Empire Faw-55-ip Owner's Manual

INSTALLATION INSTRUCTIONS

AND

OWNER’S MANUAL

FAN TYPE

VENTED

WALL FURNACE

MODEL

FAW-55IP

Installer: Leave this manual with the appli-

ance.

Consumer: Retain this manual for future refer-

ence.

WARNING: If not installed, operated and maintained in accordance with the manufacturer’s

instructions, this product could expose you

to substances in fuel or from fuel combustion

which can cause death or serious illness.

WARNING: If the information in these instructions are not followed exactly, a fire or explosion may result causing property damage,

personal injury or loss of life.

— Do not store or use gasoline or other flamma-

ble vapors and liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

— Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

Page 1

TABLE OF CONTENTS

SECTION PAGE

INTRODUCTION ..................................................................................................................3

SAFETY INFORMATION FOR USERS OF LP-GAS .........................................................4

INSTALLATION ................................................................................................................ 5-9

LIGHTING INSTRUCTIONS .............................................................................................10

SERVICE AND MAINTENANCE SUGGESTIONS ................................................... 11-12

TROUBLESHOOTING .......................................................................................................13

S8600H TROUBLESHOOTING GUIDE ...................................................................... 14-15

PARTS LIST .........................................................................................................................16

PARTS VIEW .......................................................................................................................17

VENTING ............................................................................................................................18

SERVICE NOTES ................................................................................................................19

12429-10-0408Page 2

INTRODUCTION

Introduction

Always consult your local Building Department regarding

regulations, codes or ordinances which apply to the installation of

a vented wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner fill out and mail warranty card

supplied with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be dangerous.

This is a heating appliance and any panel, door or guard

removed for servicing an appliance must be replaced prior

to operating the appliance.

General Information

This series is design certified in accordance with American National

Standard / CSA Standard Z21.86 and CSA 2.32 by the Canadian

Standards Association, as a Fan Type Vented Wall Furnace and

must be installed according to these instructions.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not shown on

the rating plate is the responsibility of the person and company

making the change.

Important

All correspondence should refer to complete Model No., Serial

No. and type of gas.

Notice: During initial firing of this unit, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate

the room in which the unit is installed.

Installation on Rugs and Tile

If this appliance is installed directly on carpeting, tile or other

combustible material other than wood flooring the appliance shall

be installed on a metal or wood panel extending the full width and

depth of the appliance.

The base referred to above does not mean the fire-proof base as

used on wood stoves. The protection is for rugs that are extremely

thick and light colored tile.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than 18” (457mm) above the floor.

Such equipment shall be located, or protected, so it is not subject

to physical damage by a moving vehicle.

Specifications

Model FAW-55IP

BTU/HR (KW/H) 55,000 (16.1)

Height 82 3/8” (2092mm)

Width 16” (406mm)

Depth 11 1/2” (292mm)

Gas Inlet 1/2” (13mm) Pipe

Vent Collar 4” (102mm) Type B Oval

CFM 400

Accessories See Page 16

THIS IS A HEATING APPLIANCE

DO NOT OPERATE THIS APPLIANCE WITHOUT FRONT PANELS INSTALLED.

• Due to high temperatures the appliance should be located

out of traffic and away from furniture and draperies.

• Children and adults should be alerted to the hazards of

high surface temperatures and should stay away to avoid

burns or clothing ignition.

• Young children should be carefully supervised when they

are in the same room as the appliance.

• Clothing or other flammable material should not be placed

on or near the appliance.

• Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

appliance.

• Keep burner and control compartment clean.

• Installation and repair should be done by a QUALIFIED

SERVICE PERSON. The appliance should be inspected

before use and at least annually by a qualified service

person. More frequent cleaning may be required due to

excessive lint from carpeting, bedding materials, etc. It

is imperative that control compartments, burners and

circulating air passageways of the appliance be kept

clean.

