Page 1

Compact Prover

Operating and maintenance instructions

Part Number: 3-9008-701, Rev. J

January 2015

Page 2

Page 3

Daniel customer service

Location Tel ephone number Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Daniel Customer Service +1.713.827.6314 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

Email

• Customer Service: tech.service@emersonprocess.com

• Customer Support: daniel.cst.support@emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: DanielEMA.CST@EmersonProcess.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason.

Download the RMA form from the Support Services web page by selecting the link below.

www2.emersonprocess.com/EN-US/BRANDS/DANIEL/SUPPORT-SERVICES/Pages/Support-Services.aspx?

Page 4

Signal words and symbols

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey

all safety messages that follow this syLmbol to avoid possible injury or death.

Safety alert symbol

Danger indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Pay special attention to the following signal words, safety alert symbols and statements:

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is a “general by-the-way” content not essential to the main flow of information.

Page 5

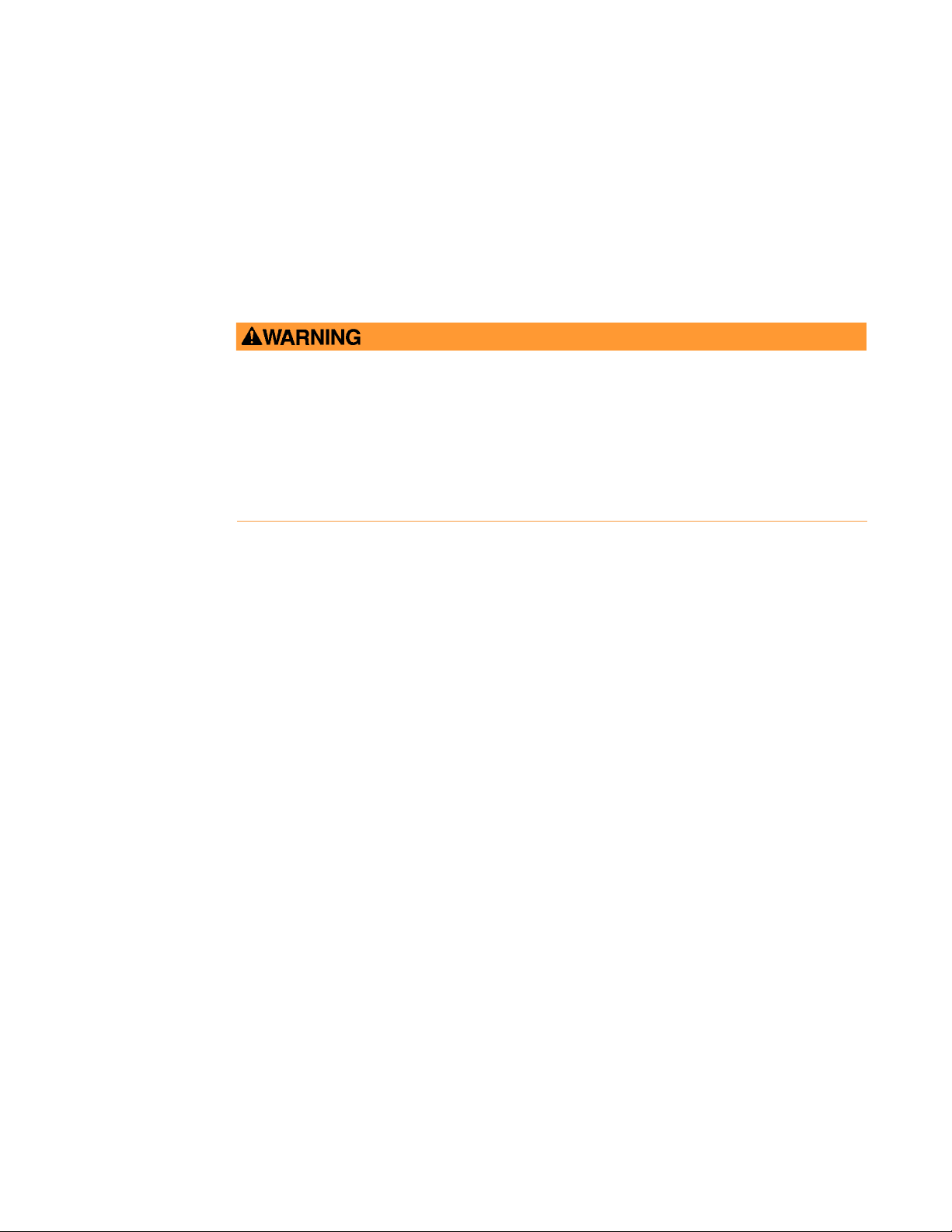

Important safety instructions

Installing, operating or maintaining a Daniel product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. To reduce this risk:

• Comply with all information on the product, in this manual, and in any local and national

codes that apply to the product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to

function within specific conditions. Because these products are sophisticated technical

instruments, it is important that the owner and operation personnel strictly adhere both to the

information printed on the product and to all instructions provided in this manual prior to

installation, operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL

NOTICES AND PRODUCT WARNINGS.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data

or product specifications for limitations. If you are unsure, discuss your needs with your

Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of

this product.

• To ensure safe and proper performance, only informed and trained personnel should

install, operate, repair and maintain this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction

manual along with the product to the new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND

TROUBLESHOOTING MANUALS AND ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may

result in property damage and/or serious personal injury or death.

Page 6

Product Operation Personnel:

• To prevent personal injury, personnel must follow all instructions of this manual prior to

and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the

instructions, contact your Daniel representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per

applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this

product.

• Connect the product to the appropriate pressure and electrical sources when and

where applicable.

• Ensure that all connections to pressure and electrical sources are secure prior to and

during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can

affect this product's performance, safety, and invalidate the warranty. “Look-a-like”

substitutions may result in deadly fire, explosion, release of toxic substances or

improper operation.

• Save this instruction manual for future reference.

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY,

AND WHILE EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO

BE CONSTRUED AS WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED, REGARDING THE

PRODUCTS OR SERVICES DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE

GOVERNED BY DANIEL'S TERMS AND CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE

RESERVE THE RIGHT TO MODIFY OR IMPROVE THE DESIGNS OR SPECIFICATIONS OF SUCH

PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF

ANY PRODUCT. RESPONSIBILITY FOR PROPER SELECTION, USE AND MAINTENANCE OF ANY

DANIEL PRODUCT REMAINS SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND

ACCURATE. DANIEL MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT

TO THIS MANUAL AND, IN NO EVENT, SHALL DANIEL BE LIABLE FOR ANY INCIDENTAL, PUNITIVE,

SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO, LOSS OF

PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY

AND MAY BE TRADEMARKS/REGISTERED TRADEMARKS OF THESE COMPANIES.

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement &

Control, Inc. ("Daniel") warrants that the licensed firmware embodied in the Goods will execute the

programming instructions provided by Daniel, and that the Goods manufactured by Daniel will be free from

defects in materials or workmanship under normal use and care and Services will be performed by trained

personnel using proper equipment and instrumentation for the particular Service provided. The foregoing

warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve

(12) months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel,

whichever period expires first. Consumables and Services are warranted for a period of 90 days from the date

of shipment or completion of the Services. Products purchased by Daniel from a third party for resale to Buyer

("Resale Products") shall carry only the warranty extended by the original manufacturer. Buyer agrees that

Daniel has no liability for Resale Products beyond making a reasonable commercial effort to arrange for

procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are

found by Daniel in the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the

Goods or firmware found by Daniel to be defective, or refund the purchase price of the defective portion of the

Goods/Services. All replacements or repairs necessitated by inadequate maintenance, normal wear and usage,

unsuitable power sources or environmental conditions, accident, misuse, improper installation, modification,

repair, use of unauthorized replacement parts, storage or handling, or any other cause not the fault of Daniel

are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay

any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance

by Daniel. All costs of dismantling, reinstallation and freight and the time and expenses of Daniel's personnel

and representatives for site travel and diagnosis under this warranty clause shall be borne by Buyer unless

accepted in writing by Daniel. Goods repaired and parts replaced by Daniel during the warranty period shall be

in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This

limited warranty is the only warranty made by Daniel and can be amended only in a writing signed by Daniel.

THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges

and agrees that corrosion or erosion of materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY

PERFORMANCE. THE REMEDIES OF BUYER SET FORTH IN THIS AGREEMENT ARE EXCLUSIVE. IN NO EVENT,

REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL DANIEL'S LIABILITY TO

BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR

SERVICES PROVIDED BY DANIEL GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO

EVENT SHALL DANIEL'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM "CONSEQUENTIAL DAMAGES" SHALL INCLUDE, BUT NOT

BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER'S CUSTOMERS.

: DANIEL SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN

Page 9

Operating and maintenance instructions Table of Contents

3-9008-701 Rev J January 2015

Contents

Daniel customer service ................................................................................... 3

• Signal words and symbols .............................................................................. 4

• Important safety instructions ......................................................................... 5

• Notice .......................................................................................................... 7

• Warranty and Limitations............................................................................... 8

Section 1: Introduction

1.1 General ...................................................................................................... 1

1.2 Description ................................................................................................. 1

1.3 Mechanical description ................................................................................ 2

1.4 Technical data............................................................................................. 6

Section 2: Installation and set-up

2.1 Installation ............................................................................................... 13

2.2 Set-up ...................................................................................................... 15

2.2.1 Supplying electrical power to the compact prover ....................................... 15

2.2.2 Connection of the operating computer ....................................................... 16

2.2.3 12 or 24V DC Interface Board....................................................................... 18

2.2.4 Charging the Pneumatic Spring Plenum....................................................... 21

2.3 Base volume certification ........................................................................... 23

2.4 Calibration integrity seal installation procedure .......................................... 24

Section 3: Operation

3.1 General operational theory ........................................................................ 27

3.2 Operating instructions .............................................................................. 30

Section 4: Maintenance

4.1 Seal Leak Check......................................................................................... 35

4.2 Base volume determination........................................................................ 37

4.2.1 Certification techniques............................................................................... 37

4.2.2 Water draw procedure: (Reference Figure 4-4 and notes on page 47).......... 42

4.3 Certification Data Sheet and Calculations.................................................... 49

4.3.1 Data Sheet Entries ....................................................................................... 49

4.3.2 Calculations................................................................................................. 50

4.4 Seal Replacement ...................................................................................... 52

4.4.1 Measurement Piston and Flow Tube ............................................................ 52

4.4.2 Optical Seal Support .................................................................................... 60

4.4.3 Hydraulic Cylinder and Hydraulic Seal Support............................................. 63

Table of Contents 9

Page 10

Table of Contents Operating and maintenance instructions

January 2015 3-9008-701 Rev J

4.5 Optical conversion kit ................................................................................67

4.6 Detector Switch Replacement .....................................................................68

Section 5: Troubleshooting

5.1 General.....................................................................................................73

5.2 Interface Signals........................................................................................ 73

5.3 Measurement Piston Movement.................................................................. 75

5.4 The auto plenum adjust panel.....................................................................80

Section 6: Special tools and equipment

6.1 Tool list ....................................................................................................85

Section 7: Parts list

7.1 General.....................................................................................................89

7.2 Replacement Parts List ...............................................................................89

10 Table of Contents

Page 11

Operating and maintenance instructions List of Tables

3-9008-701 Rev J January 2015

List of Tables

Table 1-1 Hydraulic ........................................................................................................................... 7

Table 1-2 Standard compact prover set-up data ................................................................................ 8

Table 1-3 Power requirements........................................................................................................... 9

Table 3-1 Spring plenun ‘R’ values ................................................................................................... 31

Table 4-1 Torque table ....................................................................................................................55

Table 4-2 Tie rod nut torque ............................................................................................................ 57

Table 4-3 Hydraulic cylinder tie rod nut torque................................................................................ 67

Table 4-4 Volumetric percent change for compact provers ............................................................. 71

Table 6-1 Tool size requirement ...................................................................................................... 86

Table 6-2 Torque values for pipe flange stud/nut sets...................................................................... 87

Table 7-1 Parts list ........................................................................................................................... 90

List of Tables 11

Page 12

List of Tables Operating and maintenance instructions

January 2015 3-9008-701 Rev J

12 List of Tables

Page 13

Operating and maintenance instructions List of Figures

3-9008-701 Rev J January 2015

List of Figures

Figure 1-1 Outline drawings - Compact prover .............................................................................. 4

Figure 1-1 Outline drawings - Compact prover (Continued)........................................................... 5

Figure 2-1 Typical prover installation........................................................................................... 15

Figure 2-2 Double chronometry .................................................................................................. 17

Figure 2-3 12V Prover interface board ......................................................................................... 19

Figure 2-4 12/24V Prover interface board.................................................................................... 20

Figure 2-5 Typical nitrogen adjust panel...................................................................................... 22

Figure 2-6 Connection diagram................................................................................................... 23

Figure 3-1 Standby position......................................................................................................... 28

Figure 3-2 Initial motion.............................................................................................................. 28

Figure 3-3 Proving ....................................................................................................................... 29

Figure 3-4 End of proving run ...................................................................................................... 29

Figure 3-5 Piston returning to upstream position ........................................................................ 30

Figure 3-6 Spring plenum ............................................................................................................ 31

Figure 3-7 Hydraulic system ........................................................................................................ 33

Figure 4-1 Leak detector kit......................................................................................................... 35

Figure 4-2 Leak detector kit installed........................................................................................... 36

Figure 4-3 Compact prover water draw assembly typical NEC style (non-explosion proof)........... 40

Figure 4-3 Compact prover water draw assembly (continued) Typical Ex-proof style ................... 41

Figure 4-4 Water draw system..................................................................................................... 42

Figure 4-5 Test measure temperature stabilization...................................................................... 45

Figure 4-6 Typical volumetric determination data sheet.............................................................. 48

Figure 4-7 Typical prover control panel assembly (12” shown) .................................................... 49

Figure 4-8 Poppet O-ring installation........................................................................................... 54

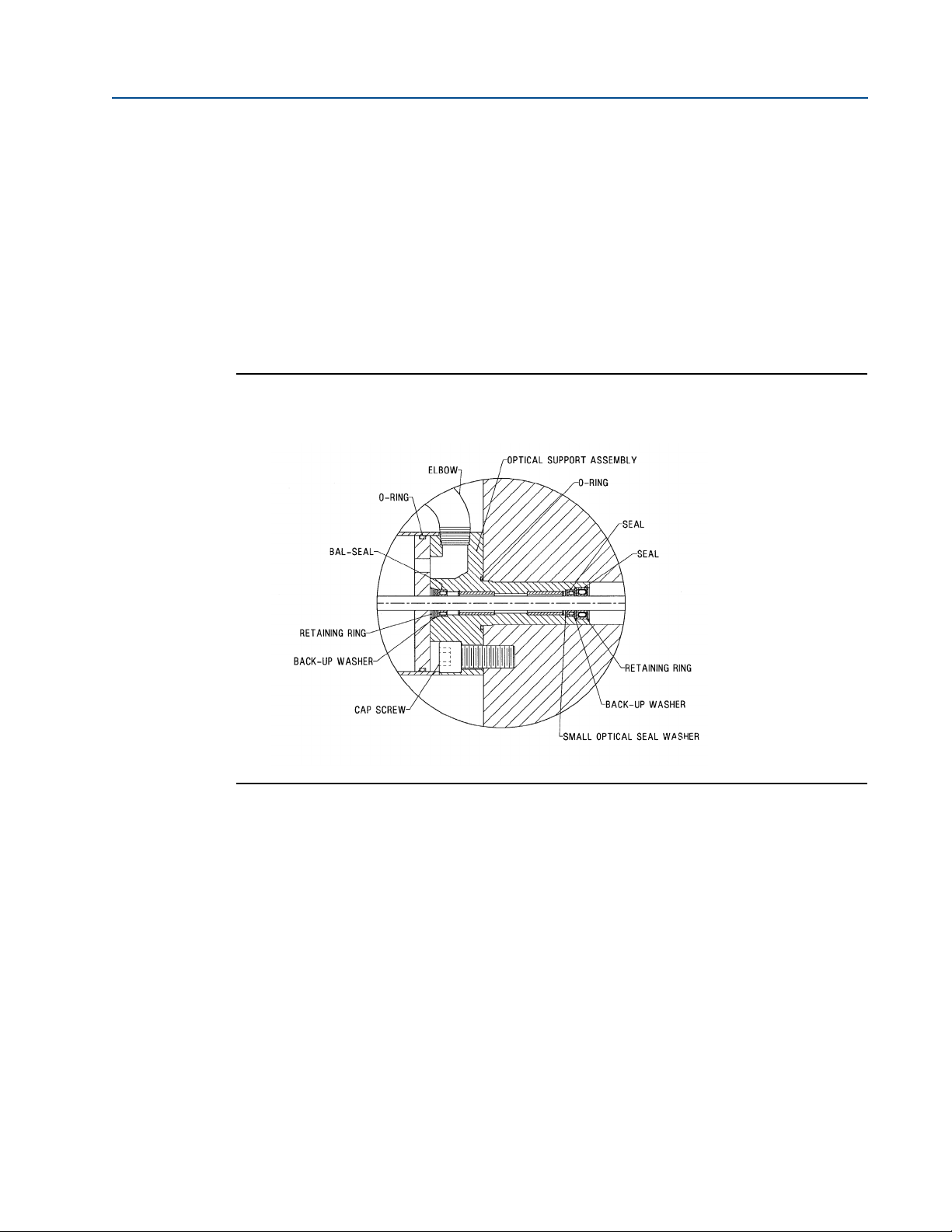

Figure 4-9 Optical seal support assembly - 8” and 18” and all units built prior to

January 1, 2006 ............................................................................................................ 61

Figure 4-10 Optical seal support assembly - 24” (built after January 1, 2006) and 34”.................... 62

