Page 1

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC MultiVariable™

Mass Flow Transmitter

www.rosemount.com

Page 2

Page 3

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Rosemount 3095FC MultiVariable

Mass Flow Transmitter

The products described in this document are NOT designed for nuclear-qualified

applications. Using non-nuclear qualified products in applications that require

nuclear-qualified hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact an Emerson Process

Management Sales Representative.

This device is intended for use in temperature monitoring applications and should not be

used in control and safety applications.

NOTICE

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure to thoroughly understand the contents before

installing, using, or maintaining this product.

The United States has two toll-free assistance numbers and one International number.

Customer Central

1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)

International

1-(952) 906-8888

National Response Center

1-800-654-7768 (24 hours a day)

Equipment service needs

www.rosemount.com

Page 4

Page 5

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Table of Contents

SECTION 1

Introduction

SECTION 2

Installation

3095FC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Automatic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Low Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3095FC Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Flow Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1992 Flow Calculations for Orifice Metering . . . . . . . . . . . . . . . 1-4

Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Power Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Rosemount User Interface Software PC Requirements . . . . . . . . . 1-6

Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Rosemount 3095FC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the Rosemount 3095FC on a Pipestand . . . . . . . . . . 2-2

Installing the 3095FC on an Orifice Plate (Direct Mount) . . . . . 2-2

Solar Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Solar Panel Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

RTD Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Communications Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Local Operator Interface Port (LOI). . . . . . . . . . . . . . . . . . . . . . 2-6

EIA-485 (RS-485) Serial Communications - Comm 1 . . . . . . . . 2-7

EIA-232 (RS-232) Communications - Comm 2 . . . . . . . . . . . . . 2-7

Ground the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Earth Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Pipelines With Cathodic Protection . . . . . . . . . . . . . . . . . . . . . . 2-8

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Apply Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Install the Rosemount User Interface Software . . . . . . . . . . . . . . . . . 2-11

Software Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Install With Autorun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Install Without Autorun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Uninstalling the Rosemount User Interface Software. . . . . . . . . . 2-12

www.rosemount.com

Page 6

Rosemount 3095FC

Reference Manual

00809-0100-4832, Rev AA

October 2004

Getting Started with the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Run the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Log into the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Establishing Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Connection Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Direct Connect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Connect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Remote Hardware Connection . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Disconnect from the 3095FC. . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Configuration Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Adding a Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Deleting a Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Adding a 3095FC transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Deleting a 3095FC transmitter . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Deleting all 3095FC transmitters . . . . . . . . . . . . . . . . . . . . . . . 2-16

Renaming a Group or 3095FC . . . . . . . . . . . . . . . . . . . . . . . . 2-16

SECTION 3

Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Basic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Select TLP Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Display TLP Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Duplicating a Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using Copy and Paste. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

New Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Open File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Save File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Download File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Print Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting the Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Configuring the System Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Advanced Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3095FC Communications Ports Configuration . . . . . . . . . . . . . . . . 3-8

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

RBX Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3095FC Device Configuration / Information . . . . . . . . . . . . . . . . . 3-10

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Points Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Other Information Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Revision Info Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Security Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Rosemount User Interface Security - Menu and Log On . . . . 3-13

3095FC Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

LCD User List Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Scanning Disabled versus Scanning Enabled. . . . . . . . . . . . . 3-15

I/O Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Analog Input (AI) Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

AI General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

AI Advanced Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

AI Alarms Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

TOC-2

Page 7

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Soft Points Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Opcode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Opcode Table Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Radio Power Control Configuration . . . . . . . . . . . . . . . . . . . . . . . 3-23

Meter Run Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

AGA Meter Inputs Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Gas Quality Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Advanced Meter Setup Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Instrument Calibration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Meter Setup Alarms Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

History Points Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Meter History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Averaging Technique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Log Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

General History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

History, Alarm, Event, and Audit Log Reports . . . . . . . . . . . . . . . 3-37

Collect Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-38

Configure History for EFM Reporting . . . . . . . . . . . . . . . . . . . . . . 3-38

Electronic Flow Measurement (EFM) Reports . . . . . . . . . . . . 3-38

Modbus Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

General Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Scale Values Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Modbus - History Collection . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

History Access Registers Tab . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Modbus - Events / Alarms Functionality . . . . . . . . . . . . . . . . . 3-45

Modbus - Detailed Point / Parameter Information . . . . . . . . . . 3-47

Configure Modbus Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

Modbus Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Custom Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

New Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

Save Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

SECTION 4

Calibration

SECTION 5

Troubleshooting and

Maintenance

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3095FC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Analog Input (AI) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Calibration Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Calibration Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Zero Shift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Verify Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Backup Configuration Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Communication Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Communication Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Debug Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Resetting the 3095FC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Warm Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cold Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Jumper Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

After Installing Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Replacing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

TOC-3

Page 8

Rosemount 3095FC

Reference Manual

00809-0100-4832, Rev AA

October 2004

Changing the Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

APPENDIX A

Specifications and

Reference Data

APPENDIX B

Product Certifications

APPENDIX C

Rosemount User

Interface Software

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Memory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Flow Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Standard Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Custom Configuration (Option Code C1) . . . . . . . . . . . . . . . . . . . A-11

Tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Optional 305 Integral Manifolds. . . . . . . . . . . . . . . . . . . . . . . . A-11

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Rosemount User Interface Software Packages . . . . . . . . . . . A-11

Windows 98 or higher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-11

Approved Manufacturing Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

European Directive Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

North American Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Point Type Parameter Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Point Type 0 InformationC-2

Device Point Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

APPENDIX Glossary

TOC-4

Page 9

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Section 1 Introduction

3095FC Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

3095FC Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

3095FC OVERVIEW The 3095FC is a 32-bit microprocessor-based transmitter. The device

electronically measures, monitors, and manages gas flow for a single meter

run using an orifice plate (DP). It reliably and accurately performs gas flow

calculations, temperature measurements, and data archival.

The 3095FC performs minute, 10-minute, hourly (periodic), daily, and

minimum / maximum historical data archival. It records the corrected gas flow

across an orifice plate, stores the data, and has the ability to send the data to

a remote host.

The 3095FC computes gas flow for both volume and energy. It provides

on-site functionality and supports remote monitoring, measurement, data

archival, communications, and control.

The 3095FC provides the following components and features:

• Weather-tight enclosure

• Termination Board

• 32-bit Processor Board

• Battery Charger Board

• Backplane Board

• 2 MB of flash ROM (Read Only Memory), which is field upgradeable

• 512 KB of battery backed-up RAM (Random Access Memory) storage

• Support for a three-wire 100-ohm Resistance Thermal Detector (RTD)

input

• Internal lead-acid batteries (optional)

• Local Operator Interface (LOI) port - EIA-232 (RS-232)

• EIA-485 (RS-485) Comm 1 port

• Communications card using EIA-232 (RS-232) on Comm 2 port

(optional)

• Extensive applications firmware

www.rosemount.com

Page 10

Reference Manual

00809-0100-4832, Rev AA

Rosemount 3095FC

October 2004

Hardware The backplane board provides the power regulation, the routing of the signals

to the termination board, the processor board, the backup battery board, the

optional communications board, the sensor module, and the battery charger

board.

The termination board provides connections to the field wiring and is located

on the terminal side of the housing. Connections include the power supply,

Local Operator Interface (LOI) communications, Comm 1 communications,

optional Comm 2 communications, RTD wiring, and the I/O field wiring. The

termination board provides surge and static discharge protection for the field

wiring. Electronics include the RTD circuits and the final I/O drivers/receivers.

The termination board also serves as an interface to the backplane board in

the electronics portion of the enclosure.

The 32-bit processor board contains the processor, memory, Local Operator

Interface (LOI) communications driver, Comm 1 communications driver, the

reset controller, and the real-time clock. The functions for the I/O of analog

conversion originate on the processor board. The processor board, also

called the central processor unit, provides the Serial Peripheral Interface

(SPI) buss, Liquid Crystal Display drivers, and Sensor module.

The microprocessor has low-power operating modes, including inactivity and

low battery condition. The 3095FC comes standard with 512 KB of built-in,

static random access memory (SRAM) for storing data and history. The

3095FC also has 2 MB of flash ROM for storing operating system firmware,

applications firmware, and configuration parameters.

The charger board controls the charging of the internal batteries, if installed.

Three D-size lead-acid batteries provide 2.5 Amp-hours of current at 6.2 volts

nominal. The charger board also serves as the interface to the optional LCD

assembly, as well as supporting the On/Off and Norm/Reset jumpers.

A backup battery provides backup power for the static RAM and the

Real-Time Clock. This battery is field replaceable. Under normal conditions,

the battery has a functional life that exceeds five years.

An RTD temperature probe typically mounts in a thermowell on the meter run.

The RTD measures the flowing temperatures under a constant current drive.

The RTD wires connect directly to the RTD connector on the termination

board located inside the enclosure.

The built-in inputs and outputs (I/O) on the 3095FC consist of a port for a

3-wire 100-ohm RTD input interface. Three diagnostic analog inputs (AI)

monitor the battery voltage, logical voltage, and enclosure/battery

temperature.