• DO NOT put anything around the furnace that will

obstruct the flow of combustion and ventilation air.

• DO keep the appliance area clear and free from combustible

material, gasoline and other flammable vapors and

liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO make a periodic visual check of pilot and burners.

Clean and replace damaged parts.

• CAUTION: Pilot hole cover must be kept tightly closed

during operation.

• DO NOT use this heater if any part has been under water.

Immediately call a qualified service technician to inspect

the heater and to replace any part of the control system

and any gas control which has been under water.

• This furnace must not be connected to a chimney flue

serving a separate solid-fuel burning appliance.

12429-10-0408 Page 3

SAFETY INFORMATION FOR USERS OF LP-GAS

Propane (LP-Gas) is a flammable gas which can cause fires

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions which can protect both you and your family from an

accident. Read them carefully now, then review them point

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That’s your signal to go into immediate action!

• Do not operate electric switches, light matches, use your

phone. Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area.

Do that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such

as basements. When you have reason to suspect a gas leak,

keep out of basements and other low areas. Stay out until

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odor of the chemical stench put into the gas. You must find out

if you can smell the odorant in propane. Smoking can decrease

your ability to smell. Being around an odor for a time can affect

your sensitivity or ability to detect that odor. Sometimes other

odors in the area mask the gas odor. People may not smell the

gas odor or their minds are on something else. Thinking about

smelling a gas odor can make it easier to smell.

The odorant in LP-gas is colorless, and it can fade under some

circumstances. For example, if there is an underground leak, the

movement of the gas through soil can filter the odorant. Odorants

by point with the members of your household. Someday

when there may not be a minute to lose, everyone’s safety

will depend on knowing exactly what to do. If, after reading the following information, you feel you still need more

information, please contact your gas supplier.

firefighters declare them to be safe.

• Use your neighbor’s phone and call a trained LP-Gas service

person and the fire department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and firefighters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

in LP-Gas also are subject to oxidation. This fading can occur if

there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into walls,

masonry and other materials and fabrics in a room. That will take

some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest

gas odor. If you detect any odor, treat it as a serious leak. Im

mediately go into action as instructed earlier.

-

SOME POINTS TO REMEMBER

• Learn to recognize the odor of LP-gas. Your local LP-Gas

Dealer can give you a “Scratch and Sniff” pamphlet. Use it

to find out what the propane odor smells like. If you suspect

that your LP-Gas has a weak or abnormal odor, call your

LP-Gas Dealer.

• If you are not qualified, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualified, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service

or making adjustments.

• Sometimes a basement or a closed-up house has a musty

smell that can cover up the LP-Gas odor. Do not try to light

pilot lights, perform service, or make adjustments in an area

where the conditions are such that you may not detect the

odor if there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls

of new cylinders and tanks, is possible. Therefore, people

should be particularly alert and careful when new tanks or

cylinders are placed in service. Odor fade can occur in new

tanks, or reinstalled old tanks, if they are filled and allowed

to set too long before refilling. Cylinders and tanks which

have been out of service for a time may develop internal rust

which will cause odor fade. If such conditions are suspected

to exist, a periodic sniff test of the gas is advisable. If you

have any question about the gas odor, call your LP-gas

dealer. A periodic sniff test of the LP-gas is a good safety

measure under any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete “gas out,” (the container is under no vapor pressure), turn the tank valve off immediately.

If the container valve is left on, the container may draw in

some air through openings such as pilot light orifices. If this

occurs, some new internal rusting could occur. If the valve is

left open, then treat the container as a new tank. Always be

sure your container is under vapor pressure by turning it off

at the container before it goes completely empty or having it

refilled before it is completely empty.

12429-10-0408Page 4

INSTALLATION

Ventilation and Combustion Air

Wall furnaces shall be installed in a location in which the facilities

for ventilation permit satisfactory combustion of gas and proper

venting under normal conditions. In buildings of conventional

frame, brick, or stone construction without tight storm windows

and doors, infiltration is normally adequate to provide air for

combustion and draft hood dilution.

