Page 1

Instruction Manual

Form 589

April 2008

Type 99 Pressure Reducing Regulators

Introduction

Scope of the Manual

This manual describes and provides instructions and

parts lists for Type 99 pressure reducing regulators

complete with standard P590 Series integral lter.

However, complete instructions and parts listing for the

Type 1301F pilot supply regulator, and other Fisher®

equipment, such as monitoring pilots will be found in

separate instruction manuals.

Description

The Type 99 gas regulators provide a broad capacity

for controlled pressure ranges and capacities

in a wide variety of distribution, industrial, and

commercial applications.

Type 99

A Type 99 regulator has a Type 61L (low pressure),

Type 61H (high pressure), or a Type 61HP (extra

high pressure) pilot integrally mounted to the actuator

casing as shown in Figure 1. The Type 99 regulator

can handle up to 1000 psig (69,0 bar) inlet pressures

(the 1000 psig (69,0 bar) regulator requires a

Type 1301F pilot supply regulator and a Type H110 pop

relief valve). The pilot supply regulator reduces inlet

pressure to a usable 200 psig (13,8 bar) for the extra

high pressure pilot. This regulator comes standard with

O-ring seals on the guide bushing and valve carrier

(key 26, Figure 7) to keep main valve body outlet

pressure from interfering with outlet pressure in the

lower casing assembly (key 29, Figure 9).

Specications

WARNING

!

Since a pilot-operated regulator is

constructed of both a pilot and a main

valve, care should be used not to exceed

W2676

Figure 1. Type 99 Regulator with Type 61H (high pressure) Pilot

the maximum inlet pressure shown on

the nameplate of either unit. When inlet

pressure exceeds the pilot limitation, a

pilot supply reducing regulator and/or

relief valve will be required.

Specications and ratings for various Type 99

constructions are listed in the Specications section

on page 2. Some specications for a given regulator

as it originally comes from the factory are stamped

on nameplates located on the pilot and actuator

spring cases. A tag (key 159, Parts List) additionally

may be installed on the pilot to indicate a regulator

with O-ring stem seal. These regulators and their

installations should be checked for compliance with

applicable codes.

www.emersonprocess.com/regulators

D100260X012

Page 2

Type 99

Specications

Body Size and End Connection Styles

2-inch (DN 50) body with NPT; CL125, CL150,

CL250, or CL300 anged; or SWE

Maximum Allowable Inlet Pressure

(1)

160 psig (11,0 bar): When using Type 61LD pilot

400 psig (27,6 bar): When using Types 61L/

61H pilots

600 psig (41,4 bar): Type 61HP pilot

Maximum Actuator Pressures

Operating: 100 psig (6,90 bar)

Emergency: 110 psig (7,58 bar)

Maximum Pilot Spring Case Pressure for

Pressure Loading

Types 61L, 61LD

(1, 2)

(3)

with special steel closing cap

Types 61H and 61HP: 100 psi (6,90 bar)

(5/8-inch (15,9 mm) orice maximum)

1000 psig (69,0 bar): Type 61HP pilot, along with

Type 1301F pilot supply regulator and Type H110

relief valve (1/2-inch (12,7 mm) orice only)

Outlet (Control) Pressure Ranges

See Table 1

Approximate Proportional Bands

See Table 2

Maximum Allowable Pressure Drop

(1)

See Table 3

Minimum Differential Pressure Required for

Full Stroke

See Table 3

Maximum Rated Travel

1/4-inch (6,35 mm)

Temperature Capabilities

With Nitrile (NBR) / Neoprene (CR):

-20° to 180°F (-29° to 82°C)

With Fluorocarbon (FKM):

0° to 300°F (-18° to 149°C)

1. The pressure/temperature limits in this Instruction manual and any applicable standard or code limitation should not be exceeded.

2. For stability or overpressure protection, a pilot supply regulator may be installed in the pilot supply tubing between the main valve and pilot.

3. Type 61LD construction has narrower proportional band than does the standard Type 61L pilot.

4. Type 61LE construction has broader proportional band than does the standard Type 61L pilot.

(1)

, and 61LE

(1)

(4)

: 50 psi (3,45 bar)

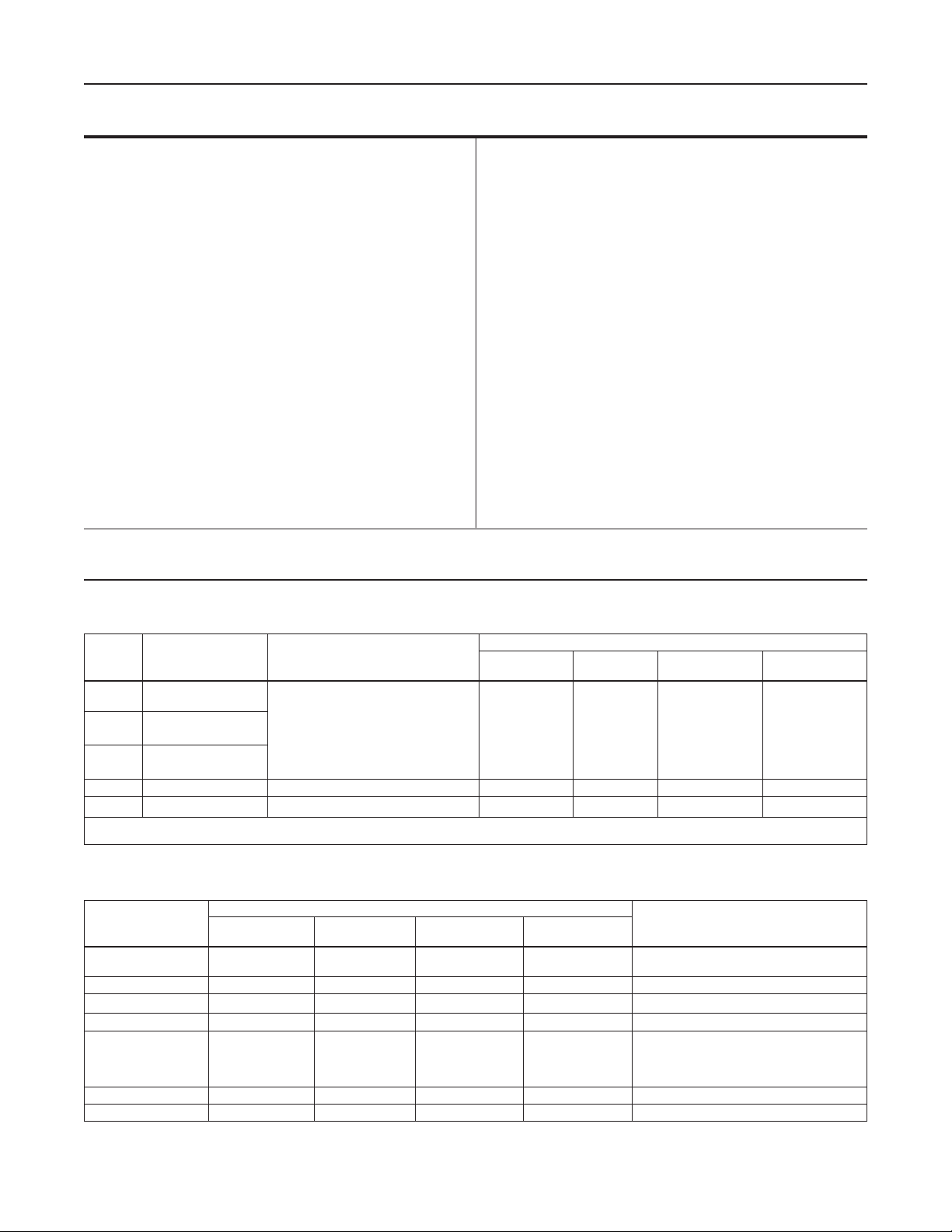

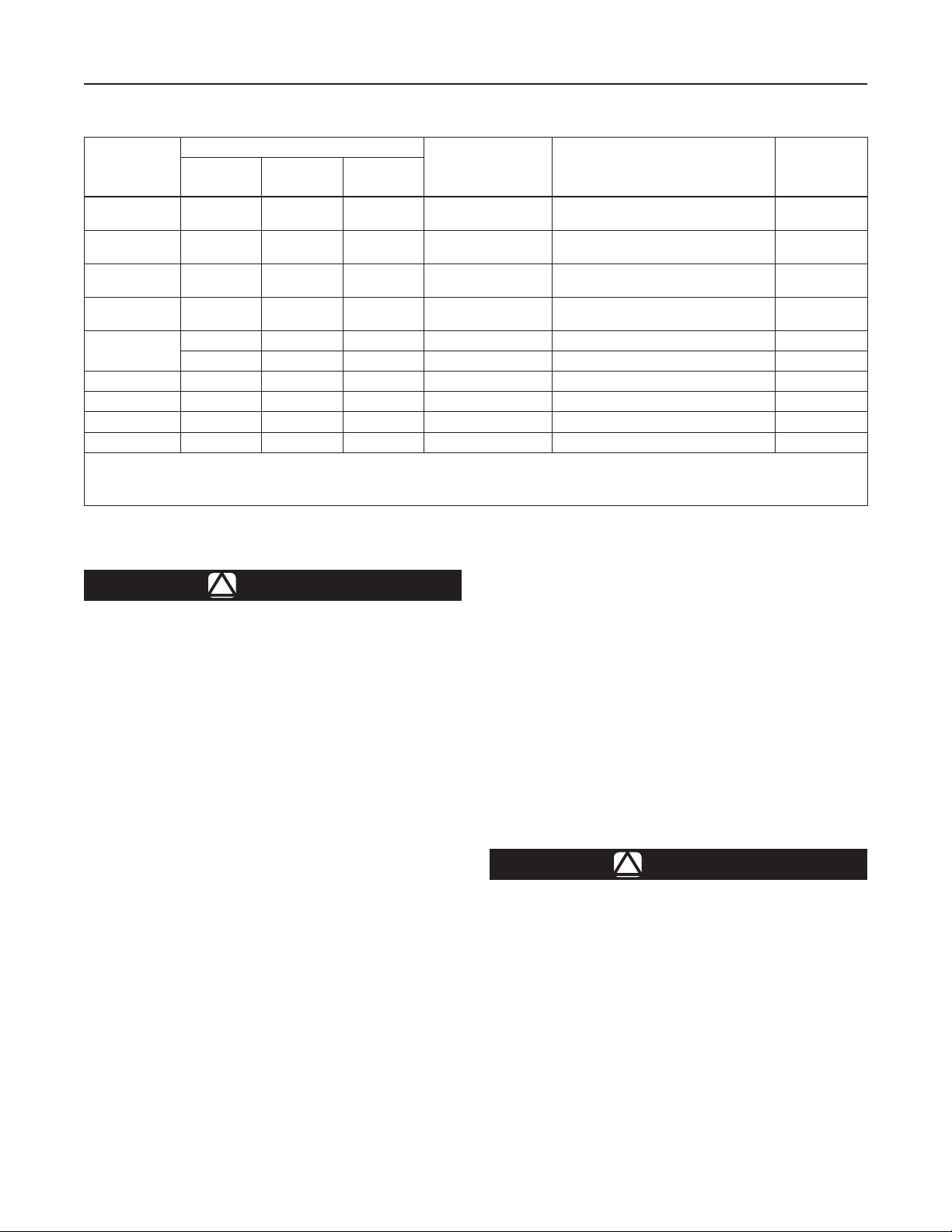

Table 1. Outlet Pressure Ranges

PILOT

TYPE

61L 400 (27,6)

