Page 1

a Free Download from AnalogRules.com

Contents

Page

Hints for unpacking and transporting 1

Small parts

A Preparing the unit for operation

A 1 Opening of the unit and

removal of the transit protections 3

A 2 Preparatory work on the unit 3

A 3 Mains connections 5

A 4 Earthing 6

A 5 Connecting the signal lines 7

A 6 Fitting and connecting of the

accessories for remote 7

A 7 Calibration of Reverberat i on

Time Indication. 8

A 8 Test tape 8

B Electrical tests and adjustments after initial installation

B 1 Setting up the amplifier gain

without reverberation plate 9

B 2 Adjusting the overall gain via

the reverberation plate 9

B 3 Frequency response measurements 10

C Connecting the reverberation unit into the signal path

C 1 Basic principles 11

C 2 Stereo / Mono operation 11

D Practical operating hints

D 1 Units without remote control 12

D 2 Units with remote control 12

D 3 Bass cut at the amplifier 13

Technical data EMT 140 FB-TS 14

Technical data EMT 162 TS 15

Page 2

a Free Download from AnalogRules.com

Outline size 17

Circuit diagram. EMT 140 FB-TS

EMT 162 TS front view 19

EMT 162 TS rear view 20

EMT 162 TS with open lid 21

Circuit diagram EMT 162 TS 22

Adjustments and test points EMT 162 TS 23

Print board EMT 162 TS 24

Frequency responses EMT 162 TS 25

Tolerance field EMT 140 TS 26

Connection diagram for reverberation generation 27

Circuit diagram for multiple control

desk arrangements 28

Spare parts 29

Service Instructions 30

EMT 140 Q 33

Page 3

a Free Download from AnalogRules.com

Small parts

EMT 140 TS

Reverberation Unit:

1 Hand wheel, complete

1 Plastic disk

2 open-end wrenches

8 Wire Clips

2 Clip guards

2 Plugs T 3084-2

or: 2 Plugs Cannon XLR-12c

2 Plugs Cannon XLR-13c

1 Power cord (US-version)

1 Power plug*

1 Driver magnet, complete

EMT 140 F

Remote control Motor unit:

1 Fuse 1 A slow-blow 20 mm x 5 mm 0

1 Fuse 1 A slow-blow 1 1/4" x 1/4"

1 Plug T 3055

1 Coupling disk (plastic)

1 Screw cap (US-version)

EMT 140 B

Remote Control Operating Unit:

1 Bulb socket

1 Bulb 24 V/80 mV

1 cap with lens

1 Resistor 2000 ohms 0.25 W 5 %

1 Condenser 0.1/uF 400 V

1 Toggle switch

2 Fuses 0.5 A, 20 mm x 5 mm

1 Screw cap (Europe version)

1 Fuse holder

2 Fuses 0.5 A, 1 1/4 " x 1/4

1 Screw cap (US-version)

Page 4

a Free Download from AnalogRules.com

Please read Carefully before unpacking

Hints for unpacking and transporting:

1. The equipment should only be moved short distances after being

unpacked.

2. Make sure the case is standing the right way up. The arrows must

point upwards.

3. The front of the case should be opened first.

Remove nails carefully. Do not use crowbars or levers.

4. The sketch on the front of the Reverberation Unit shows how if

should be lifted from the base of the packing case and moved to

it’s destination. During transport the dial indicating reverberation

time must be at the fop. The equipment should only be moved in

an upright position.

5. Only when standing at ifs final destination should the

Reverberation Unit be made ready for operation.

6. Before opening the equipment if is essential that the operating

instructions are studied carefully.

Page 5

a Free Download from AnalogRules.com

A. Preparing the unit

for operation

The reverberation unit EDIT 140 is a high precision electroacoustic device requiring particular protec

tion during transit. Only when the unit has been unpacked and placed in its final location should the pro

tecting devices be removed and the unit prepared for operation.

