Page 1

Installation Manual

20001685, Rev DA

Micro Motion® Model 1500 and Model 2500

Installation Manual

April 2012

Page 2

Safety messages

Safety messages are provided throughout this manual to protect personnel and equipment. Read each safety message carefully

before proceeding to the next step.

Micro Motion customer service

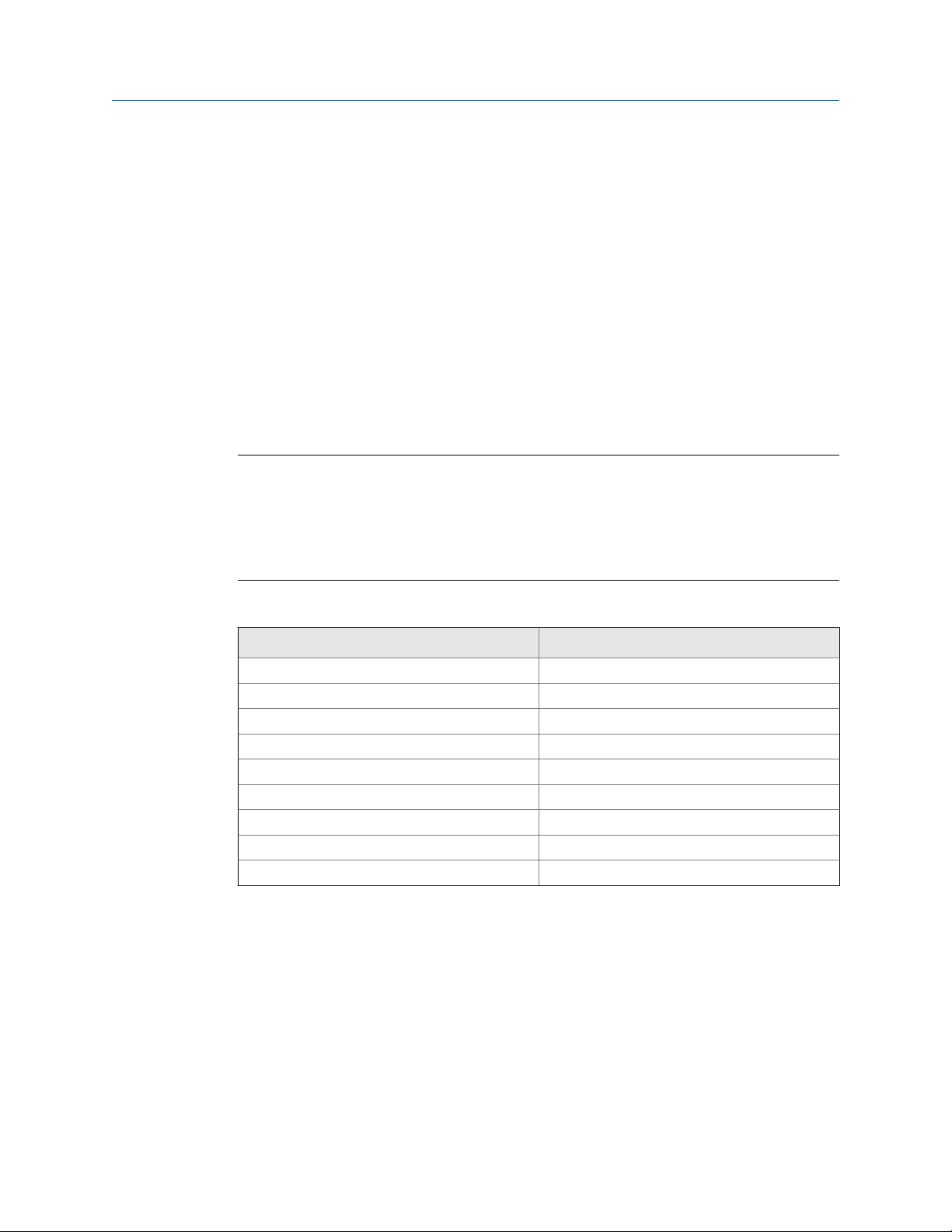

Location Telephone number Email

U.S.A. 800-522-MASS (800-522-6277) (toll free) flow.support@emerson.com

Canada and Latin America +1 303-527-5200 (U.S.A.)

