Page 1

Reference, Installation, and Operations Manual

Part Number 3-9000-743 Revision S

June 2013

Daniel

TM

Ultrasonic Gas Flow Meters

with Mark III Electronics

Supporting Multipath SeniorSonicTM - Model 3400, Multipath SeniorSonicTM - Model 3422

Single Path JuniorSonicTM - Model 3410, Dual Path JuniorSonicTM - Model 3420

Page 2

Page 3

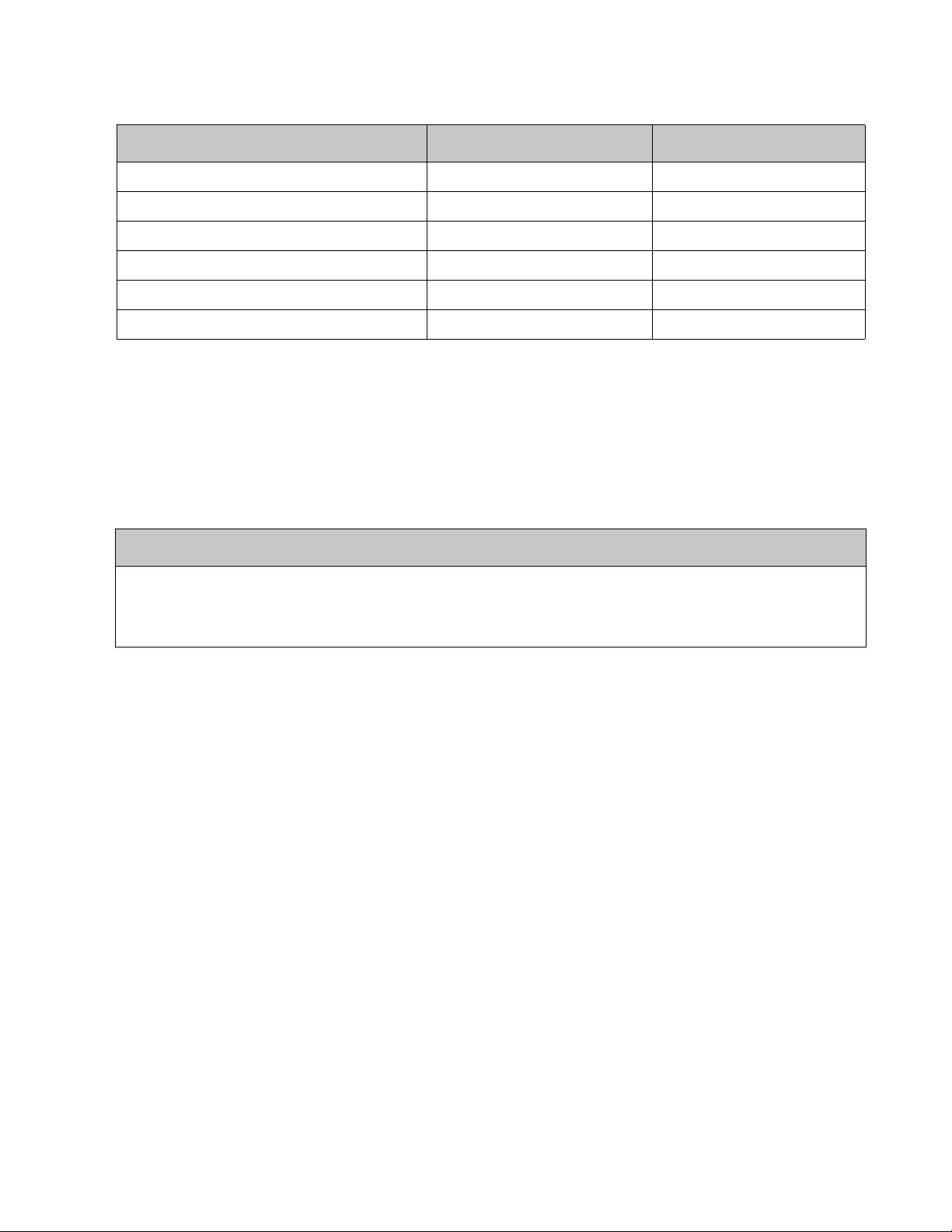

Daniel customer service

Location Tel ephone num ber Fax number

North America/Latin America +1.713.467.6000 +1.713.827.4805

Daniel Customer Service +1.713.827.6413 +1.713.827.6312

USA (toll free) +1.888.356.9001 +1.713.827.3380

Asia Pacific (Republic of Singapore) +65.6777.8211 +65.6777.0947.0743

Europe (Stirling Scotland, UK) +44 (0)1786.433400 +44 (0)1786.433401

Middle East Africa (Dubai, UAE) +971 4 8118100 +971 4 8865465

E-mail

• Customer Service: tech.service@emersonprocess.com

• Customer Support: daniel.cst.support@emerson.com

• Asia-Pacific: danielap.support@emerson.com

• Europe: DanielEMA.CST@EmersonProcess.com

Return Material Authorization (RMA)

A Return Material Authorization (RMA) number must be obtained prior to returning any equipment for any reason.

Download the RMA form from the Support Services web page by selecting the link below.

www2.emersonprocess.com/EN-US/BRANDS/DANIEL/SUPPORT-SERVICES/Pages/Support-Services.aspx?

Page 4

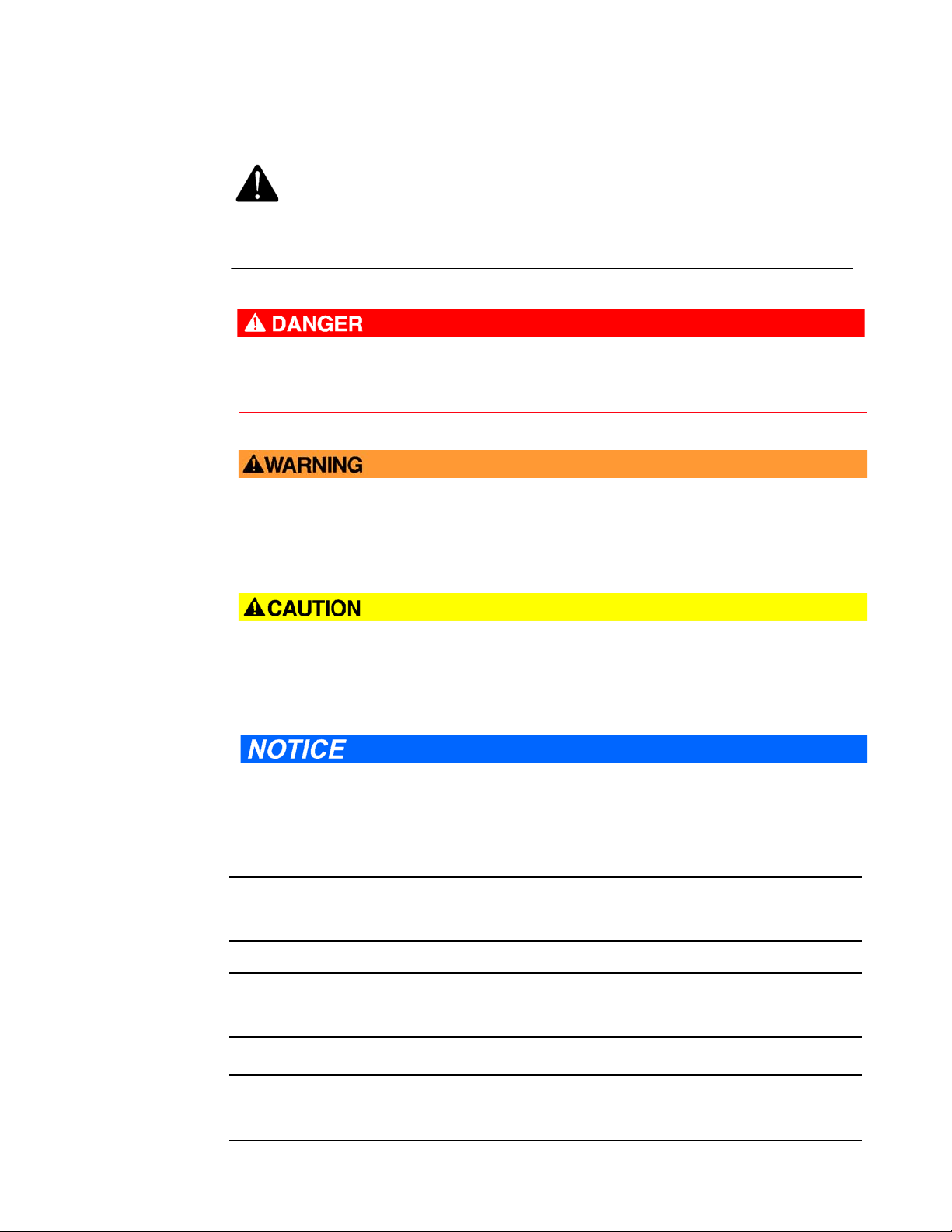

Signal words and symbols

This is a safety alert symbol. It is used to alert you to potential physical injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

Safety alert symbol

Danger indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Warning indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Caution indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Pay special attention to the following signal words, safety alert symbols and statements:

Important

Important is a statement the user needs to know and consider.

