Page 1

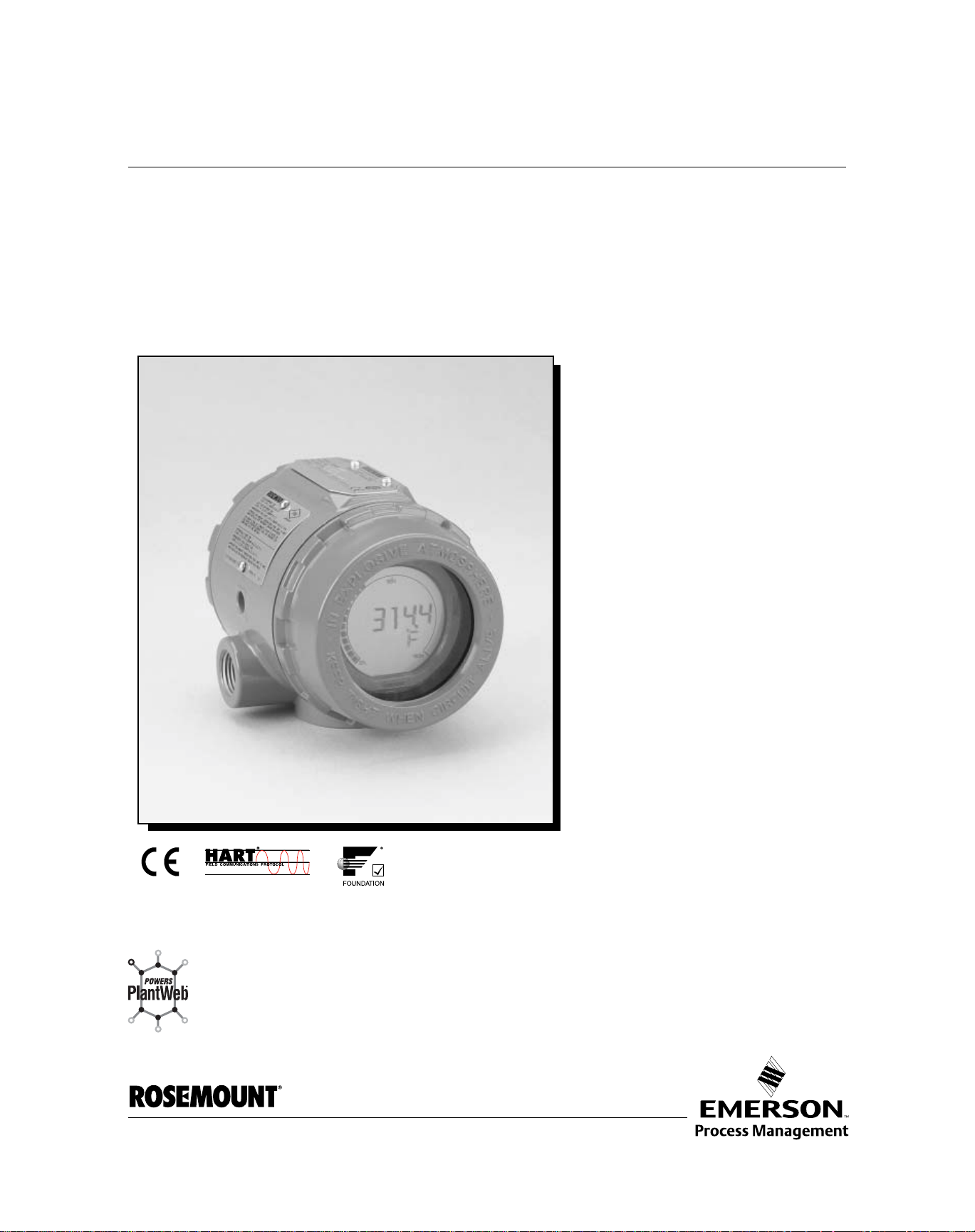

Reference Manual

b

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P Temperature Transmitter

This product is a core

component of the PlantWe

digital plant architecture.

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Rosemount 3144P Temperature

Transmitter

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers:

Customer Central

Technical support, quoting, and order-related questions.

1-800-999-9307 (7:00 am to 7:00 pm CST)

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours)

International

(952)-906-8888

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson

Process Management Sales Representative.

Rosemount 3144P Temperature Transmitter may be protected by one or more U.S. Patents

Pending. Other foreign patents pending.

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4021, Rev DA

November 2004

Table of Contents

Rosemount 3144P

SECTION 1

Introduction

SECTION 2

Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Moist or Corrosive Environments . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Rosemount 3144P and Rosemount 3144 / 3244MV Differences . . . . 1-6

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Setting the Loop to Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Set the Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Typical North American Installation . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Typical European Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

In Conjunction with a Rosemount 333 HART Tri-Loop

(HART / 4–20 mA only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Multichannel Installation (HART / 4–20 mA only) . . . . . . . . . . . . . 2-10

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

HART / 4–20 mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Foundation Fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sensor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Surges/Transients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

www.rosemount.com

Page 6

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

SECTION 3

HART Commissioning

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

375 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Updating the HART Communication Software . . . . . . . . . . . . . . . . 3-2

Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Fast Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

AMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Apply AMS Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Check Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Device Output Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Device Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Measurement Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Multidrop Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Use with the HART Tri-Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Trim the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Sensor Input Trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Transmitter-Sensor Matching . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

D/A Output Trim or Scaled Output Trim . . . . . . . . . . . . . . . . . . . . 3-33

Output Trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Scaled Output Trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

HART / 4–20 mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

AMS Software (HART / 4-20 mA only) . . . . . . . . . . . . . . . . . . . . . 3-39

AMS Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

SECTION 4

Foundation Fieldbus

Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

General Block Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Device Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Node Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Link Active Scheduler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Block Instantiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Foundation fieldbus function blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Resource Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

FEATURES and FEATURES_SEL . . . . . . . . . . . . . . . . . . . . . . . . 4-5

PlantWeb

Recommended Actions for PlantWeb Alerts . . . . . . . . . . . . . . . . . 4-9

Resource Block Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Sensor Transducer Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Sensor Transducer Block Diagnostics . . . . . . . . . . . . . . . . . . . . . 4-10

LCD Transducer Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Custom Meter Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Self Test Procedure for the LCD . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

LCD Transducer Block Diagnostics . . . . . . . . . . . . . . . . . . . . . . . 4-13

™

Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

TOC-2

Page 7

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Analog Input (AI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Simulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Configure the AI block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Process Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Advanced Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Analog Input Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Trim the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Statistical Process Monitoring (SPM) . . . . . . . . . . . . . . . . . . . . . . 4-22

SPM Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Troubleshooting Guides. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Foundation Fieldbus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

SECTION 5

Maintenance

SECTION 6

Certified Safety

Instrumented System

(SIS)

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Test Terminal (HART / 4–20 mA only) . . . . . . . . . . . . . . . . . . . . . . 5-2

Sensor Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Electronics Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

3144P SIS Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

SIS Additions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Transmitter Diagnostics Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

375 Field communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

3144P SIS Menu Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

3144P SIS Fast Key Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Operation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Proof Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Failure Rate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Product Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

SECTION 7

Prior Use (PU) Safety

Instrumented System

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Safe Failure Fraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Changing Switch Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

TOC-3

Page 8

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

HART and Foundation Fieldbus Specifications . . . . . . . . . . . . . . . . . .A-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

HART / 4–20 mA Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Foundation Fieldbus Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

Dimensional Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Rosemount 3144P With HART / 4–20 mA. . . . . . . . . . . . . . . . . . . . . . B-1

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Union Directive Information . . . . . . . . . . . . . . . . . . . . . . B-1

Hazardous Locations Installations . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Rosemount 3144P With Foundation fieldbus . . . . . . . . . . . . . . . . . . .B-6

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . B-6

European Union Directive Information . . . . . . . . . . . . . . . . . . . . . . B-6

Hazardous Locations Installations . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Installation Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

TOC-4

Page 9

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Section 1 Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

Return of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

Rosemount 3144P and Rosemount 3144 / 3244MV Differences page 1-6

OVERVIEW

Manual This manual is designed to assist in the installation, operation, and

maintenance of the Rosemount 3144P.

Section 1: Introduction

• Transmitter and Manual Overview

• Considerations

• Return of Material

Section 2: Installation

• Mounting

• Installation

• Wiring

• Power Supply

Section 3: HART Configuration

• 375 Field Communicator

• Configuration

• Multidrop Communication

• Calibration

• Trim the transmitter

Section 4: F

• Calibration

• Hardware Maintenance

• Diagnostic Messaging

• Trim the Transmitter

Section 5: Operation and Maintenance

• Maintenance

• Troubleshooting

OUNDATION Fieldbus Configuration

www.rosemount.com

Page 10

Rosemount 3144P

Appendix A: Specifications and Reference Data

• Specifications

• Dimensional drawings

• Ordering Information

Appendix B: Approvals

• Product Certifications

• Installation Drawings

Safety Instrumented System (SIS) – HART only

• Information regarding Safety Certified transmitters

Transmitter Features of the Rosemount 3144P include:

• Accepts inputs from a wide variety of sensors

• Configuration using HART protocol or F

• Electronics that are completely encapsulated in epoxy and enclosed in

a metal housing, making the transmitter extremely durable and

ensuring long-term reliability

• A compact size and two housing options allowing mounting flexibility for

the control room or the field

• Special dual-sensor features include Hot Backup

first good, differential and average temperature measurements, and

four simultaneous measurement variable outputs in addition to the

analog output signal

Reference Manual

00809-0100-4021, Rev DA

November 2004

OUNDATION fieldbus

®

, sensor drift alarm,

Refer to the following literature for a full range of compatible connection

heads, sensors, and thermowells provided by Emerson Process

Management.

• Temperature Sensors and Assemblies Product Data Sheet, Volume 1

(document number 00813-0100-2654)

• Temperature Sensors and Assemblies Product Data Sheet, Metric

(document number 00813-0200-2654)

CONSIDERATIONS

General Electrical temperature sensors, such as resistance temperature detectors

(RTDs) and thermocouples (T/Cs), produce low-level signals proportional to

temperature. The 3144P transmitter converts low-level signals to HART or

F

OUNDATION fieldbus signals. This signal is then transmitted to the control

room via two power/signal wires.

Electrical Proper electrical installation is essential to prevent errors due to sensor lead

resistance and electrical noise. The current loop must have between 250 and

1100 ohms resistance for HART communications. Refer to Figure 2-10 on

page 2-11 for sensor and current loop connections. F

devices must have proper termination and power conditioning for reliable

operation. Shield cables must be used for F

may only be grounded in one place.

