 1 to 3 (slot 15 to 17)

• Totalize

• Reset and hold

• Preset and hold

• Stop

• Operating mode configuration:

– Net flow total

– Forward flow total

– Reverse flow total

Heartbeat Verification module (fixed assignment)

Start verification (slot 23)

The range of options increases if the measuring device has one or more

application packages.

Simple device identification via:

– Control system

– Nameplate

• Measured value status

The process variables are communicated with a measured value status

• Blinking feature via the onsite display for simple device identification and

assignment

Administration of software options

Input/output value Process variable Category Slot

Output value Mass flow Process variable 1…14

Volume flow

Corrected volume flow

Density

Reference density

Temperature

Electronic temperature

Oscillation frequency

Frequency fluctuation

Oscillation damping

Oscillation frequency

Signal asymmetry

Exciter current

Empty pipe detection

Low flow cut off

Current device diagnostics

Previous device diagnostics

Output value Target mass flow Concentration

Carrier mass flow

Concentration

Output value Carrier pipe temperature Heartbeat

1)

2)

1…14

1…14

20 Endress+Hauser

Page 21

Proline Promass A 100

Input/output value Process variable Category Slot

Oscillation damping 1

Oscillation frequency 1

Oscillation amplitude 0

Oscillation amplitude 1

Frequency fluctuation 1

Tube damping fluctuation 1

Exciter current 1

Input value External density Process monitoring 18

External temperature 19

External reference density 20

Flow override 21

Zero point adjustment 22

Verification status Heartbeat Verification

1) Only available with the "Concentration" application package.

2) Only available with the "Heartbeat" application package.

2)

23

Endress+Hauser 21

Page 22

Startup configuration

Proline Promass A 100

Startup configuration

(NSU)

If startup configuration is enabled, the configuration of the most important

device parameters is taken from the automation system and used.

The following configuration is taken from the automation system:

• Management

– Software revision

– Write protection

• System units

– Mass flow

– Mass

– Volume flow

– Volume

– Corrected volume flow

– Corrected volume

– Density

– Reference density

– Temperature

– Pressure

• Concentration application package

– Coefficients A0 to A4

– Coefficients B1 to B3

• Sensor adjustment

• Process param.

– Damping (flow, density, temperature)