Tip

Tip provides information or suggestions for improved efficiency or best results.

Note

Note is a “general by-the-way” content not essential to the main flow of information.

Page 5

Important safety instructions

Installing, operating or maintaining a Daniel product improperly could lead to serious injury or

death from explosion or exposure to dangerous substances. To reduce this risk:

• Comply with all information on the product, in this manual, and in any local and national

codes that apply to the product.

• Do not allow untrained personnel to work with this product.

• Use Daniel parts and work procedures specified in this manual.

Daniel Measurement and Control, Inc. (Daniel) designs, manufactures and tests products to

function within specific conditions. Because these products are sophisticated technical

instruments, it is important that the owner and operation personnel strictly adhere both to the

information printed on the product and to all instructions provided in this manual prior to

installation, operation, and maintenance.

Daniel also urges you to integrate this manual into your training and safety program.

BE SURE ALL PERSONNEL READ AND FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND ALL

NOTICES AND PRODUCT WARNINGS.

Product owners (Purchasers):

• Use the correct product for the environment and pressures present. See technical data

or product specifications for limitations. If you are unsure, discuss your needs with your

Daniel representative.

• Inform and train all personnel in the proper installation, operation, and maintenance of

this product.

• To ensure safe and proper performance, only informed and trained personnel should

install, operate, repair and maintain this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Save this instruction manual for future reference.

• If you resell or transfer this product, it is your responsibility to forward this instruction

manual along with the product to the new owner or transferee.

• ALWAYS READ AND FOLLOW THE INSTALLATION, OPERATIONS, MAINTENANCE AND

TROUBLESHOOTING MANUALS AND ALL PRODUCT WARNINGS AND INSTRUCTIONS.

• Do not use this equipment for any purpose other than its intended service. This may

result in property damage and/or serious personal injury or death.

Page 6

Product Operation Personnel:

• To prevent personal injury, personnel must follow all instructions of this manual prior to

and during operation of the product.

• Follow all warnings, cautions, and notices marked on, and supplied with, this product.

• Verify that this is the correct instruction manual for your Daniel product. If this is not

the correct documentation, contact Daniel at 1-713-827-6314. You may also download

the correct manual from:

http://www.daniel.com

• Read and understand all instructions and operating procedures for this product.

• If you do not understand an instruction, or do not feel comfortable following the

instructions, contact your Daniel representative for clarification or assistance.

• Install this product as specified in the INSTALLATION section of this manual per

applicable local and national codes.

• Follow all instructions during the installation, operation, and maintenance of this

product.

• Connect the product to the appropriate pressure and electrical sources when and

where applicable.

• Ensure that all connections to pressure and electrical sources are secure prior to and

during equipment operation.

• Use only replacement parts specified by Daniel. Unauthorized parts and procedures can

affect this product's performance, safety, and invalidate the warranty. “Look-a-like”

substitutions may result in deadly fire, explosion, release of toxic substances or

improper operation.

• Save this instruction manual for future reference.

Page 7

Notice

THE CONTENTS OF THIS PUBLICATION ARE PRESENTED FOR INFORMATIONAL PURPOSES ONLY, AND WHILE

EVERY EFFORT HAS BEEN MADE TO ENSURE THEIR ACCURACY, THEY ARE NOT TO BE CONSTRUED AS

WARRANTIES OR GUARANTEES, EXPRESSED OR IMPLIED, REGARDING THE PRODUCTS OR SERVICES

DESCRIBED HEREIN OR THEIR USE OR APPLICABILITY. ALL SALES ARE GOVERNED BY DANIEL'S TERMS AND

CONDITIONS, WHICH ARE AVAILABLE UPON REQUEST. WE RESERVE THE RIGHT TO MODIFY OR IMPROVE THE

DESIGNS OR SPECIFICATIONS OF SUCH PRODUCTS AT ANY TIME.

DANIEL DOES NOT ASSUME RESPONSIBILITY FOR THE SELECTION, USE OR MAINTENANCE OF ANY PRODUCT.

RESPONSIBILITY FOR PROPER SELECTION, USE AND MAINTENANCE OF ANY DANIEL PRODUCT REMAINS

SOLELY WITH THE PURCHASER AND END-USER.

TO THE BEST OF DANIEL'S KNOWLEDGE THE INFORMATION HEREIN IS COMPLETE AND ACCURATE. DANIEL

MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH RESPECT TO THIS MANUAL AND, IN NO EVENT, SHALL

DANIEL BE LIABLE FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT

NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE AND COSTS INCURRED

INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF THIRD PARTIES.

PRODUCT NAMES USED HEREIN ARE FOR MANUFACTURER OR SUPPLIER IDENTIFICATION ONLY AND MAY BE

TRADEMARKS/REGISTERED TRADEMARKS OF THESE COMPANIES

Page 8

Warranty and Limitations

1. LIMITED WARRANTY: Subject to the limitations contained in Section 2 herein, Daniel Measurement &

Control, Inc. (“Daniel”) warrants that the licensed firmware embodied in the Goods will execute the

programming instructions provided by Daniel, and that the Goods manufactured by Daniel will be free from

defects in materials or workmanship under normal use and care and Services will be performed by trained

personnel using proper equipment and instrumentation for the particular Service provided. The foregoing

warranties will apply until the expiration of the applicable warranty period. Goods are warranted for twelve (12)

months from the date of initial installation or eighteen (18) months from the date of shipment by Daniel,

whichever period expires first. Consumables and Services are warranted for a period of 90 days from the date

of shipment or completion of the Services. Products purchased by Daniel from a third party for resale to Buyer

("Resale Products”) shall carry only the warranty extended by the original manufacturer. Buyer agrees that

Daniel has no liability for Resale Products beyond making a reasonable commercial effort to arrange for

procurement and shipping of the Resale Products. If Buyer discovers any warranty defects and notifies Daniel

thereof in writing during the applicable warranty period, Daniel shall, at its option, correct any errors that are

found by Daniel in the firmware or Services or repair or replace F.O.B. point of manufacture that portion of the

Goods or firmware found by Daniel to be defective, or refund the purchase price of the defective portion of the

Goods/Services. All replacements or repairs necessitated by inadequate maintenance, normal wear and usage,

unsuitable power sources or environmental conditions, accident, misuse, improper installation, modification,

repair, use of unauthorized replacement parts, storage or handling, or any other cause not the fault of Daniel

are not covered by this limited warranty, and shall be at Buyer's expense. Daniel shall not be obligated to pay

any costs or charges incurred by Buyer or any other party except as may be agreed upon in writing in advance

by Daniel. All costs of dismantling, reinstallation and freight and the time and expenses of Daniel's personnel

and representatives for site travel and diagnosis under this warranty clause shall be borne by Buyer unless

accepted in writing by Daniel. Goods repaired and parts replaced by Daniel during the warranty period shall be

in warranty for the remainder of the original warranty period or ninety (90) days, whichever is longer. This

limited warranty is the only warranty made by Daniel and can be amended only in a writing signed by Daniel.

THE WARRANTIES AND REMEDIES SET FORTH ABOVE ARE EXCLUSIVE. THERE ARE NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AS TO MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR ANY OTHER MATTER WITH RESPECT TO ANY OF THE GOODS OR SERVICES. Buyer acknowledges

and agrees that corrosion or erosion of materials is not covered by this warranty.

2. LIMITATION OF REMEDY AND LIABILITY

PERFORMANCE. THE REMEDIES OF BUYER SET FORTH IN THIS AGREEMENT ARE EXCLUSIVE. IN NO EVENT,

REGARDLESS OF THE FORM OF THE CLAIM OR CAUSE OF ACTION (WHETHER BASED IN CONTRACT,

INFRINGEMENT, NEGLIGENCE, STRICT LIABILITY, OTHER TORT OR OTHERWISE), SHALL DANIEL'S LIABILITY TO

BUYER AND/OR ITS CUSTOMERS EXCEED THE PRICE TO BUYER OF THE SPECIFIC GOODS MANUFACTURED OR

SERVICES PROVIDED BY DANIEL GIVING RISE TO THE CLAIM OR CAUSE OF ACTION. BUYER AGREES THAT IN NO

EVENT SHALL DANIEL'S LIABILITY TO BUYER AND/OR ITS CUSTOMERS EXTEND TO INCLUDE INCIDENTAL,

CONSEQUENTIAL OR PUNITIVE DAMAGES. THE TERM “CONSEQUENTIAL DAMAGES” SHALL INCLUDE, BUT NOT

BE LIMITED TO, LOSS OF ANTICIPATED PROFITS, REVENUE OR USE AND COSTS INCURRED INCLUDING

WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER, AND CLAIMS OF BUYER'S CUSTOMERS.