61LD

61LE

61H 400 (27,6) 10 to 65 psig (0,69 to 4,48 bar) 0Y0664000A2 Green stripe 0.363 (0,92) 6 (15,2)

61HP 600 (41,4) 35 to 100 psig (2,41 to 6,90 bar) 1D387227022 Blue 0.200 (0,51) 1-11/16 (4,29)

1. Type 61LD construction has narrower proportional band than does the standard Type 61L Pilot.

2. Type 61LE construction has broader proportional band than does the standard Type 61L Pilot.

MAXIMUM PILOT

SUPPLY PRESSURE,

PSIG (bar)

(1)

(2)

160 (11,0)

400 (27,6)

OUTLET (CONTROL)

PRESSURE RANGES

2 to 4-inches w.c.

3 to 12-inches w.c.

0.25 to 2 psig

1 to 5 psig

2 to 10 psig

5 to 15 psig

10 to 20 psig

(5 to 10 mbar)

(7 to 30 mbar)

(0,02 to 0,14 bar)

(0,07 to 0,34 bar)

(0,14 to 0,69 bar)

(0,34 to 1,03 bar)

(0,69 to 1,38 bar)

Part Number Color Code

1B558527052

1C680627222

1B886327022

1J857827022

1B886427022

1J857927142

1B886527022

PILOT CONTROL SPRING

Wire Diameter,

Inches (cm)

Orange

Unpainted

Red

Yellow

Blue

Brown

Green

0.075

0.080

0.109

0.142

0.172

0.187

0.363

(0,19)

(0,20)

(0,28)

(0,36)

(0,44)

(0,47)

(0,92)

Free Length,

Inches (cm)

4-1/8

3-1/4

2-3/4

2-3/4

2-7/8

2-7/8

3-1/8

Table 2. Proportional Bands

PILOT TYPES

61LD

61L 1B886327022 Red 0.109 (0,28) 2-3/4 (7,00) 1 to 2-inches w.c. (2 to 5 mbar)

61LD 1B886327022 Red 0.109 (0,28) 2-3/4 (7,00) 0.25 to 1-inch w.c. (0,62 to 2 mbar)

61LE 1B886327022 Red 0.109 (0,28) 2-3/4 (7,00) 5 to 8-inches w.c. (12 to 20 mbar)

61L, 61LD, 61LE

61H 0Y0664000A2 Green stripe 0.363 (0,92) 6 (15,2) 0.1 to 0.3 psi (0,007 to 0,02 bar)

61HP 1D387227022 Blue 0.200 (0,51) 1-11/16 (4,29) 1 to 2 psi (0,069 to 0,14 bar)

Part Number Color Code

1B558527052

1C680627222

1B886527022

1J857927142

1B886427022

1J857827022

PILOT CONTROL SPRING

Wire Diameter,

Inches (cm)

Orange

Unpainted

Green

Brown

Blue

Yellow

0.075 (0,19)

0.080 (0,20)

0.207 (0,53)

0.187 (0,47)

0.172 (0,44)

0.142 (0,36)

Free Length,

Inches (cm)

4-1/8 (10,5)

3-1/4 (8,26)

3-1/8 (7,94)

2-7/8 (7,30)

2-7/8 (7,30)

2-3/4 (7,00)

PROPORTIONAL BANDS

0.1 to 0.5-inch w.c. (0,25 to 1,0 mbar)

0.1 to 0.3 psi (0,007 to 0,02 bar)

(10,5)

(8,26)

(7,00)

(7,00)

(7,30)

(7,30)

(7,94)

2

Page 3

Type 99

A6469

Type 99

Type 99

A6469

January 2008

Type 99

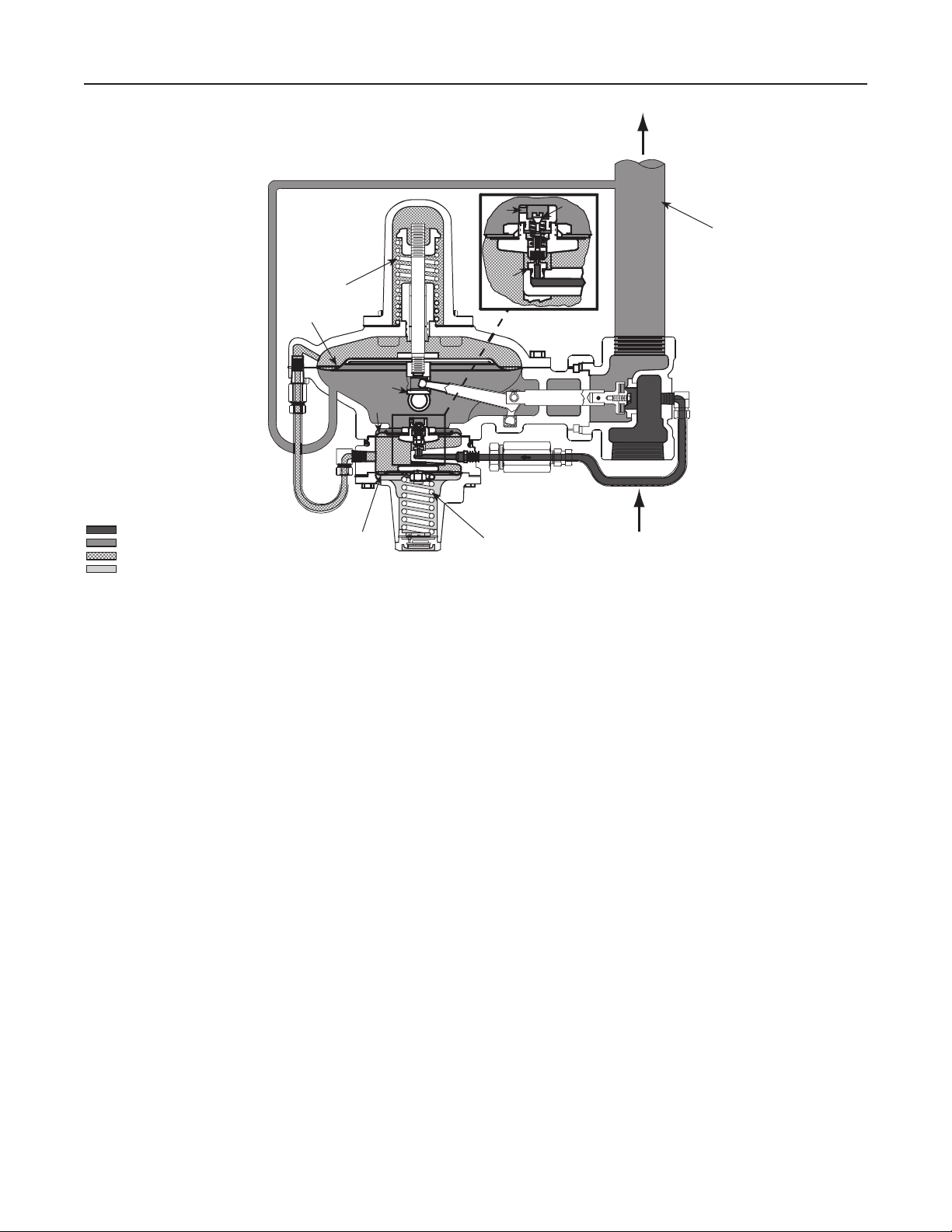

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

ATMOSPHERIC PRESSURE

A6814

Principle of Operation

The key to the operation of a Type 99 regulator is the

yoked double-diaphragm pilot (letter keys in this section

refer to both Figures 2 and 3 unless otherwise noted).

Fast response and accuracy are made possible by the

amplifying effect of the pressure-balanced pilot and

by the two-path control system. The function of the

pilot is to sense change in the controlled pressure and

amplify it into a larger change in the loading pressure.

Any changes in outlet pressure act quickly on both the

actuator diaphragm and the loading pilot, thus providing

the precise pressure control that is characteristic of a

two-path system.

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

ATMOSPHERIC PRESSURE

H

B

E

K

F

G

Figure 2. Schematic of Type 99 Regulator with Type 61L (Low Pressure) Pilot

C

A

D

OUTLET PIPE

INLET

In operation, assume the outlet pressure is less

than the setting of pilot control spring (A). The top

side of pilot diaphragm assembly (F) will have a

lower pressure than the setting of spring (A). Spring

(A) forces the diaphragm head assembly upward,

opening the relay or inlet orice (C). Additional loading

pressure is supplied to the pilot body and to the top

side of main diaphragm (E).

This creates a higher pressure on the top side of the

main diaphragm (E) than on the bottom side, forcing

the diaphragm downward. This motion is transmitted

through a lever, which pulls the valve disk open,

allowing more gas to ow through the valve.

A typical pilot has an approximate gain of 20, which

means the outlet pressure needs to droop only 1/20 as

much as a self-operated regulator in order to obtain the

same pressure differences across the main diaphragm.

Advantages of a pilot operated regulator are high

accuracy and high capacity.

Upstream or inlet pressure is utilized as the operating

medium, which is reduced through pilot operation to

load the main diaphragm chamber. Tubing connects

the inlet pressure to the pilot through a lter assembly.

Downstream or outlet pressure registers underneath the

main diaphragm (E) through the downstream control line.