The Local Operator Interface (LOI) port provides a direct link between the

3095FC and a personal computer (PC) through a Local Operator Interface

Cable using EIA-232 (RS-232) communications. Configure the functionality of

the 3095FC and monitor its operation using Rosemount User Interface

Software (see Section 3: Configuration).

The Comm 1 allows for EIA-485 (RS-485) serial communication protocols.

The EIA-232 (RS-232) activates Comm 2. “Establishing Communication” on

page 2-13

1-2

The I/O parameters, Sensor inputs, flow calculations, power control, and

security are configured and accessed using the configuration options

available in Section 3: Configuration.

Page 11

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Firmware The firmware contained in flash ROM on the termination board, determines

the functionality of the 3095FC and includes:

• 1992 AGA-3 flow calculations (with user-selectable AGA8

compressibility Detail, Gross I, or Gross II) for a single meter run

• Memory logging of 240 alarms and 240 events

• Archival of minute data from the last 60 minutes for 15 points

• Archival of 60 days of 10-minute data for 4 points

• Archival of 35 days of hourly data for 15 points

• Archival of 35 days of daily data for 15 points

• Archival of Min / Max historical data for today and yesterday

• Communications based on Modbus slave, (ASCII or RTU) protocol for

use with EFM applications

• User level security

Accessories The 3095FC supports the following options and accessories:

• Local Operator Interface (LOI) cable

• Liquid Crystal Display (LCD) with two-line alphanumeric viewing. The

LCD automatically displays information at 3-second intervals.

• Solar panel mast assembly (installed to recharge the backup battery)

Automatic Tests The 3095FC performs the following self-tests on a periodic basis:

• Battery low and high

• Software and hardware watchdog

• RTD automatic temperature compensation

• Sensor operation

• Memory validity

The 3095FC will operate with its internal batteries down to 5.4 VDC. The LCD

becomes active when input power with the proper polarity and startup voltage

(typically set greater than 8.0 Volts) is applied to the CHG+ connector

(provided the power input fusing/protection is operational). The battery and

logical voltage tests ensure that the 3095FC is operating in the optimum

mode.

The software watchdog is controlled by the central processor unit (CPU). The

software will arm the watchdog timer every second. If the watchdog timer is

not armed for a period of 6 seconds, then the watchdog timer forces the

3095FC unit to reset. If necessary, the software automatically resets. The

hardware watchdog is controlled by the CPU and monitors the power to the

hardware. If the battery voltage drops below 5.4 volts, the 3095FC

automatically shuts down.

The Rosemount 3095FC monitors its orifice-metering measurement for

accurate and continuous operation.

1-3

Page 12

Reference Manual

00809-0100-4832, Rev AA

Rosemount 3095FC

October 2004

Low Power Mode Sleep mode is used to place the CPU in a low power mode. The battery

voltage is monitored by low voltage detection circuitry and the low voltage limit

value is set at 5.4 volts. During Sleep mode, sub-modules are powered down.

The 3095FC enters Sleep mode after one minute of inactivity on the

communication ports.

Wake-up from Sleep occurs when the 3095FC receives a:

• Timed interrupt from the Real-Time Clock

• Signal from one of the communication ports

3095FC Functions Most of the 3095FC functions are determined by the firmware. The features

and applications provided by the firmware, which must be configured by using

Rosemount User Interface Software, include:

• Flow calculations for an orifice meter

• Extensive historical data archival

• Memory logging of 240 alarms and 240 events

• Security with local and remote password protection

Flow Measurement

The primary function of the 3095FC is to measure the flow of natural gas

through an orifice in accordance with the 1992 American Petroleum Institute

(API) and American Gas Association (AGA) standards.

The primary inputs used for the orifice metering flow measurement function

are DP, SP, and temperature. The DP and SP inputs are sampled once per

second. The temperature input is sampled and linearized once per second

from an RTD probe.

1992 Flow Calculations for Orifice Metering

The 1992 flow calculation is in accordance with ANSI/API 2530-92 (AGA

Report No. 3 1992), API Chapter 14.2 (AGA Report No. 8 1992 2nd printing

1994), and API Chapter 21.1. The 1992 flow calculation may be configured for

either Metric or U.S. units.

Flow Time

The DP stored for each second is compared to the configured low flow

cutoff. If the DP is less than or equal to the low flow cutoff or the converted

SP is less than or equal to zero, flow is considered to be zero for that

second. Flow time for a recalculation period is defined to be the number of

seconds the DP exceeded the low flow cutoff.

Input and Extension Calculation

Every second the Rosemount 3095FC stores the measured input for DP,

SP, and temperature and calculates the Integrated Value (IV) (the square

root of the absolute upstream SP times the DP).

1-4

Flow time averages of the inputs and the IV over the configured calculation

period are calculated, unless there is no flow for an entire calculation

period. Averages of the inputs are recorded to allow monitoring during no

flow periods.

Page 13

Reference Manual

00809-0100-4832, Rev AA

October 2004

CONSIDERATIONS

Rosemount 3095FC

Instantaneous Rate Calculations

The instantaneous value of the IV is used with the previous calculation

period of the Integral Multiplier Value (IMV) to compute the instantaneous

flow rate. The IMV is defined as the value resulting from the calculation of

all other factors of the flow rate equation not included in the IV. The

instantaneous flow rate is used with the volumetric heating value to

compute the instantaneous energy rate.

Flow and Energy Accumulation

The averages of the DP and SP, temperature, and sum of the IV are used

with the flow time to compute the flow and energy over the calculation

period. The flow and energy are then accumulated and stored at the top of

every hour. At the configured contract hour, the flow and energy are stored

to the Daily Historical Log and zeroed for the start of a new day.

Environmental

Requirements

The 3095FC is designed to operate between -40 to 75°C (-40 to 167°F).

When mounting, ambient temperatures may effect the operating temperature.

Operation beyond the recommended temperature range may cause

measurement error and erratic performance.

The 3095FC should not be exposed to levels of vibration that exceed 2g for

15 to 150 Hz and 1g for 150 to 2000 Hz.

Enclosures The 3095FC is packaged in a NEMA 4 windowed enclosure The enclosure is

fabricated from die-cast aluminum alloy with iridite plating and paint. There

are two ¾-in. pipe threaded holes for field conduit wiring, and

communications.

Mounting Provide adequate clearance for wiring, service, and solar panel. Mount on a

pipestand or to an orifice plate using a 3- or 5-valve manifold. The LCD

display can be rotated 90 degrees in either direction.

For solar-powered 3095FC units orient solar panels as follows:

• Northern Hemisphere: due south (not magnetic south)

• Southern Hemisphere: and due north (not magnetic north)

• Sunlight is not blocked from 9:00 AM to 4:00 PM.

Power Installation

Requirements

The primary power source is provided through DC voltage sources or solar

power. Route power away from hazardous areas, sensitive monitoring

devices, and radio equipment. Adhere to all local, company, and National

Electrical Code (NEC) requirements for power installations.

The 3095FC accepts input voltages from 8.0 volts to 28 volts at the charge

(CHG+ / CHG-) terminals on the termination board. The maximum power for

DC voltage sources is 130 mW, not including battery charging.

An external solar panel connects to the CHG+ / CHG- inputs on the

termination board. Circuitry on the battery charger board monitors and

regulates the charge based on battery voltage, charging voltage, and

temperature. The 3095FC requires a minimum 8-volt 200 mA solar panel.

1-5

Page 14

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

NOTE:

Do not allow the batteries to fully discharge. If the batteries fully discharge, the

battery charger board may enter thermal limiting.

Rosemount User

Interface Software PC

Requirements

The Rosemount User Interface Software operates on any PC that meets the

following requirements:

• IBM compatible

• Pentium-Class Processor (233 MHz or greater is recommended)

• CD-ROM drive

• Windows 95 (service release B), 98, ME, NT 4.0 (Service Pack 6),

2000 (Service Pack 2), or XP.

•32 MB RAM

• 10 MB of available hard disk space

• RS-232 serial communication

• SVGA color monitor, 800 x 600 pixels

Site Requirements Local, state, and federal codes may restrict monitoring locations and dictate

site requirements. Position the 3095FC to minimize the length of signal and

power wiring.

Wiring Requirements I/O wiring requirements are site and application dependent. Local, state, or

NEC requirements determine the I/O wiring installation methods. Direct burial

cable, conduit and cable, or overhead cables are options for I/O wiring

installations.

1-6

Page 15

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Section 2 Installation

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-9

Apply Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-10

Install the Rosemount User Interface Software . . . . . . . . page 2-11

Getting Started with the Software . . . . . . . . . . . . . . . . . . . page 2-12

Establishing Communication . . . . . . . . . . . . . . . . . . . . . . page 2-13

Configuration Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-14

MOUNTING Mounting the Rosemount 3095FC can be accomplished using one of the

following methods:

• Pipestand mounted – The Rosemount 3095FC can mount to a 2-in.

pipestand. Ensure that the pipestand meets all weight requirements

and installation conforms to local building codes.