– Flow override

• Low flow cut off

– Assign process variable

– Switch-on/switch-off point

– Pressure shock suppression

• Empty pipe detection

– Assign process variable

– Limit values

– Response time

– Max. damping

• Corrected volume flow calculation

– External reference density

– Fixed reference density

– Reference temperature

– Linear expansion coefficient

– Square expansion coefficient

• Measuring mode

– Medium

– Gas type

– Reference sound velocity

– Temperature coefficient sound velocity

• External compensation

– Pressure compensation

– Pressure value

– External pressure

• Diagnostic settings

• Diagnostic behavior for diverse diagnostic information

22 Endress+Hauser

Page 23

Proline Promass A 100

A

B

C

2

2.1 2.2

3

3.1 3.2

1

1.1 1.2 1.3

4

4.2

4.1

Power supply

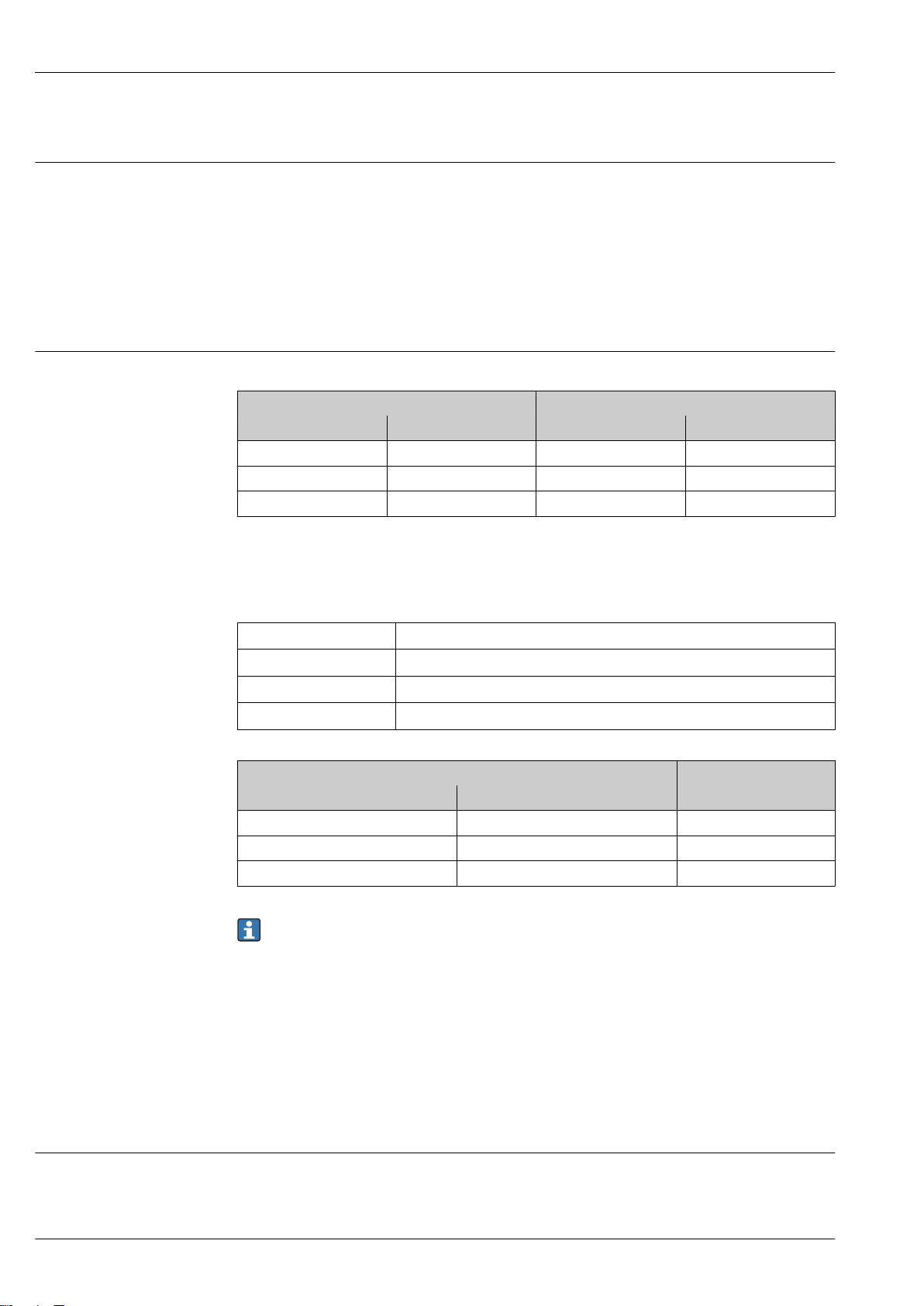

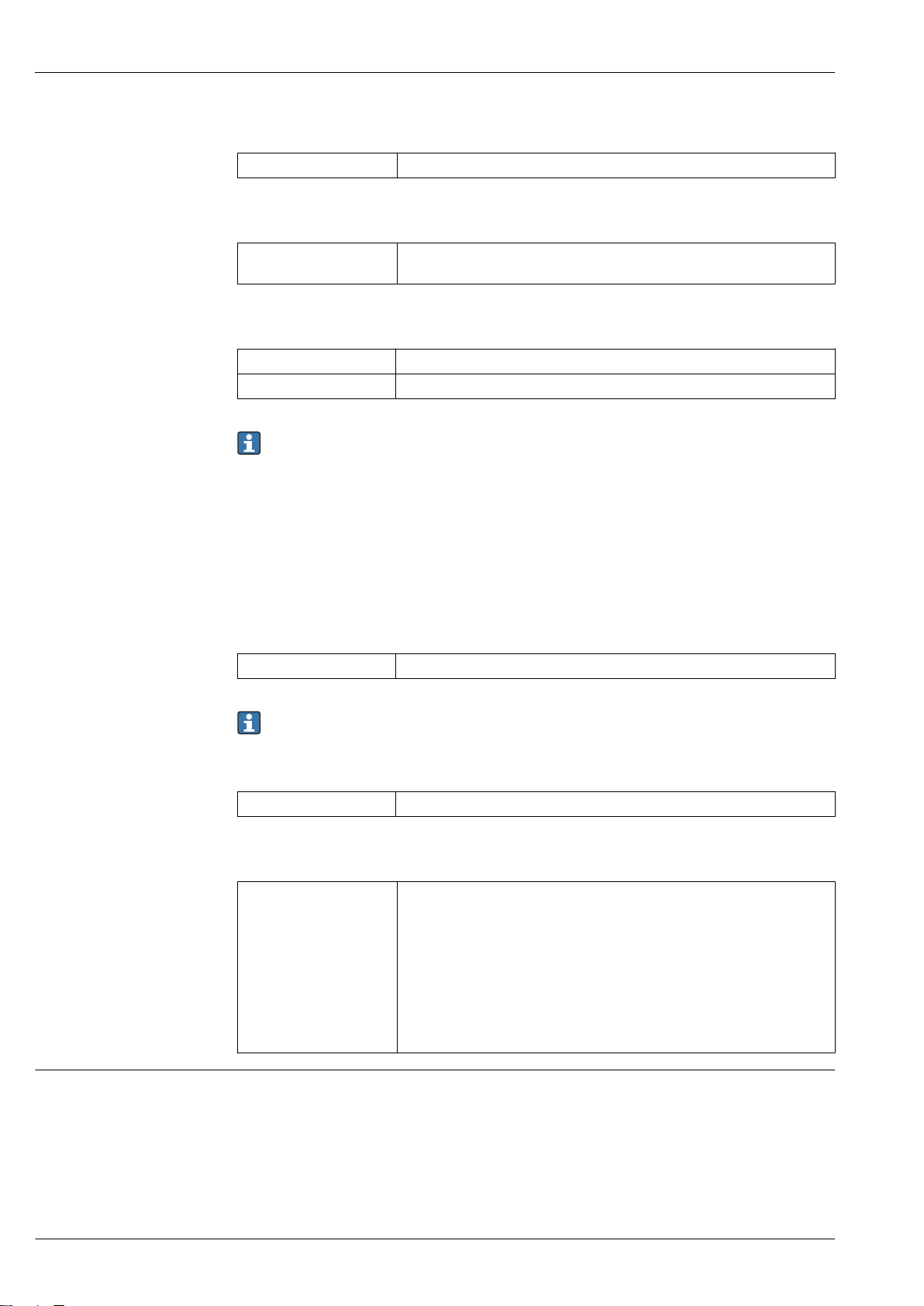

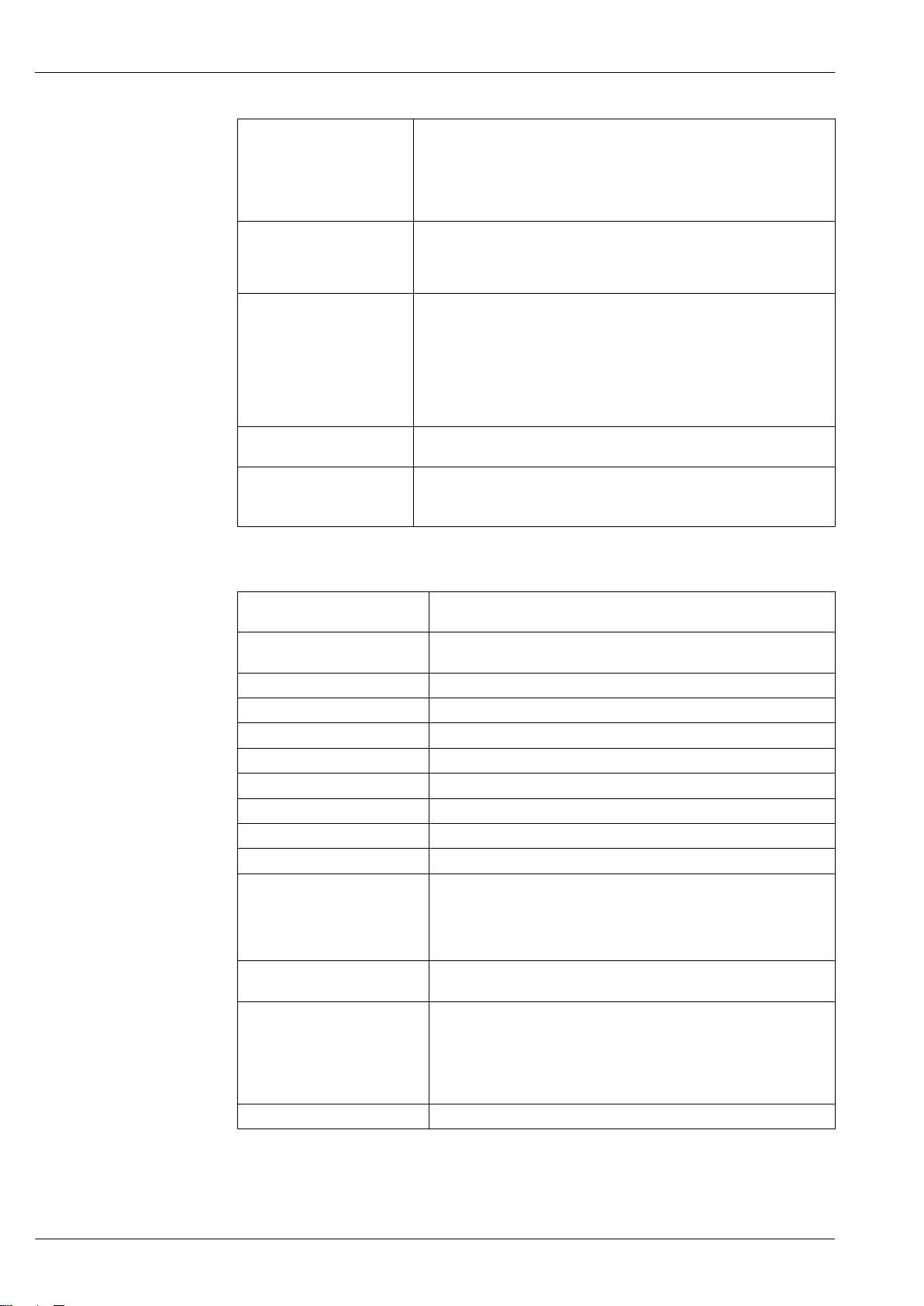

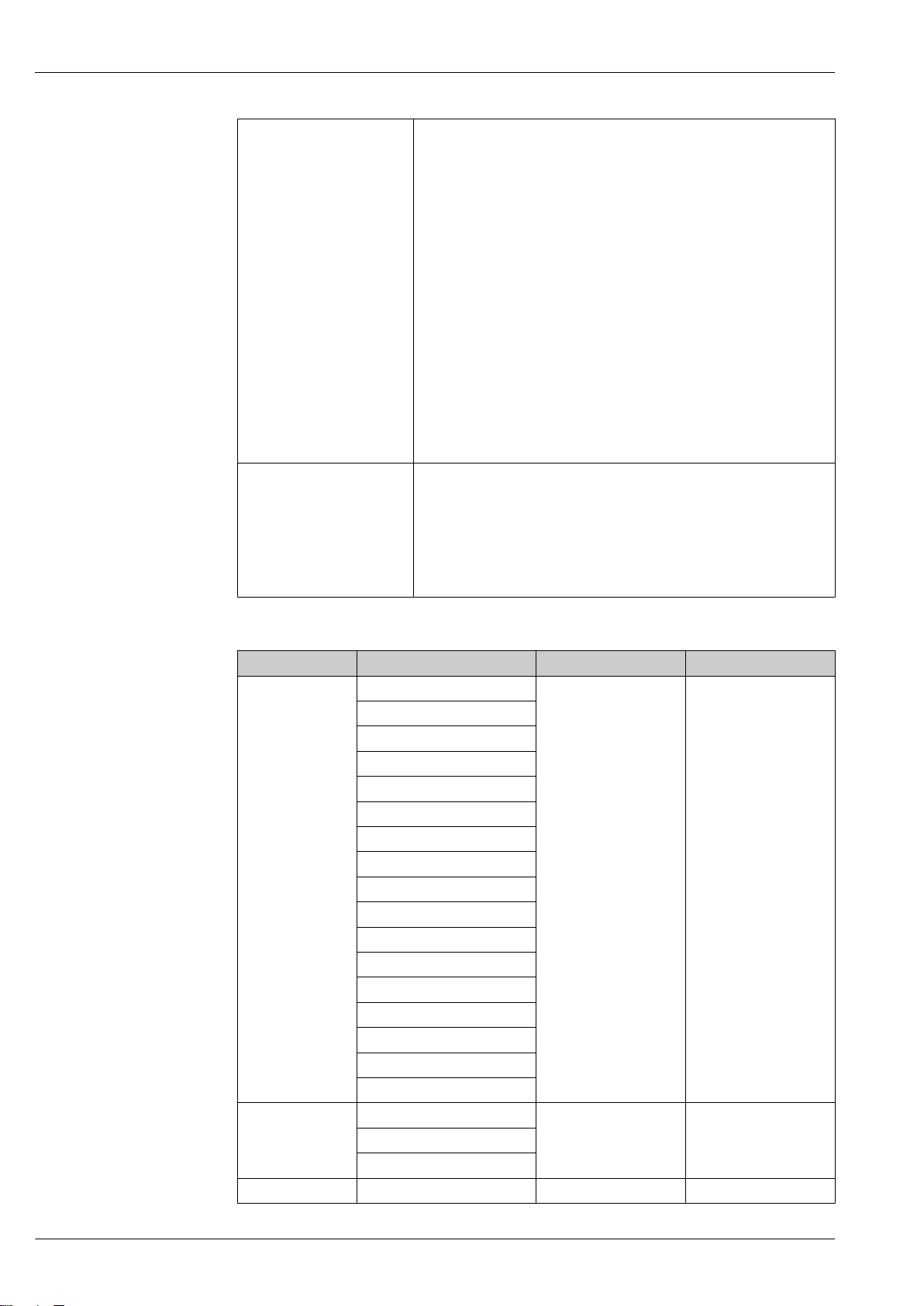

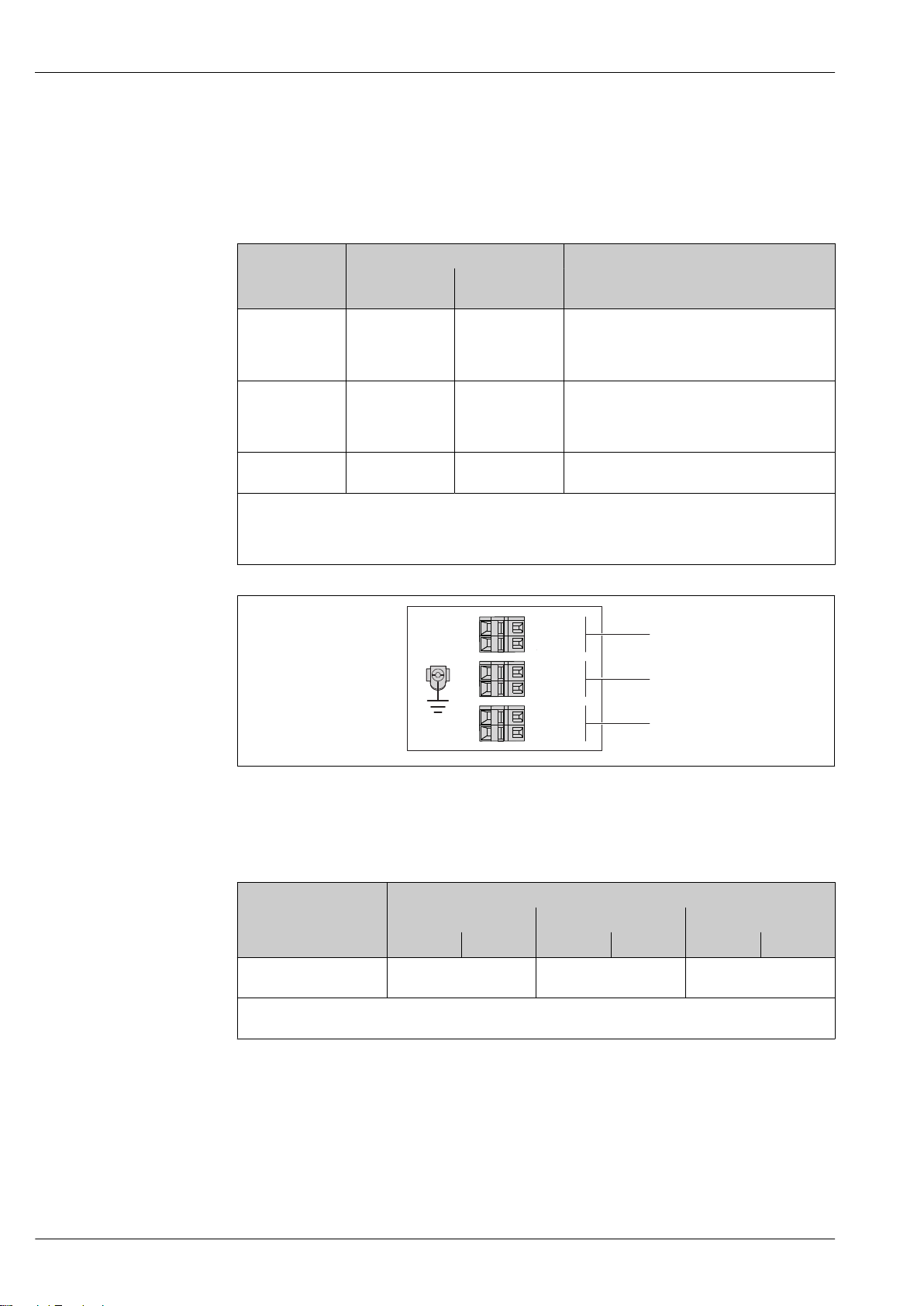

Terminal assignment Overview: housing version and connection versions

A0016770

A Housing version: compact, aluminum coated

B Housing version: compact, hygienic, stainless

C Housing version: ultra-compact, hygienic, stainless

1 Connection version: 4-20 mA HART, pulse/frequency/switch output

1.1 Signal transmission: pulse/frequency/switch output

1.2 Signal transmission: 4-20 mA HART

1.3 Supply voltage

2 Connection version: Modbus RS485

2.1 Signal transmission

2.2 Supply voltage

3 Connection versions: EtherNet/IP and PROFINET

3.1 Signal transmission

3.2 Supply voltage

4 Connection version: PROFIBUS DP

4.1 Signal transmission

4.2 Supply voltage

Endress+Hauser 23

Page 24

Proline Promass A 100

L

L

26

27

+

_

24

25

1

2

+

_

+

_

1

2

3

Transmitter

Connection version 4-20 mA HART with pulse/frequency/switch output

Order code for "Output", option B

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

Connection methods available

"Housing"

