Page 1

INSTALLATION INSTRUCTIONS

AND

OWNER'S MANUAL

GRAVITY VENTED

DUAL WALL FURNACE

MODEL

GWT-50-3 (SG, RB)

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

WARNING: If not installed, operated and maintained

in accordance with the manufacturer's instructions,

this product could expose you to substances in fuel

or from fuel combustion which can cause death or

serious illness.

WARNING: If the information in these instructions

are not followed exactly, a re or explosion may

result causing property damage, personal injury or

loss of life.

— Donot storeor usegasoline orother ammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

redepartment.

— Installation and service must be performed by a

qualiedinstaller,serviceagencyorthegassupplier.

Page 1

Page 2

TABLE OF CONTENTS

SECTION PAGE

Important Safety Information ....................................................................................3

Safety Information for Users of LP Gas ...................................................................4

Introduction ..............................................................................................................5

Specications ...........................................................................................................5

Recommended Vent Conguration ..........................................................................6

Gas Supply ...............................................................................................................7

Clearances ..............................................................................................................8

Ventilation and Combustion Air ................................................................................8

Location - All Models ................................................................................................8

Rough-In Instructions ............................................................................................8-9

Finishing Instructions ..........................................................................................9-10

Optional Thermostat Location (SG Models) ........................................................... 11

Lighting Instructions ...............................................................................................12

Vent Safety Shutoff System ...................................................................................13

Proper Main Burner Flame .....................................................................................13

Proper Pilot Flame .................................................................................................13

Troubleshooting ......................................................................................................14

Parts List ................................................................................................................15

How To Order Repair Parts ....................................................................................15

Parts View .............................................................................................................16

Remote Bulb Control Installation Instructions ........................................................17

Optional Blower Installation Instructions .......................................................... 18-19

Service Notes .........................................................................................................20

Master Parts Distributor List ...................................................................................21

Warranty .................................................................................................................22

32039-1-0314Page 2

Page 3

IMPORTANT SAFETY INFORMATION

THIS IS A HEATING APPLIANCE

DO NOT OPERATE THIS APPLIANCE WITHOUT OUTER CASING INSTALLED.

• Due to high temperatures the appliance should be

locatedoutoftrafcandawayfromfurnitureand

draperies.

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothingorotherammablematerialshouldnotbe

placed on or near the appliance.

• Any safety screen or guard removed for servicing

an appliance must be replaced prior to operating

the appliance.

• Keep burner and control compartment clean.

• Installation and repair should be done by a

QUALIFIED SERVICE PERSON. The appliance

should be inspected before use and at least annually

by a qualied service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding materials, etc. It is imperative

that control compartments, burners and circulating

air passageways of the appliance be kept clean.

• DO NOT put anything around the furnace that will

obstructtheowofcombustionandventilationair.

• DO keep the appliance area clear and free from

combustiblematerial,gasolineandotherammable

vapors and liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO make a periodic visual check of pilot and burners.

Clean and replace damaged parts.

• DO NOT use this heater if any part has been under

water.Immediatelycallaqualiedservicetechnician

to inspect the heater and to replace any part of the

control system and any gas control which has been

under water.

• This furnace must not be connected to a chimney

ueservingaseparatesolid-fuelburningappliance.

32039-1-0314 Page 3

Page 4

SAFETY INFORMATION FOR USERS OF LP-GAS

Propane(LP-Gas)isaammablegaswhichcancauseres

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions which can protect both you and your family from an

accident. Read them carefully now, then review them point by

point with the members of your household. Someday when

there may not be a minute to lose, everyone's safety will depend

on knowing exactly what to do. If, after reading the following

information, you feel you still need more information, please

contact your gas supplier.

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That's your signal to go into immediate action!

• Do not operate electric switches, light matches, use your

phone. Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such

as basements. When you have reason to suspect a gas leak,

keep out of basements and other low areas. Stay out until

reghters declare them to be safe.

• Use your neighbor's phone and call a trained LP-Gas service

person and the re department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and reghters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odorofthechemicalputintothegas.Youmustndoutifyou

can smell the odorant in propane. Smoking can decrease your

ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors in

the area mask the gas odor. People may not smell the gas odor

or their minds are on something else. Thinking about smelling a

gas odor can make it easier to smell.

The odorant in LP-gas is colorless, and it can fade under

some circumstances. For example, if there is an underground

leak, the movement of the gas through soil can lter the odorant.

Odorants in LP-Gas also are subject to oxidation. This fading can

occur if there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into

walls, masonry and other materials and fabrics in a room. That will

take some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

• Learn to recognize the odor of LP-gas. Your local LP-Gas

Dealer can give you a "Scratch and Sniff" pamphlet. Use it to

nd out what the propane odor smells like. If you suspect that

your LP-Gas has a weak or abnormal odor, call your LP-Gas

Dealer.

• If you are not qualied, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualied, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service or

making adjustments.

• Sometimes a basement or a closed-up house has a musty

smell that can cover up the LP-Gas odor. Do not try to light

pilot lights, perform service, or make adjustments in an area

where the conditions are such that you may not detect the

odor if there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are lled and allowed to set too

long before relling. Cylinders and tanks which have been

out of service for a time may develop internal rust which will

cause odor fade. If such conditions are suspected to exist,

SOME POINTS TO REMEMBER

a periodic sniff test of the gas is advisable. If you have any

question about the gas odor, call your LP-gas dealer. A

periodic sniff test of the LP-gas is a good safety measure

under any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete "gas out," (the container is under no vapor pressure), turn the tank valve off immediately.

If the container valve is left on, the container may draw in

some air through openings such as pilot light orices. If this

occurs, some new internal rusting could occur. If the valve is

left open, then treat the container as a new tank. Always be

sure your container is under vapor pressure by turning it off

at the container before it goes completely empty or having it

relled before it is completely empty.

32039-1-0314Page 4

Page 5

INTRODUCTION

Introduction

Vented wall furnace is shipped ready to install in a 2" x 4" stud wall,

with studs 16" (406mm) center to center. Always consult your local

Building Department regarding regulations, codes or ordinances

which apply to the installation of a vented wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after installation.

2. Installer must have owner ll out and mail warranty card supplied with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be dangerous.

This is a heating appliance and any panel, door or guard

removed for servicing an appliance must be replaced prior

to operating the appliance.

To conserve Gas: Turn off pilot when heater is not in use.

General Information

This series is design certied in accordance with American National

Standard / CSA Standard Z21.86 and CSA 2.32 by the Canadian

Standards Association, as a Vented Wall Furnace and must be

installed according to these instructions.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

Important

All correspondence should refer to complete Model No., Serial No.

and type of gas.

Notice: During initial ring of this furnace, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate

the room in which the furnace is installed.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than 18" (457mm) above the oor.

Such equipment shall be located, or protected, so it is not subject

to physical damage by a moving vehicle.

QualiedInstallingAgency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualied agency. The term "qualied agency"

means any individual, rm, corporation or company which either in

person or through a representative is engaged in and is responsible for

(a) the installation or replacement of gas piping or (b) the connection,

installation, repair or servicing of equipment, who is experienced in

such work, familiar with all precautions required and has complied

with all the requirements of the authority having jurisdiction.

State of Massachusetts: The installation must be made

by a licensed plumber or gas tter in the Commonwealth of

Massachusetts.

The installation must conform to local codes or, in the absence of

local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, CSA B149.1.

*Available from the American National Standards Institute, Inc., 11

West 42nd St., New York, N.Y. 10036.

High Altitudes

For altitudes/elevations above 2,000 feet (610m), input ratings

should be reduced at the rate of 4 percent for each 1,000 (305m)

feet above sea level. Canadian High Altitudes for locations having

an elevation above mean sea level between 2,000 feet (610m) and

4,500 feet (1370m), the manifold pressure is to be decreased from

3.5" w.c. (.871kPa) to 3.0" w.c. (.747kPa) for Natural Gas and from

10.0" w.c. (2.49kPa) to 8.0" w.c. (1.992kPa) for Propane Gas.

Model GWT-50

Input BTU/HR (KW/H) 50,000 (14.7)

Height 66 1/8" (1679mm)

Width 16" (406mm)

Depth (Out of wall) 6" (152mm)

Gas Inlet Pipe 1/2"

Vent Pipe Type B Oval 4" (102mm)

Accessory

Blower Package GWTB-2

Wall Thermostat Millivolt TMV

Wireless Remote Wall Thermostat TRW

Remote Bulb Thermostat GWRBT

GWT-50 (SG, RB) Is a DUAL WALL Furnace. Warmed air is discharged into two rooms which share a common wall.