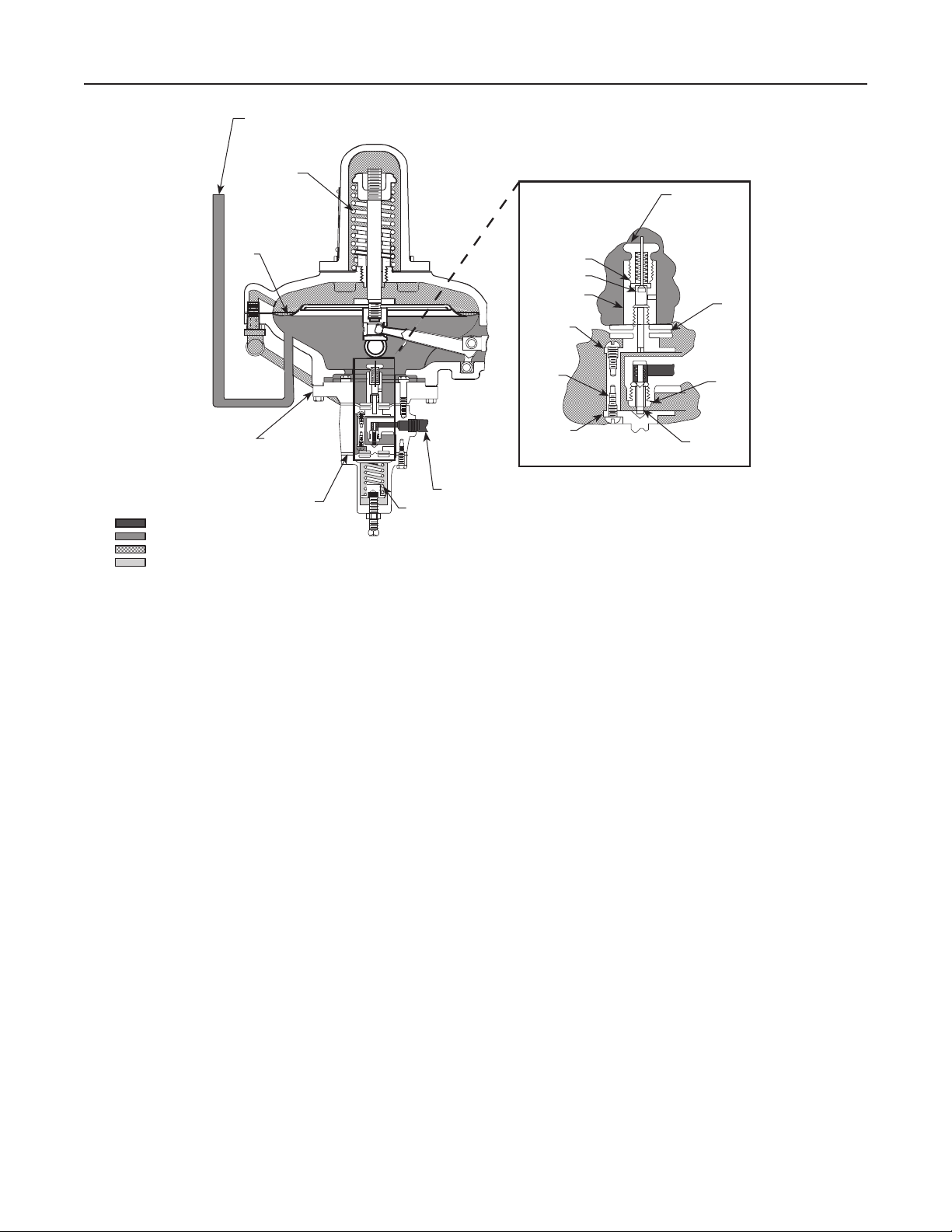

When the gas demand in the downstream system

has been satised, the outlet pressure increases.

The increased pressure is transmitted through the

downstream control line and acts on top of the

pilot diaphragm head assembly (F). This pressure

exceeds the pilot spring setting and forces the head

assembly down, closing orice (C). The loading

pressure acting on the main diaphragm (E) bleeds to

the downstream system through a small slot between

the pilot bleed valve (D) and the bleed orice (H).

Normally, excess loading pressure slowly escapes

downstream around bleed valve (D) (Figure 3) or

3

Page 4

Type 99

A2505

Type 99

Type 99

A6469

January 2008

Type 99

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

ATMOSPHERIC PRESSURE

DOWNSTREAM

CONTROL LINE

B

RELIEF

VALVE

CAP

through the relief valve body (J) (Figure 4). Since

loading pressure needs to exceed outlet pressure

only moderately to stroke the main valve fully open,

a continued increase in loading pressure differential

extends the main diaphragm (E) and the pusher

post assembly (K) far enough to separate the bleed

valve (D) and the bleed orice (H). This permits

quick dumping of excess loading pressure into the

downstream system.

With a decrease in loading pressure on top of the

main diaphragm (E), the main spring (B) exerts an

upward force on the diaphragm rod connected to the

main diaphragm (E), pulling it upward. This moves

the main valve toward its seat, decreasing ow to the

downstream system.

Diaphragm (G) in the pilot valve acts as a sealing

member for the loading chamber and as a balancing

member to diaphragm (F). These two diaphragms are

connected by a yoke so any pressure change in the

pilot chamber has little effect on the position of the pilot

valve. Therefore, the active diaphragm in the pilot is

(F) and the pressure on the top side of this diaphragm

opposes the force of the pilot control spring (A).

INLET PRESSURE

OUTLET PRESSURE

LOADING PRESSURE

ATMOSPHERIC PRESSURE

54A2767-a

A2505

E

K

YOKE

LEG

FLANGE

ADAPTOR

G

Figure 3. Schematic of Type 99 Regulator with Type 61HP (Extra High Pressure) Pilot

INLET PRESSURE

TUBING CONNECTION

A

YOKE

CAP

YOKE

CAP

H

D

J

RELAY

VALVE

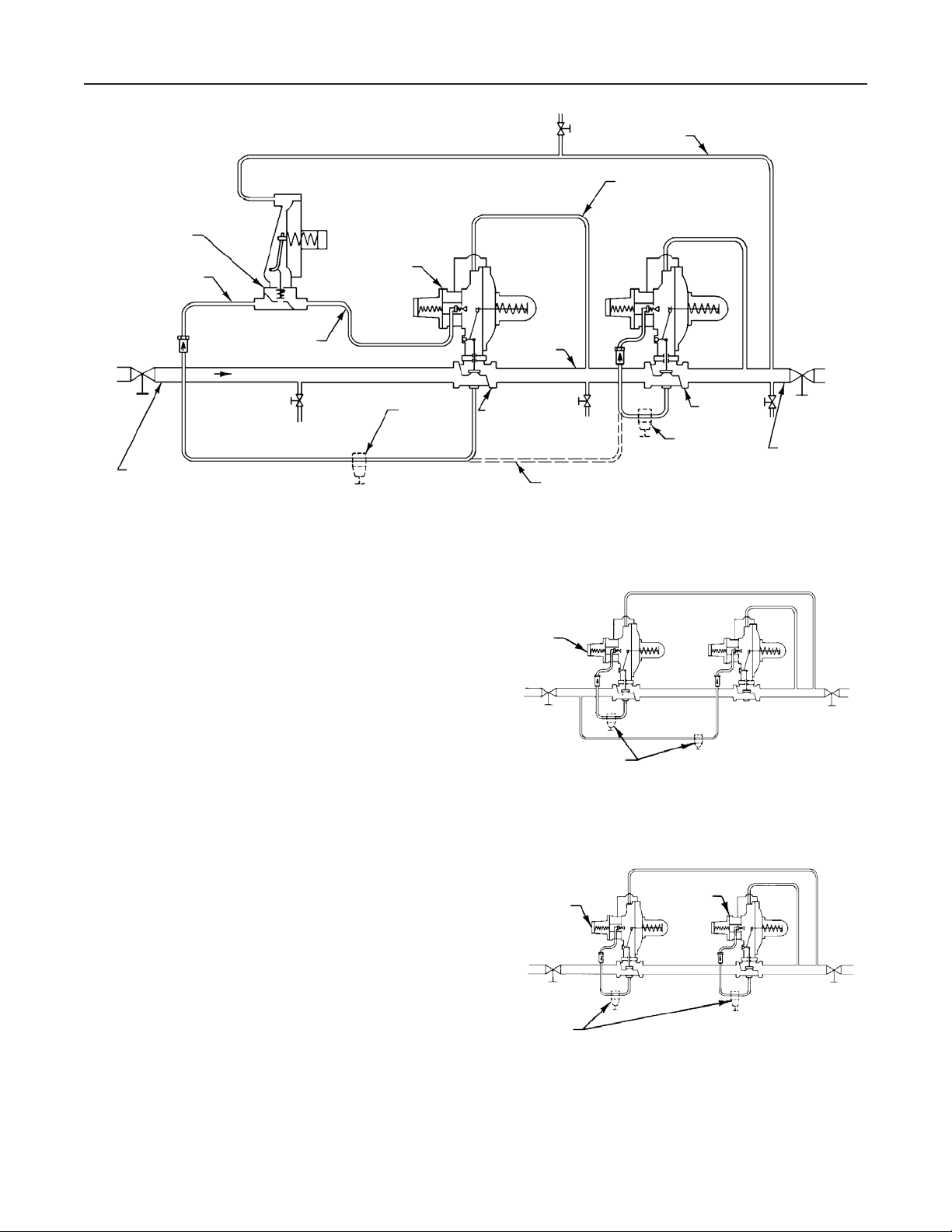

Monitoring Systems

Monitoring regulators serve as overpressure protection

devices to limit system pressure in the event of open

failure of a working regulator feeding the system. Two

methods of using Type 99 regulators in monitoring

systems are as follows:

Working Monitor

On a working monitor installation (Figure 4), the

control line of the monitoring pilot is connected

downstream of the working regulator. During

normal operation, distribution pressure causes

the monitoring pilot to stand wide open. Full pilot

supply pressure enters the working monitor pilot and

permits the working monitor regulator to control at its

intermediate pressure setting.

Open failure of the working regulator increases

distribution pressure as the working regulator goes

wide-open. Intermediate pressure is then ignored by

the monitoring regulator, which controls downstream

pressure at its own pressure setting (slightly higher

than the normal control pressure).