• Orifice Plate – Mount directly to an orifice plate using a 3- or 5-valve

manifold.

With either mounting method, the pressure inputs must be piped to the

process connections.

For solar panel mounting see “Mounting” on page 1-5. Dimensional drawings

are located on page page A-7. Solar power installation is located on page

page 2-3.

www.rosemount.com

Page 16

Reference Manual

00809-0100-4832, Rev AA

Rosemount 3095FC

October 2004

INSTALLATION

Rosemount 3095FC Piping from the static and DP meter runs connect to female ¼-18 NPT

connections. The 3095FC is an upstream device, meaning that the SP line

normally connects to the high pressure side (labeled “H” on the sensor body).

Installing the Rosemount 3095FC on a Pipestand

The following steps must be taken to install the 3095FC on a 2-in. pipestand:

1. Install the pipestand using the pipestand documentation.

2. Remove the orifice/meter run from service.

3. Install the 3095FC on a pipestand using clamps or mounting

brackets.

4. Connect the impulse lines.

5. Attach the appropriate wiring (see “Wiring” on page 2-4).

6. Using the prefabricated operator interface cable, physically connect

the 3095FC to the PC running the Rosemount User Interface

Software. One end of the cable (a 9-pin, D-shell, female connector)

plugs into a serial communications port on the PC. The other end of

the cable plugs into the 3095FC.

7. Apply power to the 3095FC (see “Apply Power” on page 2-10)

8. Log into the Rosemount User Interface Software (see page “Log into

the Software” on page 2-12)

9. Establish communication between the 3095FC and PC (see

“Establishing Communication” on page 2-13).

10. Configure the 3095FC (see “Configuration” on page 3-4)

11. Calibrate the 3095FC (see “Calibrate” on page 4-1).

12. Connect the 3095FC unit to any other external communication

devices or networks.

13. Place the meter run in service and monitor with Rosemount User

Interface Software for proper operation.

2-2

Installing the 3095FC on an Orifice Plate (Direct Mount)

The following steps must be taken to install the 3095FC on an orifice plate:

1. Remove the orifice/meter run from service.

2. Install the 3095FC on the meter run using a manifold and hardware to

secure the 3095FC to the orifice flanges.

3. Attach the appropriate wiring (see “Wiring” on page 2-4).

4. Using the prefabricated operator interface cable, physically connect

the 3095FC to the PC running the Rosemount User Interface

Software. One end of the cable (a 9-pin, D-shell, female connector)

plugs into a serial communications port on the PC. The other end of

the cable plugs into the 3095FC.

5. Apply power to the 3095FC (see “Apply Power” on page 2-10)

6. Log into the Rosemount User Interface Software (see page “Log into

the Software” on page 2-12)

7. Establish communication between the 3095FC and PC (see

“Establishing Communication” on page 2-13).

8. Configure the 3095FC (see “Configuration” on page 3-4)

Page 17

Reference Manual

00809-0100-4832, Rev AA

October 2004

9. Calibrate the 3095FC (see “Calibrate” on page 4-1).

10. Connect the 3095FC unit to any other external communication

devices or networks.

11. Place the meter run in service and monitor with Rosemount User

Interface Software for proper operation.

Rosemount 3095FC

Solar Panels Solar panels generate electrical power for the 3095FC from solar radiation.

They are the optimal choice for locations where a DC voltage source is not

available. The size of solar panels required for a particular installation

depends on several factors, including the power consumption of all devices

connected to the solar array and the geographic location of the installation. An

8-volt solar panel can provide charging power for the backup batteries (see

“Solar Panel Sizing” for information on how to determine the appropriate

panel size required for an application).

An external solar panel typically mounts to the same 2-in. pipe that supports

the 3095FC (see “Mounting” on page 2-1). The panel wiring terminates at the

charge (CHG+ / CHG-) power terminals on the termination board.

NOTE:

Solar panel size may violate certain CSA Class I, Division 1 ratings. Use

approved 3095FC enclosure connectors for routing the power wiring.

The optional solar panel is adequate for support of API Chapter 21.1

compliant measurement and the retrieval of the historical logs once a day

using the internal communication methods.

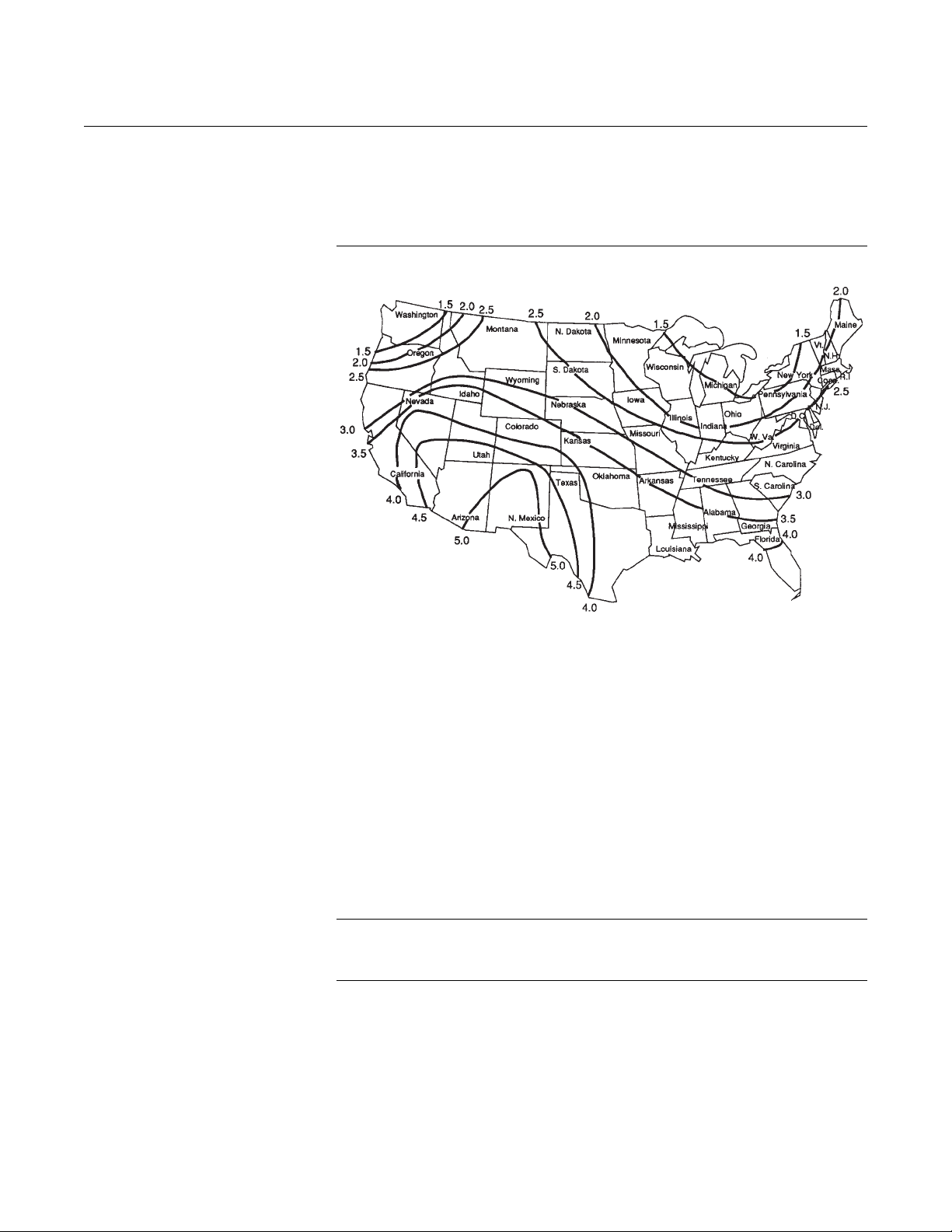

Solar Panel Sizing

To determine solar panel output requirements, first determine the solar

insolation for the geographic area. The map in Figure 2-1 shows solar

insolation (in hours) for the United States during winter months. Contact an

Emerson Process Management representative for a map detailing a specific

geographic area.

Insolation (from map) = _____ hours

Next, calculate the amount of current required from the solar array per day

using the following equation. I

I

= [ISF (amps) ´ 24 (hrs)]/Insolation (hrs) = _____ amps

array

Finally, the number of solar panels can be determined using the following

equation:

Number of Panels = I

NOTE:

The “I

to the vendor's specifications for the solar panel being used.

The current accepted by the Rosemount 3095FC is limited by its charging

circuit to around 1 Amp. Therefore, it is not practical to install a solar array that

“value varies depending on the type of solar panel installed. Refer

panel

is the system current requirement.

SF

array

amps/(I

amps/panel) = _____ panels

panel

2-3

Page 18

Rosemount 3095FC

Figure 2-1. Solar Insolation in

Hours for the United States

Reference Manual

00809-0100-4832, Rev AA

October 2004

supplies significantly more than 1 Amp to the 3095FC. The maximum input is

28 volts.

