Page 1

Configuration and Use Manual

P/N 20000327, Rev. FB

June 2011

Micro Motion

®

Model 2700 Transmitter

with PROFIBUS-PA

Configuration and Use Manual

Page 2

© 2011 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect are marks of one of the Emerson Process Management family of companies. All other trademarks are property of their

respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Determining transmitter information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 PROFIBUS-PA functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Determining version information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Communication tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.7 Planning the configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.8 Pre-configuration worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.9 Flowmeter documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.10 Micro Motion customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Setting the node address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Configuring the analog input function block channels. . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Setting the I/O mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.1 Overriding the status byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Configuring the totalizer block mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Configuring pressure compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.1 Pressure compensation values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7.2 Enabling pressure compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.7.3 Configuring a pressure source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.8 Configuring temperature compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.8.1 Enabling external temperature compensation . . . . . . . . . . . . . . . . . . . . . 16

2.8.2 Configuring a temperature source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Characterization, Smart Meter Verification, meter validation, and calibration . . . . . . 19

3.2.1 Characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.2 Smart Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.3 Meter validation and meter factors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.5 Comparison and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Performing a characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.1 Characterization parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3.2 How to characterize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Performing Smart Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.1 Preparing for the Smart Meter Verification test . . . . . . . . . . . . . . . . . . . . 26

3.4.2 Running the Smart Meter Verification test . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.3 Reading and interpreting Smart Meter Verification test results . . . . . . . . 31

3.4.4 Setting up automatic or remote execution of the

Smart Meter Verification test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configuration and Use Manual iii

Page 4

Contents

3.5 Performing meter validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.6 Performing zero calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6.1 Preparing for the zeroing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.6.2 Zeroing procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7 Performing density calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.7.1 Preparing for density calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.7.2 Density calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.8 Performing temperature calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Chapter 4 Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Default target mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.3 Configuration map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.4 Configuring standard volume flow measurement for gas . . . . . . . . . . . . . . . . . . . . . 48

4.5 Changing the measurement units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.6 Configuring the petroleum measurement application . . . . . . . . . . . . . . . . . . . . . . . . 55

4.6.1 About the petroleum measurement application . . . . . . . . . . . . . . . . . . . . 55

4.6.2 Configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7 Configuring the concentration measurement application . . . . . . . . . . . . . . . . . . . . . 59

4.7.1 About the concentration measurement application . . . . . . . . . . . . . . . . . 59

4.7.2 Configuration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.8 Changing the output scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.9 Changing process alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.9.1 Alarm values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4.9.2 Alarm hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.10 Configuring status alarm severity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4.11 Changing the damping values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4.11.1 Damping and volume measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.12 Changing slug flow limits and duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4.13 Configuring cutoffs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4.14 Changing the measurement mode parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

4.15 Configuring sensor parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

4.16 Configuring the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.16.1 Enabling and disabling display functions . . . . . . . . . . . . . . . . . . . . . . . . . 75

4.16.2 Changing the scroll rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.16.3 Changing the update period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.16.4 Changing the off-line password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.16.5 Changing the display language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

4.16.6 Changing the display variables and precision . . . . . . . . . . . . . . . . . . . . . 78

4.17 Enabling LD Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Chapter 5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.2 Using the I&M functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.3 Recording process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.4 Viewing process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4.1 With the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

5.4.2 With ProLink II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.4.3 With PROFIBUS EDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.4.4 With bus parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.5 Using sensor simulation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.6 Accessing diagnostic information with a PROFIBUS host . . . . . . . . . . . . . . . . . . . . 86

iv Model 2700 Transmitter with PROFIBUS-PA

Page 5

Contents

5.7 Viewing transmitter status and alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.7.1 With the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.7.2 With ProLink II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.7.3 With EDD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.7.4 With bus parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.8 Using the totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

5.8.1 Viewing current values for totalizers and inventories . . . . . . . . . . . . . . . . 88

5.8.2 Controlling the totalizers and inventories . . . . . . . . . . . . . . . . . . . . . . . . . 90

Chapter 6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.2 Guide to troubleshooting topics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.3 Transmitter does not operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

6.4 Transmitter does not communicate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.5 Function blocks in Out-of-Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.6 Zero or calibration failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.7 Output problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6.7.1 Damping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.7.2 Low-flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.7.3 Output scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.7.4 Characterization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.7.5 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

6.8 Status alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.9 Diagnosing wiring problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.1 Checking the power-supply wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.2 Checking the sensor-to-transmitter wiring . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.3 Checking the grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.9.4 Checking the communication wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.10 Checking slug flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.11 Restoring a working configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6.12 Checking the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.12.1 Obtaining the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.12.2 Evaluating the test points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.12.3 Excessive drive gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.12.4 Erratic drive gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

6.12.5 Low pickoff voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.13 Checking the core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.13.1 Exposing the core processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.13.2 Checking the core processor LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

6.13.3 Core processor resistance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.14 Checking sensor coils and RTD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.14.1 9-wire remote or remote core processor with

remote transmitter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.14.2 4-wire remote or integral installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix A Flowmeter Installation Types and Components . . . . . . . . . . . . . . . 115

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.2 Installation diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.3 Component diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.4 Wiring and terminal diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Configuration and Use Manual v

Page 6

Contents

Appendix B Using the Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.3 Using the optical switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.4 Using the display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.4.1 Display language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.4.2 Viewing process variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.4.3 Using display menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.4.4 Display password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.4.5 Entering floating-point values with the display. . . . . . . . . . . . . . . . . . . . 124

B.5 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

B.6 Display menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Appendix C Connecting with ProLink II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

C.2 Connecting to a personal computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

C.2.1 Connecting to the service port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Appendix D PROFIBUS-PA Status Byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

D.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

D.2 Classic-mode status byte format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

D.3 Condensed-mode status byte format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Appendix E Slave Diagnostic Response Bytes. . . . . . . . . . . . . . . . . . . . . . . . 141

E.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

E.2 PROFIBUS specification diagnostic bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Appendix F Model 2700 PROFIBUS Block Parameters . . . . . . . . . . . . . . . . . . 151

F.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

F.2 Slot identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

F.3 Physical block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

F.3.1 Physical block object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

F.3.2 Physical block views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

F.4 Transducer block 1 (measurement, calibration, and diagnosis) . . . . . . . . . . . . . . . 154

F.4.1 Transducer block 1 object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

F.4.2 Transducer block 1 (measurement, calibration,

and diagnosis) views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

F.4.3 Transducer block 2 (device information, API, CM) parameters . . . . . . . 172

F.4.4 Transducer block 2 object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

F.4.5 Transducer block 2 (device information, API, CM) views . . . . . . . . . . . . 177

F.4.6 I & M functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

F.4.7 AI function block parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

F.4.8 Analog input block objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

F.4.9 AI function block views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

F.4.10 AO function block parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

F.4.11 Analog output block objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

F.4.12 AO function block views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

F.4.13 Totalizer block parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

F.4.14 Totalizer block objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

F.4.15 Totalizer function block views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

vi Model 2700 Transmitter with PROFIBUS-PA

Page 7

Contents

Appendix G NE53 History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

G.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

G.2 Software change history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Configuration and Use Manual vii

Page 8

viii Model 2700 Transmitter with PROFIBUS-PA

Page 9

Chapter 1

2700 * 1 * G * * * * * *

Mounting code:

• R = 4-wire remote mount

• I = Integral mount

• B = 4-wire remote mount to 9-wire remote core processor

• C = 9-wire remote mount

Display code

• 1 = Display with glass lens

• 2 = Backlit display with glass lens

• 3 = No display

• 5 = Backlit display with IIC approval, glass lens

• 7 = Backlit display with non-glass lens

Output option code

• G = PROFIBUS-PA

Software code 1:

G = Concentration measurement application

A = Petroleum measurement (API) application

Software code 2:

C = Smart Meter Verification

Before You Begin

1.1 Overview

This chapter provides an orientation to the use of this manual, and includes a configuration overview

flowchart and a pre-configuration worksheet. This manual describes the procedures required to start,

configure, use, maintain, and troubleshoot Micro Motion

PROFIBUS-PA.

®

Model 2700 transmitters with

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

1.3 Determining transmitter information

Transmitter options are indicated by the model number located on the transmitter tag. The model

number is a string of the following form:

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 1

Page 10

Before You Begin

1.4 PROFIBUS-PA functionality

The transmitter supports the following methods of configuration and operation:

• Configuration methods:

- Device description (EDD) for use with a PROFIBUS configuration tool such as Siemens

Simatic

®

Process Device Manager (PDM). In this manual, the term “EDD” is used to refer

to this type of configuration.

- Direct read and write of PROFIBUS-PA bus parameters.

• Operation methods:

- GSD file with a PROFIBUS host. The transmitter supports two GSD options—

Profile-specific, which is created by PNO, and Manufacturer-specific, which is created by

by Micro Motion in order to implement a larger set of function blocks. See Section 2.5 for

more information about the two GSD options.

In this manual, the term “host” or “PROFIBUS host” is used to refer to this type of

operation.

- Device description (EDD) with PROFIBUS configuration tool (e.g., Simatic PDM). The

EDD provides a superset of the operational functionality of the GSD, plus configuration

capability.

• Identification and maintenance (I&M) functions:

®

-I&M 0

-I&M 1

-I&M 2

-PA I&M 0

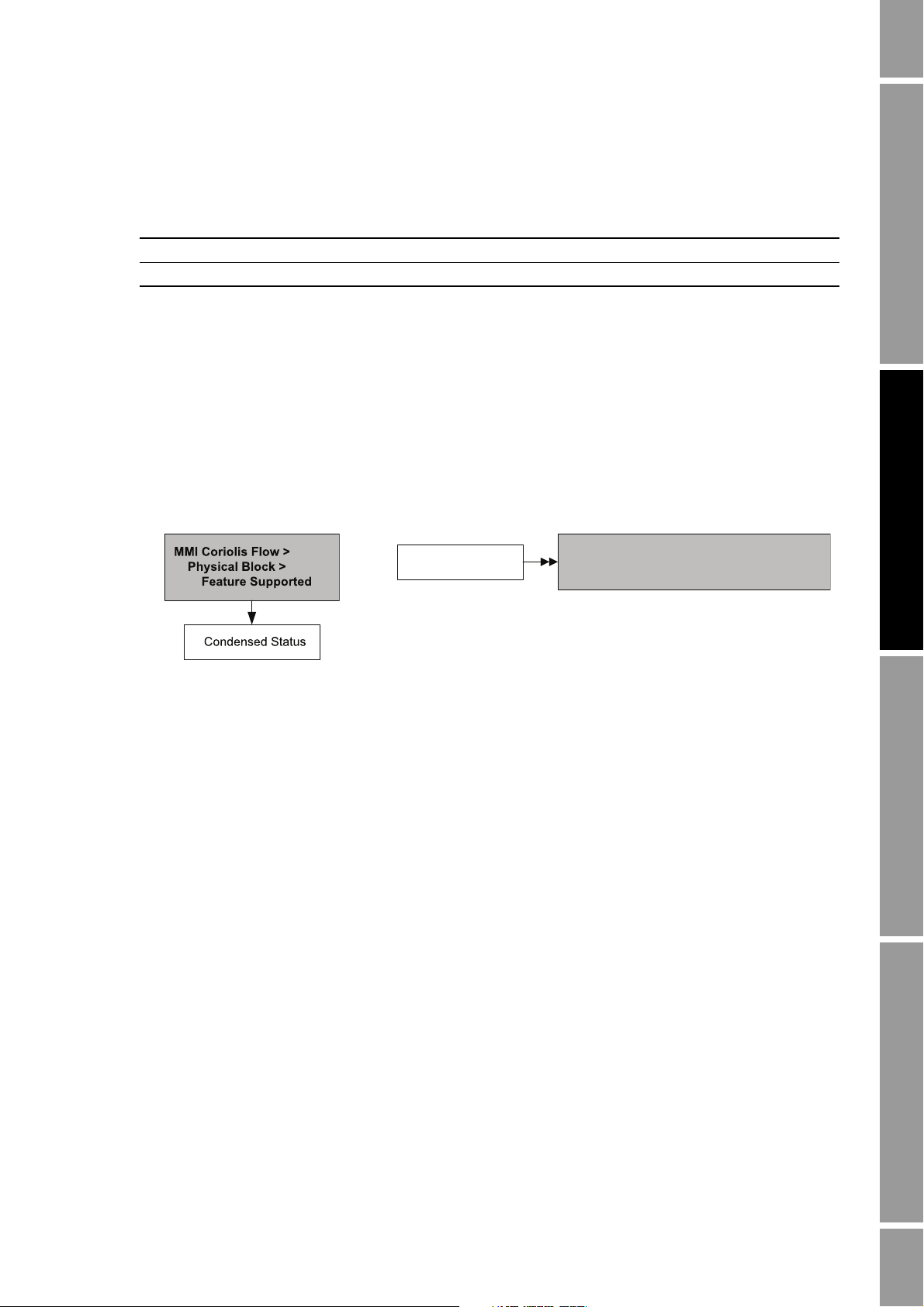

The transmitter supports both classic and condensed status byte formats.

