Page 1

Model 54eA

Amperometric HART®Analyzer/Controller

Instruction Manual

51-54eA/rev.J

May 2006

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Rosemount Analytical designs, manufactures, and tests its products to

meet many national and international standards. Because these instruments are sophisticated technical products, you must properly install, use,

and maintain them to ensure they continue to operate within their normal

specifications. The following instructions must be adhered to and integrated into your safety program when installing, using, and maintaining

Rosemount Analytical products. Failure to follow the proper instructions

may cause any one of the following situations to occur: Loss of life; personal injury; property damage; damage to this instrument; and warranty

invalidation.

• Read all instructions prior to installing, operating, and servicing the product. If this Instruction Manual is not the correct manual, telephone 1800-654-7768 and the requested manual will be provided. Save this

Instruction Manual for future reference.

• If you do not understand any of the instructions, contact your

Rosemount representative for clarification.

• Follow all warnings, cautions, and instructions marked on and supplied

with the product.

• Inform and educate your personnel in the proper installation, operation,

and maintenance of the product.

• Install your equipment as specified in the Installation Instructions of the

appropriate Instruction Manual and per applicable local and national

codes. Connect all products to the proper electrical and pressure

sources.

• To ensure proper performance, use qualified personnel to install, operate, update, program, and maintain the product.

• When replacement parts are required, ensure that qualified people use

replacement parts specified by Rosemount. Unauthorized parts and

procedures can affect the product’s performance and place the safe

operation of your process at risk. Look alike substitutions may result in

fire, electrical hazards, or improper operation.

• Ensure that all equipment doors are closed and protective covers are in

place, except when maintenance is being performed by qualified persons, to prevent electrical shock and personal injury.

WARNING

ELECTRICAL SHOCK HAZARD

Making cable connections to and servicing this instrument require access to shock hazard level voltages

which can cause death or serious injury, therefore,

disconnect all hazardous voltage before accessing

the electronics.

Relay contacts made to separate power sources must

be disconnected before servicing.

Electrical installation must be in accordance with the

National Electrical Code (ANSI/NFPA-70) and/or any

other applicable national or local codes.

Unused cable conduit entries must be securely sealed

by non-flammable closures to provide enclosure

integrity in compliance with personal safety and environmental protection requirements. Use NEMA 4X or

IP65 conduit plugs supplied with the instrument to

maintain the ingress protection rating (IP65).

For safety and proper performance this instrument

must be connected to a properly grounded three-wire

power source.

Proper relay use and configuration is the responsibility of the user. No external connection to the instrument of more than 60VDC or 43V peak allowed with

the exception of power and relay terminals. Any violation will impair the safety protection provided.

Do not operate this instrument without front cover

secured. Refer installation, operation and servicing to

qualified personnel.

WARNING

This product is not intended for use in the residential, commercial or light industrial environment per certification to EN61326.

Emerson Process Management

Liquid Division

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 757-8500

Fax: (949) 474-7250

http://www.raihome.com

© Rosemount Analytical Inc. 2006

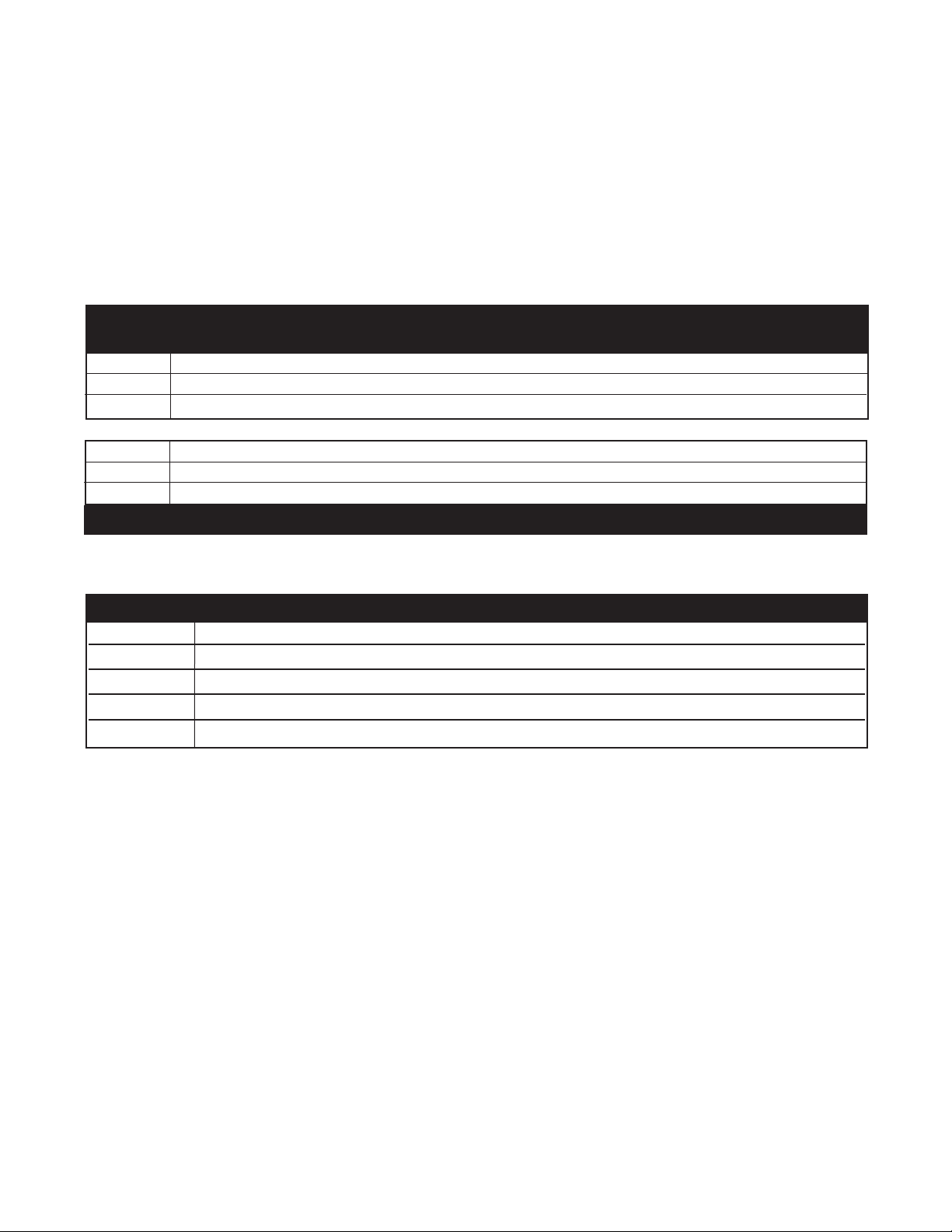

About This Document

This manual contains instructions for installation and operation of the Model 54eA Amperometric

HART Analyzer/Controller. The following list provides notes concerning all revisions of this document.

Rev. Level Date Notes

A 11/01 This is the initial release of the product manual. The manual has been reformatted to reflect the

Emerson documentation style and updated to reflect any changes in the product offering.

B 2/02 Revised wiring diagrams on pages 9, 11, & 13.

C 5/02 Added configuration note to page 10.

D 11/02 Change to intro verbiage in Section 5.3 on page 26.

E 11/02 Added note re 499A sensors to page 8.

F 4/03 Added monochloramine section and updated CE info.

G 8/03 Minor textual revisions on pages 48, 65, 67, 93.

H 12/03 Updated ISO & warranty info, and fixed minor typos throughout.

I 4/05 Added note re ordering replacement boards/integrated board stack on page 105.

J 5/06

Noted 0-20 mA limitation for HART versions on pp. 18, 25, & 31.

Page 3

Page 4

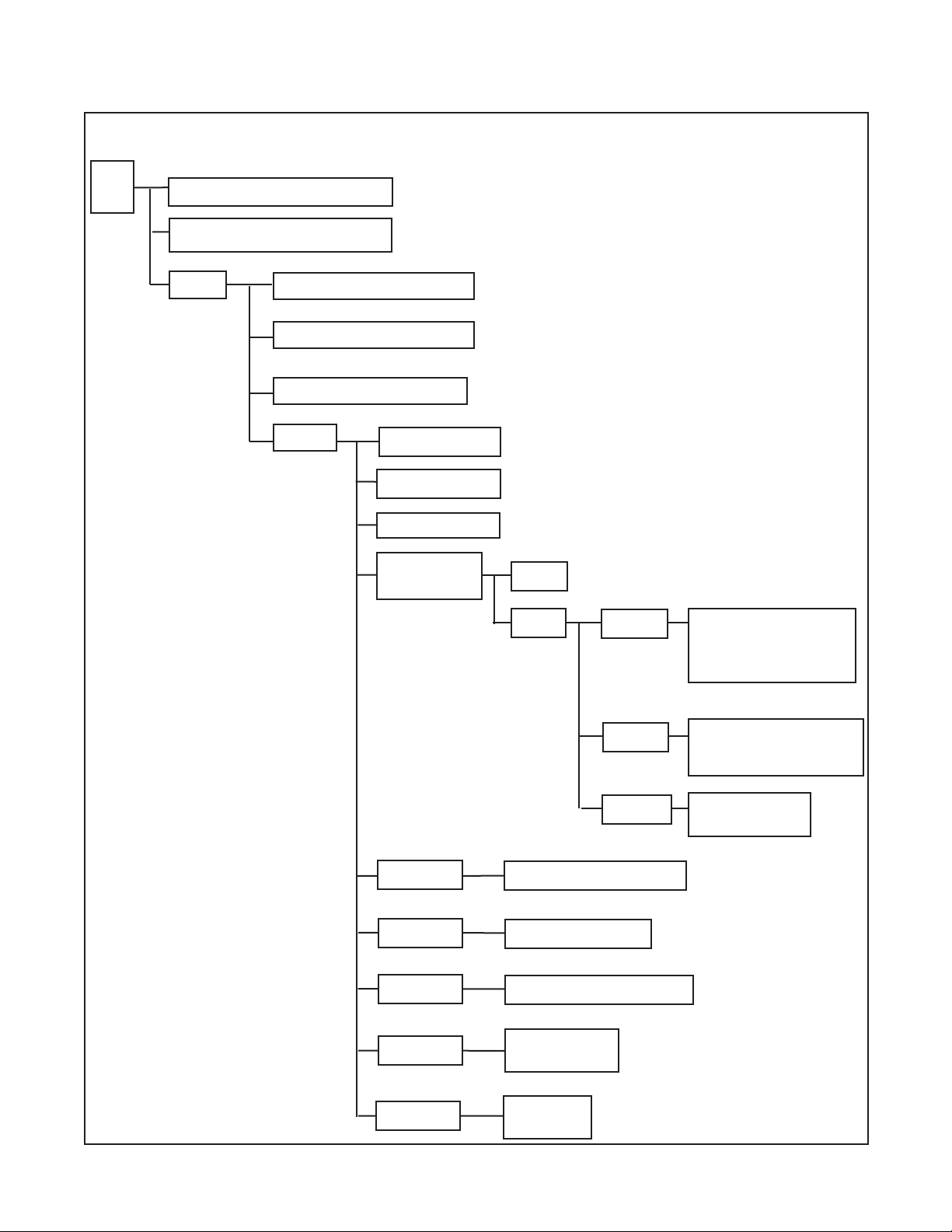

MODEL 54eA TABLE OF CONTENTS

MODEL 54eA ANALYZER/CONTROLLER

TABLE OF CONTENTS

Section Title Page

1.0 SPECIFICATIONS................................................................................................... 1

1.1 Features and Applications....................................................................................... 1

1.2 Specifications........................................................................................................... 2

1.3 Ordering Information................................................................................................ 4

2.0 INSTALLATION....................................................................................................... 5

2.1 Unpacking and Inspection ....................................................................................... 5

2.2 Installation ...............................................................................................................5

3.0 WIRING ................................................................................................................... 8

3.1 General.................................................................................................................... 8

3.2 Power, Alarm, and Output Wiring............................................................................ 8

3.3 Sensor Wiring.......................................................................................................... 10

4.0 DISPLAY AND OPERATION .................................................................................. 16

4.1 General Description................................................................................................. 16

4.2 Display..................................................................................................................... 16

4.3 Key Functions and Controls .................................................................................... 16

4.4 Alarm Status............................................................................................................ 16

5.0 SOFTWARE CONFIGURATION ............................................................................. 17

5.1 Changing Alarm Setpoints....................................................................................... 24

5.2 Ranging the Outputs ............................................................................................... 25

5.3 Changing Output Setpoints (PID only) .................................................................... 26

5.4 Testing Outputs and Alarms .................................................................................... 27

5.5 Choosing Display Options ....................................................................................... 28

5.6 Changing Output Parameters.................................................................................. 30

5.7 Changing Alarm Parameters ................................................................................... 33

5.8 Configuring the pH Measurement ........................................................................... 38

5.9 Temperature Compensation and Temperature Units............................................... 41

5.10 Noise Reduction ...................................................................................................... 42

5.11 Main Sensor Calibration Parameters ...................................................................... 43

5.12 Barometric Pressure................................................................................................ 44

5.13 Security.................................................................................................................... 45

5.14 Controller Mode Priority........................................................................................... 46

6.0 CALIBRATION - TEMPERATURE.......................................................................... 47

6.1 Introduction.............................................................................................................. 47

6.2 Temperature Calibration .......................................................................................... 48

7.0 CALIBRATION - DISSOLVED OXYGEN................................................................ 49

7.1 Introduction.............................................................................................................. 49

7.2 Zeroing the Sensor.................................................................................................. 50

7.3 Calibrating the Sensor in Air.................................................................................... 51

7.4 Calibrating the Sensor Against a Standard Instrument ........................................... 53

7.5 Calibrating Barometric Pressure ............................................................................. 54

8.0 CALIBRATION - FREE CHLORINE (499 ACL-01) ................................................ 55

8.1 Introduction.............................................................................................................. 55

8.2 Zeroing the Sensor.................................................................................................. 56

8.3 Full Scale Calibration............................................................................................... 57

8.4 Dual Slope Calibration............................................................................................. 58

i

Page 5

9.0 CALIBRATION - FREE CHLORINE (498 ACL-01) ................................................ 60

9.1 Introduction.............................................................................................................. 60

9.2 Zeroing the Sensor.................................................................................................. 61

9.3 Full Scale Calibration............................................................................................... 62

9.4 Dual Slope Calibration............................................................................................. 63

10.0 CALIBRATION - TOTAL CHLORINE ..................................................................... 65

11.0 CALIBRATION - MONOCHLORAMINE ................................................................. 67

11.1 Introduction.............................................................................................................. 67

11.2 Zeroing the Sensor.................................................................................................. 68

11.3 Full Scale Calibration............................................................................................... 69

