Endress ESE 1104 DBG ES FS DIN, ESE 904 DBG ES DIN, ESE 1104 DBG ES DIN, ESE 1304 DBG ES FS DIN, ESE 904 DBG DIN Operating Instructions Manual

...

OPERATING INSTRUCTIONS

ESE 904 DBG DIN Article No. 151003

ESE 904 DBG ES DIN Article No. 151013

ESE 904 DBG ES FS DIN Article No. 151023

ESE 1104 DBG ES DIN Article No. 151015

ESE 1104 DBG ES FS DIN Article No. 151025

ESE 1304 DBG ES DIN Article No. 151016

ESE 1304 DBG ES FS DIN Article No. 151026

Table of Contents

Manufacturer and

Document number

Publication date

Copyright

publisher

ENDRESS

Elektrogerätebau GmbH

Neckartenzlinger Str. 39

D-72658 Bempflingen

Tel.: + 49 (0) 71 23 / 9737-0

Fax: + 49 (0) 71 23 / 9737 – 50

E-mail: info@endress-stromerzeuger.de

www: http://www.endress-stromerzeuger.de

E131099

January 2013

© 2013, ENDRESS Elektrogerätebau GmbH

This documentation and parts thereof are subject to copy-

right. Any use or modification beyond the restrictions of the

Copyright Act is forbidden and subject to penalty without the

consent of ENDRESS Elektrogerätebau GmbH.

2

This applies in particular to copies, translations, microfilming,

as well as storage and processing in electronic systems.

ESE 904 - 1304 DBG DIN

Status: at January 2013

Table of Contents

Table of Contents

1

General information .......................................................................................... 7

1.1 Documentation and accessories ........................................................................ 8

1.2 Safety symbols .................................................................................................. 9

2

General Safety Regulations............................................................................ 11

2.1 Important safety warning .................................................................................. 11

2.2 Intended use .................................................................................................... 12

2.2.1

Residual risks .....................................................................................................13

2.3 Operating personnel – qualifications and obligations ....................................... 16

2.4 Personal protective equipment ......................................................................... 16

2.5 Danger zones and work areas ......................................................................... 17

2.6 Labels on the generator ................................................................................... 18

2.7 General safety instructions ............................................................................... 20

3

Operating generator ESE 904 - 1304 DBG DIN ............................................. 25