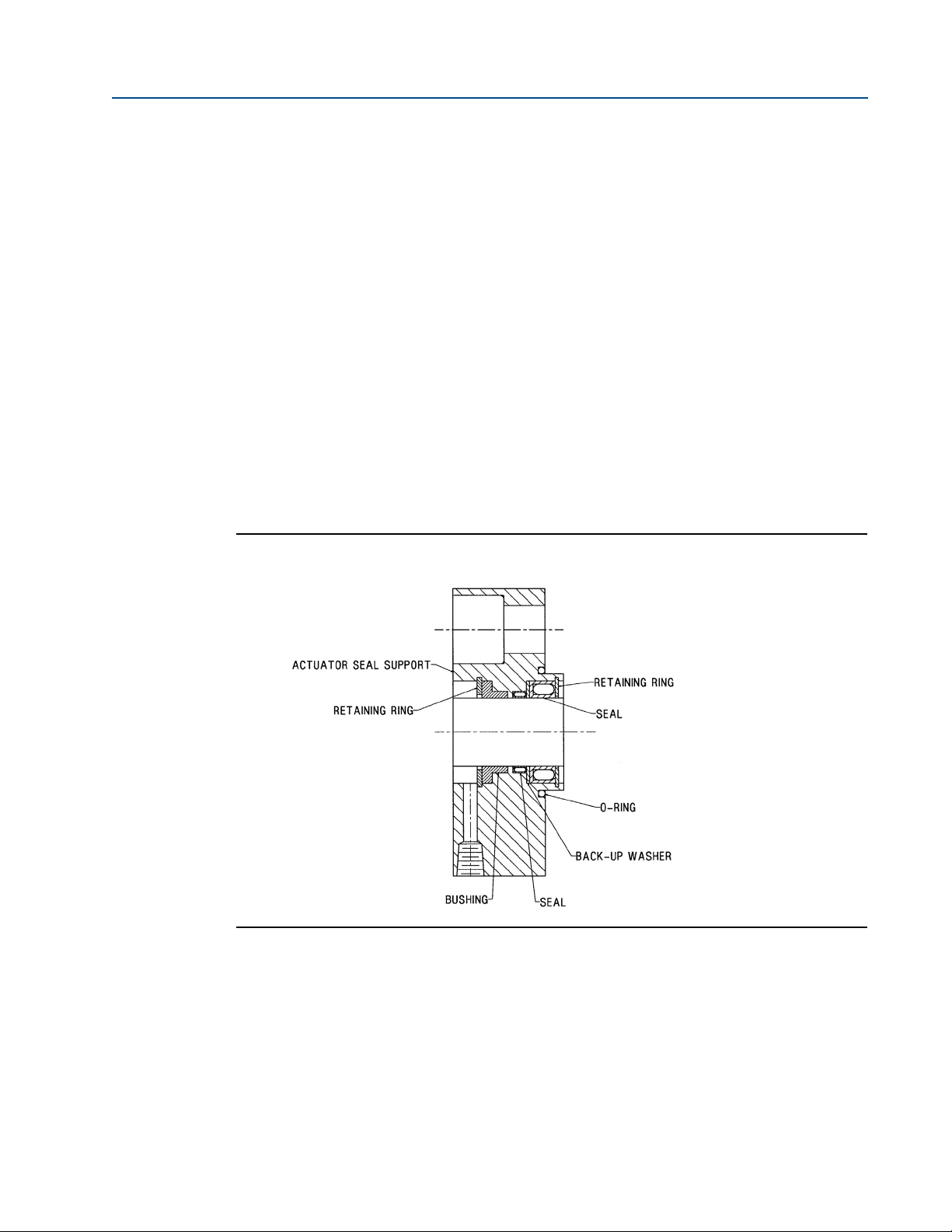

Figure 4-11 Hydraulic seal support assembly................................................................................. 63

Figure 4-12 Typical hydraulic cylinder assembly ............................................................................ 65

Figure 4-13 Detector switch removal #1........................................................................................ 68

Figure 4-14 Detector switch removal #2........................................................................................ 69

Figure 4-15 Detector switch adjustment ....................................................................................... 70

Figure 5-1 Prover signal timing.................................................................................................... 74

List of Figures 13

Page 14

List of Figures Operating and maintenance instructions

January 2015 3-9008-701 Rev J

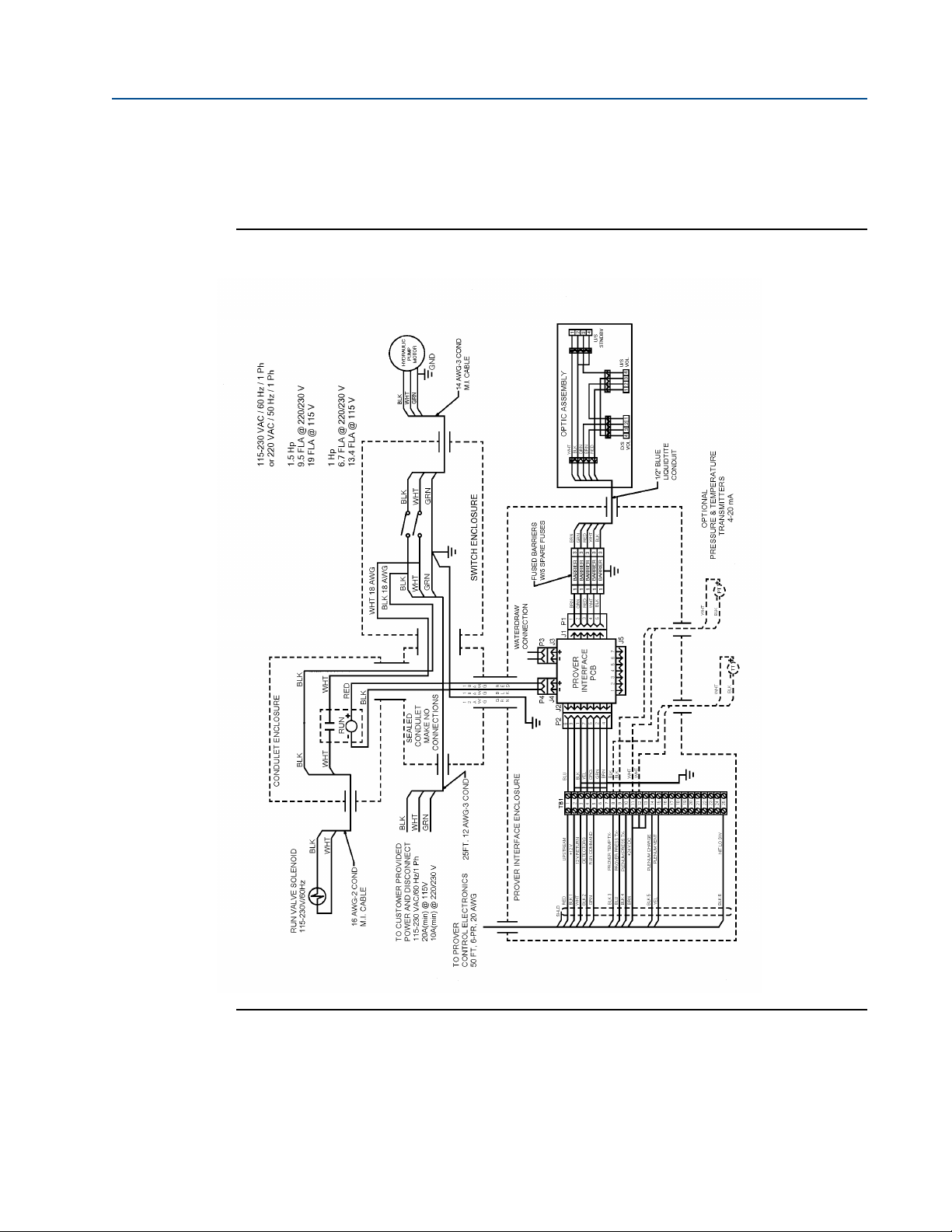

Figure 5-2 Prover wiring diagram (single phase power)................................................................76

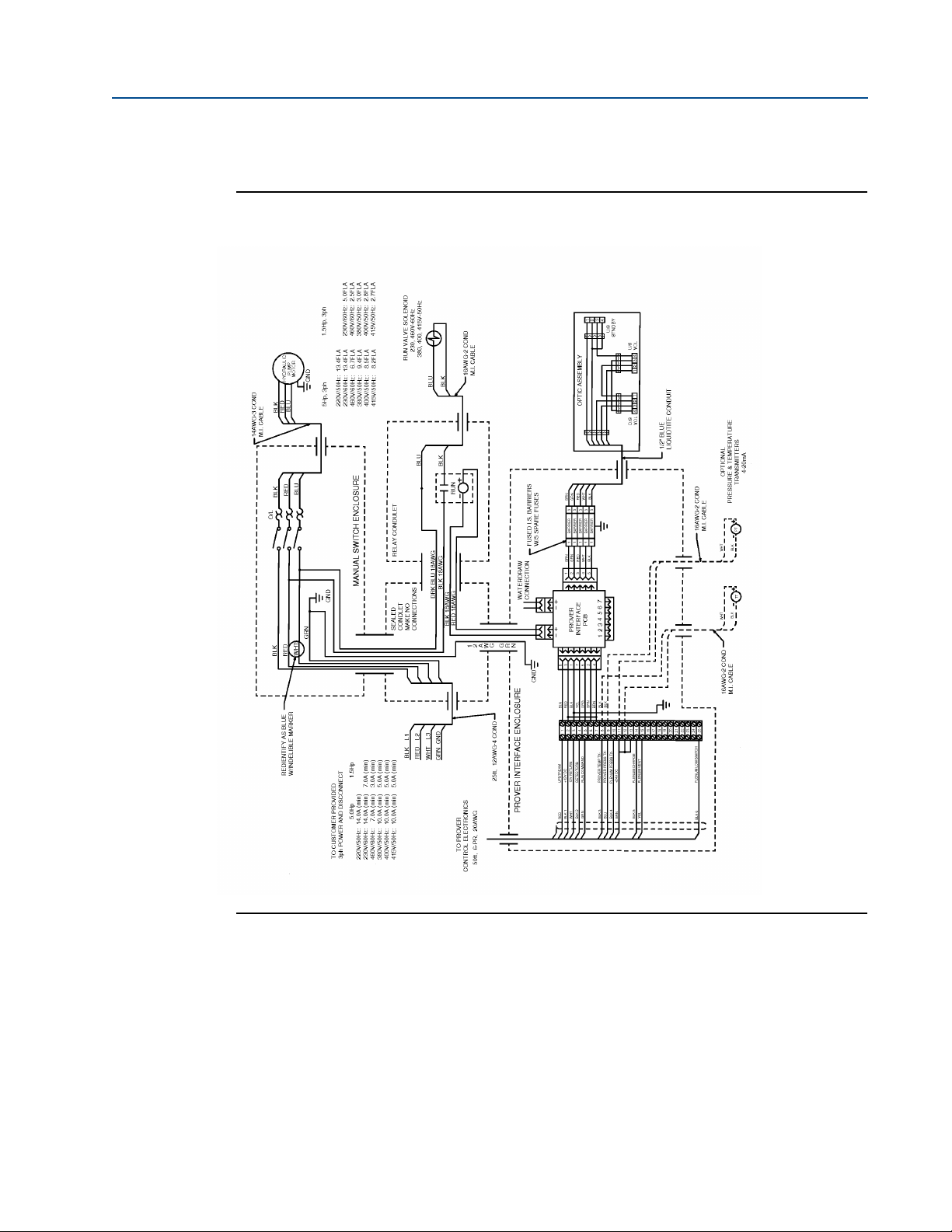

Figure 5-3 Prover wiring diagram (three phase power).................................................................77

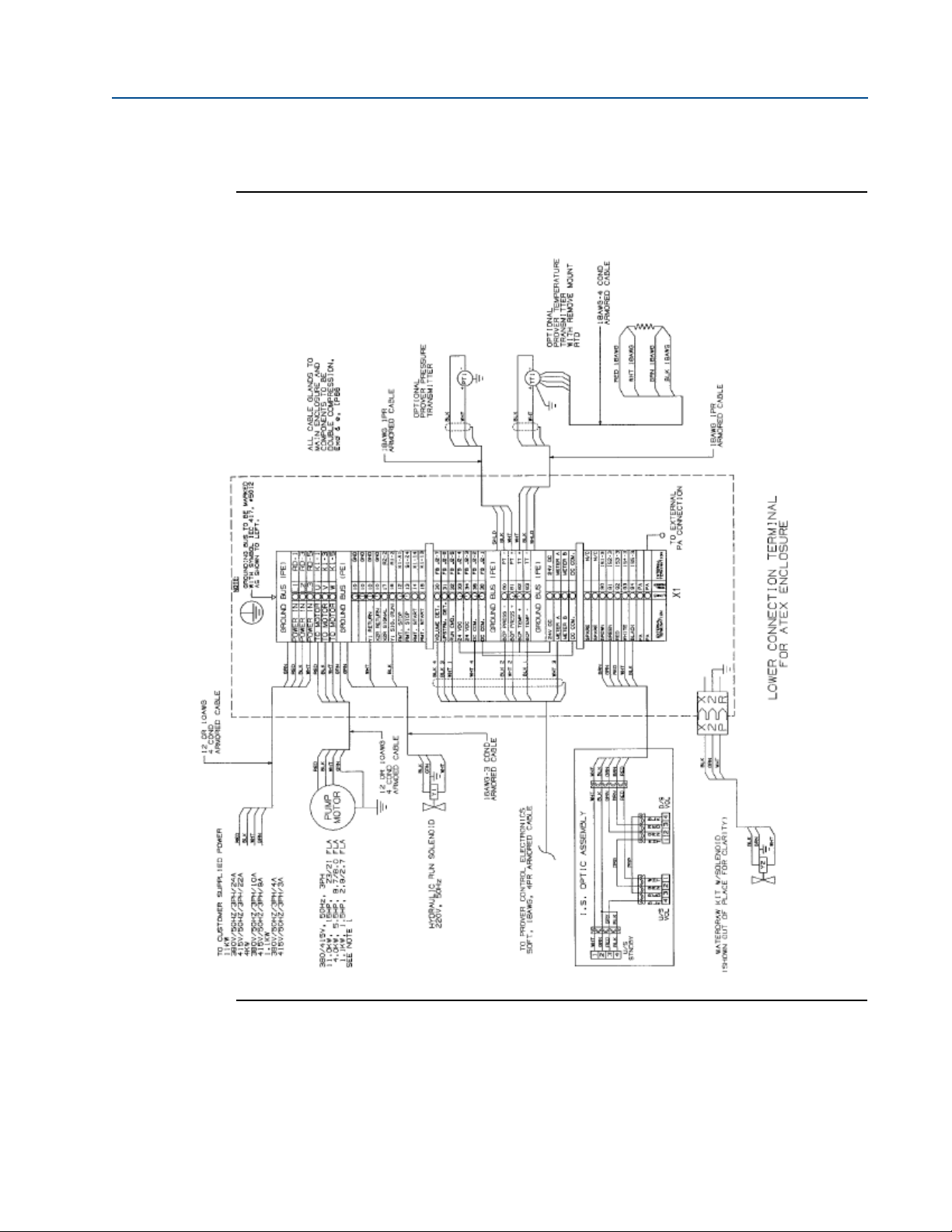

Figure 5-4 Prover wiring diagram (ATEX internal).........................................................................78

Figure 5-5 Prover wiring diagram (ATEX external)........................................................................79

Figure 5-6 DC powered solenoids ................................................................................................82

Figure 5-7 AC powered solenoids.................................................................................................83

Figure 7-1 Spare parts diagram (flow tube)..................................................................................95

Figure 7-2 Spare parts diagram (Flow tube) (continued) ..............................................................96

Figure 7-3 Spare parts diagram (Mechanical components) ..........................................................97

Figure 7-4 Spare parts diagram (Electrical components)..............................................................98

14 List of Figures

Page 15

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

11

12

13

14

15

16

Section 1: Introduction

1.1 General

This manual is designed to provide information and guidance to personnel responsible for the

operation and maintenance of the Compact Prover. The content of this manual is intended to

describe the normal operational characteristics of the Compact Prover. By necessity, this

manual is written for standard provers. It does not include specific information pertinent to

specially designed items or non-standard equipment. Operating and Maintenance Instructions

for special equipment will be supplied as necessary.

The Compact Prover is not a stand-alone system. The prover requires the use of an operating

computer that is capable of Dual Chronometry Pulse Interpolation. The operating computer will

process and summarize all proving data. Refer to the Operation section of this manual for more

information.

1.2 Description

The Compact Prover provides improved accuracy, rapid operation and continuous flow for

performance testing, or ‘proving’, of liquid flow meters in an operational line. Modern

electronics permit exact time determination and pulse counting, which provides high accuracy

proving with a smaller volume and fewer flowmeter pulses than any previous proving

technology.

Because of its reduced size and a unique patented piston design, which includes an internal

poppet valve, the Compact Prover can be easily installed in most operational lines and operated

with minimal disturbance to flow. The prover’s internal design incorporates an inherent fail-safe

feature constructed to assure uninterrupted liquid flow.

The Interface Enclosure contains a printed circuit board which conditions the signals generated

by the prover. The operating computer, which is typically located in a control room, receives

these signals and generates data from the proving passes. This data can be printed for manual

implementation to the process line flow meter. Some proving applications can be programmed

for automatic implementation.

A typical proving run should generate the following raw data:

1. The exact time interval, in seconds, for the certified volume of the prover to be

displaced.

2. The exact time interval, in seconds, to tabulate flow meter pulses.

3. The exact number of whole meter pulses generated by the liquid displaced during the

proving run.

Typical data given by the operating computer include:

• Frequency: Flowmeter pulses/second, Hz

• Flow rate: Units of volume/minute or hour (Can be gpm, bph, lpm or m /hr.)