Asia Japan 3 5769-6803

All other locations +65 6777-8211 (Singapore)

Europe U.K. 0870 240 1978 (toll-free)

All other locations +31 (0) 318 495 555 (The Netherlands)

Page 3

Contents

Contents

Chapter 1 Planning ...........................................................................................................................1

1.1 Flowmeter components ..................................................................................................................1

1.2 Outputs option identification ..........................................................................................................3

1.3 Environmental limits .......................................................................................................................4

1.4 Hazardous area classifications .........................................................................................................4

1.5 Power requirements ........................................................................................................................5

Chapter 2 Mounting and sensor wiring for 4-wire remote installations .............................................6

2.1 Mounting the transmitter to a DIN rail .............................................................................................6

2.2 Prepare the 4-wire cable ..................................................................................................................7

2.3 Wire the transmitter to the sensor ................................................................................................10

2.4 Ground the flowmeter components ..............................................................................................10

Chapter 3 Mounting and sensor wiring for remote core processor with remote sensor

installations ....................................................................................................................12

3.1 Mounting the transmitter to a DIN rail ...........................................................................................12

3.2 Mount the remote core processor .................................................................................................13

3.3 Prepare the 4-wire cable ................................................................................................................14

3.4 Wire the transmitter to the remote core processor .......................................................................17

3.5 Prepare the 9-wire cable ................................................................................................................18

3.6 Wire the remote core processor to the sensor using jacketed cable ..............................................24

3.7 Wire the remote core processor to the sensor using shielded or armored cable ............................28

3.8 Ground the flowmeter components ..............................................................................................33

Chapter 4 Wiring the power supply ................................................................................................34

4.1 Wire the power supply ..................................................................................................................34

Chapter 5 I/O wiring for Model 1500 transmitters ...........................................................................35

5.1 Basic analog wiring ........................................................................................................................35

5.2 HART/analog single loop wiring ....................................................................................................35

5.3 HART multidrop wiring ..................................................................................................................36

Chapter 6 I/O wiring for Model 2500 transmitters ...........................................................................37

6.1 mA/HART wiring ...........................................................................................................................37

6.2 Frequency output wiring ...............................................................................................................39

6.3 Discrete output wiring ..................................................................................................................42

6.4 Discrete input wiring .....................................................................................................................45

Chapter 7 Specifications .................................................................................................................47

7.1 Electrical connections ...................................................................................................................47

7.2 Input/output signals .....................................................................................................................47

7.3 Environmental limits .....................................................................................................................48

7.4 Physical specifications ...................................................................................................................49

Index .................................................................................................................................................51

Installation Manual i

Page 4

Contents

ii Micro Motion® Model 1500 and Model 2500

Page 5

1 Planning

Topics covered in this chapter:

Flowmeter components

•

Outputs option identification

•

Environmental limits

•

Hazardous area classifications

•

Power requirements

•

1.1 Flowmeter components

The transmitter is one component of a Micro Motion flowmeter. The other major

component is the sensor.

A third component, called the core processor, provides additional memory and processing

functions.