Options

Outputs

Terminals Terminals • Option A: coupling M20x1

A, B

Options

A, B

Options

A, B, C

Device plugs

→ 30

Device plugs

→ 30

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

Power

"Electrical connection"

supply

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Terminals • Option L: plug M12x1 + thread NPT ½"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Possible options for order code

Device plugs

Option Q: 2 x plug M12x1

→ 30

A0016888

2 Terminal assignment 4-20 mA HART with pulse/frequency/switch output

1 Power supply: DC 24 V

2 Output 1: 4-20 mA HART (active)

3 Output 2: pulse/frequency/switch output (passive)

Terminal number

Order code for

"Output"

Power supply Output 1 Output 2

2 (L-) 1 (L+) 27 (–) 26 (+) 25 (–) 24 (+)

Option B DC 24 V 4-20 mA HART (active) Pulse/frequency/switch

output (passive)

Order code for "Output":

Option B: 4-20 mA HART with pulse/frequency/switch output

24 Endress+Hauser

Page 25

Proline Promass A 100

L

L

26

27BA

1

2

+

_

1

2

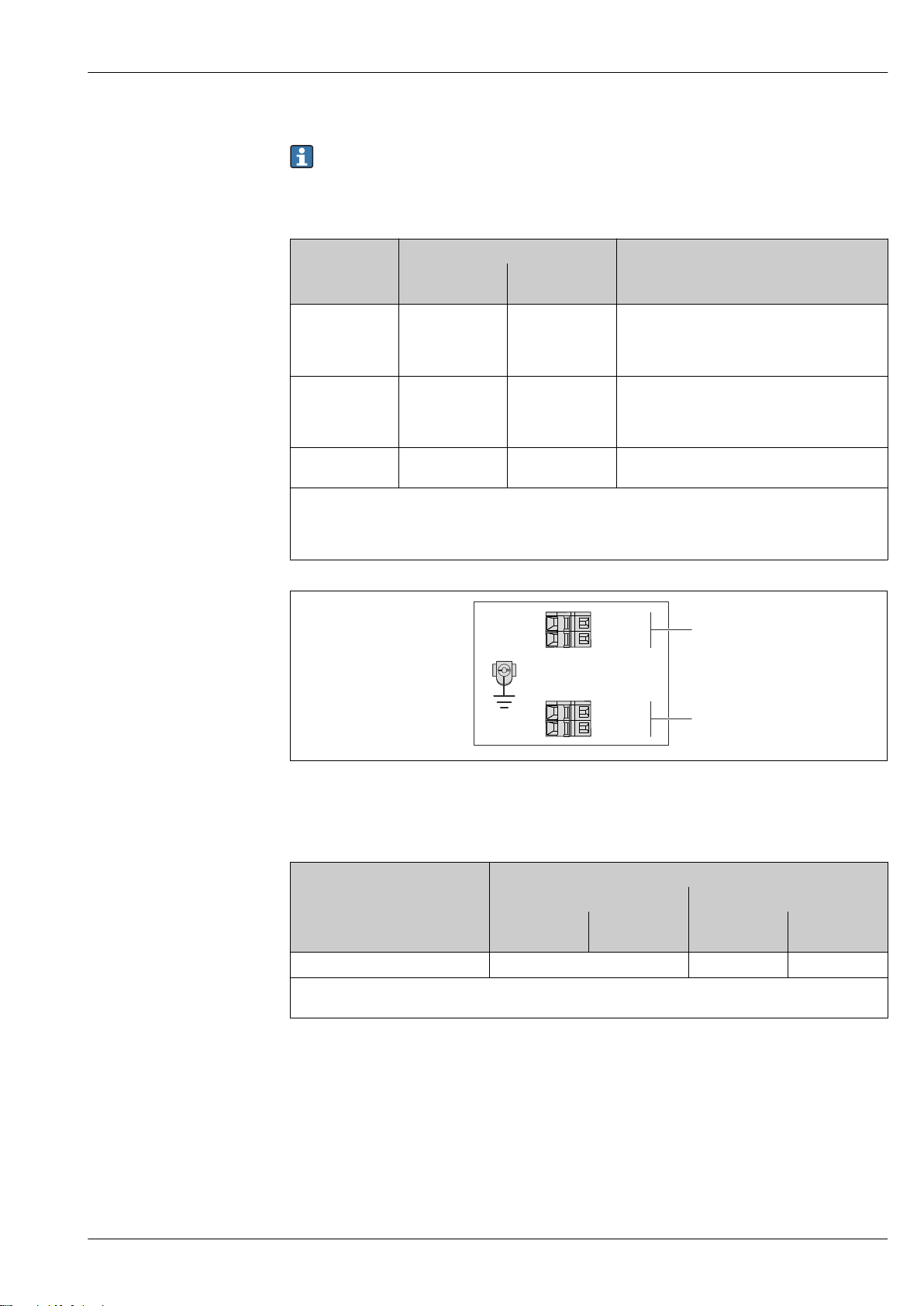

PROFIBUS DP connection version

For use in the non-hazardous area and Zone 2/Div. 2.

Order code for "Output", option L

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

"Housing"

Options

A, B

Options

A, B

Options

A, B, C

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

Connection methods available

Output

Terminals Terminals • Option A: coupling M20x1

Device plugs

→ 30

Device plugs

→ 30

Power

supply

Terminals • Option L: plug M12x1 + thread NPT ½"

Device plugs

→ 30

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Option Q: 2 x plug M12x1

A0022716

3 PROFIBUS DP terminal assignment

1 Power supply: DC 24 V

2 PROFIBUS DP

Terminal number

Order code for

"Output"

Option L DC 24 V B A

Order code for "Output":

Option L: PROFIBUS DP, for use in non-hazardous areas and Zone 2/div. 2

Power supply Output

2 (L-) 1 (L+) 26 (RxD/TxD-P) 27 (RxD/TxD-

N)

Endress+Hauser 25

Page 26

Proline Promass A 100

L

L

26

27

A

B

1

2

+

_

1

2

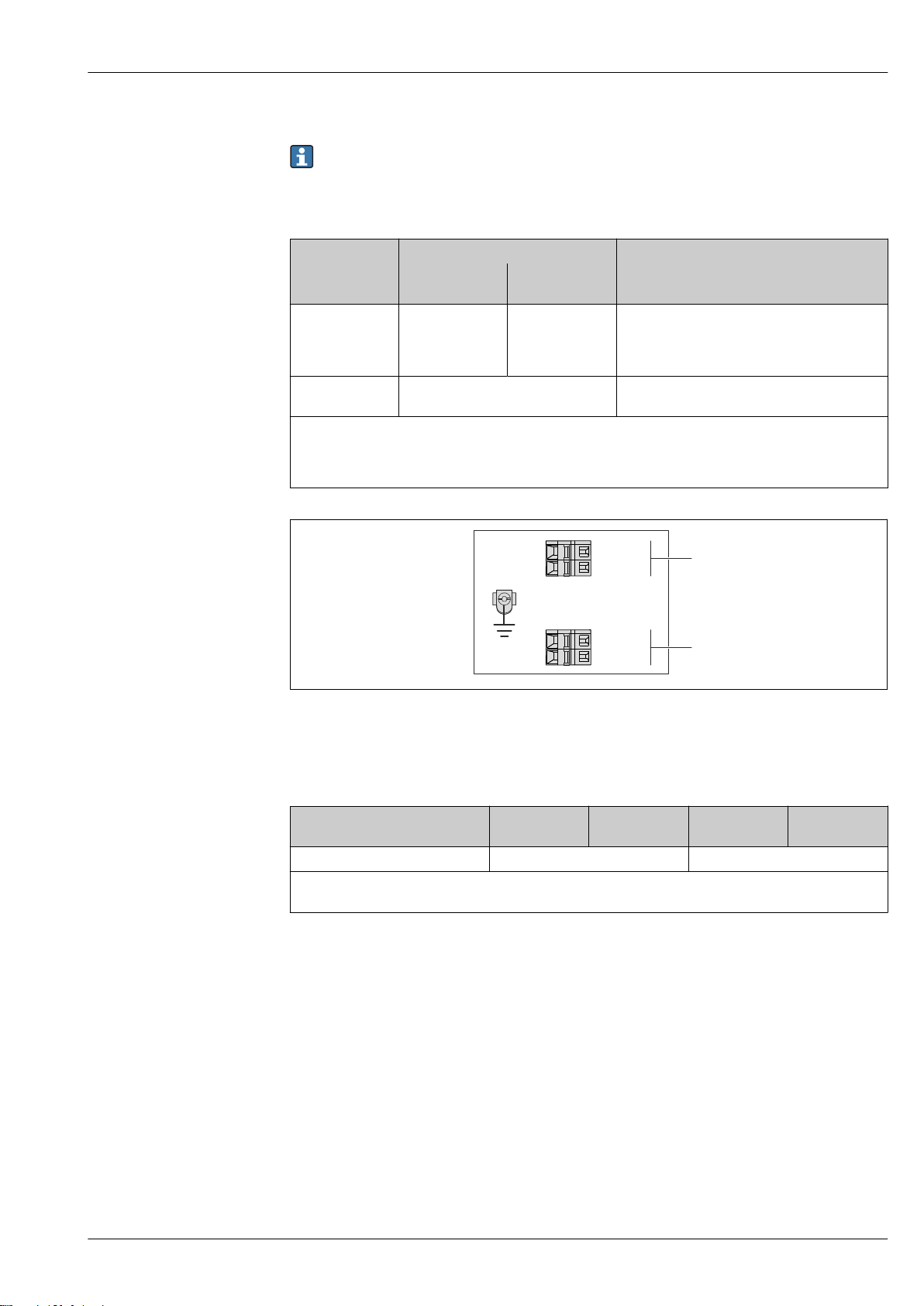

Modbus RS485 connection version

For use in the non-hazardous area and Zone 2/Div. 2.

Order code for "Output", option M

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

Connection methods available

"Housing"

Options

Output

Terminals Terminals • Option A: coupling M20x1

A, B

Options

A, B

Options

A, B, C

Device plugs

→ 30

Device plugs

→ 30

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

Power

"Electrical connection"

supply

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Terminals • Option L: plug M12x1 + thread NPT ½"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Possible options for order code

Device plugs

Option Q: 2 x plug M12x1

→ 30

A0019528

4 Modbus RS485 terminal assignment, connection version for use in non-hazardous areas and Zone 2/Div.

2

1 Power supply: DC 24 V

2 Modbus RS485

Terminal number

Order code for

"Output"

Power supply Output

2 (L-) 1 (L+) 27 (B) 26 (A)

Option M DC 24 V Modbus RS485

Order code for "Output":

Option M Modbus RS485, for use in non-hazardous areas and Zone 2/Div. 2

26 Endress+Hauser

Page 27

Proline Promass A 100

L

L

62

72

A

B

10

20

+

_

1

2

Modbus RS485 connection version

For use in the intrinsically safe area. Connection via Safety Barrier Promass 100.