• K-Factor: Flowmeter pulses/unit of volume

General 1

Page 16

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

• Meter Factor: Correction factor (multiplier) for meter readout

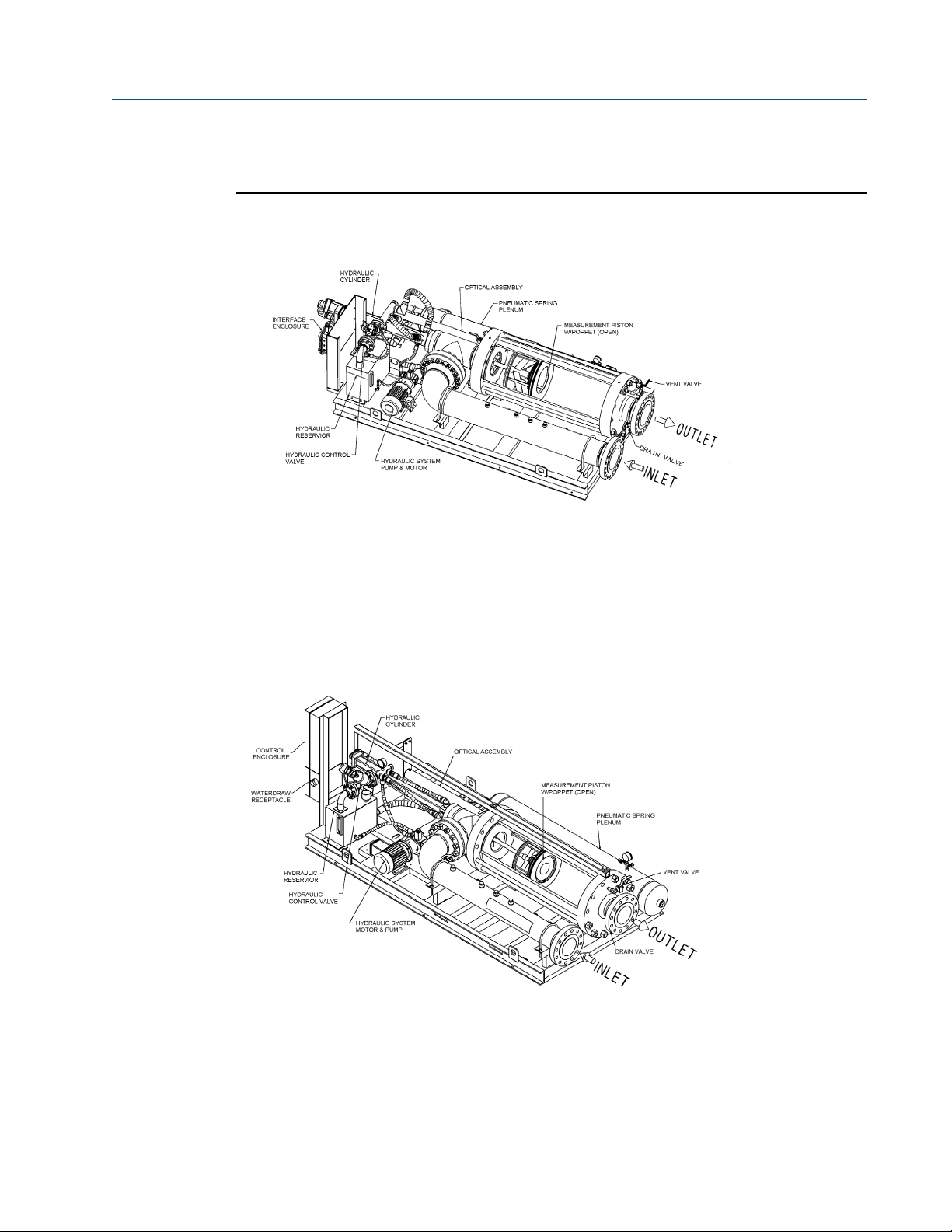

1.3 Mechanical description

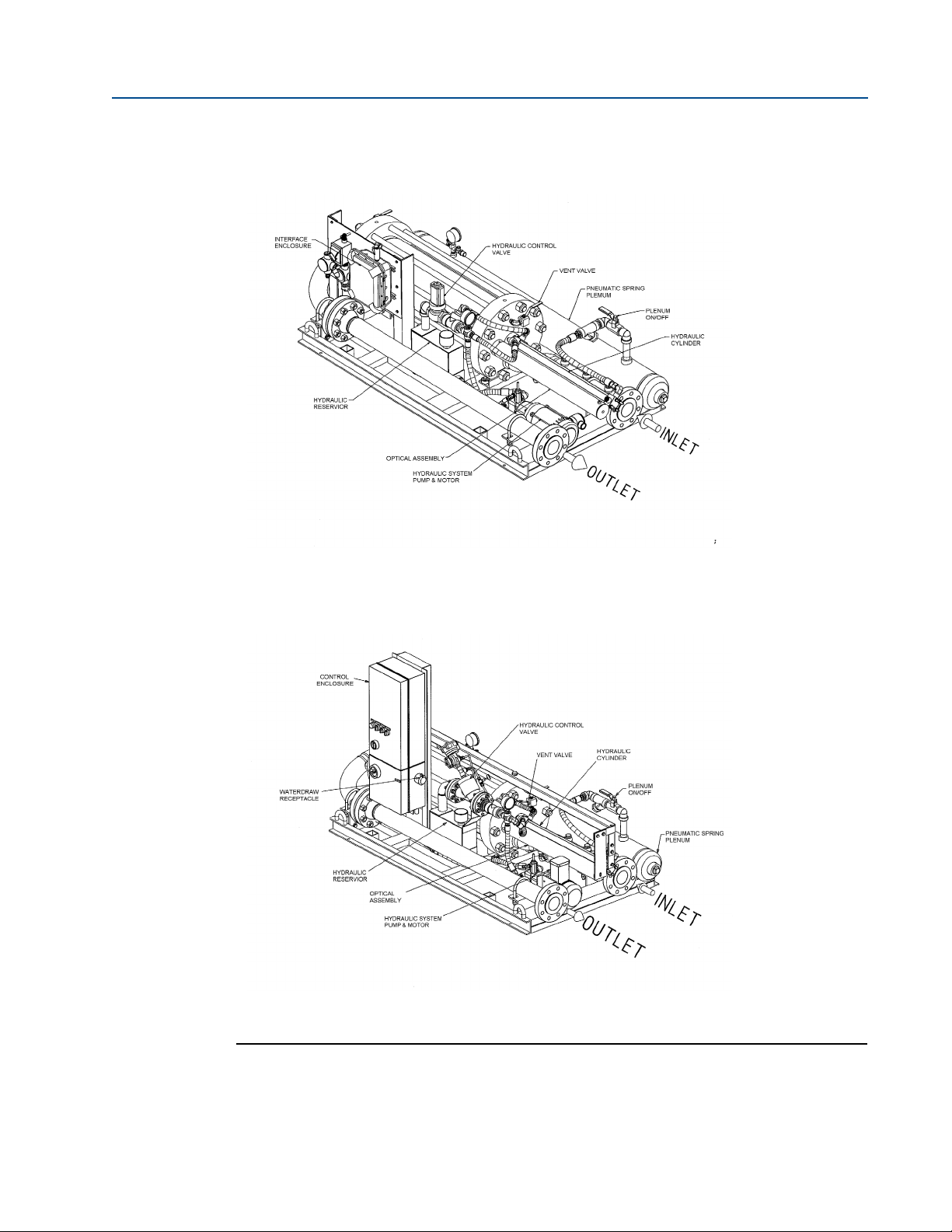

The basic outline of the compact prover and its component parts are shown in Figure 1-1. The

compact prover consists of a free flowing measurement piston and a coaxial mounted poppet

valve, all within a precision flow tube. The poppet valve is incorporated within the measurement

piston and is connected to the hydraulic cylinder by way of an actuator shaft. A calculated

pressure in the pneumatic spring plenum, in combination with the hydraulic system, operates

the actuator piston within the hydraulic cylinder. The pressure in the pneumatic spring plenum

closes the poppet valve, allowing the piston to proceed through a proving pass. Once the pass is

complete, the hydraulic system returns the piston to the upstream (standby) position while

holding the poppet valve open. Normal flow of the liquid will pass through the open poppet

valve. Optical sensors are used to detect the position of the piston inside the flow tube. These

sensors generate position signals, which are used for proper operation and data calculation.

Refer to Section 3: Operation for complete operation instructions.

Flow tube:

The flow tube is a stainless steel tube with a precision machined, hard chrome-plated bore. It

contains the prover piston, poppet valve, and fail-safe mechanism.

End connections:

The inlet and outlet end connections for installing the compact prover in line are ANSI 16.5

raised face flanges. Reference Section 1.4 for Technical data.

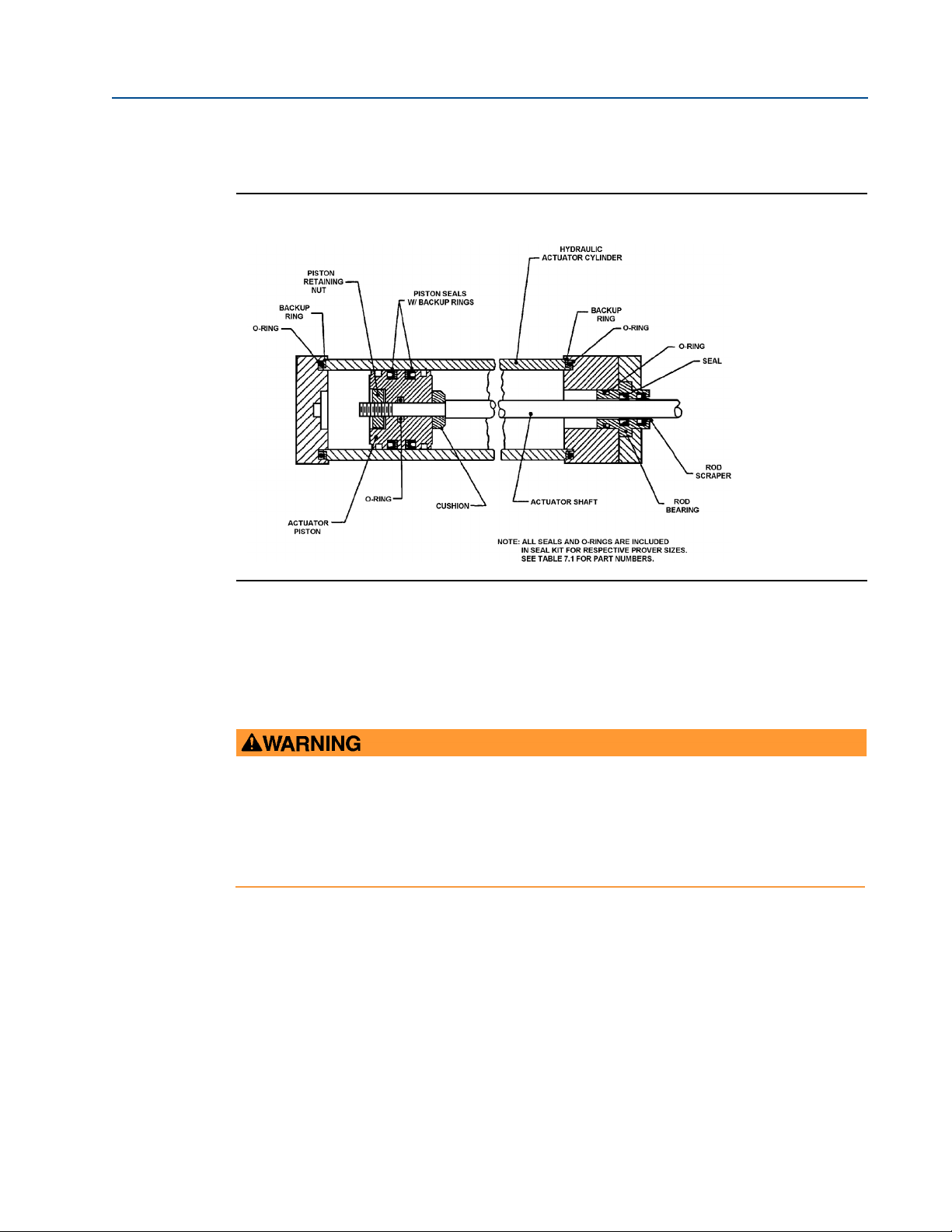

Hydraulic cylinder:

The hydraulic cylinder contains the actuator piston to act as a barrier between the gas in the

pneumatic spring plenum and the hydraulic oil. It provides the forces necessary to open and

close the poppet valve and to operate the prover through it’s cycle. Connected to the actuator

piston is the actuator shaft, which is connected to the poppet on the opposite end.

Optical assembly:

This intrinsically safe component is precision designed for accurate volume measurement within

5 ten thousandths (0.0005) of one inch or 0.0127 mm. There are three optical sensors

(switches) used: one for the upstream (standby) position, and two for defining the displaced

volume of fluid flowing through the prover. These slotted switches have an infrared LED and a

phototransistor on opposite sides of the slot. The prover generates a signal when a “flag” passes

through the slot and blocks the infrared light from the phototransistor. The flag is attached to

2 Mechanical description

Page 17

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

the measurement piston by means of the detector shaft. The passage of the flag through the

slotted optical switches defines the displaced volume (base volume) of the prover. For detailed

information on the Optical Assembly, see Section 4: Maintenance.

Hydraulic control valve:

This normally closed two-way valve controls the hydraulic operation of the prover. The valve is

energized to open during a proving pass, and de-energized to close for the piston return to the

upstream (standby) position. There are two styles of control valve used. Style is dependent

upon prover size and electrical system (NEC or ATEX Type). See Figure 1-1.

Hydraulic pump:

The hydraulic pump is a variable displacement vane-type unit driven by an electric motor. It

supplies the power necessary to overcome the plenum pressure and return the piston

upstream. Once the piston has reached the upstream position, the pump assumes a neutral

condition maintaining hydraulic pressure at no flow for minimum power consumption.

Pneumatic spring plenum:

The charge of pressurized gas in the pneumatic spring plenum supplies the energy necessary to

overcome the shaft seal friction and close the poppet valve. A portion of the charge is required

to overcome the force generated by the product pressure within the prover acting on the

actuator shaft and the detector shaft. When properly adjusted, this charge allows for minimum

pressure differential (usually only a few inches of water column) across the piston.

Mechanical description 3

Page 18

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 1-1 Outline drawings - Compact prover

Typical 8”, 12”, 18”, 24”, 34” and 40” NEC Type

Typical 8”, 12”, 18”, 24”, 34” and 40” ATEX Type

4 Mechanical description

Page 19

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

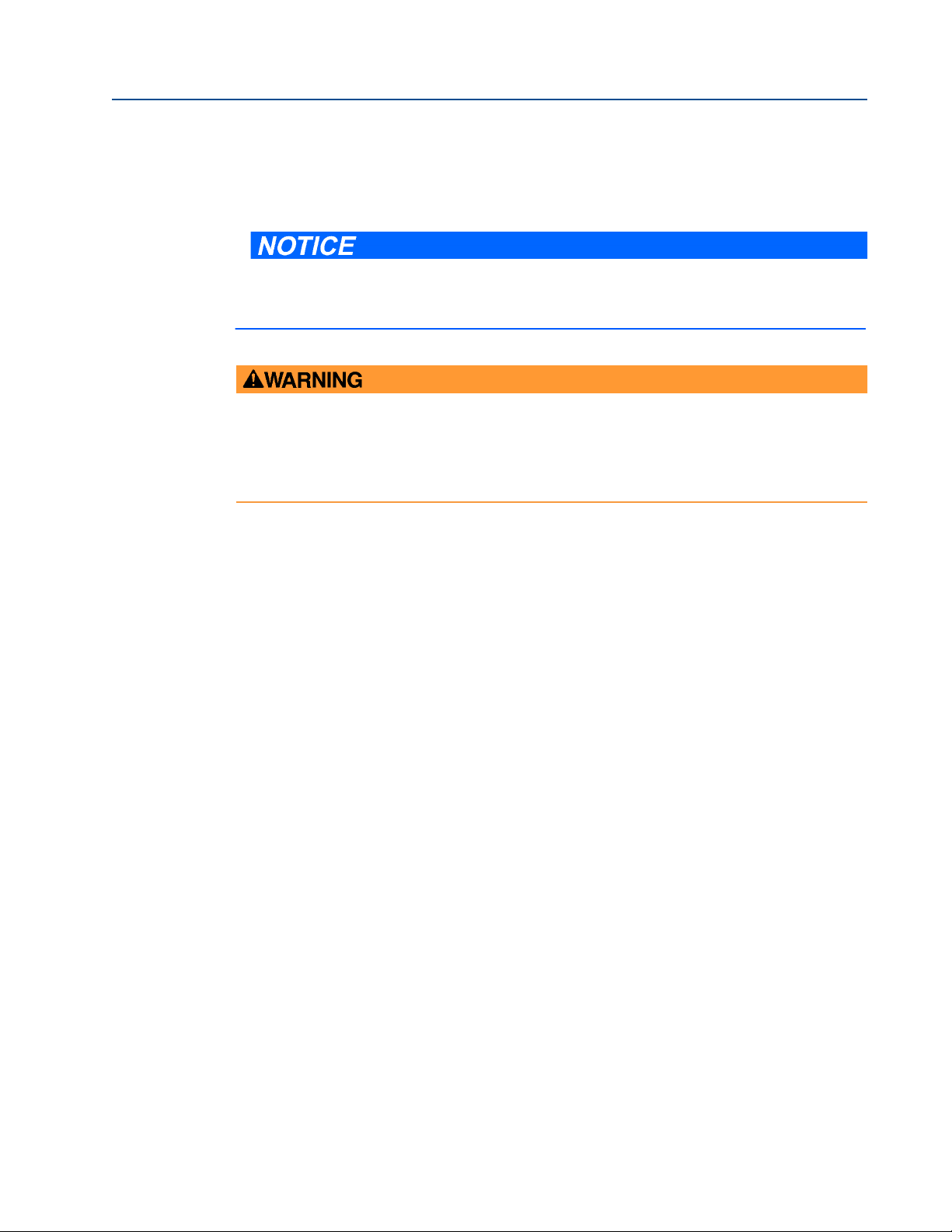

Figure 1-1 Outline drawings - Compact prover (Continued)

Typic a l 12” Mini NEC Type

Typic a l 12” Mini ATE X Type

Mechanical description 5

Page 20

Section 1: Introduction Operating and maintenance instructions

Follow all the safety and equipment limits recommended in 1.4 Technical data of this manual. It is the owner’s and/or purchaser’s responsibility to comply with these parameters.

PERSONAL PROTECTION HAZARD

Follow all parameters for the compact prover indicated below.

Failure to do so may result in injury or equipment damage.

January 2015 3-9008-701 Rev J

1.4 Technical data

Materials of construction:

Standard: 17-4 stainless steel flow tube with hard chrome plating, carbon steel pipe and flanges

Standard maximum working pressure:

8" to 24" Size: 150 lb. ANSI 285 psig (1965 kPa) @ 100.F (38.C)

260 psig (1793 kPa) @ 200.F (93.C)

8" to 24" Size: 300 lb. ANSI 740 psig (5102 kPa) @ 100.F (38.C)

675 psig (4654 kPa) @ 200.F (93.C)

8" to 24" Size: 600 lb. ANSI 480 psig (10204 kPa) @ 100.F (38.C)

1350 psig (9308 kPa) @ 200.F (93.C)

34" and 40" Size: 300 lb. ANSI 740 psig (5102 kPa) @ 100.F (38.C)

675 psig (4654 kPa) @ 120.F (49.C)

For intermediate pressures refer to ANSI B16.5

Prover size based on flow tube diameter.

Maximum working temperature:

8” to 24" Size: -20 to 200.F (-29 to 93.C)

6 Technical data

Page 21

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

34” and 40" Size: 20 to 120.F (-7 to 49.C)

Standard ambient temperature range: -4.F to 104.F (-20.C to 40.C)

Consult factory for other changes.