OUNDATION fieldbus and the shield

OUNDATION fieldbus

1-2

Page 11

Reference Manual

00809-0100-4021, Rev DA

November 2004

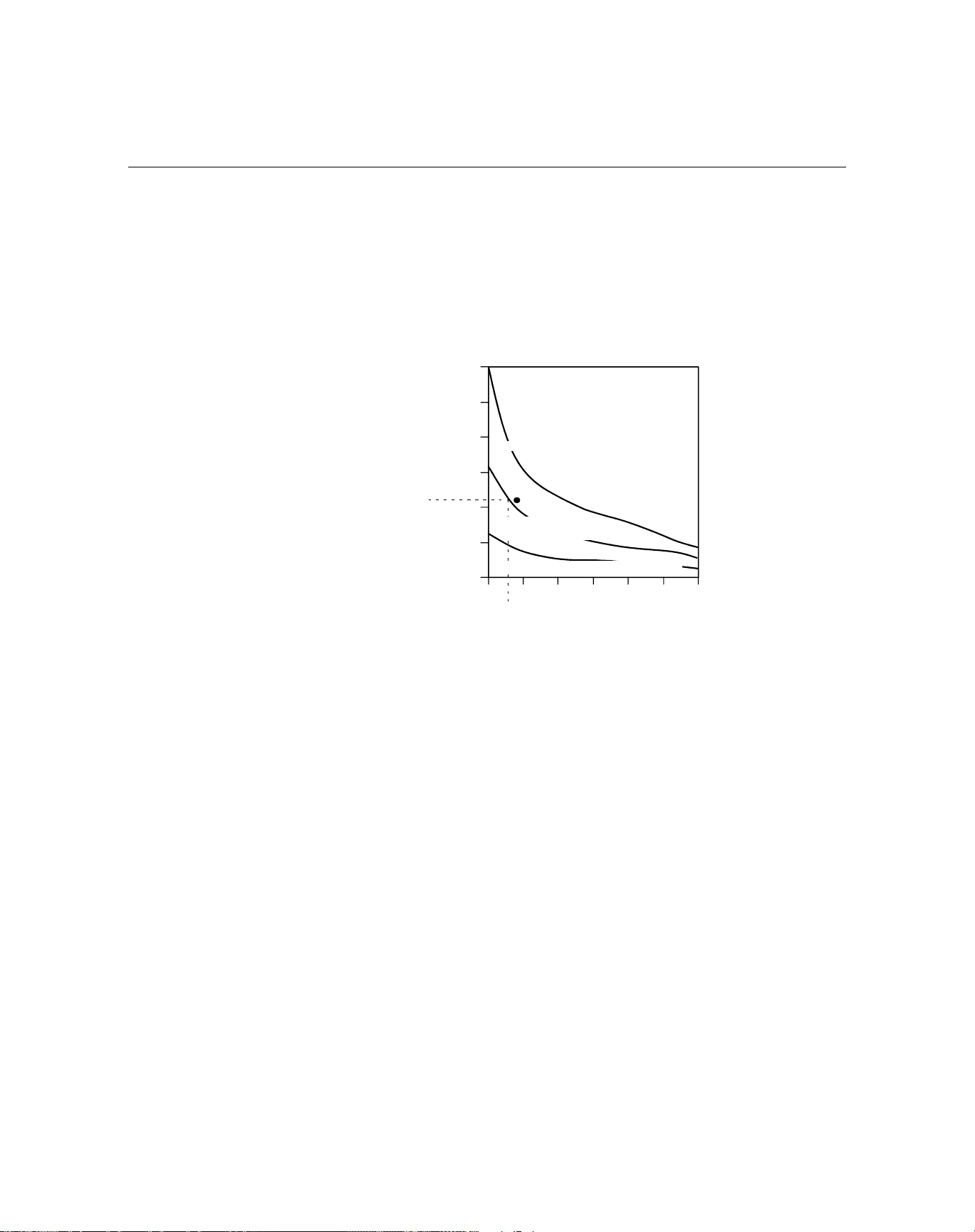

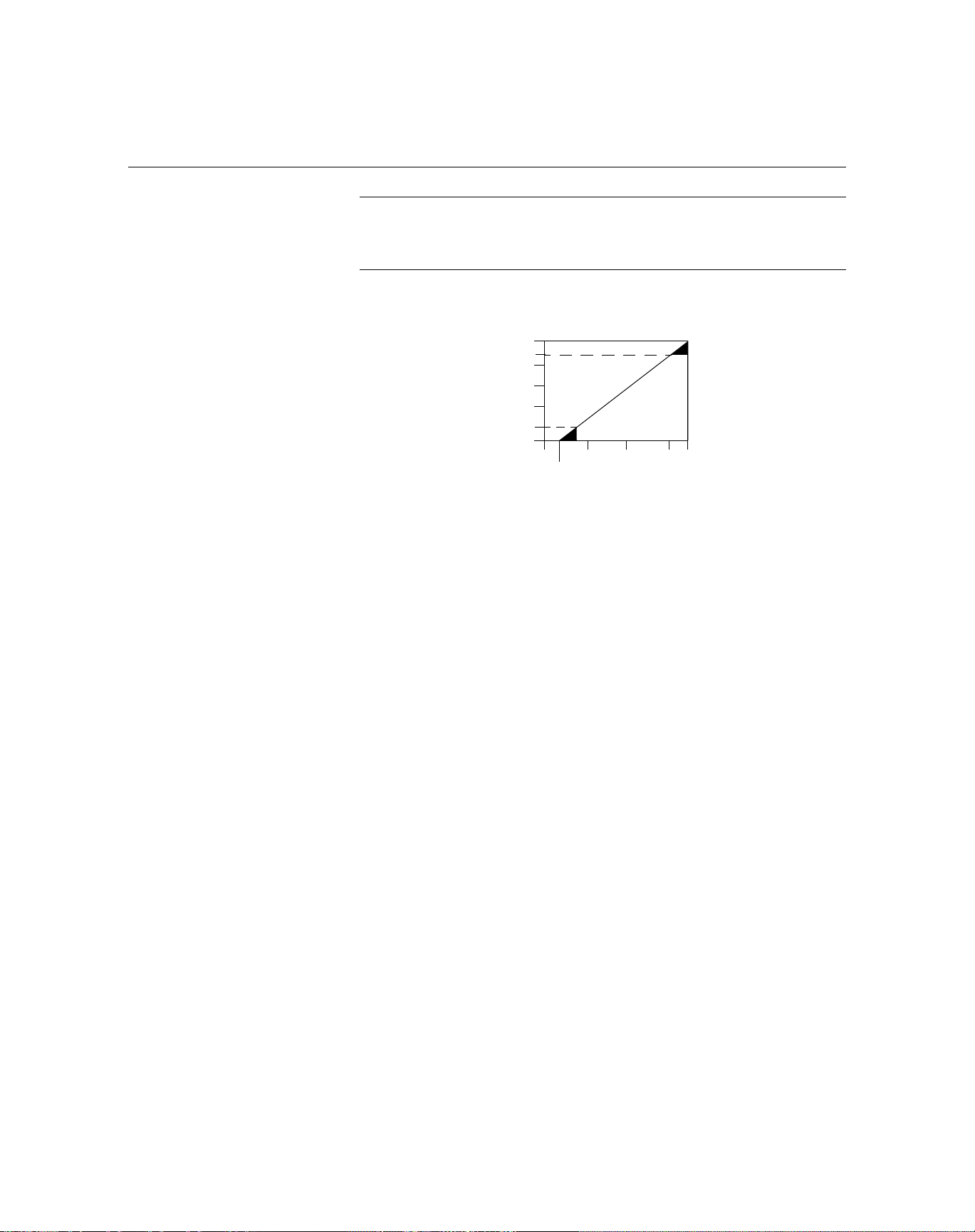

Environmental Temperature Effects

The transmitter will operate within specifications for ambient temperatures

between –40 and 185 °F (–40 and 85 °C). Heat from the process is

transferred from the thermowell to the transmitter housing. If the expected

process temperature is near or beyond specification limits, consider the use of

additional thermowell lagging, an extension nipple, or a remote mounting

configuration to isolate the transmitter from the process. Figure 1-1 describes

the relationship between housing temperature rise and extension length.

Rosemount 3144P

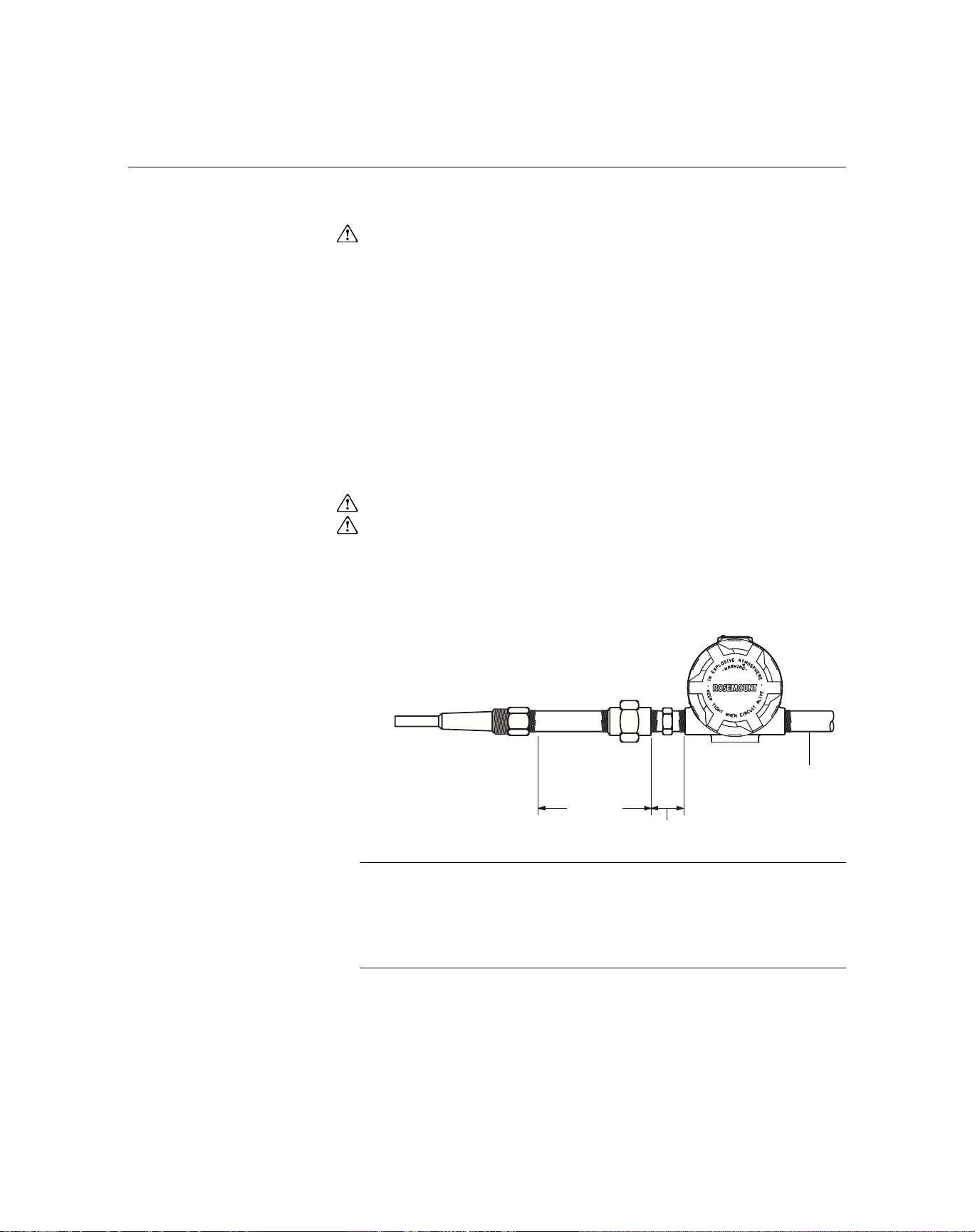

Figure 1-1. 3144P Transmitter

Housing Temperature Rise

versus Extension Length for a

Test Installation.

60 (108)

50 (90)

40 (72)

30 (54)

22

Ambient °C (°F)

Housing Temperature Rise, Above

20 (36)

10 (18)

815 °C (1500 °F) Oven Temperature

540 °C (1000 °F)

Oven Temperature

250 °C (482 °F) Oven Temperature

0

3 4 5 6 7 8 9

3.6

Extension Length (in.)

Example:

The maximum permissible housing temperature rise (T) can be calculated

by subtracting the maximum ambient temperature (A) from the

transmitter’s ambient temperature specification limit (S). For instance,

suppose A = 40 °C.

T = S - A

T = 85 °C – 40 °C

T = 45 °C

3044-0123A

Moist or Corrosive

Environments

For a process temperature of 540 °C (1004 °F), an extension length of 3.6

inches (91.4 mm) yields a housing temperature rise (R) of 22 °C (72 °F),

which provides a safety margin of 23 °C (73 °F). A six-inch extension

length (R = 10 °C (50 °F)) would offer a higher safety margin (35 °C (95

°F)) and would reduce temperature-effect errors but would probably

require extra transmitter support. Gauge the requirements for individual

applications along this scale. If a thermowell with lagging is used, the

extension length may be reduced by the length of the lagging.

The 3144P temperature transmitter has a highly reliable dual compartment

housing designed to resist moisture and corrosion. The sealed electronics

module is mounted in a compartment that is isolated from the terminal side

conduit entries. O-ring seals protect the interior when the covers are properly

installed. In humid environments, however, it is possible for moisture to

accumulate in conduit lines and drain into the housing.

1-3

Page 12

Reference Manual

00809-0100-4021, Rev DA

Rosemount 3144P

NOTE

Each transmitter is marked with a tag indicating the approvals. Install the

transmitter in accordance with all applicable installation codes and approval

and installation drawings (see Appendix B: Product Certifications). Verify that

the operating atmosphere of the transmitter is consistent with the hazardous

locations certifications. Once a device labeled with multiple approval types is

installed, it should not be reinstalled using any of the other labeled approval

types. To ensure this, the approval label should be permanently marked to

distinguish the used from the unused approval type(s).

November 2004

Mounting Take into account the need for access to the transmitter when choosing an

installation location and position.

Terminal Side of Electronics Housing

Mount the transmitter so the terminal side is accessible. Allow adequate

clearance for cover removal. Make wiring connections through the conduit

openings on the bottom of the housing.

Circuit Side of Electronics Housing

Mount the transmitter so the circuit side is accessible. Provide adequate

clearance for cover removal. Additional room is required for LCD installation.

The transmitter may be mounted directly to or remotely from the sensor.

Using optional mounting brackets, the transmitter may be mounted to a flat

surface or to a two-inch diameter pipe (see “Optional Transmitter Mounting

Brackets” on page A-8).

Software Compatibility Replacement transmitters may contain revised software that is not fully

compatible with the existing software. The 375 Field Communicator and AMS

software containing device descriptors for the 3144 and 3244MV before

December 2001 do not fully support the new features of the 3144P. The

Device Descriptors (DD) are available with new communicators or can be

loaded into existing communicators at any Emerson Process Management

Service Center.

1-4

Page 13

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

RETURN OF MATERIALS To expedite the return process in North America, call the Emerson Process

Management National Response Center (800-654-7768). This center, will

assist you with any needed information or materials.

The center will ask for the following information:

• Product model

• Serial numbers

• The last process material to which the product was exposed

The center will provide

• A Return Material Authorization (RMA) number

• Instructions and procedures that are necessary to return goods that

were exposed to hazardous substances

For other locations, contact a Emerson Process Management representative.

NOTE

If a hazardous substance is identified, a Material Safety Data Sheet (MSDS),

required by law to be available to people exposed to specific hazardous

substances, must be included with the returned materials.

1-5

Page 14

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

ROSEMOUNT 3144P

AND ROSEMOUNT 3144 /

3244MV DIFFERENCES

The following table identifies the differences between the Rosemount 3144P

and Rosemount 3144 and 3244MV Temperature Transmitters.

Improved Rosemount 3144P Previous Rosemount 3144 and 3244MV

Field Device Revision number 3 Standard 3144P: Dev v3, DD v2

Software Revision number 3 Software Revision number 1

Added sensor input types: DIN Type L, DIN

Type U, and extended temperature range of

Type N

Uses custom-configurable alarm limits Analog output and alarm levels can be ordered

Improved 2- and 3-wire EMF compensation NA

First Good Temperature is available as a

device variable

2-wire fixed lead correction is available NA

Enhanced EMI rejection and filtering resulting

in unmatched stability in process measurement

Dual-sensor configuration is field selectable Rosemount 3144 – single sensor

3144P SIS: Dev v1, DD v1 (for SIS)

NA

to be NAMUR-compliant with option codes A1

and CN

NA

NA

Rosemount 3244MV – dual-sensor configuration

1-6

Page 15

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Section 2 Installation

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-10

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-14

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

potentially raises safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres when the circuit

is live.

• Before connecting a 375 Field Communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe

or non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

Process leaks could result in death or serious injury:

• Install and tighten thermowells or sensors before applying pressure, or process

leakage may result.

• Do not remove the thermowell while in operation. Removing while in operation

may cause process fluid leaks.

Electrical shock could cause death or serious injury. If the sensor is installed in a

high-voltage environment and a fault or installation error occurs, high voltage may be

present on the transmitter leads and terminals:

• Use extreme caution when making contact with the leads and terminals.

www.rosemount.com

Page 16

Reference Manual

00809-0100-4021, Rev DA

Rosemount 3144P

November 2004

COMMISSIONING The 3144P must be configured for certain basic variables to operate. In many

cases, all of these variables are pre-configured at the factory. Configuration

may be required if the configuration variables need to be changed.

Commissioning consists of testing the transmitter and verifying transmitter

configuration data. Rosemount 3144P transmitters can be commissioned

either before or after installation. Commissioning the transmitter on the bench

before installation using a 375 Field Communicator or AMS ensures that all

transmitter components are in working order.

For more information on using the Field Communicator with the 3144P

transmitter, see “HART Commissioning” on page 3-1. For more information on

using the 3144 with Foundation fieldbus, see “Foundation Fieldbus

Configuration” on page 4-1.

