Endress+Hauser FHX50, 71197334 Installation Manual

Installation Instruction

Transmitter electronics FHX50

Levelflex FMP5x, Micropilot FMR5x, Promass 200, Prowirl 200, Promag 200, Prosonic Flow 200

EA01064F/00/A2/03.15

71279010

Instruction is valid for the following spare part set:

Designated use

The spare part set and Installation Instruction are used to replace a faulty unit with a functioning unit of the same type.

Use genuine parts from Endress+Hauser only.

Only original spare part sets, intended by Endress+Hauser for the measuring device, shall be used.

The verification has to be done via Online Support, this procedure is explained below.

Order number Original spare part set Usage Feature: Display, Operation

Option

71197334 Transmitter electronics FHX50

Levelflex FMP5x,

Micropilot FMR5x

Promass 200

Prowirl 200

Promag 200

Prosonic Flow 200

L - Prepared for display FHX50 + M12 connection

M - Prepared for display FHX50 + custom connection

We recommend that the Installation Instructions be kept with the packaging at all times.

For some devices there is an overview of the correct spare part set inside the connection compartment cover.

If the spare part is listed there, the verification is not required.

www.endress.com/support

Choose device specific information.

Enter the serial number (Ser. No.), search for product data and click on

"spare parts".

Display of all suitable spare parts.

Check the order number of the spare part.

Does the order number of spare part correspond to the order number in

the spare part list?

YES, the spare part can be used.

NO, the spare part may not be used.

Device specific information

=

?

1.

3.

4.

5.

Ser

. No.:

12345

2.

www.endress.com/support

71279010

Transmitter electronics FHX50

2 Endress + Hauser

Authorized personnel to carry out repairs

Authorization to carry out a repair depends on the approval of the measuring device. The table shows the respective group of persons for each.

Safety instructions

• Check whether the spare part matches the identification label on the

measuring device. See chapter "Designated use".

• The spare parts set and Installation Instructions are used to replace

a faulty unit with a functioning unit of the same type.

Use genuine parts from Endress+Hauser only.

• In the case of Ex-certified measuring devices: Observe the

information in the documentation "Safety Instructions" (XA, ZD).

The relevant Safety Instructions (XA) are indicated on the nameplate.

• The measuring device is energized. Danger: Risk of electric shock!

Open the measuring device in a de-energized state only.

• Before removing the device: set the process in a safe condition and

purge the pipe of dangerous materials.

• Hot surfaces! Risk of injury! Before commencing work, allow the

system and measuring device to cool down to a touchable

temperature.

• In the case of measuring devices in custody transfer, the custody

transfer status no longer applies once the lead seal has been removed.

• Comply with national regulations concerning mounting, electrical

installation, commissioning, maintenance and repair procedures.

• Requirements with regard to specialized technical staff for the

mounting, electrical installation, commissioning, maintenance and

repair of the measuring devices:

–trained in instrument safety

–familiar with the individual operation conditions of the devices

–for Ex-certified measuring devices: also trained in explosion

protection

• Follow the Operating Instructions for the device.

• Risk of damaging electronic components! Ensure you have a working

environment protected from electrostatic discharge.

• After removing the electronics cover, there is a risk of electric shock

as shock protection is removed!

Switch off the measuring device before removing internal covers.

• Modifications to the measuring device are not permitted.

• In the case of measuring devices in safety-related applications in

accordance with IEC 61508 or IEC 61511: After repair recommission

in accordance with Operating Instructions. Document the repair

procedure.

• Only open housing for a brief period. Avoid the penetration of foreign

bodies, moisture or contaminants.

• Replace defective seals/gaskets with genuine parts from

Endress+Hauser only.

• If threads are damaged or defective, the measuring device must be

repaired.

• Threads (e.g. of the cover for the electronics and terminal

compartment), which have been prepared by Endress+Hauser with

an abrasion resistant dry lubrication should not be additionally

lubricated.

Threads without lubricant must be lubricated with an acid-free,

non-hardening grease.

• If spacing is reduced or the dielectric strength of the measuring device

cannot be guaranteed during repair work, perform a test on

completion of the work

(e.g. high-voltage test in accordance with the manufacturer's

instructions).

• Service connector:

–do not connect in potentially explosive atmospheres.

–only connect to Endress+Hauser service devices.

• Observe the instructions for transporting and returning the device

outlined in the Operating Instructions.

• If you have any questions, contact your E+H service organization.

The person who carries out the repair is responsible for safety during the work, the quality of work completed and safety of the device

after repair.