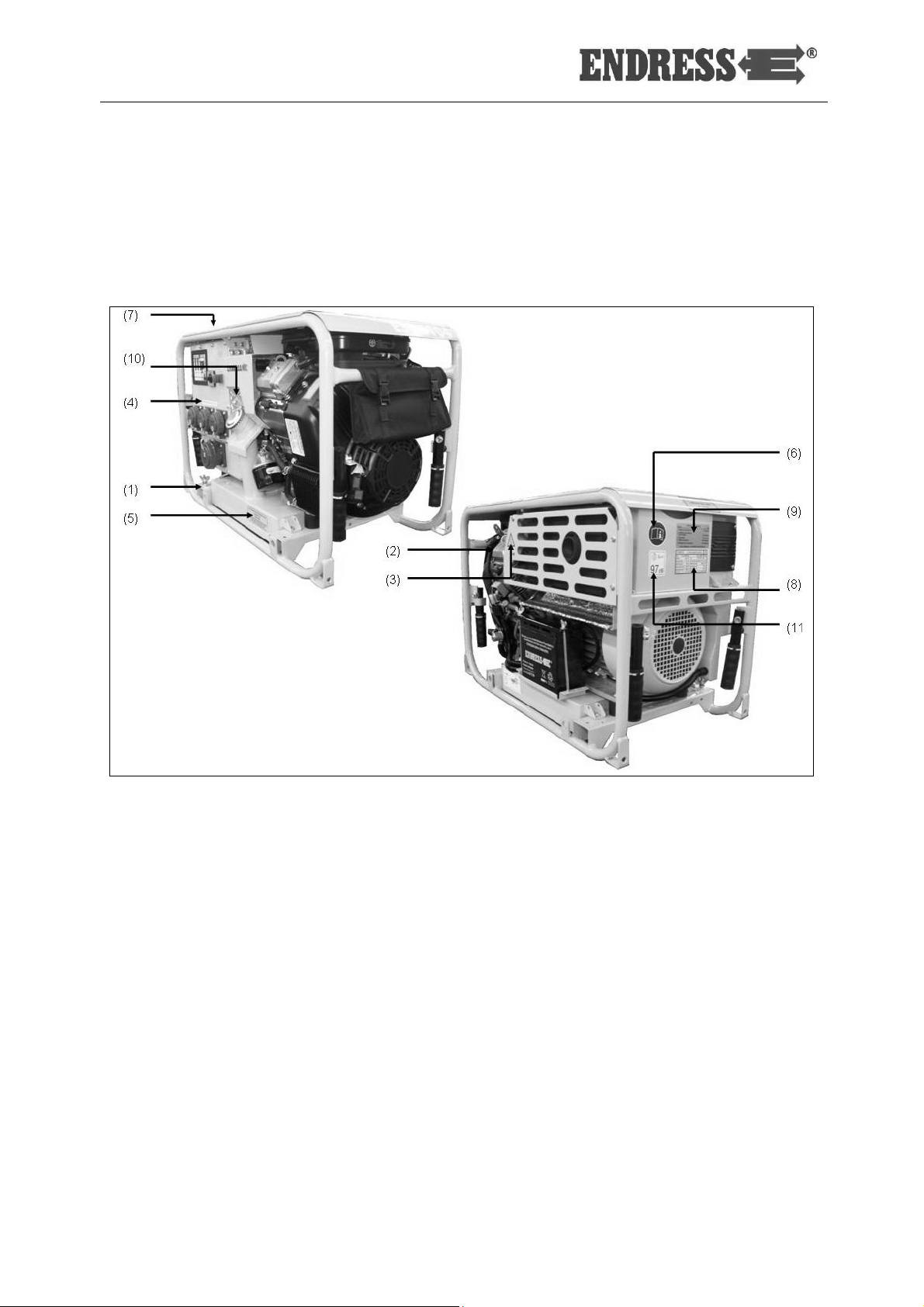

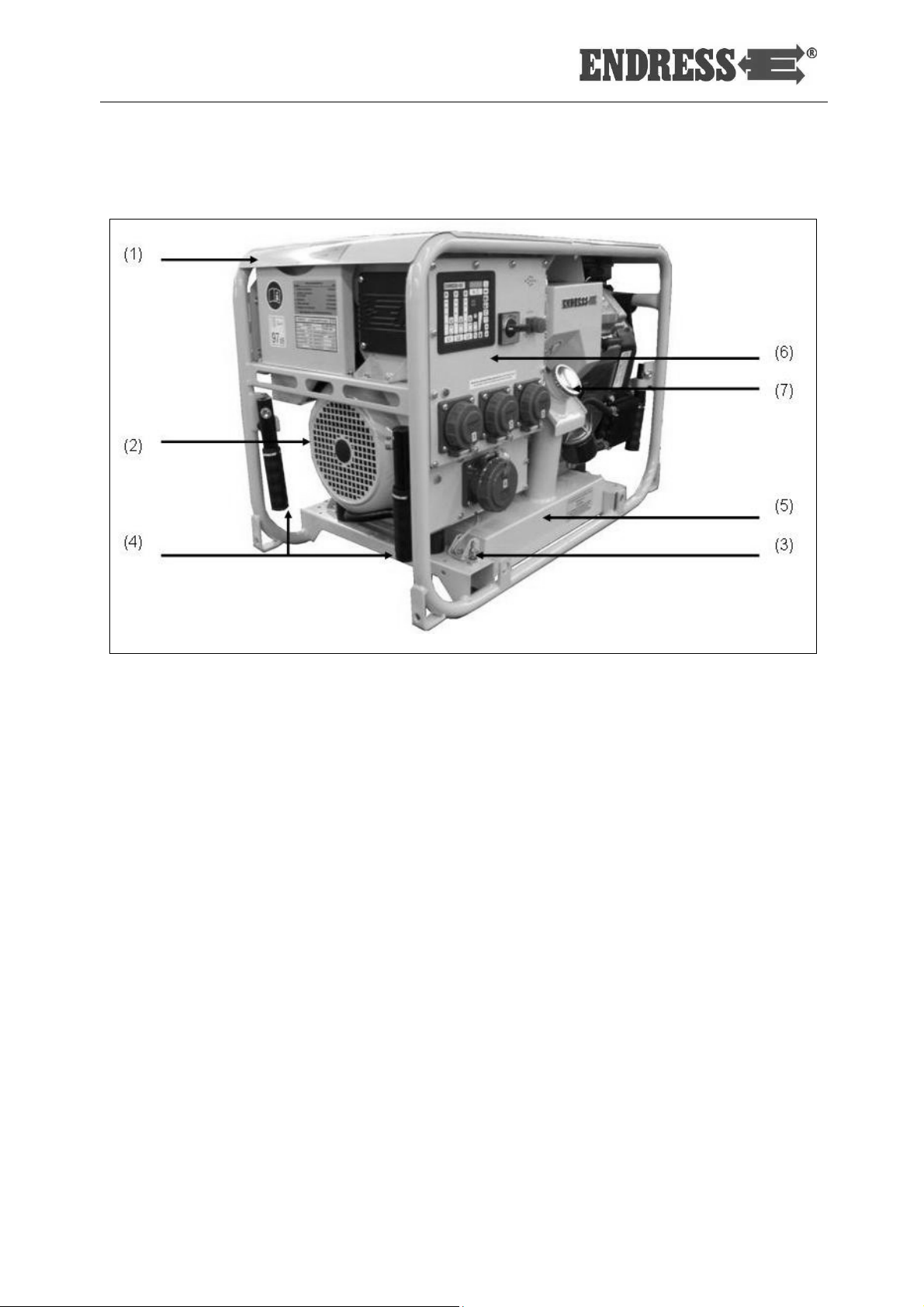

3.1 Components of generator ESE 904 - 1304 DBG DIN ....................................... 25

3.1.1

Components of the operating and alternator side ..............................................26