Important

Temperature span differential between tie rods and flow tube not to exceed 200.F (93.C) on

standard 8" to 24" models and 100.F (38.C) on 34” and 40" models.

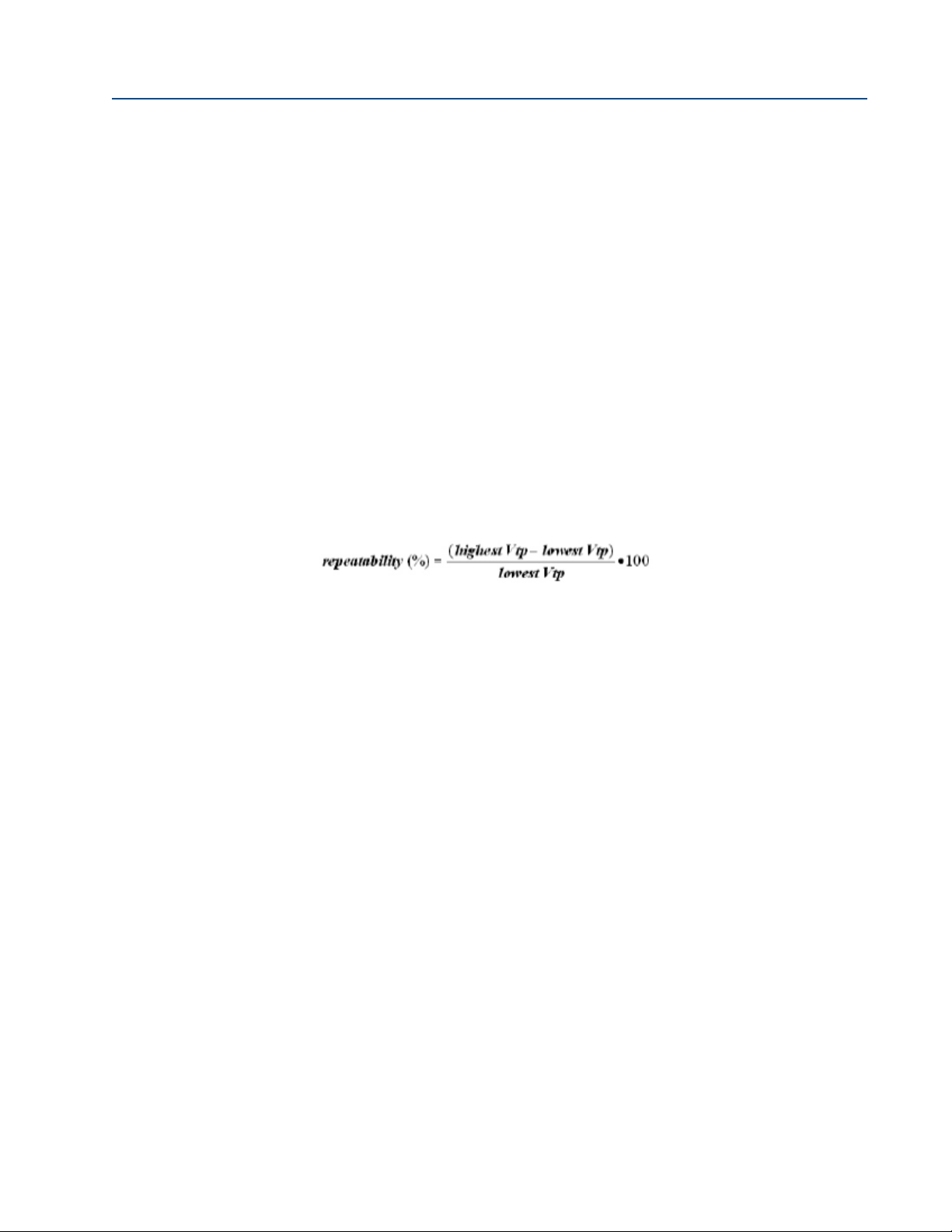

Performance:

Repeatability 0.02% or better (water draw)

Standard capacities and specifications:

• Flow Range (1000:1): See Table 1-2

• Prover Nominal Base Volume (dependent on size): See Tabl e 1- 2

• Volume Ratio (Upstream/Downstream Volume): See Ta ble 1-2

• Hydraulic System: Fill with type MIL-H-5606 (Aviation Grade E Hydraulic Fluid) or

equivalent in quantities. See Table 1-1

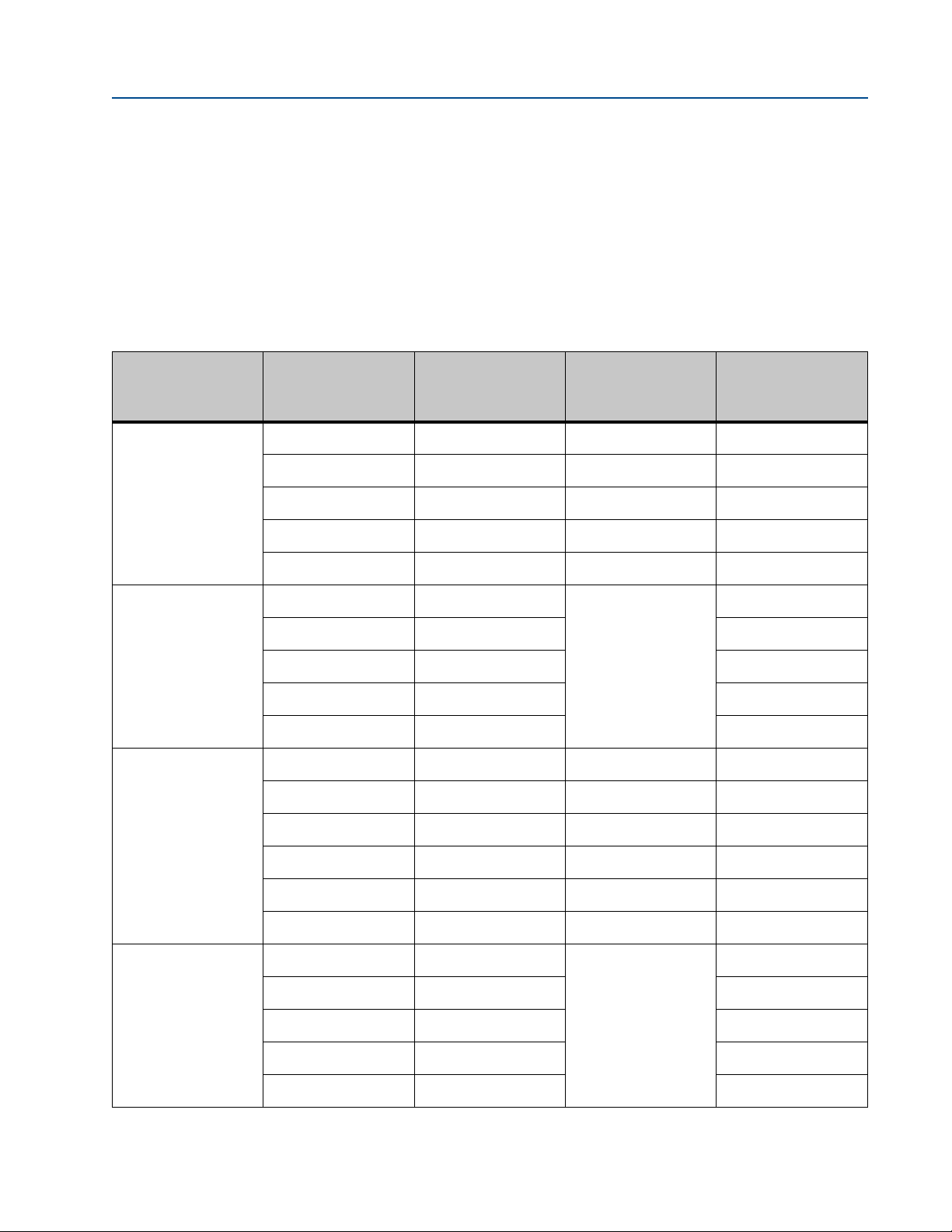

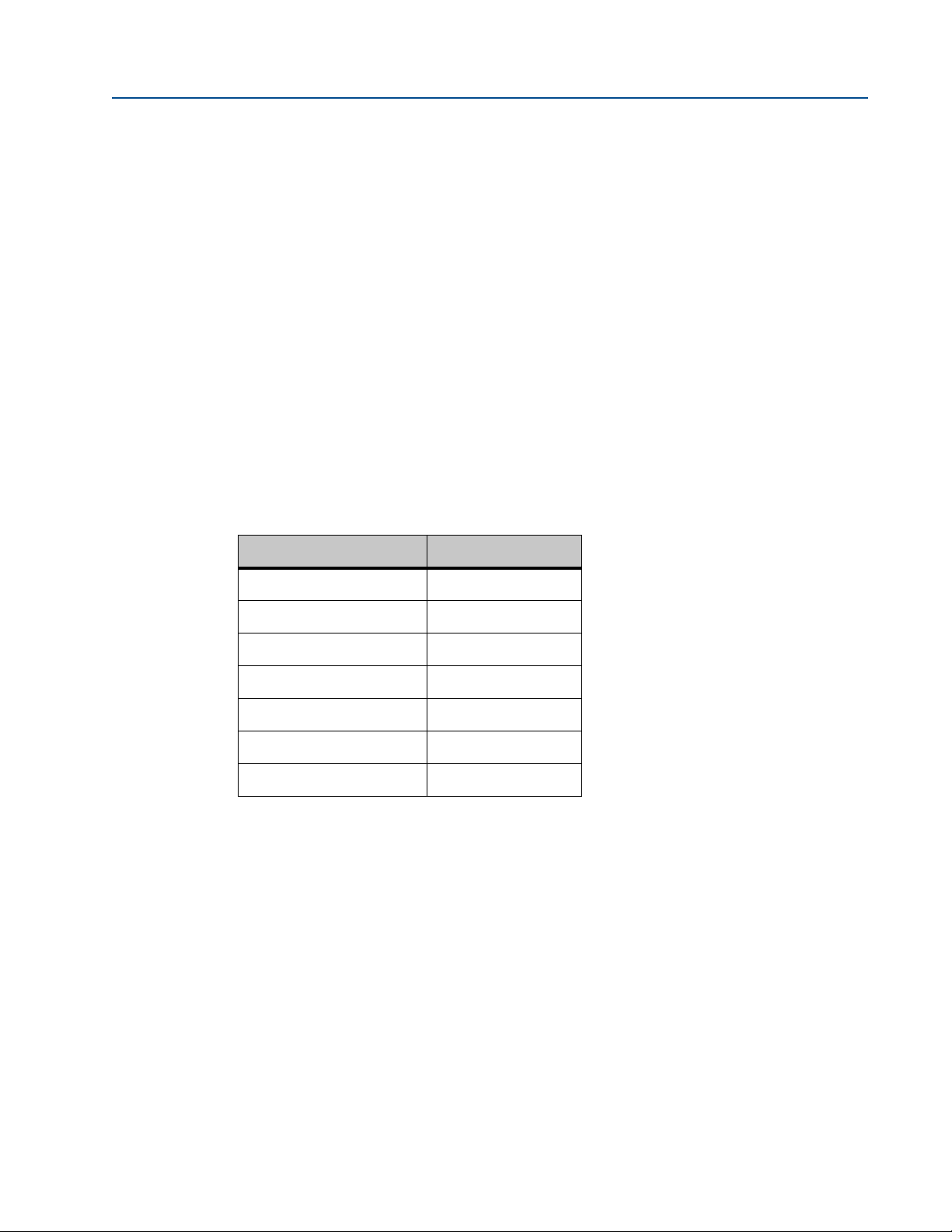

Table 1-1 Hydraulic

Prover size System capacity

8”

12” Mini

12”

18”

24”

34”

40”

3 gal (11.4 L)

3 gal (11.4 L)

3 gal (11.4 L)

10 gal (38 L)

25 gal (95 L)

60 gal (227 L)

93 gal (352 L)

Note: Possible equivalents:

• Mobile Aero HF series

• Aeroshell 41

Technical data 7

Page 22

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

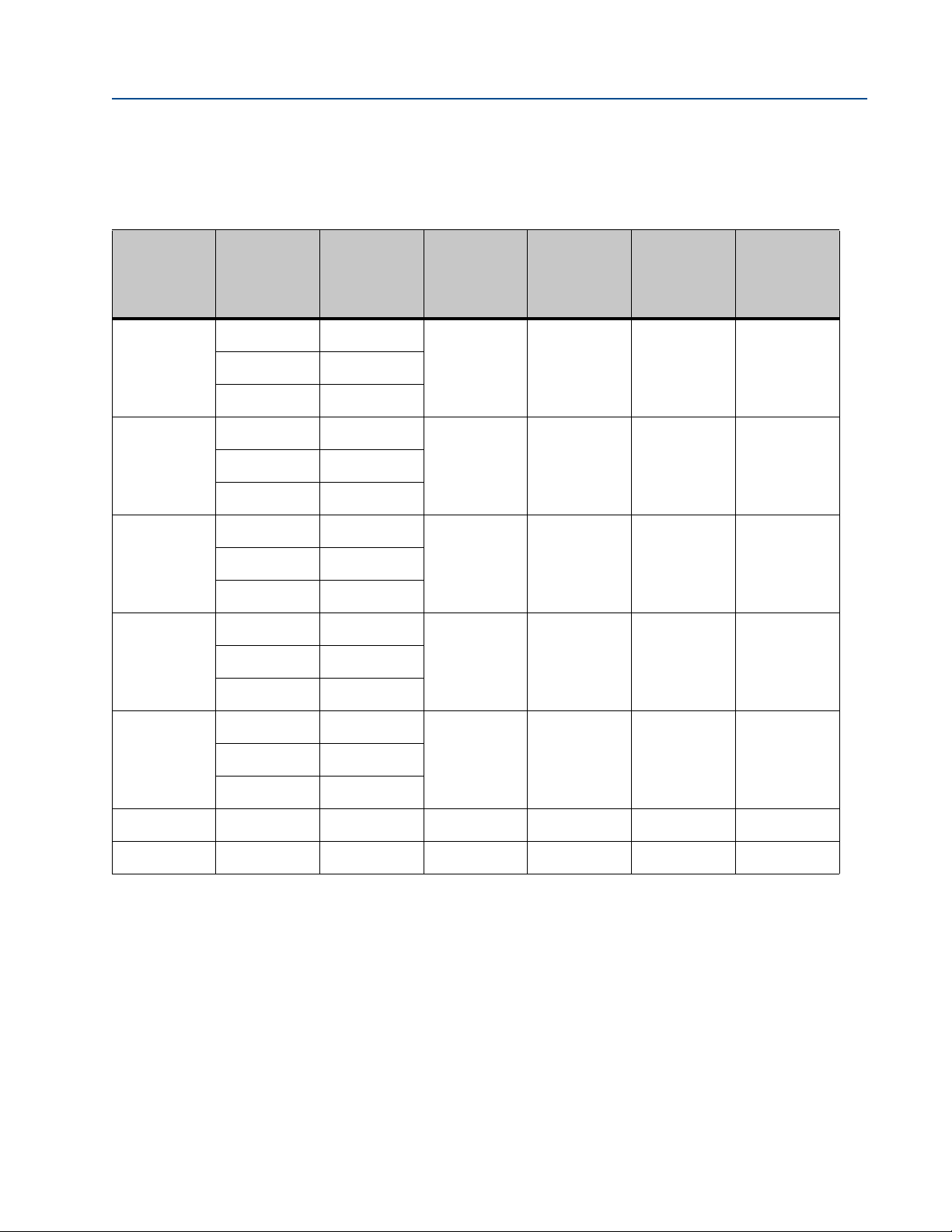

Table 1-2 Standard compact prover set-up data

Nominal

prover

shipping

dimension

s (L X W X

H)

Approxima

te shipping

weight

Nominal

flow tube

dia.

Provers rate ranges

minimum maximum

Nominal

prover

base

volume

Multiplier

for stream

volume

Flowtube

I.D

Wall

thickness

Inlet/

Outlet

flange size

8”

12” Mini

12”

18”

24”

34”

40”

0.25 gpm

0.946 lpm

0.357 bph

3

0.057 m

1.0 gpm

3.78 lpm

1.43 bph

3

0.227 m

1.75 gpm

6.623 lpm

2.5 bph

3

0.397 m

3.5 gpm

13.247 lpm

5.0 bph

3

0.794 m

7.0 gpm

24.495 lpm

10.0 bph

3

1.595 m

12.6 gpm

47.691 lpm

18.0 bph

3

2.860 m

17.5 gpm

66.237 lpm

25.0 bph

3

3.972 m

ph

ph

ph

ph

ph

ph

ph

250 gpm

946 lpm

357 bph

3

57 m

ph

1000 gpm

3.780 lpm

1430 bph

3

227 m

mp

1750 gpm

6623 lpm

2500 bph

3

397 m

ph

3500 gpm

13247 lpm

5000 bph

3

794 m

ph

7000 gpm

26495 lpm

10000 bph

3

1595 m

ph

12600 gpm

47691 lpm

18000 bph

3

2860 m

ph

17500 gpm

66237 lpm

25000 bph

3

3972 m

ph

5 gal

(20 liters)

10 gal

(40 liters)

15 gal

(60 liters)

30 gal

(120 liters)

65 gal

(250 liters)

100 gal

(400 liters)

170 gal

(650 liters)

0.990590 8.250

(20.955

cm)

0.991670 12.250

(31.115

cm)

0.991670 12.250

(31.115

cm)

0.993020 17.500

(44.450

cm)

0.993464

Pre 2006

25.500

(64.770

cm)

.992369

0.988536 34.00

(86.360

cm)

0.985938 40.00

(101.60

cm)

0.6875

(1.746 cm)

0.8750

(2.222 cm)

0.8750

(2.222 cm)

1.2500

(3.175 cm)

1.0625

(2.699 cm)

1.2500

(3.175 cm)

1.500

(3.810cm)

2” 121" x 56" x

50" (307cm

x 142cm x

127cm)

4” 147" x 62" x

55" (373cm

x 157cm x

140cm)

6” 172" x 67 x

57" (437cm

x 170cm x

145cm)

8” 193" x 76" x

56" (490cm

x 193cm x

142cm)

12” 220" x 96" x

66" (559cm

x 244cm x

168cm)

16” 230" x 102"

x 74"

(584cm x

259cm x

188cm)

20” 240" x

130"x77"

(610cm x

330cm x

196cm)

2,200 lbs

(998 kgs)

4,400 lbs

(1,995 kgs)

4,900 lbs

(2,223 kgs)

7,300 lbs

(3,311 kgs)

13,400 lbs

(6,078 kgs)

19,200 lbs

(8,709 kgs)

35,000 lbs

(13,876

kgs)

Notes:

1. Temperature and pressure tap on the outlet flange (1” dia.) can be supplied upon

request.

