Emerson Process Management BINOS 100 F, BINOS 100 M, BINOS 100, HYDROS 100, BINOS 100 2M User Manual

Page 1

Instruction Manual

ETC00781

February 2004

Series 100 Gas Analyzers

BINOS® 100, BINOS® 100 M

BINOS® 100 2M, BINOS® 100 F

OXYNOS® 100, HYDROS® 100

www.EmersonProcess.com

Software Version 5.1x

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Emerson Process Management (Rosemount Analytical) designs, manufactures and tests

its products to meet many national and international standards. Because these

instruments are sophisticated technical products, you MUST properly install, use, and

maintain them to ensure they continue to operate within their normal specifications. The

following instructions MUST be adhered to and integrated into your safety program when

installing, using and maintaining Emerson Process Management (Rosemount Analytical)

products. Failure to follow the proper instructions may cause any one of the following

situations to occur: Loss of life; personal injury; property damage; damage to this

instrument; and warranty invalidation.

• Read all instructions prior to installing, operating, and servicing the product.

• If you do not understand any of the instructions, contact your Emerson Process

Management (Rosemount Analytical) representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied with the

product.

• Inform and educate your personnel in the proper installation, operation, and

maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• To ensure proper performance, use qualified personnel to install, operate, update,

program, and maintain the product.

• When replacement parts are required, ensure that qualified people use replacement

parts specified by Emerson Process Management (Rosemount Analytical).

Unauthorized parts and procedures can affect the product’s performance, place the

safe operation of your process at risk, and VOID YOUR WARRANTY. Look-alike

substitutions may result in fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place,

except when maintenance is being performed by qualified persons, to prevent

electrical shock and personal injury.

The information contained in this document is subject to change without notice.

1. Edition: 10/2001 3. Edition: 01/2003

2. Edition: 11/2002 4. Edition: 02/2004

Emerson Process Management

Manufacturing GmbH & Co. OHG

Industriestrasse 1

D-63594 Hasselroth

Germany

T +49 (0) 6055 884-0

F +49 (0) 6055 884-209

Internet: www.EmersonProcess.com

Page 3

SAFETY SUMMARY

GENERAL

Safety Summary

I. Intended Use Statement

The series 100 instruments are intended for use an industrial measurement device only. It is not

intended for use in medical, diagnostic, or life support applications, and no independent agency

certifications or approvals are to be implied as covering such applications.

II. Safety Symbols

Several symbols attached to the analyzer or printed in the instruction manual are used to point

out special sources of danger:

Source of danger !

See Operation Manual!

Electrostatic Discharge (ESD) !

Explosives !

Hot components !

Toxic !

Risk to health !

Analyzer specific notes for the user !

For additional information to these safety symbols see instruction manual.

Strictly follow the related instructions !

ETC00781(4) Series 100 e 02/2004

S - 1

Page 4

SAFETY SUMMARY

GENERAL

III. General

X To avoid explosion, loss of life, personal injury and damages to this equipment and other

property, all personnel authorized to install, operate and service this equipment should be

thoroughly familiar with and strictly follow the instructions in this manual !

Save these instructions !

X If this equipment is used in a manner not specified in these instructions, protective features

may be impaired !

X Correct and safe operation of analyzers calls for appropriate transportation and storage,

expert installation and commissioning as well as correct operation and meticulous

maintenance !

X Emerson Process Management does not take responsibility (liability) for the customer´s

failure to comply with these requirements !

X Do not attempt internal service or adjustment unless other person, capable of rendering first

aid and resuscitation, is present !

X Because of the danger of introducing additional hazards, do not perform any unauthorized

modification to the instrument !

Return the instrument to a Emerson Process Management Sales and Service office for

service or repair to ensure that safety features are maintained !

X Instruments which appear damaged or defective should be made inoperative and secured

against unintended operation until they can be repaired by qualified service personnel.

S - 2

ETC00781(4) Series 100 e 02/2004

Page 5

SAFETY SUMMARY

GENERAL / GASES AND GAS CONDITIONING (SAMPLE HANDLING)

Do not open instrument when energized !

Component replacement and internal adjustments requires servicing by

qualified personnel only !

Read this instruction manual before attempting to operate the instrument !

Be sure to observe the additional notes, safety precautions and warnings

given in the instruction manual !

Operate analyzer as table-top version or as rack-mountable version (built-in) only

(except of BINOS® 100 F: designed for wall mounting only) !

Do not operate the instrument in the presence of flammable gases or explosive

atmosphere without supplementary protective measures !

Hot components may exist at the photometer or in heated versions !

BINOS 100 F

The analyzer has a weight of approx. 30 - 35 kg.

Lift or carry this unit with at least 2 persons.

For easy transport use a suitable cart or comparable tools.

Verify that the cable fittings with installed cables are hermetic to be

in agreement with protection class IP 65 (according to DIN standard 40050).

The permissible outside diameters of the cables are 7 to 12 mm !

The analyzer is intended to be wall mounted. Use bolts which are

suitable for the weight of the unit and appropriate anchors.

ETC00781(4) Series 100 e 02/2004

Make sure the wall where the analyzer is intended to be mounted is solid to

hold the analyzer!

S - 3

Page 6

SAFETY SUMMARY

GASES AND GAS CONDITIONING (SAMPLE HANDLING) / SUPPLY VOLTAGE

IV.Gases and Gas Conditioning (Sample Handling)

Be sure to observe the safety regulations for the gases

(sample gas and test gases / span gases) and the gas bottles !

Inflammable or explosive gas mixtures must not be purged into the instrument

without supplementary protective measures !

To avoid risks for the operators by explosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

cleaning or exchanging parts of the gas paths.

V. Supply Voltage

The socket outlet shall be installed near the equipment and shall be easily

accessible to disconnect the device from the socket outlet.

Verify whether the line voltage stated on the instrument or power supply is in

accordance with that of your mains line!

Be sure to observe the safety precautions and warnings given by

manufacturer of power supply !

X BINOS® 100(M), BINOS® 100 2M (external PS), HYDROS® 100 and OXYNOS® 100 are

Safety Class III instruments.

Verify correct polarity for 24 V DC operation !

S - 4

Use only power supply VSE 2000, UPS 01 T, DP 157, SL5, SL10 (DP 157 and

SL for rack installation only) or equivalent power supplies to keep the

instrument safe.

If using equivalent power supplies they must have SELV output voltage !

ETC00781(4) Series 100 e 02/2004

Page 7

SAFETY SUMMARY

SUPPLY VOLTAGE

X BINOS® 100 2M (internal PS) and BINOS® 100 F are Safety Class 1 instruments

The analyzer is provided with a protective earth terminal.

To prevent shock hazard, the instrument chassis and cabinet must be connected

to an electrical ground. The instrument must be connected to the AC power

supply mains through a three-conductor power cable, with the third wire firmly

connected to an electrical ground (safety ground) at the power outlet.

If the instrument is to be energized via an external power supply, that goes for the

power supply too.

Any interruption of the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard that could result in

personal injury. Deliberate disconnection is inadmissible / prohibited !

The analyzer BINOS® 100 F (field housing) has no switch with disconnect

function. The customer has to provide a switch or circuit breaker into his

installation. This switch has to be installed near by analyzer, must be easily

attainable for operator and has to be characterized as disconnector for analyzer.

Cables to external data processing have to be double-insulated against mains

voltage for analyzer BINOS® 100 F !

Use cables suitable for intrinsic safe applications only ! Install internal data lines

that they have a distance to mains voltage lines of at least 5 mm.

This distance has to be valid permanently (e.g. via cable holder) !

24 VDC supply to external components/analyzers with the internal power

supply of BINOS® 100 2M requires a fuse to be connected in series to the

consumer which limits the current consumption to max. 2 A !

Verify correct polarity for 24 V DC supply of external components !

ETC00781(4) Series 100 e 02/2004

S - 5

Page 8

SAFETY SUMMARY

ANALYZER SPECIFIC NOTES FOR USER

VI. Analyzer specific notes for the user

The installation site for the instrument has to be dry and remain above

freezing point at all times.

The instrument must be exposed neither to direct sunlight nor to strong

sources of heat. Be sure to observe the permissible ambient temperature !

For outdoor sites, we recommend to install the instrument in a protective

cabinet. At least the instrument has to be protected against rain (e.g., shelter).

Do not interchange gas inlets and gas outlets !

All gases have to be supplied to the analyzer as conditionned gases !

If corrosive gases are inserted into the instrument, it has is to be verified that there

are no gas components which may damage the gas path components.

Ensure that all gas connections are made as labeled and are leak free !

Improper gas connections could result in explosion and death !

The unit´s exhaust may contain hydrocarbons and other toxic gases such as

carbon monoxide ! Carbon monoxide is highly toxic !

Permissible gas pressure of sample gas / test gases max. 1,500 hPa !

The exhaust gas lines have to be mounted in a declining, descending,

pressureless and frost-free and according to the valid emission legislation !

In case it is necessary to open the gas paths, close the analyzers

gas connections with PVC caps immediatly to avoid pollution of gas paths !

BINOS® 100 F lift points are labeled ! Labels showing down side for transport !

Do not use electronics of the optional pressurization system as handle !

S - 6

Use only optional delivered cables from our factory or equivalent shielded cables

to be in agreement with the CE conformity.

The customer has to prove that the shield is connected correctly (chapter 29.10).

Shield and connectors housing have to be connected conductive.

Sub. min. D plugs/sockets have to be screwed to the analyzer.