12.0 CALIBRATION - OZONE........................................................................................ 70

12.1 Introduction.............................................................................................................. 70

12.2 Zeroing the Sensor.................................................................................................. 71

12.3 Full Scale Calibration............................................................................................... 72

13.0 CALIBRATION - pH................................................................................................ 73

13.1 Introduction.............................................................................................................. 73

13.2 Automatic Two-Point Calibration ............................................................................. 74

13.3 Manual Two-Point Calibration.................................................................................. 76

13.4 Standardization (One-Point Calibration).................................................................. 78

13.5 pH Slope Adjustment............................................................................................... 79

14.0 CALIBRATION - CURRENT OUTPUTS................................................................. 80

14.1 Introduction.............................................................................................................. 80

14.2 Trimming the Outputs.............................................................................................. 80

15.0 PID AND TPC CONTROL....................................................................................... 81

15.1 PID Control .............................................................................................................. 81

15.2 Time Proportional Control (TPC)............................................................................. 85

16.0 TROUBLESHOOTING ............................................................................................ 86

16.1 Overview.................................................................................................................. 86

16.2 Troubleshooting When a Fault Message is Showing.............................................. 86

16.3 Troubleshooting When No Fault Message is Showing - Temperature.................... 88

16.4 Troubleshooting When No Fault Message is Showing - Oxygen............................ 88

16.5 Troubleshooting When No Fault Message is Showing - Free Chlorine.................. 91

16.6 Troubleshooting When No Fault Message is Showing - Total Chlorine .................. 93

16.7 Troubleshooting When No Fault Message is Showing - Monochloramine ............. 94

16.8 Troubleshooting When No Fault Message is Showing - Ozone ............................. 97

16.9 Troubleshooting When No Fault Message is Showing - pH ................................... 99

16.10 Troubleshooting Not Related to Measurement Problems ....................................... 102

16.11 Simulating Inputs - Dissolved Oxygen .................................................................... 102

16.12 Simulating Inputs - Other Amperometric Measurements ........................................ 103

16.13 Simulating Inputs - pH............................................................................................. 104

16.14 Simulating Temperature........................................................................................... 105

16.15 Measuring Reference Voltage ................................................................................. 106

17.0 MAINTENANCE ...................................................................................................... 107

18.0 RETURN OF MATERIALS...................................................................................... 108

ii

MODEL 54eA TABLE OF CONTENTS

TABLE OF CONTENTS (CONTINUED)

Section Title Page

Page 6

iii

MODEL 54eA TABLE OF CONTENTS

LIST OF FIGURES

Section Title Page

2-1 Wall Mounting.......................................................................................................... 5

2-2 Pipe Mounting.......................................................................................................... 6

2-3 Pipe and Wall Mounting Dimensions....................................................................... 6

2-4 Panel Mounting........................................................................................................ 7

2-5 Panel Mounting Dimensions.................................................................................... 7

3-1 Power Input and Relay Output Wiring for Model 54eA........................................... 9

3-2 Wiring Label............................................................................................................. 10

3-3 Amperometric Sensors with Standard Cable........................................................... 10

3-4 Amperometric Sensors with Optimum EMI/RFI Cable or Variopol Cable ............... 10

3-5 Free Chlorine Sensor with Standard Cable and 399VP-09 pH Sensor without .....

Internal Preamplifier ................................................................................................ 11

3-6 Free Chlorine Sensor with Standard Cable and 399-14 pH Sensor Having Internal

Preamplifier.............................................................................................................. 12

3-7 Free Chlorine Sensor with Standard Cable and 399-09-62 pH sensor without .....

Internal Preamplifier ................................................................................................ 12

3-8 Free Chlorine Sensor with Optimum EMI/RFI Cable or Variopol Cable and .........

399VP-09 pH Sensor without Internal Preamplifier................................................. 13

3-9 Free Chlorine Sensor with Optimum EMI/RFI Cable or Variopol Cable and 399-14

pH Sensor Having Internal Preamplifier.................................................................. 13

3-10 Free Chlorine Sensor with Optimum EMI/RFI Cable or Variopol Cable and .........

399-09-62 pH Sensor without Internal Preamplifier ............................................... 14

3-11 Hx438 and Gx448 Sensors ..................................................................................... 15

4-1 Configuration of Inputs and Outputs for Free Chlorine ........................................... 16

4-2 Main Display Screen................................................................................................ 16

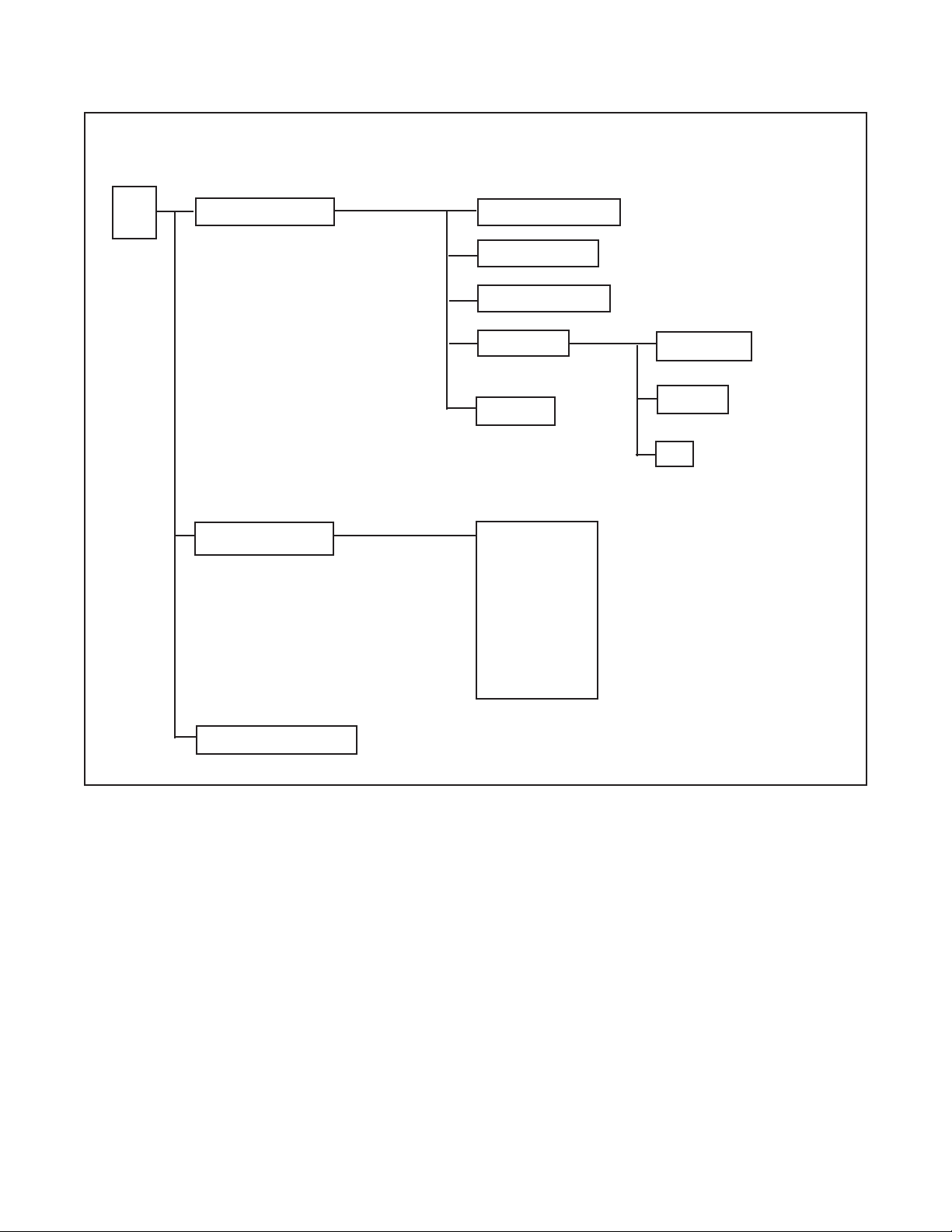

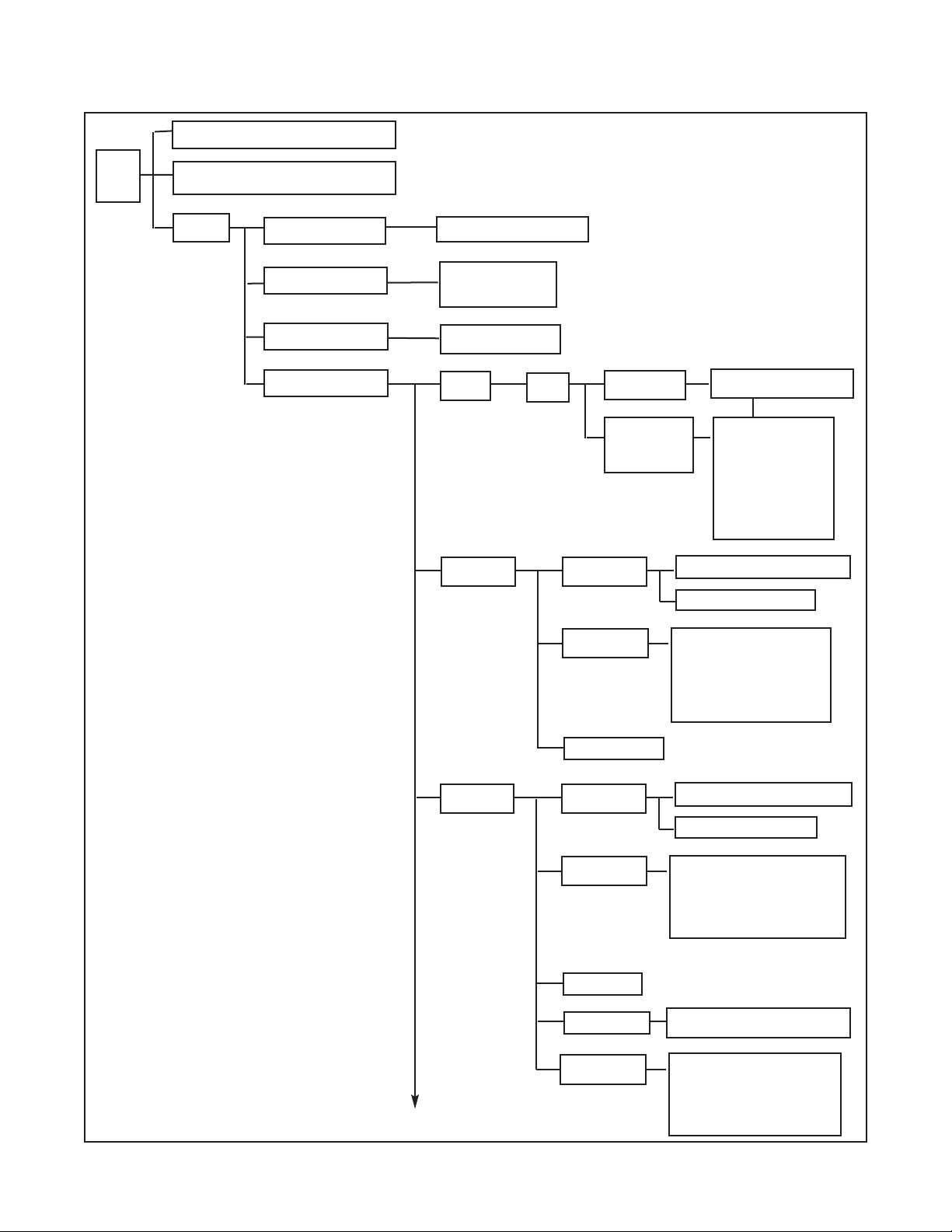

5-1 Menu Tree for the 54eA Controller .......................................................................... 21

5-2 Low Alarm................................................................................................................ 35

5-3 High Alarm............................................................................................................... 35

5-4 Interval Timer .......................................................................................................... 37

7-1 Sensor Current as a Function of Dissolved Oxygen Concentration ....................... 49

8-1 Sensor Current as a Function of Free Chlorine Concentration............................... 55

8-2 Dual Slope Calibration............................................................................................. 58

9-1 Determination of Total Chlorine ............................................................................... 60

9-2 Sensor Current as a Function of Total Chlorine Concentration............................... 60

9-3 Dual Slope Calibration............................................................................................. 63

10-1 Sensor Current as a Function of Monochloramine Concentration .......................... 65

11-1 Sensor Current as a Function of Ozone Concentration .......................................... 68

12-1 Calibration Slope and Offset ................................................................................... 71

14-1 The Process Reaction Curve .................................................................................. 81

14-2 Time Proportional Control........................................................................................ 83

15-1 Simulate Dissolved Oxygen..................................................................................... 100

15-2 Simulate Chlorine and Ozone ................................................................................. 101

15-3 Simulate pH ............................................................................................................. 102

15-4 Three-Wire RTD Configuration................................................................................ 103

15-5 Simulating RTD Inputs............................................................................................. 103

15-6 Checking for a Poisoned Reference Electrode ....................................................... 104

Page 7

1

MODEL 54eA SECTION 1.0

SPECIFICATIONS

SECTION 1.0

SPECIFICATIONS

1.1 FEATURES AND APPLICATIONS

The Model 54eA Analyzer/Controller with the appropriate sensor monitors and controls dissolved oxygen (ppm and ppb level), free chlorine, total

chlorine, and ozone in a variety of process liquids.

The analyzer is compatible with Rosemount

Analytical series 499A amperometric sensors for

oxygen, chlorine, and ozone; and with Hx438 and

Gx448 steam sterilizable oxygen sensors.

The amperometric sensors used with the Modeal

54eA produce a current directly proportional to the

concentration of the substance being determined.

Sensor currents are in the microampere to nanoampere range.

For oxygen measurements, an on-board pressure

sensor allows truly automatic air calibration. Simply

expose the sensor to water-saturated air. Wait until

readings are stable and press a button. The analyzer measures temperature and barometric pressure

and automatically completes the calibration.

For free chlorine measurements, both automatic and

manual pH correction are available. pH correction is

necessary because amperometric chlorine sensors

respond only to hypochlorous acid. To measure free

chlorine (hypochlorous acid plus hypochlorite ion)

most competing analyzers require an acidified sample. Acid lowers the pH and converts hypochlorite

ion to hypochlorous acid. The 54eA analyzer eliminates the need for messy and expensive reagents

by using the sample pH to correct the chlorine sensor signal. If the pH is relatively constant, a fixed pH

correction can be used. If the pH is greater than 7

and fluctuates more than about 0.2 units, continuous

measurement of pH and automatic pH correction is

necessary. Corrections are valid to pH 9.5.