2. Fluid viscosity ranges up to 10,000 centistokes.

3. Considerations for meter type and pulse output quality should be made for all compact

prover applications.

4. Compact prover performance depends upon the quality of the pulse signal from the

meter being proved.

8 Technical data

Page 23

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

5. For more information on pulse quality and compact provers, reference API Chapter 4.2.

6. For certified dimensional drawings, please contact the factory.

7. Upstream multipliers are approximate. Actual values can be obtained from the Base

Volume Certification (water draw) method.

Table 1-3 Power requirements

Size

8” and 12” Mini

12”

AC line voltage,

frequency and

phase

115/60/1

220/50/1 &230/60/1

380/50/3

415/50/3

460/60/3

115/60/1

220/50/1 & 230/60/1

380/50/3

415/50/3

460/60/3

115/60/1

220/50/1 & 230/60/1

Hydraulic system

motor full load

amps

13.4

6.7

3.0

2.7

2.2

19

8.4

3.0

2.7

2.2

19

19

Hydraulic system

motor

configuration

1Hp Single 10

1 Hp Single 5

1.5 Hp Single .2

1.5 Hp Single .2

1.5 Hp Single 5

1.5 Hp Single

1.5 Hp Dual, 2 Circuits .2

1.5 Hp Dual, 1 Circuit .2

Hydraulic control

valve in-rush

amperage

10

5

.2

.2

5

380/50/3

18”

24”

Technical data 9

415/50/3

460/60/3

690/50/3

230/60/3

380/50/3

415/50/3

460/60/3

690/50/3

9.4

8.2

6.5

4.8

13

9.4

8.2

6.5

4.8

5 Hp Single .2

5 Hp Single .2

5 Hp Single .2

5 Hp Single .2

5 Hp Single

.2

.2

.2

.2

.2

Page 24

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

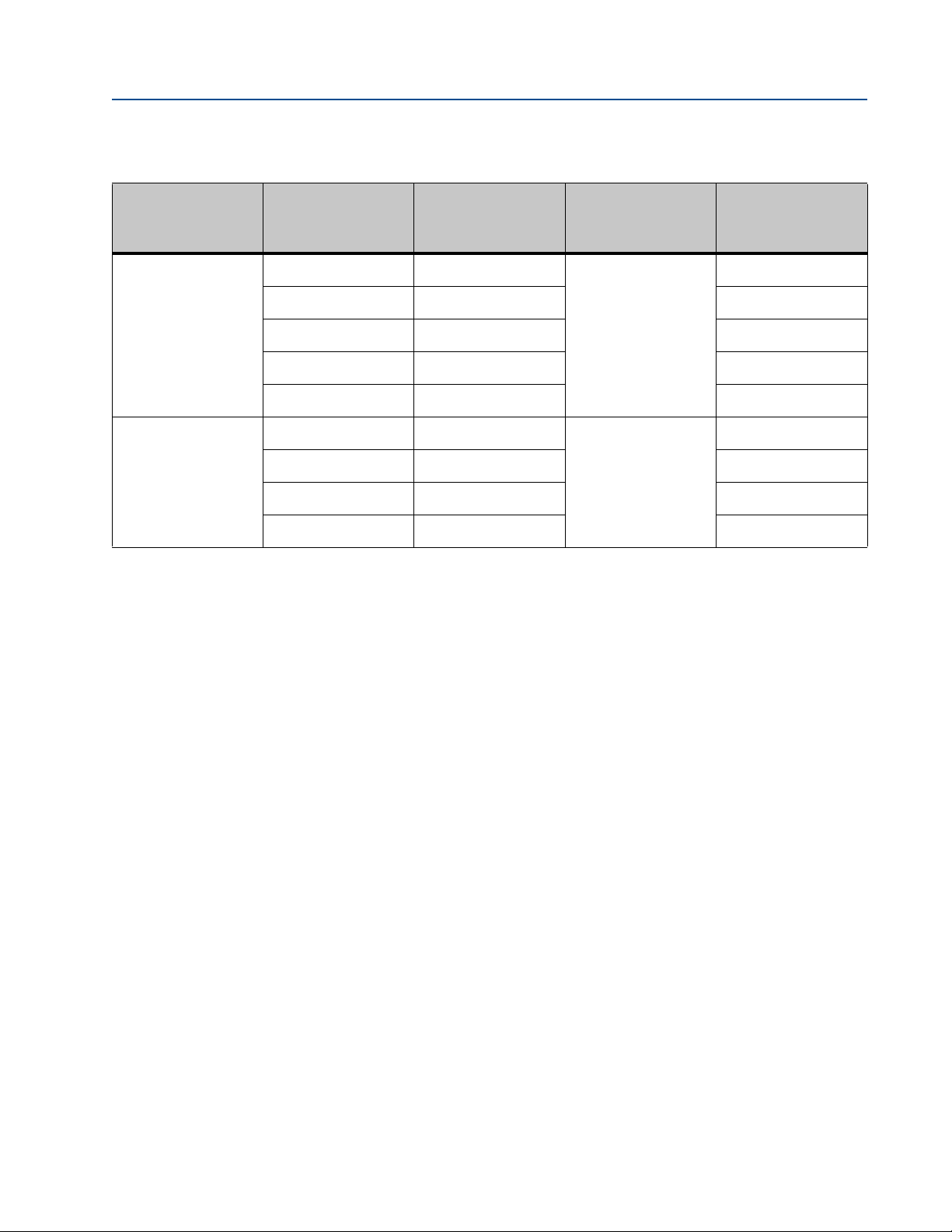

Table 1-3 Power requirements

Size

34”

40”

AC line voltage,

frequency and

phase

230/60/3

380/50/3

415/50/3

460/60/3

690/50/3

230/60/3

380/50/3

415/50/3

460/60/3

Hydraulic system

motor full load

amps

39

22

20

19.5

12.8

50

28

26

25

Hydraulic system

motor

configuration

15 Hp Single

20 Hp Single

Hydraulic control

valve in-rush

amperage

.2

.2

.2

.2

.2

.2

.2

.2

.2

Notes:

1. Consult the factory for optional voltages not listed.

2. The operating computer must be connected to a power source separate from that of

the prover to avoid variance in signal caused by line load charge and discharge.

3. Grounding wire within power cable must be connected to the installed location

electrical system grounding bus or electrical equivalent. A supplemental grounding

cable is available as an option.

4. For provers that are not equipped with a main circuit breaker, sizing of the main circuit

breaker should be based upon the hydraulic system motor full load amperage. Follow

applicable electrical codes for proper requirements.

Connection requirements:

Reference Tab le 1 - 2 for flange sizes

Pneumatic spring plenum:

Dry compressed nitrogen is required for charging the spring plenum.

Pressure drop: (Inlet flange to outlet flange)

Approximately 11.2 psig on gasoline at maximum flow (Metric units - .79 kg km ) Piston only:

Approximately 3 inches (7.6 cm) of water during a proving pass.

Approvals: For standard provers, sizes 8” thru 24” Canadian Standards Association (CSA) for

Class 1, Division 1, Group D File Number: LR 32408-18, Class 2258-02, Process Control

10 Technical data

Page 25

Operating and maintenance instructions Section 1: Introduction

3-9008-701 Rev J January 2015

Equipment for Hazardous Locations PED - sizes 12” Mini, 12”, 18” and 34”, British Standards

Institute

ATEX - 8" through 34", DEMKO 03 ATEX 0322369 (Option 1 designs only)

Ex d e ia m IIB T4

Certifications are pending for sizes not listed here.

Technical data 11

Page 26

Section 1: Introduction Operating and maintenance instructions

January 2015 3-9008-701 Rev J

12 Technical data

Page 27

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

21TOP (14)

Section 2: Installation and set-up

2.1 Installation

The compact prover may be installed permanently in a process line or used as a portable unit.

The prover is intended for above ground use and should be operated level to prevent the

formation of air pockets within the flow tube. A permanently installed standard prover should

be set up horizontally with considerations given to the accessibility of electrical power and

control operation. Consult a Daniel representative for further information regarding portable

provers.

Important

For optional vertical installation, special modifications to the prover hydraulic system and flow

tube supports will be required. The standard prover built for horizontal installation should not

be installed in a vertical position without proper modifications.

Refer to Figure 2-1 for a typical, permanent, compact prover installation in a process line.

Installation of a double block and bleed valve configuration is recommended in the process line

to assure that all metered fluid is passing through the prover. Be sure to follow API guidelines for

ANSI flanged connections and proper locating distance from the meter under test. Use gaskets

and retaining bolts of proper size and pressure rating for prover inlet and outlet flanges.

ReferenceTabl e 1 -2 for correct flange information. Consideration of available workspace around

the prover is necessary for normal operation and maintenance.

When installing this equipment, bolting must conform to the requirements of ASME B16.5

paragraph 5.3 and to the material requirements of ASME B16.5 Table 1B. Gaskets must conform

to the requirements of ASME B16.20.

It is the customer's responsibility to ensure that piping or other attachments connected to the

compact prover do not place adverse stresses on the compact prover. The design of the

compact prover has not been assessed for the effects of traffic, wind or earthquake loading.

It is the customer's responsibility to provide fire prevention measures and equipment per local

regulations.

The compact prover has been designed with a minimum of 1.5mm (1/16 inch) corrosion

allowance. The customer should implement a periodic inspection and maintenance program to

ensure that no part of the compact prover's pressure-retaining components has corrosion or

erosion exceeding this amount.

Installation 13

Page 28

Section 2: Installation and set-up Operating and maintenance instructions

EXPLOSION HAZARD

Do not exceed the maximum working pressure of prover as stamped on the nameplates.

Failure to observe pressure rating limits may result in serious personal injury and equipment

damage.

January 2015 3-9008-701 Rev J

Important:

It is the customer's responsibility to install this equipment in a system that provides adequate

over-pressure protection.

Important:

Lines should be flushed thoroughly to rid piping of potentially damaging foreign material such

as welding bead, pipe scale, etc. before the prover is placed into service. A strainer of proper size

should be installed upstream of the prover to protect it from the introduction of foreign

material.

14 Installation

Page 29

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

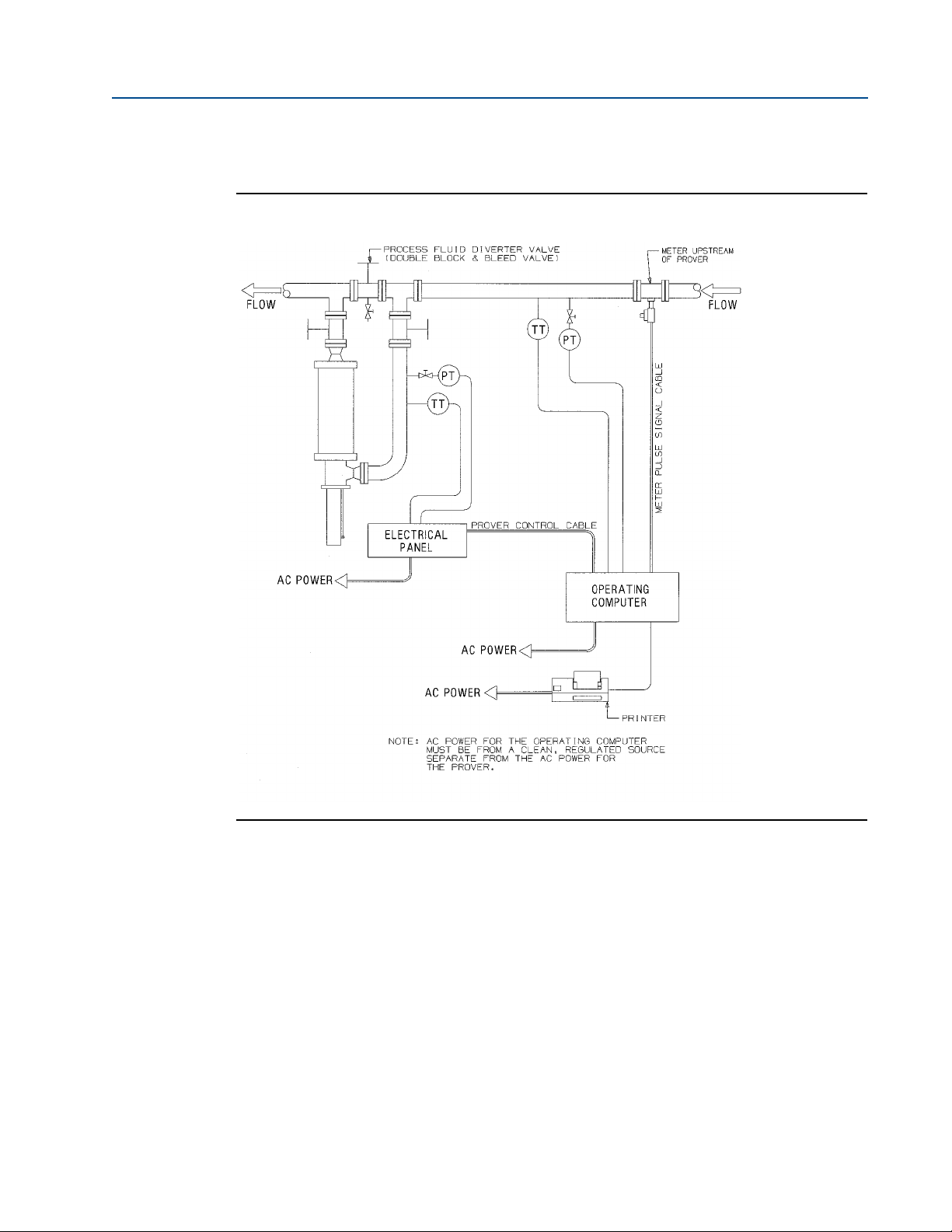

Figure 2-1 Typical prover installation

2.2 Set-up

2.2.1 Supplying electrical power to the compact prover

Reference Table 1-3 for standard voltage and amperage information. Optional voltage and

amperage information not listed in Table 1-3 is provided with the documentation package

(electrical schematic) shipped with every prover. If this information is not included with the

shipment, contact a local Daniel representative for assistance.

Standard provers are shipped with a multi-conductor power cable for connection to a power

supply. If an electrical conduit connection is desired, remove the existing power cable. Access to

Set-up 15

Page 30

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

the motor starting switch will be necessary for this conversion. Be sure to follow all applicable

electrical codes for the area of installation.

2.2.2 Connection of the operating computer

Standard provers are shipped with a control cable for connection to the operating computer. If

an electrical conduit connection is desired, remove the existing control cable. Access to the

interface enclosure will be necessary for this conversion. Be sure to follow all applicable

electrical codes for the area of installation.

The compact prover control signals are designed to worldwide control standards. This includes

digital and analog signals. The electrical schematic will define how each connection (conductor)

is used. Manuals and instructions supplied with the operational computer of choice will assist

with proper control connections. Reference Section 5.2 for additional troubleshooting

information. If you require further assistance for these connections, contact a local Daniel representative.

The operating computer will need to be properly configured for the application and must be

capable of Dual Chronometry Pulse Interpolation

computer to have a high frequency master oscillator, which counts time in 0.000001 parts of a

second.

. This calculation method requires the

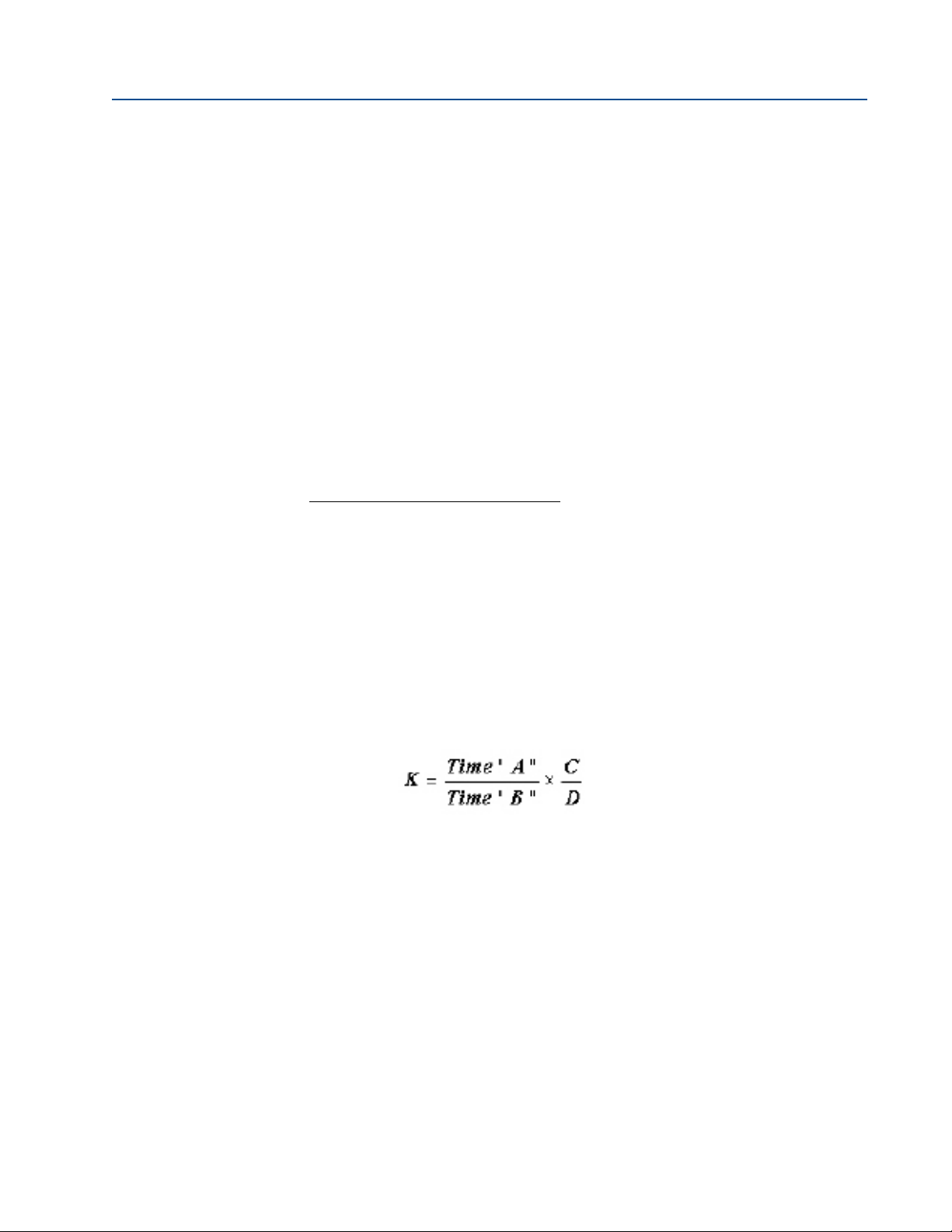

This master oscillator must operate two counters, referred to here as “Time A” and “Time B”.