The analyzer (excepting BINOS® 100 F) is not in agreement with the CE

conformity if optional terminal strip adapters are used In this case CE

conformity must be declared by customer as “manufacturer of system”.

ETC00781(4) Series 100 e 02/2004

Page 9

SAFETY SUMMARY

BINOS® 100 F SPECIFIC NOTES FOR USE IN HAZARDOUS AREAS (EX ZONES)

VII. BINOS® 100 F specific notes for use in hazardous areas (EX Zones)

Be sure to observe the additional notes, safety precautions and warnings

given in the supplemental manual for analyzers intended to be used in

hazardous areas.

If you do not have the additional manual available, please contact your

Emerson Process Management Sales Office!

VII.a Z purge for CSA-C/US Ex Zone 2 Non-Flammable Atmospheres

This enclosure shall not be opened unless the area is known to be free of

flammable materials or unless all devices within have been de-energized !

Upon start-up or after loss of continuous dilution requiring switching off the

electrical supply, purge for 11 minutes with flow rate approx. 55 scfh (26 l/min.,

see chapter 5.3.3) unless the internal atmosphere is known to be well below

the lower explosive limit (LEL) !

This analyzer is not designed for analysis of flammable sample !

Introduction of flammable samples into this equipment could result in explosion,

causing severe personal injury, death or property damage !

Consult factory if flammable samples are to be measured !

Do not open while energized unless it is known that no explosive atmosphere is

present !

ETC00781(4) Series 100 e 02/2004

S - 7

Page 10

SAFETY SUMMARY

Z PURGE FOR CSA-C/US EX ZONE 2 NON-FLAMMABLE ATMOSPHERES

VIII. Additional notes for service / maintenance

Do not open instrument when energized !

Component replacement and internal adjustments requires servicing by

qualified personnel only !

Always disconnect power, discharge circuits and remove external voltage

sources before troubleshooting, repair or replacement of component !

Any work inside the instrument without switching off the power must be

performed by a specialist who is familiar with the related danger, only !

To avoid a danger to the operators by explosive, toxic or unhealthy gas

components, first purge the gas lines with ambient air or nitrogen (N2) before

the gas paths are cleaned or parts are replaced.

Hot components may exist at the photometer or in heated versions !

In case of replacing fuses the customer has to be certain that fuses of specified

type and rated current are used. It is prohibited to use repaired fuses or defective

fuse holders or to short-circuit fuse carriers (fire hazard).

Do not open BINOS® 100 F for use in hazardous areas (EX Zones) while

energized unless it is known that no explosive atmosphere is present !

S - 8

Cleaning of BINOS® 100 F front panel for EX Zone 1:

Danger of electrostatic discharge !

Use damp cloth only for cleaning front panel !

ETC00781(4) Series 100 e 02/2004

Page 11

SAFETY SUMMARY

ADDITIONAL NOTES FOR SERVICE / MAINTENANCE

VIII.a Electrostatic Discharge

The electronic parts of the analyzer can be irreparably damaged if exposed to electrostatic

discharge (ESD).

The instrument is ESD protected when the covers have been secured and safety precautions

observed. When the housing is open, the internal components are not ESD protected anymore.

Although the electronic parts are reasonable safe to handle, you should be aware of the following

considerations:

Best ESD example is when you walked across a carpet and then touched an electrical grounded

metal doorknob. The tiny spark which has jumped is the result of electrostatic discharge (ESD).

You prevent ESD by doing the following:

Remove the charge from your body before opening the housing and maintain during work with

opened housing, that no electrostatic charge can be built up.

Ideally you are opening the housing and working at an ESD protecting workstation.

Here you can wear a wrist trap.

However, if you do not have such a workstation, be sure to do the following procedure exactly:

Discharge the electric charge from your body. Do this by touching a device that is grounded

electrically (any device that has a three - prong plug is grounded electrically when it is plugged

into a power receptacle).

This should be done several times during the operation with opened housing (especially after

leaving the service site because the movement on a low conducting floors or in the air might

cause additional ESDs).

ETC00781(4) Series 100 e 02/2004

S - 9

Page 12

SAFETY SUMMARY

ELECTROSTATIC DISCHARGE

IX. Operating Conditions according to DMT Approval

(The following is a reprint of chapter 6 of the supplement I to the DMT reports

“IBS/PFG-No. 41300392 NIII” and “IBS/PFG-No. 41300292 NIII” about the performance

test of the stationary gas analyzers BINOS

®

100 (M/2M) and OXYNOS® 100).

According to the system version and measuring results included in this report, the stationary

gas analyzers BINOS® 100 (M/2M) from Fisher-Rosemount GmbH & Co. [now: Emerson

Process Management; the editor] are suitable for measuring the concentrations of methane

between 0 and 80 % CH4, of carbon dioxide between 0 and 80 % CO2, of carbon monoxid

between 0 - 200 ppm CO and 0 - 10 Vol.% CO and the stationary gas analyzers BINOS® 100

(M/2M) and OXYNOS® 100 are suitable for measuring of oxygen between 0 - 10 Vol.-%, if the

features and system version go conform with the details contained in the enclosed documents

as stated in this report, if the analysis system is operated accordingly and if the following

requirements are met:

X

When using the gas warning system, it must be ensured that the permissible variations

will not be exceeded, taking into account the systematic failures of the measuring signals

(as indicated in this report) and the local operating conditions. Consider the Code of

Pratice No. T032 of the Labor Association of the Chemical Industry "Usage of stationary

gas warning systems for explosion protection".

X

Verify that the explosion protection requirements are met when using the gas warning

system.

X

Depending on the situation, it must be verified that the preset values are low enough to

allow the system to activate the necessary protection and emergency measures and,

thus, to prevent any critical situations in a minimum period of time.

X

When at system installation, a release of one or both measuring components in the

ambient air might occur, its influence on the measuring result should be proved. A sealed

cell or an external housing purging with sample-free air of measuring gases can be used,

if required.

X

The operability of the alarms and the displays of each system should be tested with clean

air and test gas after the initial operation, after each long-time interruption, and

periodically. The tightness of gas pathes should also be tested. The tests must be

documented by keeping accounts.

S - 10

ETC00781(4) Series 100 e 02/2004

Page 13

SAFETY SUMMARY

OPERATING CONDITIONS ACCORDING TO DMT APPROVAL

X The intervals for the periodical tests must be settled by the person being responsible for

the system´s security and in accordance with the Code of Pratice No. T023 of the Labor

Association of the Chemical Industry "Maintenance of stationary gas warning systems for

explosion protection".

X

Consider the superproportional dependency of the barometric pressure on the

measured value for CO2.

X

The system control with serial interfaces described in this operation manual have not

been subject to this investigation.

X

Sample gas condensation in analyzer (components) must be prevented by taking the

necessary steps.

X

When the system is used with aggressive gases, it is to be verified that there are no gas

components which might damage the gas path components.

X

Appropriate dust filters must precede the used systems.

X

The pressure and flow values recommended by the manufacturer should be observed.

An external monitoring of the sample gas flow through the analyzer should be provided.

X

The results of this investigation are based on the systems using software versions “3.03”,

“4.00”, “4.01” and “4.11”. A change of the software version used must be certified by the

Testing Association.

X

It should be ensured that the system parameters for the analog output have been correctly

adjusted. End of range of low concentration should not be identical or lower than the begin

of range. Disregarding these versions, the measurement range should be adjusted

between 0 to 80 % CH4, 0 to 80 % CO2, 0 to 10 % CO or 0 to 10 % O2 resp. when the systems

are used for explosion protection.

X

Read and follow the operation and maintenance manual supplied to and certified by PFG.

It is important that the temperature is kept between 5 and 45 °C.

ETC00781(4) Series 100 e 02/2004

S - 11

Page 14

SAFETY SUMMARY

OPERATING CONDITIONS ACCORDING TO DMT APPROVAL

X

The analyzer housings must be provided with a permanent type plate indicating the name

of the manufacturer, model number, serial number, and the following reference and date

of testing:

"IBS/PFG-Nr. 41300392" (for CH4, CO2 or CO)

"IBS/PFG-Nr. 41300292" (for O2)

Other designation requirements, such as these according to ElexV, are still valid. With

this type plate, the manufacturer conformes that the features and technical data of the

delivered system are identical with those described in this report. Any system which is not

provided with such a type plate does not go conform with this report.

X

The chapter 6 of this report must be included in the operation and maintenance manual.

X

The manufacturer has to supply the customer with a copy of this report, if required.

X

A print of the report in an abridged version requires the agreement of PFG.

X

The results included in this report may not be altered in publications produced by the

manufacturer.