: DANIEL SHALL NOT BE LIABLE FOR DAMAGES CAUSED BY DELAY IN

Page 9

Reference, Installation, and Operations Manual Table of Contents

3-9000-743 Rev S June 2013

Contents

Preface

Daniel customer service

Signal words and symbols

Important safety instructions

Notice

Warranty and Limitations

Section 1: Introduction

1.1 Manual overview............................................................................................. 1

1.2 Definitions, acronyms, abbreviations................................................................ 2

1.3 What’s new .................................................................................................... 5

1.4 Daniel Ultrasonic Meter reference manuals ....................................................... 6

1.5 References ..................................................................................................... 7

Section 2: Product overview

2.1 Description .................................................................................................... 9

2.1.1 Advantages and Features ................................................................................... 10

2.1.2 Mechanical installation requirements................................................................. 11

2.2 Component parts.......................................................................................... 11

2.2.1 Daniel Mark III Ultrasonic Gas Flow Meters assembly .......................................... 12

2.2.2 Model 3400 meter body..................................................................................... 17

2.2.3 Model 3422 meter body..................................................................................... 18

2.2.4 Model 3410 meter body..................................................................................... 19

2.2.5 Model 3420 meter body..................................................................................... 20

2.2.6 Transducers and cabling..................................................................................... 21

2.3 General unit specifications ............................................................................ 22

2.3.1 The application .................................................................................................. 22

2.3.2 Available meter sizes.......................................................................................... 22

2.3.3 Pressure range ................................................................................................... 22

2.3.4 Flow range limits ................................................................................................ 23

2.3.5 Flange types....................................................................................................... 24

2.3.6 Gas temperature range ...................................................................................... 24

2.3.7 Repeatability...................................................................................................... 24

2.3.8 Accuracy limits................................................................................................... 24

Contents i

Page 10

Table of Contents Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

2.4 Electronic specifications ................................................................................25

2.4.1 Power specifications ...........................................................................................25

2.4.2 Temperature ......................................................................................................25

2.4.3 Inputs .................................................................................................................25

2.4.4 Outputs ..............................................................................................................25

2.4.5 Communications ................................................................................................25

2.5 Hardware features.........................................................................................26

2.5.1 Inputs .................................................................................................................26

2.5.2 Outputs ..............................................................................................................26

2.5.3 Status Indicators.................................................................................................29

2.6 Communications...........................................................................................35

2.7 Safety .......................................................................................................... 37

2.8 FCC Compliance............................................................................................38

Section 3: Installation

3.1 Installation instructions.................................................................................39

3.2 Daniel 3400 Series Ultrasonic Flow Meter lifting instructions and precautions....41

3.2.1 Use of appropriate safety engineered swivel hoist rings in meter end flanges ..... 43

3.2.2 Safety precautions using safety engineered swivel hoist rings.............................44

3.2.3 How to obtain safety engineered swivel hoist rings.............................................47

3.2.4 Using appropriately rated lifting slings on Daniel Ultrasonic Meters....................48

3.3 Mechanical installation..................................................................................51

3.3.1 Meter body installation.......................................................................................51

3.3.2 Mounting requirements for heated or cooled pipelines ......................................53

3.3.3 Accessing the Daniel 3400 Series Ultrasonic Flow Meter components ................53

3.3.4 Transducer cables/appropriate transducer .........................................................57

3.3.5 For systems using explosion-proof conduit.........................................................58

3.3.6 For systems that use flame-proof cable...............................................................59

3.4 Wiring and Connections ................................................................................ 60

3.5 Hardware Switch Settings ..............................................................................66

3.5.1 Communication settings ....................................................................................73

3.5.2 Frequency and Digital Output switch settings.....................................................79

3.5.3 Option Board analog inputs switch settings........................................................80

3.5.4 Series 100 Option Board analog output switch settings ......................................83

3.5.5 Series 100 Plus Option Board Analog Input switch settings .................................84

3.5.6 Series 100 Plus Option Board Analog Output switch settings ..............................86

3.5.7 DHCP server switch settings ...............................................................................88

3.5.8 Configuration protection switch settings............................................................88

3.6 Security seal installation ................................................................................ 88

3.6.1 End cap security seal installation.........................................................................89

3.6.2 Upper electronics housing to base unit security seal ...........................................90

3.6.3 Transducer assembly security seal installation ....................................................91

ii Contents

Page 11

Reference, Installation, and Operations Manual Table of Contents

3-9000-743 Rev S June 2013

Section 4: Optional features

4.1 Overview ..................................................................................................... 93

4.1.1 Managing optional feature keys ......................................................................... 93

4.1.2 Obtaining optional keys ..................................................................................... 94

4.1.3 Optional Ethernet key ........................................................................................ 94

4.1.4 Optional data log access key .............................................................................. 94

4.1.5 Optional GC interface key................................................................................... 94

4.1.6 Optional Aga10 key (sound velocity calculation) ................................................ 95

4.1.7 Key status........................................................................................................... 95

4.2 Key expiration warnings (firmware v1.6X and below) ....................................... 95

4.3 Grandfathered features (firmware v1.6X and below) ........................................ 95

4.4 Trial period (firmware v1.6X and below) ......................................................... 95

Section 5: Startup and meter configuration

5.1 Communications .......................................................................................... 97

5.2 Communications setup ............................................................................... 100

5.3 Communications setup wizard ..................................................................... 102

5.3.1 Advantages of Ethernet communication ..........................................................102

5.3.2 Initial Ethernet communications connection .................................................... 103

5.3.3 Ethernet communications connection ............................................................103

5.3.4 Ethernet initial connection steps ...................................................................... 104

5.4 Ethernet PC, HUB, or LAN connections.......................................................... 108

5.4.1 Direct connection from a Mark III to a PC.......................................................... 108

5.4.2 Connect a Mark III to a PC via an Ethernet hub .................................................. 108

5.4.3 Connect a Mark III Meter to a LAN via an Ethernet Hub ..................................... 109

5.5 Serial port connections using RS-232 serial cable .......................................... 109

5.5.1 RS-232 serial connection setup ........................................................................ 111

5.5.2 RS-485 serial connection setup ........................................................................ 113

5.5.3 Writing changes while connected to the meter ................................................ 118

5.6 Meter configuration setup wizard ................................................................. 119

5.6.1 Daniel MeterLink meter configuration overview...............................................120

5.6.2 Configuration protection ................................................................................. 122

5.6.3 Configuration checksum value and date........................................................... 123

5.6.4 Meter configuration using Daniel MeterLink..................................................... 123

5.6.5 Startup page .................................................................................................... 132

5.6.6 General Page.................................................................................................... 137

5.6.7 Frequency Outputs Page .................................................................................. 138

5.6.8 Current Outputs Page ......................................................................................140

Contents iii

Page 12

Table of Contents Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

5.6.9 HART® Output Page.........................................................................................144

5.6.10 Meter Digital outputs .......................................................................................146

5.6.11 Meter Corrections page ....................................................................................147

5.6.12 Temperature and Pressure page .......................................................................149

5.6.13 Gas Chromatograph Setup page.......................................................................154

5.6.14 AGA 8 Setup page.............................................................................................155

5.6.15 Continuous Flow Analysis page.........................................................................157

5.6.16 Set Baseline Wizard ..........................................................................................159

5.7 Process parameters and calibration configuration.......................................... 160

5.7.1 Update Time Wizard .........................................................................................160

5.7.2 Calculated results .............................................................................................162

5.7.3 Set calibration parameters................................................................................163

5.8 Saving the meter configuration .................................................................... 170

5.9 Maintenance logs and reports (Logs/Reports Menu) ....................................... 171

5.9.1 Log Format .......................................................................................................175

5.10 Trend maintenance logs (Logs/reports Menu) .............................................. 178

5.10.1 Meter Archive Logs (Logs/Reports Menu) .........................................................179

5.10.2 Compare Excel Meter Configurations (Logs/Reports Menu)..............................180

Section 6: Meter operation

6.1 Measurement .............................................................................................. 181

6.1.1 Terminology .....................................................................................................183