Do not allow the batteries to fully discharge. If the batteries are fully

discharged, the battery charger board may enter thermal limiting.

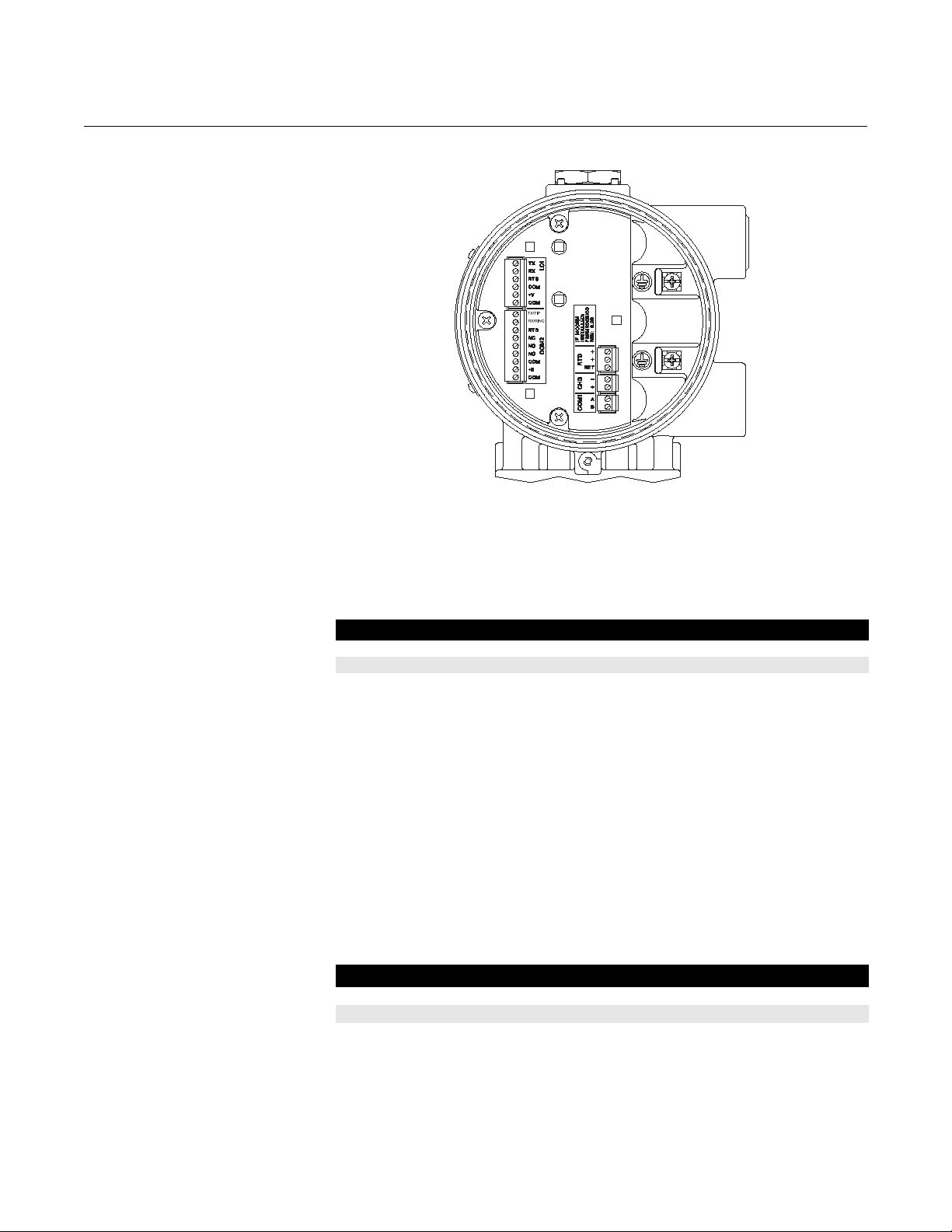

WIRING The field terminals are all located on a Termination Board. The input power

termination (CHG+ / CHG-) uses a removable connector and accommodates

wiring up to 16 AWG in size.

Use the following steps to connect wiring. See Figure 2-2 on page 2-5.

1. Remove power from transmitter (if applicable)

2. Strip the rubber coating from the end (

3. Insert the bared end into the clamp beneath the termination screw. To

prevent short circuits, the inserted wires should have as little bare

wire exposed as possible.To prevent strain, allow some slack when

making connections.

4. Tightening the screw to 0.25 N-m (2.2 lb-in.). Do not over torque the

connector screws.

5. Check the polarity before applying power.

NOTE

To avoid circuit damage, use appropriate electrostatic discharge precautions,

such as wearing a grounded wrist strap.

1

/4-in. maximum) of the wire.

2-4

Page 19

Reference Manual

00809-0100-4832, Rev AA

October 2004

Figure 2-2. Wiring Terminals

Rosemount 3095FC

Power Supply Wiring The terminals are labeled CHG+ for positive power connection and CHG- for

negative power connection on a label on the termination board. These

connections provide the input voltage and power for the battery charging

circuitry. The maximum voltage that can be applied to the CHG+ / CHGterminals is 28 Volts dc.

Pin Signal Description

1 CHG+ Battery 8.0 to 28 V Power

2 CHG– Battery Common

RTD Wiring Temperature is input through the Resistance Temperature Detector (RTD)

probe and circuitry. The 3095FC provides terminations for a 2- or 3-wire

100-ohm platinum RTD with a IEC 751 curve. The RTD has an alpha (α)

equal to 0.00385.

The RTD mounts directly to the piping using a thermowell. RTD wires should

be protected by a metal sheath or by a conduit connected to a conduit wiring

fitting on the enclosure. The RTD wires connect to the three screw terminals

designated “RTD” on the Termination Board (see Figure 2-2).

Wiring between the RTD and 3095FC should be shielded wire, with the shield

grounded only at one end to prevent ground loops. Ground loops cause RTD

input signal errors.

Table 2-1 displays the RTD terminal connections for the various RTD probes.

Table 2-1. RTD Signal Routing

Ter minal Designation 3-Wire RTD 2-Wire RTD

RTD + Signal positive input RTD + RTD +

RTD + Signal positive input RTD + Jumper to RTD +

RTD RET Return reference RTD RET RTD RET

2-5

Page 20

Reference Manual

00809-0100-4832, Rev AA

Rosemount 3095FC

October 2004

Communications Wiring The communication ports located on the 3095FC provide a data link to the

Rosemount User Interface Software, other 3095FC units, and host systems.

NOTE

All communication ports for the 3095FC are located on an optional

communications card or built into the termination board.