F

C

4

Page 5

TYPE 161AYW MONITORING

PILOT (ALSO REPRESENTATIVE

OF TYPE 627-109)

PILOT SUPPLY LINE

WORKING

MONITOR PILOT

DISTRIBUTION PRESSURE

CONTROL LINE

INTERMEDIATE PRESSURE

CONTROL LINE

Type 99

LOADING

PRESSURE

OPTIONAL

PILOT SUPPLY

REGULATOR

UPSTREAM

PRESSURE

20A1389-A

B2484

Figure 4. Working Monitor Installation

The monitoring pilot should be upstream of the working

monitor regulator. This enables a closer setpoint

between the working regulator and the monitoring

pilot. Special Types 161AYW and 627-109 monitoring

pilots with quick-bleed operation have been designed

to give faster response to abnormal downstream

conditions. Table 4 gives the spread between normal

distribution pressure and the minimum pressure at

which the working monitor regulator can be set to take

over if the working regulator fails open.

INTERMEDIATE

PRESSURE

WORKING

MONITOR

REGULATOR

PILOT SUPPLY PIPING FOR WORKING REGULATOR

WHEN PILOT IS REQUIRED TO BE SUPPLIED FROM

UPSTREAM PRESSURE

UPSTREAM

REGULATOR

(REQUIRES O-RING

STEM SEAL)

10A1388-A

A2504

OPTIONAL PILOT

SUPPLY REGULATOR

FLEXIBLE ARRANGEMENT THAT PERMITS WIDE-OPEN

MONITOR TO BE EITHER UPSTREAM OR DOWNSTREAM

WORKING

REGULATOR

OPTIONAL

PILOT SUPPLY

REGULATOR

DISTRIBUTION

PRESSURE

Wide-Open Monitor

The control line of the upstream regulator is

connected downstream of the second regulator

(Figure 5), so that during normal operation the

monitoring regulator is standing wide open with the

reduction to distribution pressure being taken across

the working regulator. Only in case of open failure of

the working regulator does the wide-open monitoring

regulator take control at its slightly higher setting.

The upstream regulator must have an O-ring seal on

the valve carrier assembly. This seals off the leak

path that otherwise would let line pressure ahead of

the working regulator inlet try to close the wide-open

monitoring regulator.

UPSTREAM

REGULATOR

(REQUIRES O-RING

STEM SEAL)

10A1386-A

A2503

OPTIONAL PILOT

SUPPLY REGULATOR

FLEXIBLE ARRANGEMENT THAT PERMITS WIDE-OPEN

MONITOR TO BE EITHER UPSTREAM OR DOWNSTREAM

WORKING

REGULATOR

Figure 5. Typical Wide-Open Monitor Installations

5

Page 6

Type 99

Table 3. Maximum Allowable Drop and Minimum Differential Pressures

MAXIMUM

ALLOWABLE

PRESSURE

DROP, PSIG (bar)

25 (1,72) 1C277127022 0.148 (0,38) 6 (15,2) 0.75 (0,05)

50 (3,45) 1N801927022 0.156 (0,40) 7-1/8 (18,1) 1.5 (0,10)

150 (10,3) 1B883327022 0.187 (0,47) 6-5/8 (16,8) 3 (0,21)

175 (12,1) 1B883327022 0.187 (0,47) 6-5/8 (16,8) 3 (0,21)

250 (17,2)

300 (20,7) 0W019127022 0.281 (0,71) 6 (15,2) 10 (0,69) Nylon (PA) 1-1/8 (28,6)

400 (27,6) 0W019127022 0.281 (0,71) 6 (15,2) 10 (0,69) Nylon (PA) 7/8 (22,2)

600 (41,4) 0W019127022 0.281 (0,71) 6 (15,2) 10 (0,69) Nylon (PA) 5/8 (15,9)

1000 (69,0) 0W019127022 0.281 (0,71) 6 (15,2) 10 (0,69) Nylon (PA) 1/2 (12,7)

1. Can use all port diameters up to maximum size listed.

2. CL125 FF anged body only.

3. O-ring seat only.

4. 1/2-inch (12,7 mm) is the only orice available for 1000 psig (69,0 bar) maximum inlet pressure regulator.

1B883327022 0.187 (0,47) 6-5/8 (16,8) 3 (0,21) Nitrile (NBR), Fluorocarbon (FKM) 7/8 (22,2)

0W019127022 0.281 (0,71) 6 (15,2) 10 (0,69) Nitrile (NBR)

Installation

MAIN VALVE SPRING MINIMUM

Part

Number

Wire Diameter,

Inches (cm)

Free Length,

Inches (cm)

DIFFERENTIAL

PRESSURE FOR FULL

STROKE, PSIG (bar)

Like most regulators, the Type 99 regulator has a outlet

SEAT MATERIAL

Nitrile (NBR), Neoprene (CR),

Fluorocarbon (FKM)

Nitrile (NBR), Neoprene (CR),

Fluorocarbon (FKM)

Nitrile (NBR), Neoprene (CR),

Fluorocarbon (FKM)

Nitrile (NBR)

(2)

, Neoprene (CR)

Fluorocarbon (FKM)

(3)

, Fluorocarbon (FKM)

(2)

(2)

,

(3)

MAXIMUM PORT

DIAMETER

INCHES (mm)

1-1/8 (28,6)

1-1/8 (28,6)

1-1/8 (28,6)

7/8 (22,2)

1-1/8 (28,6)

pressure rating lower than its inlet pressure rating.

WARNING

!

Complete downstream overpressure protection is

needed if the actual inlet pressure can exceed the

• Personal injury, equipment damage, or

leakage due to escaping gas or

bursting of pressure-containing

parts might result if this regulator

is overpressured or is installed where

service conditions could exceed

the limits for which the regulator was

designed, or where conditions exceed

any ratings of the adjacent piping or

piping connections. To avoid such

injury or damage, provide pressure-

regulator outlet pressure rating or the pressure ratings

of any downstream equipment. Although the Type H110

relief valve provides sufcient relief capacity to protect

the extra high pressure pilot of the 1000 psig (69,0 bar)

maximum inlet regulator in case the Type 1301F supply

regulator fails open, this protection is insufcient if the

main valve body fails open. Regulator operation within

ratings does not preclude the possibility of damage from

external sources or from debris in the lines. A regulator

should be inspected for damage periodically and after

any overpressure condition.

relieving or pressure-limiting devices

(as required by the appropriate code,

WARNING

regulation, or standard) to prevent

!

service conditions from exceeding

those limits.

• A regulator may vent some gas to the

atmosphere in hazardous or ammable

gas service, vented gas might

accumulate and cause personal injury,

death or property damage due to re or

explosion. Vent a regulator in

hazardous gas service to a remote,

safe location away from air intakes or

any hazardous location. The vent

line or stack opening must be

protected against condensation

or clogging.

The 1000 psig (69,0 bar) maximum

inlet regulator must not be used on

hazardous gas service unless the

Type H110 relief valve can be vented

into a safe area. If vented gas can

accumulate and become a hazard in

enclosed conditions such as in a pit,

underground, or indoors, the relief valve

must be repiped to carry the gas to a

safe location.

A repiped vent line or stack must be

located to avoid venting gas near

buildings, air intakes, or any hazardous

(1)

,

(4)

6

Page 7

Table 4. Working Monitor Performance

Type 99

MONITORING PILOT INFORMATION

Construction Spring Range

Type 161AYW with 1/8-inch

(3,18 mm) port diameter and

150 psig (10,3 bar) maximum

allowable inlet pressure

Type 627-109 with 1/8-inch

(3,18 mm) port diameter and

150 psig (10,3 bar) maximum

allowable inlet pressure for cast

iron body or 750 psig (51,7 bar)

maximum allowable inlet pressure

for malleable iron body

1. With large diaphragm plate.

2. With small diaphragm plate.

5 to 15-inches w.c. (12 to 37 mbar)

11 to 28-inches w.c. (27 to 70 mbar)

1 to 2.5 psig (0,069 to 0,17 bar)

2.25 to 4.5 psig (0,16 to 0,31 bar)

4.5 to 7 psig (0,31 to 0,48 bar)

5 to 15 psig (0,34 to 1,03 bar)

10 to 25 psig (0,69 to 1,72 bar)

20 to 35 psig (1,38 to 2,41 bar)

25 to 60 psig (1,72 to 4,14 bar)

40 to 80 psig (2,76 to 5,52 bar)

80 to 150 psig (5,52 to 10,3 bar)

130 to 200 psig (9,00 to 13,8 bar)

location. The line or stack opening must

be protected against condensation,

freezing, and clogging.

Clean out all pipelines before installation and check

to be sure the regulator has not been damaged or

collected foreign material during shipping.

Apply pipe compound to the male pipe threads only with

a screwed body, or use suitable line gaskets and good

bolting practices with a anged body. This regulator

may be installed in any position desired as long as the

ow through the body is in the direction indicated by the

arrow on the body. Install a three-valve bypass around

the regulator if continuous operation is necessary during

maintenance or inspection.

Although the standard orientation of the actuator and

pilot to the main valve body is as shown in Figure 1, this

orientation may be changed as far as the inlet tubing

(key 24, Figure 9 or 11) will permit by loosening the

union nut (key 14, Figure 9), rotating the actuator lower

casing (key 29, Figure 9) as desired, and tightening

the union nut. To keep the pilot spring case from being

plugged or the spring case from collecting moisture,

corrosive chemicals, or other foreign material, the vent

must be pointed down, oriented to the lowest possible

point on the spring case, or otherwise protected. Vent

orientation may be changed by rotating the spring

case with respect to the pilot body, or on the extra

high pressure pilot with optional tapped spring case by

rotating the vent with respect to the spring case.

To remotely vent a low pressure pilot, install the vent

line in place of the pressed-in vent assembly (key 60,

Figure 9). Install obstruction-free tubing or piping

MINIMUM PRESSURE

AT WHICH WORKING

MONITOR REGULATOR

CAN BE SET

3-inches w.c. (7 mbar)

over normal

distribution pressure

0.5 psi (0,03 bar)

over normal

distribution pressure

3.0 psi (0,21 bar)

over normal

distribution pressure

5.0 psi (0,34 bar)

over normal

distribution pressure

Part Number

1B653927022

1B537027052

1B537127022

1B537227022

1B537327052

1D892327022

1D751527022

1D665927022

1D755527142

1E543627142

1P901327142

1P901327142

Pilot Spring

Wire Diameter,

Inches (cm)

0.105 (0,27)

0.114 (0,29)

0.156 (0,40)

0.187 (0,47)

0.218 (0,55)

0.168 (0,43)

0.187 (0,47)

0.218 (0,55)

0.500 (1,27)

0.283 (0,72)

(1)

0.240 (0,61)

(2)

0.240 (0,61)

Free Length,

Inches (cm)

3-3/4 (9,52)

4-5/16 (11,0)

4-1/8 (10,5)

3-15/16 (10,0)

4-1/8 (10,5)

2-15/16 (7,46)

2-13/16 (7,14)

2-15/32 (6,27)

9-1/4 (23,5)

2-15/16 (7,46)

2-5/8 (6,67)

2-5/8 (6,67)

into the 1/4-inch (6,35 mm) vent tapping. Provide

protection on a remote vent by installing a screened

vent cap into the remote end of the vent pipe.

