Page 1

Product Data Document

118DS-16b

July 24, 2007 - Page 1

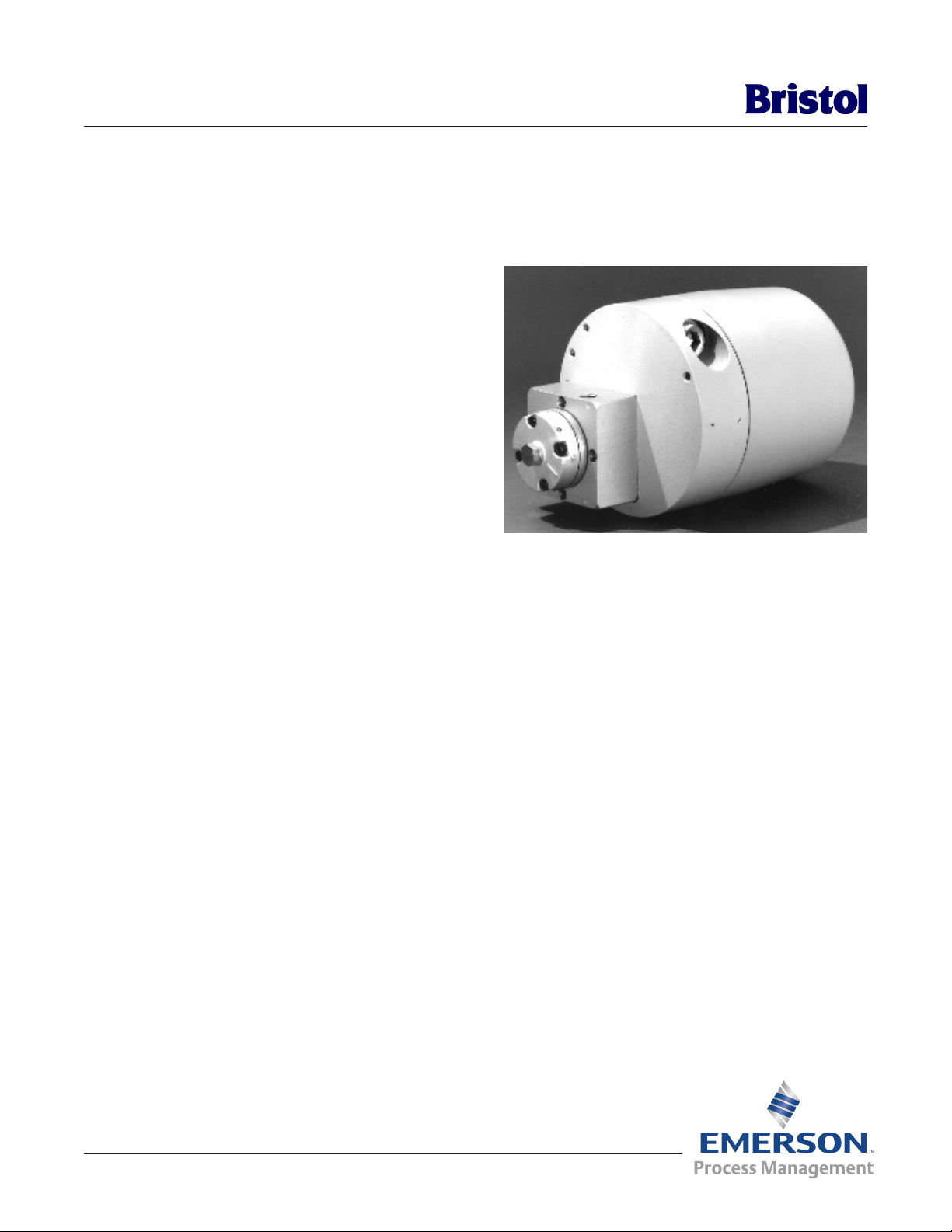

Bristol® Series 9110-00A

Remote Set Regulator

Features

Compact size

•

Integrally mounted

•

Discrete and analog inputs

•

Guard feature*

•

Analog feedback

•

Adjustable speed control

•

Incremental step change

•

Explosion – proof actuator case

•

*In the guard position, the drive mechanism will be

active only if the guard input signal is true.

General

The Bristol® 9110-RSR, from Emerson Process

Management, is a bi-directional microprocessor

based rotary actuator that sets the output of a

pneumatic regulator. The output can be adjusted

electrically by either discrete (raise/Lower) or analog

inputs. These input signals to the “RSR” can be

received from remote or local locations either by

manual switches or automatic devices.

Description

Series 9110-00A, Remote Set Regulators are transducer devices that use an electrical input signal to

set the level of a pneumatic output signal. Depending on the actual models, the output can be cong-

ured for a 1-5 Vdc or 4-20 mA dc signal. For the

Raise/Lower models, the input can be congured to

accept a continuous or pulse incremental dc signal.

The pneumatic output of a Remote Set Regulator may

be specied with a 3-15, 3-27 or 6-30 psi output. All

models can operate from pressure supplies up to 100

psi maximum.

The Remote Set Regulator is contained in a weatherproof, explosion-proof enclosure having a detachable threaded cover. Removal of the cover provides

access to the eld wiring terminals and the programmable option switches.

Regulators are factory-furnished for 12 or 24 Vdc

supply operation. These voltage ratings are xed

and cannot be changed in the eld.