32039-1-0314 Page 5

SPECIFICATIONS

Page 6

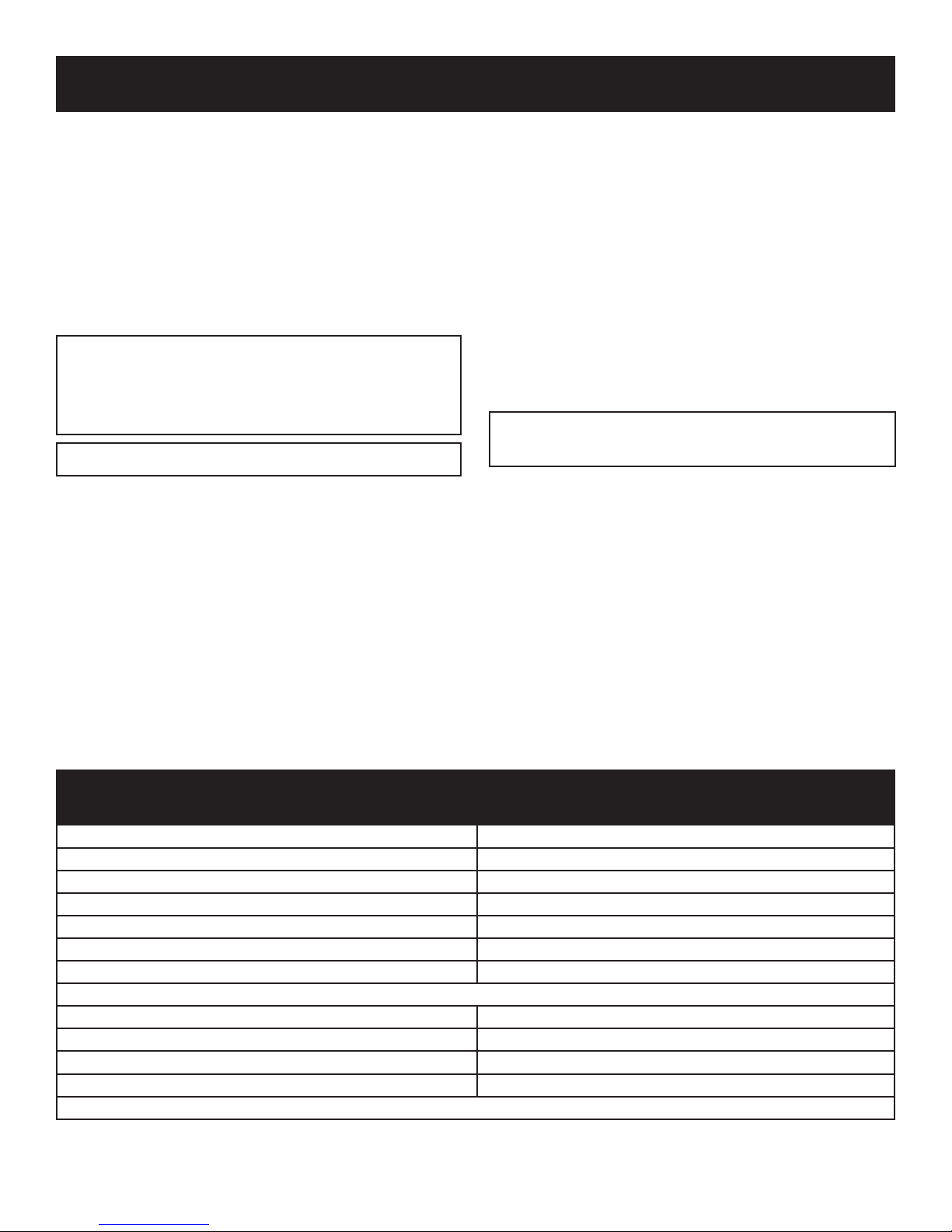

RECOMMENDED VENT CONFIGURATION

Note: No vent equipment supplied with furnace.

4" Oval (all parts purchase locally)

1. Type B-1 oval pipe

2. Single story type B-1 gas vents require a baseplate and one pair of

ceiling plate spacers.

3. Multi-story type B-1 gas vents require a baseplate, one pair of ceiling

plate spacers at the rst oor ceiling and one pair of re stop spacers

at each successive ceiling level.

Type B-W gas vent pipe is available for single story or multi-story

installations. Type B-W gas vent pipe is to be used with the

Listed base plate, ceiling plate spacers and re stop spacers.

Insulated Vent Enclosure

Gravity vented wall furnaces installed in buildings with at roofs can have

poor venting. The cold vent pipe will have a delay in proper venting and

cause the wall furnace to shut "off" by the vent safety switch. To prevent

delayed venting as well as condensation of ue products an insulated vent

enclosure is recommended.

Use Type B vent pipe and maintain at least a one inch (25mm) clearance

to combustibles.

Use metal thimble to protect vent pipe as it passes through combustibles.

Baseplate Gasket is factory installed on header. Baseplate attaches to header

with screws. B-vent snaps into and is attached to baseplate. Minimum

height of vent pipe must be six feet (1.8m) above header.

Stud space around gas vents must be free of obstructions and building paper.

Uninsulated Single-Wall Metal Pipe shall not be used outdoors in cold

climates for venting gas utilization equipment.

Attention: The main burner uses room air for combustion. As the gas/air

mixture is injected into the main burner, there is also the ow of dust and

lint particles into the main burner.

Dust and lint accumulation inside the main burner will result in a yellow main

burner ame and possible sooting inside the combustion chamber and vent

pipe. To clean main burner refer to Page 13, "Proper Main Burner Flame."

32039-1-0314Page 6

Page 7

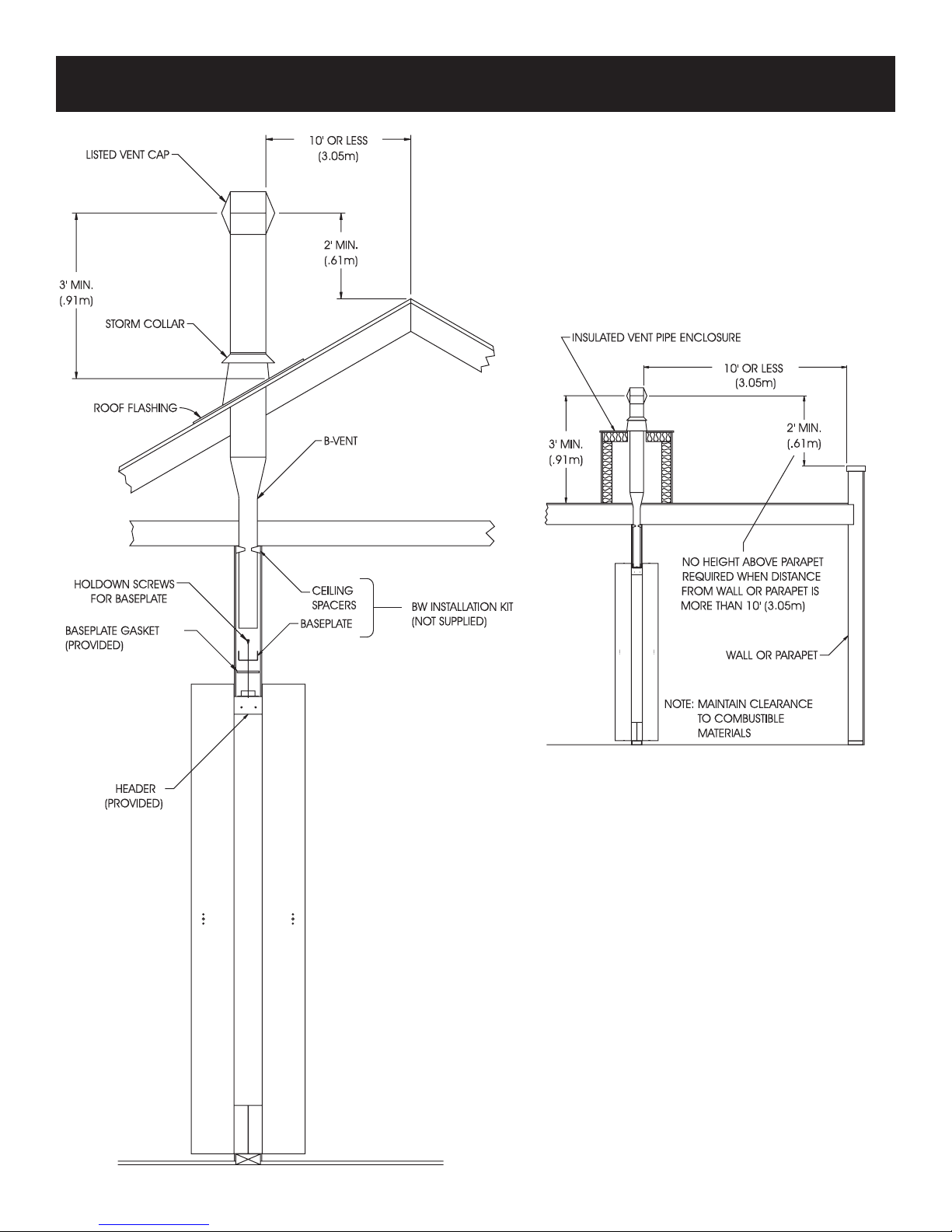

GAS SUPPLY

Check all local codes for requirements, especially for the size and

type of gas supply line required.

Recommended Gas Pipe Diameter

Pipe Length Schedule 40 Pipe

Inside Diameter

Nat. L.P. Nat. L.P.

0-10 feet

0-3 meters

10-40 feet

4-12 meters

40-100 feet

13-30 meters

100-150 feet

31-46 meters

Note: Never use plastic pipe. Check to conrm whether your local

codes allow copper tubing or galvanized.

Note: Since some municipalities have additional local codes, it is

always best to consult your local authority and installation code.

Check all local codes for requirements, especially for the size and

type of gas supply line required. On Natural gas lines less than 15'

(4.57m) long, use 1/2" pipe; on longer runs, use 3/4" iron pipe or

equal. On LP gas lines please consult LP gas supplier.

Installing a New Main Gas Cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of the unit.

Where none exists, or where its size or location is not adequate,

contact your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liqueed petroleum gases. The gas lines must be

checked for leaks by the installer. This should be done with a soap

solution watching for bubbles on all exposed connections, and if

unexposed, a pressure test should be made.

Neveruseanexposedametocheckforleaks.Appliancemust

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required by

the National Fuel Gas Code that a drip line be installed near the gas

inlet. This should consist of a vertical length of pipe tee connected

into the gas line that is capped on the bottom in which condensation

and foreign particles may collect.

1/2”

12.7mm

1/2”

12.7mm

1/2”

12.7mm

3/4”

19mm

3/8”

9.5mm

1/2”

12.7mm

1/2”

12.7mm

1/2”

12.7mm

Tubing, Type L

Outside Diameter

1/2”

12.7mm

5/8”

15.9mm

3/4”

19mm

7/8”

22.2mm

3/8”

9.5mm

1/2”

12.7mm

1/2”

12.7mm

3/4”

19mm

Figure 1

The use of the following gas connectors is recommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings

— ANS Z21.45 Assembled Flexible Appliance Connectors of Other

Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The state of Massachusetts requires that a

exible appliance connector cannot exceed three feet in length.

Pressure Testing of the Gas Supply System

1. To check the inlet pressure to the gas valve, a 1/8" (3.175mm)

N.P.T. plugged tapping, accessible for test gauge connection,

must be placed immediately upstream of the gas supply

connection to the appliance.

2. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kPa).

3. The appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

Attention! If one of the procedures results in pressures in excess

of 1/2 psig (14" w.c.) (3.5 kPa) on the appliance gas valve, it will

result in a hazardous condition.

Checking Manifold Pressure

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve. Natural gas models will have a manifold

pressure of approximately 3.5" w.c. (.871kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 4.5" w.c.