Where appliances are installed in confined and unconfined spaces

within a building, the building being of unusually tight construction,

air for combustion and ventilation must be obtained directly from

outdoors or from such spaces that freely communicate with the

outdoors. Under these conditions, the confined and unconfined

spaces shall be provided with two permanent openings, one near

the top of the enclosure and one near the bottom; each opening

shall have a free area of not less than one square inch (6,45cm

2

per 2,000 BTU hr. (.6KW/H) of total input.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualified agency. The term “qualified agency”

means any individual, firm, corporation or company which either in

person or through a representative is engaged in and is responsible

for (a) the installation or replacement of gas piping or (b) the

connection, installation, repair or servicing of equipment, who is

experienced in such work, familiar with all precautions required

and has complied with all the requirements of the authority having

jurisdiction.

The installation must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA

54,* Natural Gas and Propane Installation Code, CSA B149.1.

*Available from the American National Standards Institute, Inc., 11 West 42nd St.,

New York, N.Y. 10036.

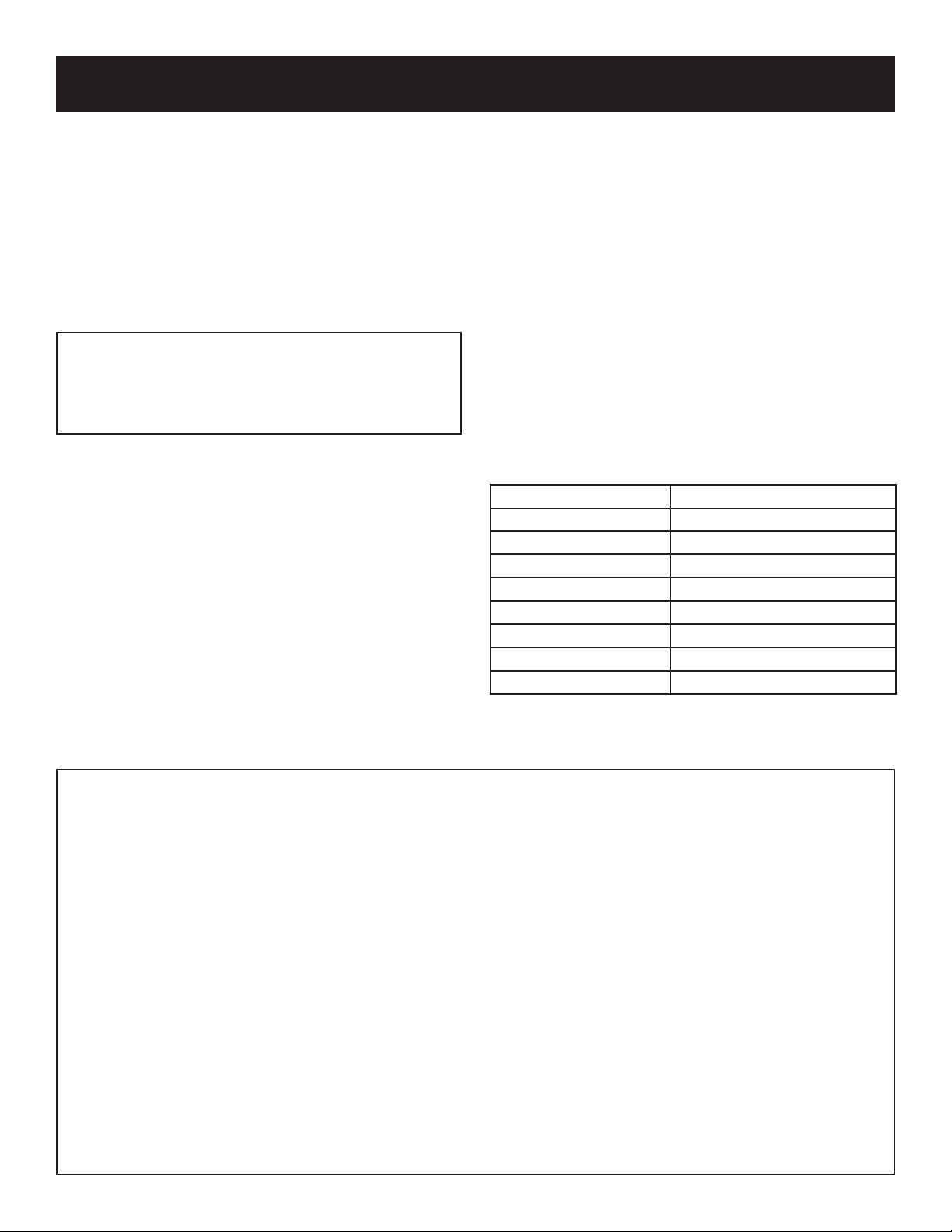

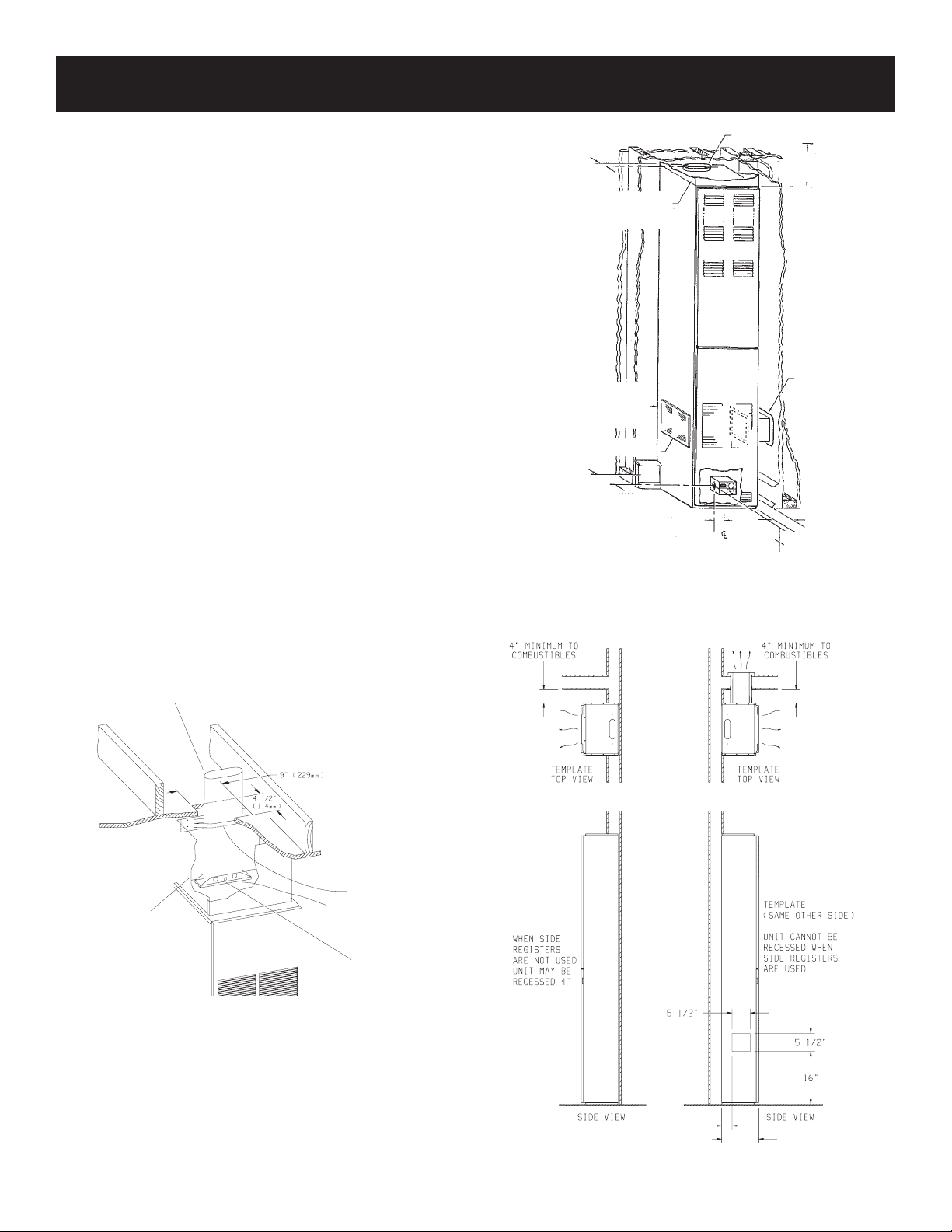

Clearances

1. In selecting a location for installation, it is necessary to provide