3.1.2

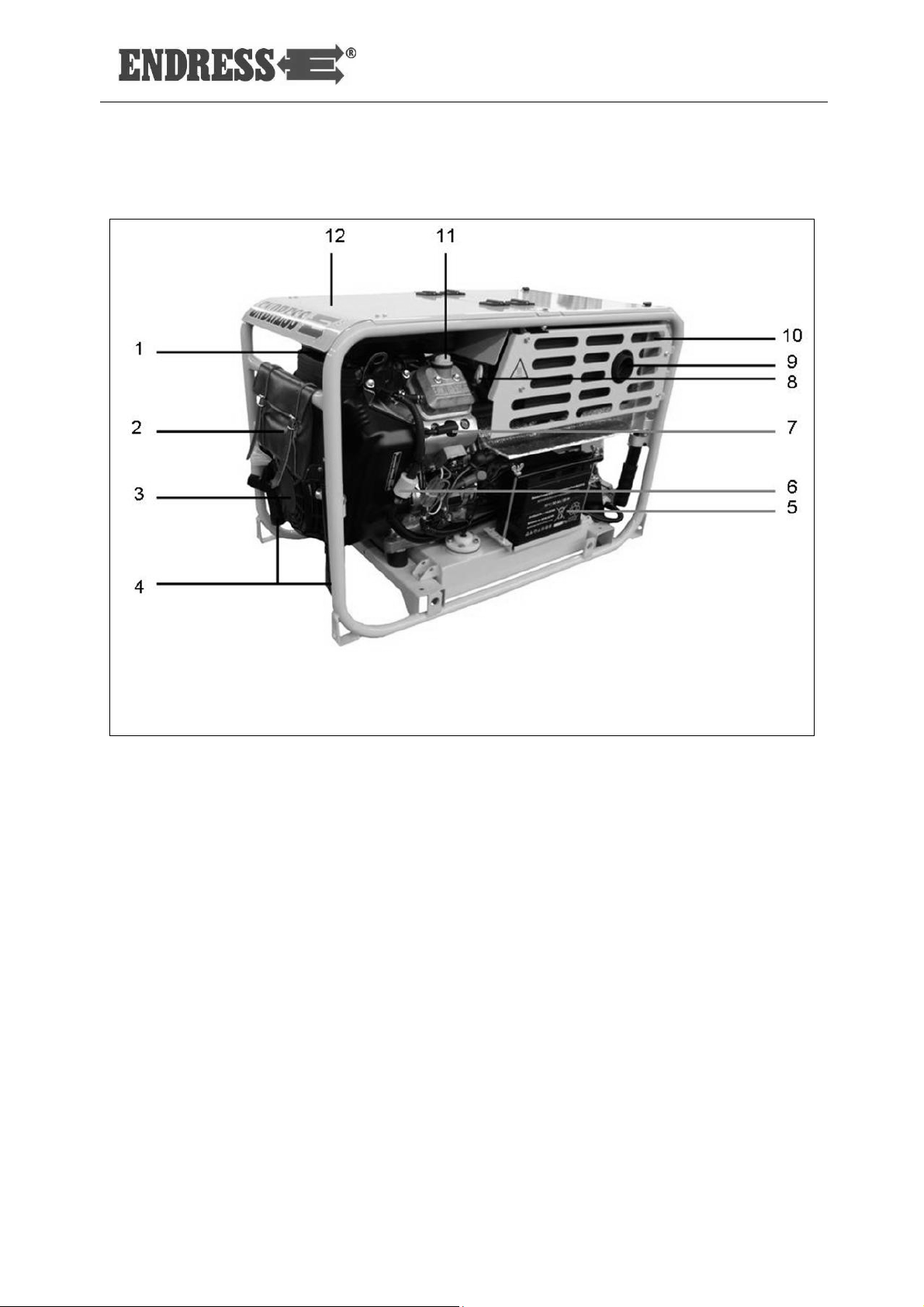

Exhaust and engine side components ...............................................................27

3.1.3

Control panel components ..................................................................................28

3.1.4

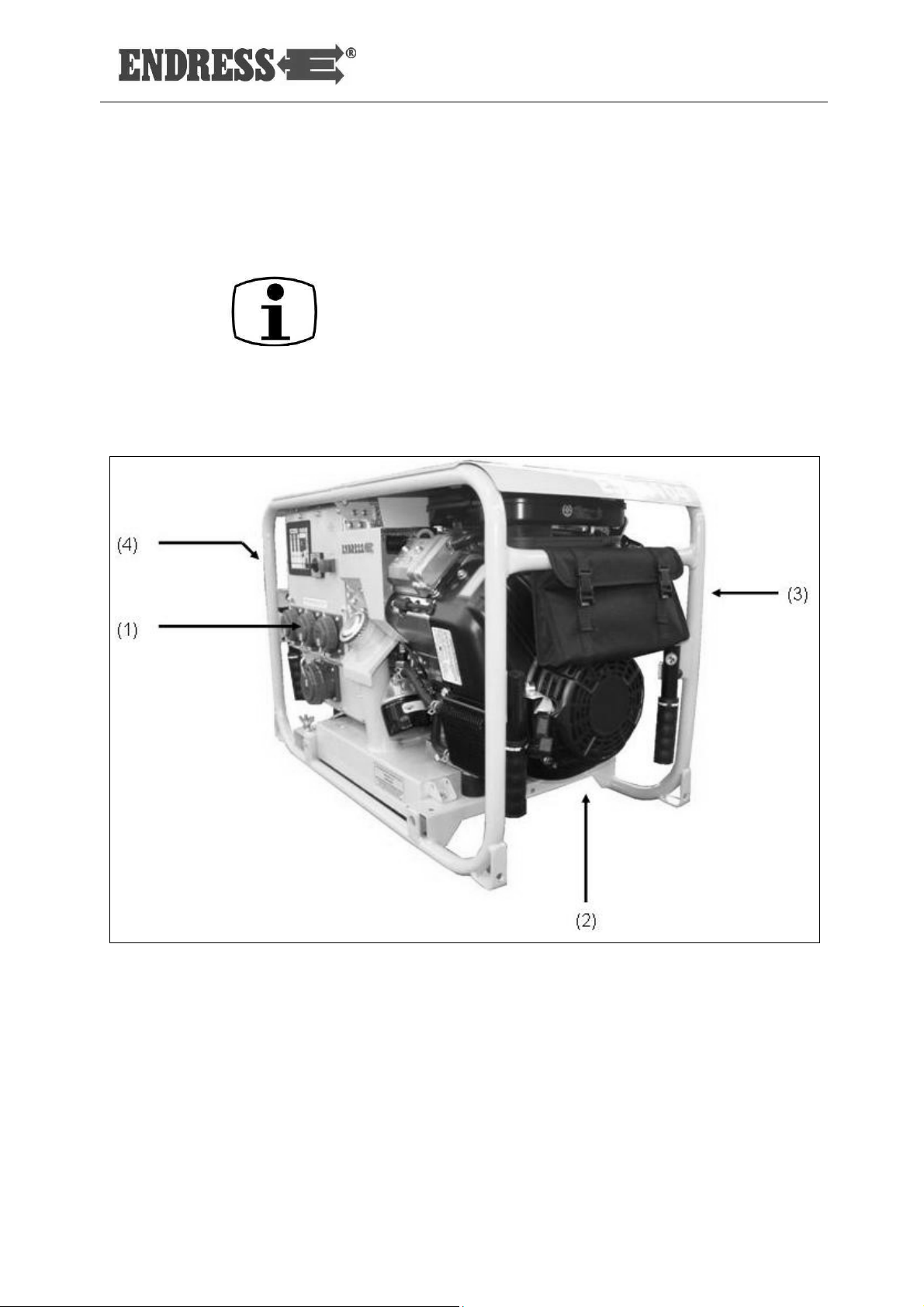

Accessory components ......................................................................................29