A1 OPENING OF THE UNIT AND REMOVAL OF THE SHIPPING PROTECTIONS

1. First unscrew the two side-plates, then the top cover-plate

(the two end-plates and the base-plate should be left on).

2. Untie the two cartons with accessories from the base-plate and remove them. Remove the card board

pieces between the reverberation plate and the traverse units. Untie the moving parts of the damp ing

plate.

When packed for airfreight, the foam rubber strips between steel -pla t e and damping plate have to be

removed.

3. Untie the shielded cables (with Co-ax plug) from the traverse and plug into the amplifier input

sockets. Plug colored Co-ax plug into "left-hand" channel.

A2 PREPARATORY WORK ON THE UNIT

The various sections should be prepared for operation as follows:

1. The reverberation plate (large steel sheet)

It is held in the tubular frame by means of two steel clips on each side - i.e. 8 altogether - (spare steel

clips are provided) which are attached to threaded bolts. The reverberation plate can be tensioned in the

frame by means of the nuts on these bolts.

Page 6

a Free Download from AnalogRules.com

these nuts (see drawing) have been loosened at the factory by exactly a quarter of a turn (90

Therefore, the standard practice is to tighten the plate by means of the same screws exactly 90* clockwise.

However, this applies only if no stressing of the steel clips occurred during transport - which may be

caused by shocks etc. In this case, more tension is necessary to obtain the original state.

In case of doubt we strictly recommend to have the plate more stressed instead of having it too loose.

With too high tension most probably the frequency response will run out of the tolerance field (too low at

bass end), but in the same way distortion with low frequencies will be reduced.

In order to vary the tension of the plate, proceed as follows:

The inner nuts must be held in position (they must not be allowed to turn) while loosening the outer lock

nuts. The inner nut should now be turned. It should be then held in this po sition while tightening up the

lock nut.

The only criterion for correct tensioning are the electroacoustic properties (check of overall response see

B 3).

If a re-tensioning of the steel-plate is neccessary (e.g. because a spring has been broken during transport)

please refer to B 3, "Frequency response measurements (T - 2 S)".

After tensioning, the top cover-plate of the wooden housing should be replaced.

2. The damping plate

Its distance from the reverberation plate can be varied by means of the parallel guide mechanism

(adjustment of reverberation time). The damping plate is adjusted at the factory so as to achieve - with

the damping plate turned in - the smallest defined reverberation time ((equal to or less than 1 s).

The hand wheel, which is supplied separately, is for adjusting the reverberation time. It is pushed through the

plate with the scale marking on the top of the unit onto the shaft which operates the lever mechanism of the

damping plate. Before fixing the hand wheel on this shaft one should ascertain that the pointer is within the

scale.

Before

shipment four of

0) counter-clockwise.

Page 7

a Free Download from AnalogRules.com

In units without internal remote control the damping plate should be easily movable by turning the hand

wheel. With minimum reverberation time the damping plate must not touch the steel plate. This applies to

units with remote control as well.

3. The driving system

The black enamelled mounting-plate around the moving coil is for mounting and adjusting the driver magnet

system which is supplied separately. The mounting plate is fixed to the central traverse by means of four

screws. It can be adjusted by loosening these screws. By means of the plastic plate which is provided, the

concentricity of the magnet and the moving coil may be checked after tensioning the reverberation plate. If

the systems are concentric the plastic adjusting plate can be pushed easily onto the moving coil and inserted

into-the four guides for the mounting plate. The driver magnet system should-then be pushed carefully over

the moving coil without brushing against it and screwed to the mounting plate. The DC resistance of the

moving coil is 12.5 ohms.

4. The pick-up systems

All versions of the EMT Reverberation Unit are equipped with two pick-up systems. They are accessible on

the two outer traverses and are protected by a shielding can. By opening the lid of these cans, it is possible to

ascertain that:

The microphone system (capacity approximately 500 pF) is able to move freely inside the can and the leads

to the soldering lugs are also free.