Order code for "Output", option M

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

"Housing"

Options

A, B

Output

Power

supply

Terminals Terminals • Option A: coupling M20x1

Possible options for order code

"Electrical connection"

• Option B: thread M20x1

• Option C: thread G ½"

• Option D: thread NPT ½"

Connection methods available

A, B, C Device plugs

Option I: plug M12x1

→ 30

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

A0017053

5 Modbus RS485 terminal assignment, connection version for use in intrinsically safe areas (connection via

Safety Barrier Promass 100)

1 Intrinsically safe power supply

2 Modbus RS485

Order code for

"Output"

20 (L-) 10 (L+) 72 (B) 62 (A)

Option M Intrinsically safe supply voltage Modbus RS485 intrinsically safe

Order code for "Output":

Option M: Modbus RS485, for use in intrinsically safe areas (connection via Safety Barrier Promass 100)

Endress+Hauser 27

Page 28

Proline Promass A 100

L

L

1

2

+

_

1

2

EtherNet/IP connection version

Order code for "Output", option N

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

"Housing"

Options

A, B

Options

A, B, C

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

6 EtherNet/IP terminal assignment

1 Power supply: DC 24 V

2 EtherNet/IP

Connection methods available

Output

Device plugs

→ 30

Device plugs

→ 30

Power

supply

Terminals • Option L: plug M12x1 + thread NPT ½"

Device plugs

→ 30

Possible options for order code

"Electrical connection"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Option Q: 2 x plug M12x1

A0017054

Order code for

"Output"

Option N DC 24 V EtherNet/IP

Order code for "Output":

Option N: EtherNet/IP

Terminal number

Power supply Output

2 (L-) 1 (L+) Device plug M12x1

28 Endress+Hauser

Page 29

Proline Promass A 100

L

L

1

2

+

_

1

2

PROFINET connection version

Order code for "Output", option R

Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

Order code for

"Housing"

Options

A, B

Options

A, B, C

Order code for "Housing":

• Option A: compact, coated aluminum

• Option B: compact, hygienic, stainless

• Option C ultra-compact, hygienic, stainless

7 PROFINET terminal assignment

1 Power supply: DC 24 V

2 PROFINET

Connection methods available

Output

Device plugs

→ 30

Device plugs

→ 30

Power

supply

Terminals • Option L: plug M12x1 + thread NPT ½"

Device plugs

→ 30

Possible options for order code

"Electrical connection"

• Option N: plug M12x1 + coupling M20

• Option P: plug M12x1 + thread G ½"

• Option U: plug M12x1 + thread M20

Option Q: 2 x plug M12x1

A0017054

Order code for "Output":

Option R: PROFINET

Terminal number

Order code for

"Output"

Option R DC 24 V PROFINET

Power supply Output

2 (L-) 1 (L+) Device plug M12x1

Endress+Hauser 29

Page 30

Safety Barrier Promass 100

A

Safe area

1

L+2L

27

26

A B

Power

supply

24V

DC

Modbus

RS485

10207262

L+L A B

Power

supply

Modbus

RS485

Hazardous area

Safety Barrier

Promass 100

Power

Communication

Lift panel for

bus termination

1

2

A

1

2

4

3

5

8 Safety Barrier Promass 100 with terminals

1 Non-hazardous area and Zone 2/Div. 2

2 Intrinsically safe area

Proline Promass A 100

A0016922

Pin assignment, device plug

Order codes for the M12x1 connectors, see the "Order code for electrical connection" column:

• 4-20 mA HART, pulse/frequency/switch output → 24

• PROFIBUS DP→ 25

• Modbus RS485 → 26

• EtherNet/IP → 28

• PROFINET→ 29

Supply voltage

For all connection versions except MODBUS RS485 intrinsically safe (device side)

Device plug MODBUS RS485 intrinsically safe with supply voltage → 31

Pin Assignment

1 L+ DC 24 V

2 Not assigned

3 Not assigned

4 L- DC 24 V

A0016809

5 Grounding/shielding

Coding Plug/socket

A Plug

The following is recommended as a socket:

• Binder, series 763, part no. 79 3440 35 05

• Alternatively: Phoenix part no. 1669767 SAC-5P-M12MS

– With the order code for "Output", option B: 4-20 mA HART, pulse/frequency/switch output

– With the order code for "Output", option N: EtherNet/IP

• When using the device in a hazardous location: Use a suitably certified socket.

30 Endress+Hauser

Page 31

Proline Promass A 100

3

2

4

1

5

3

2

4

1

5

1

2

4

3

5

4-20 mA HART with pulse/frequency/switch output

Device plug for signal transmission (device side)

Pin Assignment

1 + 4-20 mA HART (active)

2 - 4-20 mA HART (active)

3 + Pulse/frequency/switch output (passive)

4 - Pulse/frequency/switch output (passive)

A0016810

• Recommended plug: Binder, series 763, part no. 79 3439 12 05

• When using the device in a hazardous location, use a suitably certified plug.

5 Grounding/shielding

Coding Plug/socket

A Socket

PROFIBUS DP

For use in the non-hazardous area and Zone 2/Div. 2.

Device plug for signal transmission (device side)

Pin Assignment

1 Not assigned

2 A PROFIBUS DP

3 Not assigned

4 B PROFIBUS DP

A0016811

• Recommended plug: Binder, series 763, part no. 79 4449 20 05

• When using the device in a hazardous location, use a suitably certified plug.

5 Grounding/shielding

Coding Plug/socket

B Socket

MODBUS RS485

Device plug for signal transmission with supply voltage (device side), MODBUS RS485 (intrinsically

safe)

Pin Assignment

1 L+ Supply voltage, intrinsically safe

A0016809

2 A

3 B

4 L- Supply voltage, intrinsically safe

5 Grounding/shielding

Coding Plug/socket

A Plug

Modbus RS485 intrinsically safe

• Recommended socket: Binder, series 763, part no. 79 3439 12 05

• When using the device in a hazardous location: Use a suitably certified socket.

Endress+Hauser 31

Page 32

Proline Promass A 100

3

2

4

1

5

3

2

4

1

3

2

4

1

Device plug for signal transmission (device side), MODBUS RS485 (not intrinsically safe)

For use in the non-hazardous area and Zone 2/Div. 2.

Pin Assignment

1 Not assigned

2 A Modbus RS485

3 Not assigned

4 B Modbus RS485

A0016811

• Recommended plug: Binder, series 763, part no. 79 4449 20 05

• When using the device in a hazardous location, use a suitably certified plug.

EtherNet/IP

Device plug for signal transmission (device side)

5 Grounding/shielding

Coding Plug/socket

B Socket

Pin Assignment

1 + Tx

2 + Rx

3 - Tx

4 - Rx

A0016812

Recommended plug:

• Binder, series 763, part no. 99 3729 810 04

• Phoenix, part no. 1543223 SACC-M12MSD-4Q

• When using the device in a hazardous location, use a suitably certified plug.

Coding Plug/socket

D Socket

PROFINET

Device plug for signal transmission (device side)

Pin Assignment

1 + TD +

2 + RD +

3 - TD –

4 - RD –

A0016812

Coding Plug/socket

D Socket

Recommended plug:

• Binder, series 763, part no. 99 3729 810 04

• Phoenix, part no. 1543223 SACC-M12MSD-4Q

• When using the device in a hazardous location, use a suitably certified plug.

Supply voltage

The power unit must be tested to ensure it meets safety requirements (e.g. PELV, SELV).

32 Endress+Hauser

Page 33

Proline Promass A 100

Transmitter

For device version with communication type:

• HART, PROFIBUS DP, EtherNet/IP: DC 20 to 30 V

• Modbus RS485, device version:

– For use in the non-hazardous area and Zone 2/Div. 2: DC 20 to 30 V

– For use in the intrinsically safe area: power supply via Safety Barrier Promass 100

Safety Barrier Promass 100

DC 20 to 30 V

Power consumption Transmitter

Order code for "Output"

Option B: 4-20 mA HART with pulse/frequency/switch output 3.5 W

Option L: PROFIBUS DP 3.5 W

Option M: Modbus RS485, for use in intrinsically safe areas 2.45 W

Option N: EtherNet/IP 3.5 W

Option R: PROFINET 3.5 W

Safety Barrier Promass 100

Order code for "Output"

Option M: Modbus RS485, for use in intrinsically safe areas 4.8 W

Current consumption Transmitter

Order code for "Output"

Option B: 4-20mA HART, pul./freq./switch output 145 mA 18 A (< 0.125 ms)

Option L: PROFIBUS DP 145 mA 18 A (< 0.125 ms)

Option M Modbus RS485, for use in non-hazardous

areas and Zone 2/Div. 2

Option M: Modbus RS485, for use in intrinsically safe

areas

Option N: EtherNet/IP 145 mA 18 A (< 0.125 ms)

Option R: PROFINET 145 mA 18 A (< 0.125 ms)

Maximum

Power consumption

Maximum

Power consumption

Maximum

Current consumption

90 mA 10 A (< 0.8 ms)

145 mA 16 A (< 0.4 ms)

switch-on current

Maximum

Safety Barrier Promass 100

Power supply failure

Order code for "Output"

Option M: Modbus RS485, for use in intrinsically safe

areas

• Totalizers stop at the last value measured.

Maximum

Current consumption

230 mA 10 A (< 0.8 ms)

Maximum

switch-on current

• Depending on the device version, the configuration is retained in the device memory or in the

plug-in memory (HistoROM DAT).

• Configuration is retained in the plug-in memory (HistoROM DAT).

• Error messages (incl. total operated hours) are stored.

Endress+Hauser 33

Page 34

Electrical connection Connecting the transmitter

1 2 1 2 3 4

A B C

4

4...20 mA

+

–

5

2

1

3

6

+

_

A Housing version: compact, aluminum coated

B Housing version: compact hygienic, stainless

1 Cable entry or device plug for signal transmission

2 Cable entry or device plug for supply voltage

C Housing version: ultra-compact, hygienic, stainless, M12 device plug

3 Device plug for signal transmission

4 Device plug for supply voltage

Proline Promass A 100

A0016924

• Terminal assignment → 23

• Pin assignment, device plug → 30

In the case of device versions with a connector, the transmitter housing does not need to be

opened to connect the signal cable or power supply cable.