3.2 Function and mode of operation ....................................................................... 30

4

Operating generator ESE 904 - 1304 DBG DIN ............................................. 32

4.1 Transporting the generator ............................................................................... 32

4.2 Setting up the generator................................................................................... 32

4.3 Refuelling the alternator ................................................................................... 33

4.4 Starting the generator ...................................................................................... 34

4.5 Switching the generator off .............................................................................. 38

4.6 Connecting up consumers/appliances .............................................................. 38

4.7 Check the protective conductor ........................................................................ 40

4.8 Monitoring the operating condition using the multifunctional display ................ 42

4.9 Putting the generator out of service ................................................................. 46

Status at: January 2013

ESE 904 - 1304 DBG DIN

3

Table of Contents

4.10 Disposal ........................................................................................................... 46

5

Special fittings / using accessories ............................................................... 48

5.1 FI protection switch .......................................................................................... 48

5.2 Insulation monitoring with E-MCS 4.0 .............................................................. 50

5.2.1

Insulation monitoring without switching off .........................................................50

5.2.2

Insulation monitoring with switch off ...................................................................51

5.3 Speed lowering in idle ...................................................................................... 53

5.4 Remote start device ......................................................................................... 54

5.5 External start device ........................................................................................ 56

5.6 Battery charge conservation ............................................................................ 57

5.7 3-way fuel tap / fuelling device ......................................................................... 60

5.8 Exhaust hose ................................................................................................... 63

6

Maintenance .................................................................................................... 65

6.1 Maintenance plan............................................................................................. 65

6.2 Maintenance work ............................................................................................ 66

6.2.1

Charge battery ....................................................................................................66

6.2.2

Replacing the starter battery ..............................................................................66

6.2.3

Motor oil ..............................................................................................................67

6.2.4

Replacing fuses ..................................................................................................70

6.3 Checking the electrical safety .......................................................................... 71

7

Troubleshooting .............................................................................................. 72

8

Technical specifications ................................................................................. 76

9

Replacement parts .......................................................................................... 80

9.1 Frame with covers, tank and engine ................................................................ 80

9.2 Engine with exhaust and fuel system ............................................................... 83

9.3 Generator and electronics ................................................................................ 84

9.4 Fuses ............................................................................................................... 86

9.5 Accessories and markings ............................................................................... 87

4

ESE 904 - 1304 DBG DIN

Status: at January 2013

List of illustrations

Table of Contents

Fig. 2-1: Labels on the generator ........................................18

Fig. 3-1: Views of the generator ..........................................25

Fig. 3-2: Components of the operating and alternator side .26

Fig. 3-3: Exhaust and engine side components ..................27

Fig. 3-4: Control panel components ....................................28

Fig. 3-5: Components of the standard accessories .............29

Fig. 3-6: Components of the special accessories ................29

Fig. 4-1: Actuate manual choke ..........................................36

Fig. 4-2: Standard design of operating panel ......................36

Fig. 4-3: Emergency starting the pump ...............................36

Fig. 4-4: Connecting up consumers/appliances ..................39

Fig. 4-5: Check the protective conductor ............................40

Fig. 4-6: Multi-functional display .........................................42

Fig. 5-1: FI protection switch...............................................49

Fig. 5-2: Insulation monitoring with E-MCS 4.0 ...................50

Fig. 5-3: Switching the idle down on pressure switch ..........53

Fig. 5-4: Remote start device with Harting plug ..................54

Fig. 5-5: Remote start device with CAN plug ......................55

Fig. 5-6: Connecting up an external start device .................56

Fig. 5-7: Connecting up the battery charge conservation

device ..........................................................................57

Fig. 5-8: Connecting up the battery charge conservation

device ..........................................................................58

Fig. 5-9: Connecting up the battery charge conservation

device ..........................................................................59

Fig. 5-10: 3-way fuel tap .....................................................60

Fig. 5-11: Connect up fuelling device ..................................61

Fig. 5-12 Connecting the exhaust hose ..............................63

Fig. 6-1: Replacing the battery ............................................66

Fig. 6-2: Oil dipstick ............................................................68

Fig. 6-3: Change the oil ......................................................69

Fig. 6-4: Replacing a fuse ...................................................70

Fig. 8-1: Generator dimensions ..........................................76

Fig. 9-1: Operating and alternator side replacement parts ..80

Fig. 9-2: Engine and exhaust side replacement parts .........81

Fig. 9-3: Replacement parts for an engine with an exhaust

and fuel system ...........................................................83

Fig. 9-4: Replacement parts Generator and electronics ......84

Fig. 9-5: Replacement parts for fuses .................................86

Fig. 9-6: Replacement parts for accessories .......................87

Fig. 9-7: Replacement parts forspecial accessories ............88

Status at: January 2013

ESE 904 - 1304 DBG DIN

5

Table of Contents

List of charts

Table 2.1: Danger zones and work areas on the generator 17

Table 2.2: Labels on the generator .....................................20

Table 4.1: Protective conductor test lamp ...........................41

Table 5.1: FI protection switch test .....................................49

Table 5.2: Insulation monitoring without switching off .........50

Table 5.3: Insulation monitoring whilst running without

switching off ................................................................51

Table 5.4: Insulation monitoring plus switching off ..............52

Table 5.5: Insulation monitoring whilst running without

switching off ................................................................52

Table 5.6: Switchingpositions of the 3-way fuel tap ............60

Table 6.1: Generator maintenance plan .............................65

Table 6.2: Location of the fuses .........................................70

Table 7.1: Problems arising during generator operation .....74

Table 8.1: Generator technical data ....................................77

Table 8.2: Ambient conditions for the generator .................78

Table 8.3: Generator performance reduction dependent on

the ambient conditions.................................................78

Table 8.4: Maximum line length of the distribution network as

a function of the cable cross-section............................78

Table 9.1: Replacement parts for the frame with covers .....82

Table 9.2: Replacement parts for an engine with an exhaust

and fuel system ...........................................................83

Table 9.3: Alternator with electrical junction box replacement

parts ............................................................................85

Table 9.4: Replacement parts for fuses ..............................86

Table 9.5: Replacement parts for accessories / special

accessories .................................................................87

General note:

We reserve the right to make modifications in terms of

These instructions do not include technical modifications that

6

The illustrations in these operating instructions do not always

comply completely with the actual design, in particular with

regard to the colour, and are to be considered a representation of basic principles.

ongoing technical development.

occurred after printing.