Table 2-2. Communication Ports

for the 3095FC

Port

1 CPU RJ-45 (top) Local Port LOI / RS-232D

2 CPU RJ-45 (top) COMM1 Ethernet

3 CPU 5-pin (bottom) COMM2 Serial / EIA-232 (RS-232)

4

5

6

3095FC Comm

Port Location

Module Slot 1 COMM3 EIA-232 (RS-232), EIA-485

Module Slot 2 COMM4 EIA-232 (RS-232), EIA-485

Module Slot 3 COMM5 EIA-232 (RS-232), EIA-485

Default Tag Function/Type

(RS-485), Modem, or MVS

(RS-485), Modem, or MVS

(RS-485), Modem, or MVS

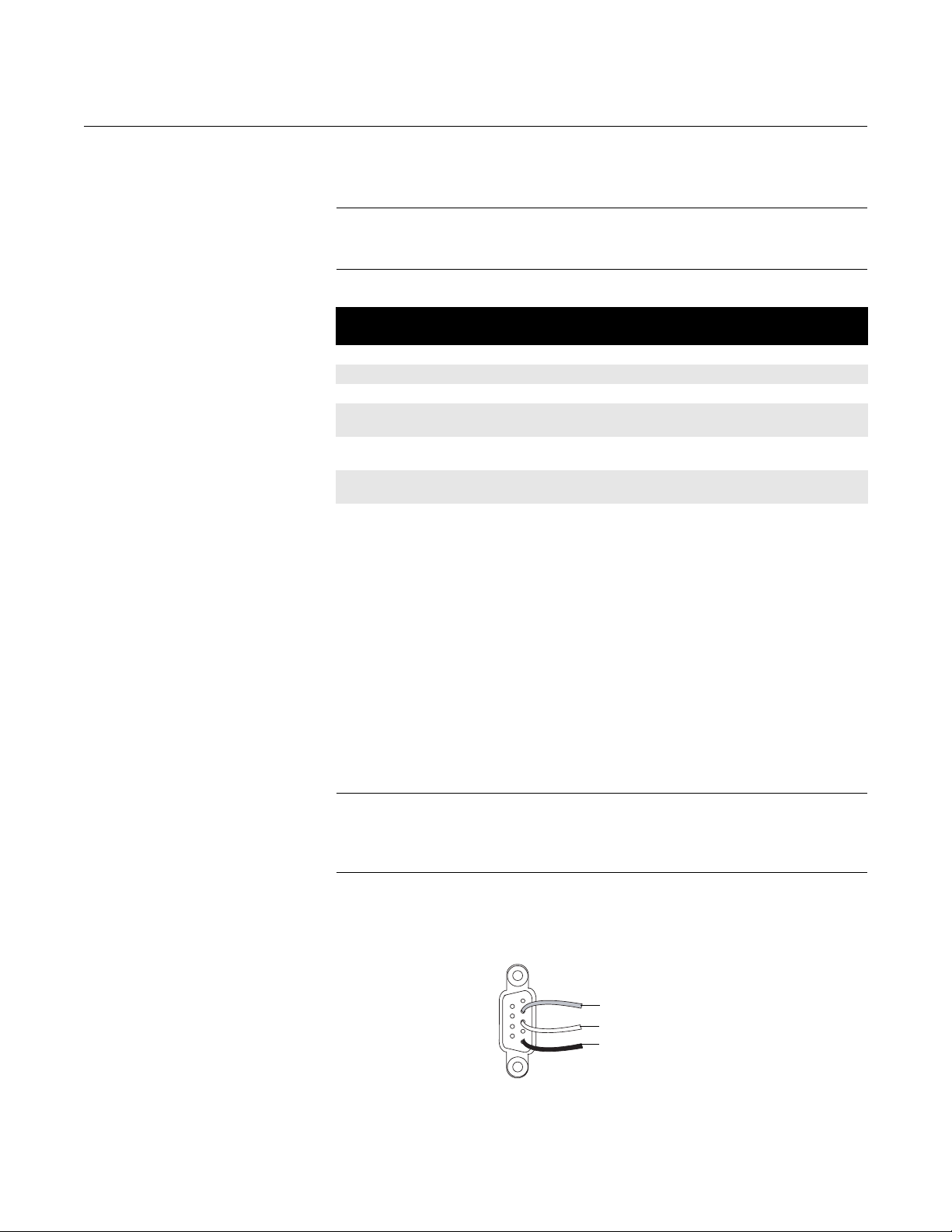

Figure 2-3. Operator Interface

Wiring

Local Operator Interface Port (LOI)

The Local Operator Interface (LOI) port provides direct communications

between the 3095FC and the serial port of an operator interface device, such

as an IBM compatible PC using an EIA-232 (RS-232) link. The interface

allows access to the 3095FC (using Rosemount User Interface Software) for

configuration and transfer of stored data.

The LOI terminal on the Termination Board provides wiring access to a built-in

EIA-232 (RS-232) serial interface, which is capable of up to 19,200 bps

operation. The operator interface port supports Modbus protocol

communications. The LOI also supports the log-on security feature of the

3095FC if the Security on LOI is Enabled in Rosemount User Interface

Software (“Security Configuration” on page 3-13).

NOTE

By default, the LOI Port is Comm Tag Local Port in the 3095FC > Comm Port

settings screen. Use the 3095FC > Direct Connect command to connect

using the LOI. See “Connection Methods” on page 2-13.

To ease wiring, operator interface cable is available as an accessory (see

“Installation” on page 2-2). Refer to Figure 2-3.

1

6

2

7

3

8

4

9

5

White TX

Red TX

Black TX

To screw

Ter min als

2-6

Connection at

PC COM Port

Page 21

Reference Manual

00809-0100-4832, Rev AA

October 2004

Table 2-3. Local Operator

Interface Port Wiring

Table 2-4. PC Comm Port

Wiring

Rosemount 3095FC

Signal Label

Common COM

LOI Power

Common COM

Ready to Send RTS

Receive (RX) RX

Transmit (TX) TX

(1) Do not use the LOI to power external devices.

Signal Pin Label

Transmit (TX) 2 TX

Receive (RX) 3 RX

Ground (GND) 5 COM

EIA-485 (RS-485) Serial Communications - Comm 1

Use Comm 1 to monitor or alter the 3095FC from a remote site using a host or

Rosemount User Interface Software. Comm 1 supports baud rates up to

19200 bps. Comm 1 also supports the log-on security feature of the 3095FC if

the Security on Comm 1 is Enabled in Rosemount User Interface Software.

(1)

TX + V

Table 2-5. EIA-485 (RS-485)

Communications Wiring

Comm 1 sends and receives messages using Modbus protocol. Comm 1

permits EIA-485 (RS-485) serial communication protocols that meet EIA-485

(RS-485) specifications for differential, asynchronous transmission of data

over distances of up to 1220 m (4000 ft). The EIA-485 (RS-485) drivers are

designed for true multi-point applications with multiple devices on a single bus.

The default values for the EIA-485 (RS-485) communications are: 9600 Baud

Rate, 8 Data Bits, 1 Stop Bit, No Parity, 10 millisecond Key On Delay, and 10

millisecond Key Off Delay. The maximum baud rate is 19200 bps. To enable or

disable the Comm 1 port, select Configure > Radio Power Control and select

the Enable (default)/Disable under Radio Power Control (see “Radio Power

Control Configuration” on page 3-23).

Wiring should be twisted-pair cable. The terminals and their functions are as

follows:

Pin Function Label

1 RS-485 B

2 RS-485 A

EIA-232 (RS-232) Communications - Comm 2

A EIA-232 (RS-232) communications card in the Comm 2 port can switch

power to an external communication devices, such as a radio, to conserve

power. A label on the termination board denotes the usage of each pin on the

connector.

The EIA-232 communications card meets all EIA-232 specifications for

single-ended RS-232 asynchronous data transmission over distances of up to

15 m (50 ft). The EIA-232 (RS-232) communications card defaults are: 9600

baud rate, 8 data bits, 1 stop bit, no parity, 10 millisecond Key On Delay, and

10 millisecond Key Off Delay. The maximum baud rate is 19200 bps. Refer to

Table 2-6 for communication card signals.

2-7

Page 22

Rosemount 3095FC

Reference Manual

00809-0100-4832, Rev AA

October 2004

Table 2-6. Communications

Card Signals

Table 2-7. EIA-232 (RS-232)

Communications Card Wiring

Signals Action

RTS The request to send signals that the modem is ready to transmit.

RX The RXD receive data signals that data is being received at the

communications card.

TX The TXD transmit data signals that data is being transmitted from

the communications card.

Signal Label

Signal Common Negative COM

Switched Power TX

Ground COM

Request to Send RTS

Tip / Receive Data RX

Ring / Transmit Data TX

(1) GND at Pin 1 and Pin 3 are identical. They are separated for ease of wiring.

(2) Switched Power is used with an internal radio or cell phone. It does not power external devices.

(3) Transmit (TX) connects to the 3095FC unit's receive.

(1)

(2)

+ B

(1)

(3)

Ground the Transmitter Grounding reduces the effects of electrical noise on the unit's operation and

protects against lightening. The 3095FC provides lightening protection for

built-in field wiring inputs and outputs. Install a surge protection device on the

DC voltage source system to protect the device against lightning and power

surges.

The 3095FC has two grounding screws inside the enclosure. It is

recommended that a minimum of 14 AWG wire be used for the ground wiring.

To minimize signal errors caused by EMI (electromagnetic interference), RFI

(radio frequency interference), and transients, The I/O signal wiring cable

should be an insulated, shielded, twisted-pair. All grounds should terminate at

a single point.

NOTE

Grounding wiring requirements for DC voltage sources equipment are

governed by the National Electrical Code (NEC). When the equipment uses

DC voltage sources, the grounding system must terminate at the service

disconnect. All equipment grounding conductors must provide an

uninterrupted electrical path to the service disconnect.

Earth Grounds

All earth grounds must have an earth to ground rod or grid impedance of 25

ohms or less as measured with a ground system tester. The grounding

conductor should have a resistance of 1 ohm or less between the 3095FC

enclosure ground and the earth ground rod or grid.

Pipelines With Cathodic Protection

The 3095FC must be electrically isolated from the pipeline. Electrical isolation

can be accomplished by using insulating flanges upstream and downstream

on the meter run. In this case, the Rosemount 3095FC could be flange

mounted or saddle-clamp mounted directly on the meter run and grounded

with a ground rod or grid system (see “Earth Grounds” on page 2-8).

2-8

Page 23

Reference Manual

00809-0100-4832, Rev AA

October 2004

Pipelines Without Cathodic Protection

The pipeline may provide an adequate earth ground and the 3095FC could

mount directly on the meter run using an orifice plate. Use a ground system

tester to make sure the pipeline to earth impedance is less than 2 ohms. If the

pipeline to earth impedance is greater than 2 ohms, the 3095FC installation

should be electrically isolated and a ground rod or grid grounding system

installed. If the pipeline provides an adequate ground, a separate ground rod

or grid system may not need to be installed.

Rosemount 3095FC

POWER SUPPLY The 3095FC accepts input voltages from 8.0 volts to 28 volts at the power

terminals (CHG+ / CHG-) with no external current limiting (internal current

limit is 200 mA). The CHG+ / CHG- terminal can accommodate up to 16 AWG

wire.