The 54eA analyzer fully compensates oxygen,

ozone, free chlorine, and total chlorine readings for

changes in membrane permeability caused by temperature changes.

For pH measurements — pH is available with free

chlorine only — the 54eA features automatic buffer

recognition with stabilization check. Buffer pH and

temperature data for commonly used buffers are

stored in the analyzer. Glass impedance diagnostics

warn the user of an aging or failed pH sensor.

The analyzer has a rugged, weatherproof, corrosionresistant enclosure (NEMA 4X and IP65) of epoxypainted aluminum. It is suitable for panel, pipe, or wall

mounting. A hinged front cover provides convenient

access to wiring. Programming and calibration are

through the front membrane keypad, which has tactile feedback. The large back-lit dot-matrix display

shows the main measurement (oxygen, chlorine, or

ozone) in large numerals. The temperature and output current are shown in smaller numerals on the

second line. Two user-selectable variables can be

displayed on the third line. The pH measurement, if

used, appears on the third line.

Two independent, galvanically isolated outputs provide

4-20 mA or 0-20 mA signals for oxygen, chlorine,

ozone, pH, or temperature. Output 1 includes a HART

digital signal superimposed on the analog signal. The

controller option allows PID control on any measurement.

The Model 54eA has three programmable alarm

relays. Alarms can be assigned to the amperometric

measurement, pH, or temperature. Alarms have programmable high or low activation, independent setpoints, adjustable deadband, and time delay. Any

relay can be configured as a timer to control a spray

cleaner for the dissolved oxygen sensor. An overfeed timer feature is also available. The controller

option allows each alarm to be configured for time

proportional control (TPC). A fourth relay is a dedicated fault alarm.

The Model 54eA analyzer is a member of the

Rosemount SMART FAMILY®of instruments. The

analyzer communicates with the Model 275 HART

®

communicator or any other host, including AMS, that

supports the 275 HART communication protocol.

®

SMART FAMILY is a registered trademark of Rosemount Inc.

®

HART is a registered trademark of the HART Communication Foundation.

Page 8

MODEL 54eA SECTION 1.0

SPECIFICATIONS

2

1.2 SPECIFICATIONS - GENERAL

Enclosure: Epoxy-painted (light gray) cast aluminum,

NEMA4X (IP65). 144 x 144 x 132 mm

(5.7 x 5.7 x 5.2 in.), DIN size.

Front Panel: Membrane keypad with tactile feedback.

Three green LEDs indicate alarm status. Red

LED indicates fault condition.

Display: Three-line, back-lit, dot matrix LCD, 70 x 35 mm.

First line is oxygen, chlorine, or ozone reading.

Second line is temperature and current output.

Third line is user-selectable. pH reading appears

on third line. Character heights: 1st line - 16 mm

(0.6 in.), 2nd and 3rd lines - 7 mm (0.3 in.).

Hazardous Location Approvals:

Class I, Division 2, Groups A, B, C, & D.

T5 Ta=50°C. Dust ignition proof: Class II,

Division 1, Groups E, F, & G; Class III.

FM: Max. relay contact rating: 28 Vdc

resistive

150 mA - Groups A & B;

400 mA - Group C;

540 mA - Group D

CSA:

Max. relay contact rating:

28 Vdc; 110 Vac; 230 Vac;

6 amps resistive. Enclosure Type 4.

Power:

Code -01: 115 VAC ± 10%, 50/60 Hz ± 6%, 8 W

230 VAC ± 10%, 50/60 Hz ± 6%, 8 W

Code -02: 20 - 30 VDC, 6 W

RFI/EMI: EN-61326

LVD (Code -01 only): EN-61010-1

Repeatability (input): ± 1 nA

Stability (input): ± 1 nA/month at 25°C

Outputs: Two 4-20 mA or 0-20 mA isolated outputs.

Continuously adjustable. Outputs can be assigned

to oxygen, chlorine, ozone, pH, or temperature.

Output dampening is user-selectable. Maximum

load at 24 Vdc or 115/230 Vac is 500 ohms.

Maximum load at 100/200 Vac is 500 ohms.

Output 1 has superimposed HART signal (option

-09 only). Outputs can be programmed for PID

control (option -20 only).

Output Accuracy: ± 0.05 mA

Alarms:

Relay 1 - Process, Interval, or Time

Proportional Control (TPC requires code -20)

Relay 2 - Process, Interval, or Time Proportional

Control (TPC requires code -20)

Relay 3 - Process, Interval, or Time Proportional

Control (TPC requires code -20)

Relay 4 - Sensor/analyzer and process fault alarm

Each relay has a dedicated LED on the front panel.

Relay Contacts: Relays 1-3: Epoxy sealed form A

contacts, SPST, normally open

Relay 4: Epoxy sealed form C, SPDT

Resistive Inductive

28 Vdc 5.0 Amps 3.0 Amps

115 Vac 5.0 Amps 3.0 Amps

230 Vac 5.0 Amps 1.5 Amps

Temperature Sensors Accepted: Pt 100 RTD,

Pt 1000 RTD, 22K NTC thermistor.

Ambient Temperature: 0 to 50°C (32 to 122°F).

Analyzer can be operated between -20 and 60°C

(-4 to 140°F) with some degradation in display

quality.

Relative Humidity: 95% (maximum) non-condensing

Weight/Shipping Weight: 5 lb/6 lb (2 kg/2.5 kg)

Page 9

MODEL 54eA SECTION 1.0

SPECIFICATIONS

SPECIFICATIONS — OXYGEN

Measurement Range: 0-99 ppm (mg/L), 0-200% sat-

uration

Resolution: 0.01 ppm, 0.1 ppb for 499A TrDO sen-

sor

Temperature correction for membrane permeabili-

ty: automatic between 0 and 50°C (can be dis-

abled)

Calibration: automatic air calibration or calibration

against a standard instrument

Pressure sensor range: 113 to 862 mmHg (151 to

1149 mbar)

RECOMMENDED SENSORS —

OXYGEN:

Model 499A DO-54 for ppm level

Model 499A TrDO-54 for ppb level

Hx438 and Gx448 steam-sterilizable oxygen sensors

SPECIFICATIONS — FREE CHLORINE

Measurement Range: 0-20 ppm (mg/L) as Cl

2

Resolution: 0.001 ppm

Temperature correction for membrane permeabili-

ty: automatic between 0 and 50°C (can be dis-

abled)

pH Correction: Automatic between pH 6.0 and 9.5.

Manual pH correction is also available.

Calibration: against grab sample analyzed using

portable test kit.

RECOMMENDED SENSOR — FREE

CHLORINE:

Model 499A CL-01-54

SPECIFICATIONS — pH

Application: pH measurement available with free

chlorine only.

Measurement Range: 0-14 pH

Resolution: 0.01 pH

Sensor Diagnostics: Glass impedance (for broken or

aging electrode) and reference offset. Reference

impedance (for fouled reference junction) is not

available.

Repeatability: ±0.01 pH at 25°C

Stability: ±0.01 pH/month, non-cumulative at 25°C

RECOMMENDED pH SENSORS:

Model 399-09-62, 399-14, and 399VP-09

See pH sensor product data sheet for complete ordering

information.

SPECIFICATIONS — TOTAL CHLORINE

Measurement Range: 0-20 ppm (mg/L) as Cl

2

Resolution: 0.001 ppm

Temperature correction for membrane permeabili-

ty: automatic between 5 and 35°C (can be dis-

abled)

Calibration: against grab sample analyzed using

portable test kit.

RECOMMENDED SENSOR — TOTAL

CHLORINE:

Model 499A CL-02-54 (must be used with SCS 921)

SPECIFICATIONS — OZONE

Measurement Range: 0-10 ppm (mg/L)

Resolution: 0.001 ppm

Temperature correction for membrane permeabili-

ty: automatic between 5 and 35°C (can be dis-

abled)

Calibration: against grab sample analyzed using

portable test kit.

RECOMMENDED SENSOR — OZONE:

Model 499A OZ-54

3

Page 10

MODEL 54eA SECTION 1.0

SPECIFICATIONS

4

1.3 ORDERING INFORMATION

The Model 54eA Microprocessor Analyzer measures dissolved oxygen, free chlorine, total chlorine, ozone,

and pH. pH is available for free chlorine only. The analyzer has an on-board pressure sensor for automatic air

calibration of oxygen sensors. Amperometric measurements are fully compensated for changes in membrane

permeability with temperature. Free chlorine is corrected for pH. Standard features include a three-line back-lit

display, dual isolated outputs, and three programmable alarm relays. HART communications and PID and TPC

control are optional.

CODE OPTIONS

01 115/230 VAC, 50/60 Hz Power

02 24 VDC

MODEL

54eA MICROPROCESSOR ANALYZER

CODE OPTIONS

09 HART Communications Protocol

20 Controller Outputs - PID and TPC

ACCESSORIES

PART NO. DESCRIPTION

2002577 Wall and two inch pipe mounting kit

23545-00 Panel mounting kit

23554-00 Cable glands, kit (Qty 5 of PG 13.5)

9240048-00 Stainless steel tag (specify marking)

54eA

-01 -20 EXAMPLE

Page 11

5

MODEL 54eA SECTION 2.0

INSTALLATION

SECTION 2.0

INSTALLATION

2.1 UNPACKING AND INSPECTION

Inspect the shipping container. If it is damaged, contact the shipper immediately for instructions. Save the box. If

there is no apparent damage, unpack the container. Be sure all items shown on the packing list are present. If

items are missing, notify Rosemount Analytical immediately.

2.2 INSTALLATION

2.2.1 General information

1. Although the controller is suitable for outdoor use, do not install it in direct sunlight or in areas of extreme

temperatures.

2. Install the controller in an area where vibrations and electromagnetic and radio frequency interference are

minimized or absent.

3. Keep the controller and sensor wiring at least one foot from high voltage conductors. Be sure there is easy

access to the controller.