ESE 904 - 1304 DBG DIN

Status: at January 2013

1 General information

These operating instructions must be read carefully and understood before using the generator.

These operating instructions are intended to familiarise you

with the basic operation of the generator.

These operating instructions contain important information

on using the generator safely and appropriately.

Complying with this information helps to:

General information

• avoid hazards

• reduce repair costs and downtime

• increase the reliability and service life of the generator.

However, not only these operating instructions but also the

laws, regulations, guidelines, and standards applicable in the

country of use and at the site of operation must be observed.

These operating instructions only describe the generator

operation.

A copy of these operating instructions must be available to

the operating personnel at all times.

Status at: January 2013

ESE 904 - 1304 DBG DIN

7

General information

1.1 Documentation and accessories

In addition to these operating instructions, the following documents are relevant for the generator:

• Operating instructions and maintenance instructions for

the engine (Briggs & Stratton Corporation)

• Briggs & Stratton Service Germany (Briggs & Stratton

Corporation)

• Circuit diagram for the generator

• Regulations for handling the battery

The operating manual and the maintenance instructions

from the engine manufacturer are integral components of

these instructions and must be observed.

8

ESE 904 - 1304 DBG DIN

Status: at January 2013

1.2 Safety symbols

General information

The safety symbol illustrates a source of danger. The safety

symbols in the work area of the machine/plant and the entire

technical documentation correspond to the Council Directive

92/58/EEC - Minimum requirements for the provision of safety and/or health signs at work.

General hazard

This warning sign indicates activities where several causes

can lead to risks.

Potentially explosive materials

This warning symbol indicates activities during which there is

an explosive hazard, possibly with lethal consequences.

Dangerous electrical voltage

This warning symbol indicates activities during which there is

the danger of an electric shock, possibly with lethal consequences.

Poisonous substances

This warning symbol indicates activities during which there is

the danger of poisoning, possibly with lethal consequences.

Environmentally damaging substances

This warning sign indicates activities during which the environment could be endangered, possibly with catastrophic

consequences.

Hot surfaces

This warning symbol indicates activities during which there is

the danger of burns, possibly with lasting consequences.

Status at: January 2013

ESE 904 - 1304 DBG DIN

9

General information

Notes

10

ESE 904 - 1304 DBG DIN

Status: at January 2013

2 General Safety Regulations

This section describes the basic safety regulations for operating the generator.

Whoever operates the generator or works with it must read

this chapter and comply with its regulations in practice.

2.1 Important safety warning

ENDRESS generators are designed to operate electrical

equipment with appropriate power output requirements. Other applications can lead to injury to the operating personnel

and to damage to the generator as well as other damage to

equipment.

The majority of injuries and damage to equipment can be

avoided if all instructions given in this manual and all instructions attached to the generator are followed.

The generator must not be modified in any way. This can

lead to an accident occurring and damage to the generator

as well as devices.

WARNING!

Status at: January 2013

ESE 904 - 1304 DBG DIN

11

•

The following actions are not permitted.

Operation in explosion-prone environments

• Operation in fire-prone environments

• Operation in confined areas

• Operation from a vehicle platform that has not been

swung out

• Operation without the necessary safety redundancies

• Operation in existing power supply networks

• Refuelling when hot

• Refuelling during operation

• Spraying with high-pressure cleaners or fire-

extinguishing equipment

• Safety equipment removal

• Incorrect vehicle installation

• Non-compliance with maintenance intervals

• Failure to measure and test for early damage identifica-

tion

• Failure to replace wearing parts

• Incorrectly performed maintenance or repair work

• Defectively performed maintenance or repair work

• Unintended use

2.2 Intended use

The generator produces electricity in place of the power grid,

in order to supply a mobile distribution system.

The generator may only be used outdoors within the indicated voltage, output, and nominal rpm ranges (see model

plate).

You are also permitted to use it on a vehicle extension or

swivelling platform in both extended and swung out states,

providing that the air circulation is uninterrupted on all sides

of the alternator and that the exhaust gases are dispersed

correctly. This is especially relevant as access to the side

with the instrument panel and the side with the exhaust gas

connection must be unrestricted.

The methods that will be used to install the generator on these surfaces of a vehicle require written approval from the

distributor that supplied the generator.

12

ESE 904 - 1304 DBG DIN

Status: at January 2013

The generator may not be connected to other energy distribution systems (e.g. public power supply) or to other energy

generation systems (e.g. other generators).

The generator may not be used in explosion-prone environments.

The generator may not be used in fire-prone environments.

The generator must be operated according to the specifica-

tions in the technical documentation.

Any non-intended use or any activity on the generator not

described in these operating instructions is considered forbidden incorrect use outside the legal limits of the manufacturer's liability.

2.2.1 Residual risks

The points analysed and evaluated before beginning the

design and planning of the

ESE 804 / 1104 / 1304 DBG DIN

generator were the residual risks identified using a risk analysis tool.