To adequately meet the needs of the 3095FC system, it is important to

determine the total power consumption and size of solar panel requirements

accordingly. To determine the total 3095FC power consumption, be sure to

add the power consumption (in mW) of any other devices used with the

3095FC in the same power system. The maximum power for DC voltage

sources is 130 mW not including the battery charging.

Convert the total value (in mW) to Watts by dividing it by 1000.

mW / 1000 = Watts

For selecting an adequate power supply, use a safety factor (SF) of 1.25 to

account for losses and other variables not factored into the power

consumption calculations. To incorporate the safety factor, multiply the total

power consumption (P) by 1.25.

PSF = P x 1.25 = _____ Watts

To convert PSF to current consumption in amps (ISF), divide PSF by the

system voltage (V) of 12 volts.

ISF = PSF / 12V = _____ Amps

Batteries

Batteries provide power for the 3095FC when the solar panels are not

generating sufficient output. The batteries are three D-size lead-acid batteries

providing 2.5 Amp-hours of current at 6.2 volts.

The batteries are connected in series by the Battery Charger Board to

achieve the required capacity. The battery capacity determines the number of

days of reserve (autonomy) desired.

When the 3095FC is configured as an API compliant Electric Flow

Management (EFM) and requires an internal communications card, a solar

panel, and the internal batteries, the 3095FC should be able to communicate

the API audit trail information once a day to a remote host using no additional

battery source, no additional solar panel, and maintain a 13 day autonomy in

the event that the solar panel is lost.

To determine the system capacity requirements, multiply the system current

load (ISF) on the batteries by the amount of reserve time required. Compute

“ISF” as described above. The equation is as follows:

System Requirement = ISF amps x Reserve hrs = _____ amp-hrs

2-9

Page 24

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

APPLY POWER To prevent unnecessary battery drainage, the 3095FC is delivered with the

reset jumper in the OFF position. To apply power to the 3095FC:

1. Complete the necessary wiring (“Wiring” on page 2-4).

1. Unscrew the front end cap cover (LCD end).

2. Place the power jumper in the ON position. The jumper is located on

the LCD (if installed) or at J1 on the Battery Charger Board.

3. Screw the front-end cap cover (LCD end).

After the 3095FC completes start-up diagnostics (RAM and other internal

checks), the optional LCD displays the date and time to indicate that the

3095FC completed a valid reset sequence. If the LCD does not come on,

refer to Section 5: Troubleshooting and Maintenance.

2-10

Page 25

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

INSTALL THE

ROSEMOUNT USER

INTERFACE SOFTWARE

If a previous version of the Rosemount User Interface Software is installed,

refer to “Uninstalling the Rosemount User Interface Software” on page 2-12.

Software Overview

The Rosemount User Interface Software is used to configure the 3095FC. For

PC requirements see “I/O wiring requirements are site and application

dependent. Local, state, or NEC requirements determine the I/O wiring

installation methods. Direct burial cable, conduit and cable, or overhead

cables are options for I/O wiring installations.” on page 1-6.

The major components of the Rosemount User Interface Software user

interface are:

• Menu bar and menus

• Function screens

• Dialog boxes

• Help system, including the Status bar and message boxes

The menu bar appears on the screen after successfully logging on. From the

menu bar, the user may activate a menu and select a function in that menu.

Functions may be selected using Toolbar Buttons or the Configuration Tree

Menu

Several buttons are commonly used on many Rosemount User Interface

Software screens.These buttons are:

• Update: updates content of the window.

• OK: approves and closes the window. A Confirm Save dialog box

appears if there are unsaved changes.

• Cancel: cancels all changes and closes the window.

• Apply: applies changes to the window.

Install With Autorun 1. Insert the Rosemount User Interface Software installation CD-ROM

into the drive

2. Click Next.

3. Click Yes to agree with the Terms and Conditions

4. Enter the users Name and the Company name. Click Next.

5. The software is saved to the default directory

C:\Program Files\Rosemount\Rosemount 3095FC User

Interface\User Interface. If another location is desired, use to Browse

button to select that location. Click Next. A warning box appears if

there are incompatible files.

6. Review the items in the list and click Next.

7. When the installation is complete click Finish.

8. Remove the Rosemount User Interface Software installation

CD-ROM.

2-11

Page 26

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Install Without Autorun 1. Insert the Rosemount User Interface Software installation CD-ROM.

2. Click the Windows Start button.

3. Select Run.

4. Click the Browse button

5. Navigate to and select the Select.exe located on the CD-ROM.

6. Click OK in the Navigation Window.

7. Click OK in the Run window.

8. Continue with in “Install With Autorun" steps 2-8, located above.

Uninstalling the

Rosemount User

Interface Software

1. Click the Windows Start button.

2. Select Settings > Control Panel.

3. Double-click the Add/Remove Programs icon.

4. Select Rosemount 3095FC User Interface.

5. Click Change/Remove.

6. Follow the instructions that appear on the screen.

GETTING STARTED

WITH THE SOFTWARE

Run the Software To run the software, perform one of the following steps

• Double-click on 3095FC User Interface located on the desktop.

• Select Start > Programs > Rosemount 3095FC User Interface >

3095FC User Interface.

• Double-click on the file 3095.exe located in C:\Program

Files\Rosemount\Rosemount 3095FC User Interface (default

directory). If the program file was saved to another location in “Install

With Autorun” on page 2-11, select this location instead.

NOTE

Only one version of Rosemount User Interface Software can run at a time.

Log into the Software To log on to Rosemount User Interface for Windows software:

1. Connect the 3095FC to the Local Operator Interface (LOI) port and

launch Rosemount User Interface Software.

2. Enter the factory-assigned 3-character login (username): LOI.

Enter the 4-digit password: 1000. The login is assigned using the

security feature of the Rosemount User Interface Software (see

“Security Configuration” on page 3-13).

NOTE

Login is case sensitive.

If the login is not valid, a dialog box appears. Click OK and reenter the login

and password. Repeat this procedure until a successful login and password is

entered. To exit the login screen press >Esc> or click Cancel.

When login is successful, the Configuration Tree appears on the screen. See

“Configuration Tree” on page 2-14 for more information.

2-12

Page 27

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

ESTABLISHING

COMMUNICATION

Connection Methods When the user is logged into the Rosemount User Interface Software, the PC

must connect to the 3095FC unit so communication can be accomplished.

Use one of the following connection methods:

• Direct Connect - Connect to the 3095FC using the Local Port (LOI) if

the default communication parameters apply.

• 3095FC (Communications) Directory View - Double-click the Station

Name to connect to the 3095FC using the parameters currently set for

that 3095FC.

NOTE

Once connected, the Configuration Tree view becomes the active screen.

Direct Connect

The Direct Connect command allows the Rosemount User Interface Software

to initiate communications with the 3095FC by performing a search of the PC

communication ports at various baud rates. Direct Connect “locks on” to the

first Comm Port and Baud Rate (1200, 2400, 4800, 9600, 19200, 38400, and

57600 bps) that successfully communicate with a 3095FC.

If unsuccessful, the program attempts to establish communications through

the remaining COM Ports of the PC, successively, until it receives a valid

reply.

For the Direct Connect option to operate correctly the PC must be connected

to the Local Operator (LOI) port of the 3095FC with communication settings

of:

• 8 Data Bits

• 1 Stop Bit

•No Parity

To use Direct Connect:

1. Physically connect the 3095FC (see “Installation” on page 2-2).

2. Launch and log into Rosemount User Interface Software (see

“Getting Started with the Software” on page 2-12).

3. Perform one of the following:

• Click on the Direct Connect icon in 3095FC Directory

(Configuration Tree.)

• Click the Direct Connect button on the toolbar.

4. If this is the first time connecting to the 3095FC, continue with

“Setting the Clock” on page 3-4.

2-13

Page 28

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Connect

When off-line, the 3095FC menu displays Connect. To use Connect:

1. Physically connect the 3095FC (see “Installation” on page 2-2).

2. Launch and log into Rosemount User Interface Software (see

“Getting Started with the Software” on page 2-12).

3. Perform one of the following:

• Select a communications port from the Device Directory and press

the <Enter> key.

• Double-click on a communications port from the Device Directory.

• Click the Connect button on the toolbar.

• Select Device > Connect to connect to the 3095FC currently

selected in the Device Directory. If a 3095FC is not currently

selected, the error “No 3095FC is Currently Selected” appears.

Remote Hardware Connection

To connect the PC to a remote 3095FC, a serial, dial-up modem, radio,

satellite, or other communications line should be installed. This connection is

typically made through the host port on the 3095FC. Use the Connect

command to connect to a serial or dial-up modem

Disconnect from the 3095FC

Close the screen to disconnect an on-line connection. This automatically

closes the connection.

CONFIGURATION TREE When communication is established with a 3095FC or opening a

configuration file, the Configuration Tree appears on the screen. The

Configuration Tree is used to perform the following:

• Add, delete, or modify communication configurations for the 3095FC

units. The communication configurations allow the Rosemount User

Interface Software to communicate to an individual 3095FC unit.