S - 12

ETC00781(4) Series 100 e 02/2004

Page 15

SAFETY SUMMARY

OPERATING CONDITIONS ACCORDING TO DMT APPROVAL

ETC00781(4) Series 100 e 02/2004

S - 13

Page 16

SAFETY SUMMARY

S - 14

ETC00781(4) Series 100 e 02/2004

Page 17

PREFACE

PREFACE

General Overview

The series 100 of analyzers offers multi-component, multi-method analysis. Different measurement methods can be combined in one analyzer. The following measuring methods of the

individual measuring channels are possible:

IR = non-dispersive infrared measurement

PO2= paramagnetic oxygen measurement

EO2= electrochemical oxygen measurement

TC = thermal conductivity measurement

All analyzers are designed to measure 1 or 2 gas components except of HYDROS® 100 and

OXYNOS® 100 in case of PO2 measurement (both 1 channel only).

a) Software Versions

Different software versions and analyzer options are available:

BINOS® 100 (M), OXYNOS® 100, HYDROS® 100 (1/4 19" housing, external power supply):

Version 4.11 with optional RS 232/485 Interface (according to DMT Approval)

Version 5.10 with optional RS 232/485 Interface

BINOS® 100 2M (1/2 19" housing, internal power supply):

Version 4.11 with optional RS 232/485 Interface (according to DMT Approval)

Version 5.10 with optional RS 232/485 Interface

*)

BINOS® 100 2M (1/2 19" housing, external power supply):

Version 4.11 with optional RS 232/485 Interface (according to DMT Approval)

Version 5.10 with optional RS 232/485 Interface*) and/or with optional 7 digital inputs

Version 5.11 with optional 7 digital inputs and FOUNDATION™ Fieldbus

**)

BINOS® 100 F (field housing, internal power supply):

Version 4.11 with optional RS 232/485 Interface (according to DMT Approval)

Version 5.10 with optional RS 232/485 Interface*) and/or with optional 7 digital inputs

Version 5.11 with optional 7 digital inputs and optional FOUNDATION™ Fieldbus

*)

not in combination with FOUNDATION™ Fieldbus

**)

not in combination with RS 232/485 interface

ETC00781(4) Series 100 e 02/2004

**)

P - 1

Page 18

PREFACE

b) Housing Versions

Different housing versions are delivered (for detailed informations see price list):

BINOS® 100 = 1/4 19" housing, ext. PS one or two IR channel

BINOS® 100 M = 1/4 19" housing, ext. PS, one IR channel and one EO2 channel

BINOS® 100 2M = 1/2 19" housing, one or two IR channel(s) or

internal or external PS, one IR channel and one EO2 channel or

one IR channel and one PO2 channel or

one IR channel and one TC channel or

one PO2 channel and one TC channel or

one EO2 channel and one TC channel or

one ot two PO2 channels

one ot two EO2 channels

one or two TC channels

with standard options: one internal sample gas pump

one internal solenoid valve block

one integrated fine dust filter

one integrated flow indicator

BINOS® 100 F = field housing, int. PS, measuring channels see BINOS® 100 2M

with standard options: see BINOS® 100 2M (dust filter for GP only)

HYDROS® 100 = 1/4 19" housing, ext. PS, one TC channel

OXYNOS® 100 = 1/4 19" housing, ext. PS, one or two EO2 channel or

one PO2 channel

P - 2

ETC00781(4) Series 100 e 02/2004

Page 19

PREFACE

Area Classification

a) General Purpose

All analyzer components are installed into a 1/4 19" housing (BINOS® 100 (M), OXYNOS® 100,

HYDROS® 100) or a 1/2 19" enclosure (BINOS® 100 2M), 3 height units. These housings are go

conform to DIN-standard protection class IP 20. The housings are available as rack-mountable

or as table-top versions. The table-top housings are fitted with an additional carrying handle and

additional rubber feets.

Additionally we can deliver a field housing version (BINOS® 100 F). All componets are installed

into a protection housing conforming to DIN-standard protection class IP 65 (approx. NEMA 4/4X).

This enclosure is designed for wall mounting.

b) Hazardous Areas

For installation in hazardous areas special versions of BINOS® 100 F are avaliable with

adapted options and specifications. These versions are not subject of this manual (except the

variation with Z-purge). For all other analyzer versions intended to be used in hazardous areas

pls. refer to the separate manuals.