adequate accessibility clearances for servicing and proper

installation.

2. The FAW-55 can be attached to the wall or recessed into the

wall up to 4 inches (102mm) in depth.

3. The wall in which the furnace is recessed has (0) zero (0mm)

clearance to the furnace sides and top.

4. When using side discharge registers, SOR-1 or SOK-1, the

furnace cannot be recessed into the wall.

5. Clearance to sidewall or combustible material is 4 inches

(102mm).

6. Ceiling clearance is 7 1/2 inches (191mm).

7. Floor and rear wall clearance is (0) zero inches (0mm).

8. Clearance of 18 inches (457mm) is required to adjacent wall or

combustible material when flush mounted SOR-1, side outlet

register is used.

Before Installing Consider The Following Venting

1. A chimney for residential-type or low-heat gas utilization

equipment shall extend at least 3 feet (914mm) above the

highest point where it passes through a roof of a building and

at least 2 feet (610mm) higher than any portion of building

within a horizontal distance of 10 feet (3m).

2. This furnace must not be connected to a chimney flue serving

a separate solid-fuel burning appliance.

3. Uninsulated Single-Wall Metal Pipe shall not be used

outdoors in cold climates for venting gas utilization

equipment.

4. Attention! This Fan Type Vented Wall Furnace is equipped

with a vent safety switch. In the event of spillage of flue

products due to improper venting the vent safety switch will