• Establish Groups of 3095FC units. A 3095FC Group is typically several

units in the same geographical area or a number of units with

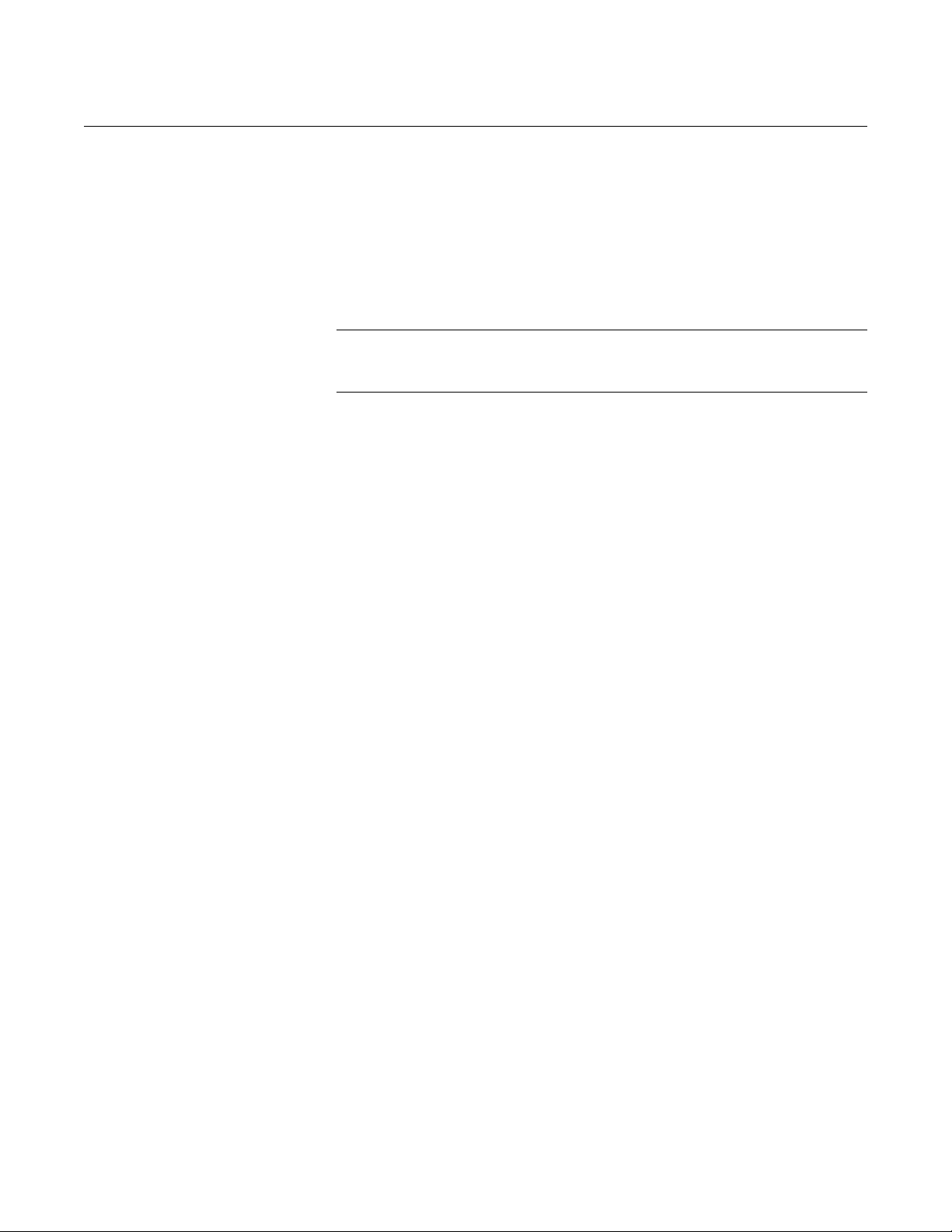

something else in common. Each group contains a list of all the

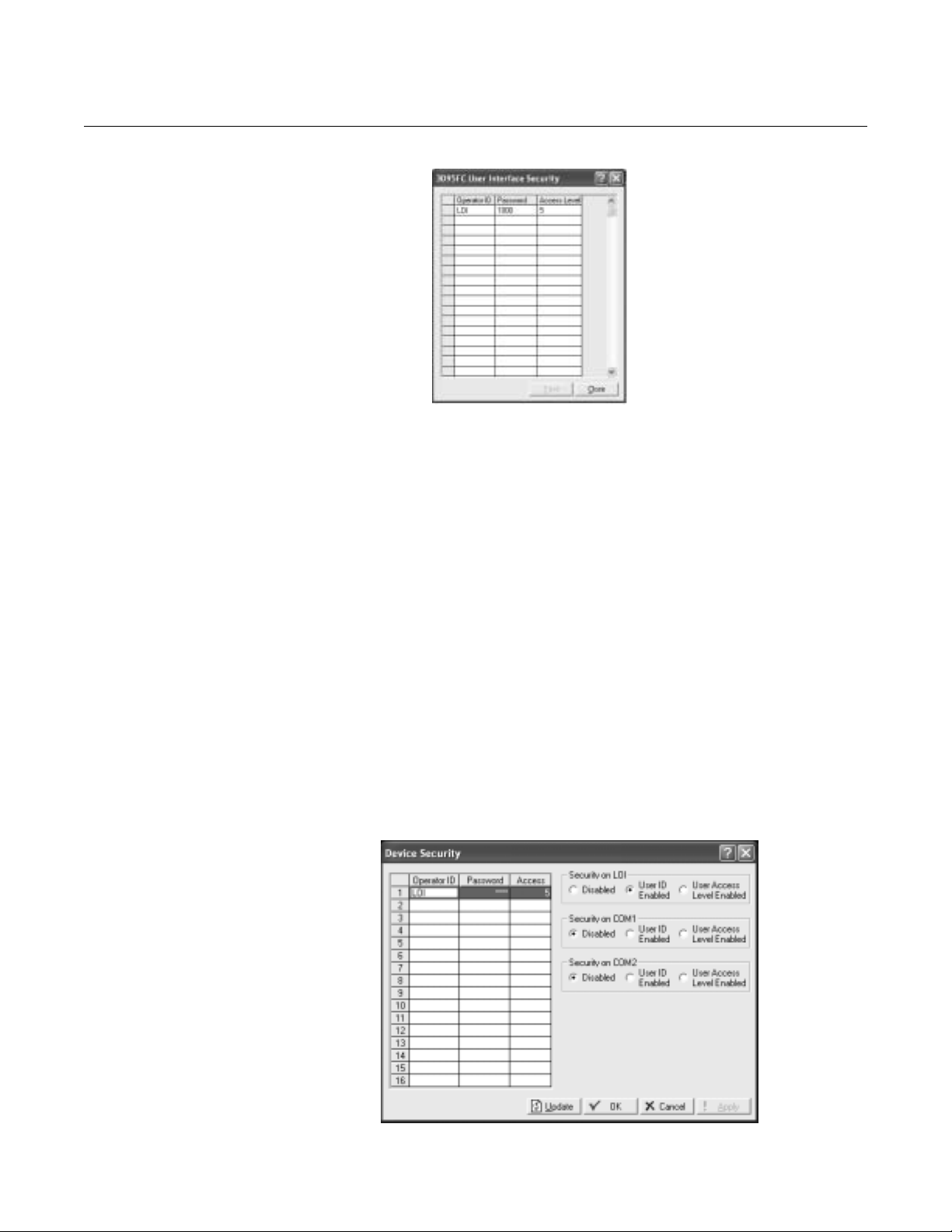

3095FC devices contained within that group.

• Assign an address for every 3095FC within a group. Each 3095FC has

a Station Name (Tag) and unique address with which to differentiate

each device. The Address must be different from any other host system

that may access the communications link.

• Setup the 3095FC Comm Ports

Use the “+” and “–” symbols to display or hide various options.

Toggle between the Online configuration screen and the Configuration

tree/device directory using Window > >select file>.

2-14

Page 29

Reference Manual

00809-0100-4832, Rev AA

October 2004

Figure 2-4. Configuration Tree

Screen

Rosemount 3095FC

NOTE

Double-click the desired communications link (3095FC name) to connect to

that 3095FC. Double-clicking an icon is the same as selecting the menu bar

or toolbar button Direct Connect or Connect commands.

Configuration of the PC Communication Ports to the 3095FC unit cannot be

performed within the 3095FC unit configuration screen. Return to the 3095FC

Directory (Configuration Tree) screen. If the user is in a configuration, select

Window > Device Directory or View > Device Directory to view the 3095FC

directory.

Adding a Group

Multiple 3095FC units can be organized to form Groups. Unit Groups are

typically units in the same geographical area or units with something else in

common. When a Group file is selected, a list of all 3095FC communication

setups in the Group appears below the Group.