• Classic mode conforms to the PROFIBUS-PA Profile v3.01, Section 3.7.3.6.

• Condensed mode conforms to the PROFIBUS-PA Specification June 2005 Amendment 2 to

the PROFIBUS Profile v3.01, Condensed Status and Diagnostic Messages v1.0.

1.5 Determining version information

Table 1-1 lists the version information you may need to know and describes how to obtain the

information. This manual assumes transmitter firmware v3.2 or a later version and ProLink v2.92

with the Build 9827 patch or a later version.

Note: The hardware for transmitters with v2.0 and lower firmware is incompatible with the hardware

needed to support v3.0 and later firmware. To upgrade from an earlier firmware version to v3.0 or

higher firmware requires hardware replacement.

Table 1-1 Obtaining version information

Component Tool Method

Transmitter software With ProLink II View > Installed Options > Software Revision

With EDD MMI Coriolis Flow > Transducer Block > Device

Information > Software Rev

With display OFF-LINE MAINT > VER

2 Model 2700 Transmitter with PROFIBUS-PA

Page 11

Before You Begin

Table 1-1 Obtaining version information (continued)

Component Tool Method

Core processor software With ProLink II Not available

ProLink II With ProLink II Help > About ProLink II

GSD version

EDD version Text editor Open file MMIcorflow.DDL and check parameter

(1) There are two GSD options available: Manufacturer-specific and Profile-specific. See Section 2.5 for more information.

(1)

1.6 Communication tools

Most of the procedures described in this manual require the use of a communication tool. Table 1-2

lists the communication tools that can be used, with their functionality and requirements.

Note: You can use ProLink II, the EDD, or PROFIBUS bus parameters for transmitter setup and

maintenance. It is not necessary to have more than one of these methods available.

With EDD Not available

With display OFF-LINE MAINT > VER

Text editor Open file V3x_057A.gsd or PA139742.GSD and

check parameter GSD_Revision

DD_REVISION

Startup ConfigurationCalibrationBefore You Begin

Table 1-2 Communication tools for Model 2700 transmitter with PROFIBUS-PA

Functionality

Tool

Transmitter display Partial Partial Transmitter with display

ProLink II Full Full ProLink II v2.92 or later

(1)

Host

EDD Full Full PDM file set

Bus parameters Full Full None

(1) There are two GSD options available: Manufacturer-specific and Profile-specific. See Section 2.5 for more information.

Partial None GSD file V3x_057A.gsd or

RequirementsView/operation Setup/maintenance

PA139742.GSD

The PDM and GSD files can be downloaded from the following address:

http://www.emersonprocess.com/micromotion/softwaredownloads

Also available at this address is a document titled Commissioning MVD Profibus PA Documentation

®

Supplement. This supplement will assist you with connecting to the transmitter with Siemens

Simatic

®

Process Device Manager (PDM). If you are using Simatic PDM, download the PDM file set

and follow the EDD instructions in this manual.

Basic information on using the display is provided in Appendix B.

Basic information on ProLink II is provided in Appendix C. For more information, refer to the

ProLink II manual, which is available on the Micro Motion web site (www.micromotion.com).

Although some functions of the Model 2700 transmitter with PROFIBUS-PA may be available

through earlier versions of ProLink II, version 2.92 with the Build 9827 patch or a later version is

required for full configuration, maintenance, and operation.

Configuration and Use Manual 3

Page 12

Before You Begin

Chapter 2

Flowmeter Startup

Chapter 1

Before You Begin

Fill out pre-configuration

worksheet

Apply power

Set node address

Chapter 3

Calibration

OPTIONAL

Characterize the flowmeter

Zero the flowmeter

Verify meter performance

Validate against a standard

Calibrate for density

Calibrate for temperature

Chapter 4

Configuration

Configure AI function block

channels

Set I/O mode

Measurement units

Output scale

Process alarms

Damping

Slug flow

Alarm severity

Gas standard volume

Petroleum measurement

Concentration measurement

Cutoffs

Measurement mode

Device settings

Sensor parameters

Display functionality

Optional:

Configure pressure

compensation

Optional:

Configure temperature

compensation

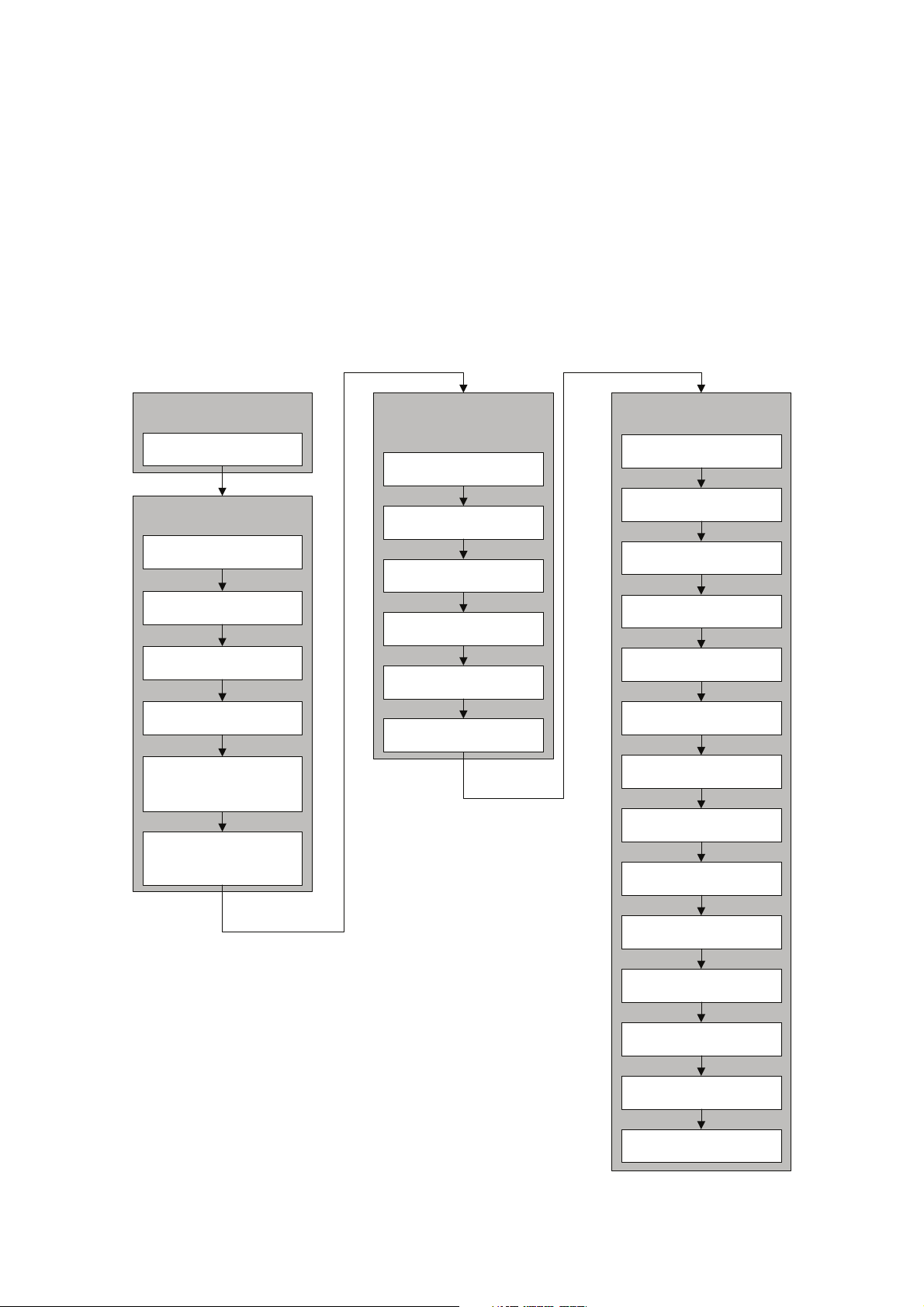

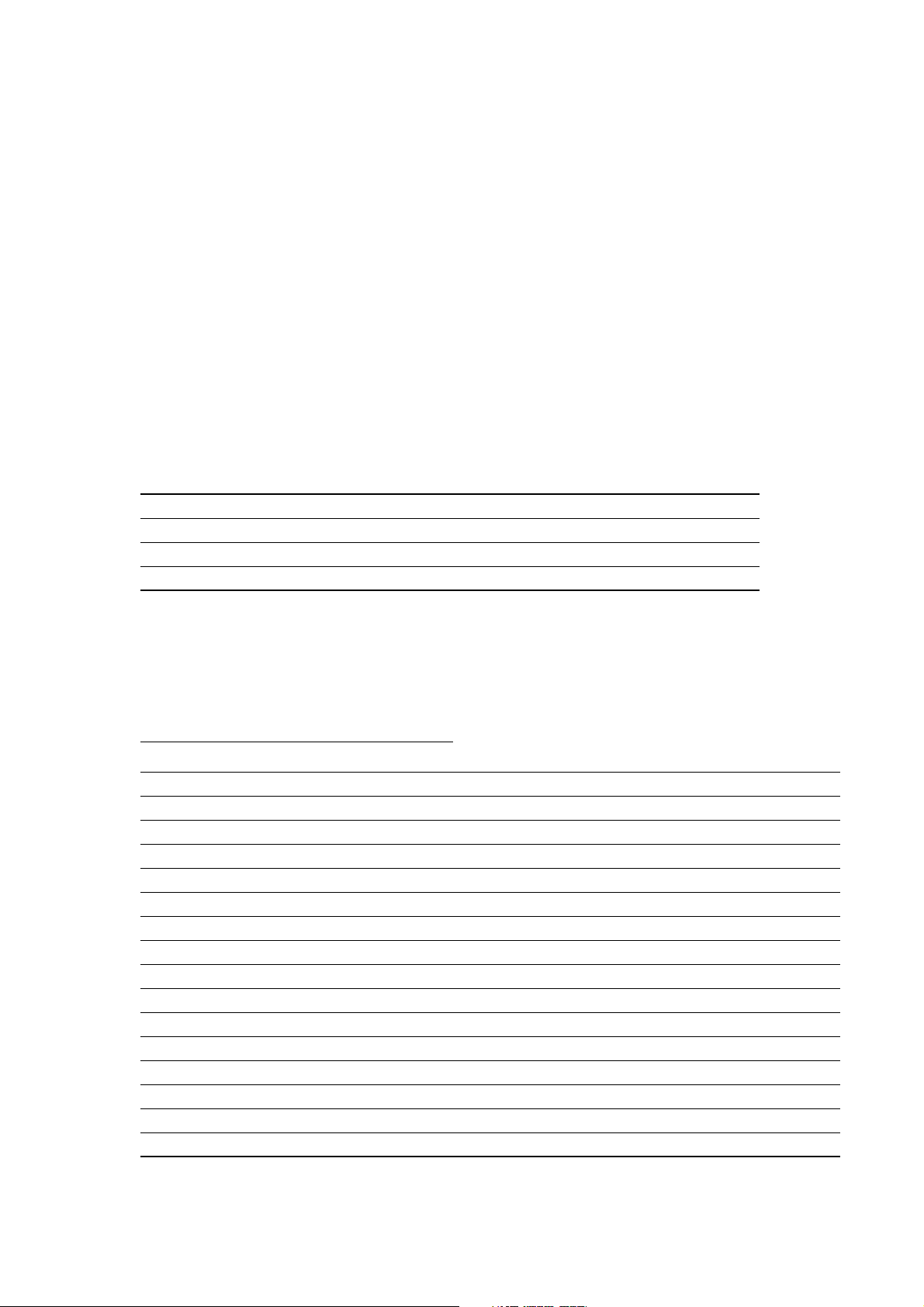

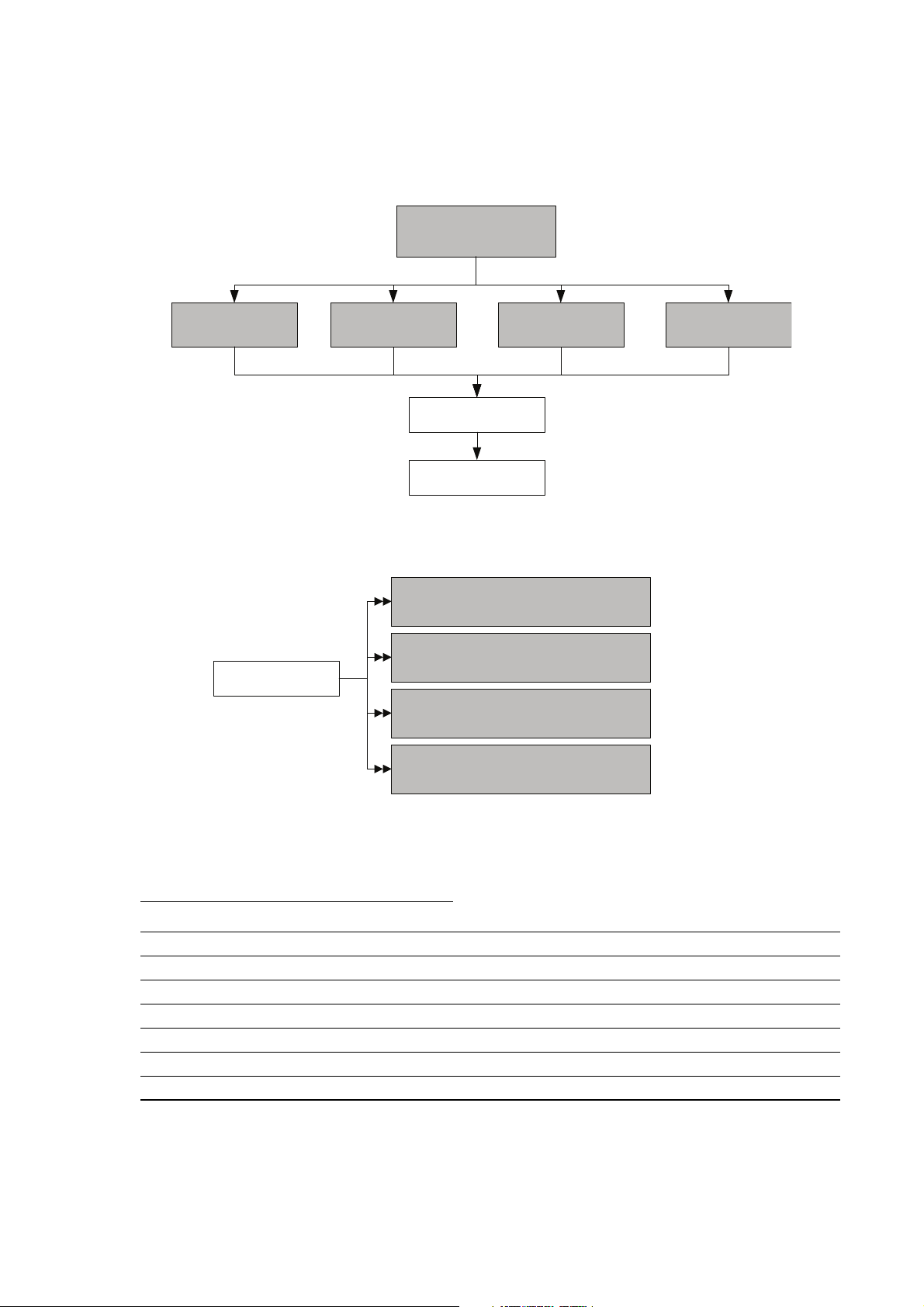

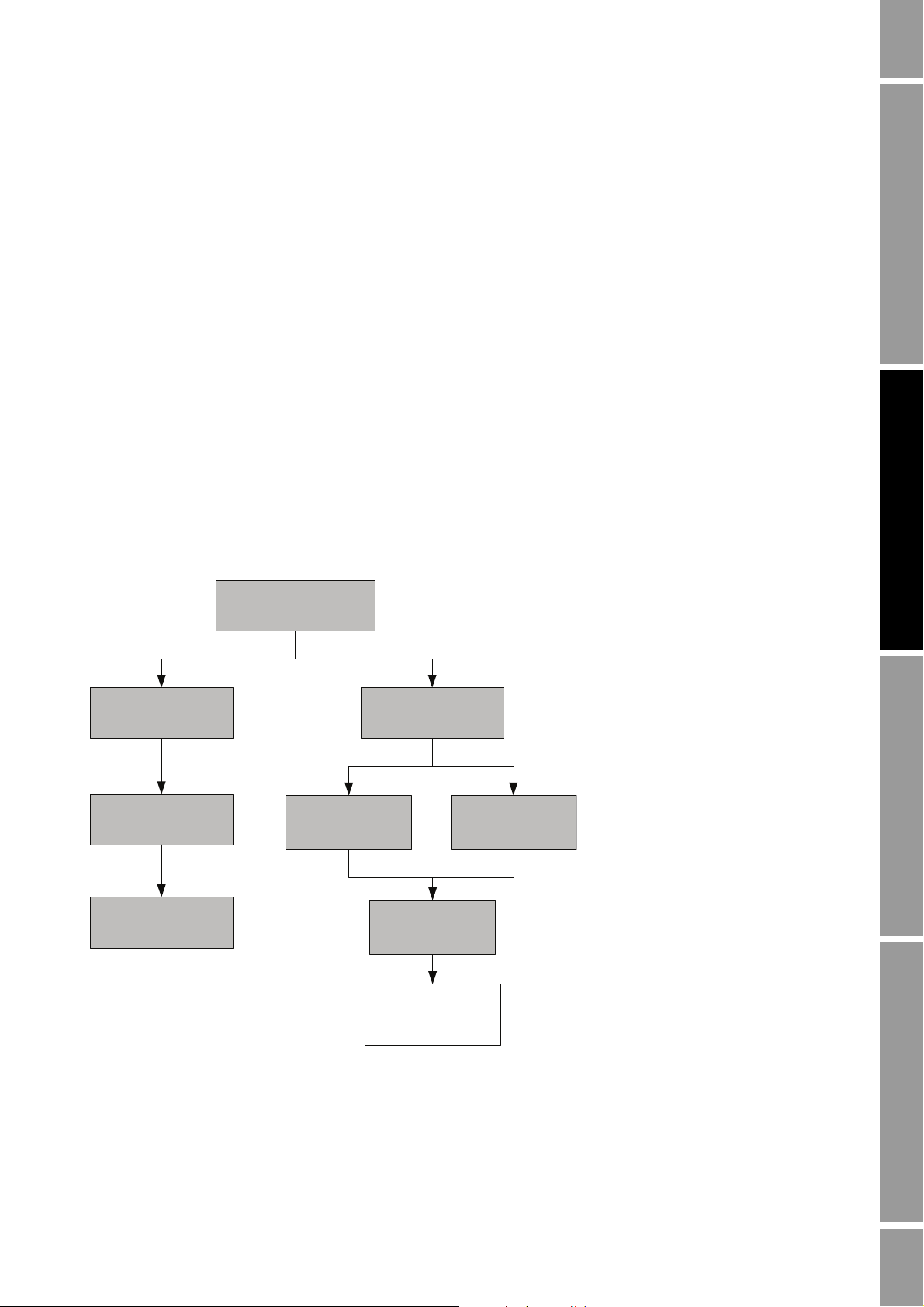

1.7 Planning the configuration

Refer to the configuration overview flowchart in Figure 1-1 to plan transmitter configuration. In

general, perform configuration steps in the order shown here.

Note: Depending on your installation and application, some configuration tasks may be optional.

Note: This manual provides information on topics that are not included in the configuration overview

flowchart, e.g., using the transmitter, troubleshooting, and calibration procedures. Be sure to review

these topics as required.

Figure 1-1 Configuration overview

4 Model 2700 Transmitter with PROFIBUS-PA

Page 13

Before You Begin

1.8 Pre-configuration worksheet

The pre-configuration worksheet provides a place to record information about your flowmeter and

your application. This information will affect your configuration options as you work through this

manual. You may need to consult with transmitter installation or application process personnel to

obtain the required information.

If you are configuring multiple transmitters, make copies of this worksheet and fill one out for each

individual transmitter.