6.1.2 Signal processing..............................................................................................184

6.1.3 Batch cycle processing......................................................................................185

6.1.4 Acquisition mode .............................................................................................186

6.1.5 Chord gas and sound velocity measurements...................................................187

6.1.6 Average weighted sound velocity .....................................................................188

6.1.7 Average weighted gas flow velocity..................................................................190

6.1.8 Calibration........................................................................................................193

6.1.9 Volumetric flow rate .........................................................................................196

6.1.10 Volume.............................................................................................................201

6.1.11 Triggered Delta Volumes..................................................................................202

6.1.12 Energy rate and totals.......................................................................................203

6.1.13 Mass rate and totals .........................................................................................204

6.1.14 Seniorsonic flow characterizations....................................................................205

6.1.15 Flow-condition pressure and temperature........................................................206

6.1.16 Gas properties ..................................................................................................210

6.1.17 AGA8 compressibility calculations....................................................................215

iv Contents

Page 13

Reference, Installation, and Operations Manual Table of Contents

3-9000-743 Rev S June 2013

6.2 Frequency, digital, and analog outputs ......................................................... 215

6.2.1 Frequency outputs ........................................................................................... 215

6.2.2 Digital outputs ................................................................................................. 219

6.2.3 Analog (Current) output................................................................................... 221

6.3 Digital Input ............................................................................................... 226

6.4 Modbus communication .............................................................................. 227

6.4.1 Mapping data points to Modbus Registers........................................................ 227

6.4.2 Log record access............................................................................................. 228

6.5 Optional gas chromatograph interface ......................................................... 228

6.5.1 Hardware configuration ................................................................................... 228

6.5.2 Software configuration.....................................................................................229

6.5.3 Gas property data............................................................................................. 229

6.5.4 Data polling...................................................................................................... 230

6.5.5 GC data validity ................................................................................................ 231

6.5.6 GC alarm handling............................................................................................ 231

6.6 Archive logs ............................................................................................... 232

6.6.1 Daily log ........................................................................................................... 232

6.6.2 Hourly log ........................................................................................................ 238

6.6.3 Audit log .......................................................................................................... 241

6.6.4 Alarm log ......................................................................................................... 252

6.6.5 System log ....................................................................................................... 254

6.6.6 Reading log records.......................................................................................... 254

6.7 Viewing transducer waveforms .................................................................... 256

6.8 Upgrading the meter program ..................................................................... 256

6.8.1 Power disruption during firmware upgrade...................................................... 257

6.9 Self-tests and data reliability ....................................................................... 259

6.9.1 RAM integrity ................................................................................................... 259

6.9.2 Program integrity.............................................................................................259

6.9.3 Stored data integrity ........................................................................................ 259

6.9.4 Hardware watchdog......................................................................................... 259

6.9.5 Program execution integrity.............................................................................260

6.9.6 Log transfer integrity........................................................................................ 260

6.9.7 Data value limit checks..................................................................................... 260

6.9.8 Configuration dependency checks ................................................................... 260

Contents v

Page 14

Table of Contents Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Section 7: Maintenance and troubleshooting

7.1 Field hydrostatic pressure testing procedures................................................ 261

7.2 T-Slot Transducer Removal and Installation Procedures .................................. 262

7.2.1 Removal with Extractor Tool .............................................................................262

7.2.2 Removal without Extractor Tool........................................................................265

7.2.3 Installing the transducers..................................................................................267

7.2.4 Replace the transformers..................................................................................270

7.2.5 Modifying the Calibration Parameters...............................................................271

7.3 Replacing the Mark III Electronics .................................................................272

7.4 Troubleshooting Communications ................................................................ 273

7.4.1 Unable to Connect Direct Serial or External Serial Modem ................................273

7.4.2 Unable to Connect to Meter..............................................................................273

7.4.3 Maintenance log files and trend files.................................................................274

7.4.4 Daniel MeterLink fails to connect or crashes using Windows® 2000 .................276

7.4.5 Windows® Hotfixes — Obtaining Hotfixes for Microsoft® Windows®...............277

7.4.6 Windows® 2000 SP-4 or a Windows® XP with security update ........................277

7.5 Troubleshooting Meter Status ...................................................................... 278

7.5.1 Meter Status Alarms .........................................................................................278

7.5.2 System Alarm ...................................................................................................279

7.5.3 Chord A to Chord D...........................................................................................280

7.5.4 Field I/O Alarm..................................................................................................280

7.5.5 Validity Alarm ...................................................................................................280

7.5.6 Comms Alarm...................................................................................................280

7.5.7 Check Status.....................................................................................................280

7.6 Maintenance logs and reports ...................................................................... 281

7.6.1 Collecting logs and viewing Excel reports..........................................................282

vi Contents

Page 15

Reference, Installation, and Operations Manual Table of Contents

3-9000-743 Rev S June 2013

Appendix A Conversion factors

A.1 Conversion factors per unit of measurement.................................................................. 293

Appendix B Miscellaneous equations

B.1 Miscellaneous conversion factors.................................................................................... 295

B.2 Chord “L” dimension calculation..................................................................................... 297

Appendix C Upgrading a Mark II to a Mark III

C.1 Meter electronics upgrade.............................................................................................. 299

C.2 What’s new In Mark III..................................................................................................... 299

C.3 Modbus Communication ................................................................................................ 302

C.3.1 Protocols .......................................................................................................... 302

C.3.2 Registers........................................................................................................... 302

C.3.3 Log Access ........................................................................................................ 302

C.4 Configuration conversion ............................................................................................... 303

C.4.1 Metrology - meter body and transducer calibration values................................ 303

C.4.2 Metrology - calibration equation parameters .................................................... 304

C.4.3 Gain .................................................................................................................. 307

C.4.4 Batch update period and stack size ................................................................... 307

C.4.5 Emission rate, stacked emission rate, and firing sequence ................................ 308

C.4.6 Chord failure threshold ..................................................................................... 308

C.4.7 Flow velocity estimation when a chord is failed ................................................. 308

C.4.8 Inactive chords.................................................................................................. 309

C.4.9 AlarmDef .......................................................................................................... 309

C.4.10 Frequency output configuration ..................................................................... 310

C.4.11 Flow pressure and temperature ...................................................................... 311

C.4.12 AGA8 method................................................................................................. 311

C.4.13 Minimum hold time ........................................................................................ 311

C.4.14 Log Format parameters................................................................................... 311

Appendix D Troubleshooting comm., mech., and elec.

D.1 Communications troubleshooting.................................................................................. 313

D.2 MARK III mechanical/electrical troubleshooting ............................................................. 315

Appendix E Meter setup and configuration worksheet

E.1 Meter setup and configuration worksheet....................................................................... 317

E.2 Meter to Flow Computer Communication Worksheet ..................................................... 322

Contents vii

Page 16

Table of Contents Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Appendix F Flow rate summary charts

F.1 Flow Rate Summary Charts ..............................................................................................331

Appendix G Write-protected configuration parameters

G.1 Write-protected configuration........................................................................................ 335

Appendix H Open source licenses

H.1 Open source licenses ......................................................................................................345

H.1.1 GNU General Public License ..............................................................................346

H.1.2 BSD Open Source License..................................................................................359

H.1.3 M.I.T. License ....................................................................................................360

H.1.4 Mird License......................................................................................................361

Appendix I Engineering drawings

I.1 Ultrasonic Meter Drawings ...............................................................................................363

Appendix J Index

J.1 Manual Index....................................................................................................................365

viii Contents

Page 17

Reference, Installation, and Operations Manual List of Tables

3-9000-743 Rev S June 2013

List of Tables

Table 1-1 Gas Ultrasonic Meter acronyms, abbreviations and definitions ............................................. 2

Table 1-2 Daniel reference manuals ..................................................................................................... 6

Table 2-1 Transducer connection ports and number of transducers ................................................... 21

Table 2-2 Temperature ranges for transducers, mounts and holders.................................................. 24

Table 2-3 Voltage level and drive capability per logic level (TTL)......................................................... 27

Table 2-4 Configurations for open collector frequency outputs.......................................................... 28

Table 2-5 CPU Board General Status Indicators................................................................................... 31

Table 2-6 CPU Board Communication Status Indicators ..................................................................... 32

Table 2-7 Option Board General Status Indicators .............................................................................. 32

Table 2-8 Series 100 Plus Option Board General Status Indicators ...................................................... 33

Table 2-9 Option Board Communication Status Indicators................................................................. 33

Table 2-1 0 Series 100 Plus Option Board Communication Status Indicators ......................................... 34

Table 2-1 1 Supported Modbus Protocols ............................................................................................. 35