To remotely vent a high pressure pilot, or an extra high

pressure pilot with optional tapped spring case, remove

the screwed-in vent assembly (key 72, Figure 9) from

the high pressure pilot spring case or the pressed-in

vent assembly from the extra high pressure pilot

spring case and install obstruction-free tubing or piping

into the 1/4-inch (6,35 mm) vent tapping. Provide

protection on a remote vent by installing a screened

vent cap into the remote end of the vent pipe.

An upstream pilot supply line is not required because

of the integral pilot supply tubing (key 24, Figure 9

or 11). However, as long as the 1/4-inch NPT

tapping in the main valve body is plugged, this

tubing may be disconnected from both the main

valve and lter assembly (key 75, Figure 9) in order

to install a pilot supply line from a desired remote

location into the lter.

If the maximum pilot inlet pressure will be exceeded

by main valve pressure, install a separate reducing

regulator (if not already provided) in the pilot supply line.

A Type 99 regulator has two 1/2-inch threaded NPT

control line pressure taps on opposite sides of the

lower casing (key 29, Figure 9). The regulator normally

comes from the factory with the tap closest to the

regulator outlet left unplugged for the downstream

control line as shown in Figure 1, and with opposite

tap plugged.

Attach the control line from the unplugged tap 2 to

3 feet (0,61 to 0,91 meter) downstream of the regulator

in a straight run of pipe. If impossible to comply with

7

Page 8

Type 99

this recommendation due to the pipe arrangement, it

may be better to make the control line tap nearer the

regulator outlet rather than downstream of a block

valve. Do not make the tap near any elbow, swage, or

nipple which might cause turbulence.

In many instances, it will be necessary to enlarge the

downstream piping to keep ow velocities within good

engineering practices. Expand the piping as close to

the regulator outlet as possible.

WARNING

!

Adjustment of the pilot control spring to

produce an outlet pressure higher than

the upper limit of the outlet pressure

range for that particular spring can cause

personal injury or equipment damage

due to bursting of pressure-containing

parts or the dangerous accumulation

of gases if the maximum actuator

emergency casing pressure in the

Specications section is exceeded. If the

desired outlet pressure is not within the

range of the pilot control spring, install a

spring of the proper range according to

the Maintenance section.

The only adjustment on the regulator is the reduced

pressure setting affected by the pilot control spring

(key 43, Figure 9 or 11). Remove the closing cap

assembly (key 46, Figure 9) and turn the adjusting

screw (key 45, Figure 9 or 11). Turning the adjusting

screw clockwise into the spring case increases the

controlled or reduced pressure setting. Turning

the screw counterclockwise decreases the reduced

pressure setting. Always replace the closing cap, if

used, after making the adjustment.

Shutdown

Isolate the regulator from the system. Vent the

downstream pressure rst; then vent inlet pressure to

release any remaining pressure in the regulator.

Maintenance

Regulator parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency

of inspection and replacement of parts depends on the

severity of service conditions or the requirements of

local, state, and federal rules and regulations.

WARNING

!

Each regulator is factory-set for the pressure setting

specied on the order. If no setting was specied, outlet

pressure was factory-set at the midrange of the pilot

control spring. In all cases, check the control spring

setting to make sure it is correct for the application.

Startup

Key numbers are referenced in Figure 9 for a low or

high pressure pilot and in Figure 12 for an extra high

pressure pilot. With proper installation completed and

downstream equipment properly adjusted, perform the

following procedure while using pressure gauges to

monitor pressure.

1. Very slowly open the upstream block valve.

2. Slowly open the hand valve (if used) in the control

line. The unit will control downstream pressure

at the pilot control spring setting. See the

adjustment paragraph following these numbered

steps if changes in the setting are necessary during

the startup procedure.

3. Slowly open the downstream block valve.

4. Slowly close the bypass valve, if any.

5. Check all connections for leaks.

Avoid personal injury or damage to

property from sudden release of pressure

or uncontrolled gas or other process uid.

Before starting to disassemble, isolate

the pilot or regulator from all pressure

and cautiously release trapped pressure

from the pilot or regulator. Use gauges to

monitor inlet, loading, and outlet pressures

while releasing these pressures.

On reassembly of the regulator, it is recommended

that a pipe thread sealant be applied to pressure

connections and ttings as indicated in Figures 7

and 9 and lubricant be applied to sliding and bearing

surfaces as indicated in Figures 7 and 9, and that an

anti-seize compound be applied to adjusting screw

threads and other areas indicated Figures 9 and 11.

Actuator and Standard P590 Series Filter

This procedure is to be performed if changing the main

spring and spring seat for those of a different range,

or if inspecting, cleaning, or replacing any other parts.

Unless otherwise indicated, part key numbers for a

Type 99 regulator with low or high pressure pilot and

8

Page 9

Type 99

disk or O-ring seat are referenced in Figure 9, part key

numbers unique to the 1000 psig (69,0 bar) maximum

inlet regulator are referenced in Figure 11, and part

key numbers for a Type 61HP (extra high pressure)

pilot is referenced in Figure 12.

1. Access to all internal actuator parts can be gained

without removing the main valve body from the

line. Disconnect the loading tubing from the

upper casing.

CAUTION

If the regulator has an indicator

assembly, perform the following step

carefully to avoid bending the travel

indicator stem (key 103, Figure 6).

Note

The O-rings and gaskets (keys 111 and

108, Figure 6) in the indicator assembly

are static seals and need not be

disturbed, unless they are leaking.

2. Remove the four cap screws (key 58, Figure 9) and

lift off the spring case (key 1, Figure 9). Remove

the travel indicator stem, if any, by unscrewing the

indicator stem adapter (key 101, Figure 6).

3. Remove the main spring seat (key 2, Figure 9)

and main spring (key 3, Figure 9).

4. Remove the 12 cap screws (key 12, Figure 9)

and hex nuts (key 13, Figure 9), and lift off the

upper casing.

5. Remove the diaphragm (key 11, Figure 9) and

diaphragm plate (key 10, Figure 9) by tipping it so

that the lever (key 9, Figure 9) slips out of the

pusher post (key 8, Figure 9).

6. Separate the diaphragm and diaphragm plate by

unscrewing the diaphragm rod (key 4, Figure 9)

from the pusher post. Inspect the diaphragm

(key 11, Figure 9) and pusher post gasket (key 7,

Figure 9). Either part must be replaced if it is

damaged or no longer pliable.

7. If the unit has a stem seal O-ring (key 64,

Figure 7 or 11), this O-ring may be replaced by

removing the retaining ring or cotter pin (key 28,

Figure 9) and disconnecting the lever from the

valve carrier (key 26, Figure 9 or 11), removing

the union nut (key 14, Figure 9 or 11),

disconnecting the pilot supply tubing (key 24,

Figure 9 or 11), and sliding the lower casing

(key 29, Figure 9) away from the valve body

(key 17, Figure 9), with a disk or O-ring seat, the

valve carrier must be pulled out of the lower

casing to gain access to the O-ring. Another

O-ring, held captive by the pressed-in bushing, is

part of the lower casing assembly on a stem seal

unit and normally does not require replacement.

8. If clogging is suspected in the upstream regulator

passages, disconnect the pilot supply tubing

(key 24, Figure 9 or 11), remove the lter assembly

(key 75, Figure 9), and blow through it to check

for lter clogging. If necessary, to clean or replace

lter parts in a standard P590 Series lter

assembly, remove the following as shown in

Figure 10: lter body (key 1), machine screw

(key 4), spring washer (key 6), gasket (key 7),

washer (key 5), and lter element (key 2). Upon

reassembly, one of the at washers must go

between the lter element and lter head (key 3)

and the other must go between the lter element

and gasket.

9. If the lower casing was removed, install a new body

gasket (key 16, Figure 9) and, with a disk or O-ring

seat, slide the valve carrier into the casing. Then

slide the entire assembly into the valve body (disk

or O-ring seat) and secure with the union nut.

Secure the lever to the valve carrier with the

retaining ring or cotter pin.

10. Loosely reassemble the diaphragm and

diaphragm plate so that the bolt holes and

loading connection hole in the diaphragm can

be properly aligned with the corresponding

holes in the casing when the lever is tted

properly into the pusher post. When this

orientation is made, install the collar (key 6,

Figure 9) and tighten the diaphragm rod into the

pusher post (key 8, Figure 9).

11. In order for the regulator to operate properly, the

assembled collar, diaphragm, diaphragm plate,

pusher post, and diaphragm rod must be

mounted on the ball of the lever so that the

pusher post (key 8, Figure 9) orientation is as

shown in Figure 9.

12. Install the upper casing and secure it to the

lower casing with the twelve cap screws torque

580 to 920 inch-pounds (65,5 to 104 N•m) and hex

nuts. Put lower casing back on body and install

union nut.

9

Page 10

Type 99

CAUTION

To avoid part damage due to over

compressing the main spring seat, always

use main spring seat 1E242724092 with

main spring 0W019127022.

13. Install the main spring and main spring seat,

turning the main spring seat until its bottom

shoulder is even with the bottom thread of the

diaphragm rod.

14. Install a new spring case gasket (key 57,

Figure 9), the spring case, and the four cap

screws with 340 to 420 inch-pounds (38,4 to

47,5 N•m) of torque, making sure the indicator

stem, O-ring, and gaskets (keys 103, 111, and

108, Figure 6) are installed If used.

15. Connect the loading tubing, then refer to the

Startup section for putting the regulator

into operation.

Type 61L, 61LD, 61LE (Low), or 61H

(High Pressure) Pilots

This procedure is to be performed if changing the

control spring for one of a different range, or if

inspecting, cleaning or replacing any other pilot parts.

Key numbers are referenced in Figure 9.

1. Remove the closing cap (key 46) if used and

unscrew the adjusting screw (key 45) to relieve

control spring compression.

2. Disconnect the loading tubing (key 53) and pilot

supply tubing (key 24).