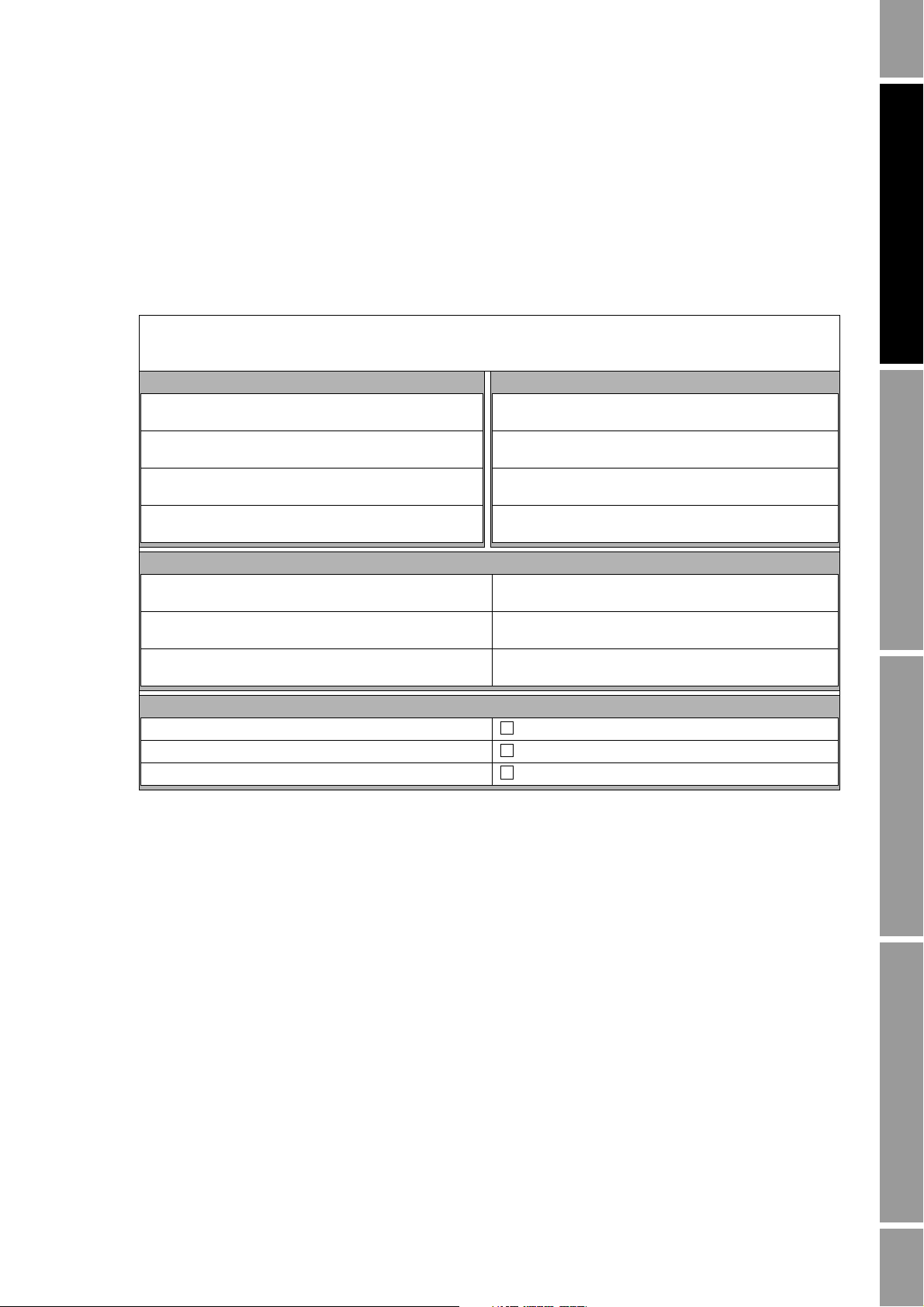

PRE-CONFIGURATION WORKSHEET FOR TRANSMITTER:

TRANSMITTER SENSOR

MODEL NUMBER MODEL NUMBER

SERIAL NUMBER SERIAL NUMBER

SOFTWARE VERSION

NODE ADDRESS

MEASUREMENT UNITS

MASS FLOW VOLUME FLOW

DENSITY PRESSURE

TEMPERATURE

INSTALLED APPLICATIONS

METER VERIFICATION SOFTWARE

PETROLEUM MEASUREMENT APPLICATION

CONCENTRATION MEASUREMENT APPLICATION

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 5

Page 14

Before You Begin

1.9 Flowmeter documentation

Table 1-3 lists documentation sources for additional information.

Table 1-3 Flowmeter documentation resources

Topic Document

Sensor installation Sensor documentation

Transmitter installation Micro Motion® Model 1700 and Model 2700

Connecting the transmitter to Simatic PDM Commissioning MVD Profibus PA Documentation

Hazardous area installation See the approval documentation shipped with the

1.10 Micro Motion customer service

For customer service, phone the support center nearest you:

• In the U.S.A., phone

800-522-MASS (800-522-6277) (toll-free)

• In Canada and Latin America, phone +1 303-527-5200 (U.S.A.)

Transmitters: Installation Manual

Supplement

transmitter, or download the appropriate documentation

from the Micro Motion web site (www.micromotion.com)

•In Asia:

- In Japan, phone 3 5769-6803

- In other locations, phone +65 6777-8211 (Singapore)

•In Europe:

- In the U.K., phone 0870 240 1978 (toll-free)

- In other locations, phone +31 (0) 318 495 555 (The Netherlands)

Customers outside the U.S.A. can also email Micro Motion customer service at:

flow.support@emerson.com.

6 Model 2700 Transmitter with PROFIBUS-PA

Page 15

Chapter 2

Startup

2.1 Overview

This chapter describes the procedures you should perform the first time you start the flowmeter. You

do not need to use these procedures every time you cycle power to the flowmeter.

The procedures in this section will enable you to:

• Apply power to the flowmeter (Section 2.2)

• Set the node address (Section 2.3)

• Configure the AI block channels (Section 2.4)

• Set the I/O mode of the transmitter (Section 2.5)

• Configure the totalizer block mode (Section 2.6)

• Optional: Configure pressure compensation (Section 2.7)

• Optional: Configure temperature compensation (Section 2.8)

Note: All procedures provided in this chapter assume that you have established communication with

the transmitter and that you are complying with all applicable safety requirements. See Appendix C or

the documentation for your PROFIBUS host or configuration tool.

2.2 Applying power

Before you apply power to the flowmeter, close and tighten all housing covers.

Operating the flowmeter without covers in place creates electrical hazards that can cause death, injury,

or property damage. Make sure all covers are in place before applying power to the transmitter.

Turn on the electrical power at the power supply. The flowmeter will automatically perform

diagnostic routines. If the transmitter has a display, the status LED will turn green and begin to flash

when the transmitter has finished its startup diagnostics.

Note: If this is the initial startup, or if power has been off long enough to allow components to reach

ambient temperature, the flowmeter is ready to receive process fluid approximately one minute after

power-up. However, it may take up to ten minutes for the electronics in the flowmeter to reach thermal

equilibrium. During this warm-up period, you may observe minor measurement instability or

inaccuracy.

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 7

Page 16

Startup

2.3 Setting the node address

The factory default setting for the node address is 126. To set the node address:

• With the display, choose

OFF-LINE MAINT > CONFG > ADDRESS PBUS.

• With ProLink II, choose

ProLink > Configuration > Device (Profibus) > Profibus Address.

• With a PROFIBUS host, use the change address function of the host.

2.4 Configuring the analog input function block channels

You can set each of the transmitter’s AI function blocks to measure one transducer block channel. The

AI blocks are set at the factory to a default setting that is adequate for most applications, but you can

change the assignment of the AI blocks to meet special needs.

The default channel configuration for each block is shown in Table 2-1.

Table 2-1 Default channel configuration

Block Default channel Default units

AI 1 Mass flow kg/s

AI 2 Temperature K

AI 3 Density kg/l

AI 4 Volume flow m

The available transducer block channels are shown in Table 2-2.

3

/h

Table 2-2 Process variables by transducer block channel

Channel value

Process variableSlot Index Value

11 (0x0B) 17 (0x11) 0x0B11 Volume flow

11 (0x0B) 21 (0x15) 0x0B15 Mass flow

11 (0x0B) 25 (0x19) 0x0B19 Density

11 (0x0B) 29 (0x1D) 0x0B1D Temperature

11 (0x0B) 64 (0x40) 0x0B40 Gas standard volume flow

11 (0x0B) 114 (0x72) 0x0B72 Pressure

11 (0x0B) 160 (0xA0) 0x0BA0 Drive gain

12 (0x0C) 29 (0x1D) 0x0C1D Petroluem measurement – corrected density

12 (0x0C) 30 (0x1E) 0x0C1E Petroluem measurement – corrected volume flow

12 (0x0C) 31 (0x1F) 0x0C1F Petroluem measurement – average corrected density

12 (0x0C) 32 (0x20) 0x0C20 Petroluem measurement – average corrected temp

12 (0x0C) 33 (0x21) 0x0C21 Petroluem measurement – CTL

12 (0x0C) 47 (0x2F) 0x0C2F Concentration measurement – reference density

12 (0x0C) 48 (0x30) 0x0C30 Concentration measurement – specific gravity

12 (0x0C) 49 (0x31) 0x0C31 Concentration measurement – standard volume flow

12 (0x0C) 50 (0x32) 0x0C32 Concentration measurement – net mass flow

8 Model 2700 Transmitter with PROFIBUS-PA

Page 17

Startup

ProLink II

Function blocks tab

Apply

ProLink >

Configuration

Select a channel for each

AI function block

Select units for each AI

and AO function block

EDD

Bus parameters

Block: Analog Input Block (Slots 1, 2, 3, and 5)

Index: 30 (transducer block channel)

Channel

Block: Analog Input Block (Slots 1, 2, 3, and 5)

Index 28, Parameter 3 (units index)

AI Block units

Block: Analog Output Block (Slots 9 and 10)

Index 27, Parameter 3 (units index)

AO Block

units

Table 2-2 Process variables by transducer block channel (continued)