In-line or pipe mounting are offered as for installations. The former uses a ¼ inch rigid pressure

line for support, while the latter includes a special

bracket for two-inch pipe mounting.

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 2

Product Data Document

118DS-16b

July 24, 2007 - Page 2

Bristol® Series 9110-00A

Remote Set Regulator

Performance Specications

Accuracy

Electrical input to pressure output: ±5% of span

•

Pressure output to feedback: ±5% of span

Feedback volts to pressure output: ±5% of span

•

Pulse input to pressure output: ±20% of span

Sensitivity

.04% of span (Min. input for readable output)

•

Repeatability

±0.5% of span

•

Environmental Effect

±1% max. full scale per 50ºF (28ºC) change

•

Supply Voltage Effects

±0.15% max. full scale per 1 volt change

•

Hysteresis Effect

(Output to Gage) ½% of span

•

Supply Pressure Effect

Environmental Specications

Primary Location

Suitable for eld or housed-in unheated

•

buildings

Temperature Limits

-20 to 150º F (-29 to 66°C) operating

•

-40 to 185º F (-40 to 85°C) storage

•

Humidity Limits

10 to 95% RH, -20 to 130° F, (-29 to 55° C)

•

operating

10 to 50% RH, 130 to 150°F (55 to 66°C)

•

operating

Vibration Limits

•

0.1 g max., 10 – 500 Hz

Interference

R.F.I. rejection of the actuator depends on the

shielding of the input and output since the aluminum

housing (with cover in place) greatly attenuates RF

eld strength.

0.1 Max. PSI change in output for 10 PSI

•

change in supply pressure (within supply limits)

Gas/Air Consumption

0.007 SCFM at 40 psig supply pressure, at

•

steady state and increasing supply pressures.

Remote Automation Solutions

Effect with wiring enclosed in conduit SAMA STD

PMC 33.1, Class 1 and 2, 20 MHz to 500 MHz:

<0.5% FS error

Case Classication

Designed to NEMA type 4 hazardous

•

Safety

Designed to meet ANSI Standard C39.5

Explosion-proof for Class 1, Division 1, Groups B,

C and D; Dust-ignition-proof for Class II, Division 1,

Groups E, F and G; Suitable for Class III, Division 1;

Nonincendive for Class 1, Division 2, Groups A, B,

C and D.

Website: www.EmersonProcess.com/Remote

Page 3

Product Data Document

118DS-16b

July 24, 2007 - Page 3

Bristol® Series 9110-00A

Remote Set Regulator

Supply Specications

Electrical

Models Requiring 12 volts: 11 to 14 Vdc, 0.35 A

•

max.

Models Requiring 24 Volts: 22 to 28 Vdc, 0.25

•

A max.

Fusing: One 1 A, 250 V 3 AG normal blow chip

•

mounted on terminal board

Power Failure: In the event that the supply

•

voltage drops below rated value or goes to zero,

mechanical memory will retain the last given

setting.

Pneumatic Supply

Models with 3 – 15 PSI range: 20 PSI min., 100

•

PSI max.

Models with 3 – 27 PSI range: 30 PSI min., 100

•

PSI max.

Models with 6 – 30 PSI range: 35 PSI min., 100

•

PSI max.

Physical Specications

General

Actuator Case:

•

Weatherproof, explosion proof

Cast aluminum housing with

gasketed screw-on cover

Light gray epoxy nish

Overall Dimensions

Actuator Case:

•

6” (152.4 mm) dia. By 7-1/8” (181 mm) long

Model 9110 complete:

10” (254 mm) long by 6” (152.4 mm) dia.

Mounting

Model 9110 complete: Line or 2” dia. Pipe

•

mount

Weight

Approx. 12 lbs.

•

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 4

Product Data Document

118DS-16b

July 24, 2007 - Page 4

Bristol® Series 9110-00A

Remote Set Regulator

Remote Set Pneumatic Regulator 9110-rsr

Series 9110-00a

A B C - D E F

Model Number: 9110-00A - __ __ __ - __ __ 0

9110-00A

SELECT DESCRIPTION CODE

A ELECTRICAL INPUT X9110BASE

10 Discrete 1

Analog 2

B POWER

20 12 Vdc 1

24 Vdc 2

C PNEUMATIC OUTPUT

30 3-15 PSI 1

3-27 PSI 2

6-30 PSI 3

D MOUNTING X9110MOUNT

40 Pipe 1

Line 2

E APPROVAL

50 None 1

FM-EXP . proof CL I, Div. 1, Groups B, C & D 2

Dust-ignition proof CL II, Div. 1, Groups E, F & G

Suitable for CL III, Div. 1

Non-incentive CL I, Div. 2, Groups A, B, C & D

NEMA 4

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 5

Product Data Document

118DS-16b

July 24, 2007 - Page 5

Bristol® Series 9110-00A

Remote Set Regulator

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division , are wholly owned subsidiaries of Emerson Electric Co. doing business as Remote Auto-

mation Solutions (“RAS”), a division of Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co. All other marks are property of their

respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or

specications of such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available upon request. RAS does not assume responsibility for

the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product remains solely with the purchaser and end-user.

Emerson Process Management

Remote Automation Solutions

Watertown, CT 06795 USA T 1 (860) 945-2200

Mississauga, ON 06795 Canada T 1 (905) 362-0880

Worcester WR3 8YB UK T 44 (1) 905-856950

Website: www.EmersonProcess.com/Remote

Loading...

Loading...