Replace the lid of the can.

Then screw on the two wooden side-covers again and fix the top cover. Now the preparation has been

finished.

The EMT-Reverberation Unit is protected against ambient noise by rubber suspension blo c ks between case

and frame. However, with excessive ambient noise, additional suspension of the total unit is advisable.

A3 POWER CONNECTIONS

A three-conductor cable may be attached to the AC connector which is provided.

The EMT Reverberation Unit will be set at the factory to the AC voltage quoted in the order. This voltage is

entered in the delivery papers. If no definite voltage was decided upon when ordering, the unit will be

supplied with the AC voltage set to 220 V/50 Hz.

The units EMT 140 FB and EMT 140 FBst (with internal remote control) which are supplied for AC voltage

of 110 V, 117 V, or 240 V are equipped with an additional transformer "S 140- B" which will be set at the

factory to the -required AC voltage.

Instructions for changing the primary voltage on the additional transformer are contained in the drawing "S

140-232.B" at the end of this operating manual.

IMPORTANT

Page 8

a Free Download from AnalogRules.com

The amplifier has to be set separately to the actual AC power voltage. The respective current of the fuse

should be observed. The setting is done by means of the slide switch (100 V - 130 V and 190 V - 260 V) at

the rear of the amp1ifier.

If a reverberation unit EMT 140 or EMT 140 st which is operated from an AC voltage other than 220 V is to

be equipped subsequently with the internal remote control outfit EMT-140 F, an additional transformer "S

140-232 W' must be used. (Please note this when ordering.)