(1.120kPa) for the purpose of input adjustment to a maximum of

10.5" w.c. (2.614kPa) Propane gas models will have a manifold

pressure approximately 10.0" w.c. (2.49kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 11.0" w.c.

(2.739kPa) for the purpose of input adjustment to a maximum of

13.0" w.c. (3.237kPa).

A 1/8" (3.175mm) N.P.T. plugged tapping, accessible for test gauge

connection, is located on the outlet side of the gas control.

32039-1-0314 Page 7

Page 8

CLEARANCES

1. In selecting a location for installation, it is necessary to provide

adequate accessibility clearances for servicing and proper

installation.

2. Clearances to combustible surfaces are 4" (102mm) from sides,

12" (305mm) to top, 1 1/2" (38mm) from oor.

NOTE: Minimum distance of 1 1/2" (38mm) must also be maintained

VENTILATION AND COMBUSTION AIR

Wall furnaces shall be installed in a location in which the facilities

for ventilation permit satisfactory combustion of gas and proper

venting under normal conditions. In buildings of conventional frame,

brick, or stone construction without tight storm windows and doors,

inltration is normally adequate to provide air for combustion and

draft hood dilution.

from top surface of carpeting, tile, etc.

Where appliances are installed in conned and unconned spaces

within a building, the building being of unusually tight construction,

air for combustion and ventilation must be obtained directly from

outdoors or from such spaces that freely communicate with the

outdoors. Under these conditions, the conned and unconned

spaces shall be provided with two permanent openings, one near

the top of the enclosure and one near the bottom; each opening

shall have a free area of not less than one square inch (6.45cm2)

per 2,000 BTU (.6KW/H) per hour of total input.

LOCATION - ALL MODELS

Select a location near the center of the space to be heated. Overow

heat will circulate through doorways into adjacent rooms.

For large homes or spread-out oor plans, two or more furnaces are

recommended. Do not locate furnace where a door could swing

over the outer casing, or where circulation could be retarded by

furniture or cabinets.

Do not install in a closet, alcove or small hallway where the furnace

could be isolated by closing doors to the heated space.

When location is selected, check the walls, attic and roof to make

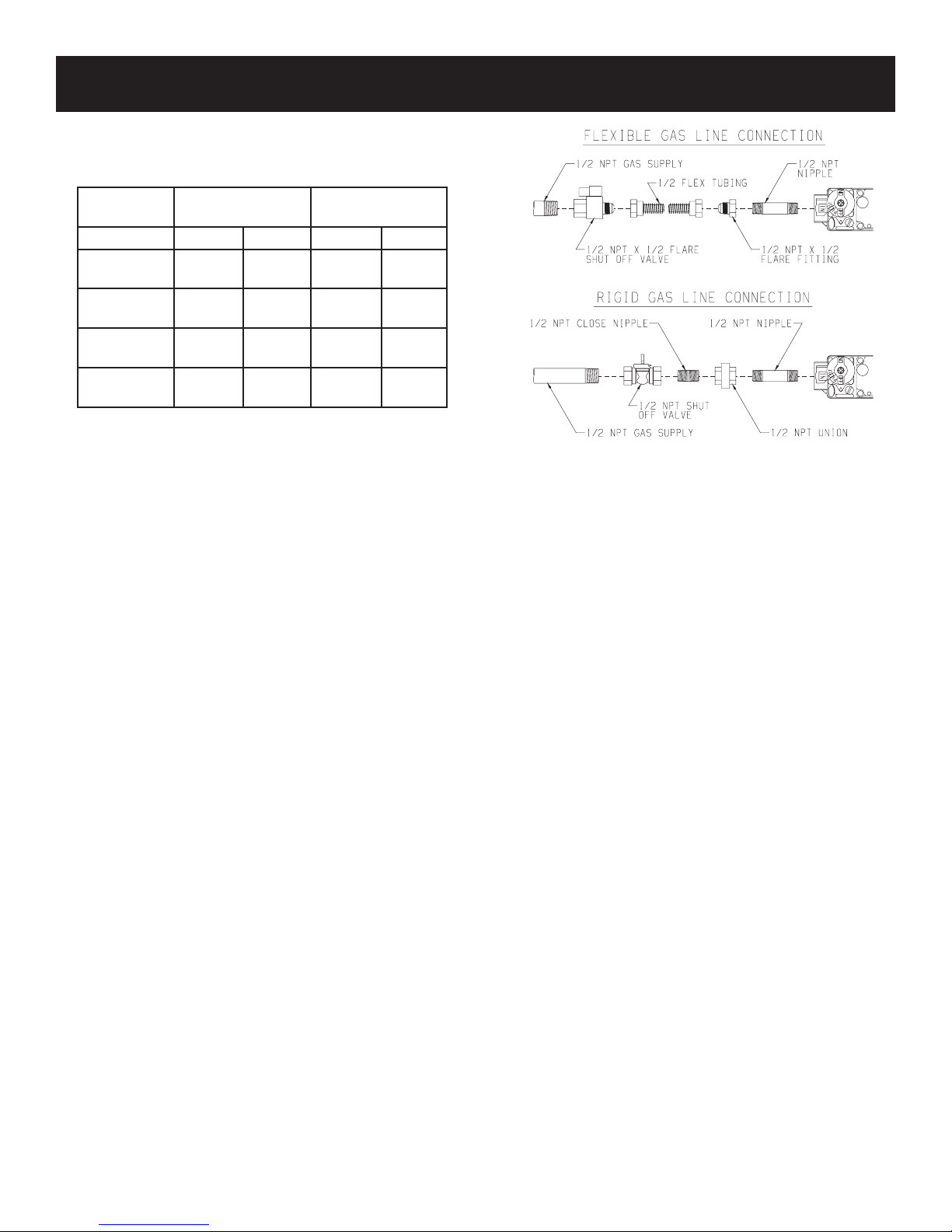

ROUGH-IN INSTRUCTIONS

Provide an opening in the wall 14 1/2" (368mm) wide and 66 1/8"

(168cm) high measured from top of oor plate (See Figure 2 and

Figure 3). Wall depth is to be 2" x 4" framing with 1/4" (6.5mm) to

5/8" (16mm) sheeting. Attach baseplate (not supplied with furnace)

to header plate with sheet metal screws at each end. Attach 4"

(102mm) oval, double wall vent pipe to baseplate. Attach enough vent

pipe so that when installed in wall opening the vent pipe will extend

above the ceiling plate by at least 6" (152mm). Install ceiling spacers

according to manufacturer's instructions. Two header extensions

are attached to the header plate. One header extension is welded

to the header plate and one header extension is screwed to the

header plate. To install header plate into wall opening remove the

header extension that is screwed to the header plate (2 screws).

sure there are no obstructions such as pipes, electric wiring, etc.,

which would interfere with the installation of the furnace or vent pipe.

NOTE: If Optional Blower is to be used, hard wiring must be

completed for the optional blower prior to installation of

header plate.

Insert header plate with attached 4" oval, double wall vent pipe

into wall opening. Position header plate at height shown in Figure

2. Locate rear edge of nailing ange at the back of the 2" x 4" stud

which will center the vent collar in the wall. Locate the angled edge

of header plate ush with the top of the wall opening. Nail header

plate to the wall studs. Replace and attach header extension onto

header plate with 2 screws.

32039-1-0314Page 8

Page 9

62 1/4”

(1581 mm)

14 ½”

(368 mm)

Figure 2

66 1/8”

(1679 mm)

WALL

OPENING

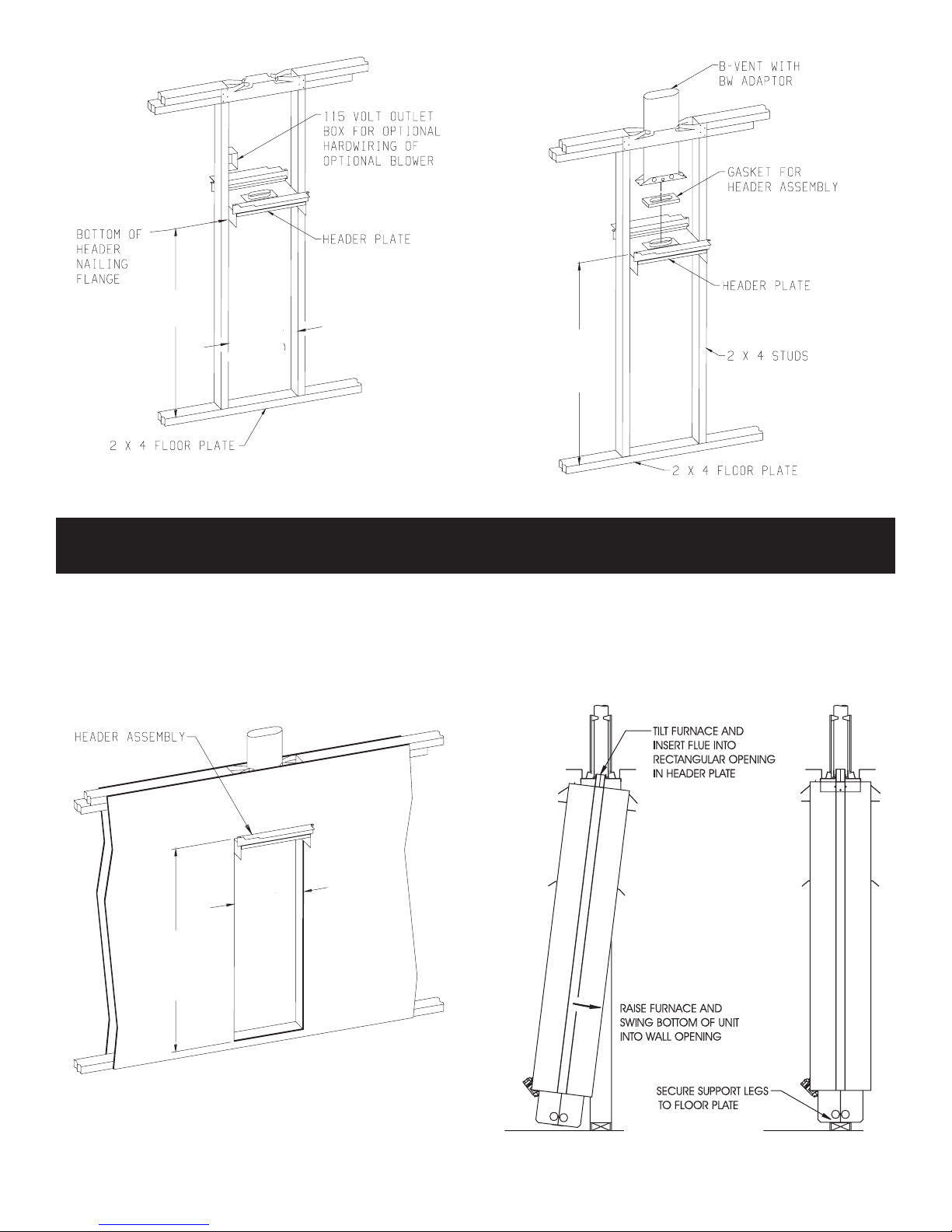

FINISHING INSTRUCTIONS

Figure 3

Plastering (Figure 4)

In new construction use only plain (not perforated) gypsum lath

around furnace and vent pipe so that plaster "Keys" will not project

into wall space.