Structurally unavoidable residual risks during the entire service life of the

ESE 804 / 1104 / 1304 DBG DIN

generator in-

clude:

• Risk of death

• Risk of injury

• Environmental hazards

• Material damage to the generator

• Material damage to other property

• Limited performance or functionality

You can avoid existing residual risks by observing and following these guidelines:

• the special warning notices on the generator

• the general safety instructions given in these operating

instructions

• the specific warnings given in these operating instruc-

tions

• The specific standing instructions (the relevant opera-

tional conditions) issued by fire-brigades, civil defence

and other relief organisations

Status at: January 2013

ESE 904 - 1304 DBG DIN

13

Risk of death

Risk of injury

Environmental hazards

Material damage to the

Material damage to other

Risk of death to persons at the generator can be caused by:

• Incorrect use

• Inappropriate handling

• Missing protective equipment

• Defective or damaged electrical components

• Fuel vapours

• Engine exhaust

• Too large a distribution network configuration

Risk of injury to persons at the generator can be caused by:

• Inappropriate handling

• Transport

• Hot components

• Recoiling starter rope on the engine

generator

Environmental hazards involving the generator may be

caused by:

• Inappropriate handling

• Operating fluids (fuel, lubricants, engine oil, etc.)

• Exhaust gas emission

• Noise emission

• Fire hazard

• Leaking battery acid

Material damage to the generator can occur through:

• Inappropriate handling

• Overloading

• Overheating

• Too low/high oil level of the engine

• Non-compliance with the operating and maintenance

specifications

• Unsuitable operating fluids

• Unsuitable hoisting gear

14

property

Material damage to other property in the operating range of

the generator can occur through:

• Inappropriate handling

• An over and/or an undervoltage

ESE 904 - 1304 DBG DIN

Status: at January 2013

Limits to performance or

• Incorrect installation in a vehicle

The generator's performance or functionality can be limited

functionality

by:

• Inappropriate handling

• Inappropriate maintenance or repair work

• Unsuitable operating fluids

• An installation altitude greater than 100 metres above

sea level

• An ambient temperature exceeding 25°C

• Too large a distribution network configuration

Status at: January 2013

ESE 904 - 1304 DBG DIN

15

2.3 Operating personnel – qualifications and obligations

Only appropriately authorised personnel may work with or on

the alternator.

The authorised operating personnel must:

• be at least 18 years old.

• be trained in first aid and able to provide it.

• be familiar with the accident prevention regulations and

generator safety instructions and be able to apply them.

• have read the chapter "General Safety Regulations".

• has understand the content of the chapter "General Safe-

ty Regulations".

• be able to use and implement the content of the chapter

"General Safety Regulations" in practice.

• be trained and instructed according to the rules of con-

duct in the event of malfunctions occurring.

• have the physical and mental abilities to carry out his

responsibilities, tasks, and activities on the generator.

• be trained and instructed in his responsibilities, tasks and

activities on the alternator.

• have understood the technical documentation concerning

his responsibilities, tasks and activities on the alternator

and be able to implement these in practice.

2.4 Personal protective equipment

This personal protection equipment must be worn during all

activities at the generator described in these operating instructions:

• hearing protection

• protective gloves

• hard hat

• protective shoes

• fireproof protective clothing (in areas where the danger of

fire is high)