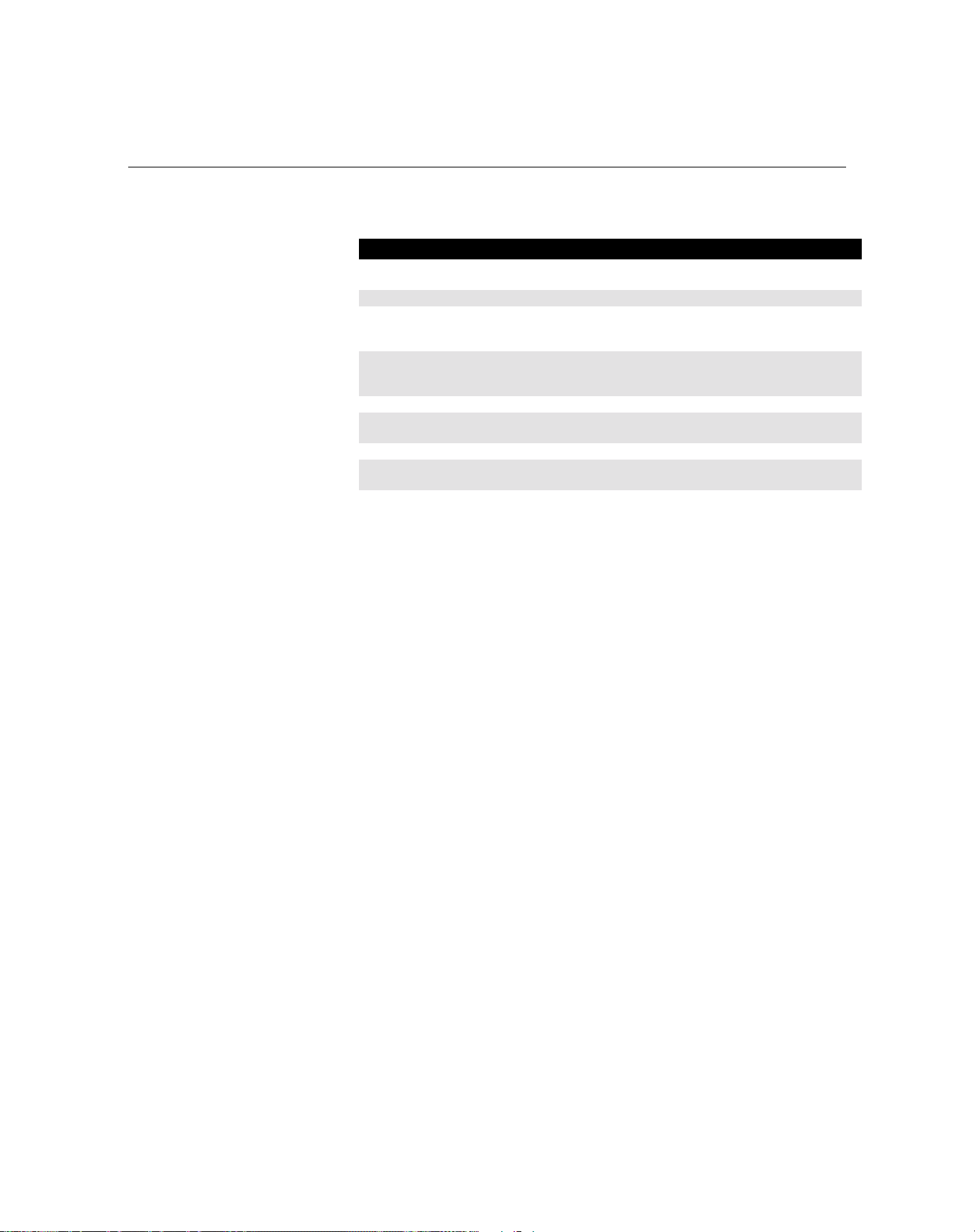

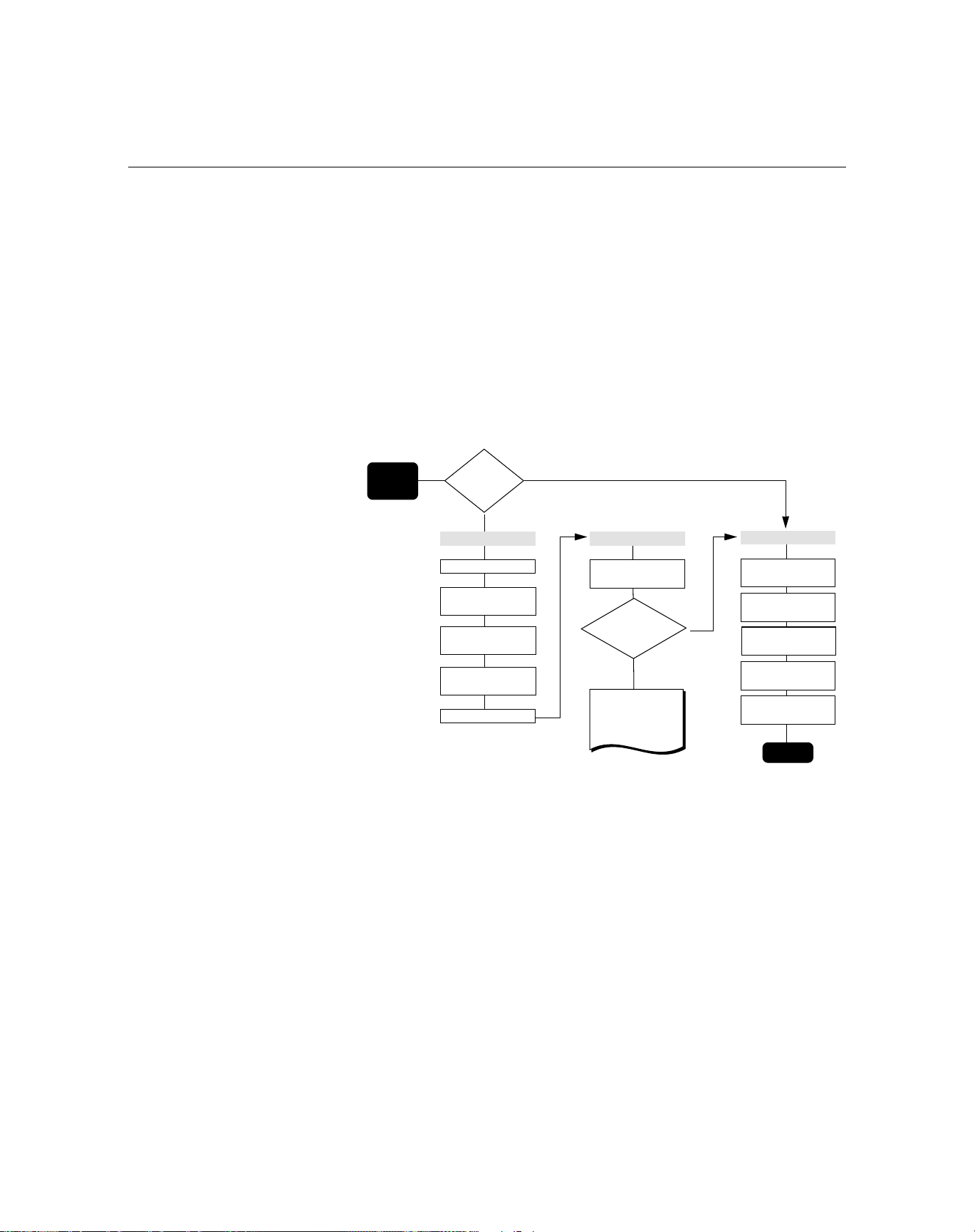

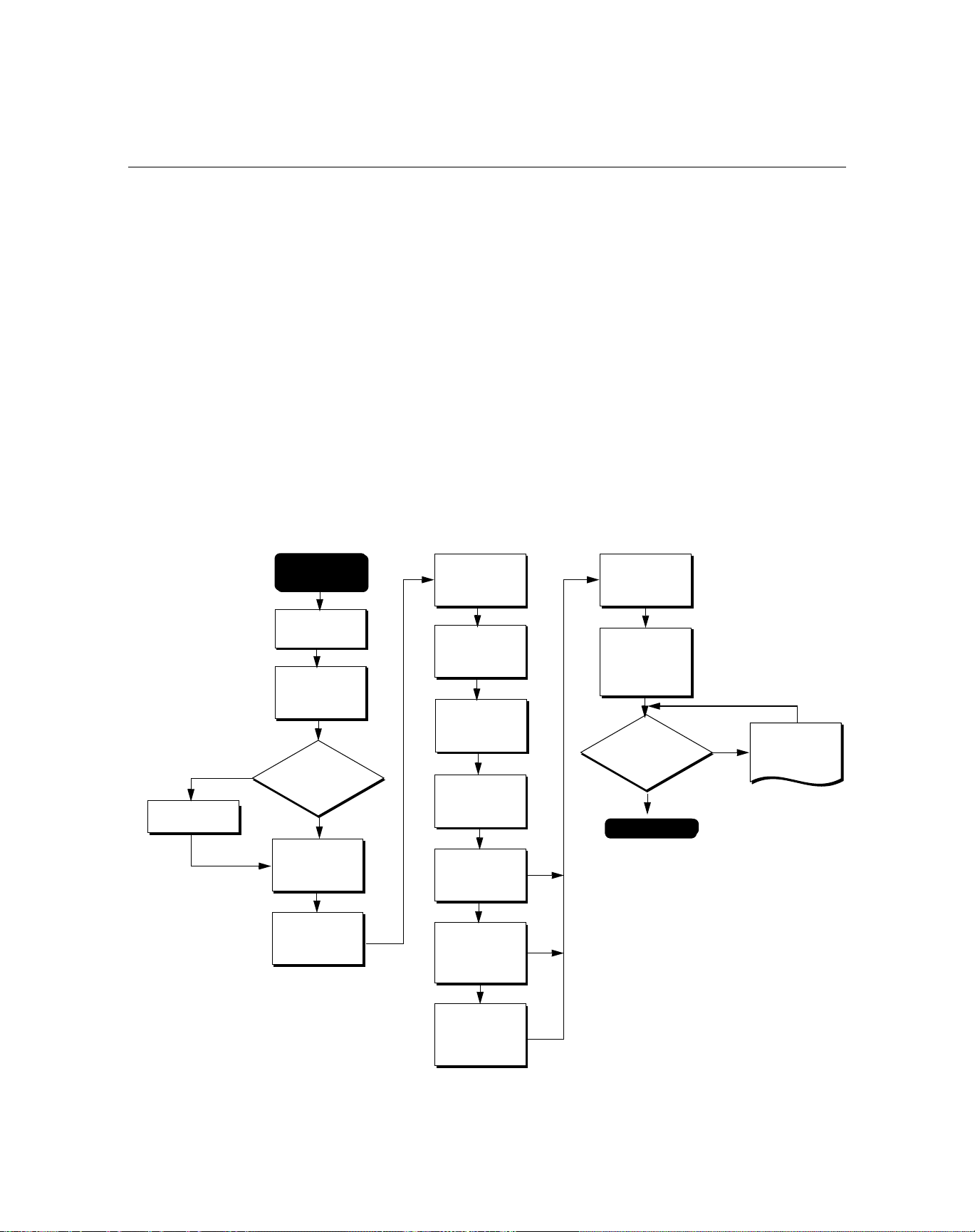

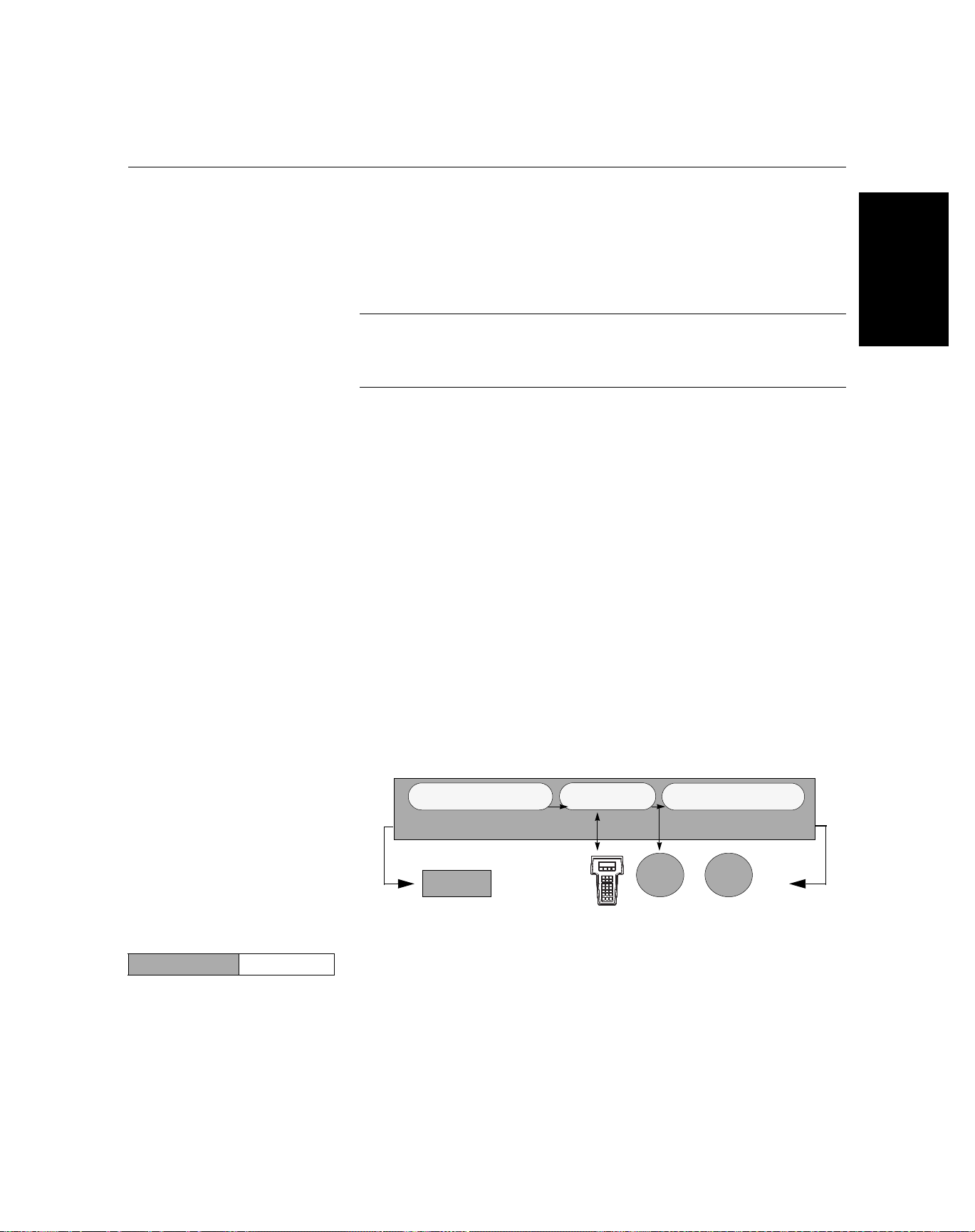

Figure 2-1. Installation

Flowchart.

START

HERE

Bench

Calibration?

Yes

BASIC SETUP

No

VERIFY

FIELD INSTALL

Setting the Loop to

Manual

Set Units

Set Range

Values - HART

Set Sensor

Typ es

Set Number

of Wires

Set Damping

Simulate

Sensor Input

Within

Specifications?

No

Refer to

Section 1:

Maintenance

Yes

Set Jumpers or

Switches

Mount the

Transmitter

Wire the

Transmitter

Power the

Transmitter

Check for

Process Leaks

Done

When sending or requesting data that would disrupt the loop or change the

output of the transmitter, set the process application loop to manual. The 375

Field Communicator or AMS will prompt you to set the loop to manual when

necessary. Acknowledging this prompt does not set the loop to manual. The

prompt is only a reminder; set the loop to manual as a separate operation.

2-2

Page 17

Reference Manual

00809-0100-4021, Rev DA

November 2004

Set the Switches HART

Without a LCD display

1. If the transmitter is installed in a loop, set the loop to manual mode and

2. Remove the housing cover on the electronics side of the transmitter.

3. Set the switches to the desired position (see Figure 2-1).

4. Replace the transmitter cover. Both transmitter covers must be fully

5. Apply power and set the loop to automatic mode.

With a LCD display

1. If the transmitter is installed in a loop, set the loop to manual mode and

2. Remove the housing cover on the electronics side of the transmitter.

3. Remove the housing cover, unscrew the LCD display screws and

4. Set the switches to the desired position (see Figure 2-1).

5. Gently slide the LCD display back into place, taking extra precautions

6. Secure the LCD display by replacing the LCD display screws.

7. Replace the transmitter cover. Both transmitter covers must be fully

8. Apply power and set the loop to automatic mode.

Rosemount 3144P

disconnect power.

Do not remove the transmitter cover in explosive atmospheres when

the circuit is live.

engaged to meet explosion-proof requirements.

disconnect power.

Do not remove the transmitter cover in explosive atmospheres when

the circuit is live.

gently slide the meter straight off.

of the 10 pin connection.

engaged to meet explosion-proof requirements.

Foundation Fieldbus

Without a LCD Display

1. If the transmitter is installed in a loop, set the loop to Out-of-Service

(OOS) mode (if applicable) and disconnect the power.

2. Remove the electronics housing cover.

3. Set the switches to the desired position. Reattach housing cover.

4. Apply power and set the loop to In-Service mode.

With a LCD Display

1. If the transmitter is installed in a loop, set the loop to Out-of-Service

(OOS) (if applicable) and disconnect the power.

2. Remove the electronics housing cover.

3. Unscrew the LCD display screws and pull the meter straight off.

4. Set the switches to the desired position.

5. Reattach the LCD display and electronics housing cover (consider LCD

display orientation).