Use wood strips nailed to inside of studs and top of bottom plate.

These must be removed before installation of furnace. Lath and

plaster against top projection of Header Plate.

Do not allow wall nish materials to project into furnace recess..

14 ½”

(368 mm)

66 1/8”

(1679 mm)

WALL

OPENING

Installing Furnace (Figure 5)

Clear the recess of all debris, and remove any wood plaster-grounds.

Stand the furnace on oor in front of wall opening.

Insert furnace ue into rectangular opening in header plate and

raise furnace carefully (see Figure 5). Swing bottom of furnace into

wall opening with back of legs ush with rear of oor plate. Secure

furnace support legs to the oor plate.

Figure 4

32039-1-0314 Page 9

Figure 5

Page 10

FINISHING INSTRUCTIONS (continued)

IMPORTANT — Avoid securing too tightly and disturbing the inner

casing. Do not try to force furnace into a wall opening which is

smaller than specied dimension.

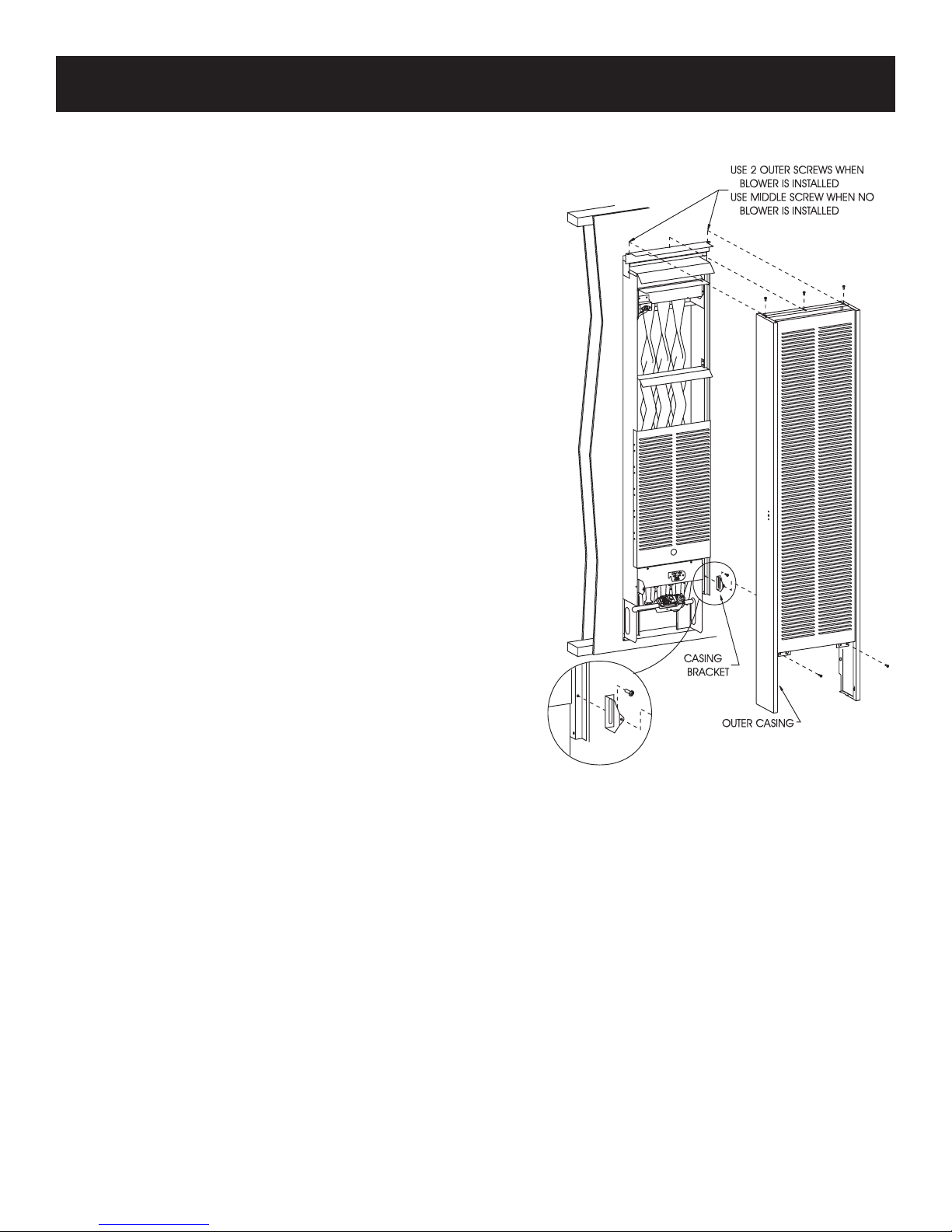

OUTER CASING (Figure 6)

1. Align 1 3/4" slot on casing bracket with bottom screw hole on

inner casing. Attach casing bracket to inner casing with one (1)

10 x 1/2" screws for each casing bracket. Do not completely

tighten screws at this time.

2. Place outer casing onto header.

Attention: Use center clearance hole on outer casing top for

attachment to header with one (1) 8 x 3/8" Phillips screw when

optional blower is not installed.

Attention: Use outside clearance holes on outer casing top

for attachment to header with two (2) 8 x 3/8" Phillips screws

when optional blower is installed.

3. Align clearance holes on outer casing bottom with screw holes

on casing brackets by adjusting slots on casing brackets.

4. Complete tightening casing bracket screws from Step 1 to inner

casing at this time.

5. Attach outer casing to casing brackets with two (2) 10 x 1-1/2"

screws.

INSTALLING CONTROL DOOR

Attach two washers supplied in hardware package to pivot pins

located at bottom of control door. Install control door to outer casing assembly.

Figure 6

32039-1-0314Page 10

Page 11

THERMOSTAT LOCATION (SG MODELS)

CAUTION — Do not run wire behind anges of Header Plate or in

any location where it might be damaged.

Millivolt wall thermostats are specially designed for use on self-

generating systems. They should never be used on line or low

voltage A.C. circuits.

Interior Wall — The thermostat should be installed on an inside

wall away from the furnace but in the same room.

It is important to use wire of a gauge proper for the length of the wire:

RECOMMENDED WIRE GAUGES

Maximum Length Wire Gauge

1' to 10' 18

10' to 25' 16

25' to 35' 14

Proper operation depends on a good pilot ame. The ame must

cover the top of the thermopile. Cleaning of the pilot orice and

burner may be required due to spiders.

System Check (Figure 7)

A millivolt meter is required to check the system. Millivolt readings

should be:

• Across the thermopile terminals, 400-450 millivolts with

thermostat OFF.

• Across the thermopile terminals, 150-250 millivolts with

thermostat ON.

• Across the thermostat wires at the valve, less than 30 millivolts

with thermostat ON.

• Across the thermostat wires at the thermostat, less than 5

millivolts with thermostat ON. (Dirty pilot or low pressure will

reduce readings.)

Figure 7

To conserve Gas: Turn off pilot when heater is not in use.

Connect thermostat wires to gas valve as shown in Figure 7.

32039-1-0314 Page 11

Page 12

GAS CONTROL KNOB SHOWN IN "OFF" POSITION

LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:Ifyoudonotfollowtheseinstructionsexactly,areorexplosion

may result causing property damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area

forgas.Besuretosmellnexttotheoorbecausesome

gasisheavierthanairandwillsettleontheoor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• Ifyoucannotreachyourgassupplier,calltheredepartment.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting (if applicable).

3. Turn off all electric power to the appliance (if applicable).

4. Remove control access panel (control door).

5. Push in gas control knob slightly and turn clockwise

to "OFF."

NOTE: Knob cannot be turned from "PILOT" to "OFF"

unless knob is pushed in slightly. Do not force.

6. Wait ten (10) minutes to clear out any gas. Then smell

forgas,includingneartheoor.Ifyousmellgas,STOP!

Follow "B" in the safety information above. If you don't

smell gas, go to the next step.

7. Find pilot - follow metal tube from gas control. The pilot

is mounted on front of main burner.

8. Turn gas control knob counterclockwise to "PILOT."

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turnbyhand,don'ttrytorepairit;callaqualiedservice

technician.Forceorattemptedrepairmayresultinare

or explosion.

D. Do not use this appliance if any part has been under water.

Immediatelycallaqualiedservicetechniciantoinspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

9. Push in control knob all the way and

hold in. Immediately light the pilot with

a match. Continue to hold the control

knob in for about one (1) minute after

the pilot is lit. Release knob and it will

pop back up. Pilot should remain lit. If

it goes out, repeat steps 5 through 9.

• If knob does not pop up when released, stop and imme-

diatelycallaqualiedservicetechnicianorgassupplier.

• If the pilot will not stay lit after several tries, turn the gas

control knob to "OFF" and call your service technician

or gas supplier.

10. Turn gas control knob counterclockwise to "ON."

11. Replace control access panel (control door).

12. Turn on all electric power to the appliance (if applicable).

13. Set thermostat to desired setting (if applicable).

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power (if applicable) to appliance if

service is to be performed.

3. Remove control access panel (control door).

4. Push in gas control knob slightly and turn clockwise

to "OFF." Do not force.