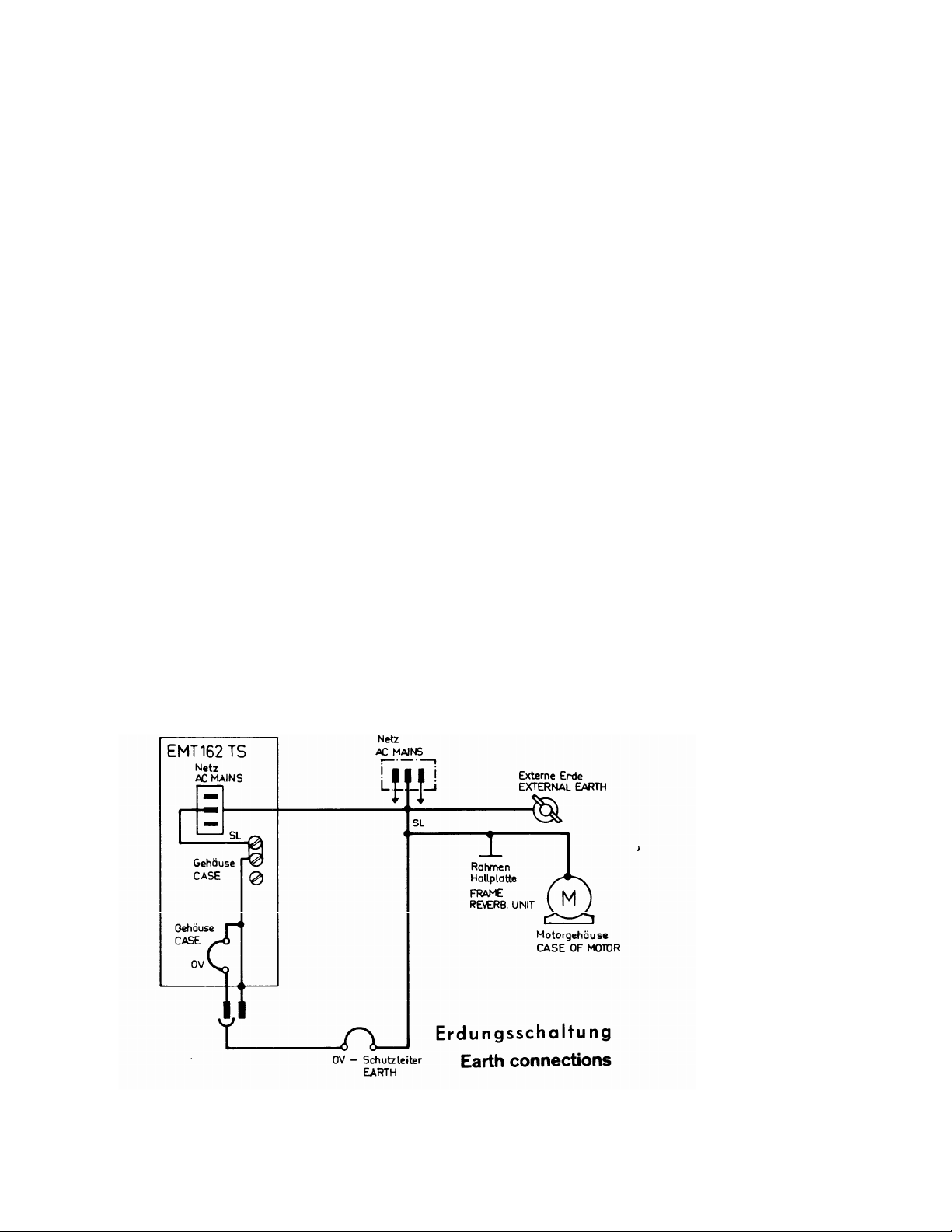

A4 OPERATING GROUND, AC GROUND, CHASSIS, ZERO-VOLT (MINUS)

In order to comply with the requirements of the numerous Safety Authorities, the following connections are

available:

AC ground: Connection via power cord.

External ground: Connection to screw on front panel.

Zero-volt/AC ground: This connection is accessible on

the print (covered by a p lastic shield) inside the unit.

In the amplifier EMT 162 TS, the following connections are available:

AC ground / Chassis: At the rear of amplifier.

Zero-volt / Chassis Soldered connection inside the amplifier

A5 CONNECTING

THE SIGNAL

Page 9

a Free Download from AnalogRules.com

LINES

The connectors which are provided should be connected to the incoming and outgoing signal leads in

accordance with the "test circuit EMT 140 FB-TS".

A6 INSTALLING AND CONNECTING THE ACCESSORIES FOR INTERNAL REMOTE CONTROL

On the units EMT 140 FB-TS the reverberation time can be varied by means of a remote control unit from the

mixer. For this purpose the remote control unit EMT 140 B which is supplied, the toggle-switch with its

accessories and the pilot lamp should be built into the mixer.

The reverberation time can be varied at any time on the unit itself - e.g. for testing - by means of the switch

on the connecting plate ("+" increase, "-" decrease reverberation time).

The control unit EMT 140 B should be connected in accordance with the circuit diagram EMT 140 FB-TS via

an 8-conductor cable and by means of the 8-pole TUCHEL connector T 3055/10 which is provided with the

reverberation unit. By means of the toggleswitch, the entire reverberation unit can be remotely switched on

and off from the mixer. The AC switch on the amplifier must in this case be permanently left in the "ON"

position. The pilot lamp on the mixer will light up when the unit is switched on.

For testing purposes the unit may be switched on directly (by

means of the switch on the mains plate of the unit) independently

of the AC switch on the mixer. However, the pilot lamp on the mixer will not light up in this case.

The remote control requires an operating voltage of 24 V DC. If a unit is ordered for other control supply

voltages, this will be specially noted in the delivery papers.

Page 10

a Free Download from AnalogRules.com

The drawing sheet X 140-20 shows a circuit arrangement whereby one reverberation unit may be remote

controlled from several mixers. It is for instance, possible to connect three indicators for the reverberation

time in series without re-calibrating them.

The circuit connections to the control terminals 1 and 2 of the 8-pole TUCHEL connector from several

mixers can be effected by means of standard techniques i.e. with plugs, relay circuits or even selector circuits.