Connection examples

Current output 4-20 mA HART

9 Connection example for 4-20 mA HART current output (active)

1 Automation system with current input (e.g. PLC)

2 Cable shield, observe cable specifications

3 Connection for HART operating devices

4 Resistor for HART communication (≥ 250 Ω): observe maximum load

5 Analog display unit: observe maximum load

6 Transmitter

A0016800

34 Endress+Hauser

Page 35

Proline Promass A 100

1

+

_

12345

2

+

–

+

–

3

1

+

_

+

_

2

+

_

3

Pulse/frequency output

A0016801

10 Connection example for pulse/frequency output (passive)

1 Automation system with pulse/frequency input (e.g. PLC)

2 Power supply

3 Transmitter: observe input values → 9

Switch output

11 Connection example for switch output (passive)

1 Automation system with switch input (e.g. PLC)

2 Power supply

3 Transmitter: observe input values

A0016802

Endress+Hauser 35

Page 36

Proline Promass A 100

2

1

A

B

A

B

A

B

3

3

2

1

A

B

A

B

A

B

3

4

4

PROFIBUS DP

A0021429

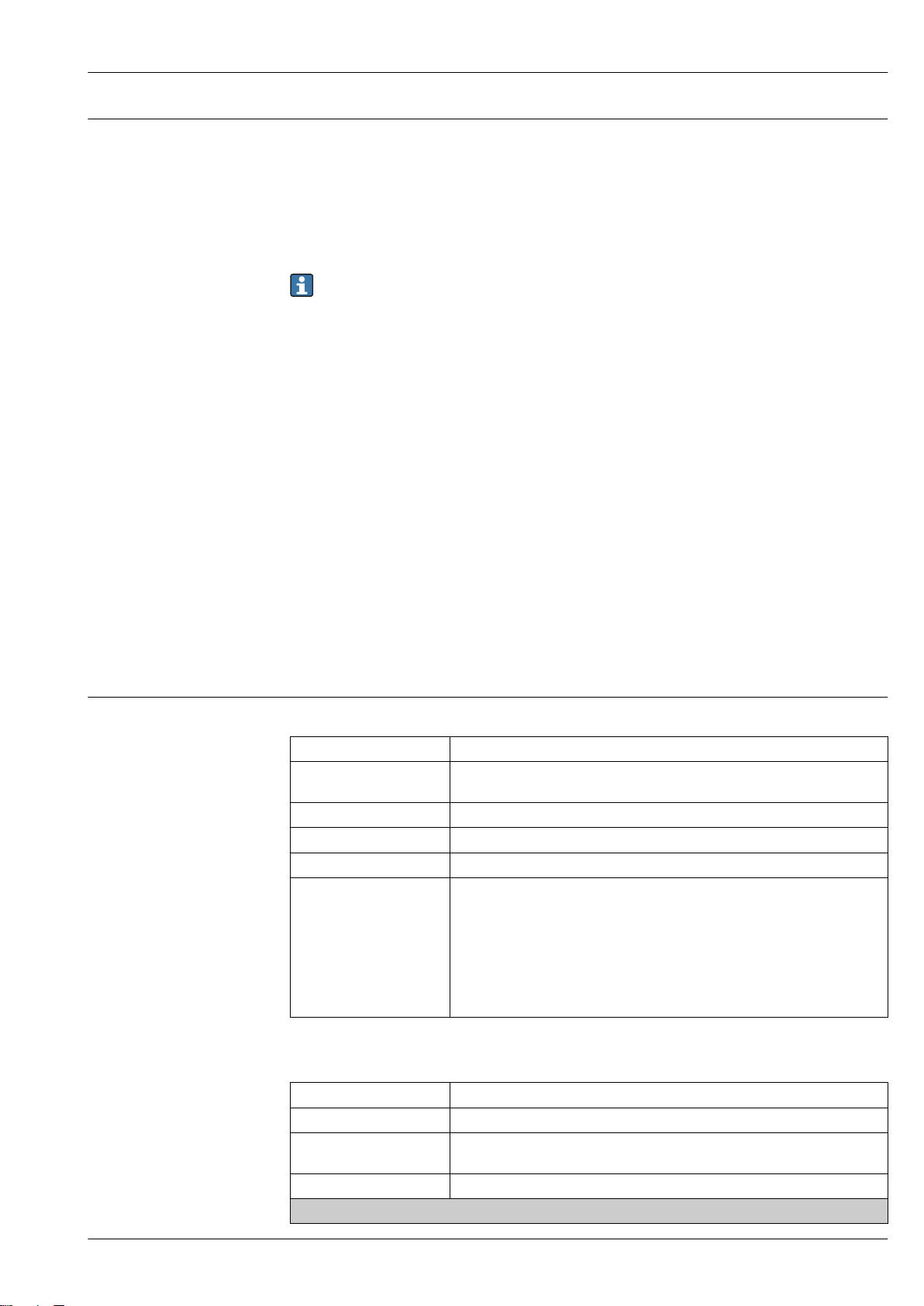

12 Connection example for PROFIBUS DP, non-hazardous area and Zone 2/Div. 2

1 Control system (e.g. PLC)

2 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications

3 Transmitter

If baud rates > 1.5 MBaud an EMC cable entry must be used and the cable shield must continue

as far as the terminal wherever possible.

Modbus RS485

Modbus RS485, non-hazardous area and Zone 2/Div. 2

A0016803

13 Connection example for Modbus RS485, non-hazardous area and Zone 2/Div. 2

1 Control system (e.g. PLC)

2 Cable shield: the cable shield must be grounded at both ends to comply with EMC requirements; observe cable

specifications

3 Distribution box

4 Transmitter

36 Endress+Hauser

Page 37

Proline Promass A 100

21

A

B

A

B

3

L+

L-

A

B

L+

L-

L- L+

A

B

5 6 7

8

4

1 2 4

5

5

3

Modbus RS485 intrinsically safe

A0016804

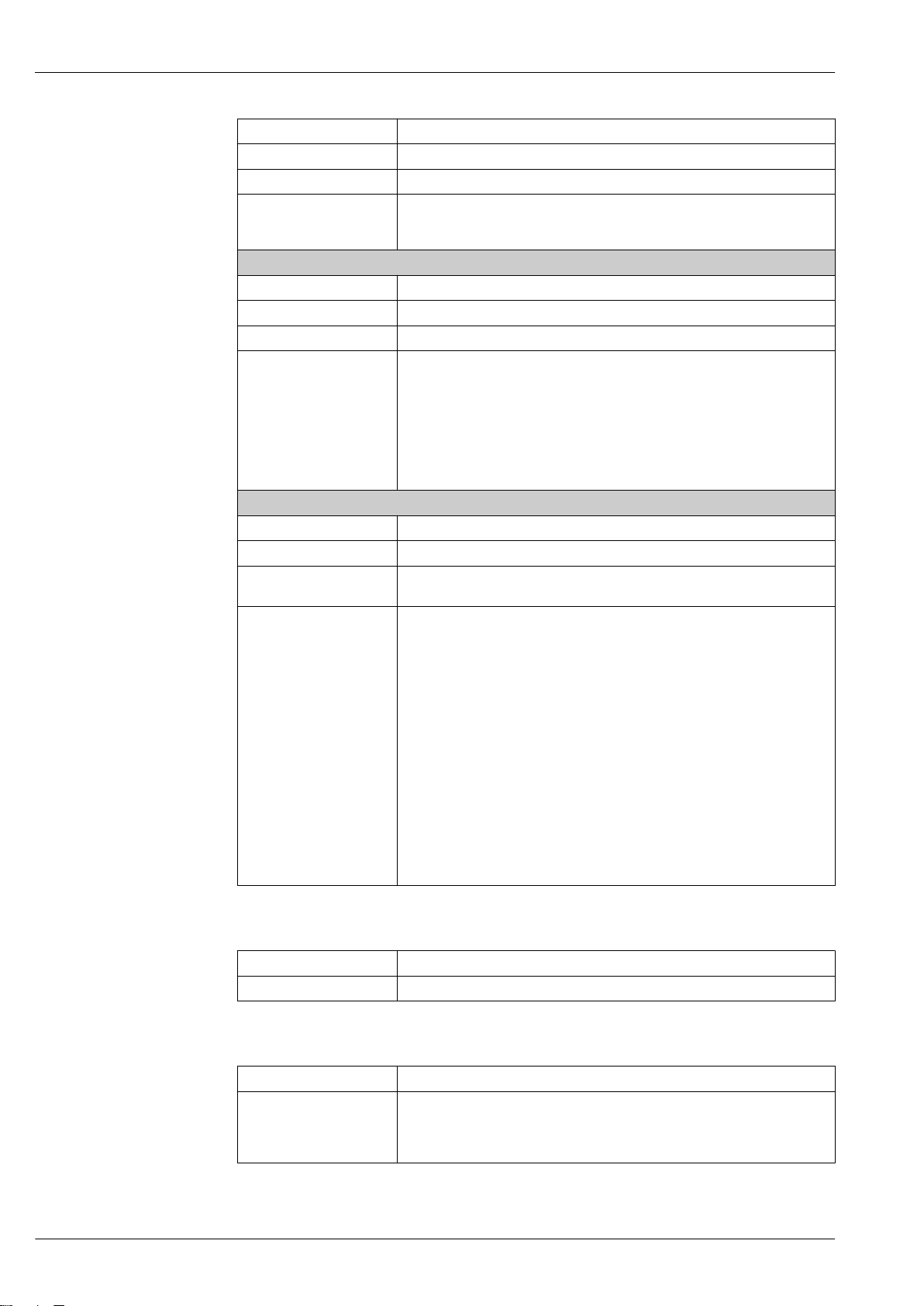

14 Connection example for Modbus RS485 intrinsically safe

1 Control system (e.g. PLC)

2 Cable shield, observe cable specifications

3 Safety Barrier Promass 100

4 Observe cable specifications

5 Non-hazardous area

6 Non-hazardous area and Zone 2/Div. 2

7 Intrinsically safe area

8 Transmitter

EtherNet/IP

15 Connection example for EtherNet/IP

1 Control system (e.g. PLC)

2 Ethernet switch

3 Observe cable specifications

4 Device plug

5 Transmitter

A0016805

Endress+Hauser 37

Page 38

PROFINET

1 2 4

5

5

3

2

4...20 mA

3

41

+

-

5

+

6

16 Connecting cable for PROFINET

1 Control system (e.g. PLC)

2 Ethernet switch

3 Observe cable specifications

4 Connector

5 Transmitter

HART input

Proline Promass A 100

A0016805

17 Connection example for HART input (burst mode) via current output (active)

1 Cable shield, observe cable specifications

2 Resistor for HART communication (≥ 250 Ω): observe maximum load

3 Connection for HART operating devices

4 Analog display unit

5 Transmitter

6 Sensor for external measured variable

A0019828

38 Endress+Hauser

Page 39

Proline Promass A 100

3

4...20 mA

4

521

+

-

6

4...20 mA

+

7

3

4

52

+

-

-

+

A0019830

18 Connection example for HART input (master mode) via current output (active)

1 Automation system with current input (e.g. PLC).

Prerequisite: automation system with HART version 6, HART commands 113 and 114 can be processed.

2 Cable shield, observe cable specifications

3 Resistor for HART communication (≥ 250 Ω): observe maximum load

4 Connection for HART operating devices

5 Analog display unit

6 Transmitter

7 Sensor for external measured variable

Potential equalization Requirements

No special measures for potential equalization are required.

Please consider the following to ensure correct measurement:

• Same electrical potential for the fluid and sensor

• Company-internal grounding concepts

For devices intended for use in hazardous locations, please observe the guidelines in the Ex

documentation (XA).

Terminals

Transmitter

Spring terminals for wire cross-sections0.5 to 2.5 mm2 (20 to 14 AWG)

Safety Barrier Promass 100

Plug-in screw terminals for wire cross-sections0.5 to 2.5 mm2 (20 to 14 AWG)

Cable entries

• Cable gland: M20 × 1.5 with cable 6 to 12 mm (0.24 to 0.47 in)

• Thread for cable entry:

– NPT ½"

– G ½"

– M20

Cable specification Permitted temperature range

• –40 °C (–40 °F) to +80 °C (+176 °F)

• Minimum requirement: cable temperature range ≥ ambient temperature +20 K

Power supply cable

Standard installation cable is sufficient.

Signal cable

Current output

For 4-20 mA HART: Shielded cable recommended. Observe grounding concept of the plant.

Pulse/frequency/switch output

Standard installation cable is sufficient.