Time “A" must start counting when the flag trips the first detector switch. Time “B” must start

counting with the leading edge of the first flowmeter pulse after Time A has started.

Time “A” is stopped when the flag trips the final detector switch. Time “B” is stopped with the

leading edge of the first flowmeter pulse after Time “A” has stopped, (Reference Figure. 2-2).

Using the ratio of Counter Time “A” and Counter Time “B” will allow for accurately counting a

fraction of a flowmeter pulse to within 1 part in 10,000 as shown below:

K= K-Factor, or counts per unit volume, from the flowmeter

A = Time for displaced volume B = Time for whole meter pulses

C = Total number of whole meter pulses

D = Displaced volume

Qualified personnel who are knowledgeable of the computer’s operating system, configuration

variables, and compact proving applications should complete the configuration of the

operating computer.

16 Connection of the operating computer

Page 31

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

Figure 2-2 Double chronometry

Connection of the operating computer 17

Page 32

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

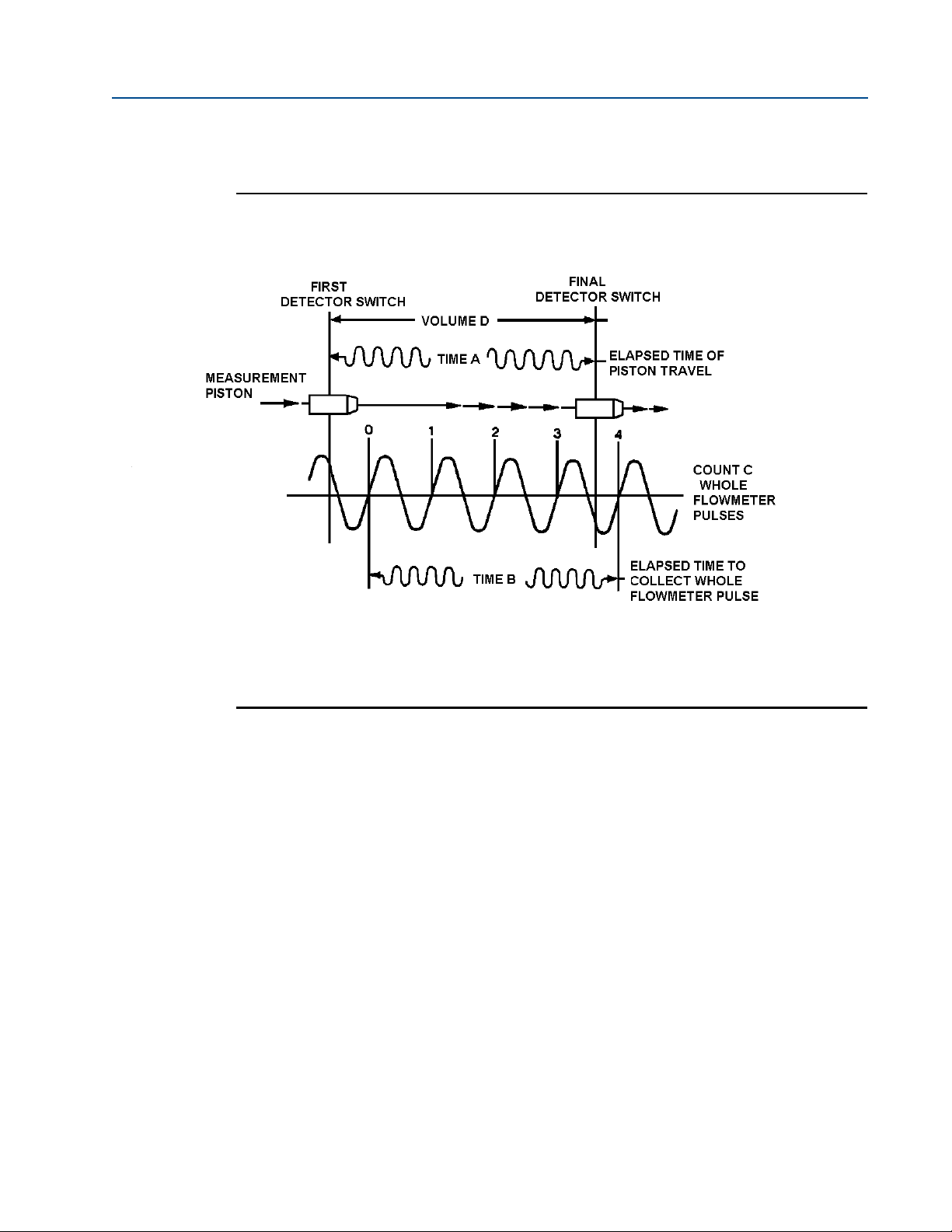

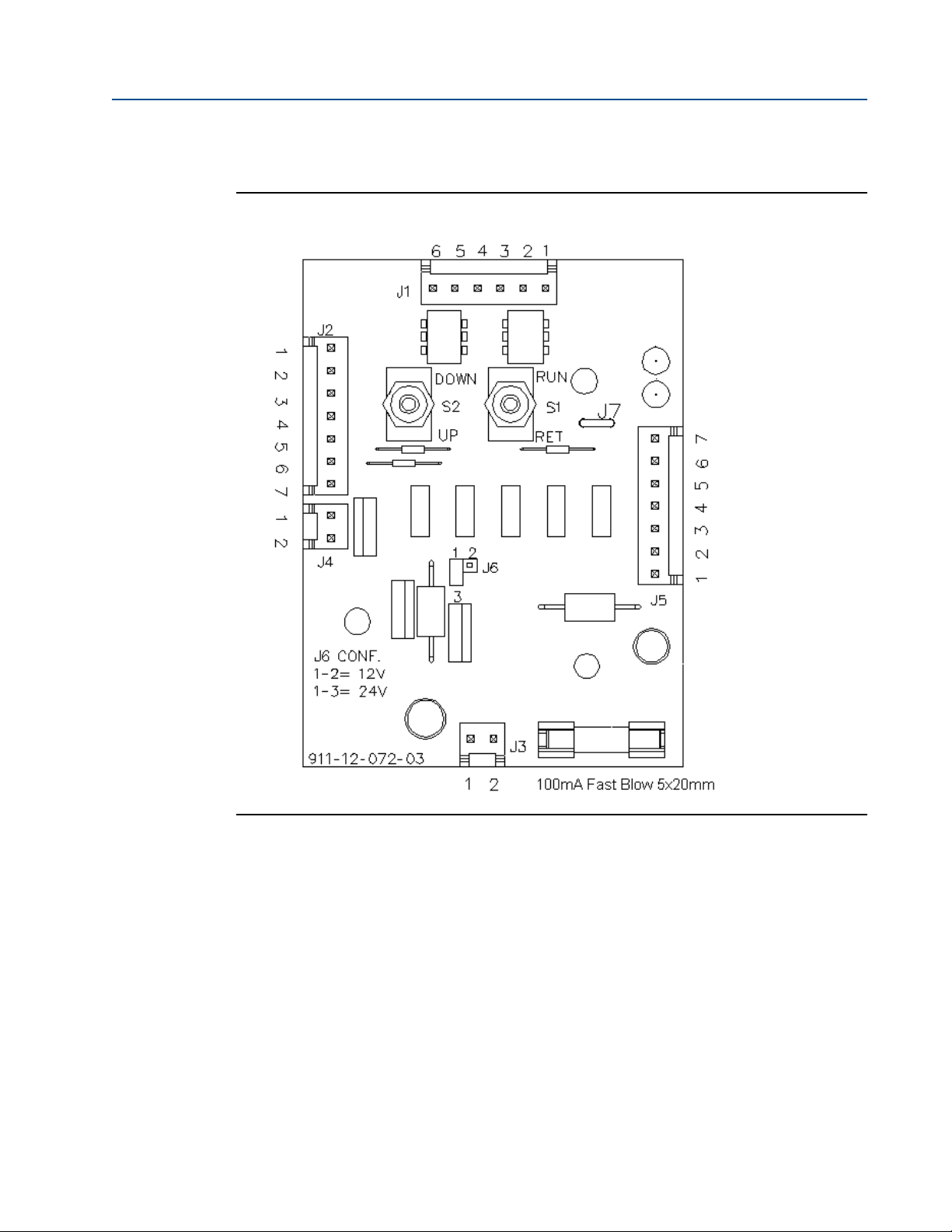

2.2.3 12 or 24V DC Interface Board

There are two (2) different styles of interface boards: 12V DC and 12/24V DC. See Figure 2-3 and

2-4. The power required for the interface board is supplied through the control cable. The DC

power source is typically located in the control room or can be supplied from the operating

computer if so equipped. See the electrical schematic provided with the prover documentation

package for proper connections of the control cable.

The 12V interface board is designed to operate on 12V DC (±15%, 100mA max). The 12/24V

interface board can operate on either 12 (±15%, 100mA max) or 24V DC (±15%, 250mA min)

depending on the configuration of jumper J6, see Figure 2-4. For 12V operating power, J6 must

be jumpered to pins 1 and 2. For 24V operation, J6 must be jumpered to pins 1 and 3. If

operating voltage is applied incorrectly, there is an integral fuse for board protection. In the

event that the fuse is blown, confirm the configuration of jumper J6 and replace the fuse with a

100mA, fast blow fuse ONLY.

The 12/24V interface board is installed in all compact provers made after September 2002. It

may also be used to replace the 12V interface board on older model provers. Contact a Daniel

representative if you are unsure which interface board your compact prover is equipped with or

if you need assistance replacing the old 12V board with the new 12/24V board. Request service

bulletin SE101 for detailed retrofit information.

Important:

Do not handle electronic-sensitive equipment without an ESD grounding wrist-strap. Failure to

use an anti-static grounding device could cause damage to the compact prover electronics and

render them inoperable.

18 12 or 24V DC Interface Board

Page 33

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

Figure 2-3 12V Prover interface board

J1: To optical assembly (pin 6 not used)

J2: To control connection

J3: To water draw hardware kit

J4: To run valve

J5: For external control of S1 and S2

S1: Run — Return

S2: Upstream - Downstream

12 or 24V DC Interface Board 19

Page 34

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 2-4 12/24V Prover interface board

J1: To optical assembly (pin 6 not used)

J2: To control connection

J3: To water draw hardware kit

J4: To run valve

J5: For external control of S1 and S2

J6: 1-2 12V Operation

1-3 24V Operation

S1: Run — Return

S2: Upstream - Downstream

20 12 or 24V DC Interface Board

Page 35

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

2.2.4 Charging the Pneumatic Spring Plenum

The pneumatic spring plenum must be charged for proper operation. The prover is shipped

from the factory with an empty spring plenum for safety. Nitrogen is NOT supplied with the

compact prover and must to be acquired locally before meter proving can begin. Calculations

for proper pressure settings of the spring plenum are discussed in Section 3.2.

As an option, the compact prover may be equipped with an automatic plenum adjustment

panel. The panel consists of charge and vent solenoid valves and a pressure transmitter. A typical

panel is shown in Figure 2-5, a connection diagram is shown in Figure 2-6. An operating

computer with the adjustment routine pre-programmed, using an analog input (4-20mA) and

two digital outputs, will be able to automatically adjust the spring plenum pressure before

proving runs begin. See Section 5.4 for troubleshooting these signals.

Charging the Pneumatic Spring Plenum 21

Page 36

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 2-5 Typical nitrogen adjust panel

22 Charging the Pneumatic Spring Plenum

Page 37

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

Figure 2-6 Connection diagram

2.3 Base volume certification

The prover base volume has been certified at the factory using the volumetric displacement

method (water draw) per API guidelines. The base volume has been adjusted to 0.0 gauge

pressure and the reference temperature as stated on the volumetric determination report

supplied with each prover documentation package. The operating computer will need to be

programmed with these base volumes. Upstream or downstream volumes will be used

depending on the application and location of the meter under test.

The volumetric displacement (water draw) technique, described in Section 4.2, is the factory

recommended procedure for certification of the base volume of the compact prover. It is

recommended that this procedure be repeated at regular intervals to confirm proper operation.

Frequency of base volume determination is dependent on usage, but should not exceed 3 years.

Certification may be necessary following repair or service procedures involving any disassembly

or seal replacement of the piston, poppet or flow tube. Certification is not necessary following

repair of the hydraulic cylinder if the flow tube is not disassembled. For specific information

regarding prover base volume certification related to maintenance of the optical assembly, see

Section 4.6. A lead seal wire should be installed to assure calibration integrity once certification

is completed as described in Section 2.5.

The upstream volume of any compact prover is slightly smaller than the downstream volume

due to the main piston shaft and optical shaft which are both located on the upstream side of

the piston.

If the meter is located upstream, or on the inlet side of the prover, then the upstream volume

must be used.

If the meter is located downstream, or on the outlet side of the prover, then the downstream

volume must be used.

Base volume certification 23

Page 38

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

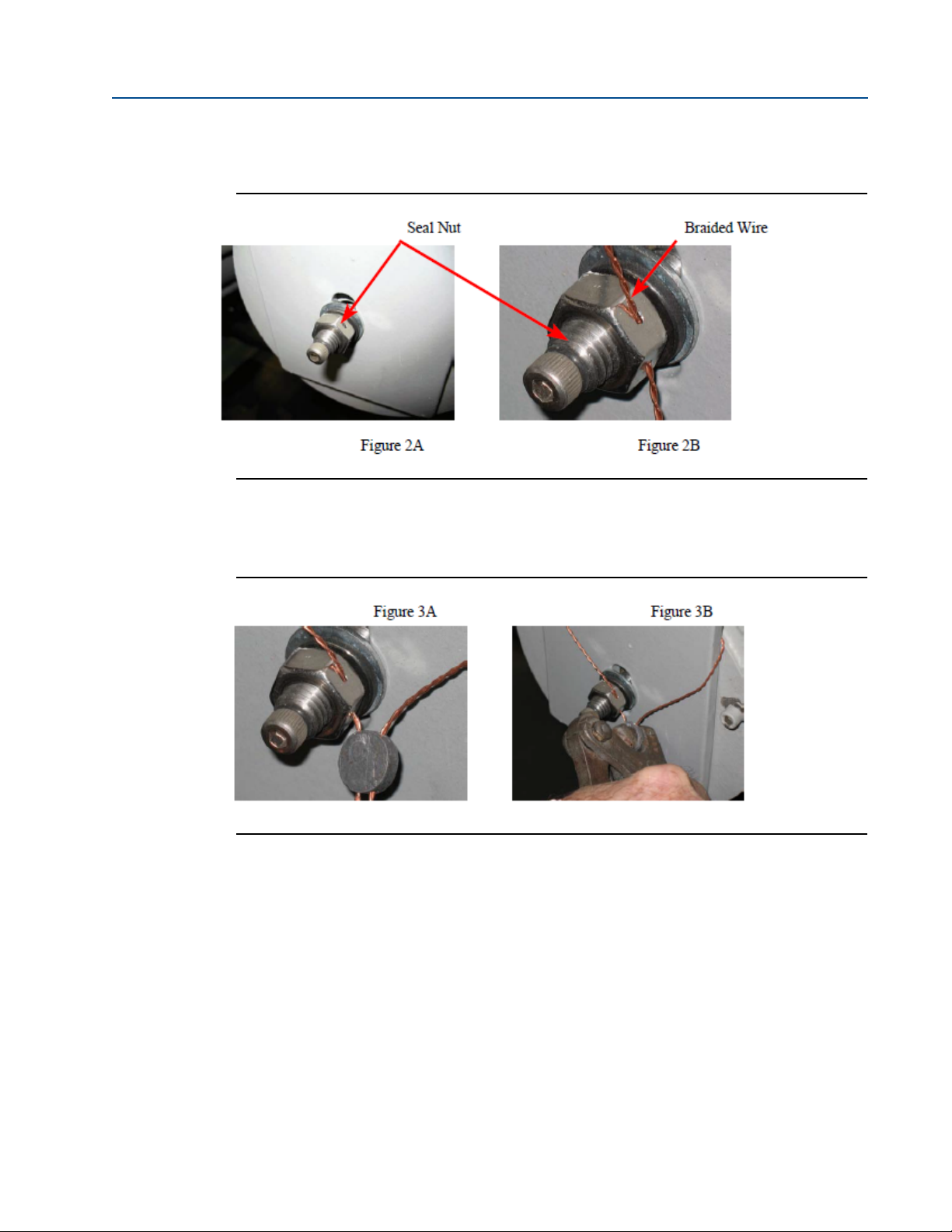

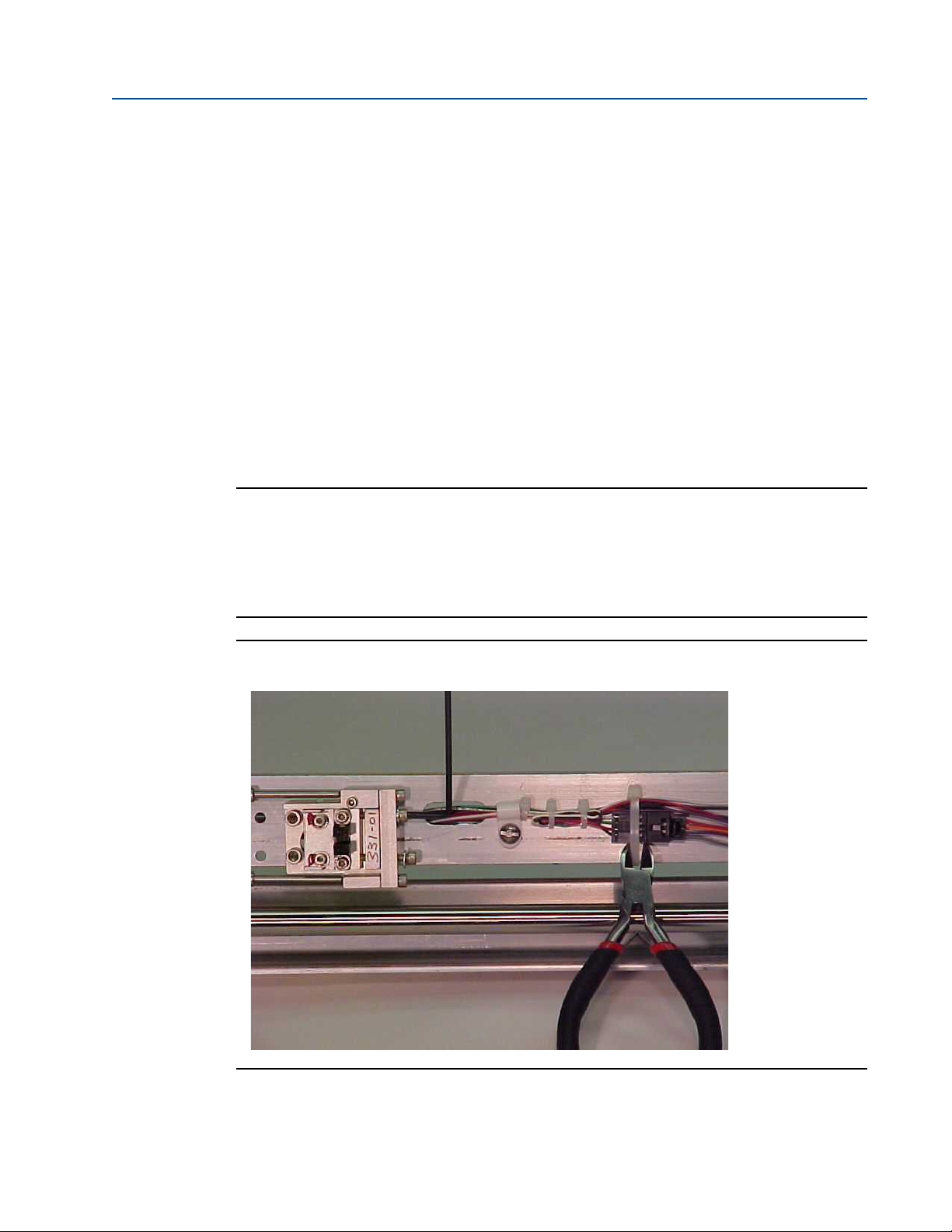

2.4 Calibration integrity seal installation procedure

Purpose:

The purpose is to provide a procedure for ensuring the calibrated volume integrity of the

compact prover. The optical assembly as shown in figures 1A and 1B have a simple but sure way

of ensuring the integrity of the assembly.