3. Unscrew the eight cap screws (key 47) and remove

the pilot assembly from the lower casing (key 29).

4. Use the projecting prong in the relay valve body

(key 39) as the restraining member and remove

the diaphragm nuts (keys 13 and 51). Separate

the parts and inspect the diaphragms (keys 30

and 40) and O-ring seal (key 33). Replace if worn

or damaged.

Note

Before putting the relay spring case over

the diaphragm, make certain the yoke is

square with respect to the prong in the

relay body. (The yoke can bind on the

prong if it is not square.)

7. Use care in reassembly to be sure the edges of

the diaphragms slip properly into the recess on

the lower casing and relay valve body. With the

pilot in place, check to see if it can be rocked. If

it does not rock, it is in place and the diaphragm

is free of wrinkles. With both diaphragms rmly

in place, install the cap screws using torque

150 inch-pounds (16,9 N•m) of torque. Tighten

using a crisscross pattern to avoid placing a

strain on the unit. Set the pilot control spring

(key 43) according to the adjustment information

in the Startup section.

8. Reinstall the closing cap (key 46, if used). If you

have a plastic closing cap, be sure that you have

a vent (key 60) in place of the pipe plug installed in

the low pressure pilot spring case.

Type 61HP (Extra High Pressure) Pilot

This procedure is to be performed if changing the

control spring for one of a different range, or if

inspecting, cleaning, or replacing any other pilot parts.

Key numbers are referenced in Figure 12.

1. Unscrew the adjusting screw (key 45) to relieve

control spring compression.

2. Disconnect the loading tubing and pilot supply tubing.

3. Remove the six cap screws (key 123) which fasten

the spring case (key 44) spring seat (key 68) and

control spring (key 43) to the pilot body.

4. Unscrew the diaphragm nut (key 128) and remove

a diaphragm plate (key 41), diaphragm (key 40),

and another diaphragm plate.

5. Unscrew the eight cap screws and remove the

pilot body (key 39) and gasket. Remove six cap

screws, seal washers and the ange adapter.

5. Unscrew the bleed orice (key 52) from the yoke

(key 37). Also removed with the bleed orice are

the relay disk assembly (key 48) and bleed valve

(key 50). These parts can be unscrewed for

inspection and replacement, if necessary.

6. When reassembling the pilot, the relay disk holder

assembly and both diaphragms should be

tightened on the yoke after it is placed in the body.

10

6. Unscrew the relief valve body (key 119) and remove

a diaphragm plate, diaphragm, and another

diaphragm plate. Inspect the diaphragm inserts

(key 150) and both diaphragms. Replace if worn

or damaged.

7. The relief valve assembly can be further

disassembled for inspection by unscrewing the

relief valve cap (key 118).

Page 11

Type 99

8. Four machine screws (key 130) hold both yoke

caps (keys 37 and 116) to the yoke legs (key 31).

Separate these parts to expose the pilot valve.

9. Unscrew the inlet orice (key 38) to inspect its

seat, the inlet valve plug (key 117), and valve

spring (key 124).

Note

Make certain that the yoke assembly is

square with respect to the cross member

of the body casting so that it will not

bind on the body.

10. When reassembling, screw in the inlet orice all

the way and secure the yoke caps to the yoke

legs. Replace two diaphragm plates, the

diaphragms, and inserts, two more diaphragm

plates, the hex nut, and the relief valve assembly.

11. Assemble the control spring and spring seat

into the body and spring case, being careful

that the diaphragms are free of wrinkles and

properly in place, and evenly installing the cap

screws in a crisscross pattern to avoid placing a

strain on the unit. Install the body ange adapter

with seal washers and cap screws. Install a new

gasket and secure the pilot to the lower casing

with eight cap screws. Set the control spring

according to the adjustment information in the

Startup section.

low to high pressure pilot or vice versa, everything below

the lower pilot diaphragm (key 40, Figure 9) except the

cap screws and the hex nut (keys 47 and 13, Figure 9)

will need to be replaced. Actuator and main valve parts

may remain unchanged unless a change in service

conditions requires a change in seat construction, main

spring, or main spring seat. See the Parts List sections

for obtaining the appropriate conversion parts.

Main Valve Trim with Disk or O-ring Seat

This procedure is to be performed if inspecting,

cleaning, or replacing trim parts. Part key numbers

for a Type 99 regulator with disk or O-ring seat are

referenced in Figure 9, and part key numbers for

the disk seat unique to the 1000 psig (69,0 bar)

maximum inlet regulator are referenced in Figure 11.

Note

All trim maintenance may be performed

with the valve body (key 17, Figure 9

or 11) in the line and with the elbow

(key 23, Figure 9 or 11), pilot supply

tubing (key 24, Figure 9 or 11), and pilot

supply regulator (key 155, Figure 11, if

used) attached to the valve body unless

the valve body itself will be replaced.

1. Disconnect the pilot supply tubing and downstream

control line.

Converting the Pilot

Note

A complete pilot assembly rather than

individual parts may be ordered for

the following conversion procedure.

When a low pressure pilot is ordered

for eld conversion of a high pressure

pilot or vice versa, the replacement pilot

assembly comes complete with a pilot

cover (key 132, Figure 9). Remove this

cover before installing replacement pilot

on the existing regulator. The cover can

then be installed on the removed pilot

to form a complete Type 61 (low or high

pressure) pilot for use elsewhere.

When changing one pilot construction (low pressure, high

pressure, or extra high pressure) for another, all parts

attached to the lower casing (key 29, Figure 9) may need

to be replaced with those appropriate for the desired

construction. At the very least, when changing from a

2. Loosen the union nut (key 14, Figure 9) and

remove the lower casing (key 29, Figure 9) with

the cap screw (key 22, Figure 9) or disk and

holder assembly (key 18, Figure 11) on

disassembly or reassembly. A thin-walled socket

may be used to remove the orice.

3. Access to the disk or O-ring (key 19, Figure 9) can

be gained by removing the cap screw and retainer

(key 21, Figure 9), while on the 1000 psig

(69,0 bar) maximum inlet regulator the entire

disk and holder assembly is removed as a unit.

If necessary, the holder (key 18, Figure 9 or 11) or

adapter (key 157, Figure 11) can be removed by

taking out the cotter pin (key 25, Figure 9 or 11).

4. Install a new body gasket (key 16, Figure 9) and

a new disk, O-ring, or disk and holder assembly

as necessary. Then slide the entire assembly into

the valve body and secure with the union nut.

5. Connect the pilot supply tubing and downstream

control line, then refer to the Startup section for

putting the regulator into operation.

11

Page 12

Type 99

20A7146-B

Figure 6. Travel Indicator Assembly

Parts Ordering

A serial number is assigned to each regulator, and it

is stamped on both the actuator and pilot nameplates.

If the pilot is replaced, the new pilot will have its own

serial number different from the main valve serial

number. Always indicate one or both serial numbers

when communicating with your local Sales Ofce.

When ordering a replacement part, be sure to include

the complete eleven-character part number.

Parts List

Key Description Part Number

Repair kits include parts for regulator with composition

trim only, key numbers 7, 11, 16, 19, 20, and 57. Also

included are parts for pilot, key numbers 30, 33, 38, 40,

48, 49, 50, 52, 71, 117, 126, 129, 150, 153, and

P590 Series lter, key numbers 2 and 7.

With low pressure pilot

7/8-inch (22,2 mm) orice R99LX000012

1-1/8-inch (28,6 mm) orice R99LX000022

With high pressure pilot

7/8-inch (22,2 mm) orice R99HX000012

1-1/8-inch (28,6 mm) orice R99HX000022

With extra high pressure pilot

7/8-inch (22,2 mm) orice R99HPX00012

1-1/8-inch (28,6 mm) orice R99HPX00022

*Recommended Spare Parts

Travel Indicator Assembly (Figure 6)

Key Description Part Number

Complete Assembly (includes individual parts

listed below) 20A7146X0C2

1 Spring Case, Cast iron 2L296219012

101 Indicator Stem Adaptor, Aluminum 1R395909012

102 Indicator Cap, Aluminum 1L290809012

103 Indicator Stem, Aluminum 1L296509022

104 Disk Nut, Plastic 1F730506992

105 Machine Screw Nut, Plated steel (2 required) 1A342024152

106 Retainer, Aluminum 1L291009012

107 Indicator Window, Glass 1L296706992

108* Gasket, Neoprene (CR) (2 required) 1L291103012

109* Indicator Cover, Plastic (2 required) 1L296405032

110 Machine Screw, Plated steel (8 required) 1A899028982

111* O-ring, Nitrile (NBR) (2 required) 1E591406992

112 Indicator Scale, Stainless steel 1J511638982

Actuator and Main Body Assembly

(Figures 6, 7, 8, 9, 10, and 11)