Planning

1.1.1 Installation types

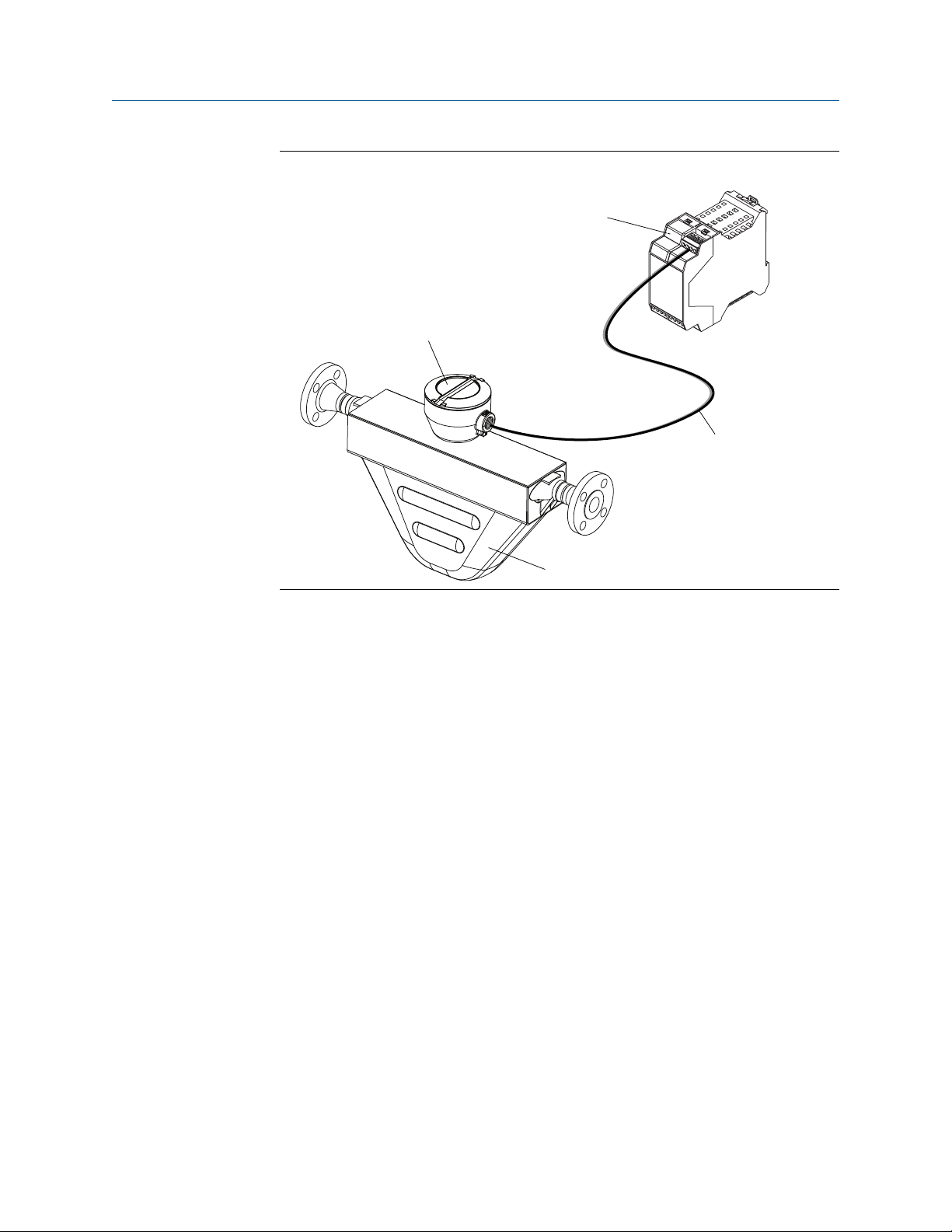

Model 1500 and Model 2500 transmitters can be installed two different ways, only one of

which applies to your specific installation.

• 4-wire remote – The transmitter is installed remotely from the sensor. You need to

mount the transmitter separately from the sensor, connect a 4-wire cable between

the transmitter and sensor, and connect power and I/O wiring to the transmitter.