Ex Zone 2

The BINOS® 100 F is equipped with

- Pressurization system for ATEX EX Zone 2 Applications

- Z purge for CSA-C/US EX Zone 2 Non-Flammable Atmospheres

Ex Zone 1

The BINOS® 100 F is equipped with

- Pressurization system for ATEX EX Zone 1 Applications

ETC00781(4) Series 100 e 02/2004

P - 3

Page 20

PREFACE

P - 4

ETC00781(4) Series 100 e 02/2004

Page 21

CONTENTS

Table of Contents

SAFETY SUMMARY S - 1

I. Intended Use Statement S - 1

II. Safety Symbols S - 1

III. General S - 2

V. Supply Voltage S - 4

VI. Analyzer specific notes for the user S - 6

VII. BINOS® 100 F specific notes for use in hazardous areas (EX Zones) S - 7

VII.a Z purge for CSA-C/US Ex Zone 2 Non-Flammable Atmospheres S - 7

VIII. Additional notes for service / maintenance S - 8

VIIIa Electrostatic Discharge S - 9

IX. Operating Conditions according to DMT Approval S - 10

PREFACE P - 1

General Overview P - 1

a) Software Versions P - 1

b) Housing Versions P - 2

Area Classification P - 3

a) General Purpose P - 3

b) Hazardous Areas P - 3

Ex Zone 2 P - 3

Ex Zone 1 P - 3

1. TECHNICAL DESCRIPTION 1 - 1

1.1 Front Panel 1 - 1

1.2 Rear Panel 1 - 5

1.3 Internal Construction 1 - 11

1.3.1 Internal Gas Paths 1 - 25

a) Gas Path Material 1 - 25

b) Gas Path Layout (internal tubing) 1 - 26

ETC00781(4) Series 100 e 02/2004

I

Page 22

CONTENTS

2. MEASURING PRINCIPLE 2 - 1

2.1 IR Measurement 2 - 1

2.1.1 Interference Filter Correlation (IFC Principle) 2 - 1

2.1.2 Opto-Pneumatic Measuring Principle 2 - 3

2.1.3 Technique 2 - 5

2.2 Oxygen Measurement 2 - 6

2.2.1 Paramagnetic Measurement 2 - 6

2.2.2 Electrochemical Measurement 2 - 8

2.3 Thermal Conductivity Measurement 2 - 10

2.3.1 Sensor Design 2 - 10

2.3.2 Analysis Cell 2 - 10

2.3.3 Measurement Method 2 - 11

3. PHOTOMETER ASSEMBLY 3 - 1

3.1 Photometer with Pyroelectrical Detector (Solid-state detector) 3 - 1

3.2 Photometer with Gas Detector 3 - 4

5. PREPARATION OF START-UP 5 - 1

5.1 Installation Site 5 - 2

5.2 Gas Conditioning (Sample Handling) 5 - 3

5.2.1 Fine Dust Filter (Option BINOS® 100 2M/F) 5 - 4

5.2.2 Gas Sampling Pump (Option BINOS® 100 2M/F) 5 - 4

5.2.3 Pressure Sensor (Option) 5 - 4

5.2.4 Gas Flow 5 - 4

5.3 Gas Connections 5 - 5

5.3.1 Standard 5 - 5

5.3.2 Internal Solenoid Valves (Option BINOS® 100 2M/F) 5 - 8

5.3.3 Purge gas connection of BINOS® 100 F for Ex zones 5 - 10

5.4 Additional Hints to BINOS® 100 F (Field Housing) 5 - 11

5.4.1 Wall Mounting 5 - 12

5.4.2 Electrical Connections 5 - 13

II

ETC00781(4) Series 100 e 02/2004

Page 23

CONTENTS

6. SWITCHING ON 6 - 1

6.1 General 6 - 1

6.2 24 V DC Supply 6 - 2

6.3 230/120 V AC Supply 6 - 2

6.3.1 BINOS® 100 2M 6 - 4

6.3.2 BINOS® 100 F 6 - 5

7. KEY FUNCTIONS 7 - 1

7.1 FUNCTION 7 - 2

7.2 ENTER 7 - 4

7.3 INPUT - CONTROL 7 - 6

7.4 PUMP (BINOS® 100 2M/F only) 7 - 7

8. SETTING SYSTEM PARAMETERS 8 - 1

8.1 Pressure Correction 8 - 2

8.2 Cross Compensation (internal) 8 - 2

8.3 Cross Compensation Calibration (internal) 8 - 3

8.4 Hold 8 - 4

8.5 Automatic Calibration 8 - 4

8.6 Tolerance Check 8 - 5

8.7 Display Off 8 - 6

8.8 Analog Signal Outputs 8 - 7

8.9 Flushing Period 8 - 8

8.10 User Code 8 - 8

8.11 Response Time (t90) 8 - 9

8.12 Offset (Begin of range) 8 - 10

8.13 End of Range Value 8 - 11

8.14 Reset 8 - 12

8.15 Program Version 8 - 13

8.16 Serial - No. 8 - 13

8.17 Pump *) 8 - 14

8.18 Pump Control *) 8 - 14

ETC00781(4) Series 100 e 02/2004

III

Page 24

CONTENTS

9. CALIBRATION 9 - 1

9.1 Manual Calibration 9 - 2

9.1.1 Zeroing 9 - 2

9.1.2 Spanning 9 - 4

9.2 Time-Controlled Calibration Mode (Option) 9 - 7

9.2.1 Zeroing 9 - 7

9.2.2 Combined Zeroing and Spanning 9 - 9

9.3 Remote-Controlled Calibration Mode (Option) 9 - 10

10. MEASUREMENT / SWITCHING OFF 10 - 1

10.1 Measurement 10 - 1

10.2 Switching Off 10 - 1

11. DIGITAL OUTPUTS 11 - 1

11.1 Concentration Limits 11 - 2

11.2 Valve Control 11 - 4

11.3 Status Signals (Option non-voltage-carrying relay contacts) 11 - 4

12. SERIAL INTERFACE (OPTION) 12 - 1

12.1 Upgrading Serial Interface / Status Signals 12 - 1

12.2 General 12 - 2

12.3 Start Up 12 - 4

12.3.1 RS 232 C 12 - 4

12.3.2 RS 485 12 - 5

12.3.3 Switching ON/OFF Interface Operation 12 - 6

12.3.4 Setting Interface Parameters 12 - 6

12.4 Telegram Syntax 12 - 8

12.4.1 Start Character ( “$” = Hex 24) 12 - 8

12.4.2 Terminate Character ( “CR” = Hex OD) 12 - 8

12.4.3 Instruction Code 12 - 8

12.4.4 Hyphen Character ( “;” = Hex 3B) 12 - 8

12.4.5 Status Telegram 12 - 9

12.4.6 Numerical Representations 12 - 10

12.4.7 Block Parity Check 12 - 10

12.5 Instruction Syntax 12 - 11

12.5.1 Instruction Listing 12 - 12

12.5.2 Response Telegrams 12 - 13

IV

ETC00781(4) Series 100 e 02/2004

Page 25

CONTENTS

13. DIGITAL INPUTS / FOUNDATION™ FIELDBUS

(BINOS® 100 2M/F OPTION ONLY) 13 - 1

13.1 Digital Inputs 13 - 1

13.1.1 General 13 - 1

13.1.2 Start of Calibration 13 - 1

13.1.3 Valve Control 13 - 2

13.1.4 Pump Control 13 - 2

13.2 Foundation™ Fieldbus *) 13 - 2

14. CROSS COMPENSATION / SETTING OF RESPSONSE TIME

(TC OPTION ONLY) 14 - 1

14.1 Cross Compensation 14 - 1

14.1.1 Preparing Actions 14 - 2

14.1.2 Adjustment Procedure 14 - 3

16. LIST OF FAILURES 16 - 1

17. MEASURING POINTS OF BKS AND OXS 17 - 1

17.1 Measuring points of BKS 17 - 1

17.1.1 Supply Voltage + 6 V 17 - 1

17.1.2 Reference Voltage positive 17 - 1

17.1.4 Motor Drive (for IR channel only) 17 - 2

17.1.5 Temperature Sensor 17 - 3

17.1.6 Light Barrier Signal 17 - 4

17.1.7 Analog Preamplifiering 17 - 5

17.2 Measuring points of OXS (EO2 measurement) 17 - 6

17.2.1 Sensor Signal 17 - 6

ETC00781(4) Series 100 e 02/2004

V

Page 26

CONTENTS

18. PLUG PIN ALLOCATION OF PRINTED CIRCUIT BOARDS 18 - 1

18.1 Plug Pin Allocation of BKS 18 - 1

18.1.1 IR measurement without oxygen channel 18 - 2

18.1.2 Oxygen Measurement without IR channel 18 - 2

18.1.3 IR / Oxygen Measurement combined 18 - 3

18.1.4 TC Measurement without IR channel 18 - 3

18.1.5 IR / TC Measurement combined 18 - 4

18.1.6 Oxygen / TC Measurement combined 18 - 4

18.2 Plug Pin Allocation OXS (EO2 measurement only) 18 - 5

18.3 Plug Pin Allocation WAP 100 (TC measurement only) 18 - 6

19. JUMPER ALLOCATION OF BKS 19 - 1

21. FINE DUST FILTER (OPTION) 21 - 1

22. LEAK TESTING 22 - 1

23. HOUSING 23 - 1

23.1 Cleaning of Housing Surface 23 - 1

23.2 Opening the Housing 23 - 2

23.2.1 1/4 19" Housing 23 - 2

23.2.2 BINOS® 100 2M 23 - 3

a) Housing Cover 23 - 3

b) Front Panel 23 - 4

23.2.3 BINOS® 100 F (Field Housing) 23 - 5

24. REPLACEMENT AND CLEANING OF PHOTOMETRIC

COMPONENTS 24 - 1

24.1 Taking out the Photometer Assembly 24 - 1

24.2 Light Source Replacement 24 - 2

24.3 Cleaning of Analysis Cells and Windows 24 - 3

24.3.1 Removal of Analysis Cells 24 - 3

24.3.2 Cleaning 24 - 4

24.3.3 Reinstalling the Analysis Cells 24 - 5

24.4 Chopper Replacement 24 - 6

24.5 Reinstalling of the Photometer Assembly 24 - 6

24.6 Physical Zeroing 24 - 7

24.6.1 Standard Photometer (not sealed version) 24 - 7

VI

ETC00781(4) Series 100 e 02/2004

Page 27

CONTENTS

24.6.2 Sealed Photometer (Option) 24 - 8

25. CHECKING / REPLACING AN ELECTROCHEMICAL

OXYGEN SENSOR 25 - 1

25.1 Checking the Sensor 25 - 2

25.2 Replacing the Sensor 25 - 3

25.2.1 Remove the old Sensor 25 - 3

a) Oxygen Measurement without IR - channel 25 - 3

b) IR / Oxygen Measurement combined 25 - 5

25.2.2 Removing the Sensor 25 - 6

25.2.3 Reinstalling the Sensor 25 - 6

a) Oxygen Measurement without IR - channel 25 - 6

b) Combined IR / Oxygen Measurement 25 - 6

25.2.4 Basic settings for the Oxygen Sensor 25 - 7

27. TECHNICAL DATA 27 - 1

27.1 Options 27 - 1

27.2 Housing 27 - 1

27.3 Signal Inputs / Outputs, Interfaces 27 - 2

27.4 General Specifications 27 - 3

27.5 Voltage Supply 27 - 9

27.5.1 Electrical Safety 27 - 9

27.5.2 Power Supplies [UPS 01 T / SL10 / SL5] 27 - 9

28. REPLACING THE EPROM 28 - 1

30. CABLES AND CORDS 30 - 1

30.1 24 V DC Supply Cable 30 - 1

30.2 230/120 V AC Input (BINOS® 100 2M, UPS power supply) 30 - 2

30.3 Power Supply for Wall Mounted Analyzers (BINOS® 100 F) 30 - 2

30.3 Data / Signal Lines 30 - 3

30.3.1 Sub D Sockets, 9 pin 30 - 3

30.3.2 Sub D Plugs, 9 pin 30 - 3

32. FAILURE CHECK LIST 32 - 1

a) Customer Service 32 - 4

b) Training 32 - 4

ETC00781(4) Series 100 e 02/2004

VII

Page 28

CONTENTS

VIII

ETC00781(4) Series 100 e 02/2004

Page 29

CONTENTS

ETC00781(4) Series 100 e 02/2004

IX

Page 30

CONTENTS

X

ETC00781(4) Series 100 e 02/2004

Page 31

TECHNICAL DESCRIPTION

FRONT VIEW

1. Technical Description

The different analyzers are based on the same internal main components and differ only by

available options and enclosures.

BINOS® 100 (M), OXYNOS® 100, HYDROS® 100 (1/4 19" enclosures)

BINOS® 100 2M (1/2 19" enclosure )

All analyzer components are installed into enclosure, 3 height units tall. These housings are

classified protection class IP 20. The housings are available as rack-mountable or as table-top

versions. The table-top housings are fitted with an additional carrying handle and additional

rubber feets.

BINOS® 100 F (field housing, wall mountable)

Additional we can deliver a field housing version . All components are installed into a protective

enclosure, classified IP 65 acc. IEC 60529 (approx. NEMA 4/4X). This enclosure is designed

for wall mounting. An magnetically operated impact tested front panel is available as an option.

Special versions are available for installation in hazardous areas, which meet the

requirements of either ATEX (Europe), CENELEC (outside Europe) or North America

(CSA-C/US; Z-purge).

The special conditions for operating ATEX analyzers are described in a supplemental manual.

1.1 Front Panel

The front panel includes the LED displays for both analysis channels and all of the analyzer

operating controls.

The BINOS® 100 2M and BINOS® 100 F front panels show status LEDs for the options

“Solenoid Valves” and “Gas Sampling Pump” and include a key “PUMP” *) to switch on and off

the gas sampling pump.

The front panels of BINOS® 100 2M and BINOS® 100 F may be equipped with an optional fine

dust filter with integrated needle valve or/and a flow meter (for general purpose applications

only).

These options are not available if BINOS® 100 F is intended to be used in hazardous areas (EX

Zones) or if IP 65 is required.

ETC00781(4) Series 100 e 02/2004

1 - 1

Page 32

TECHNICAL DESCRIPTION

FRONT VIEW

1

11

12

250 ppm

CO

% O

para. oxygen sensor

% O

2

FUNCTION ENTER INPUT - CONTROL

2

chem.