16

ESE 904 - 1304 DBG DIN

Status: at January 2013

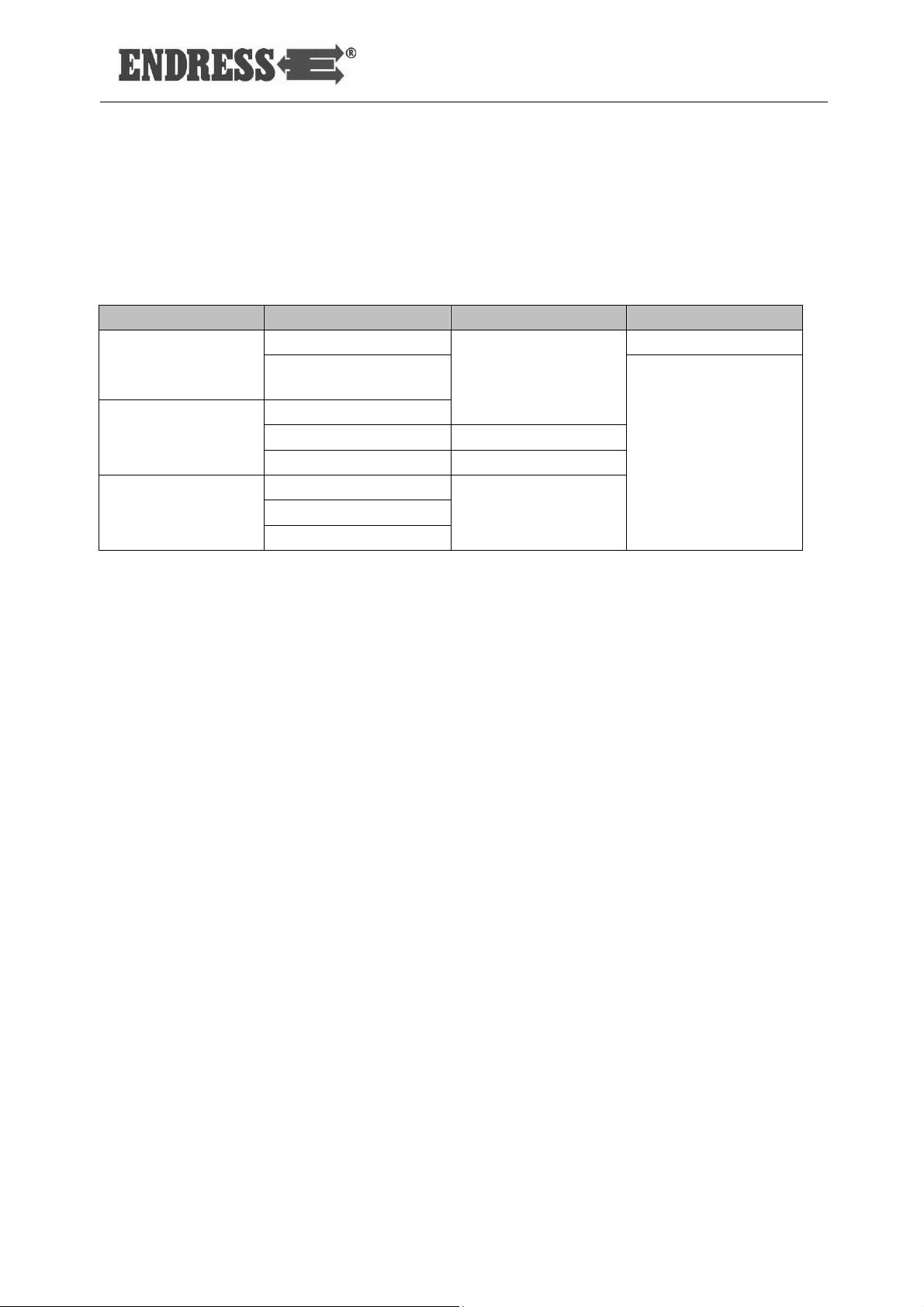

Life cycle

Activity

Danger zone

Work area

2.5 Danger zones and work areas

The danger zones work places (work areas) on the generator are determined by the activities to be performed within

the individual life cycles:

Transport in the vehicle Radius of 1.0 m none

by the operating per-

sonnel

Operation Setting up

Operating Radius of 5.0 m

Refuelling Radius of 2.0 m

Service and

maintenance

Cleaning Radius of 1.0 m

Shutting down

Maintenance

Table 2.1: Danger zones and work areas on the generator

Radius of 1.0 m

Status at: January 2013

ESE 904 - 1304 DBG DIN

17

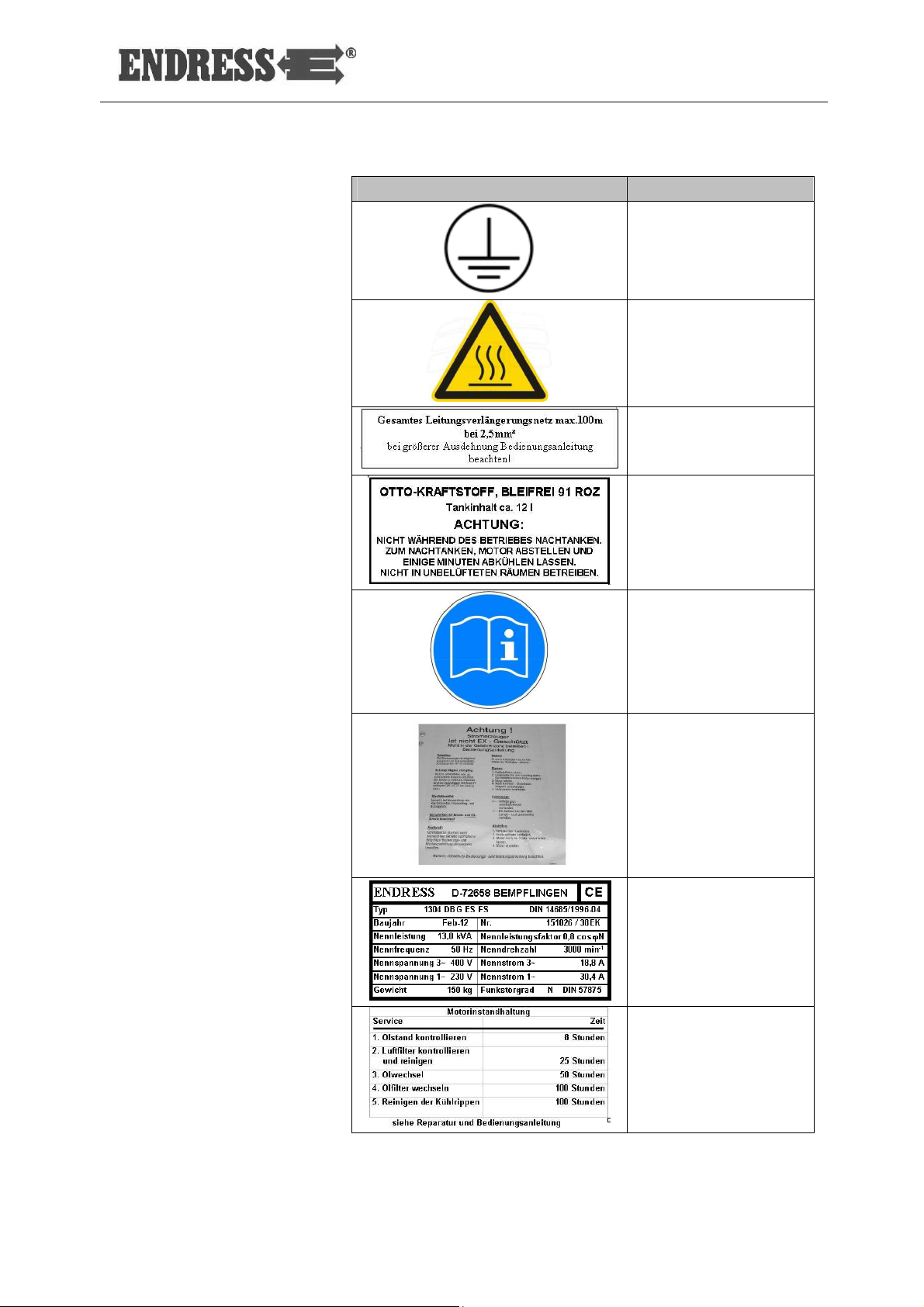

2.6 Labels on the generator

These labels must be attached to the generator and be kept

in a clearly legible condition:

Fig. 2-1: Labels on the generator

1 Potential equalization (earthing for FI) 6 Reference note - "read operating in-

structions"

2 Motor model plate 7 Short operating instructions (interior)/

Reference note regarding short oper-

ating instructions (exterior)

3 Reference note - "hot surface" 8 Model plate

4 Reference note - "cable extension"

9 Reference note - "maintenance"

(under the flap)

5 Reference note - "fuel note" 10 Reference note - "open flame"

11 Reference note - “noise emission”

18

ESE 904 - 1304 DBG DIN

Status: at January 2013

Label

Designation

Potential equalization

(earthing for FI)

Reference note - "hot

surface"

Reference note - "ca-

ble extension"

Reference note - "fuel

note"

Reference note - "read

operating instructions"

Short operating in-

structions (inner side

flap)

Generator model plate

Status at: January 2013

Reference note - "en-

gine

maintenance"

ESE 904 - 1304 DBG DIN

19

Label

Designation

Reference note - "no

naked flames"

Note

Noise emission

Table 2.2: Labels on the generator

2.7 General safety instructions

The generator's construction may not be modified in any

way.