4. The controller is suitable for panel, pipe, or wall mounting. Refer to the table below.

2.2.2 Wall or surface mounting

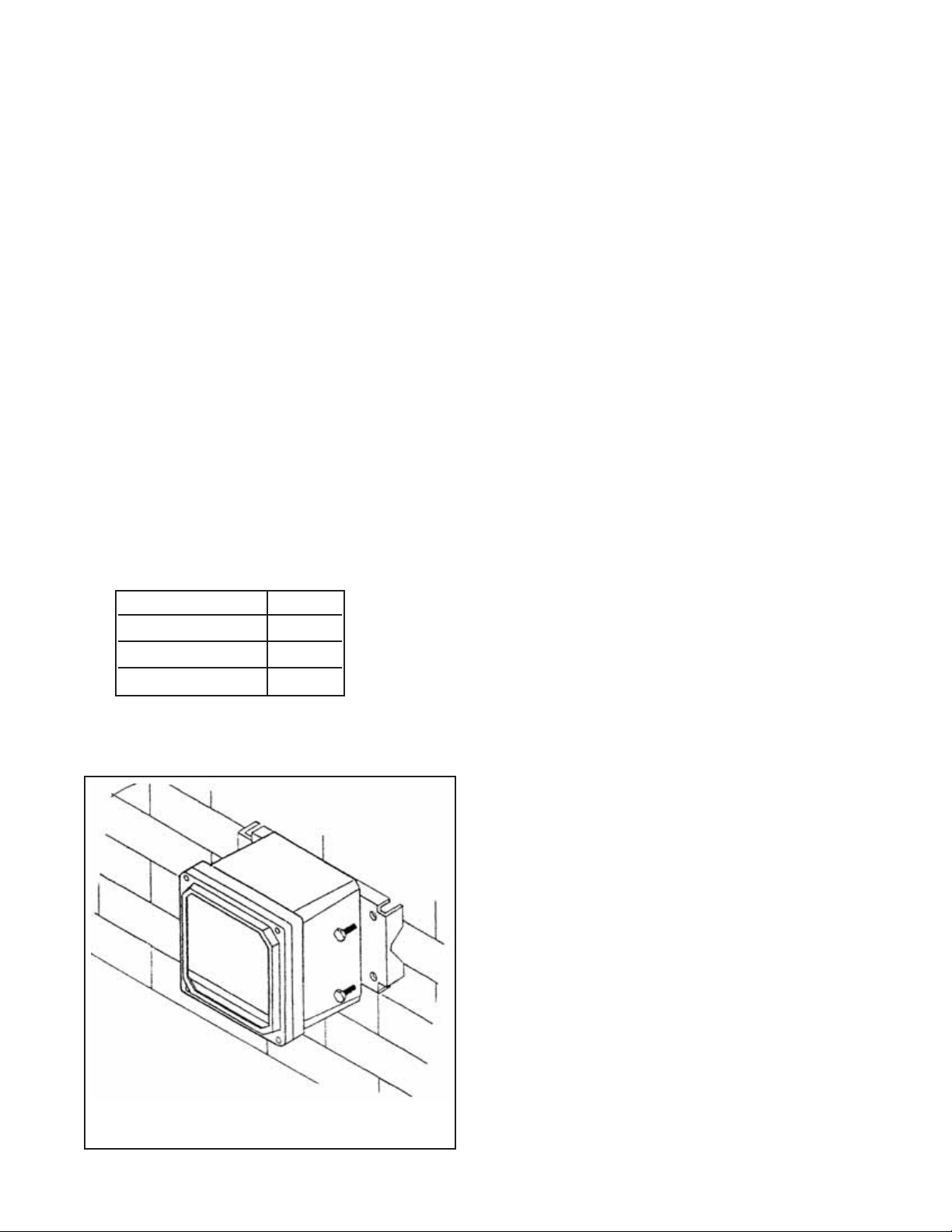

FIGURE 2-1. Wall Mounting

Type of mounting Section

Wall 2.2.2

Pipe 2.2.3

Panel 2.2.4

Page 12

6

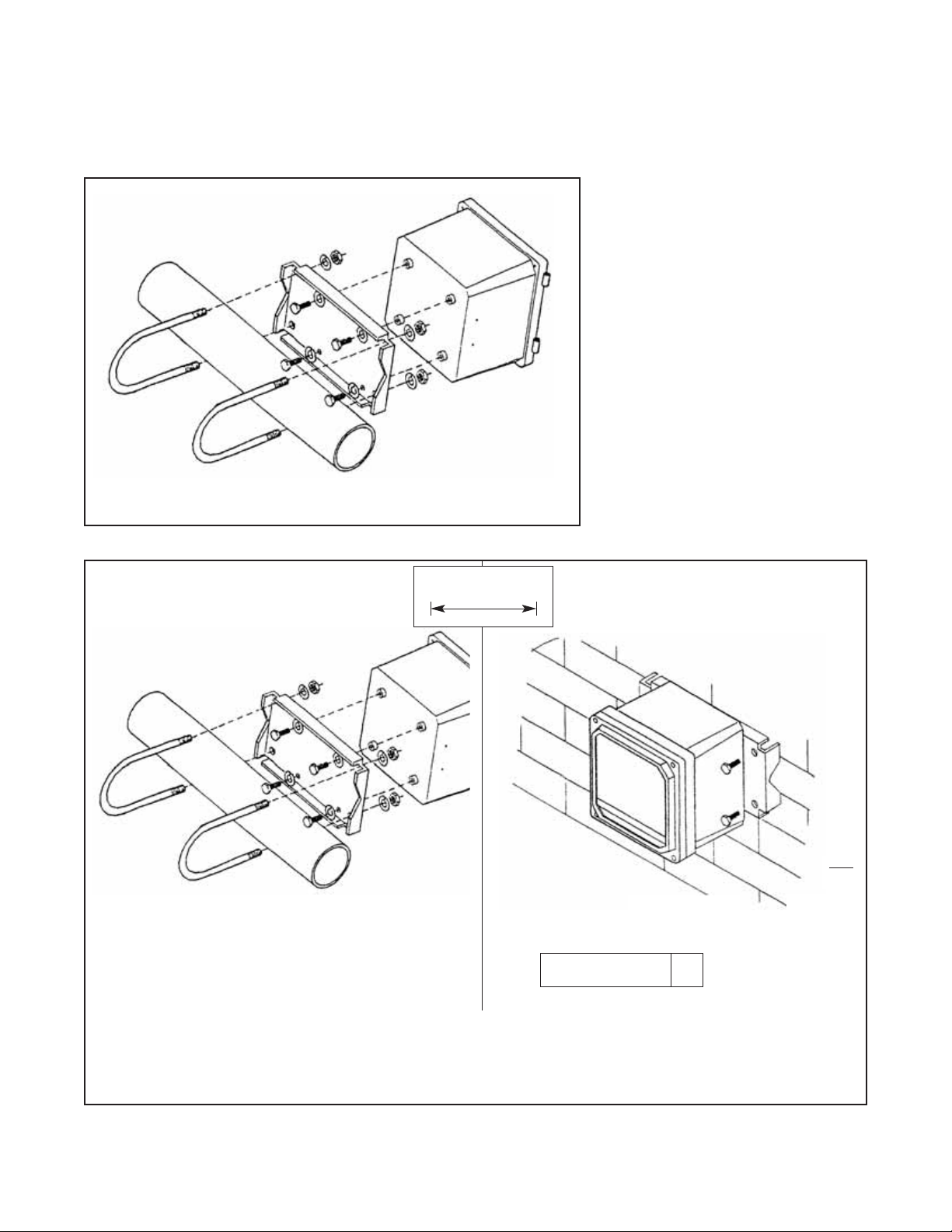

FIGURE 2-2. Pipe Mounting

MODEL 54eA SECTION 2.0

INSTALLATION

2.2.3 Pipe mounting

9.52

.375

SIDE VIEW

FRONT VIEW

4 MOUNTING

HOLES

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

PIPE MOUNTING PN 2002577 WALL MOUNTING

FIGURE 2-3. Pipe and Wall Mounting Dimensions

DWG. NO. REV.

40005402 E

Page 13

MODEL 54eA SECTION 2.0

INSTALLATION

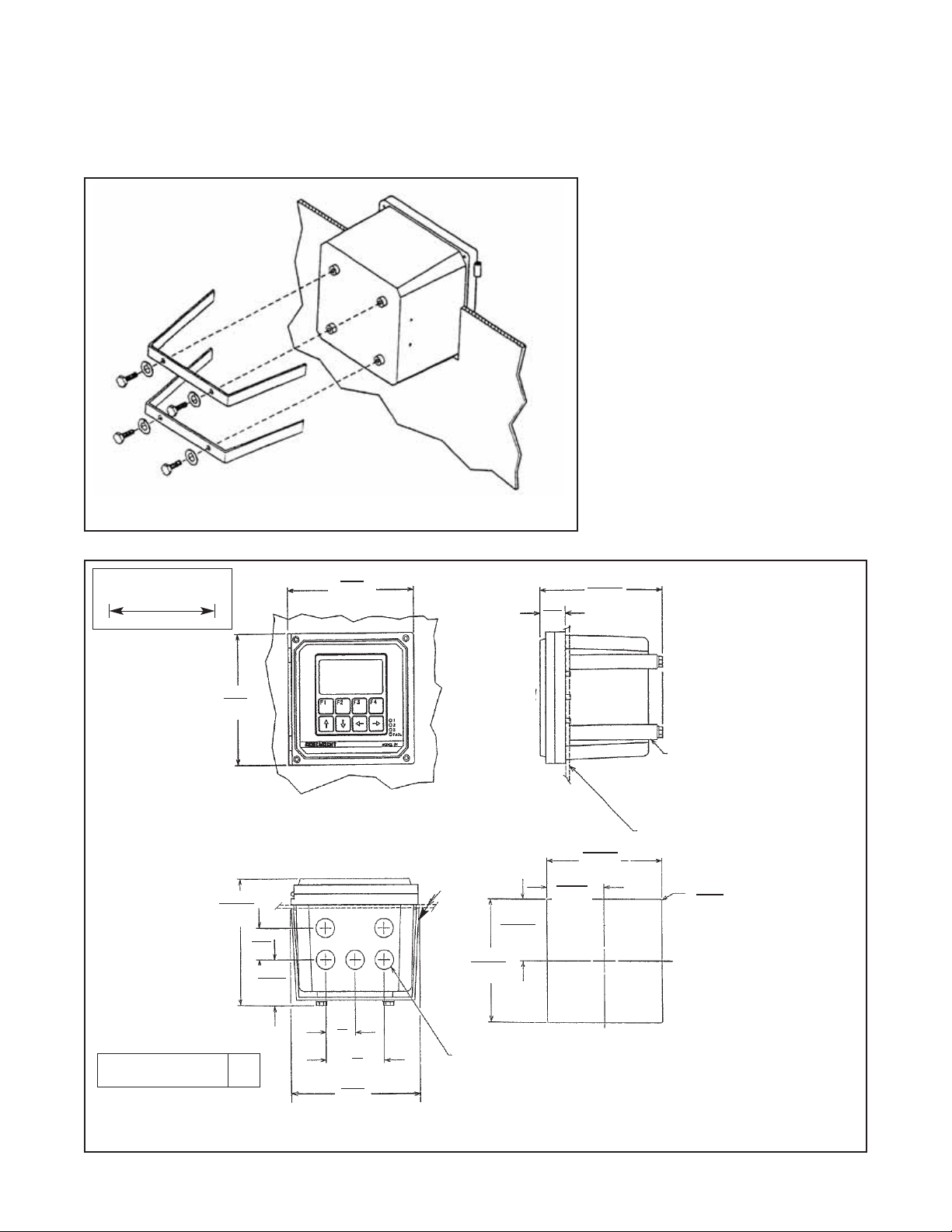

FIGURE 2-4. Panel Mounting

2.2.4 Panel mounting

WHEN INCH AND METRIC DIMS

ARE GIVEN

MILLIMETER

INCH

FIGURE 2-5. Panel Mounting Dimensions

144

5.7

35

1.38

50.8

2

1.52

.06

33

1.3

66

2.6

28.72

1.17

139.7

5.5

139.7

5.5

155.7

6.13

137.9

5.43

68.96

2.715

137.9

5.43

144

5.7

FRONT VIEW

BOTTOM VIEW

SIDE VIEW

PANEL SUPPLIED BY OTHERS

RADIUS MAX

4 PLACES

PANEL FLUSH

TO BEZEL

PANEL MOUNTING BRACKET WITH BOLTS, WASHERS

AND

SCREWS. 2 PLACES

.843 DIA

ELECTRICAL CONDUIT ENTRANCE 5 PLACES

(FOR PG 13.5 CABLE GLANDS OR 1/2 INCH CONDUIT

FITTINGS

68.96

2.715

PANEL CUT-OUT INFORMATION

7

DWG. NO. REV.

40005401 D

Page 14

8

MODEL 54eA SECTION 3.0

WIRING

SECTION 3.0

WIRING

3.1 GENERAL

WARNING

Electrical installation must conform to the National Electrical Code, all state and local codes, and all plant

codes and standards for electrical equipment. Electrical installation and wiring must be done by qualified

personnel.

The five holes in the bottom of the instrument case accept 1/2-in. strain relief connectors or conduit fittings. The

rear openings are for power and alarm relay wiring. The left front opening is for sensor wiring and the right front

opening is for analog output wiring. Seal unused openings with conduit plugs.

3.2 POWER, ALARM, AND OUTPUT WIRING

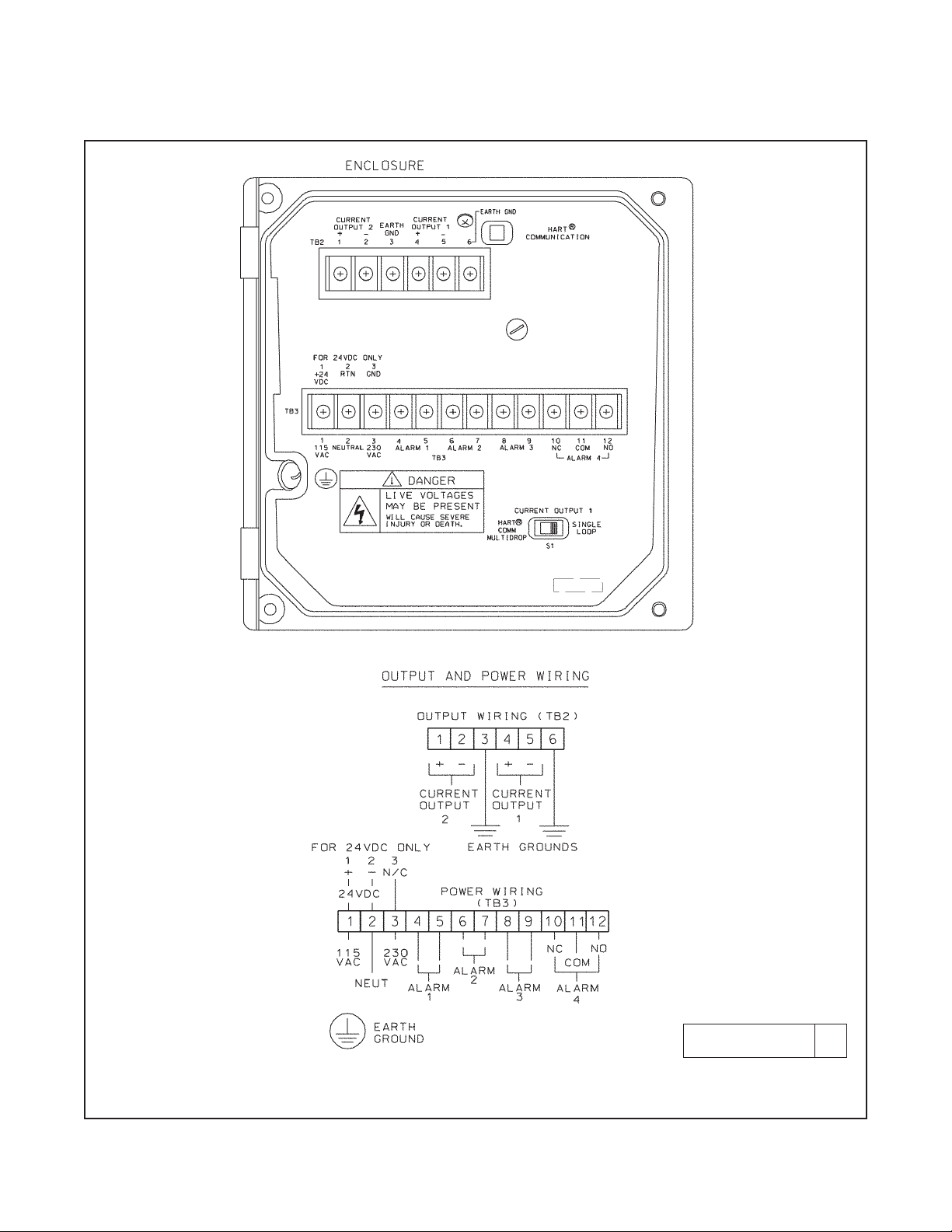

Refer to Figure 3-1. Make power and alarm connections on TB3. Make analog output wiring connections on TB2. For

access to power and alarm terminals, loosen the screw holding the protective cover in place and remove the cover.

DANGER

Live voltages may be present.

Will cause severe injury or death.

Alarm contacts are dry (i.e., not powered) and are normally open. Refer to Section 1.0 for relay specifications.

For best EMI/RFI protection, shield the output cable and enclose it in an earth-grounded, rigid, metal conduit.

Connect the outer shield of the output cable to the earth ground connection on TB2 (see Figure 3-1).

Keep sensor and output signal wiring separate from power wiring. Do no run sensor and power cables in the same

conduit or close together in a cable tray.

AC wiring must be 14 gauge or greater. Be sure to connect earth ground from the power cable to the nearby

ground lug. A good earth ground is necessary for proper operation of the controller. Provide a switch or breaker to

disconnect the analyzer from the main power supply. Install the switch or breaker near the analyzer and label it as

the disconnecting device.

WARNING: RISK OF ELECTRICAL SHOCK

AC connections and grounding must comply with UL 508 or local electrical code. DO NOT apply

power to the analyzer until all electrical connections are verified and secure.

NOTE

The Model 54eA analyzer leaves the factory configured for use with the Model 499ADO sensor

(ppm dissolved oxygen). If a 499ADO sensor is NOT being used, turn to Section 5.5 and configure the transmitter for the desired measurement (ppb oxygen, oxygen measured using a

steam-sterilizable sensor, free chlorine, total chlorine, monochloramine, or ozone) before wiring

the sensor to the analyzer. Operating the analyzer and sensor for longer than five minutes while

the analyzer is improperly configured will greatly increase the stabilization time for the sensor.

Be sure to turn off power to the analyzer before wiring the sensor.

Page 15

9

MODEL 54eA SECTION 3.0

WIRING

FIGURE 3-1. Power Input and Relay Output Wiring for Model 54eA

DWG. NO. REV.