Approval of the measuring device Group of persons authorized to carry out repairs

Without approval 1, 2, 3

With approval (for Ex. IECEx, ATEX, FM, CSA, TIIS, NEPSI) 1, 2, 3

1 = Trained customer technician, 2 = Service technician authorized by Endress+Hauser, 3 = Endress+Hauser (send measuring device back to manufacturer)

Transmitter electronics FHX50

Endress + Hauser 3

Tool list

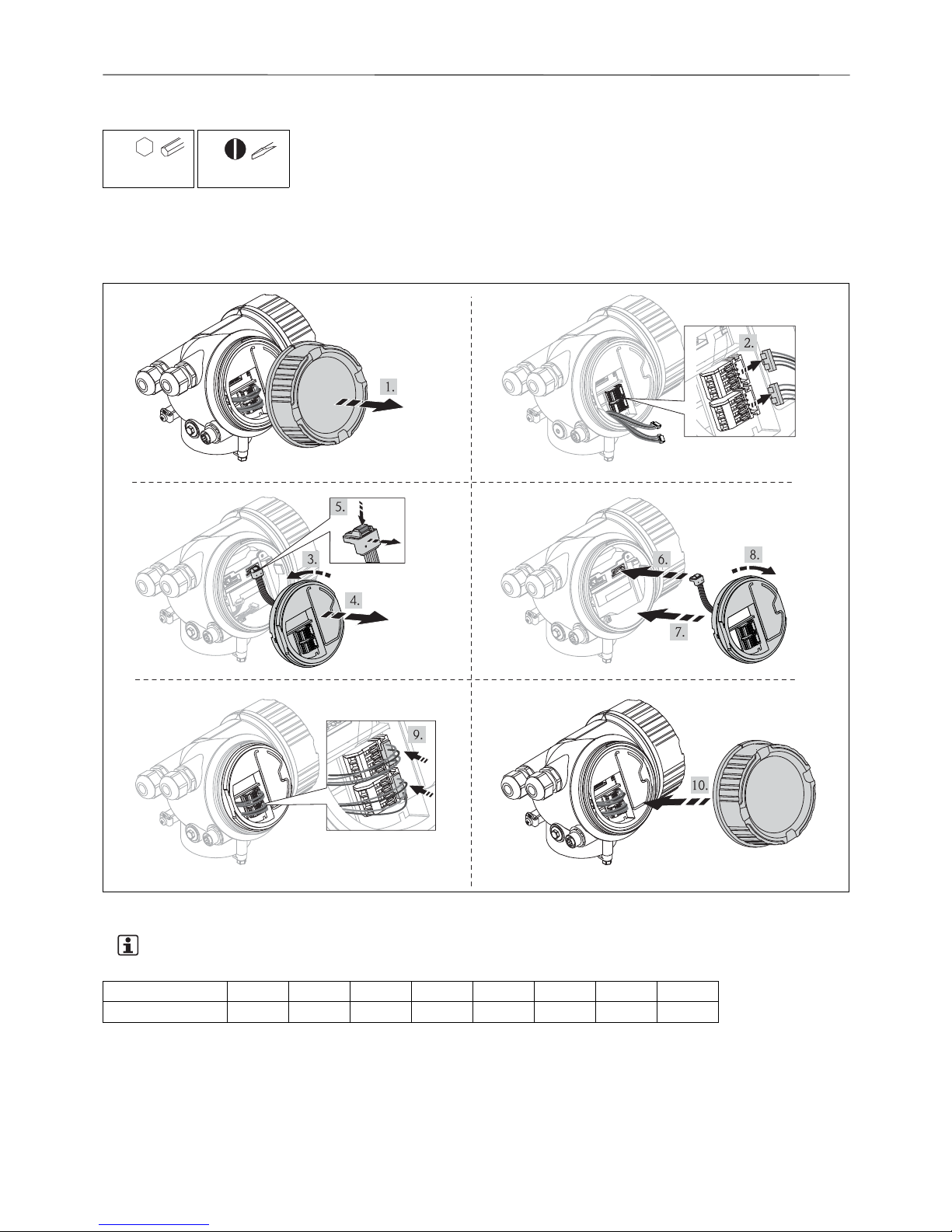

Exchange of electronics FHX50 at transmitter

Connection with M12 plug

Terminal assignment

3 mm,

(Locking clamp of lid)

2.5 x 0.4 mm

(Terminals)

The terminal assignment at the transmitter and at the FHX50 must coincide.

Observe the position of plug connectors.

Terminal 12345678

Color of strand white brown green yellow gray pink blue red

Loading...

Loading...