6. Apply power and set the loop to In-Service mode.

2-3

Page 18

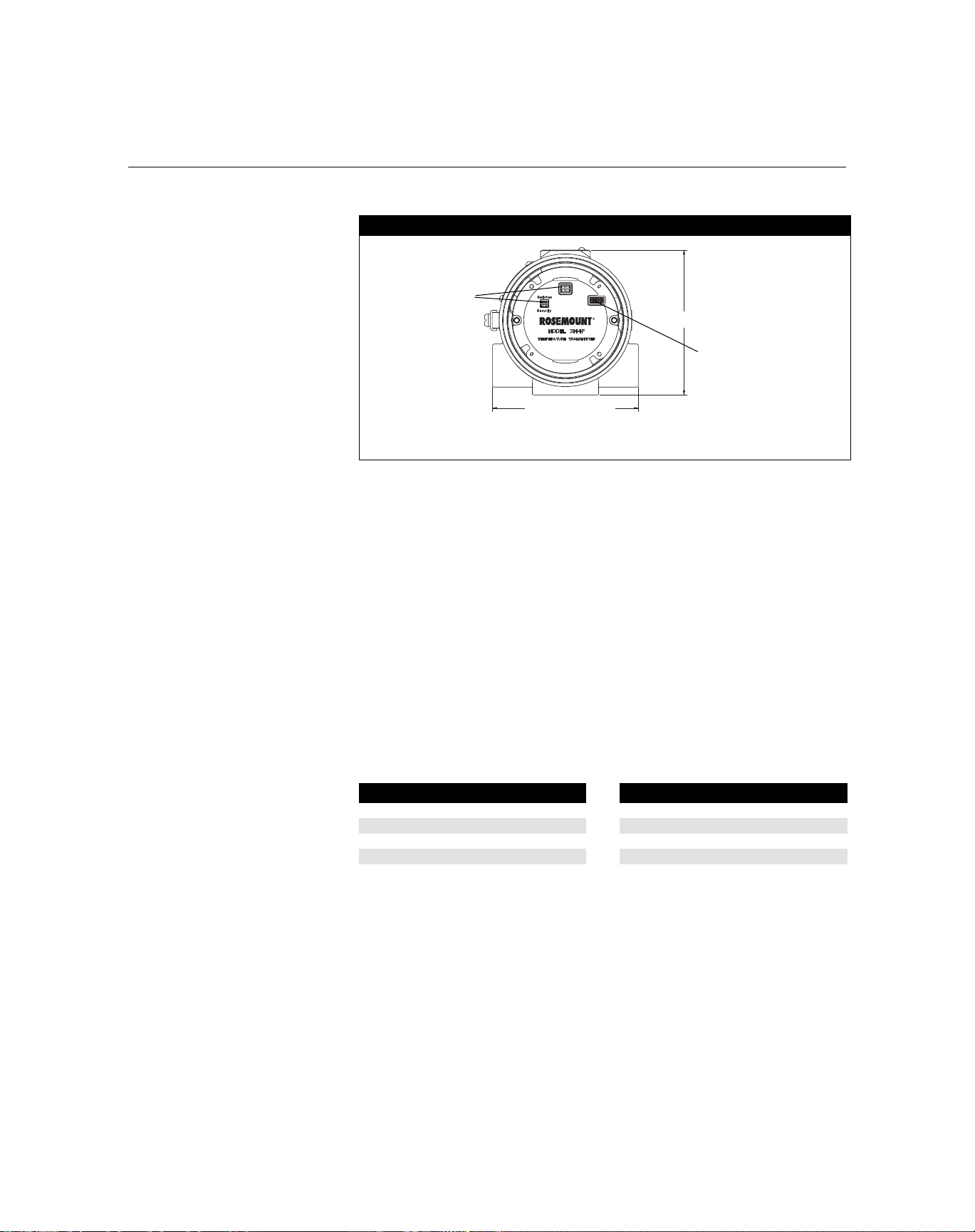

Rosemount 3144P

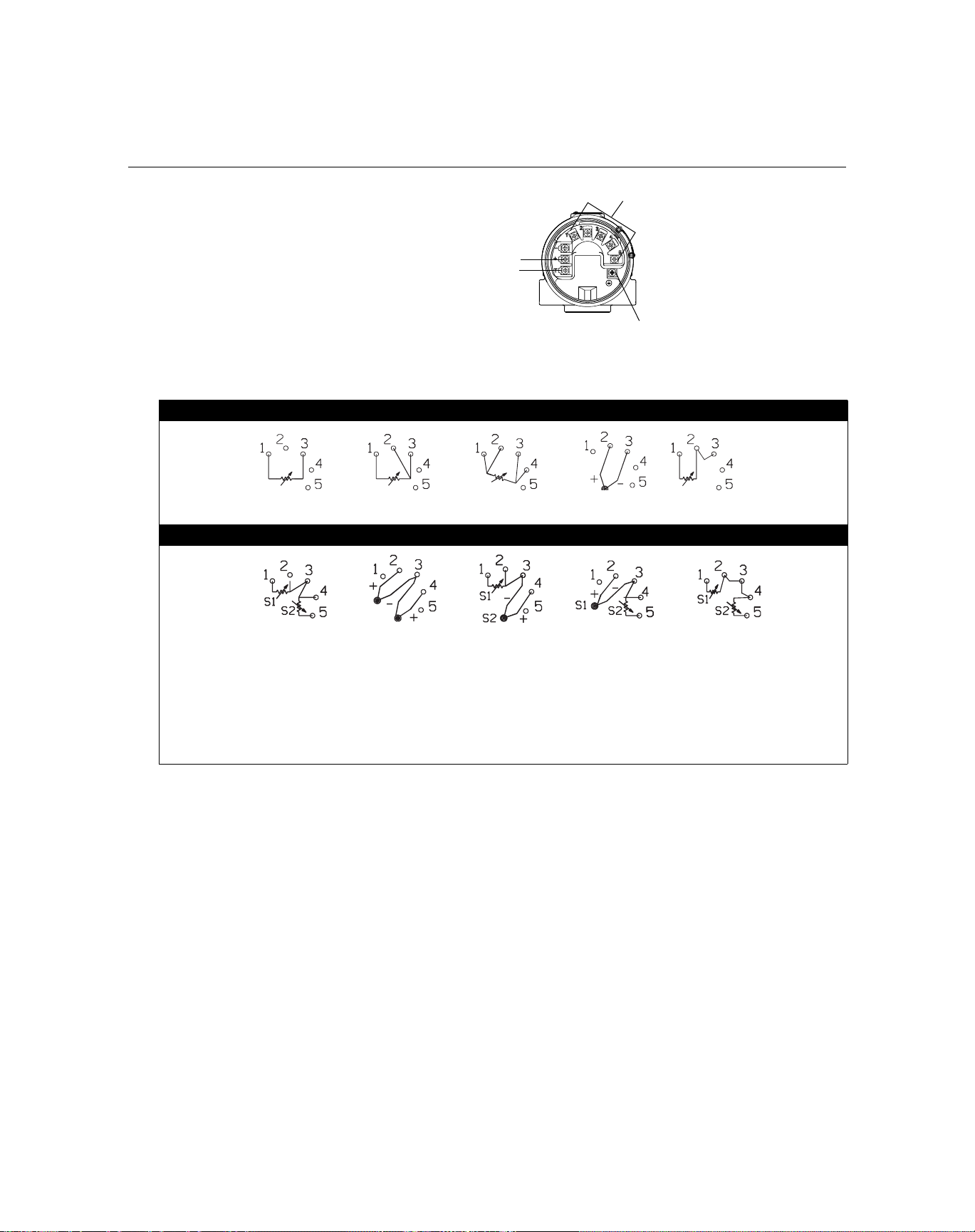

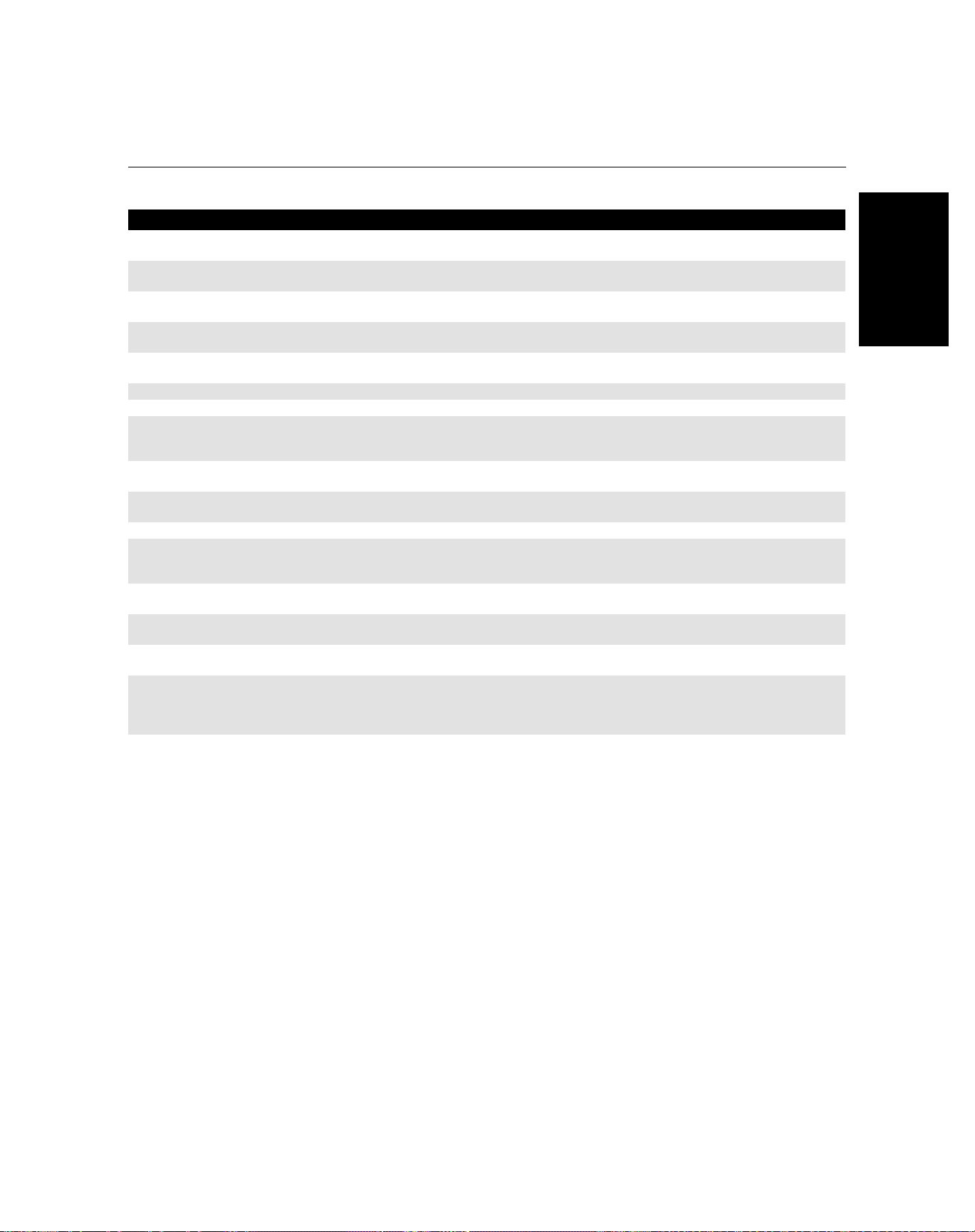

Table 2-1. Transmitter Switch

Locations.

Reference Manual

00809-0100-4021, Rev DA

November 2004

Switch Location

Switches

Write Protect Switch (HART and F

(1)

4.4 in. (112 mm)

(1) Alarm and Write Protect (HART),

Simulate and Write Protect (F

OUNDATION Fieldbus)

OUNDATION Fieldbus)

4.4 in. (112 mm)

LCD

Connector

The transmitter is equipped with a write-protect switch that can be positioned

to prevent the accidental or deliberate change of configuration data.

Alarm Switch (HART)

The transmitter monitors itself during normal operation with an automatic

diagnostic routine. If the diagnostic routine detects a sensor failure or a failure

in the transmitter electronics, the transmitter goes into alarm (high or low,

depending on the position of the failure mode switch).

The analog alarm and saturation values that the transmitter uses depend on

whether it is configured to standard or NAMUR-compliant operation. These

values are also custom-configurable in both the factory and the field using the

HART Communications. The limits are

•21.0 ≤ I ≤ 23 for high alarm

• 3.5 ≤ I ≤ 3.75 for low alarm

Table 2-2. Values for standard

and NAMUR operation

Standard Operation (factory default) NAMUR-Compliant Operation

Fail High 21.75 mA ≤ I ≤ 23.0 mA Fail High 21 mA ≤ I ≤ 23.0 mA

High Saturation I ≥ 20.5 mA High Saturation I ≥ 20.5 mA

Low Saturation I ≤ 3.90 mA Low Saturation I ≤ 3.8 mA

Fail Low I ≤ 3.75 mA Fail Low I ≤ 3.6 mA

Simulate Switch (F

OUNDATION Fieldbus)

Simulate switch is used to replaces the channel value coming from the

Sensor Transducer Block. For testing purposes, it manually simulates the

output of the Analog Input Block to a desired value.

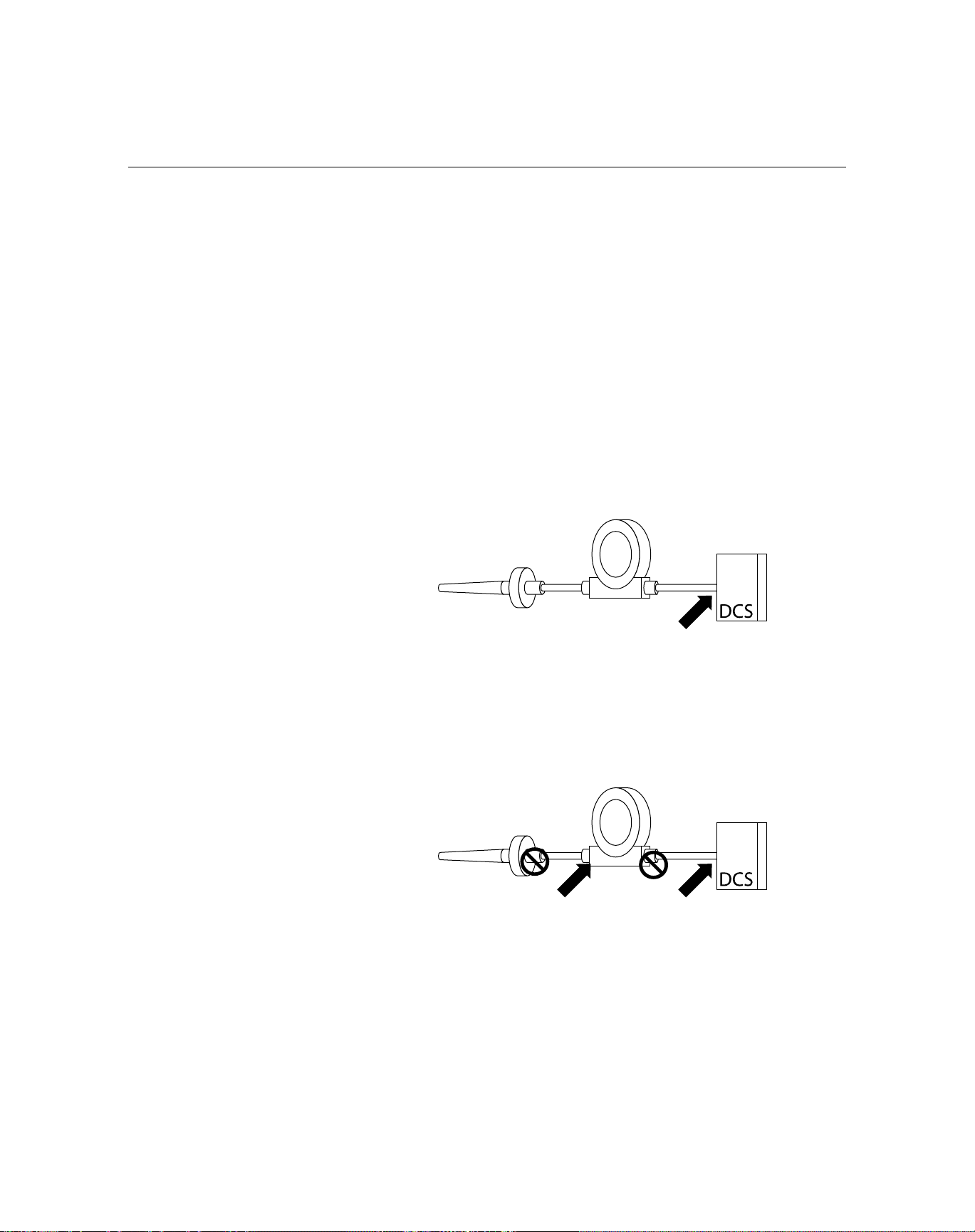

MOUNTING If possible, mount the transmitter at a high point in the conduit run so moisture

from the conduits will not drain into the housing. The terminal compartment

could fill with water If the transmitter is mounted at a low point in the conduit

run. In some instances, the installation of a poured conduit seal, such as the

one pictured in Figure 2-3, is advisable. Remove the terminal compartment

cover periodically and inspect the transmitter for moisture and corrosion.