454EPH02 D

Page 16

10

MODEL 54eA SECTION 3.0

WIRING

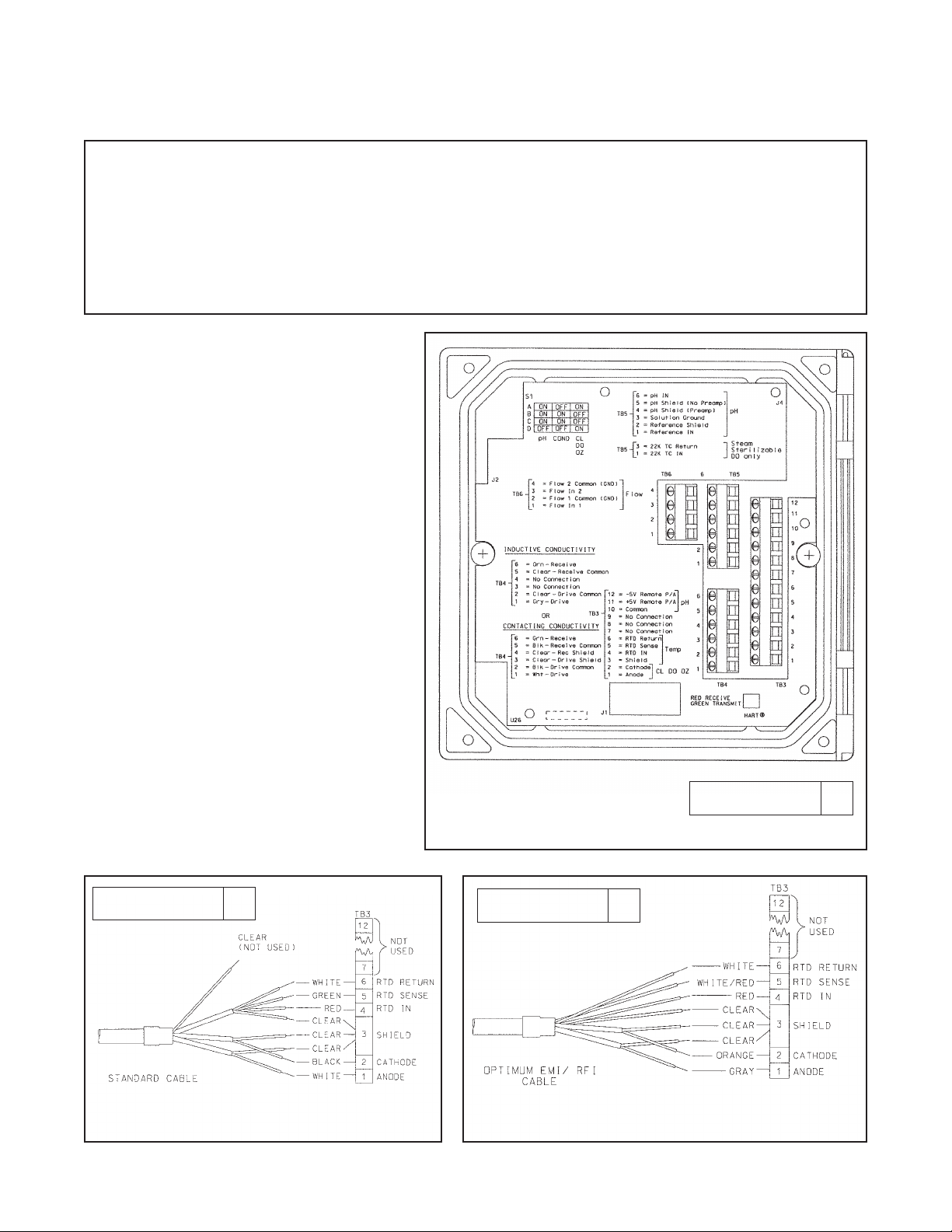

FIGURE 3-3. Amperometric sensors

with standard cable.

FIGURE 3-4. Amperometric sensors

with optimum EMI/RFI cable or Variopol cable.

FIGURE 3-2. Wiring Label

3.3 SENSOR WIRING

3.3.1 General

The wiring label, which is shown in Figure 3-2,

is a general purpose label. It has wiring information concerning other sensors, for example,

contacting and inductive conductivity sensors,

that can be used with the 54e instrument platform. For amperometric measurements, only

TB3 and TB5 are used. Wire the amperometric

sensor to TB3. Wire the pH sensor, if one is

being used, to TB5.

3.3.2 Wiring Model 499A oxygen, chlorine,

and ozone sensors

All 499A amperometric sensors (499ATrDO,

499ADO, 499ACL-01, 499ACL-02, 499ACL-03,

and 499AOZ) have identical wiring.

Use the pigtail wire and wire nuts provided with

the amperometric sensor when more than one

wire must be attached to a single terminal.

See Figures 3-3 and 3-4.

DWG. NO. REV.

40054e03 A

DWG. NO. REV.

40499A23 A

DWG. NO. REV.

40499A24 A

NOTE

The Model 54eA analyzer leaves the factory configured for use with the Model 499ADO sensor

(ppm dissolved oxygen). If a 499ADO sensor is not being used, turn to Section 5.5 and configure the analyzer for the desired measurement (ppb oxygen, oxygen measured using a steamsterilizable sensor, free chlorine, total chlorine, monochloramine, or ozone) before wiring the

sensor to the analyzer. Operating the analyzer and sensor for longer than five minutes while the

analyzer is improperly configured will greatly increase the stabilization time for the sensor.

Be sure to turn off power to the analyzer before wiring the sensor.

Page 17

11

MODEL 54eA SECTION 3.0

WIRING

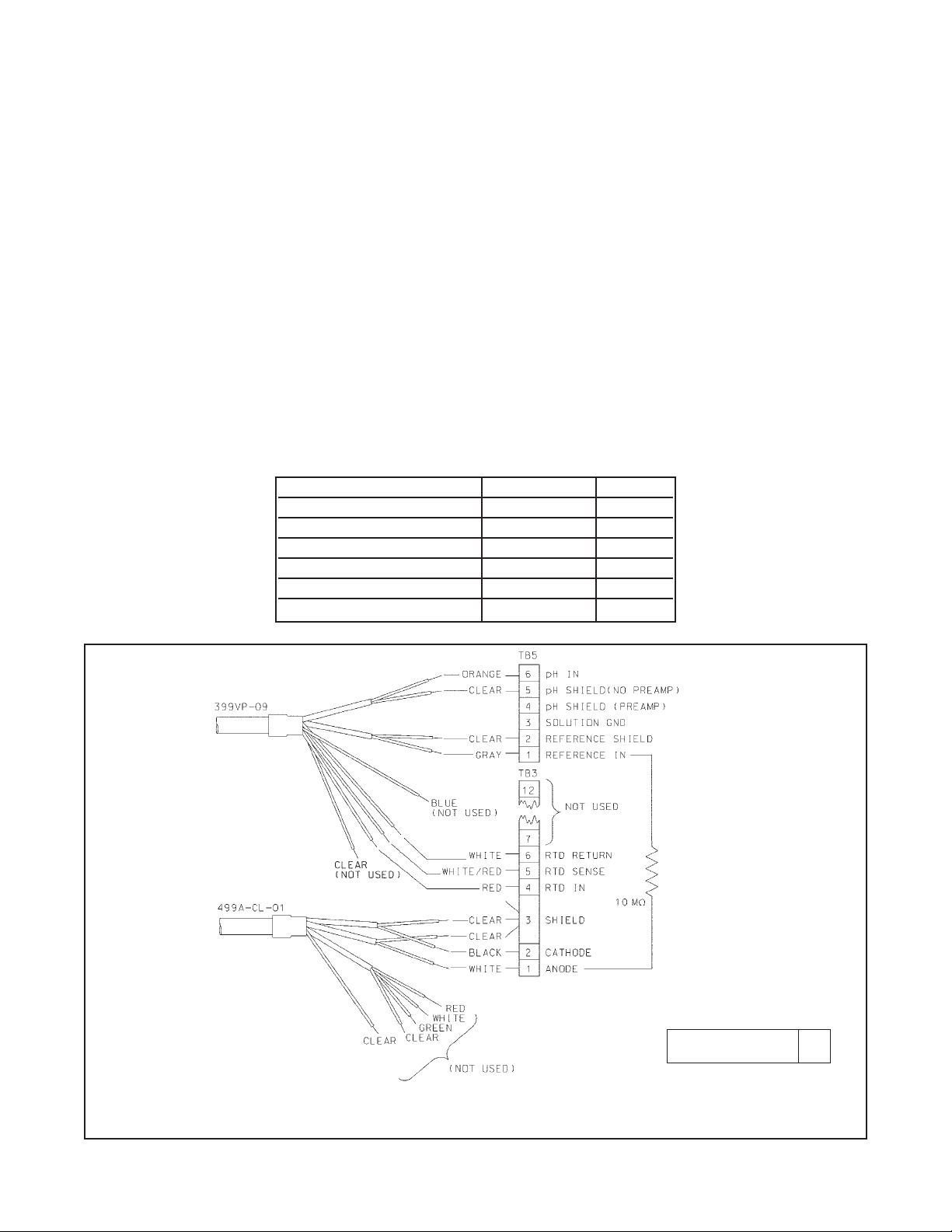

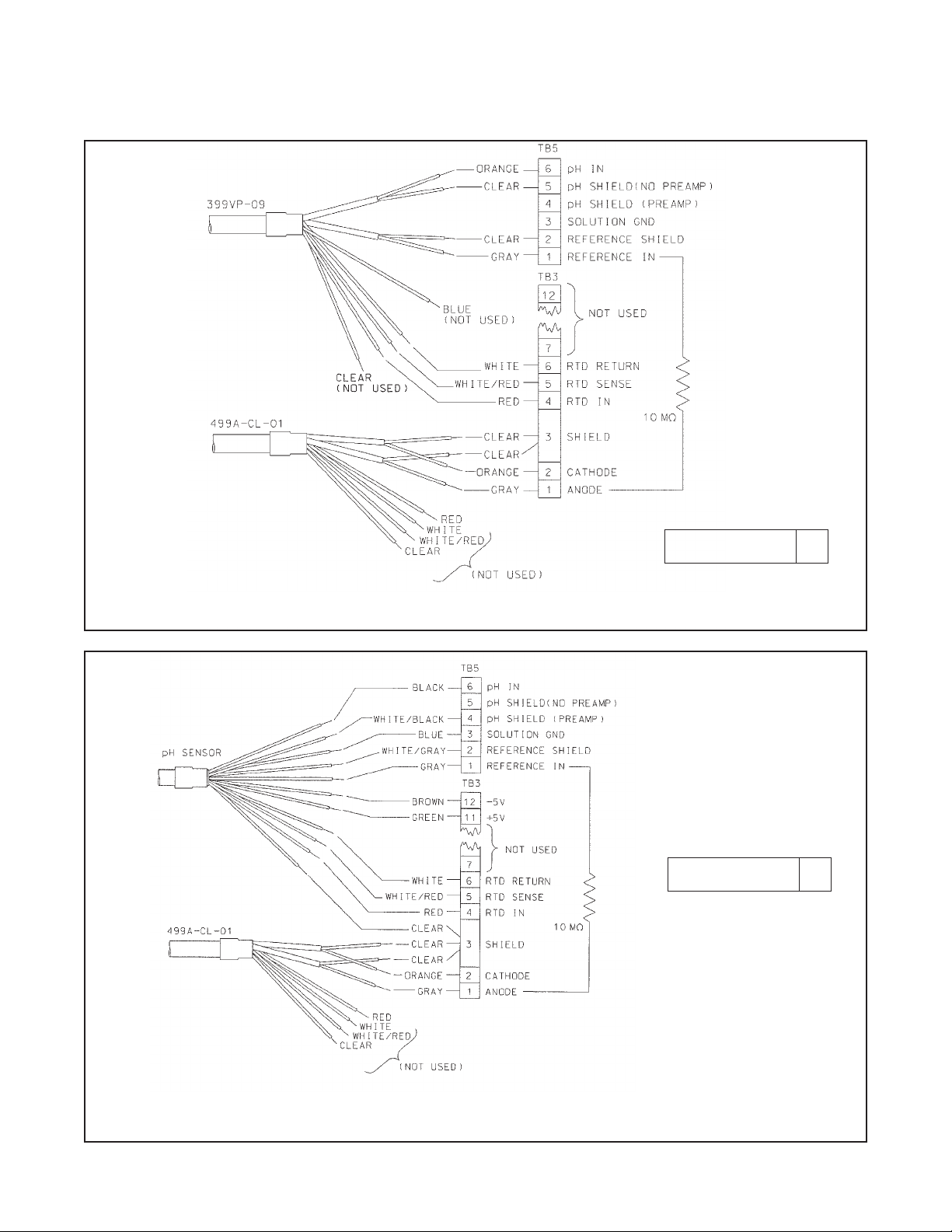

3.3.3 Wiring 499ACL-01 (free chlorine) sensors and pH sensors for automatic pH correction.

If free chlorine is being measured using the 499ACL-01 sensor and the pH of the liquid varies more than 0.2 pH

unit, a continuous correction for pH must be applied to the chlorine reading. Therefore, a pH sensor must also be

wired to the 54eA controller. This section gives wiring diagrams for the pH sensors typically used.

When using the 499ACL-01 sensor (free chlorine) with a pH sensor, use the RTD in the pH sensor for measuring temperature. DO NOT use the RTD in the free chlorine sensor.

The pH sensor RTD is needed for temperature measurement during buffer calibration. During normal operation,

the RTD in the pH sensor also provides the temperature measurement required for the free chlorine membrane

permeability correction.

NOTE

When wiring a pH and a 400ACL-01 amperometric sensor to the controller, connect the anode

and reference terminals (TB3-1 and TB5-1) with the 10MΩ jumper (PN 23980-00) provided with

the analyzer.

Refer to the table to select the appropriate wiring diagram. Most of the wiring diagrams require that two or more

shield wires be attached to a single terminal. Use the pigtail wire and wire nuts packed with the chlorine sensor to

make the connection.

Free chlorine sensor cable pH sensor Figure

Standard 399VP-09 3-5

Standard 399-14 3-6

Standard 399-09-62 3-7

EMI/RFI or Variopol 399VP-09 3-8

EMI/RFI or Variopol 399-14 3-9

EMI/RFI or Variopol 399-09-62 3-10

FIGURE 3-5. 499ACL-01 sensor with standard cable

and 399VP-09 pH sensor without internal preamplifier.

DWG. NO. REV.