5. Replace control access panel (control door).

32039-1-0314Page 12

Page 13

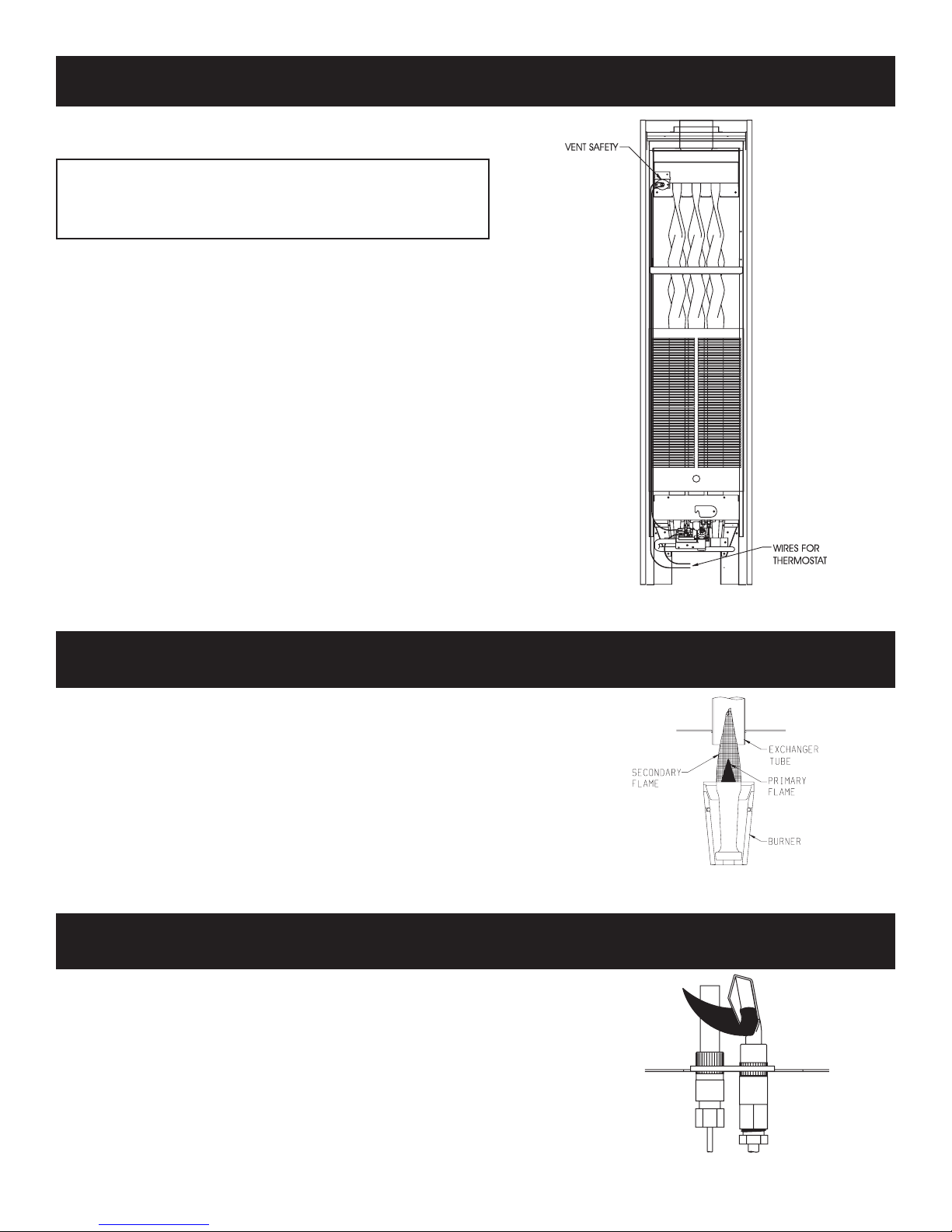

VENT SAFETY SHUTOFF SYSTEM

This appliance must be properly connected to a venting system. This

appliance is equipped with a vent safety shutoff system.

Warning: Operation of this wall furnace when not connected

to a properly installed and maintained venting system or

tampering with the vent safety shutoff system can result in

carbon monoxide (CO) poisoning and possible death.

This furnace is equipped with a manual reset vent safety switch. The

manual reset vent safety switch will cause gas ow to the main burner

to "shut off" due to improper venting or a blocked ue.

To reset the manual reset vent safety switch:

1. Remove outer casing.

2. Depress manual reset button. The manual reset vent safety switch

is located on the draft diverter.

3. Replace outer casing.

If the manual reset vent safety switch continues to "shut off" the gas

ow to the main burner a qualied service person must be contacted to

inspect for improper venting, blockage in the vent pipe or the manual

reset vent safety switch for being defective.

PROPER MAIN BURNER FLAME

The correct ame will be a short blue inner ame with a much larger light

blue outer ame. The burner does not have a primary air adjustment.

The ame will be proper if the factory-set pressure and orice are used.

After the furnace has begun operating, cleaning of the burner may be

needed for proper ame, examine at least 2 times per season.

To clean burner ports, disconnect the gas supply to the valve. Remove the

burner assembly from the combustion chamber. Remove pilot burner from

main burner and then remove the main burner. Force water into the ports

and blow dry with vacuum cleaner air, or low pressure compressed air.

PROPER PILOT FLAME

The correct ame will be blue, extending past the thermopile. The ame

will surround the thermopile just below its tip.

Natural gas pilots require adjusting when the inlet gas pressure is above

5" w.c. (1.245kPa). Remove the pilot cover screw on the control valve

and turn the adjustment screw clockwise to reduce ame. Replace

pilot cover screw to eliminate gas leaking at that control valve opening.

LP gas (propane) will not require adjustment.

After use, cleaning may be required for the proper ame.

Examine the pilot ame before and during each heating season.

Figure 8

Figure 9

32039-1-0314 Page 13

Figure 10

Page 14

TROUBLESHOOTING

GENERAL All furnaces have been re-tested to check for proper

operation. This includes main burner ame, pilot ame, and gas

control operation. If the furnace fails to function on initial installation,

it is advisable to re-check the following:

1. Inlet gas pressure.

2. Type of gas being used and that shown on the rating plate.

The Service Department at Empire Comfort Systems, Inc. may be

contacted to assist in servicing furnace.

ServicingthePilotandMainBurner,PilotOrice,Thermopile

andMainBurnerOrice

Disconnect the gas supply at the inlet to the control valve. Remove

the burner assembly to which the above components are attached.

Pilot Does Not Light

With air in the gas line, such as when the furnace is rst installed

or was "OFF" all summer, the pilot ame may be too lean to ignite

on the rst few trials. Turn the gas control knob to PILOT position

and depress the gas control knob. Hold the gas control knob down

to bleed the line;

1. Use lighter rod to light pilot with a match.

If Pilot Does Not Light By Any Means

1. Check gas control knob for being in the "Pilot" position.

2. Check pilot adjustment for being full open (counterclockwise

to open).

3. If gas is available in the supply tubing, the pilot orice and/

or pilot burner is probably restricted by a spider web. Clean

pilot assembly and relight.

If Pilot Does Not Remain "On" After Releasing Gas Control Knob

1. Follow instructions and hold gas control knob down longer

and harder.

2. Determine if pilot ame extends past thermopile; if not, adjust

pilot ame or clean pilot burner.

3. Replace thermopile if millivolt reading is less than 300 millivolts

when wall thermostat or remote bulb is turned OFF. Replace

gas control if magnet dropout millivolt reading is over 100

millivolts.

Pilot Outage During Normal Operation

1. Check input by manifold pressure gauge or gas meter.

2. Check millivolt output when furnace is in operation. If millivolt

output decreases during furnace operation gas control may

be defective.

Main Gas Valve Does Not Open When Thermostat Is Turned "On"

1. Check millivolt output of thermopile.

2. Thermostat wires may be broken.

3. Thermostat may be defective.

32039-1-0314Page 14

Page 15

PARTS LIST

ATTENTION: When ordering parts, it is very important that part number and description of part coincide.

INDEX PART

NO. NO. DESCRIPTION

1 WFA-115 HEADER GASKET

2 GWT-175

2 15756

3 GWT-184 INNER CASING ASSEMBLY

4 GWT-151 DIVERTER ASSEMBLY (2 REQUIRED)

5 GWT-020 FRONT SHIELD (2 REQUIRED)

6 GWT-077 HEAT SHIELD (2 REQUIRED)

7 GWT-177

8 GWT-186 CASING BRACKET (4 REQUIRED)

9 GWT-087

9 15739

10 R-885 NYLON WASHER (4 REQUIRED)

11 R-3763 MAGNET (4 REQUIRED)

12 DV-064 COVER PLATE (2 REQUIRED)

13 GWT-008

14 R-3046 VENT SAFETY SWITCH

15 R-3038-A ECO LEAD ASSEMBLY

16 26466 EXCHANGER ASSEMBLY - REAR

17 26465 EXCHANGER ASSEMBLY - FRONT

18 R-3036 PILOT - NAT

18 R-3037 PILOT - LPG

19 R-1054 THERMOPILE

20 GWT-096 BURNER BRACKET ASSEMBLY

HEADER ASSEMBLY

(INCLUDES NO. 1, GASKET) (USA)

HEADER ASSEMBLY (INCLUDES

NO. 1, GASKET) (CANADA)

CASING FRONT ASSEMBLY

(2 REQUIRED)

CASING DOOR ASSEMBLY

(2 REQUIRED) (USA)

CASING DOOR ASSEMBLY

(2 REQUIRED) (CANADA)

BURNER COMPARTMENT FRONT

(2 REQUIRED)

INDEX PART

NO. NO. DESCRIPTION

21 R-5245 GAS VALVE - NAT

21 R-5246 GAS VALVE - LPG

22 R-3031 BURNER (6 REQUIRED)

23 P-88-55

23 P-88-65

24 GWT-014

25 GWT-015

26 GWT-054

27 23906 VALVE SHIELD

28 23385

29 24752 LOWER SHIELD

30 29011 EXCHANGER TUBE ASSEMBLY

NOT

SHOWN

NOT

SHOWN

NOT

SHOWN

NOT

SHOWN

NOT

SHOWN

GWT-099 PILOT TUBING

R-3178

R-3179

R-734 MATCH HOLDER

GWT-190

BURNER ORIFICE - NAT (6

REQUIRED)

BURNER ORIFICE - LPG (6

REQUIRED)

AIR SHUTTER FRONT - LPG

(2 REQUIRED)

AIR SHUTTER REAR -

LPG (2 REQUIRED)

AIR SHUTTER BOTTOM -

LPG (2 REQUIRED)

CASING ASSEMBLY COMPLETE

(INCLUDES #7, #9 AND TWO #10)

PILOT ORIFICE

(HONEYWELL K14 .014 LPG ONLY)

PILOT ORIFICE

(HONEYWELL A26 .026 NAT ONLY)

HARDWARE PACKAGE (2

REQUIRED)

USE ONLY MANUFACTURER'S REPLACEMENT PARTS. USE OF ANY OTHER PARTS COULD CAUSE INJURY OR DEATH.