2-4

Page 19

Reference Manual

00809-0100-4021, Rev DA

November 2004

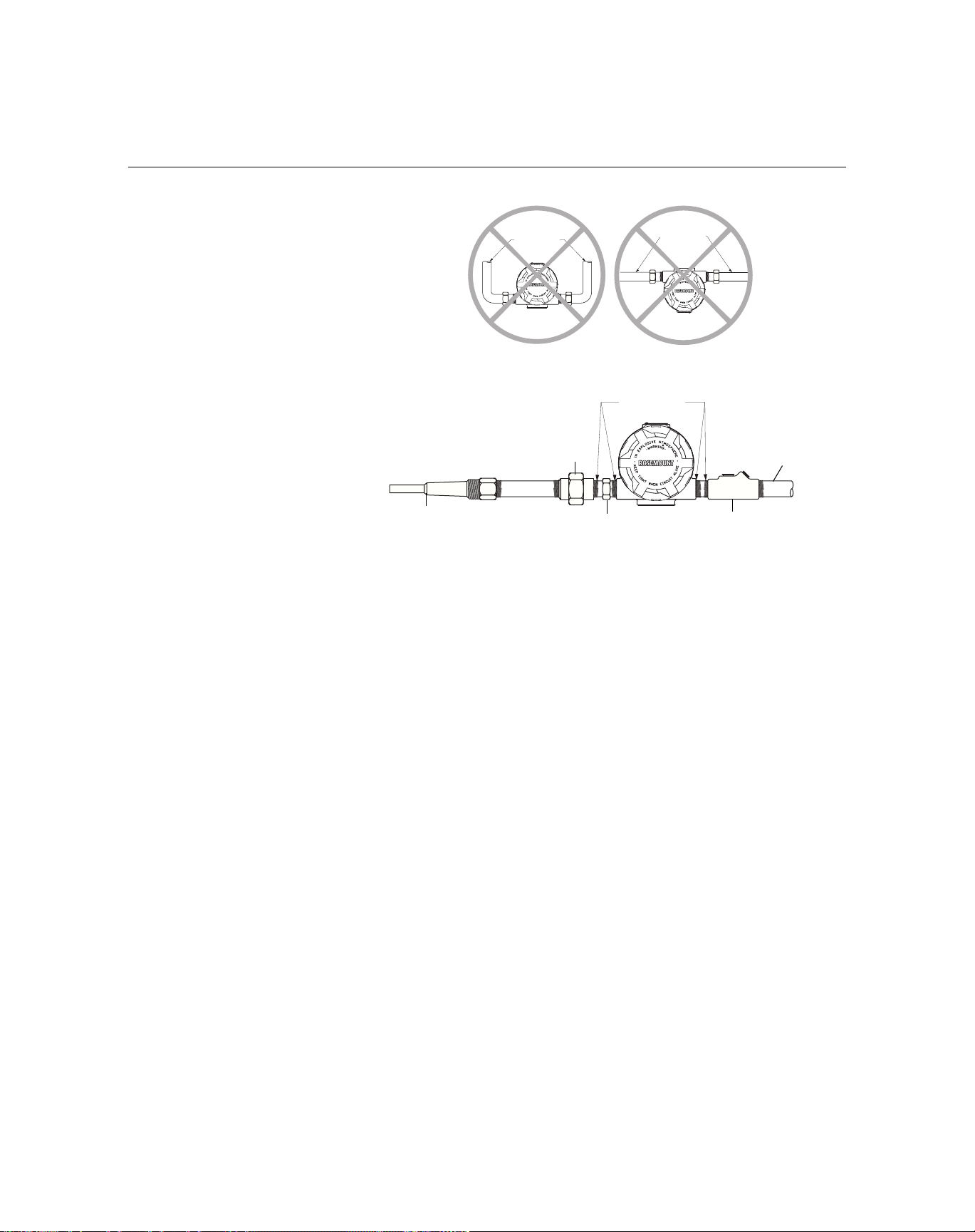

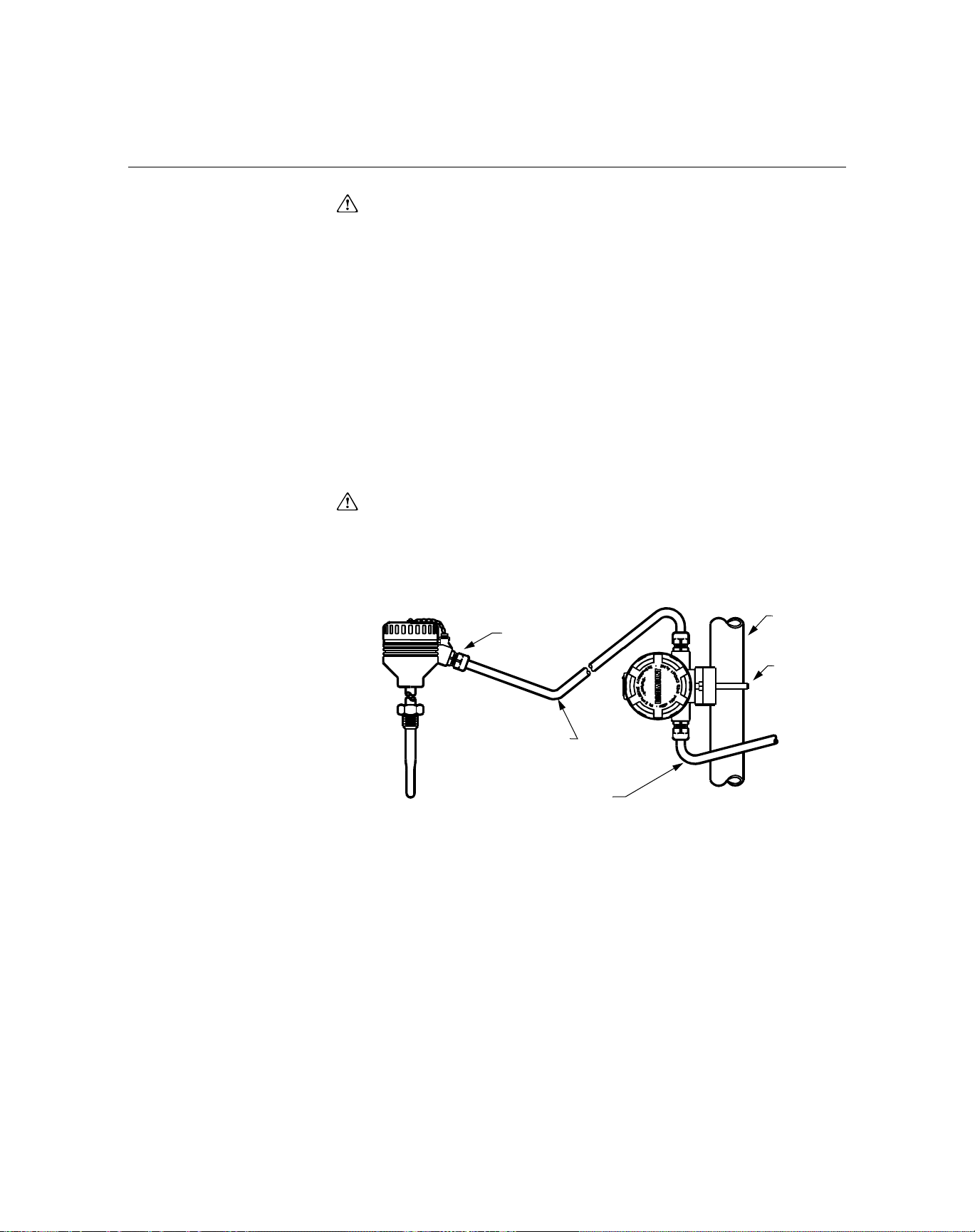

Figure 2-2. Incorrect Conduit

Installation

Conduit

Lines

Rosemount 3144P

Conduit

Lines

3144-0429A, 0429B

Figure 2-3. Recommended

Mounting with Drain Seal

Sealing

Compound

Union Coupling with Extension

Thermowell

Sensor Hex

Poured Conduit Seal (Where Required)

Conduit for

Field Wiring

If mounting the transmitter directly to the sensor assembly, use the process

shown in Figure 2-4. If mounting the transmitter apart from the sensor

assembly, use conduit between the sensor and transmitter. The transmitter

1

accepts male conduit fittings with

1

(PG 11), or JIS G

/2 threads (M20 × 1.5 (CM 20), PG 13.5 (PG 11), or JIS G1/2

/2–14 NPT, M20 × 1.5 (CM 20), PG 13.5

threads are provided by an adapter). Make sure only qualified personnel

perform the installation.

The transmitter may require supplementary support under high-vibration

conditions, particularly if used with extensive thermowell lagging or long

extension fittings. Pipe-stand mounting, using one of the optional mounting

brackets, is recommended for use in high-vibration conditions.

3144-0430B

2-5

Page 20

Rosemount 3144P

INSTALLATION

Reference Manual

00809-0100-4021, Rev DA

November 2004

Typical North American

Installation

Figure 2-4. Typical North

American Mounting

Configuration.

1. Attach the thermowell to the pipe or process container wall. Install and

tighten thermowells and sensors. Apply process pressure to perform a

leak test.

2. Attach necessary unions, couplings, and extension fittings. Seal the

fitting threads with teflon

®

(PTFE) tape (if required).

3. Screw the sensor into the thermowell or directly into the process

(depending on installation requirements).

4. Verify all sealing requirements for severe environments or to satisfy code

requirements.

5. Attach the transmitter to the thermowell/sensor assembly. Seal all

threads with Teflon (PTFE) tape (if required).

6. Pull sensor leads through the extensions, unions, or couplings into the

terminal side of the transmitter housing.

7. Install field wiring conduit to the remaining transmitter conduit entry.

8. Pull the field wiring leads into the terminal side of the transmitter housing.

9. Attach the sensor leads to the transmitter sensor terminals. Attach the

power leads to the transmitter power terminals.

10. Attach and tighten both transmitter covers. Both transmitter covers must

be fully engaged to meet explosion-proof requirements.

Union or

Thermowell

Extension

Coupling

2-6

Conduit for Field

Extension

NOTE: Dimensions are in inches (millimeters).

Fitting

Length

3.2

(81)

Wiring (dc power)

NOTE

The National Electrical Code requires that a barrier or seal be used in addition

to the primary (sensor) seal to prevent process fluid from entering the

electrical conduit and continuing to the control room. Professional safety

assistance is recommended for installation in potentially hazardous

processes.

3144-0433B

Page 21

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Typical European

Installation

Figure 2-5. Typical European

Process Mounting

Configuration.

1. Mount the thermowell to the pipe or the process container wall. Install

and tighten thermowells and sensors. Apply pressure and perform a leak

check before starting the process.

2. Attach a connection head to the thermowell.

3. Insert the sensor into the thermowell and wire it to the connection head.

The wiring diagram is located on the inside of the connection head.

4. Mount the transmitter to a 2-inch (50 mm) pipe or a suitable panel using

one of the optional mounting brackets. The B4 bracket is shown in

Figure 2-5.

5. Attach cable glands to the shielded cable running from the connection

head to the transmitter conduit entry.

6. Run the shielded cable from the opposite conduit entry on the transmitter

back to the control room.

7. Insert the shielded cable leads through the cable entries into the

connection head and the transmitter. Connect and tighten the cable

glands.

8. Connect the shielded cable leads to the connection head terminals

(located inside of the connection head) and the sensor wiring terminals

(located inside of the transmitter housing). Avoid contact with the leads

and the terminals.

2-inch

Cable

Gland

Pipe

B4

Mounting

Bracket

Shielded Cable from

Sensor to Transmitter

Shielded Cable

from Transmitter

to Control Room

644-0000B05B

2-7

Page 22

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

In Conjunction with a

Rosemount 333 HART

Tri-Loop (HART / 4–20

mA only)