12 (0x0C) 51 (0x33) 0x0C33 Concentration measurement – net volume flow

12 (0x0C) 52 (0x34) 0x0C34 Concentration measurement – concentration

12 (0x0C) 53 (0x35) 0x0C35 Concentration measurement – Baume

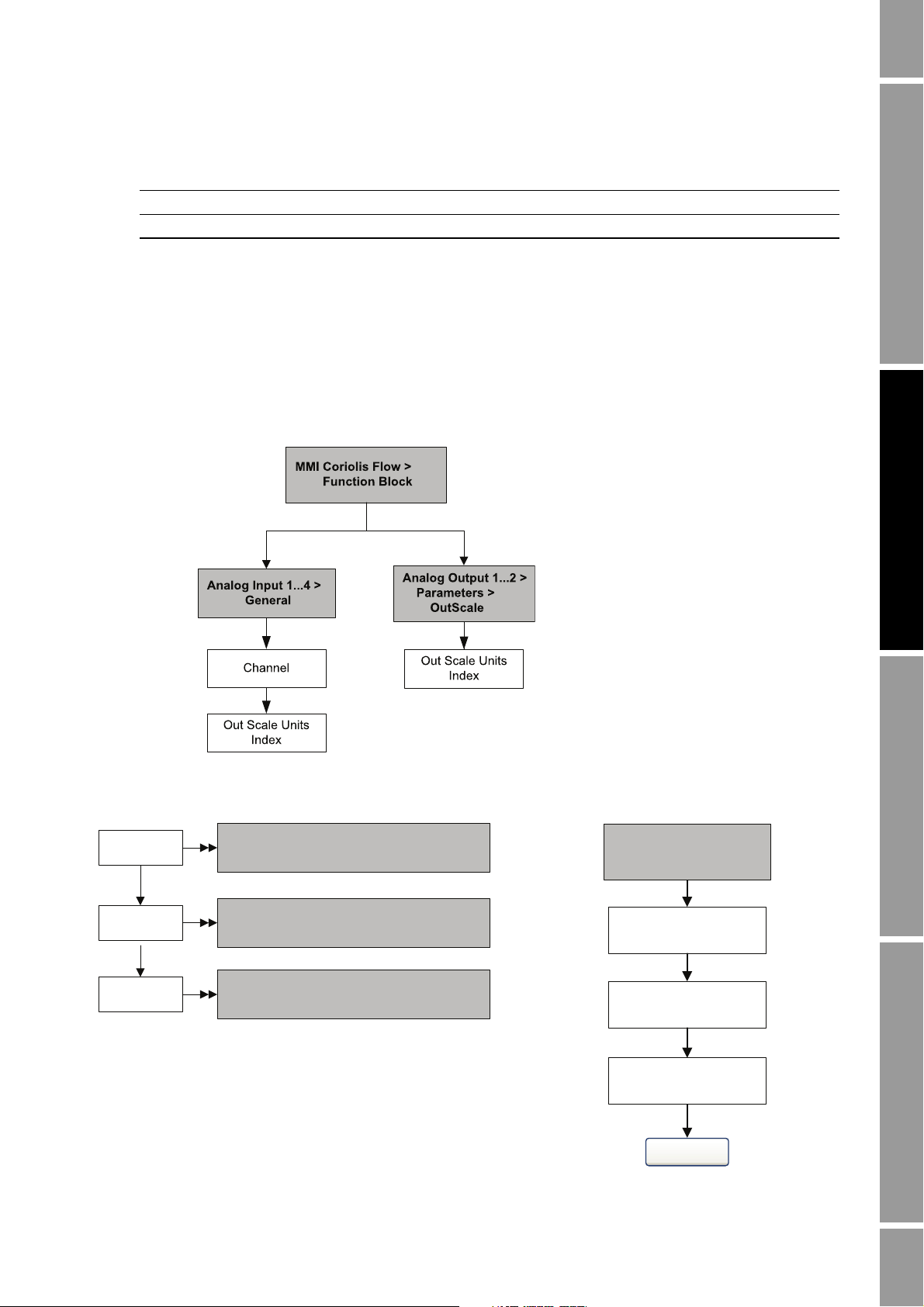

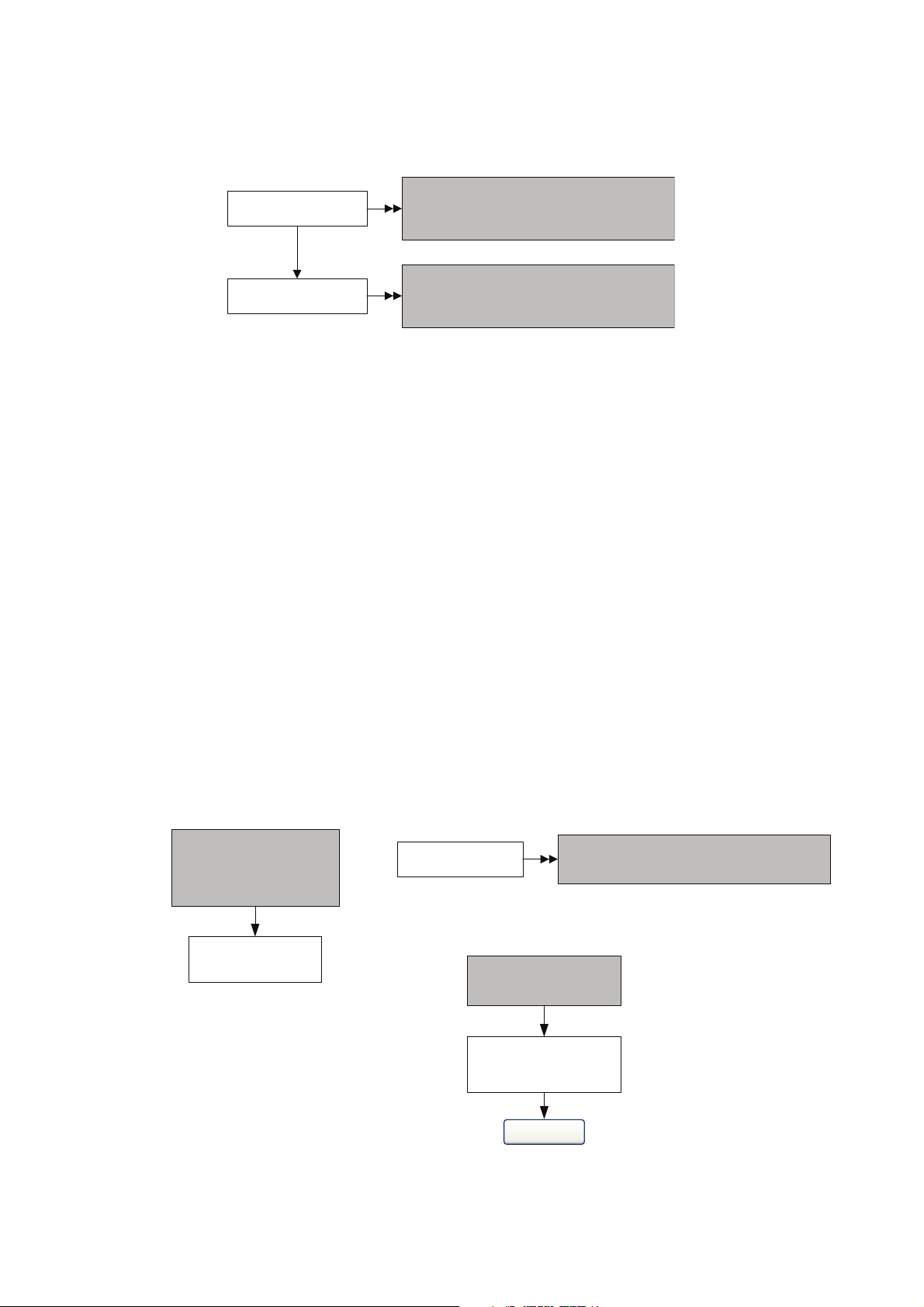

To configure the AI function block channels:

• With the EDD, bus parameters, or ProLink II, see the menu flowcharts in Figure 2-1.

• With the display, see the menu flowchart in Figure B-14.

Figure 2-1 Configuring channels and units – EDD, bus parameters, and ProLink II

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 9

Page 18

Startup

EDD Bus parameters

2.5 Setting the I/O mode

The transmitter can function in two different I/O modes: Profile-specific and Manufacturer-specific.

The factory default is Manufacturer-specific. The two modes control which function blocks are

available for use, and whether the format of the status byte is “classic” or “condensed.” (See

Appendix D for more information on the format of the status byte.)

• In Profile-specific mode, the transmitter has the use of three AI blocks and one totalizer block.

The status byte output format defaults to classic mode.

• In Manufacturer-specific mode, the transmitter has the use of four AI blocks, four totalizer

blocks, and two AO blocks. The status byte output format defaults to condensed mode.

Refer to Table 2-3 for the slot identifications and blocks permitted by each mode. You must select

modules exactly as described in Table 2-3, or select an empty module for slots that you do not intend

to use. If any modules are left unconfigured, the transmitter will not send data.

Table 2-3 I/O mode slot configurations

Slot Profile-specific mode Manufacturer-specific mode

1 AI 1 AI 1

2 AI 2 AI 2

3 AI 3 AI 3

4 Totalizer 1 Totalizer 1

5AI 4

6 Totalizer 2

7 Totalizer 3

8 Totalizer 4

9AO 1

10 AO 2

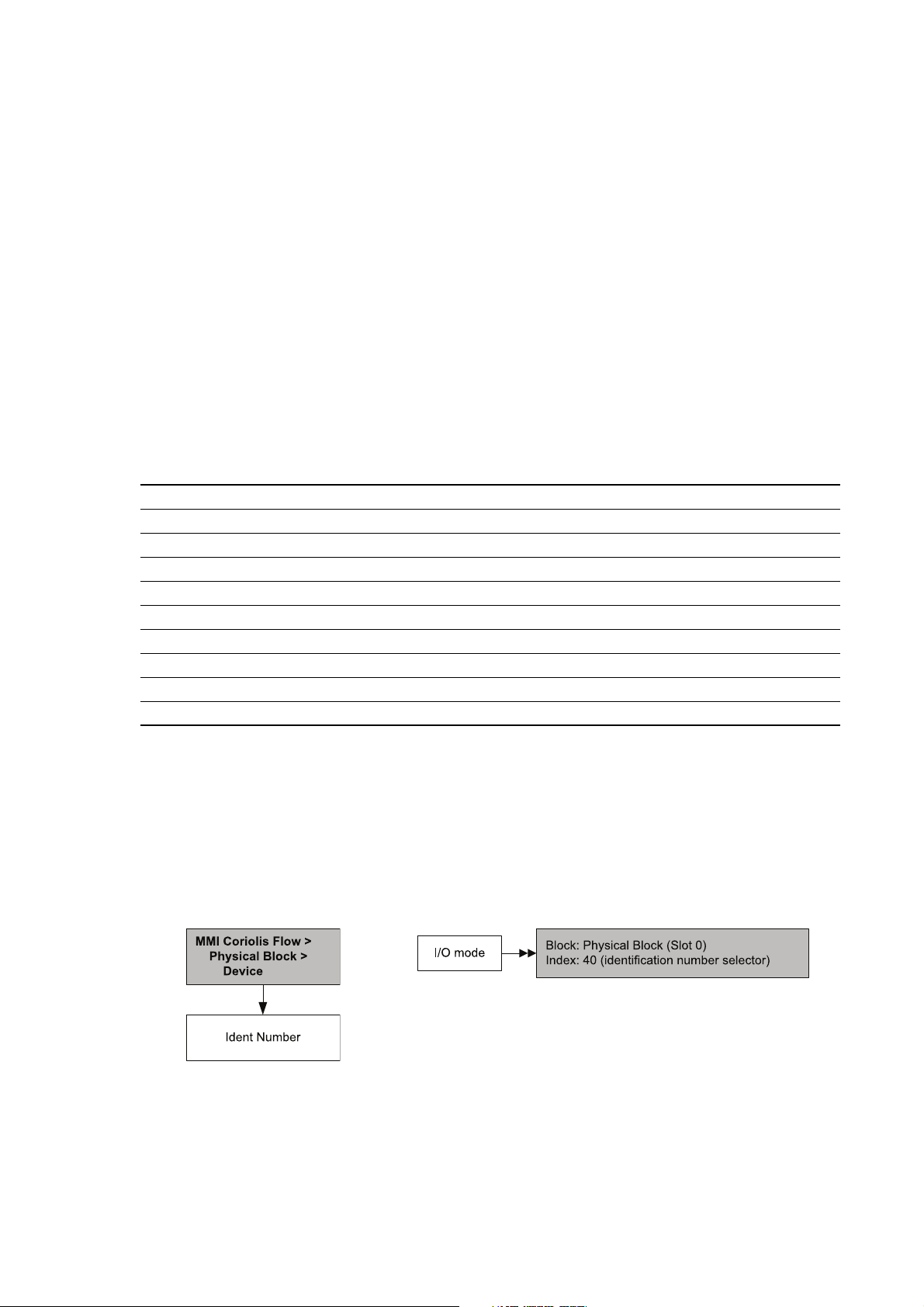

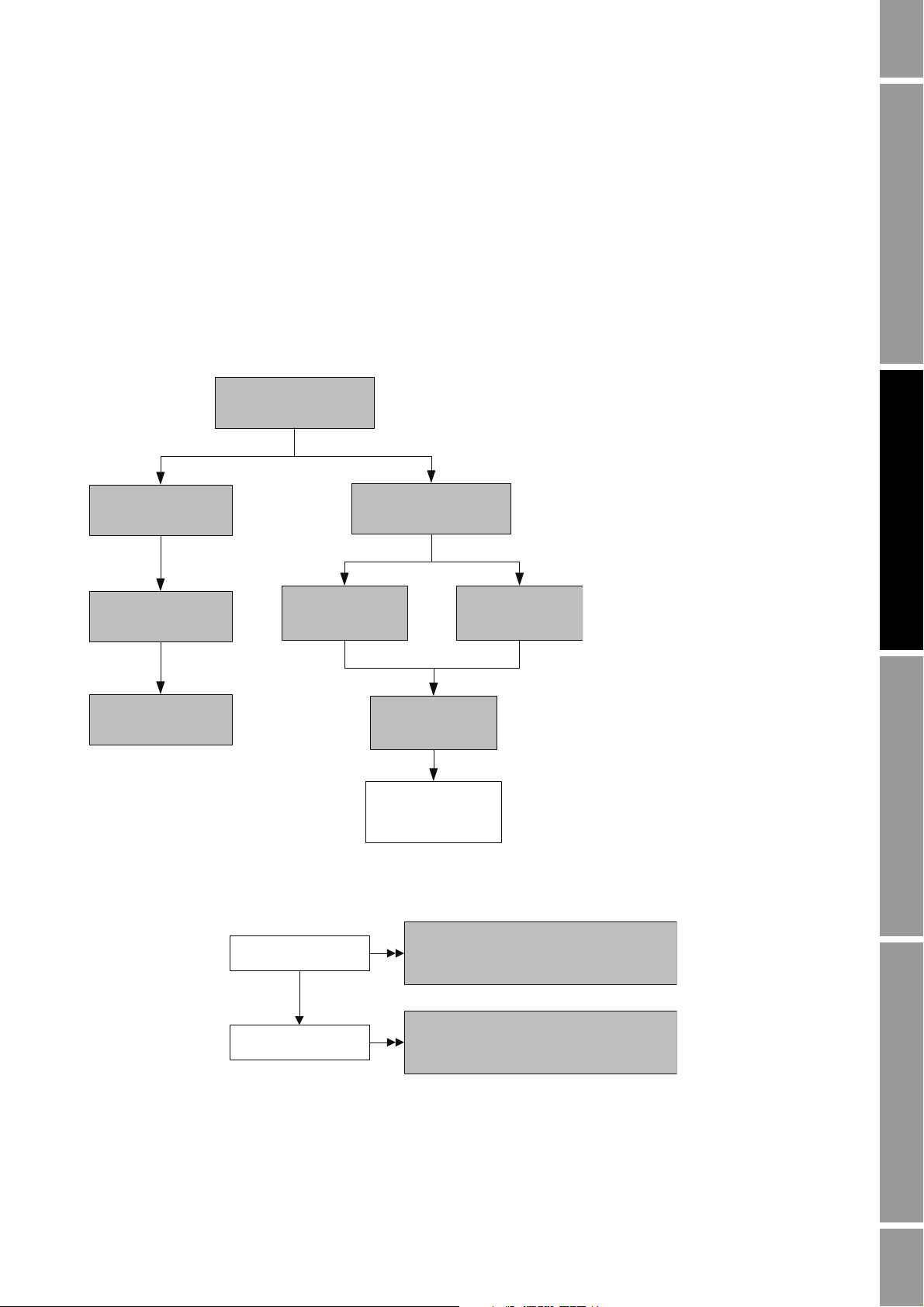

To set the I/O mode of the transmitter:

• With the EDD or bus parameters, see the menu flowcharts in Figure 2-2.