4054eA01 B

Page 18

12

MODEL 54eA SECTION 3.0

WIRING

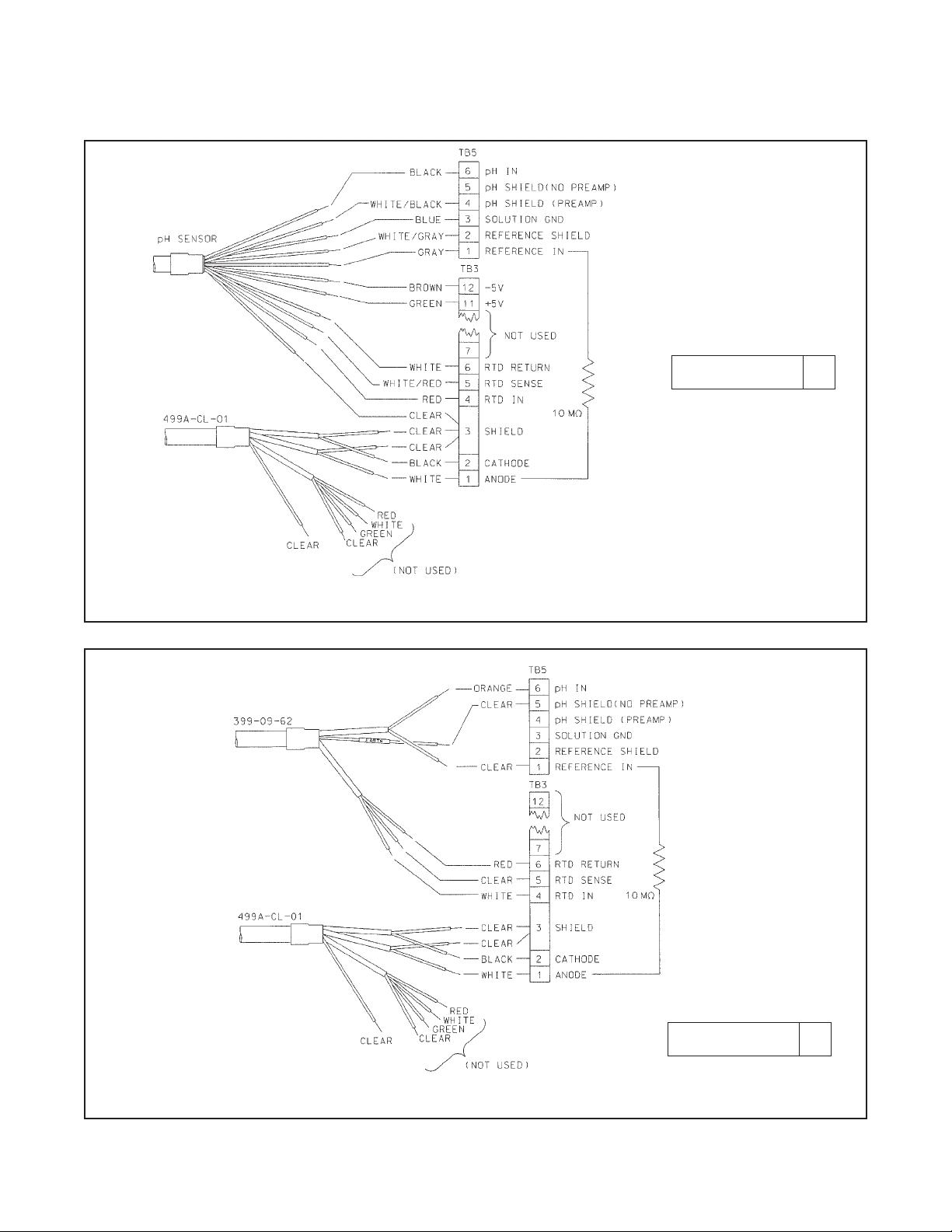

FIGURE 3-6. 499ACL-01 sensor with standard cable and 399-14 pH sensor having internal preamplifier.

FIGURE 3-7. 499ACL-01 sensor with standard cable and 399-09-62 pH without internal preamplifier.

Although the blue wire is connected to a terminal labeled solution

ground, the blue wire does not

connect to a solution ground in the

sensor. The 399-14 sensor has no

solution ground. The blue wire,

instead, ties the preamplifier in the

sensor to instrument common.

DWG. NO. REV.

4054eA05 A

DWG. NO. REV.

4054eA03 A

Page 19

MODEL 54eA SECTION 3.0

WIRING

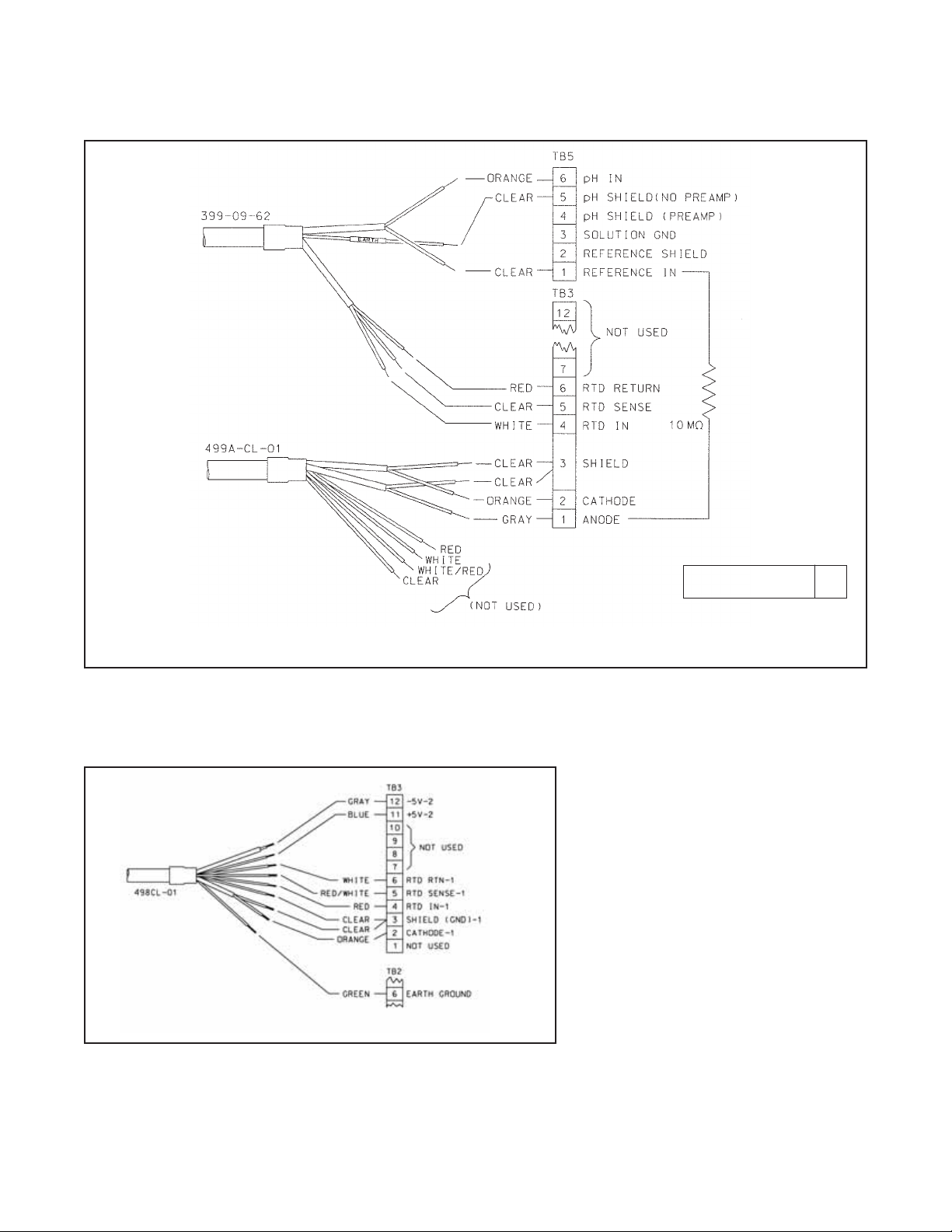

FIGURE 3-9. 499ACL-01 sensor with optimum EMI/RFI cable or

Variopol cable and 399-14 pH sensor having internal preamplifier.

FIGURE 3-8. 499ACL-01 sensor with optimum EMI/RFI cable or Variopol cable

and 399VP-09 pH sensor without internal preamplifier.

13

Although the blue wire is connected to a terminal labeled solution

ground, the blue wire does not

connect to a solution ground in the

sensor. The 399-14 sensor has no

solution ground. The blue wire,

instead, ties the preamplifier in the

sensor to instrument common.

DWG. NO. REV.

4054eA02 B

DWG. NO. REV.

4054eA06 A

Page 20

14

MODEL 54eA SECTION 3.0

WIRING

FIGURE 3-10. 499CL-01 sensor with optimum EMI/RFI cable or

Variopol cable and 399-09-62 pH sensor without internal preamplifier.

DWG. NO. REV.

4054eA04 A

3.3.4 Wiring 438ACL-01 (pH independent free chlorine) sensors

FIGURE 3-11. 498CL-01 (pH-independent free chlorine) sensor

Page 21

Insulate and tape back unused wires.

3.3.5 Wiring Hx438 and Gx448 sensors

Hx438 and Gx448 steam-sterilizable dissolved oxygen sensors use a 22k NTC thermistor. The thermistor is wired

to terminals 1 and 3 on TB5.

FIGURE 3-12. Hx438 and Gx448 sensors.

MODEL 54eA SECTION 3.0

WIRING

15

DWG. NO. REV.

4054eA07 A

Page 22

16

MODEL 54eA SECTION 4.0

DISPLAY AND OPERATION

SECTION 4.0

DISPLAY AND OPERATION

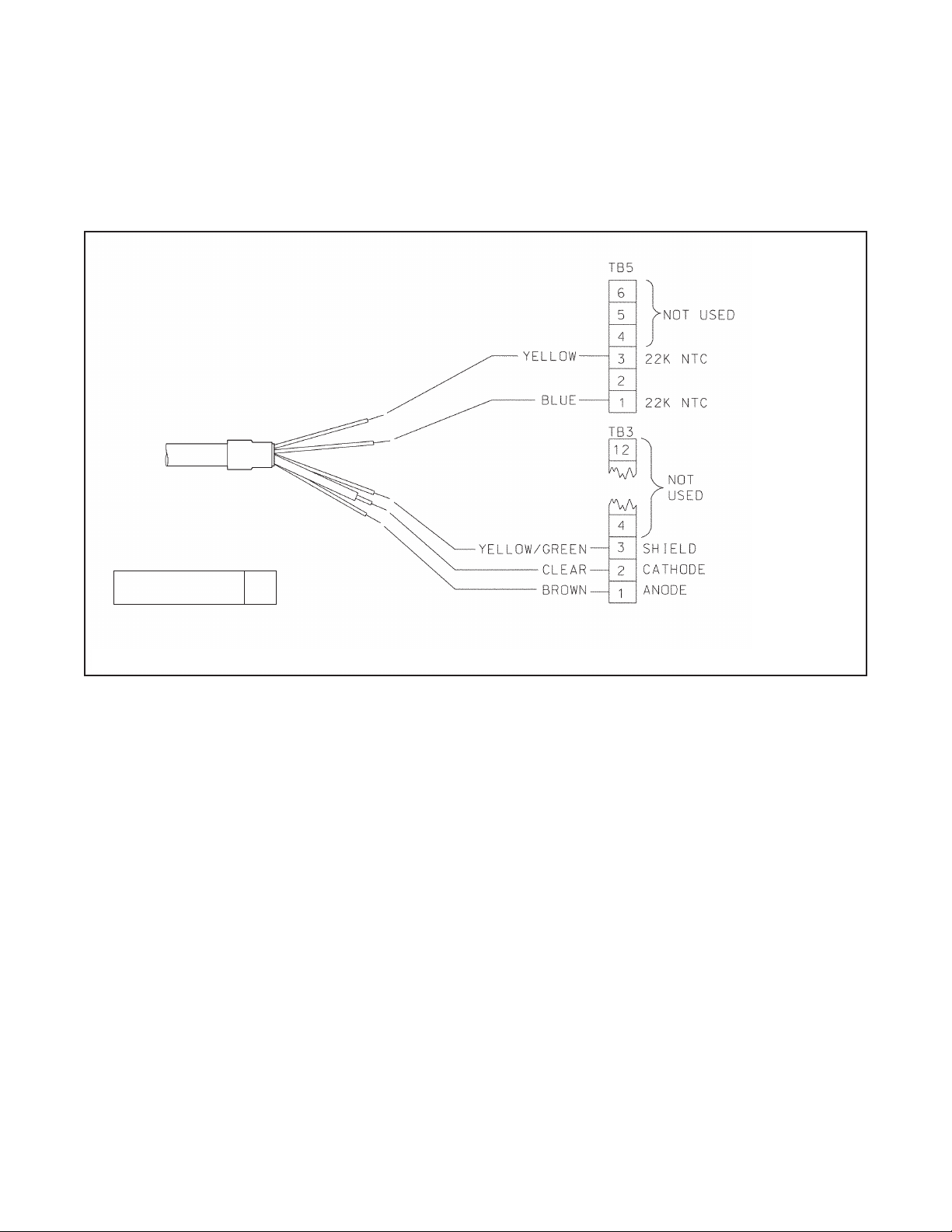

4.1 GENERAL DESCRIPTION

The 54eA analyzer/controller is a normally a single

input, dual output instrument. It does, however, accept

a second input for pH when the main measurement is

free chlorine. Figure 4-1 shows how the instrument

inputs and outputs can be configured for free chlorine.

In addition to PID control, the 54eA controller can be

used for time proportional control (TPC). TPC control

uses the alarm relays.

4.2 DISPLAY

Figure 4-2 shows the main display.

4.3 KEY FUNCTIONS AND CONTROLS

The keys labeled F1, F2, F3, and F4 are multi-function.

The function appears in the main display just above the

key. For example, F1 is usually labeled Exit and F4

may be labeled Edit, Save, or Enter.

1. To enter the main menu, press any key.

2. Use the é and ê keys to move the cursor to the

desired sub-menu. The position of the cursor is

shown in reverse video.

NOTE

When the last item of a menu has been

reached, the cursor will be on the third line

of the display. If the cursor is on the second

line of the display more items remain.

Continue pressing the ê key.

3. Press Enter (F4) to access a sub-menu or an item

in a sub-menu.

4. To change a number or a setting press Edit (F4).

The display will change to show the cursor on the

first digit or on a + or - sign. Use the é and ê keys

to increase or decrease a digit or to toggle the +

and - signs. Use the ç and è keys to move the

cursor left and right.

5. If an entire number or a word is highlighted, use the

é and ê keys to scroll through the list of choices.

6. To store a number or setting in memory, press

Save (F4).

7. To leave without storing changes, press Esc (F3).

8. To leave and return to the previous screen, press

Exit (F1).

9. To end a calibration step and leave the previous

calibration in place, press Abort (F1).

10. Occasionally, information screens will appear. To

leave the information screen and move to the next

screen press Cont (F3).

4.4 ALARM STATUS

Green LEDs (labeled 1, 2, and 3) indicate when alarm

relays 1, 2, and 3 are energized. The fourth relay indicates a fault condition. When a fault occurs, the red

LED (labeled FAIL) lights up, a descriptive error message appears, and the outputs and alarm relays act as

described in Section 5.6 and Section 5.7 under fault

value.