% O

chem. oxygen sensor

7

paramagnetic

2

electrochemical

2

4

65

1 - 2

Fig. 1-1: BINOS® 100 (M), OXYNOS® 100, HYDROS® 100 Front view

1 LED display (channel 1)

2 LED display (channel 2)

4 Input setting control key DOWN

5 Input setting control key UP

6 Key ENTER

7 Key FUNCTION

11 Fastening screws for the carrying-strap bracket

or rack-mounting purposes

12 Housing cover fastening screw

ETC00781(4) Series 100 e 02/2004

Page 33

TECHNICAL DESCRIPTION

FRONT VIEW

Needle valve (option)

³

12

% O

2

1000

ppm

45678391011

Fig. 1-2: BINOS® 100 2M (standard version), front view

1 LED display (channel 1)

2 LED display (channel 2)

3 Function LED for options "Solenoid Valves / Gas Sampling Pump"

4 Input setting control key DOWN

5 Input setting control key UP

6 ENTER key

7 FUNCTION key

8 Key for option “Gas Sampling Pump”

9 Flow indicator (option)

10 Fine dust view filter with needle valve (option)

11 Fastening screws for the carrying strap bracket

or rack-mounting purposes

ETC00781(4) Series 100 e 02/2004

1 - 3

Page 34

TECHNICAL DESCRIPTION

FRONT VIEW

Wall mounting

holder

Fastener

front panel

Fig. 1-2 for

General Purpose

Operation front panel

Fig. 1-4 for

hazardous areas

(ex zones)

Fig. 1-3: BINOS® 100 F, front view

Front panel

1 - 4

Fig. 1-4: BINOS® 100 F magnetically operated front panel , impact tested, front view

ETC00781(4) Series 100 e 02/2004

Page 35

1.2 Rear Panel

The rear panels include

R the gas line fittings

R the plug for the electrical supply input

R the subminiature “D” mating socket for the analog signal outputs

TECHNICAL DESCRIPTION

REAR PANEL

R the subminiature “D” plug for the digital outputs (concentration limits / valve control)

R optionally the subminiature “D” mating plug for analog signal inputs

(interference cross compensation, TC only)

R optionally the subminiature “D” mating socket for the RS 232 C / RS 485 interface

R optionally the subminiature “D” mating plug for the status signals (relay outputs)

For BINOS® 100 2M/F only:

R optionally the solenoid valve block

R optionally the terminal strips for the 7 digital inputs

R optionally the terminal strips for the FOUNDATION™ Fieldbus

**)

**) ***)

*)

*)

not in combination with FOUNDATION™ Fieldbus

**)

BINOS® 100 2M with external power supply only

***)

not in combination with RS 232/485 interface

ETC00781(4) Series 100 e 02/2004

1 - 5

Page 36

TECHNICAL DESCRIPTION

REAR PANEL

K1 K2 K1 K2

1

IN

OUT

CROSS COMP.

6

5

8

X1 OUTPUT

7

INTERFACE

24 V

max. W

X2 OUTPUT

3

12+ 1

X3 OUTPUT

2

MADE I N GERMANY

9

4

1 - 6

3

Fig. 1-5: BINOS® 100 (M), OXYNOS® 100 (EO2), HYDROS® 100, Rear view

1 Gas inlet line fittings

2 Analog signal output mating socket

3 24 VDC supply input terminal

4 Plug for Digital signal output

5 Gas outlet line fittings

6 Housing cover fastening screws

7 mating socket Serial Interface [RS 232 C / 485] (Option)

8 Plug for Output Relays (Option)

9 Plug for analog signal inputs

(interference cross compensation, HYDROS® 100 only)

ETC00781(4) Series 100 e 02/2004

Page 37

TECHNICAL DESCRIPTION

REAR PANEL

X2 OUTPUT

7

INTERFACE

X1 OUTPUT

6

IN

1

2

8

3

24 V

max. 40 W

3

12+1

OUT

5

4

X3 OUTPUT

MADE I N GERMANY

ETC00781(4) Series 100 e 02/2004

Fig. 1-6: OXYNOS® 100 (PO2), Rear view

1 Gas inlet line fittings

2 Analog signal output mating socket

3 24 VDC supply input terminal

4 Plug for Digital signal output

5 Gas outlet line fittings

6 Housing cover fastening screws

7 mating socket Serial Interface [RS 232 C / 485] (Option)

8 Plug for Output Relays (Option)

1 - 7

Page 38

TECHNICAL DESCRIPTION

REAR PANEL

12 34 56789

17

FLOW

10

11

Fig. 1-7: BINOS

15

®

100 2M, version A (shown with internal power supply), Rear view with all options

12131416

1 Gas inlet line fitting

22

nd

gas inlet line fitting (option)

3 Gas outlet line fitting

42

nd

gas outlet line fitting (option)

5 Plug for analog signal inputs

(interference cross compensation, TC only)

6 “Solenoid valves”: common gas outlet line fitting

7 “Solenoid valves”: Test gas inlet 1

8 “Solenoid valves”: Test gas inlet 2

9 24 VDC output (max. 2 A, see technical data)

10 Power supply [UPS 01 T (Universal Power Supply)]

11 Plug Power Supply (Mains line)

12 “Solenoid valves”: Zero gas inlet

13 “Solenoid valves”: Sample gas inlet

14 Plug Digital Outputs (threshold contacts)

15 Mating socket Serial Interface [RS 232 C / 485] (option)

16 Mating socket Analog Signal Outputs

17 Plug Output Relays (status signal option)

1 - 8

ETC00781(4) Series 100 e 02/2004

Page 39

TECHNICAL DESCRIPTION

REAR PANEL

1234 5

K1 K2 K1 K2

IN OUT

X1 OUTPUT

FLOW

IN/OUT

X2 OUTPUT X3 OUTPUT

DURCHFLUSS

MAX. 1 L/ MIN

87

ANALOG I N

SPAN 1

SPAN 2

SAMPLE

ZERO

1

3

OUT

2

24V

max.120W

9

DIGI TAL IN

V+

V-

E1

E2

E3

E4

E5

E6

E7

FB+

FBFB+

FB-

16 15 17 14 13 12

Fig. 1-8: BINOS

®

100 2M, version B (with external power supply), Rear view with all options

6

1 Gas inlet line fitting

22

nd

gas inlet line fitting (option)

3 Gas outlet line fitting

42

nd

gas outlet line fitting (option)

5 Plug for analog signal inputs

(interference cross compensation, TC only)

6 “Solenoid valves”: common gas outlet line fitting

7 “Solenoid valves”: Test gas inlet 1

8 “Solenoid valves”: Test gas inlet 2

9 Terminal strips for the 7 Digital Inputs (option)

10 Terminal strips for FOUNDATION™ Fieldbus (option)

11 24 V DC supply input terminal

12 “Solenoid valves”: Zero gas inlet

13 “Solenoid valves”: Sample gas inlet

14 Plug Digital Outputs (threshold contacts)

15 Mating socket Serial Interface

16 Mating socket Analog Signal Outputs

17 Plug Output Relays (status signal option)

*)

**)

[RS 232 C / 485] (option)

1011

ETC00781(4) Series 100 e 02/2004

*)

only possible if serial interface RS 232/485 is not request !

**)

only possible if FOUNDATION™ Fieldbus is not request !

1 - 9

Page 40

TECHNICAL DESCRIPTION

REAR PANEL

1234 5

OUTIN

X1 OUTPUT

IN/OUT

X4

X2 OUTPUT

!

FLOW

DURCHFLUSS

MAX.1L/MIN

X3 OUTPUT

87

K2K1K2K1

ANALOG IN

SPAN 1

SPAN 2

SAMPLE

ZERO

OUT

24V

120W

1

8

7

!

SPAN 1

SPAN 2

OUT

2

3

SAMPLE

ZERO

16

Fig. 1-9: BINOS

15

14 13

17

®

100 2M (special version), Rear view with all options

6

12

11 12

1 Gas inlet line fitting channel 1

2 Gas inlet line fitting channel 2

3 Gas outlet line fitting channel 1

4 Gas outlet line fitting channel 2

5 Plug for analog signal inputs

(interference cross compensation, TC only)

6 “Solenoid valves”: common gas outlet line fitting

7 “Solenoid valves”: Test gas inlet 1

8 “Solenoid valves”: Test gas inlet 2

9 (open)

10 (open)

11 24 V DC supply input terminal

12 “Solenoid valves”: Zero gas inlet

13 “Solenoid valves”: Sample gas inlet

14 Plug Digital Outputs (threshold contacts)

15 Mating socket Serial Interface [RS 232 C / 485] (option)

16 Mating socket Analog Signal Outputs

17 Plug Output Relays (status signal option)

13

1 - 10

ETC00781(4) Series 100 e 02/2004

Page 41

1.3 Internal Construction

The analyzers includes the following components:

R Depending on analyzer configuration

- one or two IR photometer benches

- one IR photometer and one EO2 sensor

- one IR photometer and one PO2 sensor

- one IR photometer and one TC sensor

- one PO2 sensor and one TC sensor

- one EO2 sensor and one TC sensor

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

- one or two PO2 sensors

- one ot two EO2 sensors

- one or two TC sensors

R Optionally one pressure sensor (range of 800 to 1,100 hPa).

The concentration values computed by the analyzer will then be corrected to reflect the

barometric pressure to eliminate faulty measurements due to changes in barometric

pressure (see technical data).

R Optionally one gas sampling pump (BINOS® 100 2M/F only, see chapter 7.4 and 8.17).

[pumping rate maxi. 2,5 l/min. (special solution with 2 pumps with parallel gas paths)].

R BINOS® 100 2M (standard version) / BINOS® 100 F:

Integrated power supply (230/120 V AC).

R Optionally solenoid valve unit

(BINOS® 100 2M/F only, special solution with 2 valve blocks with parallel gas paths).

For this case there are built-in 4 (8) solenoid valves (Sample Gas - Zero Gas Span Gas 1- Span Gas 2) at the analyzer.

For manual or automatical adjustment the zero gas and the span gases will be fed to

the solenoid valves controlled by the analyzer.

If a solenoid valve is open there is illuminated a green LED (Fig. 1-2, Item 3) at the front

panel.

