Emico EA-307 User Manual

Three-Piece ball valve

EA-307 User Manual

English Version

[DRAFT VERSION]

For use for company in Europe who will place the product on the market.

Please amend which necessary.

EA-307 Series

PED Category I, II

Document No: 3-29-06

Date: 92/6/10

Version: 1

PREPARED BY

REVIEWED BY

APPROVED BY

DATE

DATE

DATE

Eayuan Metal Industrial Co., Ltd.

3F-8, No. 665, Sec. 2, Wu Chuan W Rd.,

T aichung, Taiwan, R.O.C.

Contents

1. General Precautions

2. Product Description

3. Design Specification

4. Pressure Temperature Ratings

5. Delivery Condition and Storage

6. Installation and Operation

7. Maintenance

Page- 2~3

Page- 4~6

Page- 7

Page- 7~8

Page- 8

Page- 9~12

Page-13~15

8. Torqure Data

9. Corrosion Data

Page-16

Annex 1.

1

1.General Precautions

a. Material Selection:

The possibility of material deterioration in service and the need for periodic

inspections is depended on the contained fluid. Carbide phase conversion to

graphite, oxidation of ferrite materials, decrease in ductility of carbon steels at

low temperature (even in applications above -29℃) are among those items. Even

information about corrosion data is provided in this user manual, the user is

requested to take attention or consideration to determine the suitability of material

in their application.

b. Pressure-Temperature rating:

The Pressure-Temperature rating is considered for static pressure. Please refer to

P & T rating section on page 9 for working precaution. The allowable temperature

is between -29℃ and 180℃, Do not exceed the temperature range to avoid

danger accident happen.

c. Fluid thermal expansion:

Pressure, built-up in the body cavity by heating volatile fluid, can damage the

seats or the ball. The hole in the ball beneath the stem slot can equalize pressure

between body cavity and the line when valve in the open position. An optional

internal pressure equalizing hole drilled in upstream side of ball is suggested for

certain applications e.g. ammonia, chlorine, LPG, for pressure equalization when

valve in the close position.

d. Static electric effect:

The ball valves are provided with anti-static devices for ball-stem-body. When

service conditions require electrical continuity to prevent static discharge, the user

is responsible for specifying static grounding.

e. Fire safe condition:

Generally, the application of the valve shall comply with the

Pressure-Temperature rating range. If the risk of fire is major effect, user is

recommended to select our fire-safe products, which with API-607 4th edition

approval. Contact to the valve distributor or manufacturer for details.

f. Liquids with high fluid velocity:

When ball valves must be operated frequently on liquids with very high velocity,

a check shall be made with the valve distributor or manufacturer for appropriate

2

advice to minimize the possibility of seat deformation, especially when they are

highly pressurized on high-temperature line.

g. Throttling service: Ball valves are generally not recommended for throttling

service, where both the fluid flow and the leading edge of the ball can damage or

deform the resilient ball seats causing leakage. High fluid velocity or the presence

of solid particles in suspension will further reduce seat life in throttling

applications.

h. Do not open the bonnet or cap when bearing pressure. Valve is not equipped with

pressure access device. User should check it by other method through its piping

system.

i. No touch the surface of valve on high temperature.

j. Not allowed for unstable fluid, otherwise specified with catogory III in

Declaration of conformity or/and in this user manual.

k. Lock design on the handle to avoid the valve operated by non-related people is

optional requested by the user.

3

2. Product Description

2.1 Feature

a. STANDARD type, FULL BORE ball valve.

b. Blowout proof stem.

c. Anti-static devices for ball-stem-body.

d. Pressure balance hole in ball slot.

e. Pressure self-relief seat to prevent pressure built up.