The red LED also indicates when the interval timer routine is activated and when the time limit has been

reached on a feed limit timer. For more information on

these subjects, see Section 5.7.

FIGURE 4-1. Configuration of Inputs and Outputs

for Free Chlorine

The main sensor is always the chlorine sensor and the secondary sensor is always the pH sensor. Outputs can be

assigned to free chlorine, to pH, or to temperature. The

outputs can be configured as either linear (4-20 mA) or PID

outputs.

FIGURE 4-2. Main Display Screen

The amperometric measurement (oxygen, ozone, free

chlorine, or total chlorine) is always displayed continuously

in large numerals. The temperature and output current are

always displayed on the second line of the main display.

The third line can be configured by the user. In the example, the third line shows the pH reading and the amperometric sensor current in nA.

1.00 ppm

26.2°C. 12.00 mA

pH: 8.00 I: 340 nA

Page 23

17

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

SECTION 5.0

SOFTWARE CONFIGURATION

The instrument is configured at the factory to measure oxygen.

Figure 5-1 is an outline of the menu structure.

Table 5-1 lists the default settings and the range of choices available for each setting. To reduce the chance of

error when configuring the controller the first time, enter settings in the order shown in the table.

TABLE 5-1. Program Settings List

Continued on the following page

ITEM CHOICES FACTORY SETTINGS

SETPOINTS

A. Alarms (Section 5.1)

1. Alarm 1 (low action)

a. if oxygen (ppm) -99 to 99 ppm 0 ppm

b. if oxygen (ppb) -999 to 999 ppb 0 ppb

c. if oxygen (% saturation) 0 to 200% 0 %

d. if chlorine, monochloramine, or ozone -9999 to 9999 ppm 0 ppm

e. if pH -2.00 to 20.00 0.00

f. if temperature -5 to 130°C 0.1°C

2. Alarm 2 (high action)

a. if oxygen (ppm) -99 to 99 ppm 20 ppm

b. if oxygen (ppb) -999 to 999 ppb 900 ppb

c. if oxygen (% saturation) 0 to 200% 200 %

d. if chlorine, monochloramine, or ozone -9999 to 9999 ppm 20 ppm

e. if pH -2.00 to 20.00 14.00

f. if temperature -5 to 130°C 130°C

3. Alarm 3 See alarm 2 See alarm 2

B. Outputs (Section 5.2 and 5.3)

1. Output 1 or 2: 4 mA setting

a. if oxygen (ppm) -99 to 99 ppm 0 ppm

b. if oxygen (ppb) -999 to 999 ppb 0 ppb

c. if oxygen (% saturation) 0 to 200% 0 %

d. if chlorine, monochloramine, or ozone -9999 to 9999 ppm 0 ppm

e. if pH -2.00 to 20.00 0.0

f. if temperature -5 to 130°C 0.1°C

2. Output 1 or 2: 20 mA setting

a. if oxygen (ppm) -99 to 99 ppm 20 ppm

b. if oxygen (ppb) -999 to 999 ppb 900 ppb

c. if oxygen (% saturation) 0 to 200% 200%

d. if chlorine, monochloramine, or ozone -9999 to 9999 ppm 20 ppm

e. if pH -2.00 to 20.00 14.00

f. if temperature -5 to 130°C 130°C

3. Setpoint (PID)

a. if oxygen (ppm) -99 to 99 ppm 1.00 ppm

b. if oxygen (ppb) -999 to 999 ppb 100 ppb

c. if oxygen (% saturation) 0 to 200% 100%

d. if chlorine, monochloramine, or ozone -9999 to 9999 ppm 1.00 ppm

e. if pH -2.00 to 20.00 7.00

f. if temperature -5 to 130°C 25°C

Page 24

18

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

Continued on the following page

ITEM CHOICES FACTORY SETTINGS

CONFIGURE

A. Display options (Section 5.5)

1. Measurement Oxygen, ozone, free chlorine, total chlorine, monochloramine Oxygen

2. Sensor (Oxygen only) Rosemount standard, Rosemount biopharm, or Rosemount standard

other steam sterilizable

3. Units (Oxygen only) ppm, ppb, % saturation ppm

4. Temperature units °C or °F °C

5. Output 1 mA or % of full scale mA

6. Output 2 mA or % of full scale mA

7. Language English, Français, Español, Deutsch, Italiano English

8. Main display left See section 5.5 Sensor current

9. Main display right See section 5.5 Output 1 current

10 Display contrast 00-99 (darkest) 50

11. Test timeout On or off On

12. Timeout value 1 to 60 min 10 min

B Outputs (Section 5.6)

1. Output 1 Control

a. Measurement Oxygen, chlorine, ozone, pH, or temperature Oxygen

b. Control Normal or PID Normal

2. Output 1 Setup (normal)

a. Current 4-20 mA or 0-20 mA* 4-20 mA

b. Dampening 0-299 sec 0 sec

c. Hold mode Hold last value or go to fixed value Hold last value

d. Fixed hold value 0-22 mA 21 mA

e. Fault value 0-22 mA 22 mA

3. Output 1 Setup (PID)

a. Proportional 0 to 299.9% 100 %

b. Integral 0 to 2999 sec 0 sec

c. Derivative 0 to 299.9% 0/0%

4. Output 2 Control

a. Measurement Oxygen, chlorine, ozone, pH, or temperature Temperature

b. Control Normal or PID Normal

5. Output 2 Setup (normal) See output 1 See output 1

6. Output 2 Setup (PID) See output 1 See output 1

7. Hold feature Enable, disable, or 20 min timeout Disable

C. Alarms (Section 5.7)

1. Alarm 1 Control

a. Activation method Oxygen, chlorine, ozone, temperature, pH Oxygen

b. Control mode Normal or TPC Normal

2. Alarm 1 setup (normal)

a. Configuration Low, high, or off High

b. Hysteresis

if oxygen (ppm) 0 to 20 ppm 0 ppm

if oxygen (ppb) 0 to 999 ppb 0 ppb

if oxygen (% saturation) 0 to 200% 0%

if chlorine, monochloramine, or ozone -9999 to 9999 ppm 0 ppm

if pH 0 to 14.00 0 pH

if temperature 0 to 10°C 0.1°C

c. Delay time 0-99 sec 0 sec

d. Relay fault none, open, closed None

TABLE 5-1. Program Settings List (continued)

* Option-09, HART-enabled version operates at 4-20 mA only on output 1.

Page 25

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

ITEM CHOICES FACTORY SETTINGS

CONFIGURE (continued)

C. Alarms (Section 5.7) (continued)

3. Alarm 1 setup (TPC)

a. Setpoint

if oxygen (ppm) -20 to 20 ppm 1 ppm

if oxygen (ppb) -999 to 999 ppb 100 ppb

if oxygen (% saturation) 0 to 200% 100%

if chlorine, monochloramine, or ozone -9999 to 9999 ppm 1.0 ppm

if pH -2.0 to 20.00 7.00

if temperature -5 to 130°C 25°C

b. Proportional 0 to 299.9% 100 %

c. Integral 0 to 2999 sec 0 sec

d. Derivative 0 to 299.9% 0.0%

e. Time period 10 to 2999 sec 30 sec

f. LRV (100% on)

if oxygen (ppm) -20 to 20 ppm 0 ppm

if oxygen (ppb) -999 to 999 ppb 0 ppb

if oxygen (% saturation) 0 to 200% 0%

if chlorine, monochloramine, or ozone -9999 to 9999 ppm 0 ppm

if pH -2.0 to 20.00 0.00

if temperature -5 to 130°C 0°C

g. URV (100% off)

if oxygen (ppm) -20 to 20 ppm 2 ppm

if oxygen (ppb) -999 to 999 ppb 100 ppb

if oxygen (% saturation) 0 to 200% 200%

if chlorine, monochloramine, or ozone -9999 to 9999 ppm 2 ppm

if pH -2.0 to 20.00 2.00

if temperature -5 to 130°C 100°C

h. Relay fault None, open, or closed None

4. Alarm 2 Control

a. Activation method Oxygen, chlorine, monochloramine, ozone, temperature, pH Oxygen

b. Control mode Normal or TPC Normal

5. Alarm 2 setup (normal)

a. Configuration Low, high, or off Low

Rest of alarm 2 setup is the same as alarm 1

6. Alarm 3 control and setup is the same as alarm 1

7. Alarm 4 control

Alarm Fault or off Fault

8. Feed limit timer

a. Feed limit Disable, alarm 1, alarm 2, or alarm 3 Disable

b. Timeout value 0 to 10,800 sec 600 sec

9. Interval timer

a. Select alarm Disable, alarm 1, alarm 2, or alarm 3 Disable

b. Interval time 0 to 999.9 hr 24.0 hr

c. Repeats 1 to 60 1

d. On time 0 to 2999 sec 120 sec

e. Off time 0 to 2999 sec 1 sec

f. Recovery time 0 to 999 sec 600 sec

TABLE 5-1. Program Settings List (continued)

Continued on the following page

19

Page 26

20

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

TABLE 5-1. Program Settings List (continued)

ITEM CHOICES FACTORY SETTINGS

CONFIGURE (continued)

D. pH measurement (Section 5.8)

1. pH sensor Enable or disable Enable

2. pH compensation (free chlorine only) Auto or manual Auto

3. pH value 0.00 - 14.00 7.00

4. pH diagnostic On or off Off

a. Glass impedance high 0-2000 MΩ (0 disables) 1000 MΩ

b. Glass impedance low 0-900 MΩ (0 disables) 20 MΩ

c. Reference impedance high 0-140 kΩ (0 disables) 140 kΩ

d. Zero offset 0-999 mV 60 mV

e. Impedance temp. compensation On or off On

5. pH calibration

a. Auto calibration (buffer list) Manual, Standard, Merck, Ingold, DIN 19267 Standard

b. Stabilize pH 0.01 - 0.50 0.1

c. Stabilization time 0-30 sec 10 sec

6. Solution temperature coefficient

a. Temperature coefficient -0.044 to 0.028 pH/°C 0.000

b. Operating isopotential -1.35 to 20.12 pH 7.00

c. Sensor isopotential 0 to 14 pH 7.00

E. Temperature compensation (Section 5.9)

1. Temperature compensation Auto or manual Auto

2. Manual temperature -15 to 130°C 25°C

F. Noise Reduction (section 5.10)

Noise rejection 50 or 60 Hz 60 Hz

G. Main sensor calibration (Section 5.11)

1. Stabilize reading

a. oxygen (ppm) 0 to 20 ppm 0.05 ppm

b. oxygen (ppb) 0 to 999 ppb 50 ppb

c. oxygen (% saturation) 0 to 200% 1%

d. chlorine, monochloramine, or ozone 0 to 9999 ppm 0.05 ppm

2. Stabilize time 0 - 30 sec 10 sec

3. Sensor zero stabilization value

4. Dual range calibration Enable or disable disable

5. Salinity (parts per thousand) 0.0 - 99.9

o

/oo 0.0 o/oo

H. Barometric Pressure (Section 5.12)

1. Barometric pressure (oxygen only) Auto or manual Auto

2. Barometric pressure manual 0.4 - 1.2 atm (or equivalent units) 1.00 atm

3. Barometric pressure units mm Hg, in Hg, bar, kPa mm Hg

I. Security (Section 5.13)

1. Lock all 000-999 (000 disables) 000

2. Lock program 000-999 (000 disables) 000

3. Lock configuration 000-999 (000 disables) 000

Page 27

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

FIGURE 5-1. Menu Tree for the 54eA Controller

Calibrate

Program (see page 23)

Diagnostic Variables

Main

Menu

Calibrate main sensor

Zero main sensor

Adjust temperature

Calibrate pH

Slope

Buffer calibration

Standardize

Main measurement

Main sensor current

Sensitivity (µA/ppm)

Zero current

pH reading

pH mV reading

pH slope (mV/pH)

pH offset

Barometric pressure

Glass impedance

Noise rejection

Software version

Device ID

Output trim

21

Page 28

22

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

Program

Calibrate (see page 21)

Diagnostic Variable (see page 21)

Main

Menu

Alarms 1, 2, and 3 setpoints

4 mA or 0 mA

20 mA

Present output current

Alarm Setpoints

Output setpoints

Test output 1 or 2

Test alarm 1, 2, 3, or 4

Simulated tests

Configure

Display

Main

Sensor

Oxygen

Free Chlorine

Total Chlorine

Monochloramine

Ozone

Outputs

Output 1 and 2

control

Measurement: main snr, pH, temp.

Control mode: normal, PID

Output 1 and 2

setup

Range (0-20 or 4-20 mA)

Dampen*

Hold - keep last value

Hold - go to specified value

Fault

Setpoint, proportional, integral

Derivative**

Hold feature setup

*Normal only

**PID only

Alarms

Alarm 1, 2, & 3

control

Measurement: main snr, pH, temp.

Control mode: normal, TPC

Alarm 1, 2, & 3

setup

Alarm: High, low, or off*

Setpoint

Hysteresis*

Delay*

Time period, URV, LRV**

Relay default

Interval timer

Timer: Alarm 1, 2, or 3 or disable

Interval

Repeats

On time

Off time

Recovery time

Alarm 4 setup

Feed limit timer

Feed limit: Alarm 1, 2, or 3 or disable

Timeout

*Normal only **TPC only

Continued on page 23

FIGURE 5-1. Menu Tree for the 54eA Controller

(continued)

Sensor type and manufac.

Units: ppm, ppb, % sat

°C or °F

Output 1 (mA or %FS)

Output 2 (mA or %FS)

Language

Line 3 display

Display contrast

Timeout (on or off)

Timeout - limit

Polling address

Page 29

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

FIGURE 5-1. Menu Tree for the 54eA Controller (continued)

Display (see page 22)

Outputs (see page 22)

Alarms (see page 22)

Program

Calibrate (see page 21)

Diagnostic Variable (see page 21)

Main

Menu

Alarm Setpoints (see page 22)

Output setpoints

(see page 22)

Simulated tests

(see page 22)

Configure

pH

(available with free

chlorine only)

Disable

Enable

pH

diagnostics

Diagnostics: on or off

Glass impedance high

Glass impedance low

Zero offset

Impedance temp comp: on or off

Temperature

Temperature comp: auto or manual

Units: °C or °F

Noise

Rejection

Noise rejection: 50 or 60 Hz

Barometric

Pressure

Measurement: Auto or manual

Units: mm Hg, kPa, atm, barg, in Hg

Main sensor cal

Stabilize conc’n

Stabilize time

Salinity (oxygen only)

Security

pH

calibration

Autocal: standard, manual,

Merck, Ingold, DIN 19267

Stabilize pH

Stabilize time

Temperature

coefficient

Temperature coeff

Operating isopotential

Sensor isopotential

Lock all

Lock program

Lock configure

(oxygen only)

23

Page 30

24

5.1 CHANGING ALARM SETPOINTS

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Press Enter (F4).