open, which results in the main burners to “shut off”.

Refer to Figure 1 and page 16 for additional information regarding

U.L. Listed gas vent equipment.

Installing Optional Side Outlets

Side outlet register, SOR-1 may be installed on one or both sides

of the furnace at the required clearances of 18 inches (457mm) to

)

adjacent wall or combustible material as shown in Figure 2.

1. Locate and cut the 5 1/2” (140mm) square opening in the cabinet

side using the template from the kit, exposing the inner liner

knock-out.

2. Remove the knock-out.

3. Place the register on the 5 1/2” (140mm) opening with the

louvers set for the desired direction and mark the mounting

holes using the register as a template.

4. Drill (2) 1/8” (3mm) diameter holes in cabinet side and fasten the

register in place with (2) #10 x 1” (25mm) screws provided.

Side outlet kit, 10” (254mm) boot assembly with register, SOK-1

for warm air discharge into an adjoining room may be installed on

either side of the furnace at the required clearance of 4 inches to

adjacent wall as shown in Figure 3A.

1. Locate and cut the 5 1/2” (140mm) square opening in the cabinet

side using the template from the kit, exposing the inner liner

knock-out.

2. Remove the knock-out.

3. Using the inner and outer boots as hole templates, mark and

drill (8) 1/8” (3mm) diameter holes in the inner liner and cabinet

side.

4. Using Figure 3A locate and cut a 6 3/4” (171mm) square

opening through walls.