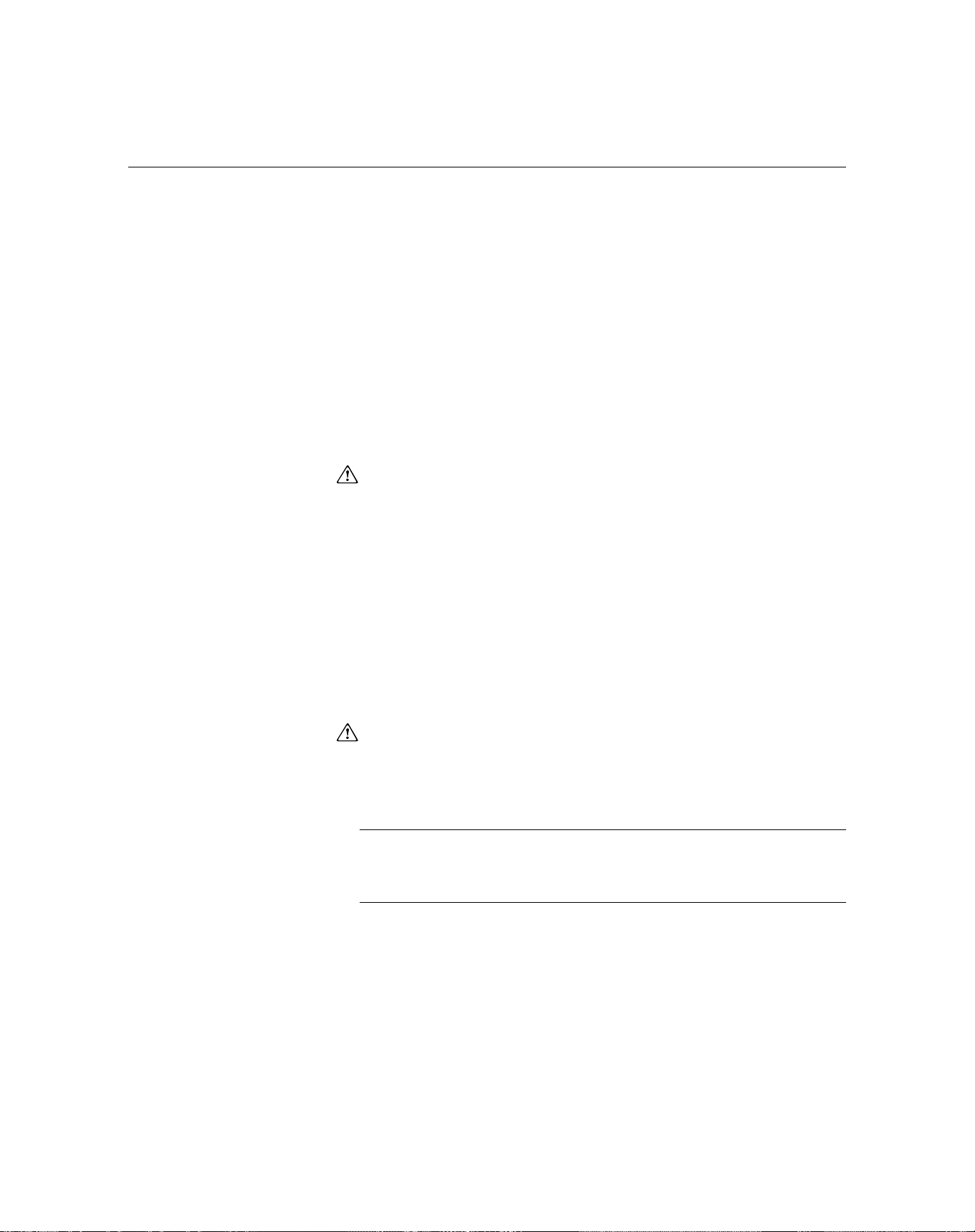

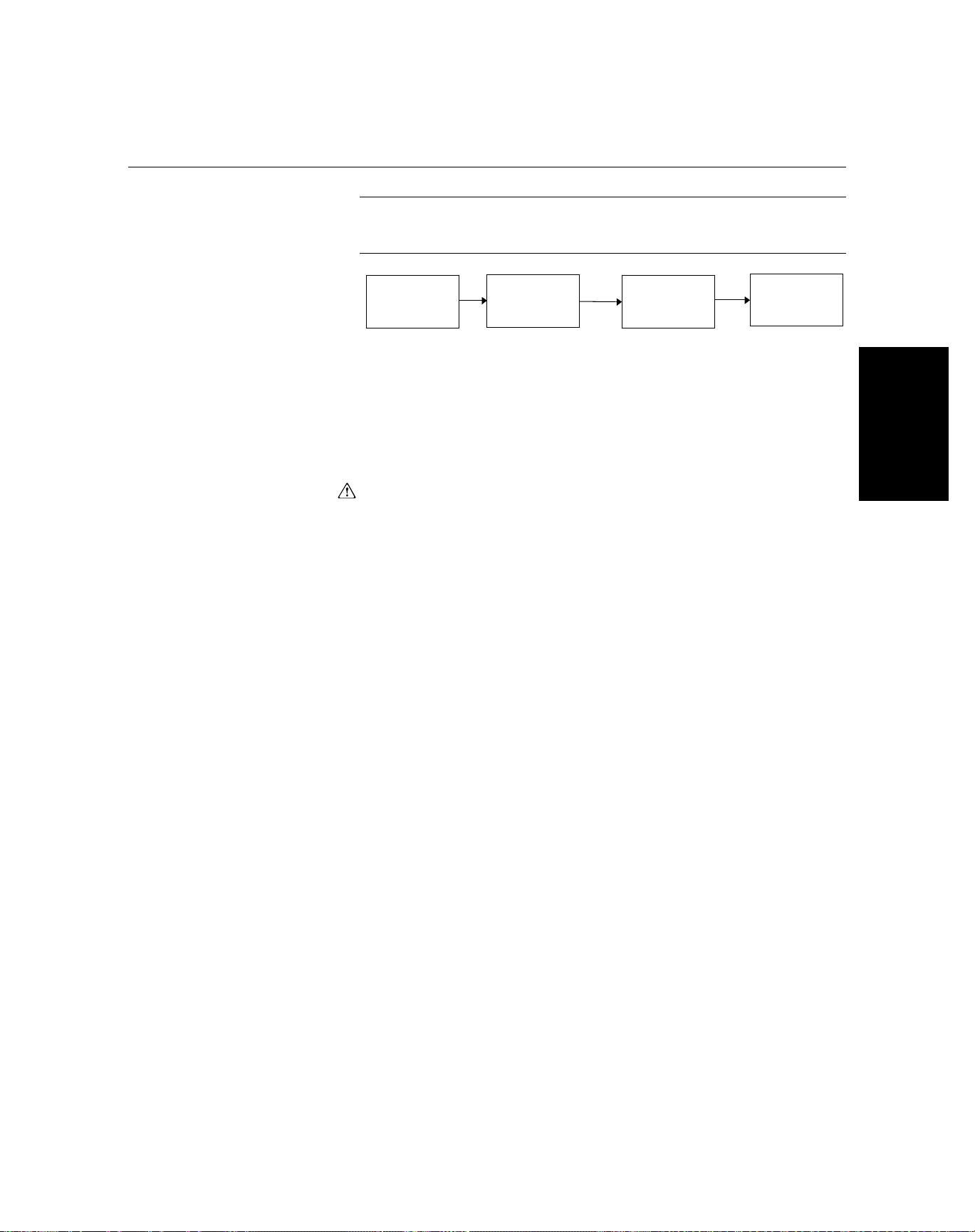

Figure 2-6. HART Tri-Loop

Installation Flowchart

(1)

START

HERE

Use the dual-sensor option 3144P transmitter that is operating with two

sensors in conjunction with a 333 HART Tri-Loop

®

HART-to-Analog Signal

Converter to acquire an independent 4–20 mA analog output signal for each

sensor input. The 3144P transmitter can be configured to output four of the six

following digital process variables:

•Sensor 1

•Sensor 2

• Differential temperature

• Average temperature

• First good temperature,

• Transmitter terminal temperature.

The HART Tri-Loop reads the digital signal and outputs any or all of these

variables into as many as three separate 4–20 mA analog channels.

Refer to Figure 2-6 for basic installation information. Refer to the 333 HART

Tri-Loop HART-to-Analog Signal Converter Reference Manual (document

number 00809-0100-4754) for complete installation information.

INSTALL THE

TRI-LOOP

COMMISSION

THE TRI-LOOP

Install the

3144P

No

Unpack the

Tri-Loop

Review the

Tri-Loop

Reference

Manual

3144P

Installed?

Yes

Set the 3144P

Burst

Command

Order

Set the 3144P

to Burst HART

Command 3

Review

Tri-Loop

Installation

Considerations

Mount the

Tri-Loop to a

DIN Rail

Run Wires from

3144P to Burst

Input Terminals

Install Channel

1 Wires from

Tri-Loop to

Control Room

OPTIONAL:

Install Channel

2 Wires from

Tri-Loop to

Control Room

OPTIONAL:

Install Channel

3 Wires from

Tri-Loop to

Control Room

Configure the

Tri-Loop to

Receive 3144P

Burst

Commands

Pass System

Tes t?

Yes

DONE

No

Refer to the

HART Tri-Loop

Reference

Manual

(1) See “Use with the HART Tri-Loop” on page 3-24 for configuration information.

2-8

Page 23

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

LCD Display Transmitters ordered with the LCD display option (code M5) are shipped with

the LCD display installed. After-market installation of the LCD display on a

conventional 3144P transmitter requires a small instrument screwdriver and

the LCD display kit, which includes:

• LCD display assembly

• Extended cover with cover O-ring in place

• Captive screws (quantity 2)

• 10-pin interconnection header

Use the following procedure to install the LCD display. Once the LCD display

is installed, configure the transmitter to recognize the meter option. Refer to

“LCD Meter Options” on page 3-19 (HART) or “LCD Transducer Block” on

page 4-11 (F

1. If the transmitter is installed in a loop, set the loop to manual (HART) /

out-of-service (F

2. Remove the housing cover from the electronics side of the transmitter.

Do not remove the transmitter covers in explosive atmospheres if the

circuit is live.

3. Ensure that the transmitter write protect switch is set to the Off position.

If transmitter security is On, then you will not be able to configure the

transmitter to recognize the LCD display. If security On is desired, first

configure the transmitter for the LCD display and then install the meter.

4. Insert the interconnection header in the 10-pin socket on the face of the

electronics module. Insert the pins into the electronics LCD interface.

5. Orient the meter. The meter can be rotated in 90-degree increments for

easy viewing. Position one of the four 10-pin sockets on the back of the

meter to accept the interconnection header.

6. Attach the LCD display assembly to the interconnection pins. Thread and

tighten the LCD display screws into the holes on the electronics module.

7. Attach the extended cover; tighten at least one-third turn after the O-ring

contacts the transmitter housing. Both transmitter covers must be fully

engaged to meet explosion proof requirements.

8. Apply power and set the loop to automatic (HART) / in-service

(F

OUNDATION fieldbus).

OUNDATION Fieldbus) mode and disconnect the power.

OUNDATION Fieldbus) mode.

NOTE

Observe the following LCD display temperature limits:

Operating:–4 to 185 °F (–20 to 85 °C)

Storage:–50 to 185 °F (–45 to 85 °C)

2-9

Page 24

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

Multichannel Installation

(HART / 4–20 mA only)

You can connect several transmitters to a single master power supply (see

Figure 2-7). In this case, the system may be grounded only at the negative

power supply terminal. In multichannel installations where several

transmitters depend on one power supply and the loss of all transmitters

would cause operational problems, consider an uninterrupted power supply or

a back-up battery. The diodes shown in Figure 2-7 prevent unwanted

charging or discharging of the back-up battery.

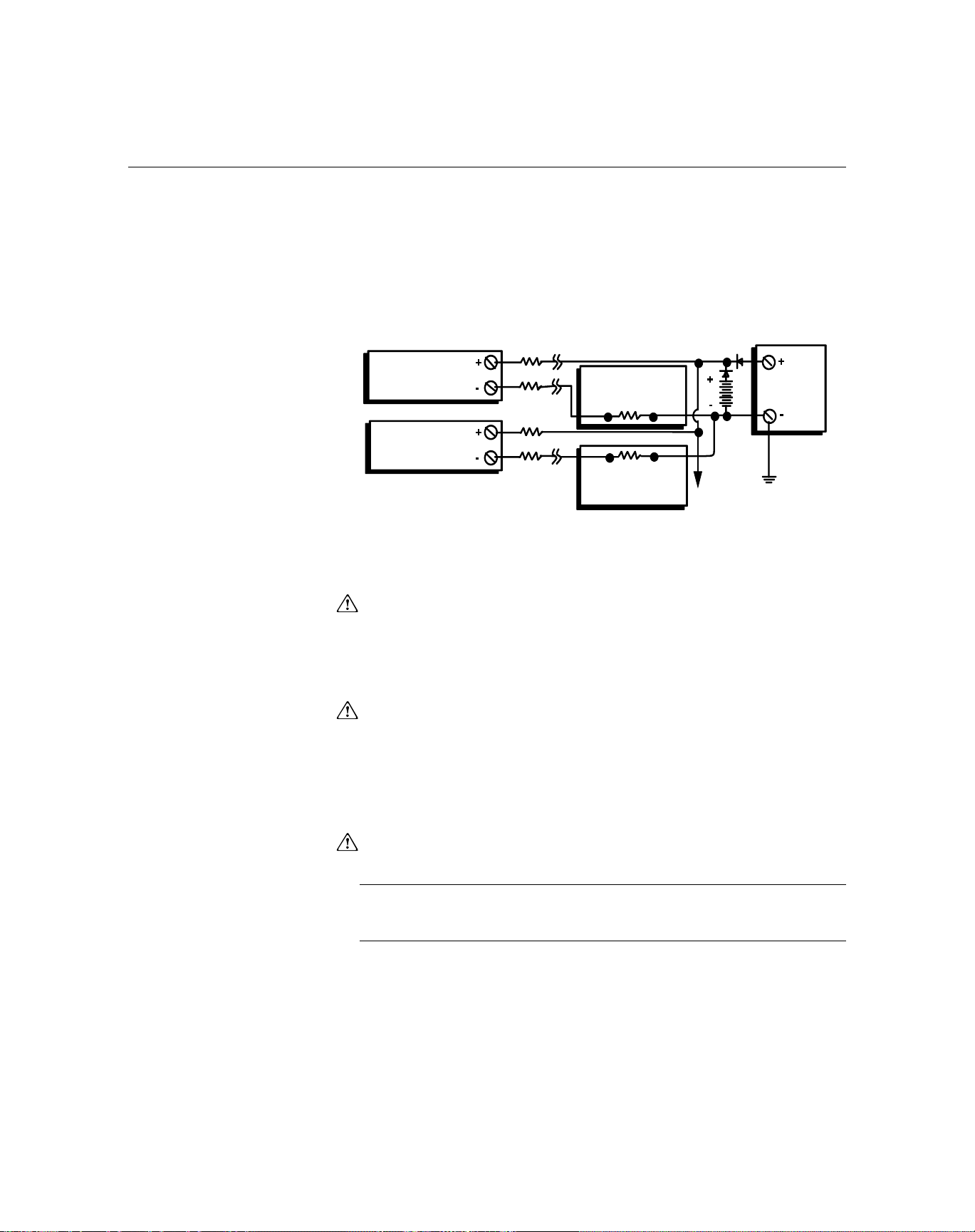

Figure 2-7. Multichannel

Installations.

Transmitter

No. 1

Transmitter

No. 2

Between 250 and 1100 Ω

If No Load Resistor

WIRING

HART / 4–20 mA Field Wiring

All power to the transmitter is supplied over the signal wiring. Signal wiring

does not need to be shielded, but twisted pairs should be used for the best

results. Do not run unshielded signal wiring in conduit or open trays with

power wiring or near heavy electrical equipment. High voltage may be present

on the leads and may cause electrical shock. To wire the transmitter for

power, follow the steps below.

R

Lead

R

R

Lead

Lead

Readout or

Controller No. 1

Readout or

Controller No. 2

Battery

Backup

To Additional

Transmitters

dc

Power

Supply

3044-0131A

1. Remove the transmitter covers. Do not remove the transmitter covers in

an explosive atmosphere when the circuit is live.

2. Connect the positive power lead to the terminal marked “+” and the

negative power lead to the terminal marked “–” as shown in Figure 2-8.

Crimped lugs are recommended when wiring to screw terminals.

3. Tighten the terminal screws to ensure that good contact is made. No

additional power wiring is required.

4. Replace the transmitter covers. Both transmitter covers must be fully

engaged to meet explosion-proof requirements.

NOTE

Do not apply high voltage (e.g., ac line voltage) to the transmitter terminals.

Abnormally high voltage can damage the unit.

2-10

Page 25

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Figure 2-8. Transmitter Terminal

Block

Figure 2-9. HART / 4–20 mA

Wiring Diagram

2-wire RTD

and Ohms

W

R

∆T/Hot Backup/Dual

Sensor with

2 RTDs

W & G

***

**

3-wire RTD

and Ohms**

G

B

Thermocouples

“+”

Tes t

3144P Single-Sensor Connections Diagram

4-wire RTD

and Ohms

3144P Dual-Sensor Connections Diagram

∆T/Hot

Backup/Dual

Sensor with 2

∆T/Hot

Backup/Dual

Sensor with

RTDs/

Thermocouples

Sensor with RTDs/

**

Sensor Terminals (1 – 5)

Ground

T/Cs and

Millivolts

Backup/Dual

Thermocouples

Compensation Loop*

∆T/Hot

RTD with

∆T/Hot Backup/Dual

Sensor with 2 RTDs

with Compensation

** **

Loop

* Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a compensation loop.

** Emerson Process Management provides 4-wire sensors for all single-element RTDs. You can use these RTDs in 3-wire configurations by

leaving the unneeded leads disconnected and insulated with electrical tape.

*** Typical wiring configuration of a Rosemount dual-element RTD is shown (R=Red, W=White, G=Green, B=Black)

2-11

Page 26

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

Power/Current Loop Connections

Use copper wire of a sufficient size to ensure that the voltage across the

transmitter power terminals does not go below 12.0 V dc.

1. Connect the current signal leads as shown in Figure 2-10.

2. Recheck the polarity and correctness of connections.

3. Turn the power ON.

For information about multichannel installations, refer to page 2-17.

NOTE

Do not connect the power/signal wiring to the test terminal. The voltage

present on the power/signal leads may burn out the reverse-polarity

protection diode that is built into the test terminal. If the test terminal’s reverse

polarity protection diode is burned out by the incorrect power/signal wiring, the

transmitter can still be operated by jumping the current from the test terminal

to the “–” terminal. See “Test Terminal” on page 4-3 for use of the terminal.