• With the display, choose

Figure 2-2 Setting the I/O mode

There are two GSD files that correspond to the two I/O modes. If you are using a PROFIBUS host

with GSD files to operate the transmitter, you must use the GSD that corresponds to the I/O mode you

have chosen. Table 2-4 lists the GSD file names. Load the correct GSD file into your PROFIBUS host

or configuration tool.

OFFLINE_MAINT > CONFG > IDENT SEL.

10 Model 2700 Transmitter with PROFIBUS-PA

Page 19

Startup

Block: Physical Block 1 (Slot 0)

Index 43 (Condensed status diagnostics)

Status byte format

EDD Bus parameters

Note: Set the I/O mode in the Physical Block before loading the GSD file.

Table 2-4 PROFIBUS GSD file names

Identification number GSD file name

Profile specific PA139742.GSD

Manufacturer specific V3x_057A.gsd

2.5.1 Overriding the status byte format

Each I/O mode has a default status byte format – classic or condensed. To override this default:

• With the GSD, set the Condensed Status parameterization bit to either 1 (for condensed status)

or 0 (for classic status).

• With the EDD or bus parameters, use the menu flowcharts in Figure 2-3.

Figure 2-3 Status byte format

2.6 Configuring the totalizer block mode

The behavior of the four totalizer function blocks can be configured in two ways:

• Standard, which provides standard PROFIBUS totalizer function block behavior.

In this mode, the totalizer block will integrate whatever data it receives. The Out value of a

totalizer in this mode has no relationship to the totalizer data reported by the transducer block,

ProLink II, or the display.

• Any of the values in Table 2-5, which cause the totalizer function block to pass through the

specified totalizer value from the transducer block.

Micro Motion recommends using one of these modes, because the totalizer block output will

be more accurate and will match readings taken with ProLink II and the display.

To configure the totalizer block mode:

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 11

• With the EDD or bus parameters, refer to the menu flowcharts in Figure 2-4.

• With the display, refer to the menu flowcharts in Figure B-16.

Page 20

Startup

EDD

Block: Totalizer 1 (Slot 4)

Index 52 (set to Mode value from table)

Mode

Block: Totalizer 1 (Slot 4)

Index 52 (set to Mode value from table)

Block: Totalizer 1 (Slot 4)

Index 52 (set to Mode value from table)

Block: Totalizer 1 (Slot 4)

Index 52 (set to Mode value from table)

Bus parameters

MMI Coriolis Flow >

Function Block

Totalizer 1 >

Parameter

Integrator Function

Block

Totalizer 2 >

Parameter

Totalizer 3 >

Parameter

Totalizer 4 >

Parameter

Selection

Figure 2-4 Configuring totalizer function block mode

Table 2-5 Process variables by transducer block channel

Channel value

Process variableSlot Index Value

11(0x0B) 17(0x11) 0x0B11 Volume flow

11(0x0B) 21(0x15) 0x0B15 Mass flow

11(0x0B) 64(0x40) 0x0B40 Gas standard volume flow

12(0x0C) 30(0x1E) 0x0C1E Petroleum measurement – corrected volume flow

12(0x0C) 49(0x31) 0x0C31 Concentration measurement – standard volume flow

12(0x0C) 50(0x32) 0x0C32 Concentration measurement – net mass flow

12(0x0C) 51(0x33) 0x0C33 Concentration measurement – net volume flow

12 Model 2700 Transmitter with PROFIBUS-PA

Page 21

Startup

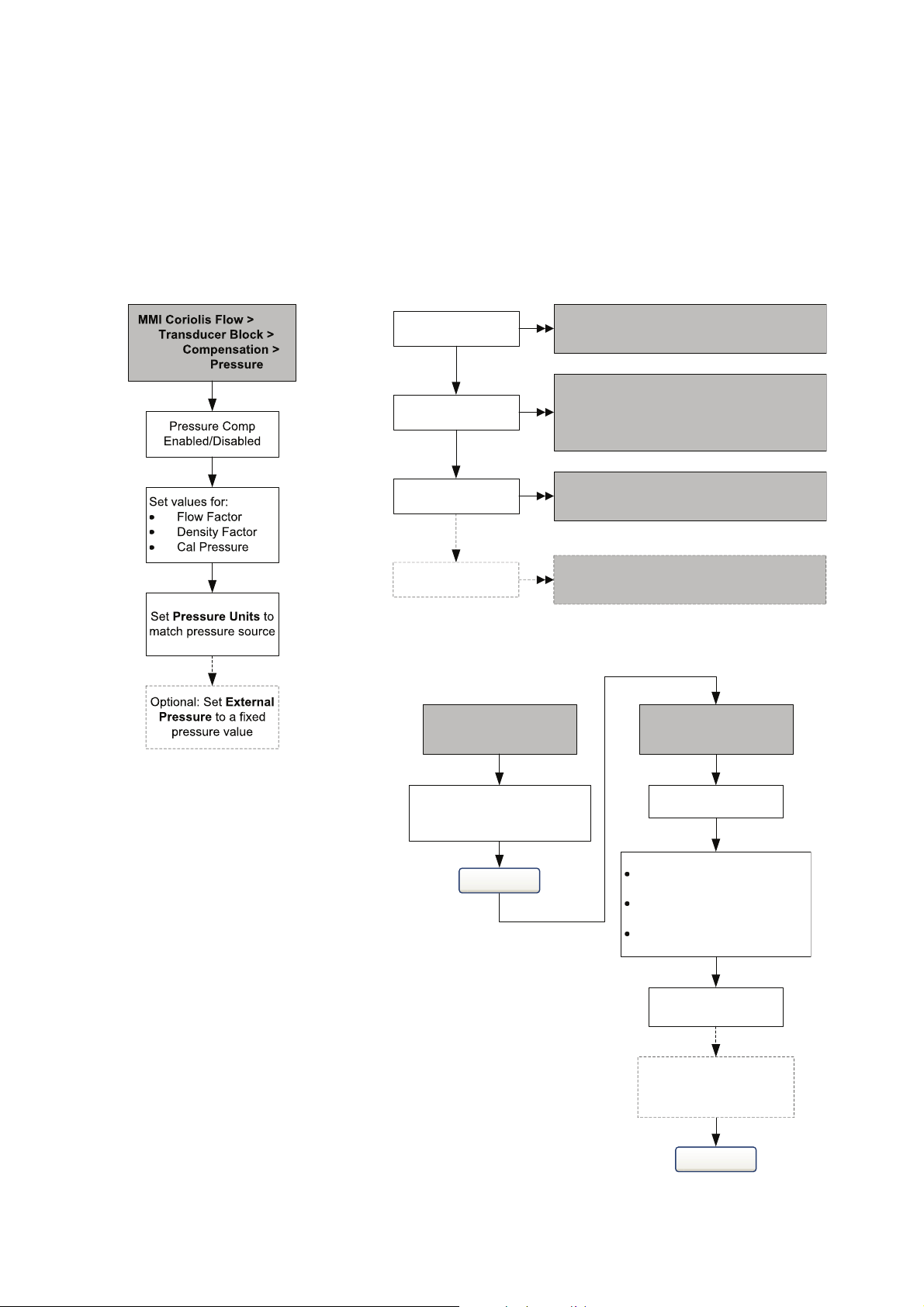

2.7 Configuring pressure compensation

Due to process pressure change away from calibration pressure, there can be a change in sensor flow

and density sensitivity. This change is called pressure effect. Pressure compensation corrects for these

changes.

Not all sensors and applications require pressure compensation. Contact Micro Motion Customer

Service before you configure pressure compensation.

Configuring pressure compensation requires three steps:

1. Determining pressure compensation values (Section 2.7.1)

2. Enabling pressure compensation (Section 2.7.2)

3. Selecting a pressure source (Section 2.7.3)

2.7.1 Pressure compensation values

There are three values involved in pressure compensation:

• Flow factor – The flow factor is the percent change in flow rate per psi. Consult the product

data sheet for your sensor for this value. You will need to reverse the sign of the flow factor.

For example, if the flow factor in the product data sheet is –0.001% per psi, the pressure

compensation flow factor would be +0.001% per psi.

• Density factor – The density factor is the change in fluid density, in g/cm

product data sheet for your sensor for this value. You will need to reverse the sign of the

density factor. For example, if the density factor in the product data sheet is –0.00004 g/cm

per psi, the pressure compensation flow factor would be +0.00004 g/cm

• Flow calibration pressure – The pressure at which the flowmeter was calibrated. Refer to the

calibration document shipped with your sensor. If the data is unavailable, use 20 psi (1,4 bar).

3

per psi. Consult the

3

per psi.

Startup ConfigurationCalibrationBefore You Begin

3

Configuration and Use Manual 13

Page 22

Startup

Block: Transducer Block 1 (Slot 11)

Index 112 (enable pressure compensation)

Enable pressure

comp.

Block: Transducer Block 1 (Slot 11)

Index 116 (flow factor)

Index 117 (density factor)

Index 118 (flow calibration pressure)

Pressure correction

values

Block: Transducer Block 1 (Slot 11)

Index 115 (pressure units)

Pressure units

Block: Transducer Block 1 (Slot 11)

Index 113 (pressure value)

Optional: Fixed

pressure value

View >

Preferences

Select Enable External

Pressure Compensation

Apply

ProLink >

Configuration

Enter values:

Flow factor in Flow factor

box

Density factor in Dens

factor box

Flow calibration pressure in

Cal pressure box

Apply

Pressure tab

Set pressure units to

match source

Optional: Enter a fixed

pressure value in the

External Pressure box

EDD Bus parameters

ProLink II

2.7.2 Enabling pressure compensation

To enable pressure compensation, see the menu flowcharts in Figure 2-5. You will need the three

pressure compensation values from Section 2.7.1.

Figure 2-5 Enabling pressure compensation

14 Model 2700 Transmitter with PROFIBUS-PA

Page 23

Startup

Function Block

Analog Output 1

Set IN Channel to

Pressure

Parameters >

General

Analog Output 2

MMI Coriolis Flow

Transducer Block

Compensation

AO Compensation

Note: When setting the IN channel

to Pressure via the EDD, the OUT

channel will be automatically set

to Pressure as well. Setting the IN

channel via bus parameters does

not automatically change the OUT

channel. You must manually set the

OUT channel to Pressure or the

block will go into Out of Service

mode.