5. Attach furnace to wall (see Attaching Furnace to Wall).

6. With furnace in place, after checking alignment of side outlet

opening in wall and furnace, place the 9 3/8” x 9 3/8” (238mm

x 238mm) side outlet wall plate over outer boot, pass the outer

boot through the wall and attach side outlet wall plate to furnace

side of wall with (2) #10 x 1” (25mm) screws provided.

7. Fasten outer boot to the cabinet side with (4) #8 x 1/4” (6mm)

screws provided.

8. Position and attach inner boot to inner liner with (4) #8 x 1/4”

(6mm) screws provided.

9. Locate the register with its louvers positioned for the desired

air discharge direction and mark the mounting holes using the

register as a template.

10. Drill (2) 1/8” (3mm) diameter holes in the wall and fasten the

register in place with (2) #10 x 1” (25mm) screws provided

12429-10-0408 Page 5

VENT CENTER TO COMBUSTIBLES

MINIMUM CLEARANCE 9/16” (40mm)

4”(102mm) OVAL TYPE “B”

CONNECTION

7/1/2” (191mm) MINIMUM

CLEARANCE TOP T

O

COMBUSTIBLES

VENT ENCLOSURE

DV-651 or DV-665 or

DV-666

MINIMUM CLEARANCE

TO COMBUSTIBLES

18”(457mm)

SIDE OUTLET

KIT PART SOK-1

Register

Part SOR-

1

6 5/8 (168mm)

WALL TO VALVE INLET

3”(76mm) TO

CENTER OF

½”(13mm) INLET ELBOW

3 3/4”(95mm) FLOOR TO

CONTROL VALV

E INLET

4”(102mm) MINIMUM

CLEARANCE TO

COMBUSTIBLES

REAR OUTLET

REGISTER KIT #ROK-1

ALL CONNECTIONS MUST BE MECHANICALLY

MADE AND LISTED CLERANCES MAINTAINED

*PARTS LISTED ARE TO BE PURCHASED

LOCALLY

SPACER STRAP*

BASE PLATE*

MOUNTING HOLE

2 PIECE VENT ENCLOSURE

CUT TO THE PROPER LENGTH

BASE PLATE

GASKET

(140mm)

(406mm)

(102mm)

(102mm)

(140mm)

(102mm)

3 1/4” (83mm)

11 ½”(292mm)

INSTALLATION

Installing Optional Rear Outlet

Rear outlet kit, 10” (254mm) boot assembly with register, ROK-1

for warm air discharge into an adjoining room.

Attention: Before furnace is attached to the wall, the wall opening

for the rear outlet must be cut, in addition to removal of the outer

and inner casing knockouts on furnace.

1. The wall opening measurements for the rear outlet are the

following.

A. From floor to bottom of wall opening is 14 3/4”

(375mm).

B. From bottom of wall opening to top of wall opening is 8

1/2” (216mm) .

C. Wall opening width is 12 1/8” (308mm).

2. Remove outer casing knockout from outer casing back.

3. Remove inner casing knockout from inner casing.

4. Attach furnace to wall (see Attaching Furnace to Wall).

5. Align clearance holes on 8” x 12” (203mm x 305mm) boot with

screw holes on outer casing back and mark boot to be flush

with wall surface. Remove boot and cut to proper length.

6. Attach 8” x 12” (203mm x 305mm) boot to outer casing back

with (6) #10 x 1/2” (13mm) screws provided.

7. Align clearance holes on 6” x 10” (152mm x 254mm) duct with

screw holes on inner casing and mark duct to be 2 1/4” (57mm)

shorter than 8” x 12” (203mm x 305mm) boot. Remove duct

and cut to proper length.

8. Attach 6” x 10” (152mm x 254mm) duct to inner casing with

(6) #10 x 1/2” (13mm) screws provided.

9. Insert rear register into 8” x 12” (203mm x 305mm) boot.

Attach rear register to wall with (2) #10 x 1” (25mm) screws

provided.

Figure 2

Figure 1

Figure 3 Figure 3A

12429-10-0408Page 6

Loading...

Loading...