Installation Manual 1

Page 6

Sensor

Core processor

Transmitter

4-wire cable

Planning

4-wire remote installationFigure 1-1:

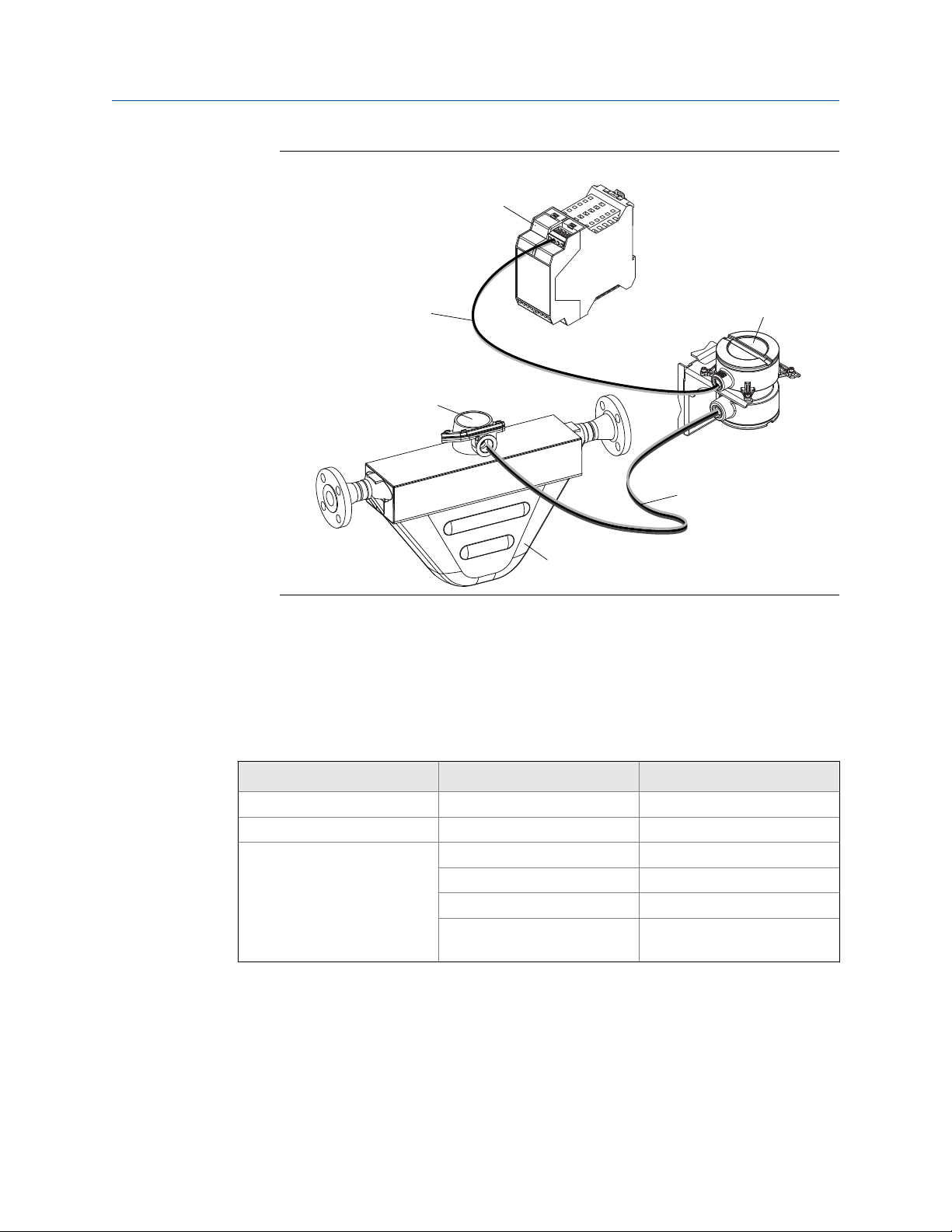

• Remote core processor with remote sensor

– A remote core process with remote

sensor installation separates all three components – transmitter, core processor,

and sensor – all of which are installed separately. A 4-wire cable connects the

transmitter to the core processor, and a 9-wire cable connects the core processor to

the sensor.