Table 3-1 Daniel hoist ring part numbers............................................................................................ 47

Table 3-2 Hoist Ring lookup table for Daniel Gas SeniorSonic Meters* ............................................... 47

Table 3-3 Hoist ring lookup table for Daniel Gas JuniorSonic Meters................................................... 48

Table 3-4 Piping recommendations uni-directional flow .................................................................... 51

Table 3-5 Piping recommendations bi-directional flow ...................................................................... 52

Table 3-6 Acquisition board wiring..................................................................................................... 57

Table 3-7 J7 Port B Wiring................................................................................................................... 60

Table 3-8 J2 Power ............................................................................................................................. 61

Table 3-9 J3 Chassis Ground ...............................................................................................................62

Table 3-1 0 J18 Digital Input.................................................................................................................. 62

Table 3-1 1 J11 Analog Output (AO1).................................................................................................... 62

Table 3-1 2 J12 Analog Input (AI1)......................................................................................................... 62

Table 3-1 3 J12 Analog Input 2 (AI2)...................................................................................................... 63

Table 3-1 4 J10 Analog Output Series 100 Plus Option Board (AO2) ...................................................... 63

Table 3-1 5 J11 Analog Output Series 100 Plus Option Board (AO1) ...................................................... 63

Table 3-1 6 J12 Analog Input Series 100 Plus Option Board (AI1) ........................................................... 63

Table 3-1 7 J12 Analog Input Series 100 Plus Option Board (AI2) ........................................................... 64

Table 3-1 8 J6 Port A.............................................................................................................................. 64

Table 3-1 9 J7 Port B.............................................................................................................................. 64

List of Tables ix

Page 18

List of Tables Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Table 3-2 0 J16 Port C............................................................................................................................65

Table 3-2 1 J8 Ethernet Port................................................................................................................... 65

Table 3-2 2 DC Power Jumper Settings ..................................................................................................65

Table 3-2 3 Case Ground Jumper Settings..............................................................................................66

Table 3-2 4 Digital Input Connector.......................................................................................................66

Table 3-2 5 Port A driver settings...........................................................................................................74

Table 3-2 6 Port A RS-485 full duplex settings........................................................................................75

Table 3-2 7 Port A RS-485 half duplex settings.......................................................................................75

Table 3-2 8 Port B RS-232 driver settings...............................................................................................76

Table 3-2 9 Port B RS-485 full duplex .....................................................................................................77

Table 3-3 0 Port B RS-485 half duplex ....................................................................................................77

Table 3-3 1 Port C RS-232 settings.........................................................................................................78

Table 3-3 2 Port C RS-485 half duplex....................................................................................................78

Table 3-3 3 Option Board Analog In 1 temperature sin k settings...........................................................81

Table 3-3 4 Option Board Analog In 1 temperature source settings .......................................................81

Table 3-3 5 Option Board Analog In 2 pressure sink settings..................................................................82

Table 3-3 6 Option Board Analog In 2 pressure source settings..............................................................82

Table 3-3 7 Series 100 Option board Analog Out sink setting ................................................................83

Table 3-3 8 Series 100 Option board Analog Out source setting ............................................................83

Table 3-3 9 Series 100 Plus Option board Analog In 1 temperature sink setting.....................................84

Table 3-4 0 Series 100 Plus Option board Analog In 1 temperature source setting.................................85

Table 3-4 1 Series 100 Plus Option board Analog In 2 pressure sink setting ...........................................85

Table 3-4 2 Series 100 Plus Option board Analog In 2 pressure source setting .......................................86

Table 3-4 3 Series 100 Plus Option Board Analog Out 1 sink settings.....................................................86

Table 3-4 4 Series 100 Plus Option Board Analog Out 1 source settings.................................................87

Table 3-4 5 Series 100 Plus Option Board Analog Out 2 sink settings.....................................................87

Table 3-4 6 Series 100 Plus Option Board Analog Out 2 source settings.................................................87

Table 3-4 7 DHCP server settings........................................................................................................... 88

Table 3-4 8 CPU configuration protection switch...................................................................................88

Table 5-1 Daniel MeterLink setup wizards...........................................................................................98

Table 5-2 Supported Modbus Protocols............................................................................................101

Table 5-3 Data Points for Ethernet Port Configuration ......................................................................103

Table 5-4 Data Points for serial ports configuration ..........................................................................110

Table 5-5 Serial Port B RS-232 Configuration Switch Settings ........................................................... 112

x List of Tables

Page 19

Reference, Installation, and Operations Manual List of Tables

3-9000-743 Rev S June 2013

Table 5-6 Serial Port A RS-485 Full duplex configuration switch settings........................................... 114

Table 5-7 Serial Port A RS-485 half duplex configuration switch settings .......................................... 115

Table 5-8 Serial Port B RS-485 full duplex configuration switch settings ........................................... 116

Table 5-9 Serial Port B RS-485 half duplex configuration switch settings .......................................... 116

Table 5-1 0 Register reference help file ............................................................................................... 121

Table 5-1 1 Daniel MeterLink Field Setup Wizard................................................................................. 124

Table 5-1 2 Enabling Meter Corrections .............................................................................................. 135

Table 5-1 3 Enable Temperature/Pressure Meter Corrections Data Points, Source .............................. 136

Table 5-1 4 Data Points for Meter Real-Time Clock.............................................................................. 137

Table 5-1 5 Data Points for Analog (Current) Output Configuration .................................................... 141

Table 5-1 6 Live Temperature Inputs................................................................................................... 150

Table 5-1 7 Fixed Temperature Inputs................................................................................................. 151

Table 5-1 8 Live Pressure Inputs .......................................................................................................... 152

Table 5-1 9 Fixed Pressure Inputs ........................................................................................................ 153

Table 5-2 0 Field Setup Wizard - AGA 8 Setup...................................................................................... 156

Table 5-2 1 Data Points for Batch Cycle Processing, or Update Time Control....................................... 161

Table 5-2 2 Data Points for Dry Calibration.......................................................................................... 165

Table 5-2 3 Data Point for wet calibration method.............................................................................. 167

Table 5-2 4 Data Points for Piece-Wise linearization calibration........................................................... 168

Table 5-2 5 Data Points for Polynomial Wet Calibration ...................................................................... 169

Table 5-2 6 Ultrasonic Meter Archive Log Types .................................................................................. 180

Table 6-1 Actual meter update period.............................................................................................. 185

Table 6-2 AGA10 calculation status.................................................................................................. 189

Table 6-3 Volume Accumulation Data Points ................................................................................... 201

Table 6-4 Energy total data points.................................................................................................... 204

Table 6-5 Mass Total Data Points...................................................................................................... 205

Table 6-6 Flow-condition pressure and temperature data source..................................................... 207

Table 6-7 Fixed gas composition data points.................................................................................... 211

Table 6-8 GC-reported gas composition data points ........................................................................ 212

Table 6-9 “In-Use” gas composition data points............................................................................... 213

Table 6-1 0 C6+ breakdown to standard components by component ID............................................. 214

Table 6-1 1 FreqXB phase options ....................................................................................................... 216

Table 6-1 2 Data points for frequency outputs test ............................................................................. 218

Table 6-1 3 Data points for digital outputs test ................................................................................... 220

Table 6-1 4 Data points for output test mode ..................................................................................... 225

List of Tables xi

Page 20

List of Tables Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Table 6-1 5 Gas Chromatograph Sim 2251 Registers...........................................................................228

Table 6-1 6 GC Communication status list...........................................................................................230

Table 6-1 7 GC-read gas property invalid conditions............................................................................231

Table 6-1 8 Daily log content...............................................................................................................233

Table 6-1 9 Hourly log content ............................................................................................................238

Table 6-2 0 Audit log content..............................................................................................................242

Table 6-2 1 Alarm log non-boolean data points monitored..................................................................252

Table 6-2 2 Alarm log boolean data points monitored......................................................................... 253

Table 7-1 Tools and supplies for disassembly and assembly..............................................................265

Table 7-2 Electronics serial numbers.................................................................................................272

Table 7-3 Chord alarms.....................................................................................................................280

Table 7-4 Maintenance log collection ...............................................................................................281

Table A-1

Conversion Factors per unit of measurement ........................................293

Table C-1 Mark II chord inactive conversion to Mark III data points ........................309

Table C-2 FreqXContent Conversion Mapping......................................................310

Table D-1 Mark III Mechanical/Electrical Troubleshooting ......................................315

Table E-1 Daniel 3400 Series Gas Ultrasonic Flow Meter setup

and configuration reference sheet ......................................................317

Table E-2 Meter to Flow Computer Communication Worksheet .............................322