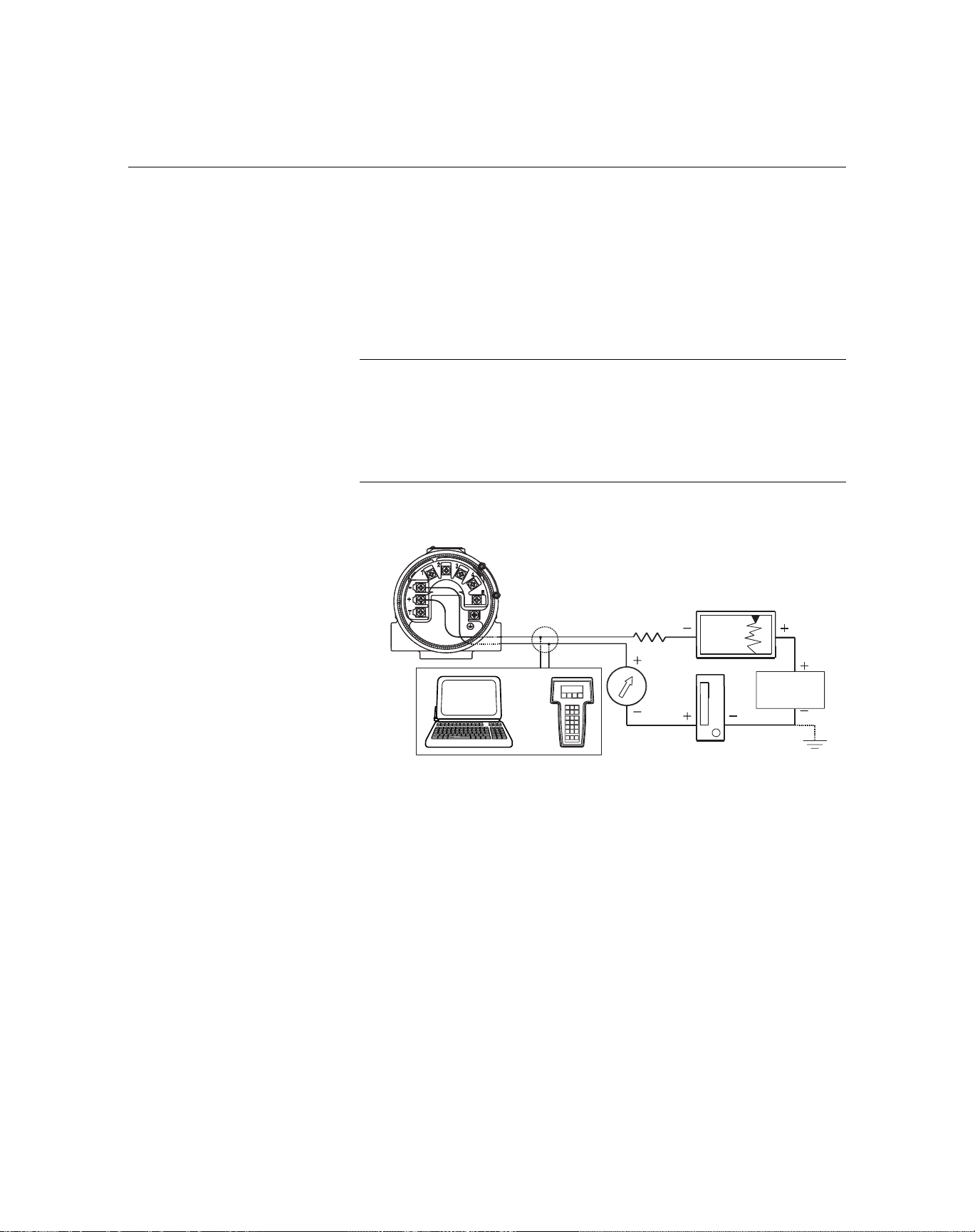

Figure 2-10. m Connecting

a Communicator to a

Transmitter Loop (HART/ 4–20

mA).

Power/Signal Terminals

The signal wire may be grounded at

any point or left ungrounded.

250 ≤ R

or*

AMS software or a 375 Field Communicator can be connected at any termination

point in the signal loop. The signal loop must have between 250 and 1100 ohms

load for communications.

≤ 1100

L

Power

Supply

3144-0000A04A

2-12

Page 27

Reference Manual

00809-0100-4021, Rev DA

November 2004

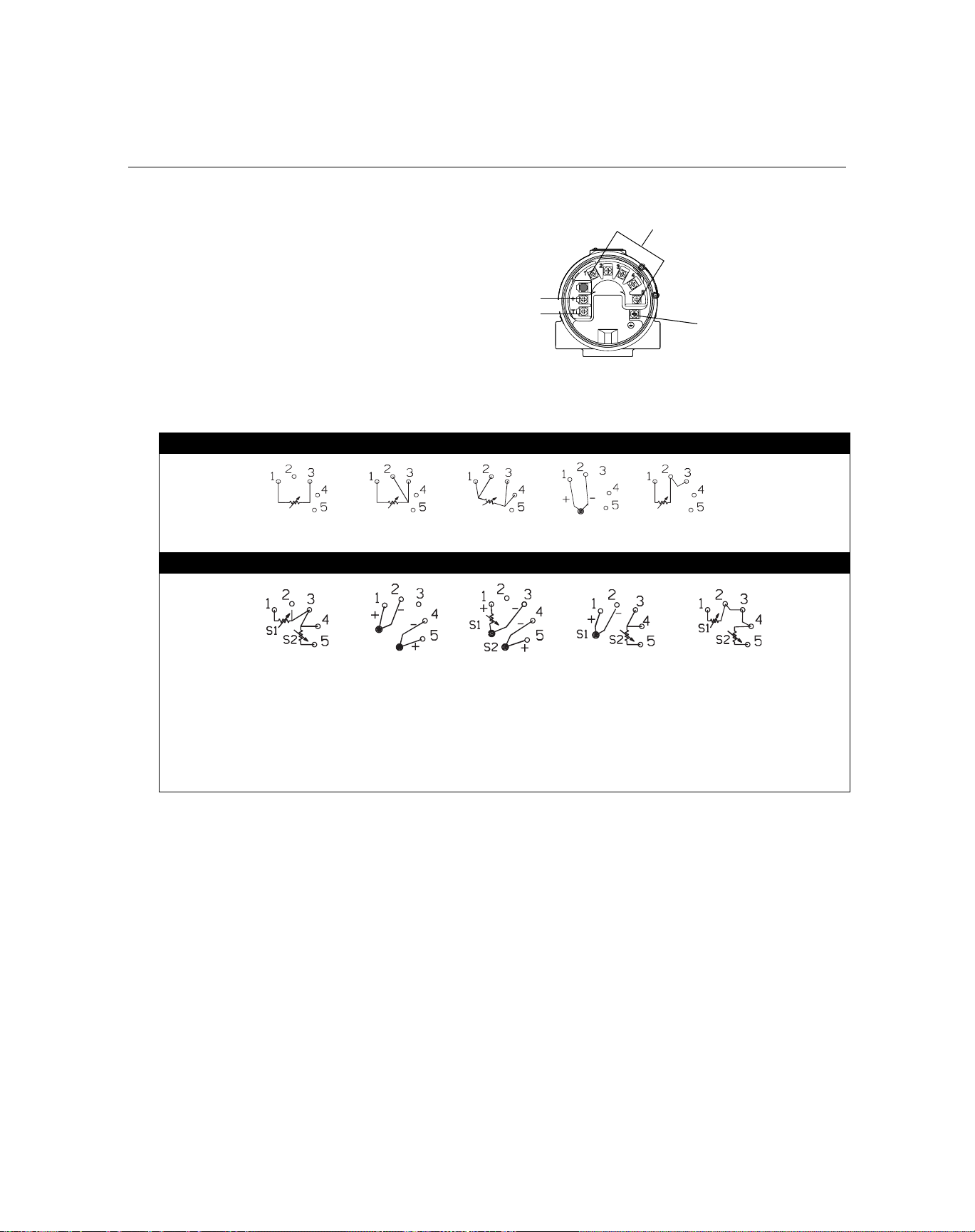

FOUNDATION Fieldbus

Rosemount 3144P

Figure 2-11. Transmitter

Terminal Block

Figure 2-12. F

OUNDATION

Fieldbus Field Wiring Diagram

2-wire RTD

and Ohms

W

R

W & G

G

B

Power Terminals

3144P Single-Sensor Connections Diagram

3-wire RTD

and Ohms**

3144P Dual-Sensor Connections Diagram

4-wire RTD

and Ohms

T/Cs and

Millivolts

Sensor Terminals (1 – 5)

Ground

RTD with

Compensation Loop*

∆T/Hot

Backup/Dual

Sensor with 2

RTDs

* Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a compensation loop.

** Emerson Process Management provides 4-wire sensors for all single-element RTDs. You can use these RTDs in 3-wire configurations by leaving

the unneeded leads disconnected and insulated with electrical tape.

*** Typical wiring configuration of a Rosemount dual-element RTD is shown (R=Red, W=White, G=Green, B=Black)

∆T/Hot Backup/Dual

Sensor with 2

Thermocouples

**

***

∆T/Hot

Backup/Dual

Sensor with RTDs/

Thermocouples

**

∆T/Hot

Backup/Dual

Sensor with RTDs/

Thermocouples

∆T/Hot Backup/Dual

Sensor with 2 RTDs

with Compensation

**

Loop

**

2-13

Page 28

Reference Manual

00809-0100-4021, Rev DA

Rosemount 3144P

November 2004

Sensor Connections Figure 2-9 on page 2-11 (HART) and Figure 2-12 on page 2-13 (FOUNDATION

fieldbus) shows the correct sensor wiring connections to the transmitter

sensor terminals. To ensure an adequate sensor connection, anchor the

sensor lead wires beneath the flat washer on the terminal screw. Do not

remove the transmitter cover in explosive atmospheres if the circuit is live.

Both transmitter covers must be fully engaged to meet explosion-proof

requirements. Use extreme caution when making contact with the leads and

terminals.

RTD or Ohm Inputs

If the transmitter is mounted remotely from a 3- or 4-wire RTD, it will operate

within specifications, without recalibration, for lead wire resistances of up to

10 ohms per lead (equivalent to 1,000 feet of 20 AWG wire). In this case, the

leads between the RTD and transmitter should be shielded. If using only two

leads (or a compensation loop lead wire configuration), both RTD leads are in

series with the sensor element, so significant errors can occur if the lead

lengths exceed one foot of 20 AWG wire. For longer runs, attach a third or

fourth lead as described above. To eliminate 2-wire lead resistance error, the

2-wire offset command can be used. This allows the user to input the

measured lead wire resistance, resulting in the transmitter adjusting the

temperature to correct the error.

Thermocouple or Millivolt Inputs

For direct-mount applications, connect the thermocouple directly to the

transmitter. If mounting the transmitter remotely from the sensor, use

appropriate thermocouple extension wire. Make connections for millivolt

inputs with copper wire. Use shielding for long runs of wire.

NOTE

For HART transmitters, the use of two grounded thermocouples with a dual

option 3144P transmitter is not recommended. For applications in which the

use of two thermocouples is desired, connect either two ungrounded

thermocouples, one grounded and one ungrounded thermocouple, or one

dual element thermocouple.

POWER SUPPLY HART

An external power supply is required to operate the 3144P (not included). The

input voltage range of the transmitter is 12 to 42.4 V DC. This is the power

required across the transmitter power terminals. The power terminals are

rated to 42.4 V DC. With 250 ohms of resistance in the loop, the transmitter

will require a minimum of 18.1 V DC for communication.

The power supplied to the transmitter is determined by the total loop

resistance and should not drop below the lift-off voltage. The lift-off voltage is

the minimum supply voltage required for any given total loop resistance. See

Figure 2-13 to determine the required supply voltage. If the power drops

below the lift-off voltage while the transmitter is being configured, the

transmitter may output incorrect information.

2-14

The dc power supply should provide power with less than 2% ripple. The total

resistance load is the sum of the resistance of the signal leads and the load

resistance of any controller, indicator, or related piece of equipment in the

loop. Note that the resistance of intrinsic safety barriers, if used, must be

included.

Page 29

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

NOTE

Do not allow the voltage to drop below 12.0 V dc at the transmitter terminals

when changing transmitter configuration parameters, or permanent damage

to the transmitter could result.

Figure 2-13. Load Limits.

Maximum Load = 40.8 X (Supply Voltage - 12.0)

4–20 mA dc

Operating

Region

20 30 40 42.4

12.0

Supply Voltage (V dc)

F

OUNDATION fieldbus

Powered over F

OUNDATION fieldbus with standard fieldbus power supplies.

1240

1100

1000

750

500

Load (Ohms)

250

0

10

The transmitter operates between 9.0 and 32.0 V dc, 11 mA maximum.

Transmitter power terminals are rated to 42.4 VDC.

The power terminals on the 3144P with F

OUNDATION fieldbus are polarity

insensitive.

Surges/Transients The transmitter will withstand electrical transients of the energy level usually

encountered in static discharges or induced switching. However, high-energy

transients, such as those induced in wiring from nearby lightning strikes, can

damage both the transmitter and the sensor.

To protect against high-energy transients, install the integral transient

protection board (option code T1). The integral transient protection board is

available as an ordered option or as an accessory. Refer to “ Transient

Protection (Option Code T1)” on page A-16 for more information.

Grounding Sensor Shielding

The currents in the leads induced by electromagnetic interference can be

reduced by shielding. Shielding carries the current to ground and away from

the leads and electronics. If the ends of the shields are adequately grounded,

little current will actually enter the transmitter.

If the ends of the shield are left ungrounded, a voltage is created between the

shield and the transmitter housing and also between the shield and earth at

the element end. The transmitter may not be able to compensate for this

voltage, causing it to lose communication and/or go into alarm. Instead of the

shield carrying the currents away from the transmitter, the currents will now

flow through the sensor leads into the transmitter circuitry where they will

interfere with the circuit operation.

2-15

Page 30

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

Shielding Recommendations

The following are recommended practices are from API Standard 552

(Transmission Standard) section 20.7 and from field and laboratory testing. If

more than one recommendation is given for a sensor type, start with the first

technique shown or the technique that is recommended for the facility by its

installation drawings. If the technique does not eliminate the transmitter

alarms, try another technique. If all techniques unsuccessfully prevent

transmitter alarms due to high EMI, contact a Emerson Process Management

representative.

Ungrounded Thermocouple, mV, and RTD/Ohm Inputs

Option 1: recommended for ungrounded transmitter housing

1. Connect the signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from

the transmitter housing.

3. Ground the shield at the power supply end only.

4. Ensure the shield at the sensor is electrically isolated from the

surrounding fixtures that may be grounded.

Sensor Wires

Shield ground point

Connect shields together, electrically isolated from the transmitter

Option 2: recommended for grounded transmitter housing

1. Connect the sensor wiring shield to the transmitter housing, provided

the transmitter housing is grounded (see "Transmitter Housing").

2. Ensure the shield at the sensor end is electrically isolated from

surrounding fixtures that may be grounded.

3. Ground the signal wiring shield at the power supply end.

Sensor Wires

Shield ground points

2-16

Page 31

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Option 3

1. Ground the sensor wiring shield at the sensor, if possible.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated form the transmitter housing and other fixtures that may

be grounded.

3. Ground the signal wiring shield at the power supply end.

Sensor Wires

Shield ground points

Grounded Thermocouple Inputs

1. Ground the sensor wiring shield at the sensor.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated form the transmitter housing and other fixtures that may

be grounded.

3. Ground the signal wiring shield at the power supply end.

Sensor Wires

Shield ground points

Transmitter Housing

Ground the transmitter housing in accordance with local electrical

requirements. An internal ground terminal is standard. An optional external

ground lug assembly (Option Code G1) can also be ordered if needed.

Ordering certain hazardous approvals automatically includes an external

ground lug (see Table A-5 on page A-16).

2-17

Page 32

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

2-18

Page 33

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Section 3 HART Commissioning

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

375 Field Communicator . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2

AMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-5

Review Configuration Data . . . . . . . . . . . . . . . . . . . . . . . . page 3-5

Check Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-6

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-6

Device Output Configuration . . . . . . . . . . . . . . . . . . . . . . . page 3-14

Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-18

Measurement Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-19

Diagnostics and Service . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-21

Multidrop Communication . . . . . . . . . . . . . . . . . . . . . . . . . page 3-24

Use with the HART Tri-Loop . . . . . . . . . . . . . . . . . . . . . . . page 3-25

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-28

Trim the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-35

OVERVIEW This section contains information on commissioning and tasks that should be

performed on the bench prior to installation. This section contains 3144P

HART configuration only. 375 Field Communicator and AMS instructions are

given to perform configuration functions. For additional information, refer to

the HART Communication Reference Manual (document number

00809-0100-4276). AMS help can be found in the AMS on-line guides within

the AMS system.

HART

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Explosions may result in death or serious injury.