HOW TO ORDER REPAIR PARTS

Parts can be ordered only through your service person or dealer. For best results, the service person or dealer should order parts

through the distributor. Parts can be shipped directly to the service person/dealer.

All parts listed in the Parts List have a Part Number. When ordering parts, rst obtain the Model Number from the name plate on your

equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the following appropriate

illustration and list. Be sure to give all this information.

Furnace Model Number Part Description

Furnace Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, res and all causes beyond our control.

Empire Comfort Systems, Inc. Nine Eighteen Freeburg Ave. Belleville, Illinois 62222-0529

32039-1-0314 Page 15

Page 16

PARTS VIEW

28

7

5

6

4

8

9

10

1

2

3

4

5

14

15

6

29

12

30

13

22

23

24

25

26

16

20

19

18

22

26

17

23

21

8

25

30

13

12

24

27

11

7

10

9

32039-1-0314Page 16

Page 17

OPTIONAL REMOTE BULB CONTROL INSTALLATION INSTRUCTIONS

MODELS

GWT-25 RB, GWT-35 RB, GWT-50 RB

Note: The remote bulb control may be located on the left or

right side of the outer casing.

1. Remove remote bulb control from the shipping carton.

2. Remove outer casing assembly from shipping carton.

Note: If wall furnace is already installed, remove outer casing

from unit and lay on oor with front side down.

3. Attach wire assembly to remote bulb control.

4. Carefully unwind capillary wire on remote bulb control.

5. Remove three (3) hole plugs from left or right side of outer

casing where remote bulb control is to be installed.

6. Mount remote bulb control to inside of outer casting with two

(2) No. 6-32 x 1/4 screws.

Caution: Remote bulb wire routing is important. Wires

should be in proper location to avoid damage from being overheated. Incorrect routing of remote bulb control wires may result in damage to wires and incorrect operation of remote bulb

control. Follow these instructions and refer to the following

illustrations for proper wire routing.

7. If remote bulb control is located on the right side of the outer

casing, carefully bend or loop capillary wire around control.

This will enable the sensing bulb to be positioned at the bottom of the unit.

8. Secure sensing bulb on the inside, at the bottom, of the outer

casing with two (2) plastic clips.

9. Feed the wire assembly down along the inside of the outer

casing.

10. Use the third plastic clip to secure wire assembly and capillary

wire to the casing (approximately 24” (610mm) from bottom

of units).

11. Attach control knob to remote bulb control.

12. Install furnace according to instructions

in the Installation Instructions and Owner’s Manual.

Note: If wall furnace is already installed, secure outer casing

to unit.

13. Attach wire assembly to gas valve at the "TH" and "TH/TP"

terminals on the gas valve. If the wire assembly has two 1/4"

female connectors, the connectors should be cut off the wire

assembly. Strip and bare the wires and attach wires to the

"THERMO" terminals.

Note: This remote bulb control is connected to the gas valve

the same way as a wall thermostat. Any references made to

the thermostat in the lighting instructions would also apply to

the remote bulb control.

Gas Valve

32039-1-0314 Page 17

Part Number Description

R-1224 Remote Bulb Control

R-2499 Wire Assembly

R-1162 Control Knob

R-1720 Plastic Clip (3 Required)

R-1575 No. 6-32 x 1/4" (6mm) Screw (2 required)

Page 18

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

Installing Blower Using Three-Prong Plug

1. Install furnace according to Installation Instructions and Owner's

Manual.

2. Refer to Drawing for measurements to locate (2) mounting holes

on wall surface above furnace.

On Solid Wall

3. After locating mounting holes, attach (2) #10 x 1 1/2" screws provided

in blower kit into wall. Do not completely tighten screwheads to

wall, leave a 7/16" gap between screwheads and wall.

On Sheet Rock Wall

3. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert the (2) plastic expansion anchors into holes. Insert (2)

#10 x 1 1/2" screws provided in blower kit into (2) plastic expansion

anchors. Do not completely tighten screwhead to plastic expansion

anchors, leave a 7/16" gap between screwheads and plastic

expansion anchors. Refer to Figure 2.

4. At the top of outer casing remove (1) screw from center clearance

hole that attaches outer casing to header assembly. Also, remove

(2) screws that attach bottom of outer casing to inner casing.

5. Pull the outer casing forward approximately 1 inch away from wall

surface.

6. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

Caution: When removing blower front be careful not to damage

motor coil wires. Damaged coil wires will disable blower function.

7. Position blower housing on top of header assembly and route

three-prong cord set between left side of outer casing and inner

casing.

Caution: When installing blower housing onto wall be careful motor

coil is not damaged.

Installing Blower With Hard Wiring

1. When facing the wall opening, install 120V electrical outlet junction

box inside wall opening on left wall stud approximately 12 inches

above header plate.

2. Refer to Drawing for measurements to locate access hole for

electrical wiring on wall surface.

3. After locating access hole, drill a 1/2" hole into wall.

4. Route enough eld wiring from 120V electrical outlet junction box

through 1/2" access hole in wall for connection to blower housing.

5. Install furnace according to Installation Instructions and Owner's

Manual.

6. Refer to Drawing for measurements to locate (2) mounting holes

on wall surface above the furnace.

On Solid Wall

7. After locating mounting holes, attach (2) #10 x 1 1/2" screws provided

in blower kit into wall. Do not completely tighten screwheads to

wall, leave a 7/16" gap between screwheads and wall.

On Sheet Rock Wall

7. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert (2) plastic expansion anchors into holes. Insert (2) #10

x 1 1/2" screws provided in blower kit into (2) plastic expansion

anchors. Do not completely tighten screwhead to plastic expansion

anchors, leave a 7/16" gap between screwheads and plastic

expansion anchors. Refer to Figure 2.

Caution: Blower cord set routing is important. Cord set should be in

proper location to avoid being overheated. Incorrect routing of cord

set may result in damage to cord set.

8. Replace the outer casing to the wall surface.

9. Attach outer casing to header assembly. Attention: The center

clearance hole will not be used. The two outside clearance holes

will be used to attach outer casing to header assembly, (1) screw

from Step 4 and (1) screw supplied in hardware package. Refer

to Figure 1.

Figure 1

10. Attach outer casing to inner casing with (2) screws from Step 4.

11. Align key hole slots on back of blower housing with the (2) screws

attached to wall. Position blower housing ush with wall surface

and on top of outer casing. Complete tightening blower housing

screws from Step 3 to wall.

12. Attach caps and plugs from blower housing and blower front.

13. Attach blower front to blower housing with (4) 8 x 3/8" screws from

Step 6.

14. Installation of optional blower assembly is completed.

Figure 2

8. Remove three prong cord set from blower housing.

9. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

10. Position blower housing on top of header assembly.

11. Route 120V eld wiring into blower housing through cord set hole

on back of blower housing.

12. Refer to wiring diagram to make wiring connections inside blower

housing. Be sure to follow all local and National electrical codes

when making eld wiring connections.

13. Align key hole slots on back of blower housing with (2) screws

attached to wall. Position blower housing ush with wall surface

and on top of outer casing. Complete tightening blower housing

screws from Step 7 to wall.

14. Attach caps and plugs from blower housing and blower front.

15. Attach blower front to blower housing with (4) 8 x 3/8" screws from

Step 9.

16. Installation of optional blower assembly is completed.

32039-1-0314Page 18

Page 19

13”

(330 mm)

4 7/16”

(112.6 mm)

Figure 3

Fan Control

The automatic fan control is located on the bottom of the blower

assembly. The fan control is a nonadjustable, automatic type. The

fan control will require between 3 and 7 minutes of main burner

operation before the fan control "closes" and activates the blower.

The blower will continue to run between 3 and 7 minutes after the

main burner shuts off, before the fan control "opens" and deactivates

the blower.

Wiring

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical

Code, CSA C22.1, if an external electrical source is utilized. This

appliance is equipped with a three-prong [grounding] plug for

your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle. Do

not cut or remove the grounding prong from this plug. For an

ungrounded receptacle, an adapter, which has two prongs and a

wire for grounding, can be purchased, plugged into the ungrounded

receptacle and its wire connected to the receptacle mounting screws.

With this wire completing the ground, the appliance cord plug can

be plugged into the adapter and be electrically grounded.

GWTB-2 WIRING DIAGRAM

WARNING:

Unplugging of blower accessory will not stop the heater

from cycling. To shut heater off: Turn temperature dial or

thermostat to lowest setting. Turn knob on gas control to

"OFF", depressing slightly. Do not force.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Oiling

The blower motor does not have oiling holes. Do not attempt to oil

the blower motor.

32039-1-0314 Page 19

PARTS LIST

INDEX

NO.

PART NO. DESCRIPTION

1 R-2204 CORD SET

2 8720161 STRAIN RELIEF BUSHING

3 15888 BLOWER HOUSING ASSEMBLY

4 8520142 BRASS BUSHING (4 REQUIRED)

5 GWT-197 BLOWER SIDE (2 REQUIRED)

6 R-3085 WIRE ASSEMBLY

7 R-2503 FAN SWITCH

8 15887 BLOWER FRONT

9 8520141 RUBBER GROMMET (4 REQUIRED)

10 R-2804A BLOWER MOTOR

Page 20

SERVICE NOTES

EMPIRE

EMPIRE

Comfort Systems

Empire Comfort Systems Inc.

918 Freeburg Ave. Belleville, IL 62220

If you have a general question about our products, please e-mail us at

info@empirecomfort.com.