It is only necessary to ensure that one control circuit cannot contact more than one control unit at a time.

A7 ADJUSTMENT OF REVERBERATION TIME INDICATION

It may be advisable to check to Reverberation Time Indication on the meter. Calibration at 1 s is done by

means of R and at 2 s by R 3 respectively.

These potentiometers are accessible through the cover of the motor unit.

A8 TEST TAPE

Tape Speed 15 ips.

Equalization according to CCIR.

For testing the frequency response and adjusting the overall gain via the reverberation-plate EMT 140, a test

tape is available, which replaces the use of a noise generator and band pass filter and also simplifies the test

methods.

The followings signals are recorded on this tape:

1. Level for adjusting the gain.

Announcement in German.

1/3 octave band noise,mid-frequency 1kHz; peak level, running time approx. 2 minutes.

Yellow leader tape.

2. Frequency response.

Announcement in German.

1/3 octave band noise. 27 mid-frequencies from 40 Hz to 1 2. 5 kHz

each frequency with announcement in German

(running time of each frequency 20 seconds),

14 dB below peak level.'

Page 11

a Free Download from AnalogRules.com

B Electrical tests and adjustments

after initial installation

B1 SETTING UP THE AMPLIFIER GAIN WITHOUT REVERBERATION PLATE

The amplifiers are pre-aligned at the factory.

The gain controls are accessible by removing the amplifier cover plate on the front end of the reverberation

unit (2 knurled screws).

The positions of the potentiometers are shown on the inside of the amplifier cover plate and on the drawing

"Adjustment and Test points".

The drive level is to be set on R 17.

Feed a third octave 1 kHz center frequency white noise spectrum to one of the unit's inputs at a level reading

".On on a VU meter or "-6 W' on a Peak Program meter connected to it. Such a meter for constant program

feed supervision must be permanently connected to the input of the EMT unit. Adjust the drive level control

until a VTVM connected to the test jacks on the amplifier, which are connected to the drive output of the

amplifier reads 0.95 V. This completes the alignment of the drive level. This test may also be undertaken with

a sine wave signal of 1 kHz.

The output level is to be prealigned on "Output level (R 42)" for either channel. For this purpos e the Co-ax

plug on the shielded cable from the pick-up must be removed from the input socket of the output section.

With an input of 3.1 mV (-48 dB) at 1 kHz via a condenser of app. 500 pF, to obtain the equivalent source

impedance, the gain should be adjusted to obtain an output voltage of .55 V (-3 dB) into a 600 ohm resistive

load.

This alignment is only necessary if the amplifier has to be checked separately.

B2 ADJUSTING THE OVERALL GAIN VIA THE REVERBERATION PLATE

If the gain of the driver section has been aligned, only the "R 42" control for either channel should be used for

adjusting the overall gain.

For this measurement, a white noise generator or as a substitute. the white noise from a magnetic tape should

be used.

IMPORTANT

For this alignment, the reverberation time of the reverberation unit should be set to 2 seconds.

Adjusting the gain with a sine wave signal is not possible because the reverberation unit - like a reverberation

room -has a great many resonances close together and the output

level would therefore be very much a function of frequency.

Page 12

a Free Download from AnalogRules.com

The levels should be as follows:

ALIGNMENT LEVELS FOR USE WITH DIFFERENT METERING STANDARDS:_

FUNCTION PEAK INDICATING VU-METER VTVM METER

METER

EMT-140 input 0 dB 0 VU +4 to +8 dB

Driver output +1.7 dB +1.7 dB 0.95 V

EMT-140 output -3 dB...O dB 0 VU +4 to +8 dB

If the unit is used as a stereo unit (see C 2) and both inputs are fed with the "A" and the "B" - Signal, the input

alignment has to be slightly different. Depending on the correlation of the two signals, the drive level will be

raised by 3... 6 dB caused by the internal mixing. In this case we recommend to reduce the gain of the drive

amplifier by approx. 4 dB (R 17 ).