2.7.3 Configuring a pressure source

You will need to choose one of two sources for pressure data:

• Analog Output function block – This option allows you to poll for pressure data from an

external pressure source.

• Fixed pressure data – This option uses a known, constant pressure value.

Note: If you configure a fixed pressure value, ensure that it is accurate. If you configure polling for

pressure, ensure that the external pressure measurement device is accurate and reliable.

If you configure pressure compensation to use an AO block for pressure compensation, the other AO

block remains available for temperature compensation. However, only one of the AO blocks can be

set up for external pressure.

To configure fixed pressure data, refer to the menu flowcharts in Figure 2-5.

To configure an AO function block for pressure compensation:

• With the EDD, refer to the flowchart in Figure 2-6.

• With bus parameters, refer to the flowchart in Figure 2-7.

• With the display, refer to the menu flowcharts in Figure B-15.

Startup ConfigurationCalibrationBefore You Begin

Figure 2-6 Configuring an AO function block for pressure compensation – EDD

Configuration and Use Manual 15

Page 24

Startup

Block: Analog Output Block (Slots 9 and 10)

Index 37 (IN channel), value = 0x0b72

Index 38 (OUT channel), value = 0x0b72

Configure channel

Block: Transducer Block 1 (Slots 11)

Index 121 (AO Compensation), value = 1

Configure channel

MMI Coriolis Flow >

Transducer Block >

Compensation >

Temperature

Enable Disable Ext

Temp

EDD

Block: Transducer Block 1 (Slot 11)

Index 110 (enable temperature compensation)

Enable temperature

comp.

Bus parameters

View >

Preferences

Select Use External

Temperature

Apply

ProLink II

Figure 2-7 Configuring an AO function block for pressure compensation – Bus parameters

2.8 Configuring temperature compensation

External temperature compensation can be used with the petroleum measurement application or the

enhanced density application:

• If external temperature compensation is enabled, an external temperature value (or a fixed

temperature value), rather than the temperature value from the Coriolis sensor, is used in

petroleum measurement or enhanced density calculations only. The temperature value from

the Coriolis sensor is used for all other calculations.

• If external temperature compensation is disabled, the temperature value from the Coriolis

sensor is used in all calculations.

Configuring temperature compensation requires two steps:

1. Enabling external temperature compensation (Section 2.8.1)

2. Configuring a temperature source (Section 2.8.2)

2.8.1 Enabling external temperature compensation

To enable temperature compensation, refer to the flowcharts in Figure 2-8.

Figure 2-8 Enabling external temperature compensation

16 Model 2700 Transmitter with PROFIBUS-PA

Page 25

Startup

Function Block

Analog Output 1

Set IN Channel to

Temperature

Parameters >

General

Analog Output 2

MMI Coriolis Flow

Transducer Block

Compensation

AO Compensation

Note: When setting the IN

channel to Temperature via the

EDD, the OUT channel will be

automatically set to

Temperature as well. Setting

the IN channel via bus

parameters does not

automatically change the OUT

channel. You must manually set

the OUT channel to

Temperature or the block will

go into Out of Service mode.

Block: Analog Output Block (Slots 9 and 10)

Index 37 (IN channel), value = 0x0b1D

Index 38 (OUT channel), value = 0x0b6F

Configure channel

Block: Transducer Block 1 (Slots 11)

Index 121 (AO Compensation), value = 1

Configure channel

2.8.2 Configuring a temperature source

External temperature data is reported through an analog output (AO) function block. The transmitter

has two AO blocks, each of which can be assigned to a compensation variable channel.

To configure an AO function block for temperature compensation:

• With the EDD, refer to the flowchart in Figure 2-9.

• With bus parameters, refer to the flowchart in Figure 2-10.

• With the display, refer to the flowcharts in Figure B-15.

Figure 2-9 Configuring an AO function block for temperature compensation – EDD

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 17

Figure 2-10 Configuring an AO function block for temperature compensation – Bus parameters

Page 26

18 Model 2700 Transmitter with PROFIBUS-PA

Page 27

Chapter 3

Calibration

3.1 Overview

This chapter describes the following procedures:

• Characterization (Section 3.3)

• Smart Meter Verification (Section 3.4)

• Meter validation and adjusting meter factors (Section 3.5)

• Zero calibration (Section 3.6)

• Density calibration (Section 3.7)

• Temperature calibration (Section 3.8)

Note: All procedures provided in this chapter assume that you have established communication with

the transmitter and that you are complying with all applicable safety requirements. See Appendix C or

the documentation for your PROFIBUS host or configuration tool.

Startup ConfigurationCalibrationBefore You Begin

3.2 Characterization, Smart Meter Verification, meter validation, and calibration

There are four procedures:

• Characterization – adjusts the transmitter to compensate for the unique traits of the sensor

with which it is paired

• Smart Meter Verification – establishing confidence in the sensor’s performance by analyzing

secondary variables that are highly correlated with flow and density calibration factors

• Meter validation – confirming performance by comparing the sensor’s measurements to a

primary standard

• Calibration – establishing the relationship between a process variable (flow, density, or

temperature) and the signal produced by the sensor, or establishing the transmitter’s response

to a zero-flow condition.

Meter validation, characterization, and calibration are available on all Model 2700 transmitters. Smart

Meter Verification is available only if the Smart Meter Verification option was ordered with the

transmitter.

These four procedures are discussed and compared in Sections 3.2.1 through 3.2.4. Before performing

any of these procedures, review these sections to ensure that you will be performing the appropriate

procedure for your purposes.

Configuration and Use Manual 19

Page 28

Calibration

3.2.1 Characterization

Characterizing the flowmeter adjusts the transmitter to compensate for the unique traits of the sensor

it is paired with. Characterization parameters (sometimes called “calibration factors”) describe the

sensor’s sensitivity to flow, density, and temperature.

If the transmitter and the sensor were ordered together as a Coriolis flowmeter, then the flowmeter has

already been characterized. Under some circumstances (typically when pairing a sensor and

transmitter together for the first time), you may need to re-enter characterization data. If you are

unsure about whether you should characterize your flowmeter, contact Micro Motion Customer

Service.

3.2.2 Smart Meter Verification

Smart Meter Verification evaluates the structural integrity of the sensor tubes by comparing current

tube stiffness to the stiffness measured at the factory. Stiffness is defined as the load per unit

deflection, or force divided by displacement. Because a change in structural integrity changes the

sensor’s response to mass and density, this value can be used as an indicator of measurement

performance. Changes in tube stiffness are typically caused by erosion, corrosion, or tube damage.

Smart Meter Verification does not affect measurement in any way. Micro Motion recommends

performing Smart Meter Verification at regular intervals.

3.2.3 Meter validation and meter factors

Meter validation compares a measurement value reported by the transmitter with an external

measurement standard. Meter validation requires one data point.

Note: For meter validation to be useful, the external measurement standard must be more accurate

than the sensor. See the sensor’s product data sheet for its accuracy specification.

If the transmitter’s mass flow, volume flow, or density measurement is significantly different from the

external measurement standard, you may want to adjust the corresponding meter factor. A meter

factor is the value by which the transmitter multiplies the process variable value. The default meter

factors are

1.0, resulting in no difference between the data retrieved from the sensor and the data

reported externally.

Meter factors are typically used for proving the flowmeter against a Weights & Measures standard.

You may need to calculate and adjust meter factors periodically to comply with regulations.

3.2.4 Calibration

The flowmeter measures process variables based on fixed points of reference. Calibration adjusts

those points of reference. Three types of calibration can be performed:

•Zero

• Density calibration

• Temperature calibration

Density and temperature calibration require two data points (low and high) and an external

measurement for each. The density and temperature calibration procedure changes the offset and/or

the slope of the line that represents the relationship between process density and the reported density

value, or the relationship between process temperature and the reported temperature value.

Note: For density or temperature calibration to be useful, the external measurements must be

accurate.

20 Model 2700 Transmitter with PROFIBUS-PA

Page 29

Calibration

Zero calibration requires only that flow through the sensor is stopped.

Flowmeters are calibrated at the factory, and normally do not need to be calibrated in the field.

Calibrate the flowmeter only if you must do so to meet regulatory requirements. Contact

Micro Motion before calibrating your flowmeter.

Note: Micro Motion recommends using meter validation and meter factors, rather than calibration, to

prove the meter against a regulatory standard or to correct measurement error.

3.2.5 Comparison and recommendations

When choosing among Smart Meter Verification, meter validation, and calibration, consider the

following factors:

• Process and measurement interruption

- Smart Meter Verification provides an option that allows process measurement to continue

during the test.

- Meter validation for density does not interrupt the process. However, meter validation for

mass flow or volume flow requires process down-time for the length of the test.

- Calibration requires process down-time. In addition, density and temperature calibration

require replacing the process fluid with low-density and high density fluids, or

low-temperature and high-temperature fluids. Zero calibration requires stopping flow

through the sensor.

Startup ConfigurationCalibrationBefore You Begin

• External measurement requirements

- Smart Meter Verification does not require external measurements.

- Zero calibration does not require external measurements.

- Density calibration, temperature calibration, and meter validation require external

measurements. For good results, the external measurement must be highly accurate.

• Measurement adjustment

- Smart Meter Verification is an indicator of sensor condition, but does not change

flowmeter internal measurement in any way.

- Meter validation does not change flowmeter internal measurement in any way. If you

decide to adjust a meter factor as a result of a meter validation procedure, only the reported

measurement is changed—the base measurement is not changed. You can always reverse

the change by returning the meter factor to its previous value.

- Calibration changes the transmitter’s interpretation of process data, and accordingly

changes the base measurement. If you perform a zero calibration, you can return to the

factory zero (or, if using ProLink II, the previous zero). However, if you perform a density

calibration or a temperature calibration, you cannot return to the previous calibration

factors unless you have manually recorded them.

Micro Motion recommends obtaining the Smart Meter Verification transmitter option and performing

Smart Meter Verification on a regular basis.

Configuration and Use Manual 21

Page 30

Calibration

3.3 Performing a characterization

Characterizing a flowmeter involves entering parameters that are printed on the sensor tag.

3.3.1 Characterization parameters

The characterization parameters that must be entered depend on the sensor type: “T-Series” or

“Other,” as listed in Table 3-1. The “Other” category includes all Micro Motion sensors except

T-Ser ies .

The characterization parameters are provided on the sensor tag. The format of the sensor tag varies

depending on your sensor’s date of purchase. See Figures 3-1 and 3-2 for illustrations of newer and

older sensor tags.

Table 3-1 Sensor characterization parameters

Bus parameter

Characterization data EDD label

(1)

K1

(1)

K2

(1)

FD

(1)

D1

(1)

D2

DT or TC

Flow cal

FCF

FT

(1)

(2)

(2)

(2)

FTG FTG 103 ✓

FFQ FFQ 104 ✓

DTG DTG 105 ✓

DFQ1 DFQ1 106 ✓

DFQ2 DFQ2 107 ✓

(1) See the section entitled “Density calibration factors.”

(2) See the section entitled “Flow calibration values.”

K1 92 ✓✓

K2 93 ✓✓

FD 94 ✓✓

D1 97 ✓✓

D2 98 ✓✓

Density Temp Coeff (DT) 102 ✓✓

FD Value 99 ✓

FD Value 99 ✓

FD Value 99 ✓

index

Sensor type

T- Ser i e s O t her

22 Model 2700 Transmitter with PROFIBUS-PA

Page 31

Calibration

Newer tag Older tag

19.0005.13

19.0005.13

0.0010

0.9980

12502.000

14282.000

4.44000

310

12502142824.44

12500142864.44

Newer tag Older tag

Figure 3-1 Sample calibration tags – All sensors except T-Series

Figure 3-2 Sample calibration tags – T-Series sensors

Density calibration factors

If your sensor tag does not show a D1 or D2 value:

• For D1, enter the Dens A or D1 value from the calibration certificate. This value is the

line-condition density of the low-density calibration fluid. Micro Motion uses air.