Endress+Hauser 39

Page 40

Proline Promass A 100

PROFIBUS DP

The IEC 61158 standard specifies two types of cable (A and B) for the bus line which can be used for

every transmission rate. Cable type A is recommended.

Cable type A

Characteristic impedance 135 to 165 Ω at a measuring frequency of 3 to 20 MHz

Cable capacitance <30 pF/m

Wire cross-section

Cable type Twisted pairs

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shield Copper braided shielding or braided shielding with foil shield. When grounding

Modbus RS485

The EIA/TIA-485 standard specifies two types of cable (A and B) for the bus line which can be used

for every transmission rate. Cable type A is recommended.

>0.34 mm2 (22 AWG)

the cable shield, observe the grounding concept of the plant.

Cable type A

Characteristic impedance 135 to 165 Ω at a measuring frequency of 3 to 20 MHz

Cable capacitance <30 pF/m

Wire cross-section

Cable type Twisted pairs

Loop resistance ≤110 Ω/km

Signal damping Max. 9 dB over the entire length of the cable cross-section

Shield Copper braided shielding or braided shielding with foil shield. When grounding

>0.34 mm2 (22 AWG)

the cable shield, observe the grounding concept of the plant.

EtherNet/IP

The standard ANSI/TIA/EIA-568-B.2 Annex specifies CAT 5 as the minimum category for a cable

used for EtherNet/IP. CAT 5e and CAT 6 are recommended.

For more information on planning and installing EtherNet/IP networks, please refer to the

"Media Planning and Installation Manual. EtherNet/IP" of ODVA Organization

PROFINET

Standard IEC 61156-6 specifies CAT 5 as the minimum category for a cable used for PROFINET. CAT

5e and CAT 6 are recommended.

For more information on planning and installing PROFINET networks, see: "PROFINET Cabling

and Interconnection Technology", Guideline for PROFINET

Connecting cable between Safety Barrier Promass 100 and measuring device

Cable type Shielded twisted-pair cable with 2x2 wires. When grounding the cable shield,

observe the grounding concept of the plant.

Maximum cable resistance 2.5 Ω, one side

Comply with the maximum cable resistance specifications to ensure the operational reliability

of the measuring device.

40 Endress+Hauser

Page 41

Proline Promass A 100

The maximum cable length for individual wire cross-sections is specified in the table below. Observe

the maximum capacitance and inductance per unit length of the cable and connection values for

hazardous areas .

Wire cross-section Maximum cable length

[mm2] [AWG] [m] [ft]

0.5 20 70 230

0.75 18 100 328

1.0 17 100 328

1.5 16 200 656

2.5 14 300 984

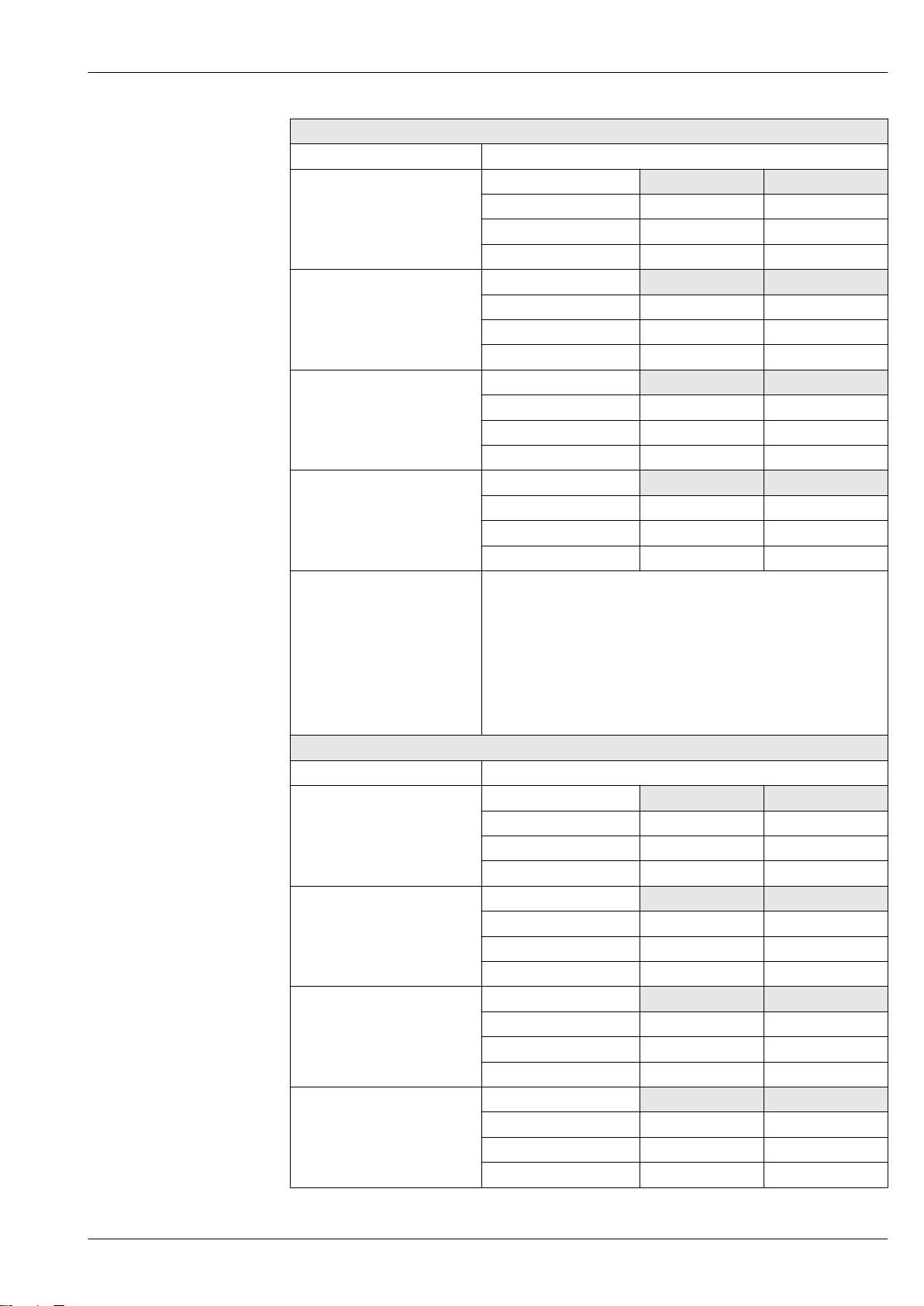

Performance characteristics

Reference operating conditions

Maximum measured error

• Error limits based on ISO 11631

• Water with +15 to +45 °C (+59 to +113 °F) at 2 to 6 bar (29 to 87 psi)

• Specifications as per calibration protocol

• Accuracy based on accredited calibration rigs that are traced to ISO 17025.