However, if the unit will be used for mono and stereo, we recommend to reduce the drive amplifier gain by 5

dB and feed both inputs with the monaural signal. This will be a good compromise and will lead to a

deviation of +1 dB (mono) or 0...-2 dB, average -1 dB (stereo).

B3 FREQUENCY RESPONSE MEASUREMENTS (T = 2 S)

The frequency response should also be measured by means of white noise with a band width of 1/3 octave.

Apart from that the frequency response measurement is carried out in the usual way i.e. with constant input

voltage to the reverberation unit and the output voltage is plotted as a function of the center frequency of the

band pass filter. The response should be referred to an output voltage of -3 dB (.55 V) into 600 ohms with a

center frequency of 1 kHz (see graph X-EMT 140-7/6A).

The frequency response should be in the tolerance field (bass cut switch in "0" position). As the frequency

response is somewhat dependent of the tension of the steel-plate, a re-tensioning may be advisable if the

frequency response is out of tolerance.

The plate must not be tensioned too weak or unequal. Missing tension will create distortion at low

frequencies and an uneven plate will show an "Oilcan" thus reducing the effective area and creating a

"metallic" sound.

Small deviations from the tolerance field are not acoustically detectable.

If a pen-recorder is available for the frequency response measurement a wobbled sine wave may be used. It

is, however, necessary that the inertia of the pen-recorder be sufficiently high to integrate the rapid changes

which occur with small variations in frequency. Further details about the frequency response measurement

with the wobbulator should be obtained from the operating manual for the pen-recorder.

Page 13

a Free Download from AnalogRules.com

C. Connecting the reverberation unit

into the signal path

C1 BASIC PRINCIPLES

The block schematic X 140-10 shows the basic method of connecting the reverberation unit into the program

chain.

The direct (unreverberated) signal goes via a channel fader to the mixing point. The signal portion which is to

be reverberated is branched off before the channel fader (echo channel input).

.An additional attenuator may be provided at this point in order to adjust the input level to the reverberatio n

unit once and for all to the nominal value.

From there the signal is taken to the reverberation unit. The reverberated signal is mixed in with the direct

signal at the mixing junction via an echo return fader. The level of the reverberated signal is usually about 6

dB below the level of the direct signal.

If it is desired to color the reverberation spectrum, a filter may be connected to the input of the echo channel.

Of course the built-in bass cut filter can be used as well.

The amplifier WIT 162 TS contains a driver section with two identical inputs and two reproduce sections for

stereo or mono operation.

The driver unit contains a switchable compressor with a ratio of 2:1 and a threshold at nominal level.

The input impedance of app. 5 kohms is sufficiently high not to load a normal output used in recording

studios. In the same way, the output impedance of the amplifier (less than 25 ohms) is sufficiently low to be

loaded with the impedance of normal studio faders.

C2 STEREO / MONO OPERATION

The reverberation units EMT 140 TS and EMT 140 FB-TS are suitable for reverberating stereo and mono

recordings. For mono recordings only one ch annel is use d. _

Depending on the process used in the stereo recording, the unit may be connected in the following ways:

AB-Stereo

Both channels may be fed to the inputs of the reverberation unit. The sum signal, which driv es the

plate, is mixed internally.

However, it is possible to mix the channels in the console. In this case, the sum signal is fed to

either input.

Page 14

a Free Download from AnalogRules.com

The two output signals are then mixed back into the left and right hand channels in the same way as described

above for mono signals. The portion mixed in may be controlled by means of two ganged or one stereo

tandem fader.

The signals induced by the two microphones - with different distances to the driver system - are noncoherent. This is necessary to obtain random directional information.

The reverberation unit has a high resonance density. Therefore phase deviations depending on frequency will

occur between the microphones. If the reverberation unit is fed with a mixture of frequencies, such as music,

then all possible phase relations between the microphone signals will be obtained.