A security seal can be applied to prevent removal of the cover of the optical assembly which

contains the solid state volume detectors.

The purpose of this seal is to prevent removal of this cover which would expose the switches to

possible tampering which could affect the calibrated volume of the compact prover. The

following steps will demonstrate the process of installing this lead seal.

Location of optical assembly with seal nut and lead seal.

24 Calibration integrity seal installation procedure

Page 39

Operating and maintenance instructions Section 2: Installation and set-up

3-9008-701 Rev J January 2015

Step 1 Once the seal nut is securely tightened in place (see Figure 2A); insert the braided wire

through the hole in the nut as shown in Figure 2B.

Step 2 Wrap the braided wire around the support plate (see Figure 1B).

Step 3 Insert the two ends of the braided wire through the lead seal and slide the seal up the

wire until the slack has been pulled out of the wire (see Figure 3A).

Step 4 Secure the seal using a clamping set of pliers thus closing the holes in the lead seal around

the braided wire.

The final result should appear similar to Figure 1B.

Calibration integrity seal installation procedure 25

Page 40

Section 2: Installation and set-up Operating and maintenance instructions

January 2015 3-9008-701 Rev J

26 Calibration integrity seal installation procedure

Page 41

Operating and maintenance instructions Section 3: Operation

A positive stop feature is incorporated into the outlet flange for fail safe operation. This prevents

any accidental blockage of the process flow stream. Reference Figure 3-4.

3-9008-701 Rev J January 2015

Section 3: Operation

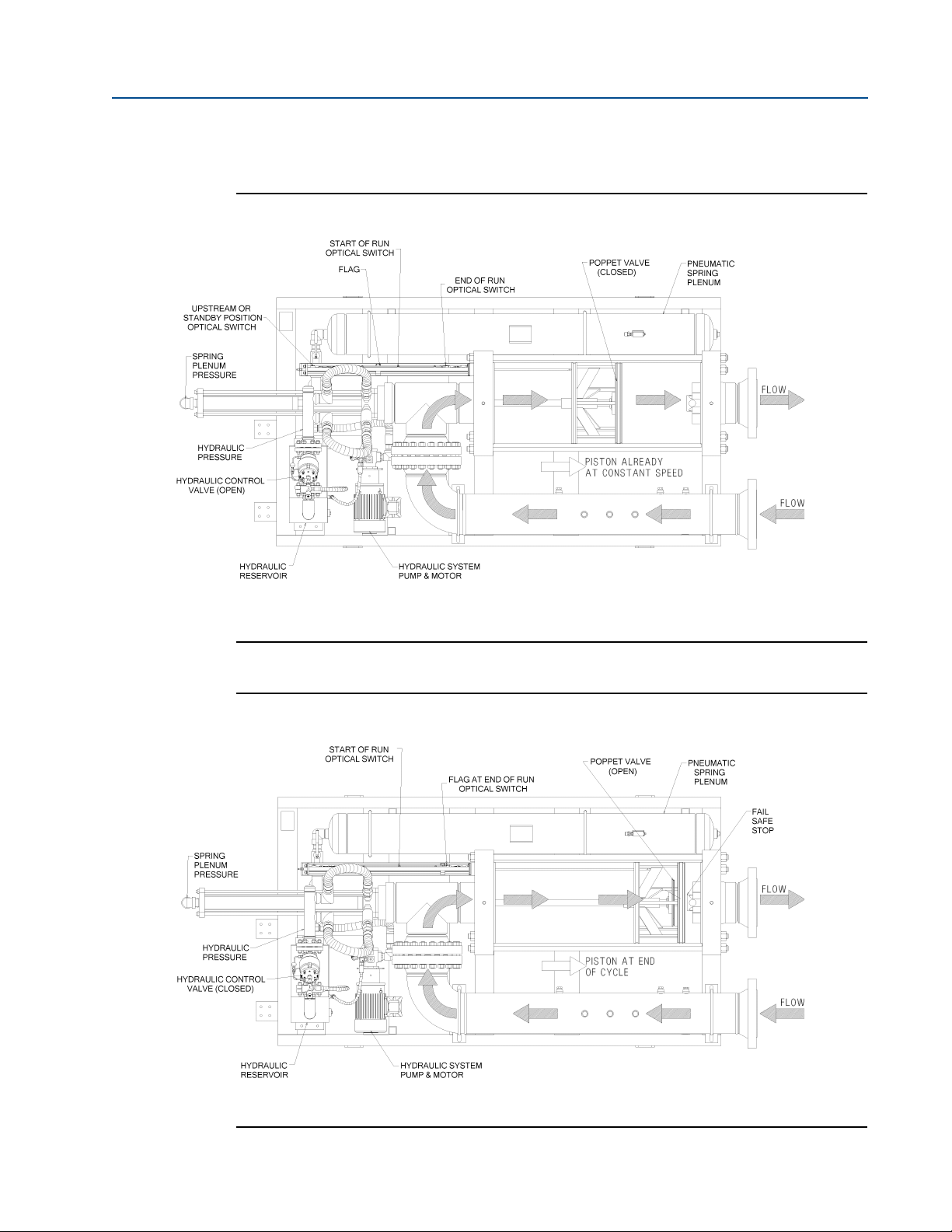

3.1 General operational theory

The operational sequence of the compact prover is as follows:

1. The measurement piston is normally in the upstream (standby) position, with the

poppet valve open, and is held in place by the hydraulic pressure on the actuator piston

(Figure 3-1).

2. The hydraulic control valve opens and releases the hydraulic pressure. Pressure from

the pneumatic spring plenum, on the upstream side of the actuator piston, closes the

poppet valve and the piston begins moving downstream at the process fluid flow rate

(Figure 3-2).

3. As the measurement piston moves downstream, the optical volume switches are

‘tripped’ by the flag connected to the piston (Figure 3-3). These volume switch signals

are instantly sent to the operating computer for calculations discussed in Section 4.6.

4. When the flag trips the second optical volume switch, the hydraulic control valve closes.

Hydraulic pressure builds and begins to push the actuator piston upstream, opening

the poppet valve. Process fluid is then allowed to flow through the piston (Figure 3-4).

5. The actuator piston, measurement piston, poppet, actuator shaft, detector shaft and

flag will then move back to the upstream (standby) position (Figure 3-5). Once the

upstream position is reached (Figure 3-1), the hydraulic pump will assume it’s neutral

condition maintaining hydraulic pressure to hold the measurement piston upstream.

The prover is now ready to begin another pass.

General operational theory 27

Page 42

Section 3: Operation Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 3-1 Standby position

Figure 3-2 Initial motion

28 General operational theory

Page 43

Operating and maintenance instructions Section 3: Operation

3-9008-701 Rev J January 2015

Figure 3-3 Proving

Figure 3-4 End of proving run

General operational theory 29

Page 44

Section 3: Operation Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 3-5 Piston returning to upstream position

3.2 Operating instructions

The compact prover should be connected to the process line, similar to Figure 2-1, either

upstream or downstream of the meter under test. Electrical power should be supplied and the

operating computer should be connected to the prover. The operating computer should also be

configured for the application. If these conditions are not met, DO NOT attempt to operate the

compact prover. Refer to Section 2 for Installation and Set-up procedures.

1. Check all drain and vent valves to be sure that they are closed. Vents and drains are

located on the top and bottom of the flow tube end flanges. Reference Figure 1-2.

2. Open the spring plenum shut-off valve.

3. The pneumatic spring plenum must be charged with dry nitrogen for proper operation.

Check the pressure in the spring plenum. There will be a factory-installed gage

mounted to the plenum tank for reference (Figure 3-6). The proper plenum pressure is

determined by the following formula:

where R is a known constant for each size prover. See Table 3-1 below.

30 Operating instructions

Page 45

Operating and maintenance instructions Section 3: Operation

3-9008-701 Rev J January 2015

Table 3-1 Spring plenun ‘R’ values

Prover size R

8”

12” Mini

12”

18”

24”

34”

40”

3.5

3.2

3.2

5

5*

3.7

4.45

* R = 5.88 for Provers shipped before January 1, 2006

Figure 3-6 Spring plenum

Operating instructions 31

Page 46

Section 3: Operation Operating and maintenance instructions

EXPLOSION HAZARD

Regulate the pressure of the supply source to the allowable level and avoid exceeding the

maximum working pressure of the tank.

Failure to do so during the filling of the Nitrogen Tank could result in serious personal injury.

January 2015 3-9008-701 Rev J

If the plenum pressure is greater than the calculated value, the excess pressure must be vented

from the plenum. If the plenum pressure is less than the calculated value, the supply bottle will

need to furnish the necessary pressure needed. Connect the supply bottle according to

manufacturer’s instructions and charge the spring plenum to the required pressure.

Notes:

1. As a guideline, spring plenum pressure should be within 0 to +5% of the calculated

pressure.

2. If prover installation is vertical, use 40 psig in the above formula in place of 60 psig.

3. For provers equipped with the automatic plenum adjustment panel, plenum pressure

should be automatically adjusted before the proving cycle begins. The operating

computer should be configured for this application. See Section 2.2.4 and Section 5.4

for troubleshooting. For vertical provers with plenum adjust panel, consult factory for

new “R” value.

4. With the hydraulic system motor not running, check to see that the hydraulic reservoir

is filled to approximately 75% capacity. If not, fill tank to proper level using hydraulic

fluid specified inSection 1.4.

5. Turn on the hydraulic pump. The hydraulic pressure should build to 380-400 psig (2728 kg/cm ) once the piston reaches the upstream (stand-by) position.This is verified by

the hydraulic system pressure gage, typically located on the hydraulic pump (Figure 3-

7).

6. Slowly open the inlet valve to allow the process fluid to flow into the prover.

32 Operating instructions

Page 47

Operating and maintenance instructions Section 3: Operation

3-9008-701 Rev J January 2015

Figure 3-7 Hydraulic system

7. Vent all air from the system using the hand valves located on the inlet and outlet flanges

of the flow tube. Slowly close the process fluid diverter valve (double block and bleed)

and open the outlet valve. The prover is now ready to begin the proving cycle.

8. Connect the signal cable from the meter under test to the operating computer for

proving operations. Once the operating computer receives all the signals, proving runs

can begin. Reference the operating computer instruction manual for proper computer

operation.

9. After proving runs are completed and results are satisfactory, the process flow may be

diverted back to the process line as described in steps 10 and 11. Once this is done,

power down the prover.

Operating instructions 33

Page 48

Section 3: Operation Operating and maintenance instructions

January 2015 3-9008-701 Rev J

If the process flow is to be left running through the prover, be sure to leave the hydraulic system

motor running. The hydraulic pump will go into by-pass mode and hold the piston upstream.

The motor will draw minimal current for low power consumption.

10. Open the process fluid diverter valve (double block and bleed) and slowly close the

inlet/outlet valves to the process line.

11. Drain the prover flow tube by opening the appropriate drain and vent valves located on

the top and bottom of the inlet and outlet flanges.

Important:

Disposal of drained fluid should be done in an environmentally responsible manner.

34 Operating instructions

Page 49

Operating and maintenance instructions Section 4: Maintenance

MAINTENANCE HAZARD

Ensure that all equipment doors are closed and protective covers are in place, except when

maintenance is being performed by qualified persons.

Failure to do so can cause personal injury.

3-9008-701 Rev J January 2015

Section 4: Maintenance

4.1 Seal Leak Check

For factory part number of seal Leak Detector Kit, see Section 7: Parts list, Parts.

Reference Figure 4-1 and Figure 4-2.

Figure 4-1 Leak detector kit

Seal Leak Check 35

Page 50

Section 4: Maintenance Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Important:

It is ESSENTIAL that the liquid and prover temperatures remain stable during the leak check

procedure as thermal expansion or contraction will give incorrect results.

The kit shown in Figure 4-1 is designed to operate with the Optical A ssembly cover tube securely

anchored in place. The mounting boss on the outboard end of the cover tube must be

approximately 90° from the support bracket. Re-position if necessary.

The Compact Prover measurement piston seals may be checked as follows:

1. Block the prover OUTLET using a double block and bleed valve (bubble-tight shut off) or

blind flanges. Check the block and eliminate any leaks.

2. Fill the prover with fluid and bleed ALL AIR from the flow tube by operating the vent

valves located on the inlet and outlet flanges. This operation may move the

measurement piston within the flow tube. Verify that all the vent and drain valves on

the prover are free from leaks. Eliminate any and all leaks if necessary.

3. Verify the spring plenum pressure for the fluid pressure applied. See Section 3.2, step 3,

for proper calculations. Adjust the spring plenum pressure to the correct calculated

value. A minimum of 75 psig (5.3 kg/cm) is required.

4. Remove the screw from the boss on the end of the optical cover. Thread the indicator

stand into the boss. Mount the dial indicator onto the indicator stand. Remove the

screw from the end of the optical support stud.

Figure 4-2 Leak detector kit installed

36 Seal Leak Check

Page 51

Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

5. Place the measurement piston in the upstream position for simple attachment of the

indicator rod. The measurement piston may be moved upstream by activating the

hydraulic system.

6. The indicator rod is designed in multiple sections to span a distance that will reach the

length of the optical assembly. This allows for multiple leak check positions along the

flow tube. The first rod piece to be used is the piece with the larger thread. Insert this

piece through the hole in the support stud and thread into the end of the detector

shaft. Add rod sections as necessary to reach leak check positions desired, pay

attention to the area between the volume switches. The measurement piston can be

moved downstream by releasing pressure on the outlet flange vent valve.

Important:

Do not allow indicator rod to completely go into the support stud while moving the

measurement piston downstream. Allowing the indicator rod to go completely into the support

stud may result in severe damage to the equipment

7. Be certain the hydraulic system motor is not running before the leak check test begins.

This assures that only the spring plenum pressure is acting on the measurement piston.

8. Position the dial indicator probe near the indicator rod. Slide the screw collar down the

indicator rod until contact is made with the probe of the dial indicator. Move the screw

collar only slightly more in order to ‘pre-load’ the dial indicator and then tighten the

collar to the indicator rod.

9. Zero the dial indicator and monitor for five minutes. A dial indicator movement greater

than 0.004 inches (.102 mm) in five minutes indicates that a leak is present in the

system. Inspect the system and eliminate any leaks. Remove any possible trapped air.

Refer to Section 5: Troubleshooting for detailed instructions on measurement piston

seal replacement if necessary.

10. Once testing is complete and results are satisfac tory, return the measurement piston to

the full upstream position and remove all parts of the indicator rod and the remaining

components of the seal leak detector kit from the prover and replace the screws in the

support stud and mounting boss.

4.2 Base volume determination

4.2.1 Certification techniques

Compact prover base volume determination varies with frequency of use and operating

environment. Annual base volume re-certification is typical. Re-certification cycles should not

exceed three (3) years. The volume determination procedures in this manual are designed to

assist the user in creating an effective certification program.

The exact upstream and downstream base volumes must be known for correct proving

calculations. For example, a 12” compact prover with a nominal volume of 15 U.S. gallons could

Base volume determination 37

Page 52

Section 4: Maintenance Operating and maintenance instructions

January 2015 3-9008-701 Rev J

be determined to have an exact volume of 15.00123 or 14.99712 gallons. These types of

numbers are typical and necessary. The particular volume used is determined by the physical

location of the meter under test, either upstream or downstream of the prover. If only one base

volume is used for proving, base volume certification will only need to be completed for the

needed volume and not for both.

The base volume of the compact prover is verified at the factory using test measures that are

traceable to the National Institute of Standards and Technologies (NIST). Additional information

about certification techniques can be found in the American Petroleum Institute (API) manual of

Petroleum Measurement Standards, Chapter 4.2 for Small Volume Provers, Chapter 4.7 for Field

Test Measures, and Chapter 12.2 for Calculation of Petroleum Quantities.

Volume Displacement Certification:

The following procedures describe the compact prover base volume determination using the

water draw method. There are three procedures explained; (a) an Upstream only, (b) a

Downstream only, and (c) the Combined method. The measurement piston seal integrity

should be verified prior to any water draw by performing the seal leak check as described in

Section 4.1.

Important:

Before certification is attempted, the prover should be level and isolated from any connecting

piping systems other than those related to the water draw. In choosing the location of the

prover during the test, temperature variations must be considered. Temperatures must be

maintained as stable as possible throughout the operation.