Key Description Part Number

1 Standard Spring Case without travel

indicator, Cast iron 1B883119012

2 Main Spring Seat, Plated steel

250 psid (17,2 bar d) maximum

allowable pressure drop, Cast iron 1B883219042

1000 psid (69,0 bar d) maximum allowable

pressure drop 1E242724092

12

Page 13

Type 99

64

LUBRICANT

SEALANT

20A7148-B

26

SEALANT

LUBRICANT

Figure 7. O-ring Stem Seal Figure 8. O-ring Sealed Handwheel

Key Description Part Number

3 Main Spring, Plated steel

25 psid (1,72 bar d) maximum allowable

pressure drop 1C277127022

50 psid (3,45 bar d) maximum allowable

pressure drop 1N801927022

250 psid (17,2 bar d) maximum

allowable pressure drop 1B883327022

1000 psid (69,0 bar d) maximum allowable

pressure drop–requires main spring

seat 1E242724092 0W019127022

4 Diaphragm Rod, 416 Stainless steel 1B883435232

5 Diaphragm Rod Guide Assembly

Brass with bronze insert 1D9712000A2

316 Stainless steel 1B883535072

6 Collar

Brass 1B883614012

316 Stainless steel 1B883635072

7* Pusher Post Gasket

Composition - for standard construction 1B883704022

Fluorocarbon (FKM) - for oxygen service 1N430306382

8 Pusher Post Assembly

Brass with bronze insert 1D9714000A2

316 Stainless steel 1B883835072

316 Stainless steel - for oxygen service 14B1320X012

9 Lever, Steel 2F823423072

10 Diaphragm Plate, Plated steel 1B989225072

11* Diaphragm

Nitrile (NBR) 1B884102052

Fluorocarbon (FKM) 1N378902312

12 Cap Screw, Plated steel (12 required) 1B884224052

13 Hex Nut, Plated steel (13 required) 1A340324122

14 Union Nut, Iron 0Z0176X0032

15 Body Snap Ring, Plated steel 0Y095828982

16* Body Gasket

Composition 1A348004032

Graphite - for oxygen service 1A3480X0022

17 Valve Body

2-inch NPT

Cast iron 1C254619012

Steel 2N153522012

Brass 1C254612012

Brass - for oxygen service 1C2546X0012

2-inch (DN 50) CL125 FF anged, Cast iron 2D986519012

2-inch (DN 50) CL250 RF anged, Cast iron 2D986619012

A6802

Key Description Part Number

17 Valve Body (continued)

2-inch (DN 50) CL150 RF anged

Steel 2E275622012

2-inch (DN 50) CL300 RF anged

Steel 2E275722012

18 Holder for Type 99 regulator

Disk seat

Brass 1B884314012

316 Stainless steel 1B884335072

O-ring Seat

7/8-inch (22,2 mm) orice

Brass 1E603214012

316 Stainless steel 1E603235072

1-1/8-inch (28,6 mm) orice

Brass 1E342414012

316 Stainless steel 1E342435072

18* Disk and Holder Assembly for 1000 psig

(69,0 bar) maximum inlet regulator, Nylon (PA)/

316 Stainless steel 1C1860000B2

19 Disk for Type 99 Regulator

250 psid (17,2 bar d) maximum

allowable pressure drop

Neoprene (CR) 1C997403032

Nitrile (NBR) 1C158703332

Fluorocarbon (FKM) 1C9974X0012

400 psid (27,6 bar d) maximum

allowable pressure drop

Nylon (PA) 1E480603152

Polytetrauoroethylene (PTFE) 1C997406242

19* O-ring

7/8-inch (22,2 mm) orice

Nitrile (NBR) 1D237506992

Fluorocarbon (FKM) 1D237506382

1-1/8-inch (28,6 mm) orice

Nitrile (NBR) 1H8498X0012

Fluorocarbon (FKM) 1H8498X0032

20* Orice

Disk seat for all regulators

3/8-inch (9,52 mm) orice, 416 Stainless steel 19A7390X012

1/2-inch (12,7 mm) orice, 416 Stainless steel 14A8410X012

5/8-inch (15,9 mm) orice, 416 Stainless steel 19A7391X012

7/8-inch x 3/8-inch (22,2 x 9,52 mm) orice

Brass 1N878114012

316 Stainless steel 1N8781X0012

*Recommended Spare Parts

13

Page 14

Type 99

AS – APPLY ANTI-SEIZE COMPOUND

PTS – APPLY PIPE THREAD SEALANT

LUB – APPLY LUBRICANT

PTS

AS

O-RING SET DETAIL

AS

AS

PTS

CONTROL

LINE TAP

(OTHER TAP

180° OPPOSITE)

DJ6642

PTS

AS

LUB

PTS

PTS

1/4-INCH (6,35 mm) VENT SHOWN 90°

COUNTERCLOCKWISE FROM NORMAL

PTS

COMPLETE REGULATOR SHOWING TYPE 61L PILOT AND DISK SEAT

14

DJ6642_B

PILOT RELAY ASSEMBLY

Figure 9. Type 99 Regulator with Type 61L (Low) or 61H (High Pressure) Pilot

Page 15

Type 99

30A6800

HIGH PRESSURE PILOT PARTS

C0289-1C

PILOT RELAY AND COVER ASSEMBLY

Figure 9. Type 99 Regulator with Type 61L (Low) or 61H (High Pressure) Pilot (continued)

15

Page 16

Type 99

Actuator and Main Body Assembly

(Figures 6, 7, 8, 9, 10, and 11) (continued)

Key Description Part Number

20* Orice (continued)

Disk seat for all regulators

7/8-inch x 1/2-inch (22,2 x 12,7 mm) orice

Brass 1C942314012

316 Stainless steel 1C942335072

7/8-inch x 5/8-inch (22,2 x 15,9 mm) orice

Brass 1C942414012

316 Stainless steel 1C9424X0012

3/4-inch (19,1 mm) orice

Brass 1C780414012

316 Stainless steel 1C780435072

7/8-inch (22,2 mm) orice

Brass 1C394714012

316 Stainless steel 1C394735072

1-inch (25,4 mm) orice, Brass 13A5017X012

1-1/8-inch (28,6 mm) orice

Brass 1B884414012

316 Stainless steel 1B884435072

1/2-inch (12,7 mm) disk seat for

1000 psig (69,0 bar) maximum inlet regulator,

416 Stainless steel 14A8410X012

O-ring seat for all regulators

7/8-inch (22,2 mm) orice

Brass 1E603014012

316 Stainless steel 1E603035072

1-1/8-inch (28,6 mm) orice

Brass 1E342514012

316 Stainless steel 1E342535072

21 Retainer

Disk seat 3/4-inch (19,1 mm)

All except 3/4-inch (19,1 mm) or

1-1/8-inch (28,6 mm) orice or

1000 psig (69,0 bar) maximum inlet regulator

Brass 1C394814012

303 Stainless steel 1C394835032

3/4-inch (19,1 mm) orice

Brass 1C780314012

316 Stainless steel 1C7803X0012

1-1/8-inch (28,6 mm) orice

Brass 1B884514012

316 Stainless steel 1B884535072

O-ring seat for all regulators

7/8-inch (22,2 mm) orice

Brass 1E603114012

316 Stainless steel 1E603135072

1-1/8-inch (28,6 mm) orice

Brass 1E342614012

316 Stainless steel 1E342635072

22 Cap Screw, Plated steel 1A391724052

25 Cotter Pin, 316 Stainless steel 1B108438992

26 Valve Carrier

Brass 1E597114072

416 Stainless steel 1E597135132

27 Lever Pin

316 Stainless steel 1B884935162

303 Stainless steel 1C911635032

28 Retaining Ring for brass trim,

Plated steel (2 required) 1B8850X0012

Cotter Pin for Stainless steel trim,

316 Stainless steel (2 required) 1A866537022

PIPE THREAD

SEALANT

AJ5004-A

A2135/IL

Figure 10. Standard P590 Series Filter Assembly

Key Description Part Number

29 Lower Casing, Cast iron

Standard 4B983719012

For use with optional protector, spring washer,

and machine screw (keys 61, 62, and 63) 2N379419012

Lower Casing Assembly for use with O-ring stem

seal, Cast iron with SST guide bushing

Complete with Nitrile (NBR) O-ring 2R7230000A2

Complete with Fluorocarbon (FKM) O-ring 2R7230X0022

32 Nameplate, Aluminum - - - - - - - - - - 56 Upper Casing, Cast iron 3B887619012

57* Spring Case Gasket

Composition 1B8877X0012

Graphite - for oxygen service 1B8877X0022

58 Cap Screw, Plated steel (4 required) 1A675124052

(1)

61

Lower casing protector (not shown), Brass 1N379514012

(1)

62

Optional Spring Washer (not shown)

Plated brass (2 required) 1N339518992

(1)

63

Optional Machine Screw (not shown)

Plated brass (2 required) 1H340518992

64* O-ring (for use only with O-ring stem seal)

Nitrile (NBR) 1E220206992

Fluorocarbon (FKM) 1R620106382

73 Pipe plug, Plated steel (not shown) 1A767524662

75 Standard P590 Series Filter Assembly

(parts listed under separate heading)

Type P594-1, Brass FSP594-1

Type P593-1, Aluminum FSP593-1

133 Pipe Elbow, Plated steel 1B860828992

134 Pipe Nipple, Plated steel 1B218826232

152 Drive Screw, 18-8 Stainless steel

(4 required for low pressure pilot and

6 required for high pressure pilot) 1A368228982

155 Type 1301F Pilot Supply Regulator

only with extra high pressure pilot) See footnote 2

156 Type H110 Pop Relief Valve, (for use only

with extra high pressure pilot) brass with

Nitrile (NBR) disk and 316 Stainless steel spring Consult Factory

159 Tag (for use only with O-ring stem seal and extra

high pressure pilot) alloy 1100 (not shown) 16A0957X012

(2)

(for use

*Recommended Spare Parts

1. Required with lower casing 2N379419012

2. Pilot supply regulator parts are found in Types 1301F and 1301G Instruction manual.

16

Page 17

Type 99

A6803

Figure 11. 1000 Psig (69,0 bar) Maximum Inlet Regulator Partial Detail

Standard P590 Series Filter Assembly

(Figure 10)

Key Description Part Number

1 Filter Body

Type P594-1, Brass 1E312414012

Type P593-1, Aluminum 1E3124X0022

2* Filter Element, Cellulose 1E312606992

3 Filter Head

Type P594-1, Brass 1E312514012

Type P593-1, Aluminum 1E3125X0022

4 Machine Screw

Type P594-1, Brass 1J500218992

Type P593-1, Aluminum 1J500209012

5 Washer (2 required)

Type P594-1, Brass 1J500018992

Type P593-1, Aluminum 1J500010062

6 Spring Washer, Plated carbon steel 1H885128982

7* Gasket, Composition 1F826804022

*Recommended Spare Parts

3. An entire pilot assembly may be ordered from your local Sales Ofce.

by specifying a Type 61L, a 61H, or a 61HP pilot for eld conversion.