• Do not remove the instrument cover in explosive atmospheres when the circuit is

live.

• Before connecting a 375 Field Communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Both covers must be fully engaged to meet explosion–proof requirements.

Electrical shock could cause death or serious injury. If the sensor is installed in a

high-voltage environment and a fault or installation error occurs, high voltage may be

present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

www.rosemount.com

Page 34

Rosemount 3144P

Reference Manual

00809-0100-4021, Rev DA

November 2004

HART

375 FIELD

COMMUNICATOR

Updating the HART

Communication Software

The Menu Tree and Fast Key sequences use the following device revisions:

• Standard 3144P: Device Revision Dev v3, DD v2

• 3144P SIS: Device Revision Dev v2, DD v1

The 375 Field Communicator exchanges information with the transmitter from

the control room, the instrument site, or any wiring termination point in the

loop. To facilitate communication, connect the Field Communicator in parallel

with the transmitter (see Figure 2-10). Use the loop connection ports on the

top of the Field Communicator. The connections are non-polarized. Do not

make connections to the NiCad recharger jack in explosive atmospheres.

Before connecting the Field Communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically

safe or non-incendive field wiring practices

The 375 Field Communicator software may need to be updated to take

advantage of the additional features available in the 3144P (field device

revision 3). Perform the following steps to determine if an upgrade is

necessary.

1. Choose “Rosemount” from the list of manufacturers and “3144 Temp”

from the list of models.

2. If the Fld Dev Rev choices include “Dev v3, DD v2,” an upgrade is not

required. If the only choice is “Dev v1” or “Dev v2” (with any DD version),

then the communicator should be upgraded. The 3144P SIS Safety

Certified transmitters requires Device Revision Dev v2, DD v1.

NOTE

If communication is initiated with an improved 3144P using a communicator

that only has a previous version of the transmitter device descriptors (DDs),

the communicator will display the following message:

NOTICE: Upgrade to the 375 software to access new XMTR functions.

Continue with old description?

Select YES: the communicator will communicate properly with the transmitter

using the existing transmitter DDs. However, new software features of the DD

in the communicator will not be accessible. I

Select NO: the communicator will default to a generic transmitter functionality.

If YES is selected when the transmitter is already configured to utilize the new

features of the improved transmitters (such as Dual Input configuration or one

of the added sensor input types–DIN Type L or DIN Type U), the user will

experience trouble communicating with the transmitter and will be prompted

to turn the communicator off. To prevent this from happening, either upgrade

the communicator to the latest DD or answer NO to the question above and

default to the generic transmitter functionality.

To see a list of enhancements included in the improved transmitters, see

“Rosemount 3144P and Rosemount 3144 / 3244MV Differences” on

page 1-6.

3-2

Page 35

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

Menu Tree Figure 3-1 displays a complete 3144P menu tree for use with the 375 Field

Communicator. Options listed in bold type indicate that a selection provides

other options.

For 3144P SIS Safety Certified transmitter, see “3144P SIS Safety Certified

Menu Tree” on page 6-4.

Figure 3-1. 3144P Menu Tree

Online Menu

1. DEVICE SETUP

2. PV is

3. PV

4. AO

5. % RNGE

6. PV LRV

7. PV URV

NOTE

The review menu

lists all of the

information

stored in the

3144P. This

includes device

information,

measuring

element, output

configuration, and

software revision.

1. PROCESS

VARIABLE

2. DIAGNOSTICS

AND SERVICE

3. CONFIGURATION

4. REVIEW

1. Device Variables

2. PV is

3. PV Digital

4. PV AO

5. PV% rnge

6. PV LRV

7. PV URV

8. PV LSL

9. PV USL

10.PV Damp

1. TEST DEVICE

2. CALIBRATION

1. VARIABLE

MAPPING

2. SENSOR

CONFIGURATION

3. DUAL-SENSOR

CONFIGURATION

4. DEV OUTPUT

CONFIGURATION

5. DEVICE

INFORMATION

6. MEASUREMENT

FILTERING

1. Revision #s

2. Dynamic Variables

3. Device Variables

4. Sensor Variables

5. Other Variables

1. Snsr 1

2. Snsr 2

3. Terminal

4. Diff.

5. Avg

6. First Good

1. Loop Test

2. Self test

3. Master Reset

4. Status

1. SNSR TRIM

2. D/A trim

3. Scaled D/A trim

1. PV is

2. SV is

3. TV is

4. QV is

5. Variable re-map

1. Chng Type/Conn

2. Show Type/Conn

3. Sensor 1 Setup

4. Sensor 2 Setup

5. Ter m Tem p Se tup

1. Diff Config

2. Avg Config

3. First Good Config

4. Config Hot Backup

5. Drift Alert

1. PV RANGE

VAL UES

2. ALARM

SATURATION

3. HART OUTPUT

4. LCD DISPLAY

OPTIONS

1. Tag

2. Date

3. Descriptor

4. Message

5. Final Assembly number

1. Universal rev

2. Field Dev Rev

3. Software Rev

4. Hardware

1. Review Snsr1

2. Review Snsr2

1. Microboard

2. A/D ASIC

3. Operation

4. Summary Byte

5. Sensor Information

1. Snsr inp trim

2. Snsr trim-fact

3. Active Calibrator

1. Sensor 1

2. Sensor 2

1. Snsr 2 Units

2. Snsr 2 damp

3. Snsr 2 S/N

4. Snsr 2 LSL

5. Snsr 2 USL

6. 2-Wire Offset

1. Diff Units

2. Diff Damp

3. Diff LSL

4. Diff USL

1. First Good Units

2. First Good Damp

3. First Good LSL

4. First Good USL

1. PV LRV

2. PV URV

3. PV Damping

4. PV Units

5. PV LSL

6. PV USL

7. PV Min. Span

1. AO alrm type

2. AO Levels

3. Non-PV Alarms

1. Poll addr

2. Num req preams

3. Burst mode

4. Burst option

1. Meter Configuration

2. Meter Decimal Point

3. Meter Bar Graph

1. 50/60 Hz Filter

2. Intermit Detect

3. Intermit Thresh

4. Open Sensor

Holdoff

1. Review PV

2. Review SV

3. Review TV

4. Review QV

1. Snsr 1 Units

2. Snsr 1 damp

3. Snsr 1 S/N

4. Snsr 1 LSL

5. Snsr 1 USL

6. 2-Wire Offset

1. Terminal Units

2. Terminal Damp

3. Terminal LSL

4. Terminal USL

1. Avg Units

2. Avg Damp

3. Avg LSL

4. Avg USL

1. Drift Alert option

2. Drift Limit

3. Drift Damping

1. Low Alarm

2. High Alarm

3. Low Sat.

4. High Sat.

5. Preset Alarms

1. Sensor 1

2. Sensor 2

3. Ter m Tem p

4. Differential Temp

5. Average Temp

6. First Good

HART

3-3

Page 36

Reference Manual

00809-0100-4021, Rev DA

Rosemount 3144P

November 2004

Fast Key Sequences Fast key sequences are listed below for common 3144P transmitter functions.

HART

NOTE:

The fast key sequences assume that “Device Revision Dev v3, DD v2 is being

used. Table 3-1 provides alphabetical function lists for all Field Communicator

tasks as well as their corresponding fast key sequences.

For 3144P SIS Safety Certified transmitter, see “3144P SIS Fast Key

Sequences” on page 6-5.

Table 3-1. Fast Key Sequence

Function HART Fast Keys Function HART Fast Keys

Active Calibrator 1, 2, 2, 1, 3 Open Sensor Holdoff 1, 3, 6, 4

Alarm Values 1, 3, 4, 2, 1 Percent Range 1, 1, 5

Analog Output 1, 1, 4 Poll Address 1, 3, 4, 3, 1

Average Temperature Setup 1, 3, 3, 2 Process Temperature 1, 1

Average Temperature Configuration 1, 3, 3, 2 Process Variables 1, 1

Burst Mode 1, 3, 4, 3, 3 Range Values 1, 3, 4, 1

Burst Option 1, 3, 4, 3, 4 Review 1, 4

Calibration 1, 2, 2 Scaled D/A Trim 1, 2, 2, 3

Configure Hot Backup 1, 3, 3, 4 Sensor 1 Configuration 1, 3, 2, 3

Configuration 1, 3 Sensor 2 Configuration 1, 3, 2, 4

D/A Trim 1, 2, 2, 2 Sensor Limits 1, 3, 2, 2

Damping Values 1, 3, 4, 1, 3 Sensor 1 Serial Number 1, 3, 2, 3, 3

Date 1, 3, 5, 2 Sensor 2 Serial Number 1, 3, 2, 4, 3

Descriptor 1, 3, 5, 3 Sensor 1 Setup 1, 3, 2, 3

Device Information 1, 3, 5 Sensor 2 Setup 1, 3, 2, 4

Diagnostics and Service 1, 2 Sensor Trim 1, 2, 2, 1, 1

Differential Temperature Setup 1, 3, 3, 1 Sensor Type 1, 3, 2, 1

Differential Temperature Configuration 1, 3, 3, 1 Sensor 1 Unit 1, 3, 2, 3, 1

Drift Alert 1, 3, 3, 5 Sensor 2 Unit 1, 3, 2, 4, 1

Filter 50/60 Hz 1, 3, 6, 1 Software Revision 1, 4, 1

First Good Temperature Setup 1, 3, 3, 3 Status 1, 2, 1, 4

First Good Temperature Configuration 1, 3, 3, 3 Ta g 1, 3, 5, 1

Hardware Revision 1, 4, 1 Terminal Temperature Setup 1, 3, 2, 5

Hart Output 1, 3, 4, 3 Test Device 1, 2, 1

Intermittent Sensor Detect 1, 3, 6, 2 Transmitter-Sensor Matching 1, 3, 2, 1

Intermittent Threshold 1, 3, 6, 3 URV (Upper Range Value) 1, 3, 4, 1, 2

Loop Test 1, 2, 1, 1 USL (Upper Sensor Limit) 1, 3, 4, 1, 6

LRV (Lower Range Value) 1, 3, 4, 1, 1 Variable Mapping 1, 3, 1

LSL (Lower Sensor Limit) 1, 3, 4, 1, 5 Wires 1, 3, 2, 1

Master Reset 1, 2, 1, 3 2-wire Offset Sensor 1 1, 3, 2, 3, 6

Message 1, 3, 5, 4 2-wire Offset Sensor 2 1, 3, 2, 4, 6

Meter Options 1, 3, 4, 4

3-4

Page 37

Reference Manual

00809-0100-4021, Rev DA

November 2004

Rosemount 3144P

AMS One of the key benefits of intelligent devices is the ease of device

configuration. When used with AMS, the 3144P is easy to configure and

provides instant and accurate alerts and alarms. The main configuration

screen of the 3144P is the “Configuration Properties” screen. From this

screen, the transmitter set-up can easily be viewed and edited.

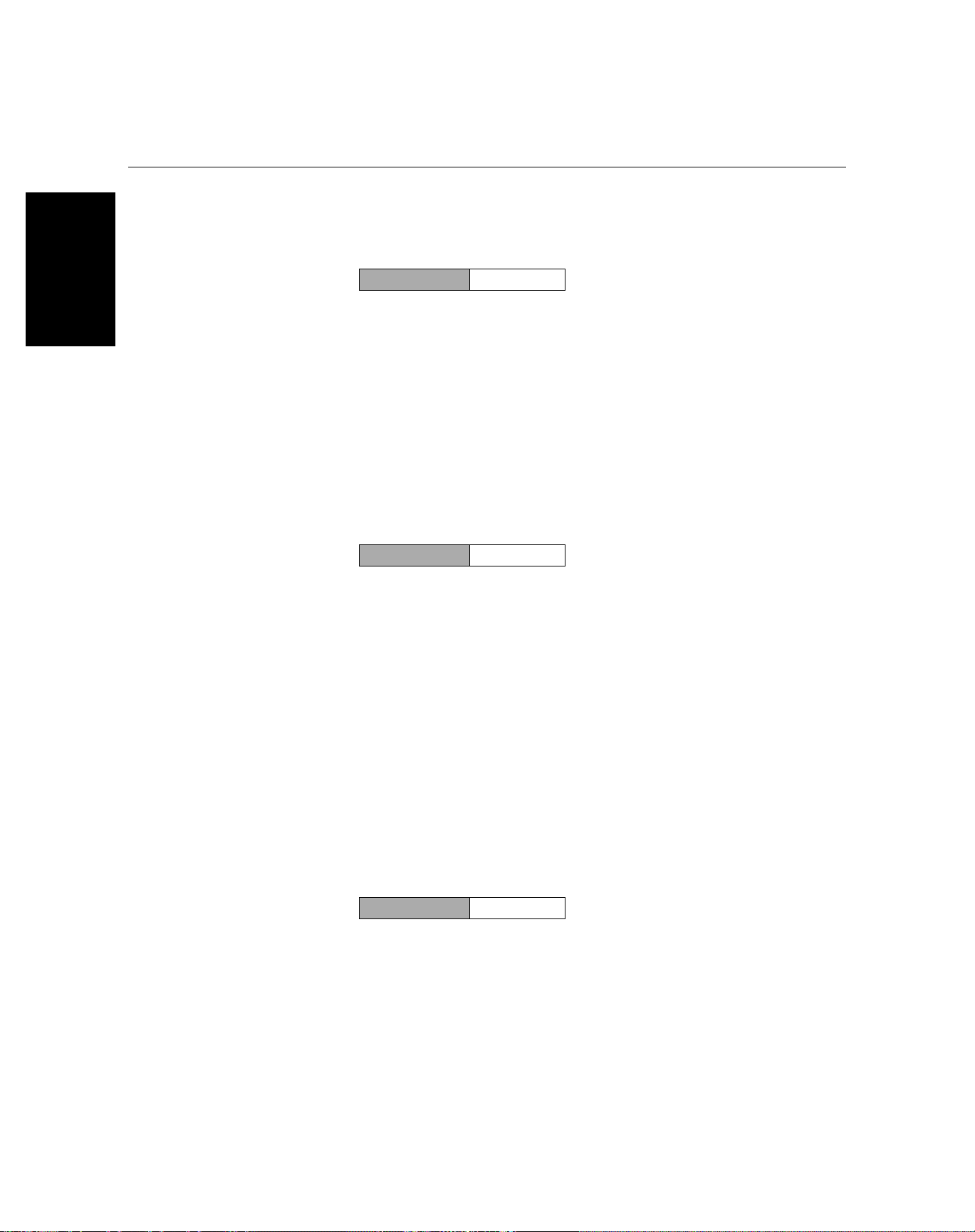

The screens use a color-coding to give visual indication of the transmitter

health and to indicate any changes that may need to be made or written to the

transmitter.

• Gray screens: indicates that all information has been written to the

transmitter

• Yellow on screen: changes have been made in the software but not

sent to the transmitter

• Green on screen: all current changes on screen have been written to

the transmitter

• Red on screen: indicates an alarm or alert that requires immediate

investigation

HART

Apply AMS Changes Changes made in the software must be sent to the transmitter in order for the

changes to take effect in the process.

1. From the bottom of the “Configuration Properties” screen, click Apply.

2. An “Apply Parameter Modification” screen appears, enter desired

information and click OK.

3. After carefully reading the warning provided, select OK.

REVIEW

CONFIGURATION DATA

Before operating the 3144P in an actual installation, review all of the

factory-set configuration data to ensure that it reflects the current application.

Review

HART Fast Keys 1, 4

Review the transmitter configuration parameters set at the factory to ensure

accuracy and compatibility with the particular application. After activating the

Review function, scroll through the data list to check each variable. If changes

to the transmitter configuration data are necessary, refer to “Configuration”

below.

AMS

Right click on the device and select “Configuration Properties” from the

menu. Select the tabs to review the transmitter configuration data.

3-5

Page 38

HART

Reference Manual

00809-0100-4021, Rev DA

Rosemount 3144P

November 2004

CHECK OUTPUT Before performing other transmitter online operations, review the