Equipment Required:

• Water draw hardware kit with manual valves and a solenoid valve similar to Figure 4-3.

For part numbers of factory available water draw hardware kits, see Section 7.

• A plumbing setup as shown in Figure 4-4. Check all valves and any threaded

connections for leaks prior to beginning the water draw procedure. The plumbing

setup must be leak free.

• Certified High Sensitivity (Field Standard) Test Measure traceable to the National

Institute of Standards and Technology (N.I.S.T.) or other certifying agency.

• A water source with a flow rate of approximately 10 gpm (38 lpm) at 30-100 psi (207 to

689 kPa) non-fluctuating and free from entrained air.

• One digital thermometer with contact probe.

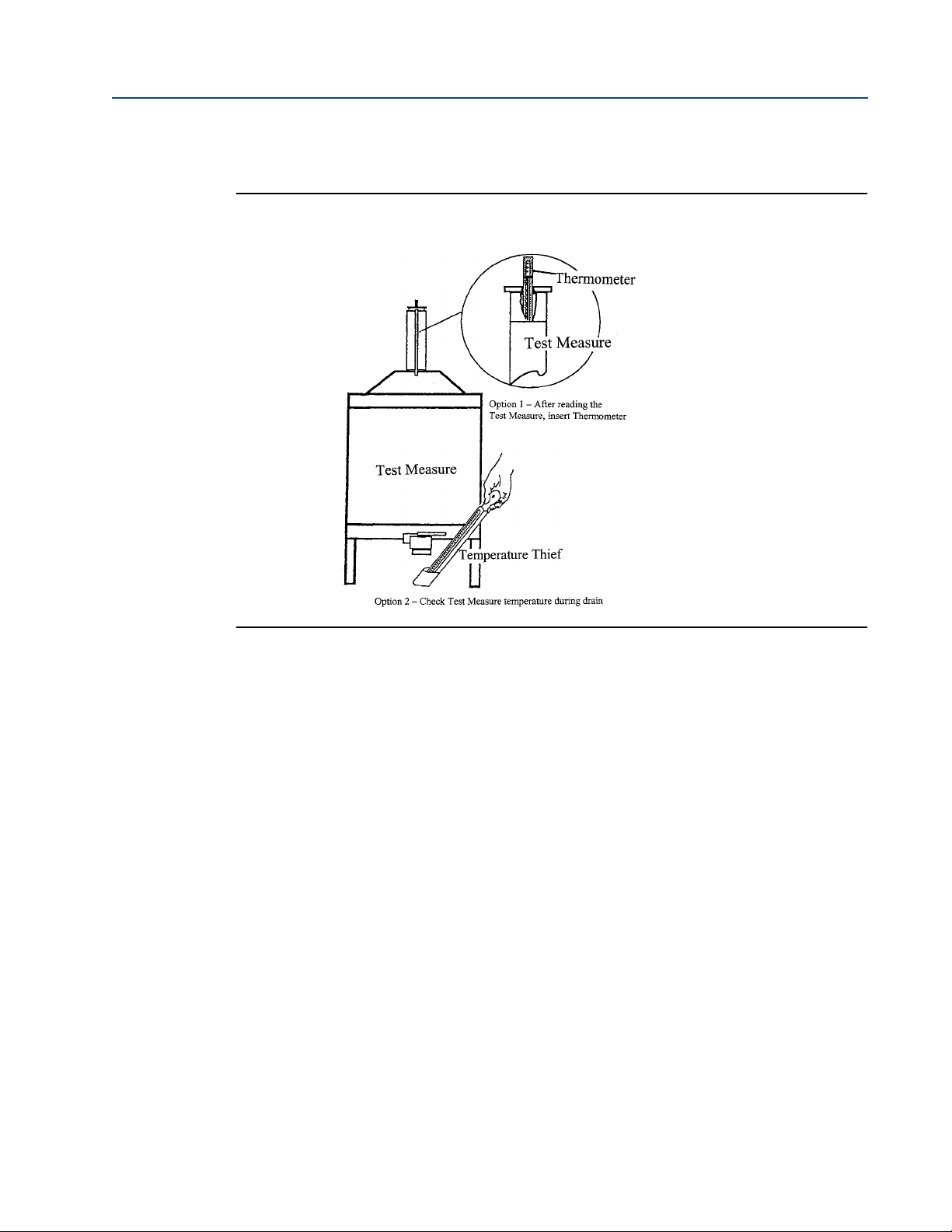

• Three (3) glass stem thermometers with 1/5 degree divisions and a range of 30 to 124.F

(-1 to 50°C), traceable to the National Institute of Standards and Technology (N.I.S.T.)

or other certifying agency, as applicable. One thermometer may be mounted in a

temperature thief device. See Figure 4-5.

• One pressure gauge, 0-100 psig range (689 kPa).

38 Certification techniques

Page 53

Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

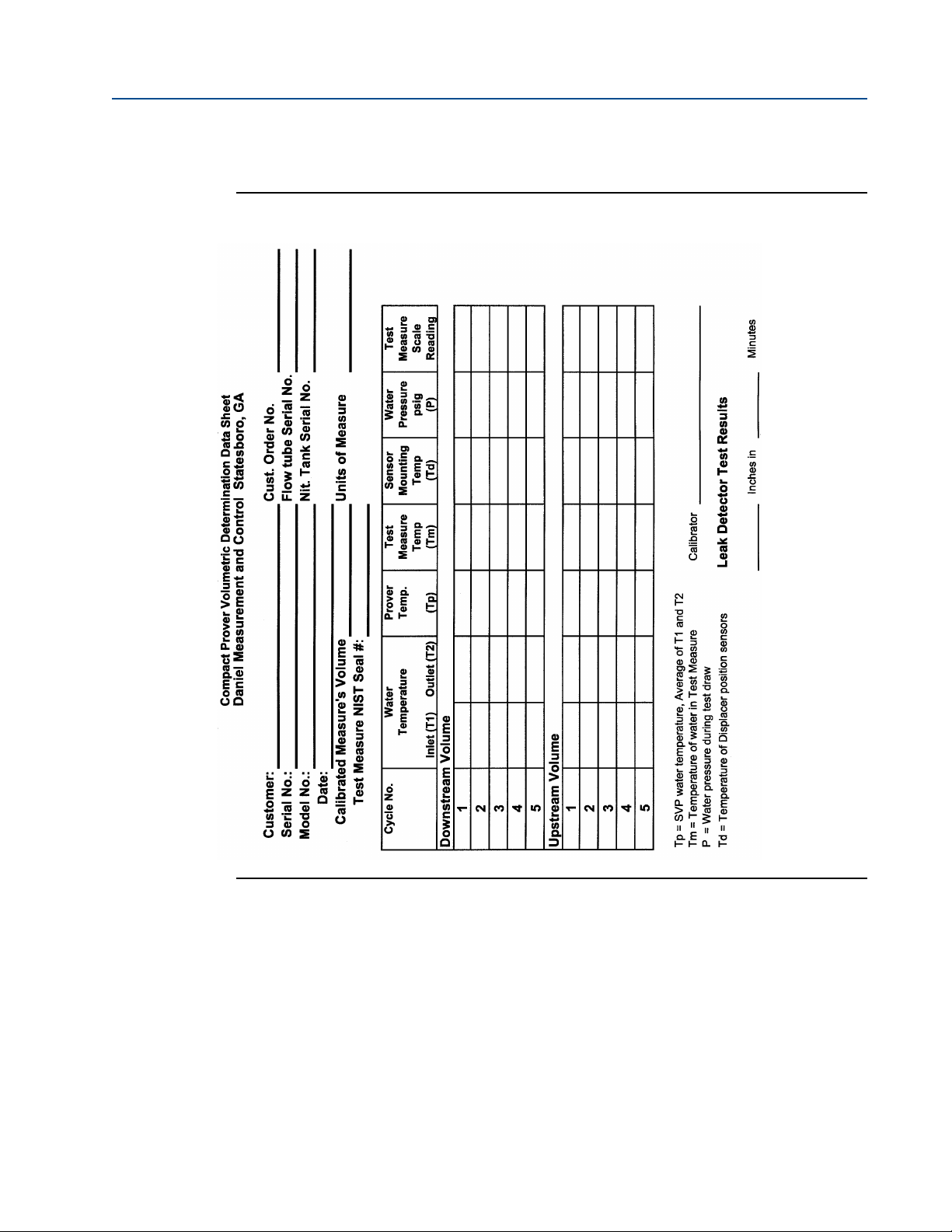

• Certification Data Sheet for recording data. Refer to Figure 4-6 for example data sheet.

Refer to Section 4.3 for explanation of symbols.

Notes:

1. Temperature transmitters are not recommended.

2. Factory water draw hardware kits are provided with (2) thermometers.

3. Pressure transmitters are not recommended.

4. Pressure gauges are not included in factory water draw hardware kits.

Certification techniques 39

Page 54

Section 4: Maintenance Operating and maintenance instructions

January 2015 3-9008-701 Rev J

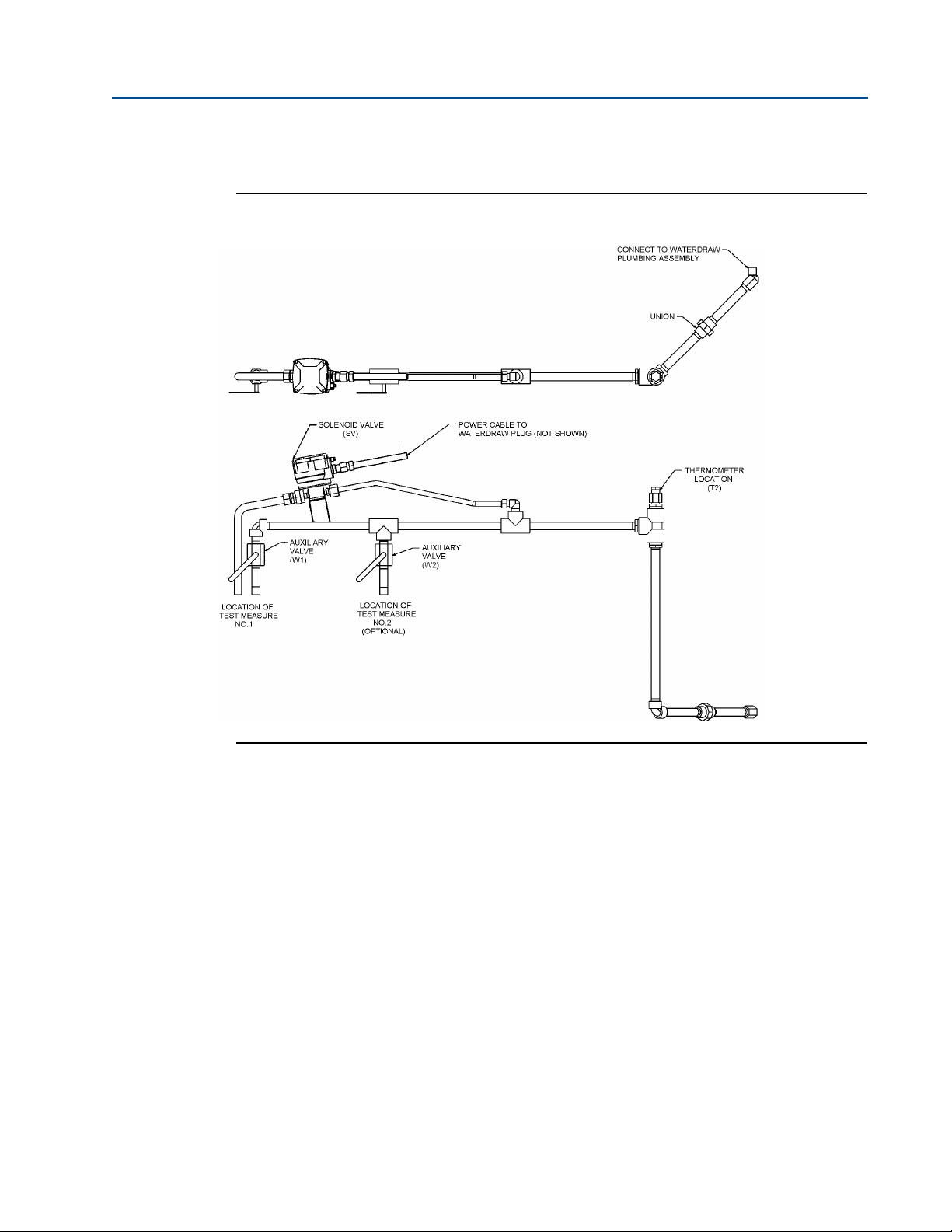

Figure 4-3 Compact prover water draw assembly typical NEC style (non-explosion proof)

40 Certification techniques

Page 55

Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

Figure 4-3 Compact prover water draw assembly (continued) Typical Ex-proof style

Certification techniques 41

Page 56

Section 4: Maintenance Operating and maintenance instructions

January 2015 3-9008-701 Rev J

Figure 4-4 Water draw system

4.2.2 Water draw procedure: (Reference Figure 4-4 and notes on page 47)

1. Isolate the prover from operational lines using double block and bleed valves or blind

flanges. Verify that the prover is level. Drain and flush all process fluid from the prover.

Dispose of all process fluids in an environmentally safe manner.

2. Assemble the water draw plumbing system. See Figure 4-4. All connections must be

leak-free to assure proper operation. It is recommended that thread sealant be used on

all pipe connections. Pipe sizing should be equal to or greater than the size of the vent

and drain connections (V1, V2, D1, D2) that are supplied on the prover.

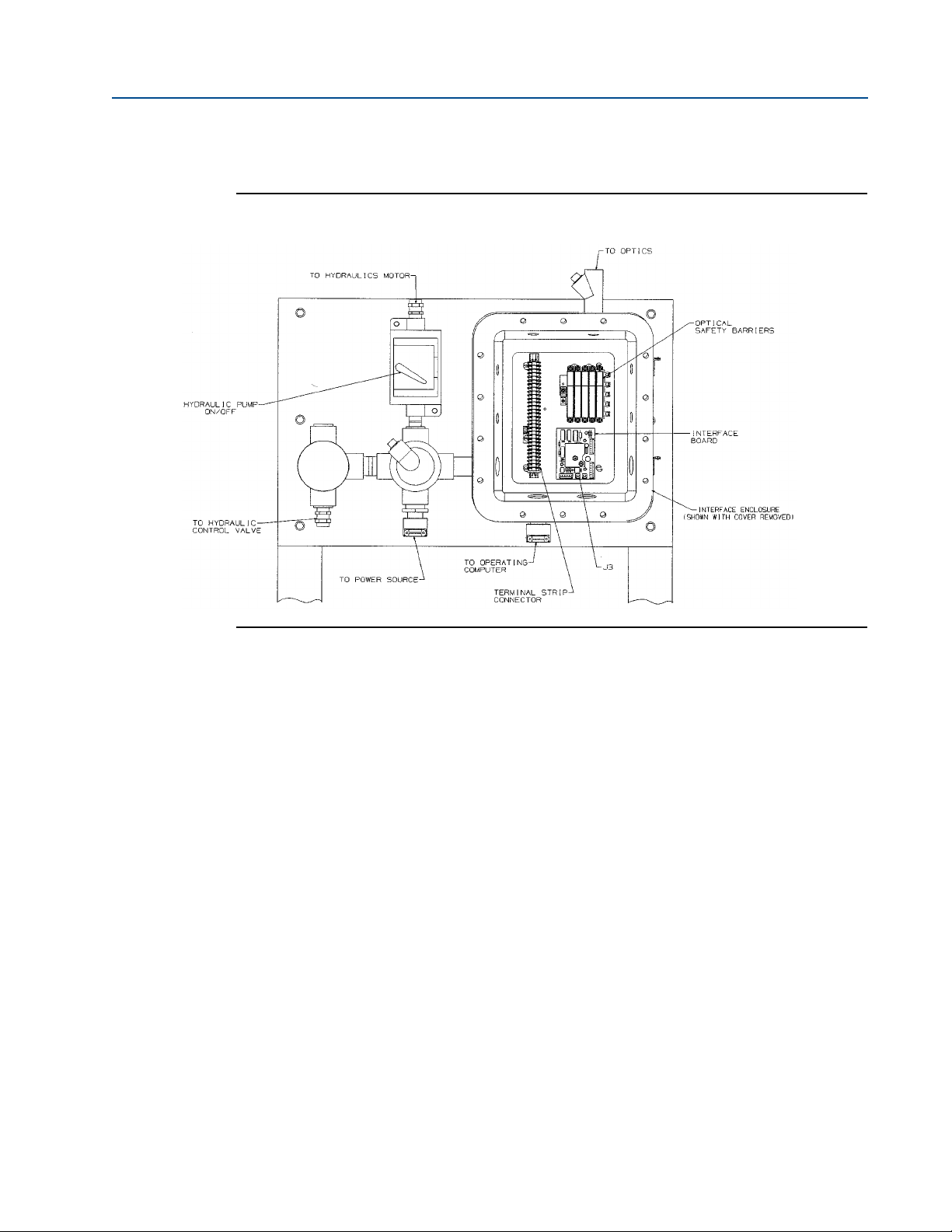

3. For factory built NEC type water draw hardware kits, connect a 3 conductor cable from

the enclosure terminal block to the correct power source, 115 or 230 VAC as applicable.

See Figure 4-3. The remaining 2 conductor cable, connects to receptacle J-3 on the

prover Interface Board. Access to the interior of the interface enclosure will be

necessary. Figure 4-7 shows the location of the interface board on the NEC-type prover

electrical panel. Figure 2-3 and Figure 2-4 show the different locations possible for J-3

on the different interface boards.

For factory built ATEX type water draw hardware kits equipped with the water draw plug, simply

connect the plug to the receptacle on the control enclosure. The water draw plug and

receptacle is available as an option for the NEC style factory built water draw hardware kits.

Contact a Daniel representative for more information.

42 Water draw procedure: (Reference Figure 4-4 and notes on page 47)

Page 57

Operating and maintenance instructions Section 4: Maintenance

3-9008-701 Rev J January 2015

4. Supply appropriate operational voltage (+12 or 24 VDC) to the prover interface board

at receptacle J-2, pins 2 (-) and 4 (+). Reference Section 2.4 to verify proper voltage

required for the interface board. Reference Figure 2-3 and Figure 2-4 for the location of

J-2.

5. Loosen and remove the cover on the optical detector switch assembly. Be careful not to

damage the optical switches on removal or replacement of optical cover during the

entire water draw process. See Note 4 on page 47.

6. Be sure the prover hydraulic system is connected to the appropriate AC power source.