Table H-1 Open source licenses .........................................................................345

xii List of Tables

Page 21

Reference, Installation, and Operations Manual List of Figures

3-9000-743 Rev S June 2013

List of Figures

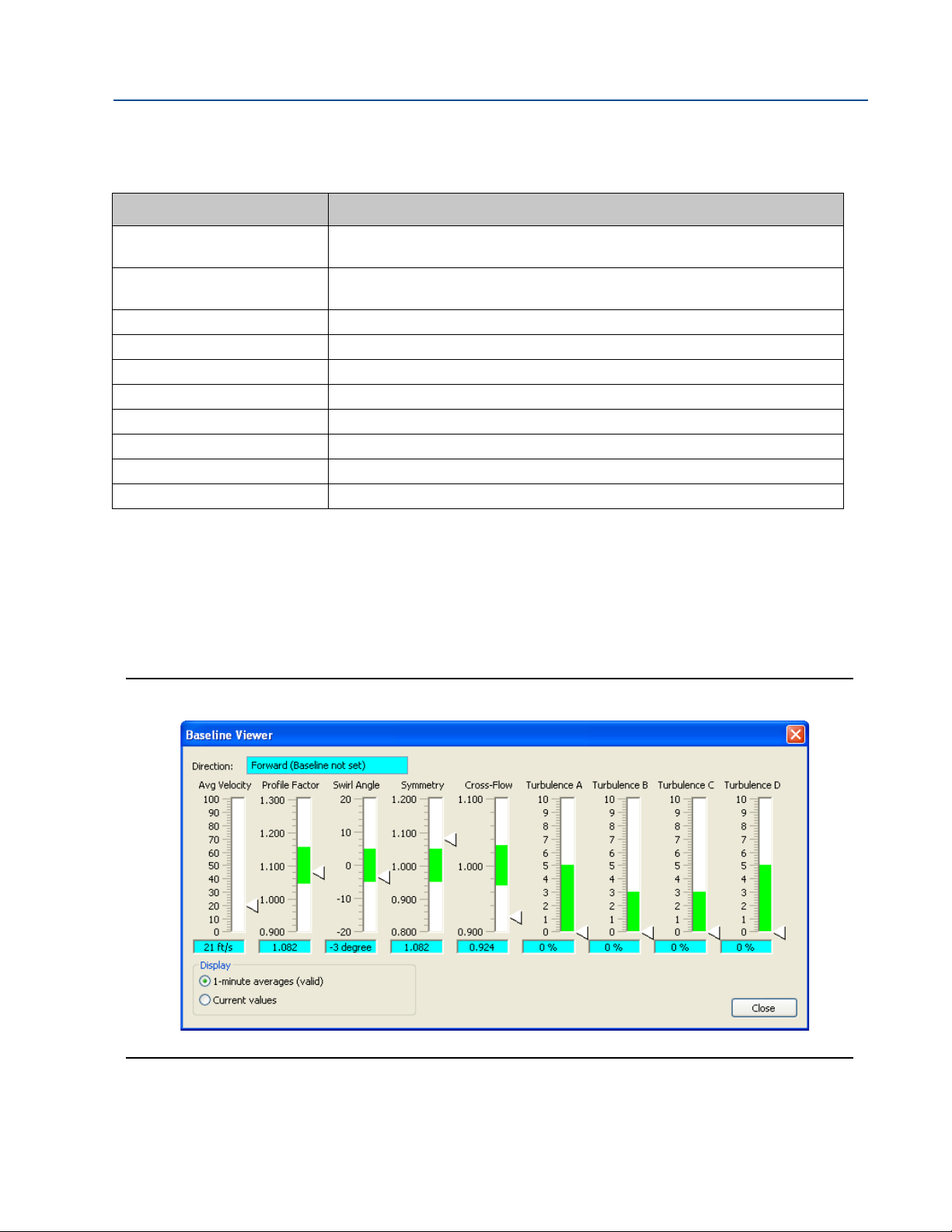

Figure 1-2 Baseline viewer............................................................................................................... 1-5

Figure 2-2 Daniel Ultrasonic Gas Flow Meter Mark III Electronics ..................................................2-12

Figure 2-3 CPU Board (switch-side view) .......................................................................................2-13

Figure 2-4 CPU Board with I.S. Interface Board Mounted (

I.S. Barrier-side view) ...................................................................................................2-14

Figure 2-5 Series 100 Option board ...............................................................................................2-14

Figure 2-6 Series 100 Plus Option Board ........................................................................................2-15

Figure 2-7 Daniel Mark III Ultrasonic Gas Flow Meter Field Connection board ................................2-15

Figure 2-8 Mark III Acquisition Module...........................................................................................2-16

Figure 2-9 SeniorSonic Model 3400 meter body .........................................................................2-17

Figure 2-10 SeniorSonic Model 3422 meter body ............................................................................2-18

Figure 2-11 JuniorSonic Model 3410 meter body ............................................................................2-19

Figure 2-12 JuniorSonic Model 3420 meter body ............................................................................2-20

Figure 2-13 T-11 (left) Transducer and T-12 Transducer (right). ...................................................... 2-21

Figure 2-14 T-21 (left) and T-22 Transducer (right) ........................................................................2-21

Figure 2-15 Mark III CPU Board General Status LED Indicators.......................................................... 2-30

Figure 2-16 Mark III CPU Board General Status LED Indicators

(I.S. Interface-Side View) .............................................................................................. 2-30

Figure 2-17 Mark III CPU Board Communication Status Indicators

(I.S. Interface-Side View) .............................................................................................. 2-31

Figure 2-18 Mark III Option Board General Status LED Indicators .....................................................2-32

Figure 2-19 Series 100 Plus Option Board General Status LED Indicators......................................... 2-33

Figure 2-20 Mark III Option Board Communication Status LED Indicators .......................................2-33

Figure 2-21 Series 100 Plus Option Board Communication

Status LED Indicators ...................................................................................................2-34

Figure 2-22 Mark III Ultrasonic flow transmitter U.L. and IECEx certification tag .............................. 2-37

Figure 3-1 Meter end flange with tapped flat-counterbore hole for hoist ring ...............................3-43

Figure 3-2 Safety approved hoist ring and non-compliant eye bolt ...............................................3-44

Figure 3-3 Ninety degree angle between slings .............................................................................3-45

Figure 3-4 Incorrect sling attachment ...........................................................................................3-46

Figure 3-5 Correct sling attachment ........................................................................................... 3-49

Figure 3-6 Incorrect sling attachment ...........................................................................................3-50