The engine's nominal rpm has been set in the factory and

may not be changed.

All protective covers must be at hand and functional.

All labels on the generator must be in place and in a clearly

legible condition.

The operational reliability and functionality must be checked

before and after each use/operation.

The generator must only be used outdoors with sufficient

ventilation.

Do not use any open flame, light or spark-generating devices

within the generator's danger zone.

20

Protect the alternator against moisture and precipitation

(rain, snow) during operation.

Protect the alternator against dirt and foreign matter during

operation.

The authorised personnel are responsible for the operational

reliability of the alternator.

ESE 904 - 1304 DBG DIN

Status: at January 2013

Transport

Setting up

The authorised personnel are responsible for safeguarding

the alternator against unauthorised operation.

The authorised personnel are obligated to observe the applicable accident prevention regulations.

The authorised personnel are obligated to obey the safety

and work instructions of superiors and/or safety officers.

The authorised personnel are obligated to wear personal

protective equipment.

Only authorised personnel may remain in the generator's

danger zone.

Smoking is absolutely prohibited in the generator's danger

zone.

Open flames and light are prohibited in the generator's danger zone.

Consumption of alcohol, drugs, medications, or other mindaltering substances is prohibited.

The authorised personnel must be familiar with the alternator

components and their function and know how to use them.

The generator may only be transported after it has cooled

down.

The generator may only be transported in a vehicle after being fastened in place correctly (on the transport device).

The generator may only be lifted by the carrying handles

provided.

The generator must be carried by at least as many persons

as there are handles provided.

Status at: January 2013

The generator may only be set up on sufficiently firm ground.

The generator may only be set up on even ground.

ESE 904 - 1304 DBG DIN

21

Generating electricity

Refuelling

Cleaning

The electrical safety must be checked before each start-up.

Do not cover the equipment during use.

Do not obstruct or block the air supply.

Do not use starting aids.

Devices must not be connected during start-up.

Only tested and authorised cables may be used for the pow-

er network.

It is prohibited to establish a connection between existing

neutral conductors, potential equalisation conductors and/or

equipment components (safety-separated circuit).

The entire drawn output must not exceed the maximum nominal output of the generator.

Do not operate the generator without a sound damper.

It is prohibited to operate the generator without air filters and

with an opened air filter cover.

It is prohibited to refill the fuel tank on the generator during

operation.

It is prohibited to refill the fuel tank on the generator when it

is still hot.

Use filling aids for refuelling.

It is prohibited to clean the generator during operation.

It is prohibited to clean the generator when it is still hot.

22

ESE 904 - 1304 DBG DIN

Status: at January 2013

Mai

ntenance and repair

Decommissioning

Do

cumentation

Environmental protection

Operating personnel may only carry out the maintenance or

work

repair work described in these operating instructions.

All other maintenance or repair tasks may only be carried out

by specially trained and authorised specialists.

Always remove the spark plug socket before beginning

maintenance and/or repair work.

The maintenance intervals specified in these operating in-

structions must be observed.

It is prohibited to service the generator during operation.

It is prohibited to service the generator when it is still hot.

The generator should be put out of service if it is not required

for more than 30 days.

Store the generator in a dry and locked room.

Use a petrol additive to prevent resinous residues in the fuel

system.

One copy of these operating instructions must always be

kept in the generator’s manual compartment.

The operating instructions and the maintenance instructions

for the engine (Briggs & Stratton Corporation) are integral

parts of this instruction manual.

The packaging material must be recycled according to the

environmental protection regulations applicable at the place

of use.

The workplace must be protected against contamination by

leaking operating fluids.

Status at: January 2013

Used or leftover fuels and lubricants must be recycled according to the environmental regulations applicable at the

place of use.

ESE 904 - 1304 DBG DIN

23

Notes

24

ESE 904 - 1304 DBG DIN

Status: at January 2013

3 Operating generator ESE 904 - 1304 DBG DIN

The components and functionality of the generator are described in this section.

3.1 Components of generator ESE 904 - 1304 DBG DIN

The generator components are distributed on all four sides.

Fig. 3-1: Views of the generator

1 Control side 3 Exhaust gas side

2 Engine side 4 Alternator side

Status at: January 2013

ESE 904 - 1304 DBG DIN

25

3.1.1 Components of the operating and alternator side

Fig. 3-2: Components of the operating and alternator side

1 Generator lid 5 Tank

2 Generator 6 Electrical compartment

3 Potential equalisation screw (for an

7 Tank cover

optional FI earthing connection)

4 Carrying handle

26

ESE 904 - 1304 DBG DIN

Status: at January 2013

3.1.2 Exhaust and engine side components

Fig. 3-3: Exhaust and engine side components

1 Air filter 7 Spark plug connector

2 Tool pouch 8 Oil dipstick

3 Briggs & Stratton engine 9 Exhaust

4 Carrying handle 10 Exhaust heat shield plate

5 Starter battery 11 Oil filler neck

6 Fuel filter 12 Motor flap

Status at: January 2013

ESE 904 - 1304 DBG DIN

27

Loading...

Loading...