2 Micro Motion® Model 1500 and Model 2500

Page 7

Core processor

Transmitter

4-wire cable

9-wire cable

Sensor

Junction box

Planning

Remote core processor with remote sensor installationFigure 1-2:

1.1.2 Maximum cable lengths

The maximum cable length between flowmeter components that are separately installed

is determined by cable type. See Table 1-1.

Maximum cable lengthsTable 1-1:

Cable type Wire gauge Maximum length

Micro Motion 4-wire Not applicable 1000 ft (300 m)

Micro Motion 9-wire Not applicable 60 ft (20 m)

User-supplied 4-wire VDC 22 AWG (0.35 mm2) 300 ft (90 m)

VDC 20 AWG (0.5 mm2) 500 ft (150 m)

VDC 18 AWG (0.8 mm2) 1000 ft (300 m)

RS-485 22 AWG (0.35 mm2) or

larger

1.2 Outputs option identification

You must know your transmitter's output option to correctly install the transmitter.

1000 ft (300 m)

Installation Manual 3

Page 8

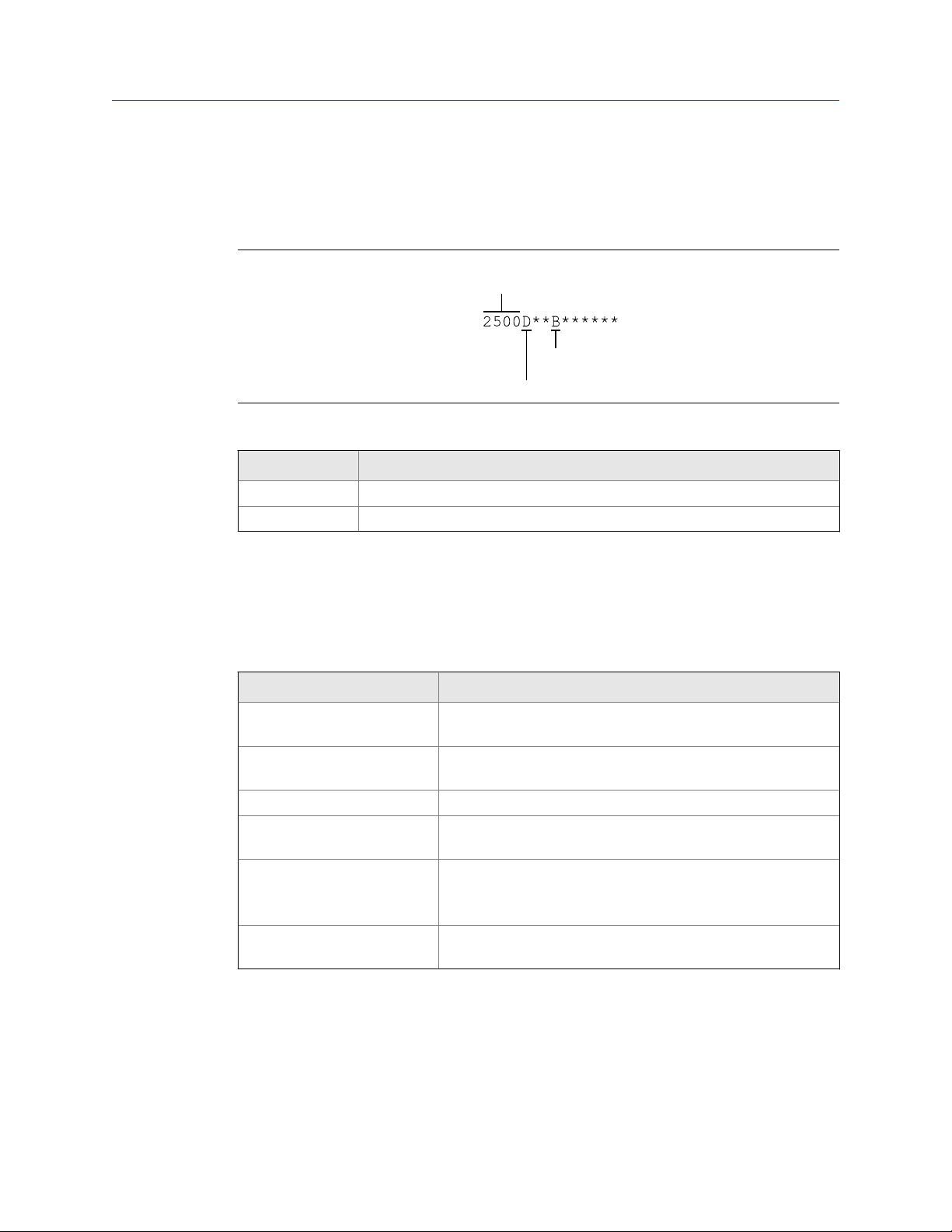

Transmitter type

Installation type

Output option

Planning

The transmitter's model number is on a tag on the side of the transmitter. You can use the

model number to determine the transmitter's output option. The first four characters are

the transmitter type. The fifth character is the installation type. The eighth character is the

output option. The remaining characters are not relevant to transmitter installation.

Model code identificationFigure 1-3:

Installation types for Model 1500 and Model 2500 transmittersTable 1-2:

Letter Description

D 4-wire remote 35 mm DIN rail

B 4-wire remote 35 mm DIN rail with 9-wire remote core processor

1.3 Environmental limits

Environmental specificationsTable 1-3:

Type Value

Ambient temperature limits

(Operating)

Ambient temperature limits