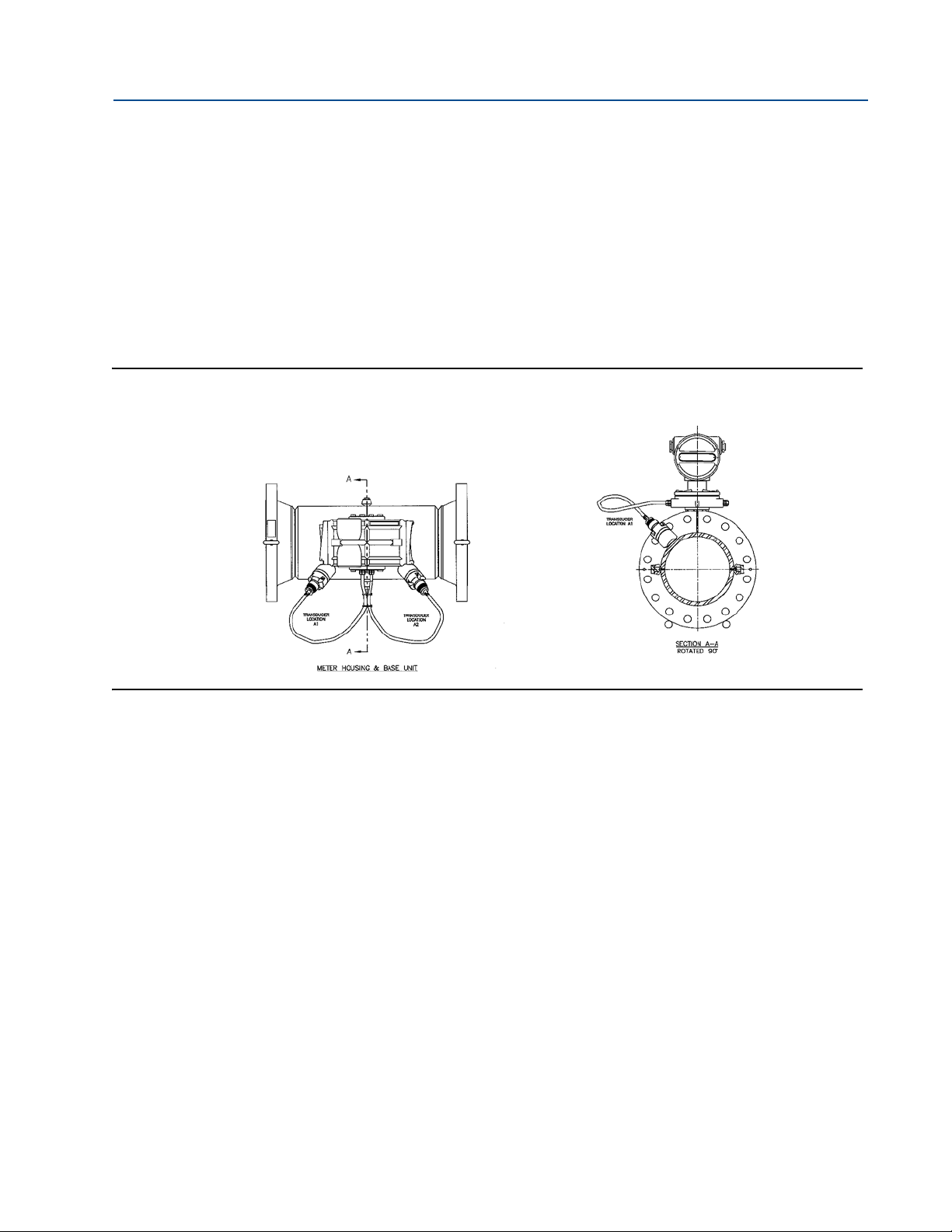

Figure 3-7 Daniel Ultrasonic Gas meter body ................................................................................3-51

Figure 3-8 Daniel Mark III Ultrasonic Gas Flow Meter .....................................................................3-53

List of Figures xiii

Page 22

List of Figures Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Figure 3-9 Upper electronics enclosure security seals ....................................................................3-54

Figure 3-10 Upper enclosure wiring card .........................................................................................3-55

Figure 3-11 Ground lug upper electronics enclosure .......................................................................3-55

Figure 3-12 Mark III base unit electronics ........................................................................................3-56

Figure 3-13 Transducer Ports and Cables Base Unit ........................................................................3-57

Figure 3-14 Field Connection Board Ethernet Connector Wiring .....................................................3-61

Figure 3-15 Port B Switch S1 Ethernet Settings ................................................................................3-61

Figure 3-16 Daniel 3400 Series Gas Ultrasonic Flow Meter

Wiring Switch Settings ................................................................................................3-66

Figure 3-17 Daniel 3400 Series Gas Ultrasonic Flow Meter

Wiring Connectors/Switches/LEDs................................................................................3-67

Figure 3-18 Option Board Wiring Connectors/Switches/LEDs ..........................................................3-68

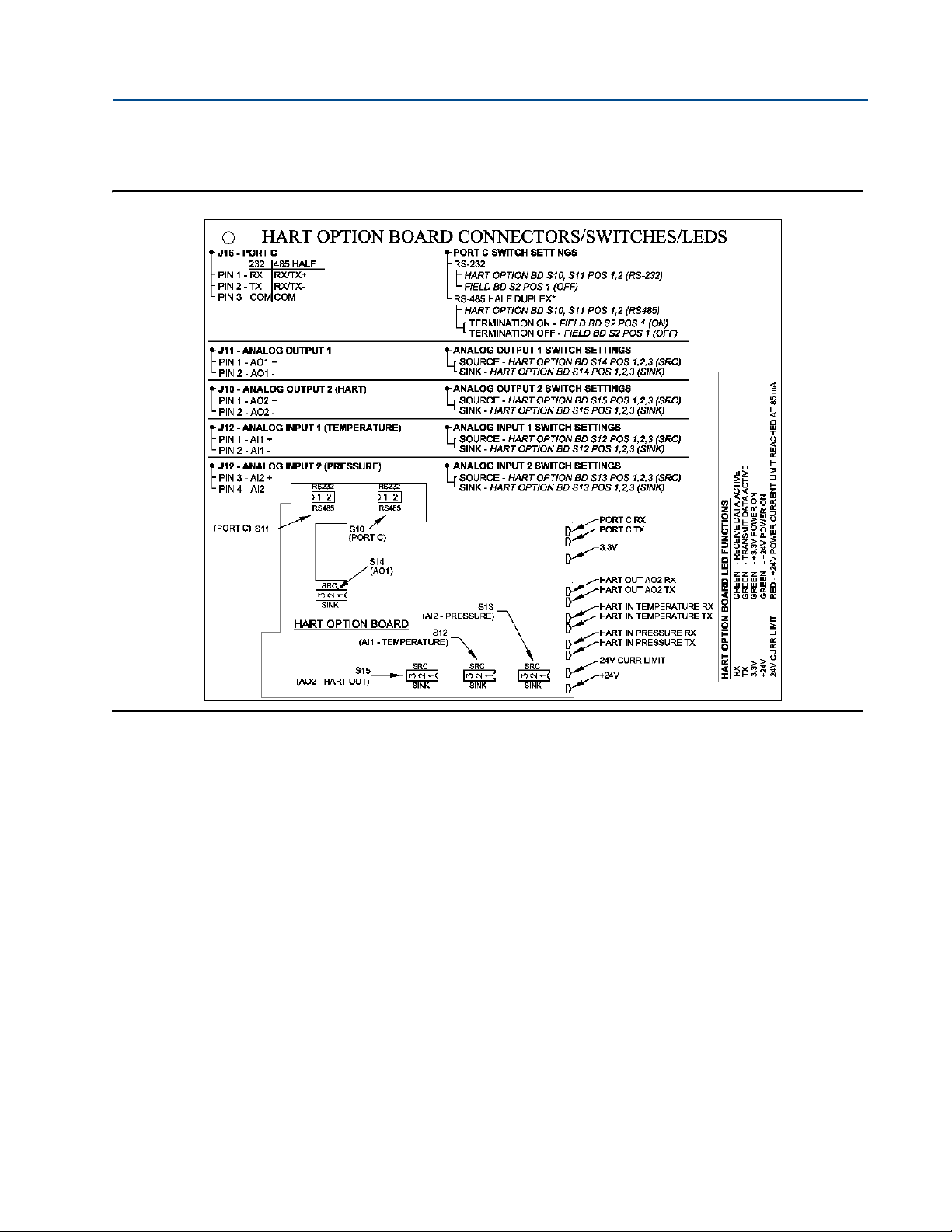

Figure 3-19 Series 100 Plus Option Board Wiring Connectors/Switches/LEDs ..................................3-69

Figure 3-20 CPU Board Switches......................................................................................................3-70

Figure 3-21 Series 100 Option Board Switches.................................................................................3-71

Figure 3-22 Series 100 Plus Option Board Switches..........................................................................3-72

Figure 3-23 Field Connection board switches ..................................................................................3-73

Figure 3-24 Field Connection and CPU Board communication

configuration switch banks ..........................................................................................3-73

Figure 3-25 CPU Board Frequency and Digital Output

configuration switch banks .........................................................................................3-79

Figure 3-26 CPU Board Switch Banks S8 and S9 ...............................................................................3-80

Figure 3-27 Upper electronics end cap security seals .......................................................................3-89

Figure 3-28 Upper electronics housing to base unit security seal .....................................................3-90

Figure 3-29 Transducer housing, cable nut and security seal ...........................................................3-91

Figure 5-1 Program directory .....................................................................................................5-105

Figure 5-2 Ethernet connections parameters...............................................................................5-105

Figure 5-3 Meter connect ............................................................................................................5-106

Figure 5-4 Communications settings Ethernet port .....................................................................5-107

Figure 5-5 Writing Ethernet port communications settings .........................................................5-118

Figure 5-6 Write protected registers ...........................................................................................5-123

Figure 5-7 Field Setup Wizard - Startup Page (Series 100 Option Board) ......................................5-132

Figure 5-8 Field Setup Wizard - Startup Page (Series 100 Plus Option Board .............................5-133

Figure 5-9 Field Setup Wizard - General Page...............................................................................5-137

Figure 5-10 Field Setup Wizard - Meter Frequency Outputs Page ..................................................5-138

xiv List of Figures

Page 23

Reference, Installation, and Operations Manual List of Figures

3-9000-743 Rev S June 2013

Figure 5-11 Field Setup Wizard - Meter Current Outputs Page .......................................................5-140

Figure 5-12 Field Setup Wizard - HART Output Page

(Series 100 Plus Option Board) ..................................................................................5-144

Figure 5-13 Field Setup Wizard - Digital Outputs Page ..................................................................5-146

Figure 5-14 Field Setup Wizard - Meter Corrections page .............................................................. 5-147