To obtain measured errors, use the Applicator sizing tool → 88

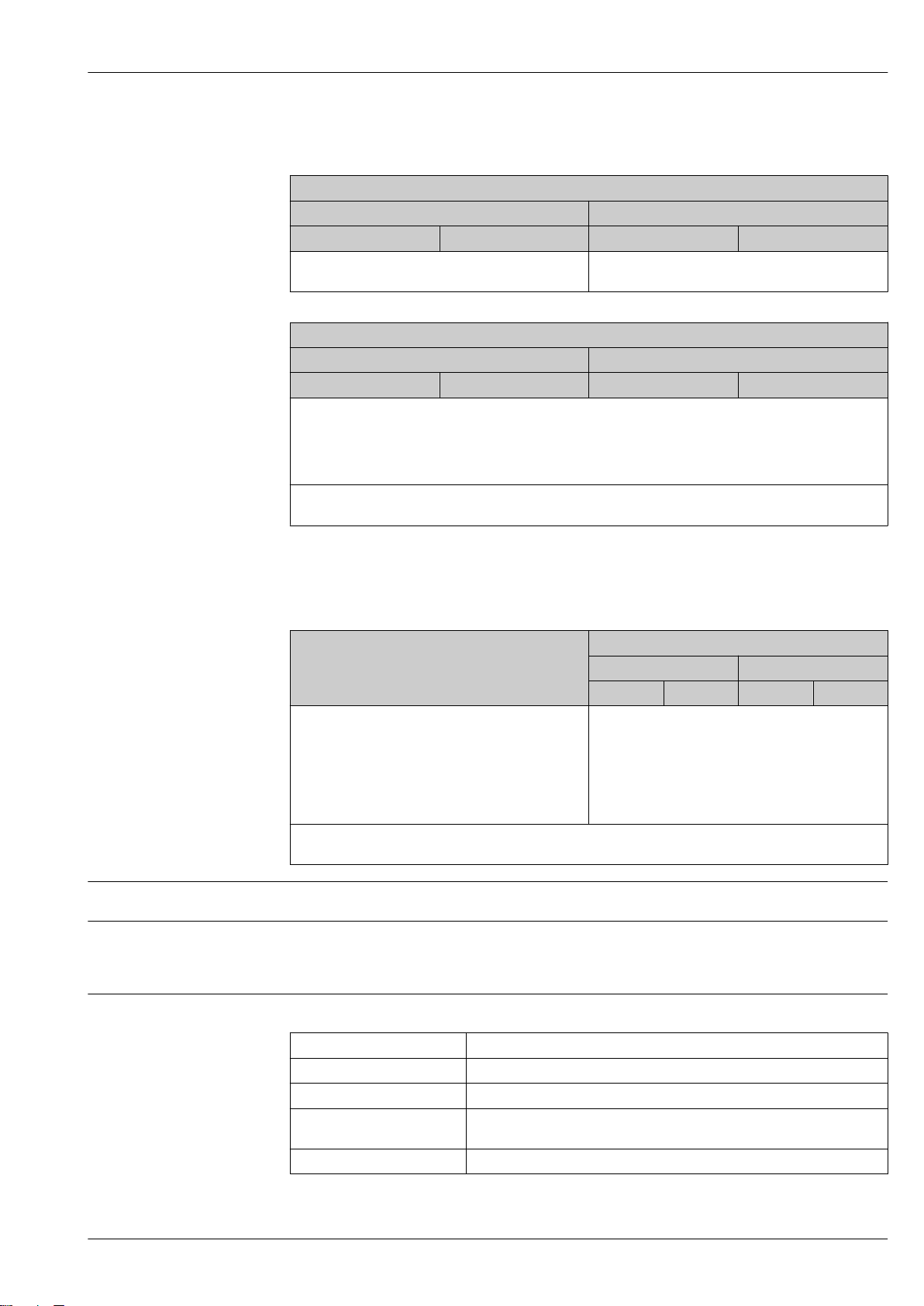

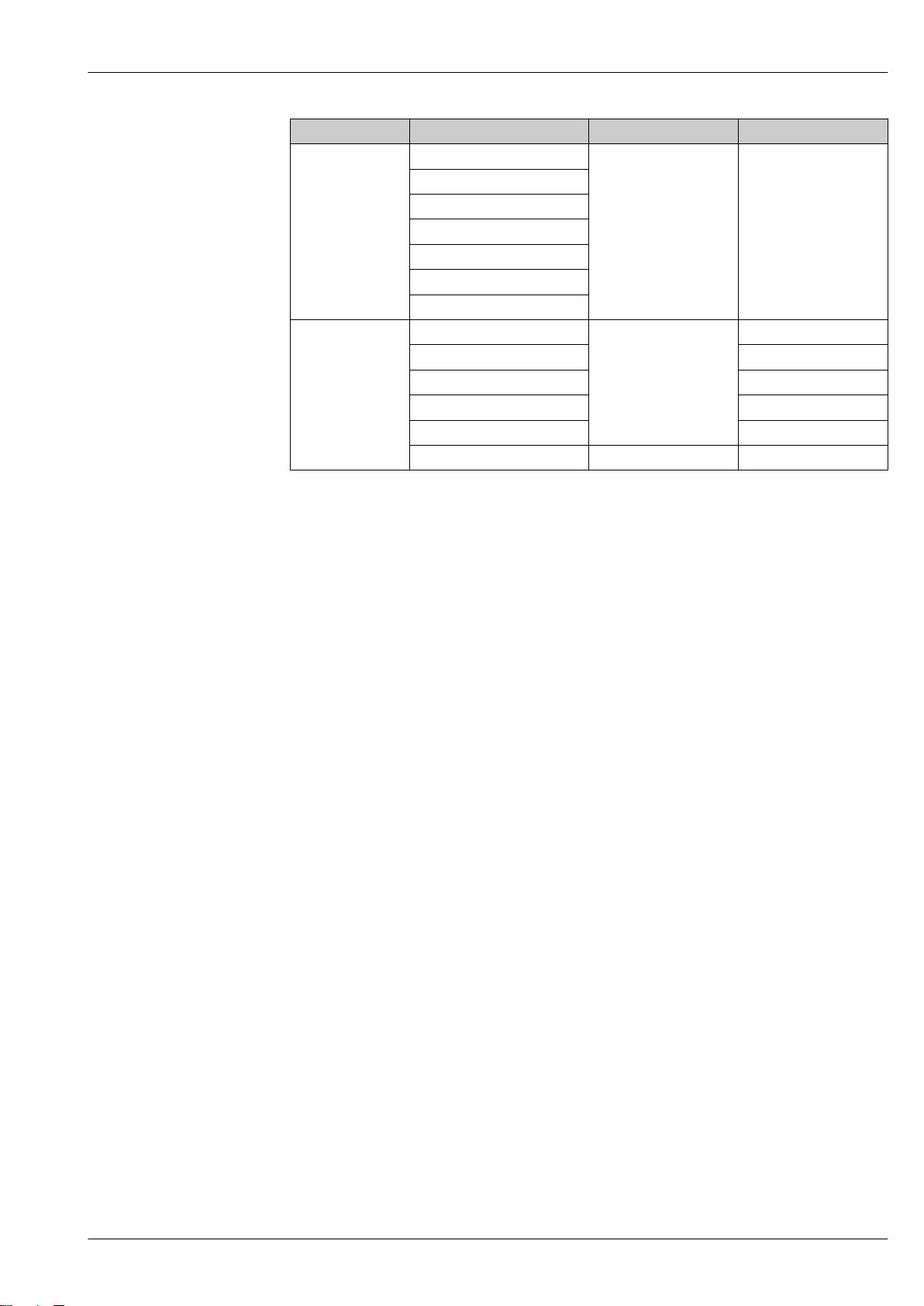

o.r. = of reading; 1 g/cm³ = 1 kg/l; T = medium temperature

Base accuracy

Design fundamentals → 43

Mass flow and volume flow (liquids)

±0.10 % o.r.

Mass flow (gases)

±0.50 % o.r.

Density (liquids)

Under

reference operating conditions

[g/cm³] [lbs/in³] [g/cm³] [lbs/in³] [g/cm³] [lbs/in³]

±0.0005 ±0.00097 ±0.02 ±0.039 ±0.002 ±0.0039

Standard density

calibration

1)

Wide-range

density specification

2) 3)

1) Valid over the entire temperature and density range

2) Valid range for special density calibration: 0 to 2 g/cm³, +5 to +80 °C (+41 to +176 °F)

3) Order code for "Application package", option EF "Special density and concentration "

Temperature

±0.5 °C ± 0.005 · T °C (±0.9 °F ± 0.003 · (T – 32) °F)

Endress+Hauser 41

Page 42

Proline Promass A 100

Zero point stability

DN Zero point stability

[mm] [in] [kg/h] [lb/min]

1 ¹⁄₂₄ 0.0010 0.000036

2 ¹⁄₁₂ 0.0050 0.00018

4 ¹⁄₈ 0.0225 0.0008

Flow values

Flow values as turndown parameter depending on nominal diameter.

SI units

DN 1:1 1:10 1:20 1:50 1:100 1:500

[mm]

1 20 2 1 0.4 0.2 0.04

2 100 10 5 2 1 0.2

4 450 45 22.5 9 4.5 0.9

[kg/h] [kg/h] [kg/h] [kg/h] [kg/h] [kg/h]

US units

DN 1:1 1:10 1:20 1:50 1:100 1:500

[inch] [lb/min] [lb/min] [lb/min] [lb/min] [lb/min] [lb/min]

¹⁄₂₄ 0.735 0.074 0.037 0.015 0.007 0.001

¹⁄₁₂ 3.675 0.368 0.184 0.074 0.037 0.007

¹⁄₈ 16.54 1.654 0.827 0.331 0.165 0.033

Accuracy of outputs

In the case of analog outputs, the output accuracy must also be considered for the measured

error; in contrast, this need not be considered in the case of fieldbus outputs (e.g. Modbus

RS485, EtherNet/IP).

The outputs have the following base accuracy specifications.

Current output

Accuracy Max. ±5 µA

Pulse/frequency output

o.r. = of reading

Accuracy Max. ±50 ppm o.r. (across the entire ambient temperature range)

Repeatability

o.r. = of reading; 1 g/cm3 = 1 kg/l; T = medium temperature

Base repeatability

Mass flow and volume flow (liquids)

±0.05 % o.r.

42 Endress+Hauser

Page 43

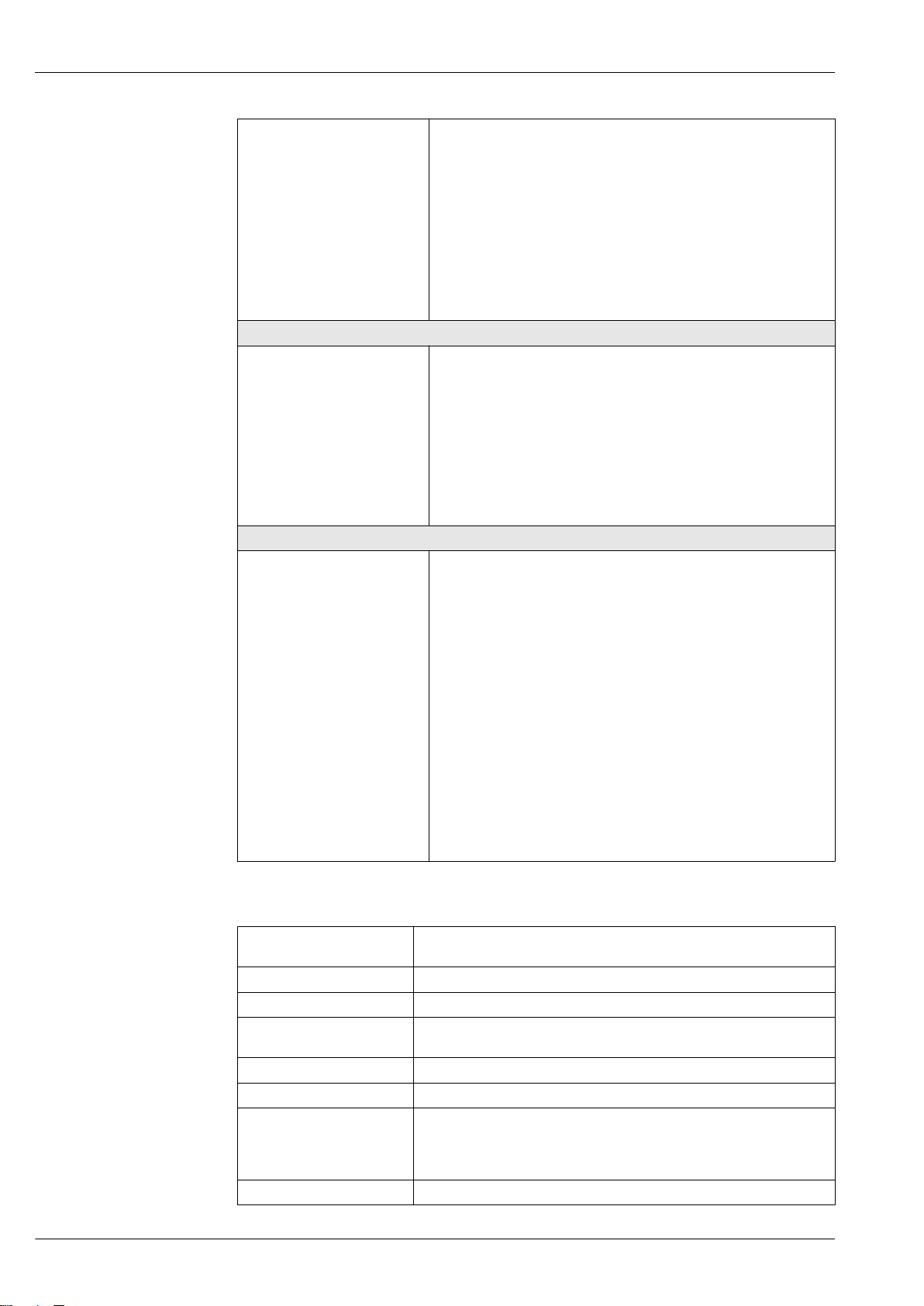

Proline Promass A 100

[kg/m ]

3

[°C]

-40 0-80 40 80 120 160 200 240 280 320 360 400

[°F]

-50 0 50 100 150 200

0

2

4

6

8

10

2

1

Mass flow (gases)

±0.25 % o.r.

Design fundamentals → 43

Response time

Influence of ambient temperature

Influence of medium temperature

Density (liquids)

±0.00025 g/cm

3

Temperature

±0.25 °C ± 0.0025 · T °C (±0.45 °F ± 0.0015 · (T–32) °F)

The response time depends on the configuration (damping).

Current output

o.r. = of reading

Temperature coefficient Max. ±0.005% o.r./°C

Pulse/frequency output

Temperature coefficient No additional effect. Included in accuracy.

Mass flow and volume flow

When there is a difference between the temperature for zero point adjustment and the process

temperature, the typical measured error of the sensor is ±0.0002 % of the full scale value/°C

(±0.0001 % of the full scale value/°F).

Density

When there is a difference between the density calibration temperature and the process

temperature, the typical measured error of the sensor is

±0.00005 g/cm3 /°C (±0.000025 g/cm3 /°F). Field density calibration is possible.

Wide-range density specification (special density calibration)

If the process temperature is outside the valid range (→ 41) the measured error is

±0.00005 g/cm3 /°C (±0.000025 g/cm3 /°F)

1 Field density calibration, for example at +20 °C (+68 °F)

2 Special density calibration

Temperature

Influence of medium pressure

Design fundamentals

±0.005 · T °C (± 0.005 · (T – 32) °F)

A difference between the calibration pressure and process pressure does not affect accuracy.