1. Right-mouse click on the Device Root directory icon.

2. Select Add a Group.

3. Right-mouse click on the New Group and select Rename. Type in the

new Group name.

4. Press <Enter>.

5. The 3095FC can now be added to the Group.

Deleting a Group

1. Right-mouse click on the group to be deleted.

2. Select Delete Group.

3. Click Yes.

2-15

Page 30

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Adding a 3095FC transmitter

1. Right-mouse click on the Device Root directory icon.

2. Select Add a Device .

3. Right-mouse click on the New Device and select Rename. Type in the

new device name.

4. Press <Enter>.

5. Configure the 3095FC communication parameters.

NOTE

Place a 3095FC connection under a Group by selecting the Group before

adding the 3095FC Connection.

Deleting a 3095FC transmitter

1. Right-mouse click on the device to be deleted.

2. Select Delete Device.

3. Click Yes.

Deleting all 3095FC transmitters

1. Right-mouse click on the Device Root directory icon.

2. Select Delete All Devices.

3. Click Yes in the Confirm Delete Message dialog box.

Renaming a Group or 3095FC

1. Right click on the Device or Group to be renamed.

2. Select Rename.

3. Type the new name.

4. Press <Enter>.

2-16

Page 31

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Section 3 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Basic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Custom Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-54

OVERVIEW The Rosemount 3095FC has parameters that must be configured before it is

calibrated and placed into operation. Configuration must be performed using

Rosemount User Interface Software. Configuration can be performed either

onsite using the LOI port or off-line and later loaded into the unit.

Default values for all parameters exist in the firmware of the 3095FC. The

following parameters should be verified and configured:

• “Setting the Clock” on page 3-4

• “Configuring the System Flags” on page 3-5

• “3095FC Communications Ports Configuration” on page 3-8

• “Security Configuration” on page 3-13

• “LCD User List Configuration” on page 3-15

• “Analog Input (AI) Configuration” on page 3-16

• “Meter Run Configuration” on page 3-25 and “Gas Quality Tab” on

page 3-28.

• “History Points Configuration” on page 3-32

BASIC FUNCTIONS Begin the configuration process with “Setting the Clock” on page 3-4.

The following functions are used throughout the configuration process. They

are provided at the beginning of the section so they can be easily referenced.

Select TLP Options

Throughout Rosemount User Interface Software, the Select TLP dialog can

be accessed by clicking the browse button with three dots. The Select TLP

dialog allows the user to assign specific inputs and outputs to parameters.

Rosemount User Interface Software uses Point Type (T), Logical Number (L),

and Parameter (P) to define point locations.

The display field at the bottom of the Select TLP dialog displays the numeric

point location of the TLP point or a text abbreviation, depending on the

Display setting (see “Display TLP Options").

Display TLP Options

Select Tools > Options to set whether the TLP displays as text or numbers in

TLP display fields throughout the Rosemount User Interface Software.

www.rosemount.com

Page 32

Rosemount 3095FC

Reference Manual

00809-0100-4832, Rev AA

October 2004

Duplicating a Configuration

Duplicate the configuration of a 3095FC using these instruction.

1. File > Save Configuration to save the configuration to a specified file.

2. Establish Communications with the second unit (see page 2-13).

3. File > Download loads the configuration into the unit.

4. After loading the configuration data into the second 3095FC (Step 3),

save the configuration to a unique disk file by repeating Step 1.

Using Copy and Paste

Use Copy and Paste to copy data from one configuration screen to another of

the same type.

1. Configure the point that is to be duplicated.

2. Click Apply.

3. Click Copy.

4. Select the next Point Number or go to the appropriate screen.

5. Click Paste.

6. Click Update.

New Configuration File

Create a configuration file off-line using the following instructions.

1. Select File > New.

2. The Type parameter indicates the type of 3095FC unit.

3. The number of orifice meters will be 1.

4. Save the configuration file.

5. Establish an on-line connection to the 3095FC unit.

6. Configure as necessary.

Open File

The Open option opens an existing configuration file. Configuration files are

created using the Save Configuration function. To open a configuration file:

1. Establish an on-line connection to the 3095FC (see “Establishing

Communication” on page 2-13).

2. Select File > Open.

3. Select the configuration file name. The extension must be .800.

4. Configure as necessary.

Once the configuration file is opened it automatically becomes active and may

be edited offline. The configuration file may also be loaded into a 3095FC

using the “Download File" function (see page 3-3).

Save File

3-2

The Save option saves the current configuration of a connected 3095FC to a

disk file. Once a backup configuration file is created it can be loaded into a

3095FC using the “Download File" function (see page 3-3).

1. Select File > Save Configuration. The Save As dialog box appears.

2. Type the desired File name of the backup file or use the default.

3. Click Save. The file is saved in the default directory C:\Program

Files\Rosemount\Rosemount 3095FC User Interface\User Interface

unless another directory was selected.

Page 33

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Download File

Use this function to download a previously saved configuration to a 3095FC.

Configuration files are created using the Save Configuration function. To

download a previously saved configuration:

1. Select File > Download.

2. Select the configuration file name with the extension .FCF

3. Click Open.

4. Select the Point Types to download. Use Select All or Deselect All to

change multiple Point Types. Select or Deselect individual Point

Types by selecting the configuration Point Type in the left column and

selecting specific Point Types in the right column.

NOTE

The Configuration Points screen changes depending on the type of device

that is connected.

5. Select only the Configuration Points to download.

6. Click Download. Downloading automatically begins.

7. Click OK when the download is complete.

Print Configuration

The Print Configuration option enable specifying Point Types to Print.

1. Select File > Print Configuration.

2. Select the Point Types to be printed. Select the All or Deselect All

buttons for multiple Point Types or select/deselect individual Point

Types by using the mouse to double click on the Point Type in the left

column and selecting specific Parameters in the right column.

3. Click OK.

4. When the Print Preview screen appears, choose one of the following

buttons:

• Print to send to a local printer.

• PDF to create a .pdf (Portable Document File).

• Excel to create an .xls spreadsheet file.

• RTF to create an .rtf (Rich Text Format) file.

• HTML to create an .htm Internet browser file.

• TXT to create a .txt text file.

5. The 3095FC Group, Address, Field, and Value information displays in

the Print Configuration results window.

3-3

Page 34

Reference Manual

00809-0100-4832, Rev AA

Rosemount 3095FC

October 2004

CONFIGURATION

Setting the Clock Immediately after connecting to a 3095FC for the first time, set the

Rosemount User Interface Software Clock to ensure proper logging of history.

The internal real-time clock provides time-stamping and control of the

historical databases, Event Log, Alarm Log, Audit Log, and Contract Hour.

NOTE

The time stamp reflects the time at the end of the period. Data collected from

0800 to 0900 is thus time-stamped 0900. This is used for the logging of

history.

See Figure 3-1

1. Select Device > Clock or click the Clock icon in the toolbar.

2. The display at the bottom of the calendar is the date and time from

the PC clock. Continue with Step 5 if correct.

3. If it is not correct:

a. use the arrow buttons to select the correct Month and Year

b. click on the desired day of the month

c. click on the time field and type in the desired value (type A or P for

the AM/PM field) or use the arrows.

4. The clock can automatically compensate for daylight savings time by

enabling this feature.

5. Click Apply and click OK.

Figure 3-1. Clock Screen

3-4

Page 35

Reference Manual

00809-0100-4832, Rev AA

October 2004

Rosemount 3095FC

Configuring the System

Flags

Use System Flags to perform actions that affect the overall operation of the

3095FC. From the Flags screen, a configuration can be saved to Flash

memory and the 3095FC can be re-initialized.

NOTE

Certain Flags cause data to be lost, parameter values to be changed, and

configuration memory to be cleared. Confirm Flag function before changing.

General Tab

Figure 3-2 on page 3-6

After a Warm Start, the 3095FC is initialized from SRAM memory if the

configuration is valid. If valid, the databases remain intact. If the memory does

not have a valid configuration, the configuration that was last saved to Flash

memory is used. To save a valid configuration, use the Save Configuration

button.

In a Cold Start, the 3095FC is initialized from the restart configuration saved in

the Flash memory. If the configuration memory does not have a valid

configuration written in it, the factory defaults are used.

NOTE

Perform a Cold Start after setting the clock and BEFORE setting any other

parameters to ensure the 3095FC memory is cleared before configuration

begins.

Cold Start reloads all restart configuration data and may also clear logs and

displays. In addition, it may cause output changes, load new accumulator

values, and disable user program tasks and User Data Types. Generally, a

Cold Start should not be used on a 3095FC that is actively gathering data or

performing control. Save or document all required data and parameter values

that could be affected before performing the Cold Start.

The following may occur when performing a Cold Start:

• Cold Start restores a configuration from default values stored in Flash

memory.

• Cold Start & Clear ALL restores a configuration from default values

stored in Flash memory and clears all History, Alarm Log/Event Log,

and displays.

• Cold Start & Clear Alarms/Events restores a configuration from default

values stored in Flash memory and clears the Alarm Log/Event Log.