f. Lock design on the handle is optional

2.2 Product specification

The scope of product specifications are as following

DN PN63 DN PN63

DN15 Art .3 para. 3 DN50 Category II

DN20 Art .3 para. 3 DN65 Category II

DN25 Art .3 para. 3 DN80 Category II

DN32 Category II DN100 Category II

DN40 Category II

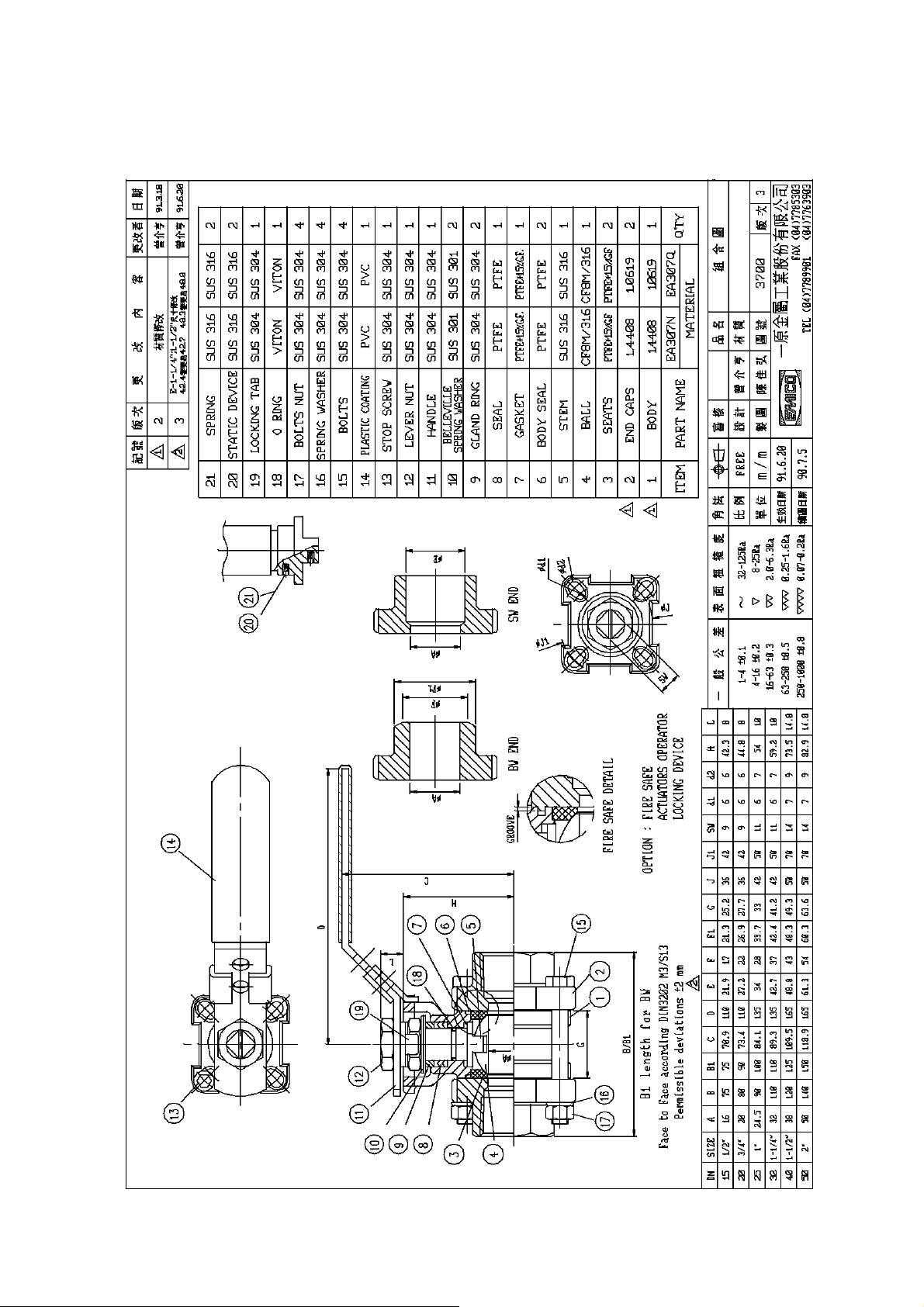

2.3 Material of construction and Common dimension

307-1/2”~2”see Fig-1

307-2-1/2”~4” see Fig-2

4

Fig-1

5

Loading...

Loading...