If you have a service or repair question, please contact your dealer.

www.empirecomfort.com

32039-1-0314Page 20

Page 21

MASTER PARTS DISTRIBUTOR LIST

To Order Parts Under Warranty, please contact your local Empire dealer. See the dealer locator at www.empirecomfort.

com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the

nature of the problem with the unit.

To Order Parts After the Warranty Period, please contact your dealer or one of the Master Parts Distributors listed below.

This list changes from time to time. For the current list, please click on the Master Parts button at www.empirecomfort.com.

Please note: Master Parts Distributors are independent businesses that stock the most commonly ordered Original Equipment repair parts for Heaters, Grills, and Fireplaces manufactured by Empire Comfort Systems Inc.

Dey Distributing

1401 Willow Lake Boulevard

Vadnais Heights, MN 55101

Phone: 651-490-9191

Toll Free: 800-397-1339

Website: www.deydistributing.com

Parts: Heater, Hearth and Grills

East Coast Energy Products

10 East Route 36

West Long Branch, NJ 07764

Phone: 732-870-8809

Toll Free: 800-755-8809

Fax: 732-870-8811

Website: www.eastcoastenergy.com

Parts: Heater, Hearth and Grills

Victor Division of F. W. Webb Company

200 Locust Street

Hartford, CT 06114

Phone: 860-722-2433

Toll Free: 800-243-9360

Fax: 860-293-0479

Toll Free Fax: 800-274-2004

Websites: www.fwwebb.com & www.victormfg.com

Parts: Heater, Hearth and Grills

Able Distributors

2501 North Central Avenue

Chicago, IL 60639

Phone: 773-889-5555

Toll Free: 800-880-2253

Fax: 773-466-1118

Website: www. abledistributors.com

Parts: Heater

HOW TO ORDER REPAIR PARTS

Parts Not Under Warranty

Parts can be ordered through your Service Person, Dealer, or a Master Parts Distributor. See this page for the Master Parts Distributors list. For best results, the service person or dealer should order parts through the distributor. Parts can be shipped directly to the

service person/dealer.

Warranty Parts

Warranty parts will need a proof of purchase and can be ordered by your Service Person or Dealer. Proof of purchase is required for

warranty parts.

All parts listed in the Parts List have a Part Number. When ordering parts, rst obtain the Model Number and Serial Number from the

name plate on your equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the following illustration and part list. Be sure to give all this information . . .

Appliance Model Number Part Description

Appliance Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, res and all causes beyond our control.

32039-1-0314 Page 21

Page 22

WARRANTY

Empire Comfort Systems Inc. warranties this space heating product to be free from defects at the time of purchase and for the periods

specied below. Space heating products must be installed by a qualied technician and must be maintained and operated safely, in

accordance with the instructions in the owner’s manual. This warranty applies to the original purchaser only and is not transferable.

All warranty repairs must be accomplished by a qualied gas appliance technician.

Limited Lifetime Parts Warranty with a Five-Year Limited Labor Warranty – Combustion Chamber and Heat Exchanger

If the combustion chamber or heat exchanger (see parts list) fails because of defective workmanship or material, Empire will

repair or replace at Empire’s option.

Withinveyearsfromthedateofpurchase,Empirewillpayreasonablelabortohavethedefectivepartrepairedorreplacedat

Empire’s option.

Limited Five-Year Parts & Labor Warranty – All Other Components (Except Thermostats)

Shouldanypartfailbecauseofdefectiveworkmanshipormaterialwithinveyearsfromthedateofpurchase,Empirewill

repair or replace at Empire’s option.

Withinveyearsfromthedateofpurchase,EmpirewillpayreasonablelabortohavethatdefectrepairedatEmpire’soption.

Limited One-Year Parts Warranty – Remote Controls, Thermostats, Accessories, and Parts

Should any remote control, thermostat, accessory, or other part fail because of defective workmanship within one year from

the date of purchase, Empire will repair or replace at Empire’s option.

Duties of the Owner

The appliance must be installed by a qualied installer and operated in accordance with the instructions furnished with the

appliance.

A bill of sale, cancelled check, or payment record should be kept to verify purchase date and establish warranty period.

Ready access to the appliance for service

What Is Not Covered

Damages that might result from the use, misuse, or improper installation of this appliance.

Travel, diagnostic costs and freight charges on warranted parts to and from the factory.

Claims that do not involve defective workmanship or materials.

Unauthorized service or parts replacements.

Removal and reinstallation cost.

Inoperable due to improper or lack of maintenance.

How To Get Service

To make a claim under this warranty, please have your receipt available and contact your installing dealer. Provide the dealer

with the model number, serial number, type of gas, and purchase verication. The installing dealer is responsible for providing

service and will contact the factory to initiate any warranted parts replacements. Empire will make replacement parts available

at the factory. Shipping expenses are not covered.

If, after contacting your Empire dealer, service received has not been satisfactory, contact: Consumer Relations Department,

Empire Comfort Systems Inc., PO Box 529, Belleville, Illinois 62222, or send an e-mail to info@empirecomfort.com with

“Consumer Relations” in the subject line.

Your Rights Under State Law

This warranty gives your specic legal rights, and you may also have other rights, which vary from state to state.

EMPIRE

EMPIRE

Comfort Systems

Empire Comfort Systems Inc.

918 Freeburg Ave. Belleville, IL 62220

If you have a general question about our products, please e-mail us at

info@empirecomfort.com.

If you have a service or repair question, please contact your dealer.

www.empirecomfort.com

32039-1-0314Page 22

Page 23

INSTRUCTIONS POUR L’INSTALLATION

ET

MANUEL DU PROPRIÉTAIRE

FOURNAISE À AIR CHAUD

PAR GRAVITÉ

POUR MUR MITOYEN

MODÈLES

GWT-50-2(SG, RB)

Inst all ateu r: Laissez cette notice avec l’appareil.

Consommateur: Conservez cette notice pour

consultation ultériure.

AVERTISSEMENT: Si l’installation, l’usage

et l’entretien de ce produit ne sont pas faits

selon les instructions du fabricant, ce produit

peut vous exposer à des matières contenues

dans le carburant ou provenant de la combustion du carburant lesquelles peuvent causer

la mort ou de sérieuses maladies.

AVERTISSEMENT: Assurez vous de bien suivre les instructions données dans cette notice

pour réduire au minimum le risque d’incendie

ou d’explosion ou pour éviter tout dommage

matériel, toute blessure ou la mort.

— Ne pas entreposer ni utiliser d’essence ni d’autres

vapeurs ou liquides inammables dans le voisnage de cet appareil ou de tout autre appareil.

— QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez a aucun interrupteur. Ne pas vous

servir des téléphones se trouvant dans le bâtiment où vous vous trouvez.

• Appelez immédiatement votre fournisseur de

gaz depuis un voisin. Suivez les instructions

du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur de

gaz, appelez le service des incendies.

— L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien qual-

iéouparlefournisseurdegaz.

Page 23

Page 24

TABLE DES MATIÈRES

SECTION PAGE

Information Importante de Sécurité ..........................................................................3

Information de Sécurité pour les Utilisateurs de Propane ........................................ 4

Introduction ..............................................................................................................5

Spécications ...........................................................................................................5

Recommended Vent Conguration ..........................................................................6

Alimentation en Gaz .................................................................................................7

Espaces Libres .........................................................................................................8

Air de Ventilation et de Combustion .........................................................................8

Emplacement - Pour Tous les Modèles ....................................................................8

Instructions Sommaires .........................................................................................8-9

Instructions pour la Finition .................................................................................9-10

Emplacement du Thermostat (Modèles SG) .......................................................... 11

Instructions d'Allumage ..........................................................................................12

Le Système de Fermeture de Sûreté de l'Évent ....................................................13

Aspect Convenable de la Flamme du Brûleur Principal ......................................... 13

Aspect Convenable de la Flamme de la Veilleuse .................................................13

Détection des Défectuosités ................................................................................. 14

Listes des Pièces ...................................................................................................15

Façon de Commander les Pièces de Réparation ..................................................15

Vue des Pièces .....................................................................................................16

Instructions pour l'Installation de la Commande Lumineuse à Distance ................ 17

Instructions pour l'Installation de la Souferie Facultative .............................. 18-19

Notes de Service ....................................................................................................20

Liste Des Distributeurs de Pièces Principaux ........................................................21

Garantie .................................................................................................................22

32039-1-0314Page 24

Page 25

INFORMATION IMPORTANTE DE SÉCURITÉ

CECI EST UN APPAREIL DE CHAUFFAGE

NE PAS FAIRE FONCTIONNER CET APPAREIL SANS QUE LA PAROI EXTÉRIEURE SOIT INSTALLÉE.

• A cause des hautes températures, cet appareil doit être

situé dans un endroit non achalandé et loin des meubles

et des rideaux.

• Les enfants et les adultes doivent être avisés des dan-

gers des parois très chaudes et doivent rester loin pour

éviter les brûlures ou l’allumage des vêtements.

• Les petits enfants doivent être surveillés étroitement

lorsqu’ils sont dans le même appartement que l’appareil.

• Les vêtements ou d’autres matériaux inammables ne

doivent pas être placés sur ou près de l’appareil.

• Tout écran de sûreté qui est enlevé lors de la répara-

tion d’un appareil, doit être replacé avant de remettre

en marche cet appareil.

• Garder propre le brûleur et le compartiment de contrôle.

• L’installation et la réparation doivent être faites par une

PERSONNE QUALIFIÉE. L’appareil doit être inspecté

avant l’usage et au moins une fois par année, par une

personne qualiée. S’il y a un excès de poussière venant

du tapis, de la litterie, etc..., de fréquents nettoyages

seront requis. Il est impératif que les compartiments de

commandes, les brûleurs et les passages de circulation

d’air de l’appareil soient gardés propres.

• Ne rien mettre autour de la fournaise qui pourrait ob-

struer le débit de combustion et la ventilation d’air.

• Les matériaux combustibles, la gazoline ou les vapeurs

et liquides inammables ne doivent jamais être dans le

même endroit que le radiateur.

• Examiner périodiquement le système de ventilation et

remplacer les pièces défectueuses.

• Faire périodiquement une inspection visuelle de la veil-

leuse et des brûleurs. Nettoyer et remplacer les pièces

défectueuses.