• For D2, enter the Dens B or D2 value from the calibration certificate. This value is the

line-condition density of the high-density calibration fluid. Micro Motion uses water.

If your sensor tag does not show a K1 or K2 value:

• For K1, enter the first 5 digits of the density calibration factor. In the sample tag in Figure 3-1,

this value is shown as 12500.

• For K2, enter the second 5 digits of the density calibration factor. In the sample tag in

Figure 3-1, this value is shown as 14286.

If your sensor does not show an FD value, contact Micro Motion customer service. If your sensor tag

does not show a DT or TC value, enter the last 3 digits of the density calibration factor. In the sample

tag in Figure 3-1, this value is shown as 4.44.

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 23

Page 32

Calibration

Flow FCF X.XXXX FT X.XX

Flow calibration values

Two separate values are used to describe flow calibration: a 6-character FCF value (including one

decimal point) and a 4-character FT value (including one decimal point). During characterization,

these are entered as a single 10-character string that includes two decimal points. In ProLink II, this

value is called the Flowcal parameter.

To obtain the required value:

• For older T-Series sensors, concatenate the FCF value and the FT value from the sensor tag, as

shown below.

• For newer T-Series sensors, the 10-character string is represented on the sensor tag as the FCF

value. The value should be entered exactly as shown, including the decimal points. No

concatenation is required.

• For all other sensors, the 10-character string is represented on the sensor tag as the Flow Cal

value. The value should be entered exactly as shown, including the decimal points. No

concatenation is required.

3.3.2 How to characterize

To characterize the flowmeter, refer to Table 3-1 and the menu flowcharts in Figure 3-3.

24 Model 2700 Transmitter with PROFIBUS-PA

Page 33

Calibration

EDD

Bus parameters

ProLink II

Calibration >

Density

Enter values from

sensor tag

MMI Coriolis Flow >

Transducer Block

Sensor Type Code

• Curved Tube

• Straight Tube

Device Information

ProLink >

Configuration

Device tab

Sensor Type

Flow tab

Enter values from

sensor tag

Density tab

Enter values from

sensor tag

(1) Refer to Table 3-1 for bus

parameter indices.

Block: Transducer Block 2 (Slot 12)

Index 12 (sensor type code)

Sensor type

Block: Transducer Block 1 (Slot 11)

See note (1)

Flow values

Block: Transducer Block 1 (Slot 11)

See note (1)

Density values

Figure 3-3 Characterizing the flowmeter

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 25

Page 34

Calibration

3.4 Performing Smart Meter Verification

Note: To use Smart Meter Verification, the transmitter must be paired with an enhanced core

processor, and the Smart Meter Verification option must be purchased for the transmitter.

3.4.1 Preparing for the Smart Meter Verification test

The Smart Meter Verification procedure can be performed on any process fluid. It is not necessary to

match factory conditions.

During the test, process conditions must be stable. To maximize stability:

• Maintain a constant temperature and pressure.

• Avoid changes to fluid composition (e.g., two-phase flow, settling, etc.).

• Maintain a constant flow. For higher test certainty, stop flow.

If stability varies outside test limits, the Smart Meter Verification procedure will be aborted. Verify

the stability of the process and retry the test.

Transmitter configuration

Smart Meter Verification is not affected by any parameters configured for flow, density, or

temperature. It is not necessary to change the transmitter configuration.

Control loops and process measurement

If the transmitter outputs will be set to Last Measured Value or Fault during the test, the outputs will

be fixed for two minutes. Disable all control loops for the duration of the test, and ensure that any data

reported during this period is handled appropriately.

3.4.2 Running the Smart Meter Verification test

To run a Smart Meter Verification test:

• With the EDD, refer to Figure 3-4.

• With bus parameters, refer to Figure 3-5 and to Table 3-2.

• With ProLink II, refer to Figure 3-6.

• With the display, refer to Figure B-6.

26 Model 2700 Transmitter with PROFIBUS-PA

Page 35

Calibration

Device >

Meter Verification

Start/Abort Meter

Verification

Start Meter Verification

Enable MV

Select Alarm

Last Value

Fault Mode

Continue

measurement

Meter Verification in

Progress

Meter verification

PASSED

Meter verification

FAILED

Abort Meter Verification

Manual Abort by

End User

Meter verification

error

Start Meter Verification

Figure 3-4 Smart Meter Verification – EDD

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 27

Page 36

Calibration

Step 2

Start/abort procedure

Step 1

Set output state (optional)

Able to

complete?

Step 8

Check abort code

Yes (>0)

Step 3

Check current algorithm state

Running?

Step 4

Read percent complete

Yes (=16)

Step 6

Check inlet stiffness

Within limits?No (>0)

Yes (=0)

Step 7

Check outlet stiffness

Within limits?No (>0)

Yes (=0)

CAUTION PASS

No (<16)

No (=0)

Manual abort (optional)

Step 5

Check algorithm abort state

Figure 3-5 Smart Meter Verification – bus parameters

28 Model 2700 Transmitter with PROFIBUS-PA

Page 37

Calibration

Table 3-2 PROFIBUS parameters for Smart Meter Verification

Step number Step description Parameters

1 Set output state Block: Transducer block 1

Index: 182

Value:

• 0: Last measured value (default)

• 1: Fault

2 Start/abort procedure Block: Transducer block 1

Index: 72 (Start/Stop Meter Verification)

•0x00: No effect

• 0x01: Start On-Line Meter Verification

3 Check current algorithm state Block: Transducer block 1

Index: 75

Value:

• Bits 4–6: State

4 Read percent complete Block: Transducer block 1

Index: 189 (Progress)

5 Check algorithm abort state Block: Transducer block 1

Index: 75

Value:

• Bits 0–3: Abort code

6 Check inlet stiffness Block: Transducer block 1

Index: 77

• 0: Within uncertainty limit

• 1: Outside uncertainty limit

7 Check outlet stiffness Block: Transducer block 1

Index: 78

• 0: Within uncertainty limit

• 1: Outside uncertainty limit

8 Read abort code Block: Transducer block 1

Index: 185

Codes: See Table 3-3

Startup ConfigurationCalibrationBefore You Begin

Configuration and Use Manual 29

Page 38

Calibration

Verify configuration

parameters

Tools >

Meter Verification >

Run Meter Verification

Enter descriptive data

(optional)

Select output behavior

Rerun

test?

Test result chart

Configuration Changed

or Zero Changed?

View details (optional)

Yes

Next

View Previous Results

Next

Report

Test resultFail Pass

Yes No

Back

Next

Next

Finish

Start Meter Verification

---------------------

No

Abort

Figure 3-6 Smart Meter Verification – ProLink II

30 Model 2700 Transmitter with PROFIBUS-PA

Page 39

Calibration

3.4.3 Reading and interpreting Smart Meter Verification test results

Pass/Fail/Abort

When the Smart Meter Verification test is completed, the result will be reported as Pass, Fail/Caution

(depending on the tool you are using), or Abort:

• Pass – The test result is within the specification uncertainty limit. In other words, the stiffness

of the left and right pickoffs match the factory values plus or minus the specification

uncertainty limit. If transmitter zero and configuration match factory values, the sensor will

meet factory specifications for flow and density measurement. It is expected that meters will

pass Smart Meter Verification every time the test is run.

• Fail/Caution – The test result is not within the specification uncertainty limit. Micro Motion

recommends that you immediately repeat the Smart Meter Verification test. If you previously

set outputs to Continue Measurement, change the setting to Last Measured Value or Fault.

- If the meter passes the second test, the first Fail/Caution result can be ignored.

- If the meter fails the second test, the flow tubes may be damaged. Use your process

knowledge to determine the possibilities for damage and the appropriate actions for each.

These actions might include removing the meter from service and physically inspecting

the tubes. At minimum, you should perform a flow validation and a density calibration.

• Abort – A problem occurred with the Smart Meter Verification test (e.g., process instability).

Abort codes are listed in Table 3-3, and suggested actions are provided for each code.

Startup ConfigurationCalibrationBefore You Begin

Table 3-3 Smart Meter Verification abort codes

Abort code Description Suggested action

1 User-initiated abort None required. Wait for 15 seconds before starting

another test.

3 Frequency drift Ensure that temperature, flow, and density are stable,

and rerun the test.

5 High drive gain Ensure that flow is stable, minimize entrained gas, and

rerun the test.

8 Unstable flow Review the suggestions for stable flow in Section 3.4.1

and rerun the test.

13 No factory reference data for Smart

Meter Verification test performed on air

14 No factory reference data for Smart

Meter Verification test performed on

water

15 No configuration data for Smart Meter

Verification

Other General abort Repeat the test. If the test aborts again, contact

Contact Micro Motion customer service and provide the

abort code.

Contact Micro Motion customer service and provide the

abort code.

Contact Micro Motion customer service and provide the

abort code.

Micro Motion customer service and provide the abort

code.

Configuration and Use Manual 31

Page 40

Calibration

Detailed test data with ProLink II

For each test, the following data is stored on the transmitter:

ProLink II stores additional descriptive information for each test in a database on the local PC,

including:

If you run a Smart Meter Verification test from ProLink II, ProLink II first checks for new test results

on the transmitter and synchronizes the local database if required. During this step, ProLink II

displays the following message:

• Powered-on seconds at the time of the test

• Test result

• Stiffness of the left and right pickoffs, shown as percentage variation from the factory value. If

the test aborted, 0 is stored for these values.

• Abort code, if applicable

• Timestamp from the PC clock

• Current flowmeter identification data

• Current flow and density configuration parameters

• Current zero values

• Current process values for mass flow rate, volume flow rate, density, temperature, and external

pressure

• (Optional) User-entered customer and test descriptions

Synchronizing x out of y

Please wait

Note: If you request an action while synchronization is in process, ProLink II displays a message

asking whether or not you want to complete synchronization. If you choose No, the ProLink II

database may not include the latest test results from the transmitter.

Test results are available at the end of each test, in the following forms:

• A test result chart (see Figure 3-7).

• A test report that includes the descriptive information for the current test, the test result chart,

and background information about Smart Meter Verification. You can export this report to an

HTML file or print it to the default printer.

Note: To view the chart and the report for previous tests without running a test, click View Previous

Test Results and Print Report from the first Smart Meter Verification panel. See Figure 3-7. Test

reports are available only for tests initiated from ProLink II.

32 Model 2700 Transmitter with PROFIBUS-PA

Page 41

Calibration

Initiated from ProLink II

Initiated from the display or other tool

Figure 3-7 Test result chart

Startup ConfigurationCalibrationBefore You Begin

The test result chart shows the results for all tests in the ProLink II database, plotted against the

specification uncertainty limit. The inlet stiffness and the outlet stiffness are plotted separately. This

helps to distinguish between local and uniform changes to the sensor tubes.

This chart supports trend analysis, which can be helpful in detecting meter problems before they

become severe.

Configuration and Use Manual 33

Page 42

Calibration

Note the following:

Detailed test data with the display

For each Smart Meter Verification test, the following data is stored on the transmitter:

• The test result chart may not show all test results, and test counters may not be continuous.

ProLink II stores information about all tests initiated from ProLink II and all tests available on

the transmitter when the test database is synchronized. However, the transmitter stores only the

twenty most recent test results. To ensure a complete result set, always use ProLink II to

initiate the tests, or synchronize the ProLink II database before overwriting occurs.

• The chart uses different symbols to differentiate between tests initiated from ProLink II and

tests initiated using a different tool. A test report is available only for tests that were initiated

from ProLink II.

• You can double-click the chart to manipulate the presentation in a variety of ways (change