4. Move the cursor to the desired alarm and press Enter (F4).

5. The screen appearing at this point depends on how the alarm was

configured.

6. If the alarm is a normal (i.e., not TPC) alarm, a screen like the one

shown will appear. The alarm is a low alarm and the setpoint is 0.00

ppm. Press Edit (F4). Use the arrow keys to change the setpoint.

Press Save (F4) to store the new value. Press Exit (F1) to return to

the screen in step 4. Choose a new alarm.

7. If the alarm is TPC, a screen like the one shown will appear. The setpoint is +1.000 ppm. Press Edit (F4). Use the arrow keys to change

the setpoint. Press Save (F4) to store the new value. Press Exit (F1)

to return to the screen in step 4. Choose a new alarm.

Alarm setpoints

Output setpoints

Simulate tests

Exit Enter

Alarm 1 setpoint

Alarm 2 setpoint

Alarm 3 setpoint

Exit Enter

Alarm Low : 0.000 ppm

Exit Edit

Setpoint : 1.000 ppm

Exit Edit

1. Before changing alarm setpoints, be sure that alarms are properly configured. See Section 5.7.

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

Page 31

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.2 RANGING THE OUTPUTS

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Move the cursor to "Output setpoints" and press Enter (F4).

4. Move the cursor to the desired output and press Enter (F4).

5. This screen confirms that changes to output 1 are going to be made.

Use caution. Changes may degrade process control. Press Cont

(F3) to continue. Otherwise, press Abort (F1).

6. This screen shows the present settings for Output 1. If the output

was configured to be 0-20 mA, the first line will show "0mA" instead

of "4mA". The live current output is shown on the third line.

Move the cursor to the desired line and press Edit (F4). Use the

arrow keys to change the setpoint. Press Save (F4) to store the new

value.

Press Exit (F1) to return to the screen in step 4. Choose the other

output and continue.

Note: 0-20 mA output range is disabled on output 1 with HARTenabled version (-09 option).

Output 1 setpoints

Output 2 setpoints

Exit Enter

Alarm setpoints

Output setpoints

Simulated test

Exit Enter

CAUTION: Current

Output 1 will be

affected.

Abort Cont

1. Ranging the outputs means assigning values to the low (0 or 4 mA) and high (20 mA) outputs. Before rang-

ing the outputs, be sure the outputs are properly configured. See Section 5.6.

4 mA : 0.00 ppm

20 mA: 20.00 ppm

Output 1: 12.00 mA

Exit Edit

25

Page 32

26

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.3 CHANGING OUTPUT SETPOINTS (PID ONLY)

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Move the cursor to "Output setpoints" and press Enter (F4).

4. Move the cursor to the desired output and press Enter (F4).

5. This screen confirms that changes to output 1 are going to be made.

Use caution. Changes may degrade process control. Press Cont

(F3) to continue. Otherwise, press Abort (F1).

6. This screen shows the present settings for Output 1. If the output

was configured to be 0-20 mA, the second line will show "0mA"

instead of "4mA". The live current output is shown on the fourth line.

Press the ê key once to view the live output.

Move the cursor to the desired line and press Edit (F4). Use the

arrow keys to change the value. Press Save (F4) to store the new

value.

Press Exit (F1) to return to the screen in step 4. Choose the other

output and continue.

Setpoint : 1.000 ppm

4mA: 0.000 ppm

20mA: 10.00 ppm

Exit Edit

1. This section describes how to assign the setpoint and the upper and lower range values (URV and LRV) when

the 54eA is being used for PID control. Assign the LRV to 4 mA and the URV to 20 mA. The LRV is the deviation from the setpoint that will result in a 4 mA output. The URV is the deviation from the setpoint that will

result in a 20 mA output.

Example: The setpoint is 1.00 ppm. The URV is +0.50 and the LRV is 0.00. If the present reading is 1.20 ppm,

the output will be (1.20 - 1.00)/(0.50 - 0.00) or 40% of the range (10.40 mA). If the present reading is 1.50 ppm,

the output will be (1.50 - 1.00)/(0.50 - 0.00) or 100% of the range (20.00 mA). If the present reading is less

than the setpoint, the output will be 4 mA.

The control setpoint is usually the condition where the output current is a minimum. The P and I control calculations use the setpoint to adjust the output to the desired level based on the parameters established in

Section 5.6.

To configure the controller for PID control, see Section 5.6.

Alarm setpoints

Output setpoints

Simulated test

Exit Enter

CAUTION: Current

Output 1 will be

affected.

Abort Cont

Output 1 setpoints

Output 2 setpoints

Exit Enter

Page 33

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.4 TESTING OUTPUTS AND ALARMS

2. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

3. Move the cursor to "Simulated tests" and press Enter (F4).

4. Move the cursor to the desired output or alarm. Both outputs and all

four alarms can be tested. Press Enter (F4).

A screen will appear warning that the output or alarm will change.

Press Cont (F3) to continue. Press Abort (F1) to cancel the simulation.

5. This screen appears when an output is being simulated. To change

the simulation current, press Edit (F4). Use the arrow keys to change

the current to the desired value. Press Test (F4), then Esc (F3).

The simulated current will be generated for 10 minutes, then the output returns to normal operation. To change the timeout to a different

value see Section 5.5.

To end the simulation at any time, press Exit (F1).

6. This screen appears when an alarm is being simulated. To change

the state of the relay, press Edit (F4). Use the é or ê keys to change

from open to closed. Press Test (F4), then Esc (F3).

The alarm will be simulated for 10 minutes, then the alarm returns to

normal operation. To change the timeout to a different value, see

Section 5.5.

To end the simulation at any time, press Exit (F1).

Output setpoints

Simulated tests

Configure

Exit Enter

Test output 1

Test output 2

Test alarm 1

Exit Enter

Test output 1: 10.00 mA

Simulating output1

Exit Edit

Test alarm 1: Open

Simulating alarm1

Exit Edit

1. For testing purposes, the controller can be programmed to generate simulated outputs and to activate and

deactivate alarms.

27

Page 34

28

Output setpoints

Simulated tests

Configure

Exit Enter

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.5 CHOOSING DISPLAY OPTIONS

3. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

4. Move the cursor to "Configure" and press Enter (F4).

5. With the cursor on "Display", press Enter (F4).

6. A screen showing the present main measurement will appear. To

change the measurement, for example, from oxygen to ozone, press

Edit (F4), then use the é key to scroll through the choices. Press

Save (F4) to store the setting.

A screen will appear warning that if the measurement is changed, the

analyzer will return to factory default settings. Press Cont (F3) to continue. Press Abort (F1) to cancel the change.

7. If oxygen is being measured, the screen at left appears. Use the ê

key to move the cursor to "Sensor" and press Edit (F4). Use the é or

ê keys to scroll through the choices. Press Save (F4) to store the

selection.

Use the ê key to move the cursor to "Meas units" and press Edit (F4).

Use the é or êkeys to scroll through the choices. Press Save (F4)

to store the selection.

Display

Outputs

Alarms

Exit Enter

Measure : Oxygen

Sensor: RMT Standard

Meas units: ppm

Exit Edit

Measure : Oxygen

Sensor: RMT Standard

Meas units: ppm

Exit Enter

1. The 54eA controller can be used with most amperometric sensors manufactured by Rosemount Analytical. The

user must configure the analyzer to match the sensor being used.

2. The display menu also lets the user customize the third line in the display, change timeout values, choose a language other than English, and change the display contrast.

RMT Standard 499ADO or 499ATrDO

RMT Biopharm Hx438 or Gx448

SSDO Other Steam sterilizable sensor from other manufacturers

ppm (mg/L) use with any sensor except 499ATrDO

ppb (ug/L) use with 499ATrDO sensor

% sat (concentration as a percent of saturation value)

use with any sensor except 499ATrDO

Page 35

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.5 CHOOSING DISPLAY OPTIONS (CONTINUED)

8. Set the remainder of the display parameters. Use the é and ê keys

to choose the desired parameter. Then press Edit (F4). Use the é

key to move the cursor to the desired selection. Press Save (F4) to

store.

SECURITY CAUTION

The controller uses the timeout value to activate security. Once

the controller is unlocked by entering a security code, security will

not re-activate until a display timeout occurs. If timeout has been

turned off, security will never reactivate.

Temp units: °C

Output 1: mA

Output 2: mA

Exit Edit

Language: English

Display left: I

Display right: Out 2

Exit Edit

Display contrast: 40

Timeout: On

Timeout value: 10 min

Exit Edit

Temp units °C or °F

Output 1 mA or % of full scale

Output 2 mA or % of full scale

Language English, Français, Español, Deutsch, Italiano

Display left sensor current (I), pH (appears only if free chlorine

is being measured and pH was enabled), alarm 1

setpoint (no units), alarm 3 setpoint (no units),

or blank

Display right sensor current (I), pH (appears only if free chlorine

is being measured and pH was enabled), alarm 2

setpoint (no units), alarm 3 setpoint (no units),

output 2, or blank

Display Contrast 00 (lightest)-99 (darkest); the display contrast

changes as the number changes

Timeout Timeout returns the display from any other screen

to the main display if no key is pressed before the

timeout value is exceeded.

Polling address Identifies controller in multi-drop HART applications.

Timeout value

29

Page 36

30

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.6 CHANGING OUTPUT PARAMETERS

3. Press any key to enter the main menu. Move the cursor to "Program"

and press Enter (F4).

4. Move the cursor to "Configure" and press Enter (F4).

5. Move the cursor to "Outputs" and press Enter (F4).

6. Five menu headers relate to outputs. Each output has a control header and a setup header. The fifth header allows the output hold feature

to be configured.

Always configure the control parameters BEFORE making

changes in the output setup.

To access a header, move the cursor to the desired header and press

Enter (F4).

7. Output Control Settings:

a. Move the cursor to the desired output control header. Press Enter

(F4).

b. With the cursor on "Output Measurement" press Enter (F4).

c. Press Edit (F4).

d. Use the é key to scroll through the choices: "Process",

"Temperature", and “pH” (if free chlorine is being measured and

pH was enabled). "Process" means the measurement made by

the main sensor (oxygen, ozone, free chlorine, or total chlorine).

Press Save (F4) to store the selection.

Output 1 control

Output 1 setup

Output 2 control

Exit Enter

Output Measurement

Control Mode

Exit Enter

Output : Process

Exit Edit

Display

Outputs

Alarms

Exit Enter

1. This section describes how to configure the controller outputs. Outputs can be configured to represent the

main amperometric measurement (oxygen, ozone, free chlorine, or total chlorine), temperature, or pH (if free

chlorine is being measured and pH was enabled).

2. The output can be configured as either a normal or PID output. Normal means the output current is directly

proportional to the measurement assigned to the output. PID means the output is used for PID control.

Output setpoints

Simulated tests

Configure

Exit Enter

Page 37

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

5.6 CHANGING OUTPUT PARAMETERS (continued)

e. The display returns to the “Output: Process” screen. Press Exit

(F1). The display returns to the “Output Measurement” screen.

Move the cursor to "Control mode" and press Enter (F4).

f. Press Edit (F4). Use the é key to toggle between "Normal" and

"PID". Press Save (F4) to store the selection.

8. Output setup for normal outputs:

a. Move the cursor to the desired output setup and press Enter (F4).

b. Use the é and ê arrow keys to move the cursor to the desired

parameter. Press Edit (F4). Use the arrow keys to change the setting to the desired value and press Save(F4) to store the value.

Range: Choose 4-20 mA or 0-20 mA.

Dampen: Dampening averages the output current, thus smooth-

ing out a noisy reading. Higher values provide more smoothing

but increase the response time of the output.

Hold and Fixed Hold: If the analyzer is placed in hold, the outputs will either remain at the last value or go to a fixed value

selected by the user. The fixed value must be between 0 and

22.00 mA.

Fault: If the analyzer detects a fault, the output will signal the fault

by going to a user-selected current between 0 and 22.00 mA.

For allowed values, see Table 5-1.

Note: 0-20 mA output range is disabled on output 1 with HARTenabled version (-09 option).

9. Output setup for PID outputs:

a. Move the cursor to the desired output setup and press Enter (F4).

b. Use the é and ê keys to move the cursor to the desired param-

eter. Press Edit (F4). Use the arrow keys to change the setting to

the desired value and press Save (F4) to store the value.

Setpoint: Setpoint is usually the value at which the process is

being controlled. Typically, the output will be 4 mA (or 0 mA) when

the value is near the setpoint.

Ctrl mode : Normal

Exit Edit

Range : 4-20 mA

Dampen: 0 sec

Hold: Last Value

Exit Edit

Output 1 Control

Output 1 Setup

Output 2 Control

Exit Enter

Output 1 Control

Output 1 Setup

Output 2 Control

Exit Enter

Setpoint : 1.000 ppm

Proportional: 100.0%

Integral: 0 sec

Exit Edit

31

Page 38

32

MODEL 54eA SECTION 5.0

SOFTWARE CONFIGURATION

Proportional: Proportional is the same as proportional band and

is the range over which control is being used. It is the opposite of

process gain. Smaller values provide tighter control.

Integral: Integral is the number of seconds over which deviations from the setpoint are integrated to remove continuing offsets. Smaller values provide higher response.

Derivative: Derivative is a form of control that resists all changes

in readings. Higher readings increase the derivative function. To

prevent process oscillation, use caution in setting the derivative

value.

Range: Choose 4-20 mA or 0-20 mA.

For an explanation of Hold, Fixed Hold, and Fault, see step 8b

above.

For allowed values, see Table 5-1.

For more information using PID control, see Section 13.0.

10. Hold setup.

a. Move the cursor to "Hold feature setup" and press Enter (F4).

b. Press Edit (F4). Use the é to scroll through the choices: "Disable

feature", "Enable feature", and "20 min timeout". If "20 min timeout" is selected, hold mode will automatically disengage after

being on for 20 minutes.

NOTE

Selecting "Enable hold" or "20-min timeout" does not put

the controller in hold. It only allows the user to put the

controller in hold when the controller is in calibrate mode.

11. Using hold.

If hold was enabled in step 10 above, the hold screen will appear as

soon as the user enters the Calibrate menu. To activate Hold, press

Edit (F4). Use the é key to change Off to On and press Save (F4).

"Hold Mode Activated" will be displayed. Outputs and relays will go to

the values programmed in step 8b.

"Hold Mode Activated" will continue to flash in the main display even