• Ne pas utiliser cette fournaise s’il y a une pièce qui

a été en contact avec l’eau. Appeler immédiatement

un technicien qualié pour inspecter la fournaise et

remplacer toute pièce du système de commande et les

commandes de gaz qui ont été en contact avec l’eau.

• Cette fournaise ne doit pas être branchée à une chemi-

née servant à un autre appareil brûlant un combustible

solide.

32039-1-0314 Page 25

Page 26

INFORMATION DE SÉCURITÉ POUR LES UTILISATEURS DE PROPANE

Lepropaneestungazinammablequipeutcauserdesfeuxetdes

explosions. Dans son état naturel, le propane est inodore et sans

couleur. Peut-être que vous ne connaissez pas toutes les précautions

décrites ci-dessous? Elles peuvent vous protéger ainsi que votre

famille contre un accident. Lisez-les attentivement dès maintenant,

AVERTISSEMENT À PROPOS DE L’ODEUR DU PROPANE

Si une fuite de gaz survient, vous devriez sentir le gaz parce qu’il y a une odeur incorporée au propane.

C’est le signal que vous devez agir immédiatement.

• N’utiliser pas les interrupteurs électriques, n’allumer pas des allumettes ou n’utiliser pas le téléphone. Ne rien faire qui pourrait

enammer le gaz.

• Évacuer tout le monde du bâtiment, des véhicules et des lieux. Faire

ceci immédiatement.

• Fermer toutes les soupapes d’approvisionnement des réservoirs et

des bouteilles de gaz.

• Le propane est plus pesant que l’air et peut s’accumuler dans des

endroits bas comme les soubassements. Lorsque vous avez des raisons

de suspecter une fuite de gaz, n’allez pas dans les soubassements

ou les endroits bas. Attendez que les pompiers vous assurent de la

AUCUNE ODEUR DÉCELÉE - FAIBLE ODEUR

Il y a des personnes qui ne peuvent pas sentir très bien. Il y a des

personnes qui ne peuvent pas sentir l’odeur chimique mis dans le

gaz. Vous devez vérier si vous pouvez sentir cette odeur. Fumer peut

décroître votre capacité de sentir. Sentir une odeur pour un certain temps,

peut affecter votre sensibilité ou votre capacité de déceler cette odeur.

Quelquefois d’autres odeurs, dans le même endroit, peuvent masquer

l’odeur du gaz. Il y a des personnes qui ne peuvent pas sentir l’odeur du

gaz ou que leur attention est sur quelque chose d’autre. Penser à sentir

l’odeur du gaz peut faciliter la capacité de sentir.

L’odeur dans le propane est sans couleur et peut s’affaiblir selon

certaines circonstances. Par exemple, s’il y a une fuite souterraine, le

mouvement du gaz à travers le sol peut ltrer l’odeur. Aussi, l’odeur dans

le propane peut être exposée à l’oxydation. Cet affaiblissement peut

puis réexaminez les, point par point avec les membres de votre famille.

Un jour, lorsqu’il n’y aura pas une minute à perdre, la sécurité de chacun dépendra de votre savoir-faire. Si après avoir lu les informations

suivantes, vous pensez avoir besoin de plus amples informations,

s’il vous plaît contactez votre fournisseur de gaz.

sûreté de ces endroits avant d’y aller.

• Utiliser le téléphone de votre voisin et appeler les pompiers et une

personne entraînée avec le propane.

• Ne pas ouvrir les soupapes d’approvisionnement de gaz même si

vous ne le sentez plus. Ne retourner pas dans le bâtiment, sur les

véhicules ou sur les lieux.

• Finalement, laisser la personne qualiée et les pompiers vérier

les fuites de gaz. Laisser-les aérer les lieux avant d’y retourner. Les

personnes entraînées avec le propane devront réparer la fuite, vérier

et réallumer l’appareil au gaz, pour vous.

survenir s’il y a de la rouille à l’intérieur des réservoirs ou dans les tuyaux

de fer pour le gaz.

L’odeur de la fuite de gaz peut être adsorbée ou absorbée sur ou dans les

murs, maçonnerie et d’autres matériaux et tissus dans une chambre. Ceci

enlèvera une quantité de l’odeur du gaz, affaiblissant l’intensité de la senteur.

Le propane peut stratier dans un endroit fermé et l’intensité de l’odeur peut

varier à différents niveaux. Puisque le propane est plus pesant que l’air,

l’odeur peut être plus prononcée à un bas niveau. Toujours être sensible à

la moindre odeur de gaz. Si vous décelez une odeur, réagissez comme si

vous aviez une sérieuse fuite. Passez à l’action immédiatement en suivant

les informations précédentes.

• Apprendre à reconnaître l’odeur du propane. Votre distributeur de

propane peut vous donner un échantillon que vous grattez et sentez.

Utilisez-le pour savoir reconnaître l’odeur du propane. Si vous pensez

que votre gaz propane a une faible ou anormale odeur, appelez votre

distributeur.

• Si vous n’êtes pas qualié, n’allumer pas la veilleuse, n’effectuer pas

l’entretien ou n’ajuster pas les appareils fonctionnant au propane. Si

vous êtes qualié, soyez conscient de l’odeur du propane avant et

pendant que vous allumez la veilleuse, effectuez l’entretien ou faites

les ajustements.

• Quelquefois un soubassement ou une maison fermée a une senteur de

moisi qui peut dissimuler l’odeur de propane. N’essayez pas d’allumer

des veilleuses, d’effectuer l’entretien ou de faire des ajustements dans

des endroits où les conditions sont de telle sorte que vous ne pouvez

pas déceler l’odeur du propane en cas de fuite.

• L’affaiblissement d’odeur, attribuable à l’oxydation par la rouille ou

l’adsortion sur les parois des nouveaux réservoirs et bouteilles, est

possible. Par conséquent, les personnes doivent être particulièrement

prudentes lorsque de nouveaux réservoirs ou bouteilles sont mis en

service. L’affaiblissement d’odeur peut se produire dans les nouveaux

réservoirs ou dans les vieux réservoirs qui sont réinstallés, s’ils sont

remplis et inutilisés pour une longue période de temps. La formation

QUELQUES POINTS À RETENIR

de rouille à l’intérieur des bouteilles et des réservoirs qui ne sont

pas utilisés pour une longue période de temps, peut provoquer un

affaiblissement de l’odeur. Si vous pensez que de telles conditions

existent, un test de senteur de gaz est recommandé périodiquement.

Si vous avez des questions à propos de l’odeur du gaz, appelez

votre distributeur de propane. En toute circonstance, un test de

senteur périodique du gaz propane est une mesure de prudence.

• Si en aucun temps vous ne sentez pas l’odeur du propane et que vous

devriez, assumez que vous avez une fuite. Agissez immédiatement

selon les recommandations ci-dessus, décrivant les actions à suivre

en cas de décèlement de gaz propane.

• Si vous découvrez que le réservoir est complètement vide de gaz

(le réservoir n’a aucune pression de vapeur), fermez la soupape du

réservoir immédiatement. Si la soupape du réservoir reste ouverte,

le réservoir peut aspirer de l’air par les ouvertures, par exemple les

orices de la veilleuse. Si ceci survient, l’intérieur peut subir une

additionnelle formation de rouille. Si la soupape est restée ouverte,

considérez le contenant comme étant un nouveau réservoir. Soyez

toujours certain que le réservoir est sous pression de vapeur; fermez

la soupape du réservoir avant qu’il ne soit complètement vide et faites

le remplir.

32039-1-0314Page 26

Page 27

INTRODUCTION

Introduction

Lorsque la fournaise murale à air chaud est expédiée, elle est

prête à être installer entre les montants du mur 2" x 4" (51mm

x 102mm) et ceux-ci doivent avoir 16" (406mm) d’un centre à

l’autre centre. Toujours consulter le département de construction

de votre région en ce qui regarde les règlements, les codes ou

les ordonnances qui s’appliquent à l’installation d’une fournaise

murale à air chaud.

Instructions pour l’Installateur

1. Après l’installation, l’installateur doit laisser le manuel

d’instructions au propriétaire.

2. L’installateur doit demander au propriétaire de compléter et

poster la carte de guarantie qui est fournie avec la fournaise.

3. L’installateur doit expliquer au propriétaire la mise en marche

et le fonctionnement de la fournaise et du thermostat.

AVERTISSEMENT:

Tout changement fait à cette fournaise ou à ces

commandes peut être dangereux. Ceci est un appareil

de chauffage et si un panneau, une porte ou un dispositif

protecteur est enlevé pour l’entretien de cet appareil, il

doit être replacé avant de remettre en marche.

Information Générale

Ce radiateur est un modèle conformément certié avec

l'American National Standard / CSA Standard Z21.86 et

CSA 2.32 par Canadian Standards Association comme étant

une fournaise murale à air chaud, devant être installée en

accordance avec ces instructions.

Tout changement du modèle d’origine, installé autrement

que décrit dans ces instructions ou fonctionnant avec

un genre de gaz qui n’est pas indiqué sur la plaque

d’identication, est la responsabilité de la personne et

de la compagnie faisant ce changement.

Important

Toute la correspondance doit mentionner le numéro complet

du modèle et de la série et le genre de gaz.

Avis: Pendant le premier allumage de cette unité, la peinture

cuira et de la fumée se produira. Pour prévenir les détecteurs

de fumée de se déclencher, bien ventiler l’appartement dans

lequel l’unité est installée.

Installation dans les Garages Résidentiels

Tous les équipements dans les garages résidentiels employant

du gaz, doivent être installés de façon à ce que les brûleurs

et les appareils pour allumer les brûleurs doivent être situés

à au moins 45.7cm au dessus du plancher.

Tous ces équipements doivent être situés ou protégés de façon

à ce qu’un véhicule en se déplaçant ne puisse les endommager.

Agenced’InstallationQualiée

L’installation et le remplacement des tuyaux à gaz, des

équipements ou accessoires, la réparation et l’entretien de

l’équipement doivent être faits seulement par une agence

qualiée. Le terme “agence qualiée” signie tout individu,

rme, corporation ou compagnie qui est, en personne ou par

un représentant, engagé et responsable de: (a) l’installation

ou le remplacement des tuyaux à gaz, ou (b) la connexion,

l’installation, la réparation ou l’entretien de l’équipement, qui

possède l’expérience nécessaire en ce genre de travail, est