Figure 5-15 Daniel MeterLink Field Setup Wizard -

Temperature and Pressure Page ................................................................................5-149

Figure 5-16 Field Setup Wizard - Gas Chromatograph Setup page.................................................5-154

Figure 5-17 Field Setup Wizard - AGA8 Setup page........................................................................5-155

Figure 5-18 Field Setup Wizard - Continuous Flow Analysis ...........................................................5-157

Figure 5-19 Meter Monitor - Baseline Viewer ................................................................................5-159

Figure 5-20 Daniel MeterLink Update Time Wizard ......................................................................5-160

Figure 5-21 Calibration - Meter Factors Page ................................................................................5-163

Figure 5-22 Maintenance logs and reports ...................................................................................5-171

Figure 5-23 Log file pathname .....................................................................................................5-172

Figure 5-24 Maintenance Logs and Reports - Data Collection ........................................................ 5-173

Figure 6-1 SeniorSonic measurement principle ...........................................................................6-181

Figure 6-2 Juniorsonic Measurement principle ............................................................................6-182

Figure 6-4 Update time, stack size, emission rate and filter .........................................................6-183

Figure 6-5 Meter Outputs Test Page with Option Board .............................................................6-223

Figure 6-6 Meter Outputs Test page with Expansion Board with HART® .....................................6-224

Figure 6-7 Program settings dialog FTP-only connection ............................................................6-257

Figure 6-8 Port A and B direct connection settings ......................................................................6-258

Figure 7-1 J-Mount Transducer Assembly ....................................................................................7-262

Figure 7-2 J-Mount Transducer Disassembly................................................................................7-263

Figure 7-3 M-Mount Transducer Disassembly.............................................................................. 7-263

Figure 7-4 M-Mount Transducer Disassembly .............................................................................7-264

Figure 7-5 T-21 and T-22 transducer assembly ...........................................................................7-266

Figure 7-6 Transducer holder, stalk and transducer assembly......................................................7-267

Figure 7-1 Transducer holder, stalk and transducer assembly......................................................7-267

Figure 7-7 M-mount cover and chordset with “V” arrowhead mark ............................................7-268

Figure 7-8 T-22 transducer assembly, holder, transformer, retainer, cable nut and chordset ...... 7-269

Figure 7-9 Daniel MeterLink Transducer Swap-out Wizard...........................................................7-271

Figure 7-10 Excel® Tools Menu ....................................................................................................7-275

Figure 7-11 Excel® Trusted Access Setting ...................................................................................7-276

List of Figures xv

Page 24

List of Figures Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

Figure 7-12 Meter Monitor Status Alarms .....................................................................................7-278

Figure 7-13 Meter Monitor Status Summary .................................................................................7-279

Figure 7-14 Maintenance Logs and Reports Dialog ........................................................................7-282

Figure 7-15 Log collection parameters ........................................................................................7-283

Figure 7-16 Excel custom view settings ........................................................................................7-283

Figure 7-17 Maintenance logs and reports start dialog .................................................................7-284

Figure 7-18 Speed of Sound dialog ..............................................................................................7-285

Figure 7-19 Log complete dialog ..................................................................................................7-285

Figure 7-20 Microsoft® Excel report view toolbar .........................................................................7-286

Figure 7-21 Microsoft® Excel charts view ......................................................................................7-287

Figure 7-22 Microsoft® Excel inspection report view ....................................................................7-288

Figure 7-23 Microsoft® Excel Speed of Sound View ......................................................................7-289

Figure 7-24 Microsoft® Excel Meter Config View ..........................................................................7-289

Figure 7-25 Microsoft® Excel Raw Data View ................................................................................7-290

xvi List of Figures

Page 25

Reference, Installation, and Operations Manual Section 1: Introduction

3-9000-743 Rev S June 2013

11

Section 1: Introduction

1.1 Manual overview

The Daniel Ultrasonic Gas Flow Meter Daniel Mark III Ultrasonic Gas Flow Meter Electronics

Reference, Installation, and Operations Manual (P/N 3-9000-743) provides descriptions and

explanations of the Daniel Multipath SeniorSonic

JuniorSonic

The Daniel 3400 Series Gas Ultrasonic Flow Meter was originally developed and tested by British

Gas. The unit was further developed by Daniel and features hardware and electronics designed

for easy use and minimum maintenance. All parts and assemblies have been tested prior to

shipment. Daniel holds an exclusive license from British Gas, obtained in 1986, to manufacture

and sell this product.

This manual consists of the following sections and appendices:

Sections:

TM

, Model 3410 and the Dual Path JuniorSonic

TM

Model 3400 and Model 3422, Single Path

TM

Model 3420.

Section 1- Introduction

Section 2 - Product Overview

Section 3 - Installation

Section 4 - Optional Features

Section 5 - Communications and Meter Configuration

Section 6 - Meter Operation

Section 7 - Maintenance

Appendices

Appendix A - Conversion Factors

Appendix B - Miscellaneous Equations

Appendix C - Upgrading from a Mark II to a Mark III

Appendix D - Communications, Mechanical, Electrical, Troubleshooting

Appendix E - Meter Setup and Configuration Worksheet

Appendix F - Flow Rate Summary

Appendix G - Write-Protected Configuration Parameters

Appendix H - Open Source Licenses

Appendix I - Engineering Drawings

Appendix J - Daniel Ultrasonic Gas Flow Meter Index

Manual overview 1

Page 26

Section 1: Introduction Reference, Installation, and Operations Manual

June 2013 3-9000-743 Rev S

1.2 Definitions, acronyms, abbreviations

The following terms, acronyms, and abbreviations are used in this document:

Table 1-1 Gas Ultrasonic Meter acronyms, abbreviations and definitions

Acronym or abbreviation Definition

° degree (angle)

o

C

o

F

ADC analog-to-digital converter

AGA American Gas Association

AI analog input

AMS™ Suite Asset Management Software

AO analog output

ASCII MODBUS A Modbus protocol message framing format in which ASCII characters are used to

boolean a type of data point that can only take on values of TRUE or FALSE (generally TRUE is

bps bits per second (baud rate)

Btu British thermal unit (heat unit)

cfh cubic feet per hour

cPoise centipoise (viscosity unit)

CPU central processing unit

CTS Clear-to-Send; the RS-232C handshaking signal input to a transmitter indicating that

DAC Digital-to-Analog Converter

Daniel CUI Daniel Customer Ultrasonic Interface

Daniel MeterLink Daniel software application for ultrasonic flow meters

DI digital input

DO digital output

Daniel MeterLink Daniel Customer User Interface

DHCP Dynamic Host Configuration Protocol

dm

ECC Error Correction Code

EEPROM Electrically-Erasable, Programmable Read-Only Memory

Flash non-volatile, programmable read-only memory

degrees celsius (temperature unit)

degrees fahrenheit (temperature unit)

delineate the beginning and end of the frame. ASCII stands for American Standard

Code for Information Interchange.

represented by a value of 1, FALSE is represented by a value of 0)

it is okay to transmit data – i.e., the corresponding receiver is ready to receive data.

Generally, the Request-to-Send (RTS) output from a receiver is input to the Clear-toSend (CTS) input of a transmitter.

decimeter (10

-1

meters, length unit)

2 Definitions, acronyms, abbreviations

Page 27

Reference, Installation, and Operations Manual Section 1: Introduction

3-9000-743 Rev S June 2013

Table 1-1 Gas Ultrasonic Meter acronyms, abbreviations and definitions

Acronym or abbreviation Definition

ft feet (length unit)

3

/d

ft

ft3/h

3

ft

/s

GC gas chromatograph

g-mol gram mole

HART®

hr hour (time unit)

Hz hertz (cycles per second, frequency unit)

I/O Input/Output

IS Intrinsically Safe

K kelvin (temperature unit)

3

kcal/m

kg kilogram (mass unit)

kg-mol kilogram mole

kg/d kilograms per day (mass rate)

kg/h kilograms per hour (mass rate)

kg/s kilograms per second (mass rate)

kHz

kJ

3

kJ/m

3

kwh/m

LAN Local Area Network

lbm pound mass

lbm-mol pound mass mole

lbm/d pounds (mass) per day (mass rate)

lbm/h pounds (mass) per hour (mass rate)

lbm/s pound (mass) per second (mass rate)

LED light-emitting diode

m meter (length unit)

3

m

/d

cubic feet per day (volumetric flow rate)

cubic feet per hour (volumetric flow rate)

cubic feet per second (volumetric flow rate)

Highway Addressable Remote Transducer

kilocalories per cubic meter (heating value)

kilohertz (103 cycles per second, frequency unit)

3