As a result the directional information contained in the reverberated signals is statistically distributed to all

possible directions of the room.

MS-Stereo

In this case the sum signal M is simply fed to one input of the reverberation unit. Apart from that the same

applies as with AB-stereo. We recommend feeding the output signal from output I to the sum channel and

that from the output 11 to the S (difference) channel to avoid confusion.

D Practical operating hints

D1 UNITS WITHOUT REMOTE CONTROL EMT 140 TS

Turn on the amplifier by means of the AC switch on the front face of the unit.

The pilot lamp should light up.

Select the reverberation time by means of the hand wheel before the recording.

D2 UNITS WITH REMOTE CONTROL EMT 140 FB-TS

1.Select the reverberation unit if one is controlled from several control units.

2. Switch the reverberation unit on by means of the toggle

switch on the mixer. The pilot lamp should light up.

Page 15

a Free Download from AnalogRules.com

For testing: Switch on at the unit (on the front panel).

Remember to switch off after use.

The AC switch on the amplifier should be

left permanently in the "ON" position!

To adjust the reverberation time press the buttons beside the indicator instrument until the desired

reverberation time is shown on the meter.

"+" -Button to increase and

"-" -Button to decrease reverberation time.

Avoid pressing the buttons intermittantl as this will cause vibrations in the reverberation plate. If the

reverberation time is altered during a recording the signal to noise ratio will be approx. dB with Ion

reverberation times.

The spectrum of this noise is primarily below 100 Hz.

Adjustment of the reverberation time during soft passages, or pauses, with the fader turned up should be

avoided.

D 3 BASS CUT AT THE AMPLIFIER

In the drive section of amplifier EMT 162 TS the low frequencies may be cut with three different time

constants. For this purpose the switch which comes out through the amplifier cover plate on the front edge of

the unit should be turned by hand or by means of a screw driver. The attached graph shows the frequency

response corresponding to the switch positions "0" to "3".

The purpose of the bass cut is as follows: The reverberation time in a room is greater for low frequencies than

for high. The reverberation plate behaves in the same way. In many cases, however, it is desirable to reduce

the low frequency proportion in the reverberated sound in order to achieve certain effects.

In a room this requires special acoustical treatment of the walls. With the EMT Reverberation Unit the same

effect is achieved by means of the bass filter which is variable in steps.

13

Page 16

a Free Download from AnalogRules.com

Technical data EMT 140 FB-TS

with Amplifier EMT 162 TS

Reverberation Time

(measured at 500 HZ) 1......4 seconds

Accuracy of time scale division

(re 500 Hz) +8 %

Frequency response

at 2 seconds reverb. time see curve

Noise

with a reproduce gain of 45 dB =< -50 dB eff.

with running remote control motor =< -38 dB eff.

weighted =< -60 dB peak

Input level

for full modulation 0--+21dBm

Input impedance => 5000 Ohms

Output level

of amplifier max. +21 dBm

of complete unit max. +15 dBm

Usual direct channel mix-in level -6 to -10 dB

Output impedance =< 25 Ohms

Load impedance => 200 Ohms, 600 Ohms nominal

Moving coil impedance

of drive system 12.5 Ohms

Power Supply requirement 110/220 Volts 50 Hz;

or 117 Volts 60 Hz

Remote Control

(140 FB-TS only)

built-in servo motor with relay

control; indicating instrument

External voltage required 24 Volts DC, 250 ma

Weight

Without remote control 374 lbs. (170 kg)

With remote control 418 lbs. (190 kg)

Dimensions 81 1/2" (2.4 m) long

11 1 1/2" (0.34 m) wide

41 4" (1.32 m) high

Page 17

a Free Download from AnalogRules.com

Technical data EMT 162

I. DRIVER SECTION

NOTE Unless otherwise indicated, all data is measured

under the following conditions:

Oscillator source impedance 25 Ohms

Terminating resistance 15 Ohms

Frequency range 40- 15,000 Hz

MAX.GAIN at 1 kHz approx. 7.5 dB

FREQUENCY RESPONSE Deviation from nominal curve (a)

referred to a 1 kHz level 20 dB

below line level; ^gain to be

adjusted to reach an output

level of 2 V at 1 kHz =< 2 dB

DISTORTION THD at any output level to <0.5% at 40 Hz

+15 dB with gain of 3 dB at <0.7% at 1 kHz

1 kHz <1.0% at 5 kHz

INPUT Adjustable +1.5 dB_+21 dB

INPUT IMPEDANCE =>5 KOhms

OUTPUT IMPEDANCE =<1 Ohm

NOISE LEVEL Unweighted <- 68 dB rms

Weighted <- 70 dB rms

HUM INTERFERENCE (With an external stray field

of 50 mGauss, under worst con

ditions of amplifier position

and power line polarity) <62 dB rms

11. REPRODUCTION SECTIONS

NOTE Unless otherwise indicated, all data is measured

under the following conditions:

Oscillator source impedance 200 Ohms

Terminating resistance 600 Ohms

Frequency range 40 - 15,000 Hz

Gain at 1 kHz 45 dB

MAX.GAIN at 1 kHz; 0 dB output approx. 54 dB

FREQUENCY RESPONSE Deviation from nominal curve (b)

at -58 dB input level =<2dB

DISTORTION THD 40 HZ 1 kHz 5 kHz

at + 6 dB output: <0.3% <0.2% <0.2%

at +24 dB output: <0.6% <0.3% <0.3%

OUTPUT IMPEDANCE <25 Ohms

INPUT IMPEDANCE capacitative

Page 18

a Free Download from AnalogRules.com

NOISE LEVEL (1 nF source) Unweighted < - 52 dB rms

Weighted < - 60 dB rms

HUM INTERFERENCE W ith an external stray field of

50 mGauss, under worst conditions

of amplifier location and power

line polarity < -40 dB rms

Ill. OVER-ALL SPECIFICATIONS

AC POWER LINE VOLTAGE RANGE 100 - 130 V

200 - 260 V

AC POWER LINE FREQUENCY 50 - 60 Hz

POWER CONSUMPTION approx. 22 W

INSULATION RESISTANCE

Between O-V and chassis;

measured with 100 Volts 10 Mohms

STRAY FIELD GENERATION

Measured at the unit's

outlines approx. 70 mGauss rms

Dimensions Front panel 20.5" x 4"

Depth 5.5"

Weight approx. 11 lbs.

Data subject to change without notice

16

Spare parts

(Only parts are listed which are normally subject to wear and tear.)

Wire clip S-140 - 36

Clip guard S 140 - 37

Coupling disk (plastic) S 140 - 702

Relais UA 3 A - 24 V 4 220 - 056

Driver System, complete 7 140 011

Magnet for Driver System, complete 7 140 328

Pick up, complete 7 140 336

Potentiometer 5 kOhm 120 e 33

Plastic disk (Jig for aligning

the driver magnet) 6 140 124

Rubber-Metal-Suspension 4 271 008

Pertinax-disk 4 mm } (for damping plate) 6 140 044

Page 19

a Free Download from AnalogRules.com

Page 20

a Free Download from AnalogRules.com

Page 21

a Free Download from AnalogRules.com

Page 22

a Free Download from AnalogRules.com

Page 23

a Free Download from AnalogRules.com

Page 24

a Free Download from AnalogRules.com

Page 25

a Free Download from AnalogRules.com

Page 26

a Free Download from AnalogRules.com

Page 27

a Free Download from AnalogRules.com

Page 28

a Free Download from AnalogRules.com

Page 29

a Free Download from AnalogRules.com

Page 30

a free download from AnalogRules.com

Footer Page 1 of 1.

Loading...

Loading...