ETC00781(4) Series 100 e 02/2004

1 - 11

Page 42

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Cover metal plate

Gas line fittings

PCB BKS

(channel 2)

Front panel

IR photometer bench

(depending on analyzer

configuration)

(channel 1)

Pressure sensor

(option)

1 - 12

Fig. 1-10: Inside View BINOS® 100

(1 IR channel analyzer, high measuring range with gas detector)

ETC00781(4) Series 100 e 02/2004

Page 43

Gas line fittings

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Cover metal plate

PCB BKS

IR photometer bench

(depending on analyzer

configuration)

(channel 2)

electrochemical

oxygen sensor

with PCB “OXS”

(channel 1)

Pressure sensor

(option)

ETC00781(4) Series 100 e 02/2004

Front panel

Fig. 1-11: Inside View BINOS® 100 M

(IR channel / electrochemical oxygen measurement)

1 - 13

Page 44

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas line fittings

Security dust filter

O2 sensor

Inlet

Outlet

Heat exchanger

PCB BKS

to Sensor

from Sensor

Heat exchanger view "X" (180° rotate)

1 - 14

Front panel

Fig. 1-12: OXYNOS® 100, Inside View with paramagnetic sensor

ETC00781(4) Series 100 e 02/2004

Page 45

Gas line fittings

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

channel 2 channel 1

Security dust filter

Pressure sensor

(Option)

ETC00781(4) Series 100 e 02/2004

Front panel

Fig. 1-13: OXYNOS® 100, Inside view with electrochemical sensor

1 - 15

Page 46

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas line fittings

PCB BKS

PCB WAP 100

Out

Thermal conductivity sensor

In

1 - 16

Front panel

Fig. 1-14: HYDROS® 100, Inside view

ETC00781(4) Series 100 e 02/2004

Page 47

Solenoid valves

(Option)

Power supply option

(UPS 01)

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas line fittings

Circuit board BKS

(below physical bench)

IR photometer bench

(depending on analyzer

configuration)

Paramagnetic

oxygen sensor

(depending on analyzer

configuration)

(Channel 1)

(Channel 2)

Electrochemical

oxygen sensor

with circuit board “OXS”

(depending on analyzer

configuration)

(Channel 1)

Pressure sensor

(option)

Gas sampling pump

(option)

Fine dust filter

with integrated

needle valve for

regulation of gas

flow rate (option)

ETC00781(4) Series 100 e 02/2004

Flow indicator

(option)

Fig. 1-15: Inside View dual-channel BINOS® 100 2M (version A)

(IR channel / oxygen measurement, combined)

1 - 17

Page 48

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Solenoid valves

(Option)

Power supply option

(UPS 01)

Gas line fittings

Circuit board BKS

(Channel 1)

Electrochemical

oxygen sensor

with circuit board “OXS”

Pressure sensor

(option)

Gas sampling pump

(option)

Fine dust filter

with integrated

needle valve for

regulation of gas

flow rate (option)

1 - 18

Flow indicator

(option)

Fig. 1-16: Inside View BINOS® 100 2M (version A)

(1 channel oxygen measurement, electrochemical)

ETC00781(4) Series 100 e 02/2004

Page 49

Solenoid valves

(Option)

Power supply option

(UPS 01)

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas line fittings

Circuit board BKS

(below physical bench)

IR photometer bench

(depending on analyzer

configuration)

PCB WAP 100

Thermal conductivity

sensor

(depending on analyzer

configuration)

Electrochemical

oxygen sensor

with circuit board “OXS”

(depending on analyzer

configuration)

Gas sampling pump

(option)

Fine dust filter

with integrated

needle valve for

regulation of gas

flow rate (option)

ETC00781(4) Series 100 e 02/2004

Flow indicator

(option)

Fig. 1-17: Inside View dual-channel BINOS® 100 2M (version A)

(IR / EO2 , TC / EO2 or IR / TC measurement, combined)

1 - 19

Page 50

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Solenoid valves

(Option)

Power supply option

(UPS 01)

Gas line fittings

Circuit board BKS

PCB WAP 100

Paramagnetic

oxygens sensor

Thermal conductivity

sensor

Gas sampling pump

(option)

Fine dust filter

with integrated

needle valve for

regulation of gas

flow rate (option)

(oxygen measurement (paramagnetic) / thermal conductivity measurement, combined)

1 - 20

Flow indicator

(option)

Fig. 1-18: Inside View dual-channel BINOS® 100 2M (version A)

ETC00781(4) Series 100 e 02/2004

Page 51

Solenoid valves

(Option)

Digital inputs and

FOUNDATION™

Fieldbus

(options)

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Gas line fittings

Circuit board BKS

(below physical bench)

IR photometer bench

(depending on analyzer

configuration)

PCB`s WAP 100 and

HEX 01

(intrinsically safe TC

measurement for

potentially explosive

atmosphere,

consult factory)

Thermal conductivity

sensor

(depending on analyzer

configuration)

(Channel 1)

(Channel 2)

Electrochemical

oxygen sensor

with circuit board “OXS”

(depending on analyzer

configuration)

(Channel 1)

Gas sampling pump

(option)

ETC00781(4) Series 100 e 02/2004

Fig. 1-19: Inside View dual-channel BINOS® 100 2M (version B)

(IR channel / oxygen measurement, combined)

1 - 21

Page 52

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Solenoid valves

(Option)

Digital inputs and

FOUNDATION™

Fieldbus

(options)

Gas line fittings

Circuit board BKS

PCB`s WAP 100 and

HEX 01

(intrinsically safe

measurement for

potentially explosive

atmosphere,

consult factory)

Paramagnetic

oxygen sensor

Thermal conductivity

sensor

Gas sampling pump

(option)

1 - 22

Fig. 1-20: Inside view dual-channel BINOS® 100 2M w. external P/S (here: version for CAT)

(parmagnetic oxygen measurement & thermal conductivity measurement)

ETC00781(4) Series 100 e 02/2004

Page 53

Gas line fittings

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Solenoid valves

channel 2

(option)

Solenoid valves

channel 1

(option)

Gas sampling pump

channel 2 (option)

***

*

IR photometer benches

(depending on analyzer

configuration)

Fig. 1-21: Inside View dual-channel BINOS® 100 2M (special version)

ETC00781(4) Series 100 e 02/2004

Gas sampling pump

channel 1

(option)

(two gas sampling pumps and two solenoid valve blocks)

1 - 23

Page 54

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

Terminal strips

for output / input signals

Power Input Fuses

DC 24 V distribution

Photometer / sensor assembly

is dependening on

analyzer configuration

Power supply

Fig. 1-22: Inside View BINOS® 100 F (field housing)

1 - 24

ETC00781(4) Series 100 e 02/2004

Page 55

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

1.3.1 Internal Gas Paths

The materials used for the gas paths are selected according to the application. In marking such

selection the diffusion rates of the individual gas components, their corrosivity, and the temperature and pressure of the sampled gas must be taken into account.

a) Gas Path Material

The physical and chemical properties of the sampled gas and the operating conditions

(temperature and pressure) of the analyzer determine the materials which are used for gas paths

and gas fittings.

Safety Dust Filter

All analyzers are equipped with a PTFE safety dust filter. This filter is no substitute for the necessary

dust filter to be provided with sample handling systems (described in chapter 5.2).

Fittings

As standard the analyzers are provided with PVDF fittings, 6/4 mm. The analyzers can be delivered

with swagelok® fittings, stainless steel, 6/4 mm or 1/4" as option.

Additional fittings are delivered as special options.

Tubing

As standard the analyzers are provided with Viton tubings or PTFE tubings (6/4 mm).

Additional tubings (e.g. stainless steel) are delivered as special options.

ETC00781(4) Series 100 e 02/2004

1 - 25

Page 56

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

b) Gas Path Layout (internal tubing)

The principle various possible layouts of the internal gas lines are summarized in the following

figures.

Analyzer

Gas outlet

(OUT K1)

Gas inlet

(IN K1)

Fig. 1-23: Tubing in series (BINOS® 100 (M), OXYNOS® 100, HYDROS® 100 analyzers)

Gas outlet

Analyzer

Gas inlet

(IN K1)

Gas inlet

(IN K2)

(OUT K1)

Gas outlet

(OUT K2)

1 - 26

Fig. 1-24 Tubing in parallel (BINOS® 100 (M), OXYNOS® 100, HYDROS® 100 analyzers)

ETC00781(4) Series 100 e 02/2004

Page 57

TECHNICAL DESCRIPTION

INTERNAL CONSTRUCTION

span gas 1

(SPAN 1 / V1)

span gas 2

(SPAN 2 / V2)

sample gas

(SAMPLE / V3)

zero gas

(ZERO / V4)

Gas outlet

(OUT)

Analyzer

solenoid valves

(Option)

sample gas pump

(Option)

Gas inlet

(IN K1)

Flow indicator,

Filter and throttle

(Options)

*)

*)

not for BINOS® 100 F in hazardous areas

Fig. 1-25: Tubing in series (BINOS® 100 2M analyzers)

(equipped with all options)

Gas outlet

(OUT K1)

span gas 1

(SPAN 1 / V1)

not used

not used

span gas 2

(SPAN 2 / V2)

sample gas

sample gas pump

sample gas

zero gas

(Option)

zero gas

(ZERO / V4)

(ZERO / V4)

(SAMPLE / V3)

(SAMPLE / V3)

(OUT)

Gas outlet

(OUT)

Gas outlet

(IN K1)

Gas inlet

(IN K2)

Gas inlet

Gas outlet

(OUT K1)

Flow indicator

Gas outlet

(OUT K2)

Fig. 1-26: Tubing in parallel (special version of BINOS® 100 2M analyzer)

ETC00781(4) Series 100 e 02/2004

(equipped with all options)

1 - 27

Page 58

TECHNICAL DESCRIPTION

1 - 28

ETC00781(4) Series 100 e 02/2004

Page 59

MEASURING PRINCIPLE

IR MEASUREMENT

2. Measuring Principle

Depending on the gas to be analyzed different measuring methods will be used.