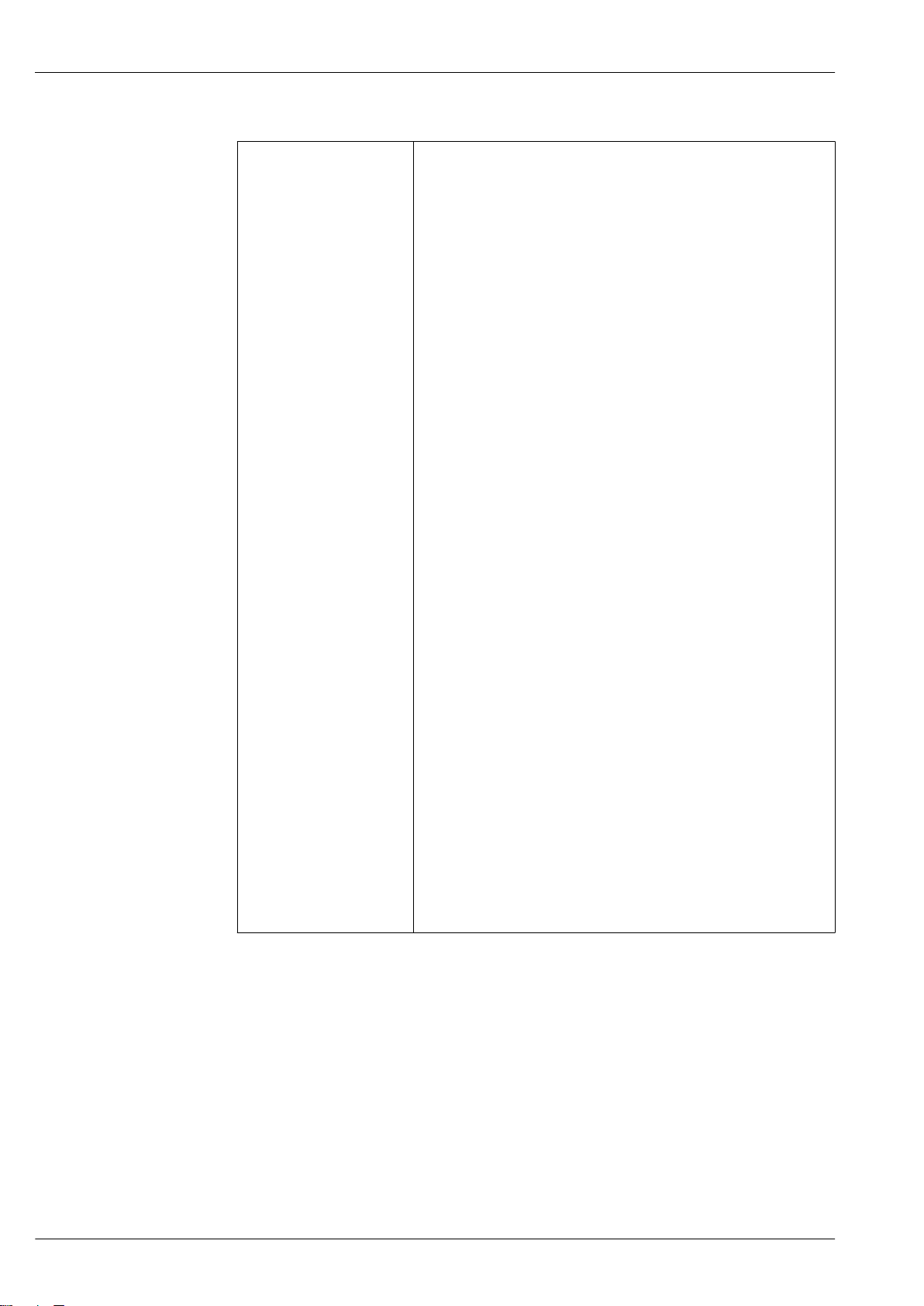

o.r. = of reading, o.f.s. = of full scale value

BaseAccu = base accuracy in % o.r., BaseRepeat = base repeatability in % o.r.

Endress+Hauser 43

A0016616

Page 44

MeasValue = measured value; ZeroPoint = zero point stability

ZeroPoint

BaseAccu

⋅ 100

³

± BaseAccu

ZeroPoint

BaseAccu

⋅ 100

<

ZeroPoint

MeasValue

⋅ 100

±

½ ⋅ ZeroPoint

BaseRepeat

⋅ 100

³

½ ⋅ ZeroPoint

BaseRepeat

⋅ 100

<

ZeroPoint

MeasValue

⋅ 100

½ ⋅±

0 10 20 30 40 50 60

0

0.5

1.0

1.5

2.0

2.5

70 80 90 100

Q [%]

E [%]

Calculation of the maximum measured error as a function of the flow rate

Flow rate Maximum measured error in % o.r.

Proline Promass A 100

A0021332

A0021333

Calculation of the maximum repeatability as a function of the flow rate

Flow rate Maximum repeatability in % o.r.

A0021335

A0021336

Example for max. measured error

A0021339

A0021334

A0021340

A0021337

E Error: Maximum measured error as % o.r. (example)

Q Flow rate as %

Installation

No special measures such as supports are necessary. External forces are absorbed by the construction

of the device.

Mounting location

44 Endress+Hauser

A0024173

A0023344

Page 45

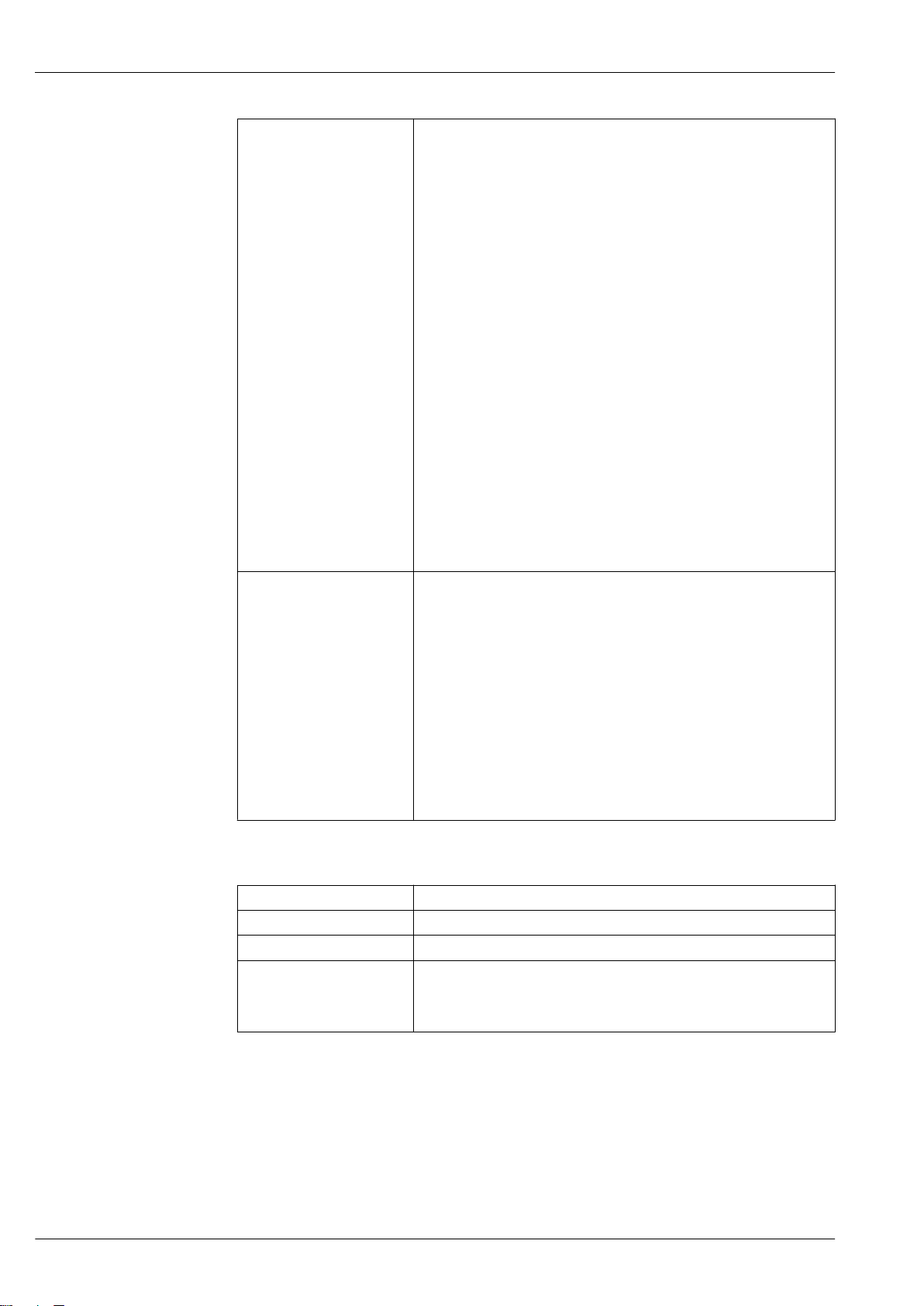

Proline Promass A 100

1

2

3

4

5

To prevent measuring errors arising from accumulation of gas bubbles in the measuring tube, avoid

the following mounting locations in the pipe:

• Highest point of a pipeline.

• Directly upstream of a free pipe outlet in a down pipe.

Installation in down pipes

However, the following installation suggestion allows for installation in an open vertical pipeline.

Pipe restrictions or the use of an orifice with a smaller cross-section than the nominal diameter

prevent the sensor running empty while measurement is in progress.

Orientation

A0015596

19 Installation in a down pipe (e.g. for batching applications)

1 Supply tank

2 Sensor

3 Orifice plate, pipe restriction

4 Valve

5 Batching tank

DN Ø orifice plate, pipe restriction

[mm] [in] [mm] [in]

1 ¹⁄₂₄ 0.8 0.03

2 ¹⁄₁₂ 1.5 0.06

4 ¹⁄₈ 3.0 0.12

The direction of the arrow on the sensor nameplate helps you to install the sensor according to the

flow direction (direction of medium flow through the piping).

Orientation Recommendation

A Vertical orientation

A0015591

B Horizontal orientation, transmitter

head up

A0015589

1)

Exceptions:

Endress+Hauser 45

Page 46

Proline Promass A 100

G

E

D

F

45°

RUPTURE DISK

i

1

2

3

B

C

A

Orientation Recommendation

C Horizontal orientation, transmitter

head down

A0015590

D Horizontal orientation, transmitter

head at side

1) Applications with low process temperatures may decrease the ambient temperature. To maintain the

minimum ambient temperature for the transmitter, this orientation is recommended.

2) Applications with high process temperatures may increase the ambient temperature. To maintain the

maximum ambient temperature for the transmitter, this orientation is recommended.

A0015592

2)

Exceptions:

Inlet and outlet runs

Special mounting instructions

No special precautions need to be taken for fittings which create turbulence, such as valves, elbows

or T-pieces, as long as no cavitation occurs → 55.

Rupture disk

Make sure that the function and operation of the rupture disk is not impeded through the

installation of the device. The position of the rupture disk is indicated on a sticker beside it. For

additional information that is relevant to the process → 54.

The existing connecting nozzles are not intended for the purpose of rinsing or pressure monitoring,

but instead serve as the mounting location for the rupture disk.

In the internal thread of the rupture disk a discharge device can be screwed to drain the leaking

medium in case of a failure of the rupture disk.

A0019676

1 Rupture disk label

2 Rupture disk with 1/2" NPT internal thread with 1" width across flat