Pilot and Tubing Parts

(3)

Low or High

Pressure Pilot (Figure 9)

Key Description Part Number

13 Hex Nut, Plated steel (13 required) 1A340324122

23 Elbow (2 required)

Brass 15A6002X292

316 Stainless steel 15A6002X612

24 Pilot Supply Tubing, disk or O-ring main valve seat

Copper 1D8793000A2

Copper - for oxygen service 0500201701W

316 Stainless steel 0500213809W

30* Upper Relay Diaphragm

Nitrile (NBR) 1B885202052

Fluorocarbon (FKM) 1N162802332

31 Upper Relay Diaphragm Plate, Plated steel

For use with all low pressure pilots except LE 1B989225072

For use with all high pressure pilots and LE

low pressure pilot 1D558425072

17

Page 18

Type 99

Pilot and Tubing Parts

(3)

Low or High

Pressure Pilot (Figure 9) (continued)

Key Description Part Number

33* O-ring Seal

Nitrile (NBR) 1B885506992

Fluorocarbon (FKM) 1B8855X0012

34 Connector

Brass 1D692214012

316 Stainless steel 15A6002X602

37 Yoke

Zinc 1D662544012

38* Relay Orice, Stainless steel

For use with 25 psi (1,72 bar) maximum allowable

pressure drop actuator main spring 1D373735032

For use with all other main springs 1C520135032

For use with oxygen service 1N162314042

39 Relay Valve Body, Cast iron 2J581919012

40* Lower Relay Diaphragm

Low pressure pilot

Nitrile (NBR) 1B886002052

Fluorocarbon (FKM) 1N536102332

High pressure pilot

Nitrile (NBR) 1B894202192

Fluorocarbon (FKM) 1N162702302

41 Lower Relay Diaphragm Plate, Plated steel

Low pressure pilot 1B989425072

High pressure pilot 1D558325072

42 Spring Seat, Plated steel

Low pressure pilot 1B886225072

High pressure pilot 1D558525072

43 Control Spring, Plated steel

For use only with LD low pressure pilot

0 to 4-inches w.c. (0 to 10 mbar), Orange 1B558527052

3 to 12-inches w.c. (7 to 30 mbar), Silver 1C680627222

For use with all low pressure pilots

0.25 to 2 psig (0,02 to 0,14 bar), Red 1B886327022

1 to 5 psig (0,07 to 0,34 bar), Yellow 1J857827022

2 to 10 psig (0,14 to 0,69 bar), Blue 1B886427022

5 to 15 psig (0,34 to 1,03 bar), Brown 1J857927142

10 to 20 psig (0,69 to 1,38 bar), Green 1B886527022

For use with high pressure pilot, Green stripe 0Y066427022

44 Spring Case, Cast iron

Low pressure pilot 1B983919012

High pressure pilot, Standard 1B984119012

For use with closing cap (not shown) 1H232619012

45 Adjusting Screw

Low pressure pilot, Standard, Zinc 1B537944012

Handwheel-style, Plated steel 1J496428982

O-ring seated handwheel assembly 1R759414012

High pressure pilot, Standard, Plated steel 1A279128982

For use with closing cap 1H236514012 1J881524102

46 Closing Cap

For use with standard low pressure pilot, Plastic T11069X0012

For use with handwheel-style low pressure

pilot, Brass (not shown) 1A926114012

For use with O-ring sealed handwheel 1R759314012

For use with high pressure pilot with spring

case 1H232619012, Brass (not shown) 1H236514012

47 Cap Screw, Plated steel (8 required) 1B989624052

48* Relay Disk Assembly

Brass/Nitrile (NBR) 1B8868000A2

303 Stainless steel/Nitrile (NBR) 1B8868000B2

Key Description Part Number

48* Relay Disk Assembly (continued)

Brass/Fluorocarbon (FKM) 1B8868X0012

303 Stainless steel/Fluorocarbon (FKM) 1B8868X0022

49* Bleed Valve Spring, Stainless steel

For use with low pressure pilot with relay orice

1D373735032 or bleed valve 1H951635132 1E643637022

For use with all low and high pressure pilots

Inlet pressure up to 250 psig (17,2 bar) 1C911537022

Inlet pressure over 250 psig (17,2 bar) 1N859137022

50* Bleed Valve, Stainless steel

For use with LD low pressure pilot with bleed

valve spring 1E643637022 1H951635132

For use with all low and high pressure pilots 1D986735132

51 Diaphragm Nut

Brass 1B989514012

316 Stainless steel 1B989535072

52* Bleed Orice, 316 Stainless steel 1B887335032

53 Loading Tubing

Copper 1J4928000A2

316 Stainless steel 0500213809W

54 Connector

Brass 1H628114012

316 Stainless steel 15A6002X992

55 Pipe Nipple

Plated steel (1 required with copper tubing

and 2 required with aluminum tubing) 1C488226232

316 Stainless steel 1C488238982

59 Pipe plug, Steel (not shown) 1A369224492

60 Type Y602-1 Vent Assembly 27A5516X012

68 Spring Seat

Handwheel-style low pressure pilot,

Steel, (not shown) 1J618124092

High pressure pilot, Zinc 16A9812X012

71* Closing Cap Gasket (for use only with

low pressure pilot), Neoprene (CR) 1P753306992

72 Type Y602-1 Vent Assembly (for use only with

standard high pressure pilot spring case),

Zinc/18-8 Stainless steel 17A6570X012

78 Handwheel (for use only with handwheel-style

low pressure pilot), Zinc 1J496144012

79 Machine Screw (for use only with handwheel-style

low pressure pilot), Plated steel 16A5763X012

80 Lockwasher (for use only with handwheel-style

low pressure pilot), Steel 1A352332992

81 O-ring (for use only with O-ring sealed

handwheel assembly) 1D541506992

82 Hex nut

For use only with O-ring sealed

handwheel assembly 1A351124122

For use with high pressure pilot, Plated steel 1A352224122

114* Gasket (for use only with high pressure pilot

with spring case 1H232619012), Steel/

Composition (not shown) 1B487099202

115 Adaptor (for use only with high pressure pilot with

spring case 1H232619012), Steel (not shown) 1J881624092

132 Pilot Cover (used only with complete replacement

pilot assembly for eld conversion), Cast iron 2C518619012

152 Drive Screw, 18-8 Stainless steel

(4 required for low pressure pilot and

6 required for high pressure pilot) 1A368228982

154 Drive Screw (for use only with low pressure

pilot), 18-8 Stainless steel (2 required) 1A368228982

*Recommended Spare Parts

3. An entire pilot assembly may be ordered from your local Sales Ofce.

by specifying a Type 61L, a 61H, or a 61HP pilot for eld conversion.

18

Page 19

A.S. – APPLY ANTI-SEIZE COMPOUND

Type 99

A6804

Figure 12. Type 61HP (Extra High Pilot) Pilot

Type 61HP (Extra High Pressure) Pilot

(Figure 12)

Key Description Part Number

23 Elbow

For use with all standard regulators

Brass 15A6002X292

316 Stainless steel 15A6002X202

For use with 1000 psig (69,0 bar) maximum inlet

regulator, Steel 1J139628982

24 Pilot Supply Tubing

For use with all standard regulators

Copper 1D7703000A2

316 Stainless steel 0500213809W

For use with 1000 psig (69,0 bar) maximum inlet

regulator, Steel 0500213809W

30* Diaphragm

Neoprene (CR) 13A9840X012

Fluorocarbon (FKM)/Dacron® 13A9840X022

31 Yoke Leg, 416 Stainless steel (2 required) 13A9838X012

Key Description Part Number

34 Connector (3 required)

For use with all standard regulators

Brass 1D692214012

316 Stainless steel 15A6002X602

For use with 1000 psig (69,0 bar) maximum

inlet regulator, Steel 15A6002XW22

35 Cap Screw, Plated steel (6 required) 1A930424052

36 Elbow, Plated steel 1B860828992

37 Yoke Cap, 416 Stainless steel 13A9837X012

38 Inlet Orice

303 Stainless steel 1D318135032

39 Pilot Body, Cast iron 33A9845X012

40* Diaphragm

Neoprene (CR) 13A9841X022

Fluorocarbon (FKM)/Dacron

41 Diaphragm Plate,

416 Stainless steel (4 required) 13A9839X012

43 Control Spring, Plated steel (blue) 1D387227022

44 Spring Case, Cast iron

Standard 2P969419012

(4)

13A9841X012

*Recommended Spare Parts

4. Dacron® is a mark owned by E.I. du Pont de Nemours and Co.

19

Page 20

Type 99

Type 61HP (Extra High Pressure) Pilot

(Figure 12) (continued)

Key Description Part Number

45 Adjusting Screw, Plated carbon steel

Standard 1C216032992

47 Cap Screw, Plated steel (8 required) 1B787724052

49 Relief Valve Spring, 316 Stainless steel 1C374037022

50 Relief Valve Plug, 316 Stainless steel 1K377535162

52 Bleed Orice

Brass 1B329014012

53 Loading Tubing

For use with all standard regulators

Copper 1D7702000A2

317 Stainless steel 0500213809W

For use with 1000 psig (69,0 bar) maximum

inlet regulator, Steel 1K5466X0042

55 Pipe Nipple, Plated steel (2 required) 1C488226232

60 Pipe plug, Steel (not shown) 1A649528982

68 Spring Seat, Plated steel 10A3963X012

72 Type Y602-12 Vent Assembly (for use only

with tapped spring case 20A4735X012),

Zinc with 18-8 Stainless steel screen 27A5516X012

82 Locknut, Plated steel 1A352224122

116 Yoke Cap, 416 Stainless steel 13A9836X012

117* Inlet Valve Plug

304 Stainless steel/Nitrile (NBR) 1D5604000B2

304 Stainless steel/Fluorocarbon (FKM) 1N3798000C2

Key Description Part Number

118 Relief Valve Cap

Brass 1D904914012

303 Stainless steel 1D904935072

119 Relief Valve Body

Brass 1D904814012

316 Stainless steel 1D904835072

120 Spring Seat

Brass 1K377718992

316 Stainless steel 1K377735072

121 Spring Seat Washer

Brass 1B495118992

316 Stainless steel 1K377835072

122 Pipe Bushing, Carbon-plated steel 1C379026232

123 Cap Screw, Plated steel (6 required) 1P327028982

124 Valve Spring, 316 Stainless steel 1B797937022

125 Flange Adaptor, Steel 23A9846X012

126* Gasket, Composition 0U0365X0032

128 Diaphragm Nut, Plated steel 1A346524122

129* Valve Spring Seat, Aluminum 1L251135072

130 Machine Screw, 303 Stainless

steel (4 required) 1A866935032

131 Pipe plug, Steel (not shown) 1A369224492

150 Diaphragm Insert (2 required)

Nitrile (NBR) 13A9842X012

Fluorocarbon (FKM) 13A9842X022

152 Drive Screw, 18-8 Stainless

steel (2 required) 1A368228982

153 Seal Washer, Nitrile (NBR)/Plated

steel (6 required) 13A9849X012

*Recommended Spare Parts

Industrial Regulators

Regulator Division

Emerson Process Management

USA - Headquarters

McKinney, Texas 75070 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Regulator Division

Emerson Process Management

USA - Headquarters

McKinney, Texas 75070

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Regulator Division

Emerson Process Management

USA - Headquarters

Elk River, Minnesota 55330 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Fis her C ontr ols Intern ational, In c., 1979, 2008; All Rights Reserved

Loading...

Loading...