2.1 IR Measurement

The analyzers are non-dispersive infrared photometers (NDIR) using measurement of selective

absorption in a column of gas.

The measuring effect derived from absorption of infrared radiation is due to the gas being

measured. The gas specific wavelengths of the absorption bands characterize the type of gas

while the strength of the absorption gives a measure of the concentration of the component

measured. Due to a rotation chopper wheel, the radiation intensities coming from measuring and

reference side of the analysis cell produce periodically changing signals within the detector.

The detector signal amplitude thus alternates between concentration dependent and concentration independent values. The difference between the two is a reliable measure of the concentration

of the absorbing gas component.

Dependent on measuring component and measuring concentration, two different measuring

methods will be used.

2.1.1 Interference Filter Correlation (IFC Principle)

The undivided analysis cell is alternately illuminated with filtered light concentrated in one of two

spectral separated wave length ranges. One of these two spectrally separated wave length bands

is chosen to coincide with an absorption band of the sample gas, and the other is chosen such

that none of the gas constituents expected to be encountered in practice absorbs anywhere within

the band.

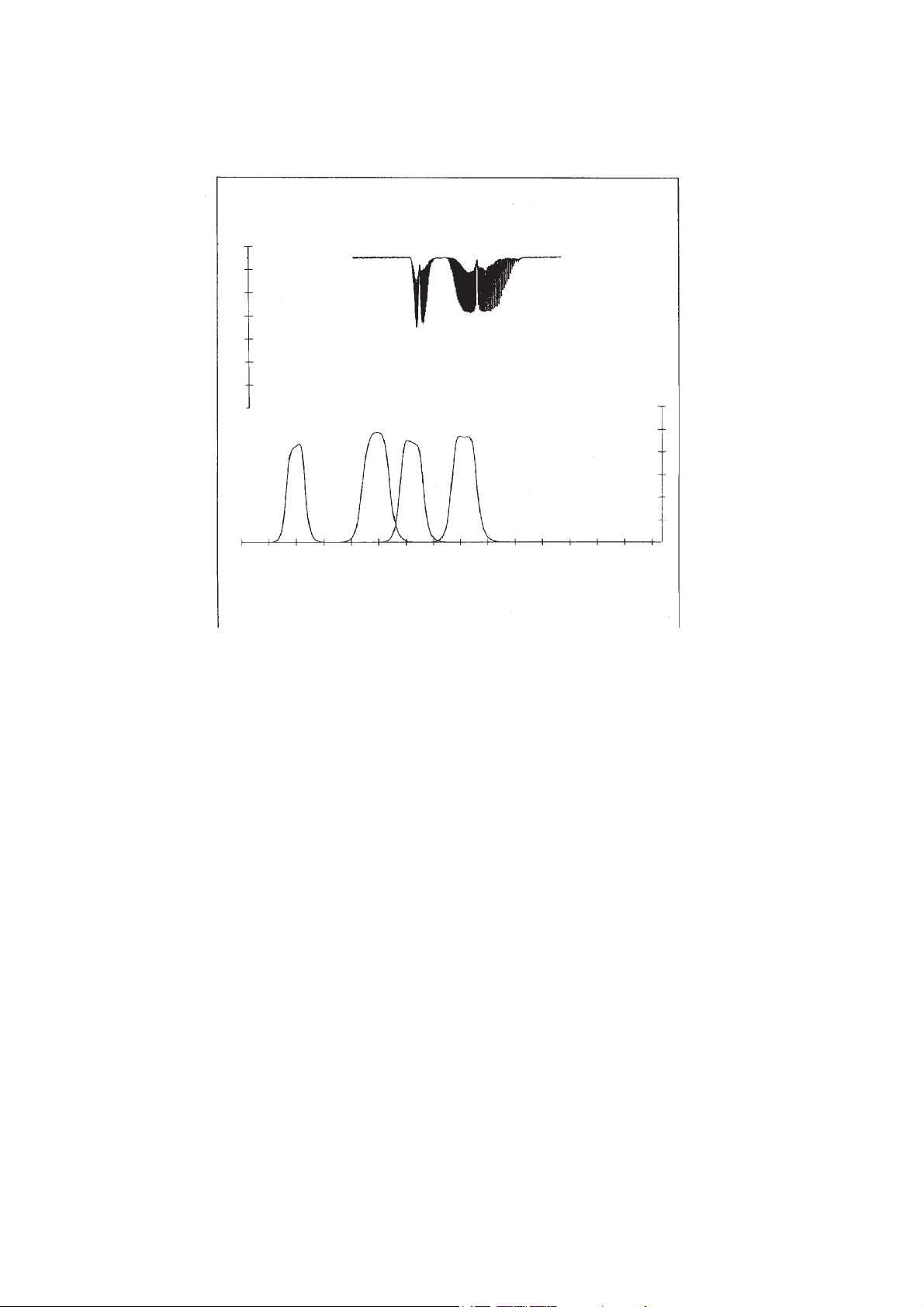

The spectral transmittance curves of the interference filters used in the 100 series analyzer and

the spectral absorption of the gases CO and CO2 are shown in Fig. 2-1. It can be seen that the

absorption bands of these gases each coincide with the passbands of one of the interference

filters. The fourth interference filter, used for generating a reference signal, has its passband in a

spectral region where none of these gases absorb. Most of the other gases of interest also do not

absorb within the passband of this reference filter.

ETC00781(1) Series 100 e 10/2001

2 - 1

Page 60

MEASURING PRINCIPLE

IR MEASUREMENT

9075604530150

Transmittance [%]

HC

Transmittance [%]

CO

2

CO

2

Reference

4400 460042004000 48003000 3200 3400 3600 3800 5000 5200 5400 5600 5800 6000

Wave Length [nm]

CO

CO

Interference -

Absorption Band

Filter

18 36 54 72 900

Fig. 2-1: Absorption Bands of Sample Gases and Transmittance of the

Interference Filters used

The signal generation happens by a pyroelectrical (solid-state) detector.

The detector records the incoming IR radiation. This radiation intensity is reduced by the

absorption of the gas at the corresponding wave lengths. By comparing the intensity at measuring

and reference wave length an alternating voltage signal is developed. This signal results from

cooling and heating of the pyroelectrical material of the detector.

2 - 2

ETC00781(1) Series 100 e 10/2001

Page 61

MEASURING PRINCIPLE

IR MEASUREMENT

2.1.2 Opto-Pneumatic Measuring Principle

A thermal radiator generates the infrared radiation passing through a chopper wheel. This

radiation alternately passes through a filter cell and reaches the measuring and reference side of

the analysis cell with equal intensity.

After passing another filter cell the radiation reaches the pneumatic detector.

The pneumatic detector compares and evaluates the radiation from the measuring and reference

sides and converts them into voltage signals proportional to their intensity via a preamplifier.

The detector consists of a gas-filled absorption and a compensation chamber which are

interconnected via a flow channel.

Absorption chamber

Flow channel with

Microflow sensor

CaF2 Window

Gas intake connection

Compensation chamber

ETC00781(1) Series 100 e 10/2001

Fig. 2-2: Principle Design of Gas Detector

2 - 3

Page 62

MEASURING PRINCIPLE

IR MEASUREMENT

In principle the detector is filled with the infrared active gas to be measured and is only sensitive

to this distinct gas with its characteristic absorption spectrum. The absorption chamber is sealed

with a window which are transparent for infrared radiation [usually CaF2 (Calcium fluoride)].

When the IR radiation passes through the reference side of the analysis cell into the detector, no

preabsorption occurs. Thus the gas inside the absorption chamber is heated, expands and some

of it passes through the flow channel into the compensation chamber.

When the IR radiation passes through the open measurement side of the analysis cell into the

detector, a part of it is absorbed depending on sample gas concentration. The gas in the absorption

chamber then is heated less than in the case of radiation coming from reference side. Absorption

chamber gas become colder, gas pressure in the absorption chamber is reduced and some gas

of compensation chamber passes through the flow channel into the absorption chamber.

The flow channel geometry is designed in such a way that it hardly impedes the gas flow by

restriction. Due to the radiation of chopper wheel, the different radiation intensities lead to

periodically repeated flow pulses within the detector.

The microflow sensor evaluates this flow and converts it into electrical voltages.

The electronics, which follow, evaluate the signals and convert them into the corresponding display

format.

2 - 4

ETC00781(1) Series 100 e 10/2001

Page 63

MEASURING PRINCIPLE

123

123

IR MEASUREMENT

2.1.3 Technique

The broadband emission from two IR sources (in the case of dual channel analyzers) passes

through the chopper blade, then, if IFC, through combinations of interference filters, if

optopneumatic principle depending on application through an optical filter (reduction of influences) and enters the analysis cells. The light transmitted through these cells is focused by filter

cells onto the according detector. The preamplified detector output signal is sent to microprocessor

circuitry, which converts the analytical signals to results expressed directly in physical concentration units (Vol.-%, ppm, mg/Nm3 etc.).

Light source

Analysis cell measuring side

Analysis cell reference side

MOTOR

Duplex filter disc

Adapter cell

(high measuring range)

Analysis cell

(undivided)

Filter cell

Preamplifier

Filter cell

Gas detector

ETC00781(1) Series 100 e 10/2001

Pyroelectrical detector

(solid-state detector)

Preamplifier

Chopper blade

Fig. 2-3: Principle Representation

2 - 5

Page 64

MEASURING PRINCIPLE

OXYGEN MEASUREMENT (PO2 PARAMAGNETIC PRINCIPLE)

2.2 Oxygen Measurement

Depending on analyzer model different measuring methods will be used.

The installed type of oxygen sensor is to identify at the channel code (see Fig. 1-1).

% O2 para. = paramagnetic Sensor

% O2 chem. = electrochemical Sensor

2.2.1 Paramagnetic Measurement

The determination of O2 concentration is based on the paramagnetic principle (magnetomechanic principle).

Two nitrogen filled (N2 is diamagnetic) quartz spheres are arranged in a "dumbbell" configuration

and suspended free to rotate on a thin platinum ribbon in a cell.

A small mirror that reflects a light beam coming from a light source to a photodetector, is mounted

on this ribbon. A strong permanent magnet especially shaped to produce a strong highly inhomogeneous magnetic field inside the analysis cell, is mounted outside the wall.

When oxygen molecules enter the cell, their paramagnetism will cause them to be drawn towards

the region of greatest magnetic field strength. The O2 molecules thus exert different forces which

produce a torque acting on the sphere arrangement, and the suspended “dumbbell”, along with

the mirror mounted on its suspension ribbon, will be angulary rotated away from the equilibrium

position.

The mirror then will deflect an incident light beam onto the photodetector which itself produces an

electric voltage. The electric signal is amplified and fed back to a conducting coil at the “dumbbell”,

forcing the suspended spheres back to the equilibrium position.

The current required to generate the restoring torque to return the “dumbbell” to its equilibrium

position is a direct measure of the O2 concentration in the gas mixture.

The complete analysis cell consists of analysis chamber, permanent magnet, processing

electronics, and a temperature sensor. The sensor itself is thermostat controlled up to approx. 55

°C. For warming up the measuring gas is conducted via a heat-exchanger.

Optionally we have built-in a solvent resistant cell or an intrinsic safe cell for potentially explosive

atmosphere.

2 - 6

ETC00781(1) Series 100 e 10/2001

Page 65

MEASURING PRINCIPLE

OXYGEN MEASUREMENT (PO2 PARAMAGNETIC PRINCIPLE)

ETC00781(1) Series 100 e 10/2001

Fig. 2-4: Principle Construction of paramagnetic Analysis Cell

1 Permanent magnet

2 Platinum wire

3 Mirror

4 Quartz spheres

5 Wire loop

6 Photodetector

7 Light source

8 Amplifier

9 Display

2 - 7

Page 66

MEASURING PRINCIPLE

OXYGEN MEASUREMENT (EO2 ELECTROCHEMICAL PRINCIPLE)

2.2.2 Electrochemical Measurement

The determination of O2 concentrations is based on the principle of a galvanic cell.

The principle structure of the oxygen sensor is shown in Fig. 2-5.

Lead wire (Anode)

Lead wire (Cathode)

Anode

O - ring (8)

Plastic disc (9)

Plastic top (10)

(1)

(Lead)

(Black)

Thermistor (5)

Acid electrolyte (3)

Sponge disc (7)

Cathode

(2)

Teflon membrane (4)

(Red)

Resistor (6)

(Gold film)

Fig. 2-5: Structure of electrochemical Oxygen Sensor

The oxygen senor incorporate a lead/gold oxygen cell with a lead anode (1) and a gold cathode

(2), using a specific acid electrolyte. To avoide moisture losses at the gold electrode a sponge sheet

is inserted on the purged side.

Oxygen molecules diffuse through a non-porous Teflon membrane (4) into the electrochemical cell

and are reduced at the gold-cathode. Water results from this reaction.

On the anode lead oxide is formed which is transferred into the electrolyte. The lead anode is

regenerated continuously and the electrode potential therefore remains unchanged for a long

time.

The rate of diffusion and so the response time (t90) of the sensor is dependent on the thickness

of the Teflon membrane.

2 - 8

ETC00781(1) Series 100 e 10/2001

Page 67

MEASURING PRINCIPLE

OXYGEN MEASUREMENT (EO2 ELECTROCHEMICAL PRINCIPLE)

(Red) (Black)

Thermistor (5)

(-)

Gold-

Cathode (2)

O2 + 4 H+ + 4 e- ¤ 2 H2O

Summary reaktion O

(11)

Electrolyte (3)

(ph 6)

+ 2 Pb ¤ 2 PbO

2

Resistor (6)

2 Pb + 2 H2O ¤ 2 PbO + 4 H+ + 4 e

Fig. 2-6: Reaction of galvanic cell

(+)

Lead-

Anode (1)

-

The electric current between the electrodes is proportional to the O2 concentration in the gas

mixture to be measured. The signals are measured as ter minal voltages of the resistor (6) and the

thermistor (5) for temperature compensation.

The change in output voltages (mV) of the senor (11) represents the oxygen concentration.

Note !

Depending on measuring principle the electrochemical O

of oxygen (residual humidity avoids drying of the cell). Supply cells continuously with dry sample gas

of low grade oxygen concentration or with oxygen-free sample gas could result a reversible detuning

sensitivity. The output signal will become instabil.

of O

2

For correct measurement the cells have to be supplied with O

We recommend to use the cells in intervall measurement (purge cells with conditioned (dust removal

but no drying) ambient air during measurement breaks).

If it is necessary to interrupt oxygen supply for several hours or days, the cell has to regenerate (supply

cell for about one day with ambient air). Temporary flushing with nitrogen (N2) for less than 1 h (e.g.

analyzer zeroing) will have no influence to measuring value.

cell needs a minimum internal consumption

2

concentrations of at least 0.1 Vol.-%.

2

ETC00781(1) Series 100 e 10/2001

2 - 9

Page 68

MEASURING PRINCIPLE

THERMAL CONDUCTIVITY (TC) MEASUREMENT

2.3 Thermal Conductivity Measurement

To measure gases like Hydrogen (H2), Argon (Ar) or Helium (He), the measurement method of

thermal conductivity (TC) will be used.

2.3.1 Sensor Design

The sensor consists of four small PT 100 resistors arranged in a Wheatstone Bridge which is

mounted into a block made of either aluminum, stainless steel or hastelloy, depending on the

application (e.g. stainless steel / hastelloy for corrosive gases). The block is thermostatted to

supress influence of external temperature change.

Fig. 2-7: Thermal conductivity sensor

2.3.2 Analysis Cell

Both the volume of the block and the mass of the resistors have been minimized on order

to obtain short response time.

The block contains two gas paths for sample and reference gas, whereat the reference gas

path is closed for standard applications. Always two sensors are located in the sample and

the reference gas path. The resistors are full glass packaged to withstand agressive gases.

The material in contact with the gases are glass, Gold, Aluminum, stainless steel and

Hastelloy, so a high resistance against corrosion by agressive gases is provided by this

cell.

2 - 10

ETC00781(1) Series 100 e 10/2001

Page 69

MEASURING PRINCIPLE

THERMAL CONDUCTIVITY (TC) MEASUREMENT

2.3.3 Measurement Method

The entire measurement cell is thermostatted to a temperature of up to 75 °C. The four sensors

are electrically heated to a higher temperature and the signal of the Wheatstone Bridge is

monitored. Depending on the thermal conductivity of the gases that pass the cell, the

temperature of the sensors in contact with the gas changes and thus their electrical resistance.

This changes the output signal of the Wheatstone Bridge and electronic circuitry processes this

signal to obtain standardized signal amplitudes, and transmits these to both an indicator

instrument and to the signal output connector.

ETC00781(1) Series 100 e 10/2001

2 - 11

Page 70

MEASURING PRINCIPLE

THERMAL CONDUCTIVITY (TC) MEASUREMENT

2 - 12

ETC00781(1) Series 100 e 10/2001

Page 71

PHOTOMETER ASSEMBLY

PYROELECTRICAL DETECTOR

3. Photometer Assembly

Depending on gas component and measuring range, different photometer assemblies will be

realized in 100 series.

Optional the photometer can be sealed to ambient air. In this case all par ts are sealed with O- rings.

The entire photometer assembly is mounted as a unit on the main circuit board (BKS) by means

of a bracket. The main circuit board is inserted into guide rails in the analyzer housing, to which

the front panel (membrane keypad) and the rear panel are assembled.

3.1 Photometer with Pyroelectrical Detector (Solid-state detector)

Fig. 3-1 shows the schematical photometer assembly for dual channel operation.

The base element for the photometer assembly is the chopper housing (03), upon which the light

source (thermal radiator, 07), the analysis cell (cuvette, 09), and the signal detection unit [filter cell

(14/15), pyroelectrical (solid-state) detector with integrated preamplifier (16)] are all mounted.

The chopper housing also incorporates the duplex filters (04/05) for the selection of spectral bandpass ranges from the broadband emission of the light sources.

Between the two halves of the chopper housing (03), which are sealed together with an O-ring,

is the chopper blade, driven by a stepping motor. Both the chopper housing and the motor