(Storage)

Humidity limits 5 to 95% relative humidity, non-condensing at 140 °F (60 °C)

Vibration limits Meets IEC68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cy-

EMI effects Complies with EMC Directive 2004/108/EC per EN 61326 Indus-

Ambient temperature effect

(analog output option)

–40 to +131 °F (–40 to +55 °C)

–40 to +185 °F (–40 to +85 °C)

cles at 1.0 g

trial

Complies with NAMUR NE-21 (22.08.2007)

On mA output: ±0.005% of span per °C

1.4 Hazardous area classifications

If you plan to mount the transmitter in a hazardous area:

4 Micro Motion® Model 1500 and Model 2500

Page 9

• Verify that the transmitter has the appropriate hazardous area approval. Each

M

= 19.2V + (R × L × 0.33A)

transmitter has a hazardous area approval tag attached to the transmitter housing.

• Ensure that any cable used between the transmitter and the sensor meets the

hazardous area requirements.

1.5 Power requirements

The transmitter must be connected to a DC voltage source.

• Minimum 19.2 to 28.8 VDC

• 6.3 watts

• Meets Installation (Overvoltage) Category II, Pollution Degree 2 requirements

Cable sizing formulaFigure 1-4:

A. M: minimum supply voltage

B. R: cable resistance

C. L: cable length

Planning

Typical power cable resistance at 68 °F (20 °C)Table 1-4:

Wire gauge Resistance

14 AWG

16 AWG

18 AWG

20 AWG

2.5 mm

1.5 mm

1.0 mm

0.75 mm

0.50 mm

2

2

2

2

2

0.0050 Ω/ft

0.0080 Ω/ft

0.0128 Ω/ft

0.0204 Ω/ft

0.0136 Ω/m

0.0228 Ω/m

0.0340 Ω/m

0.0460 Ω/m

0.0680 Ω/m

Installation Manual 5

Page 10

A

B

C

Mounting and sensor wiring for 4-wire remote installations

2 Mounting and sensor wiring for 4-

wire remote installations

Topics covered in this chapter:

Mounting the transmitter to a DIN rail

•

Prepare the 4-wire cable

•

Wire the transmitter to the sensor

•

Ground the flowmeter components

•

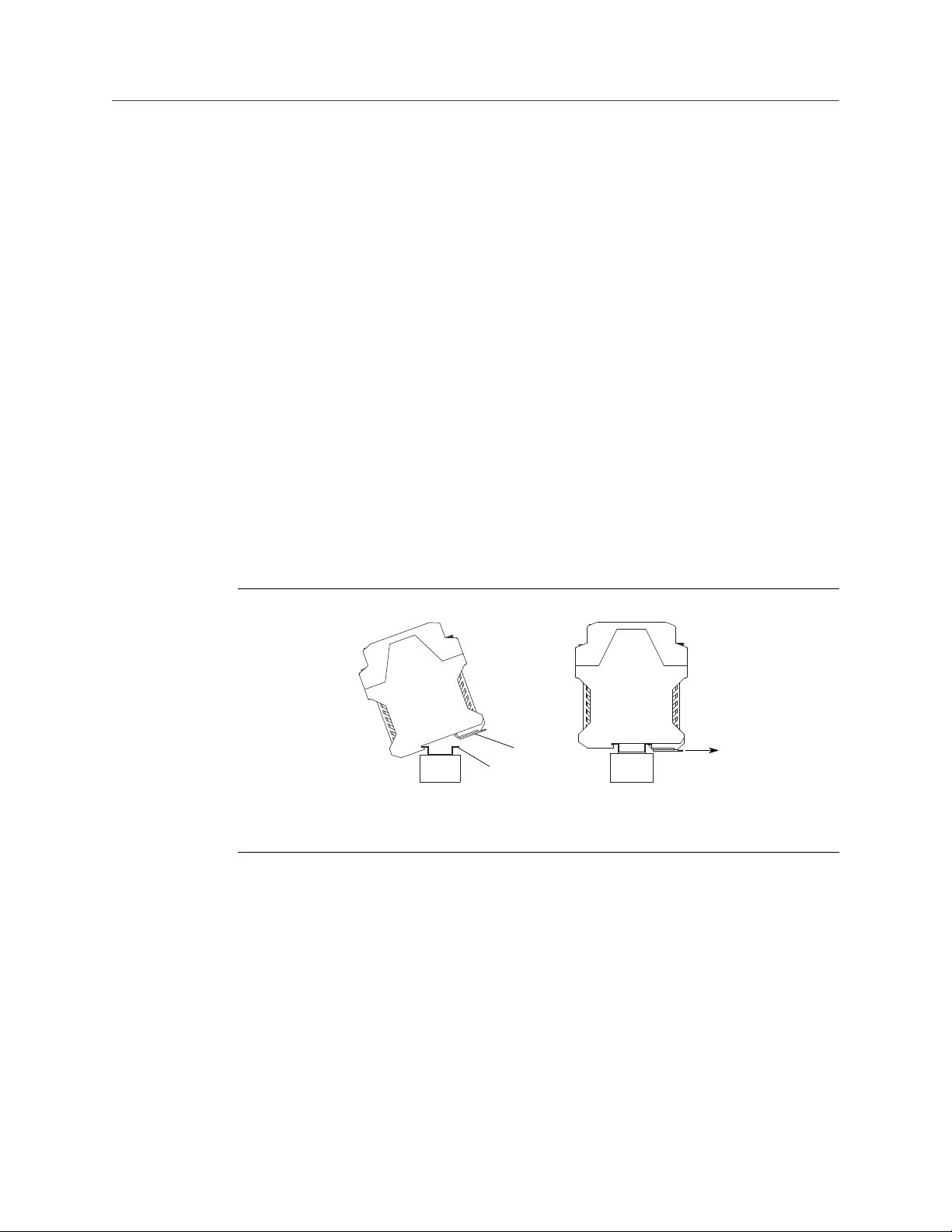

2.1 Mounting the transmitter to a DIN rail

The transmitter is designed to be mounted on a 35 mm DIN rail. The DIN rail must be

grounded.

2.1.1

Mounting the transmitterFigure 2-1:

A. Spring clamp

B. DIN rail

C. Spring clamp release loop

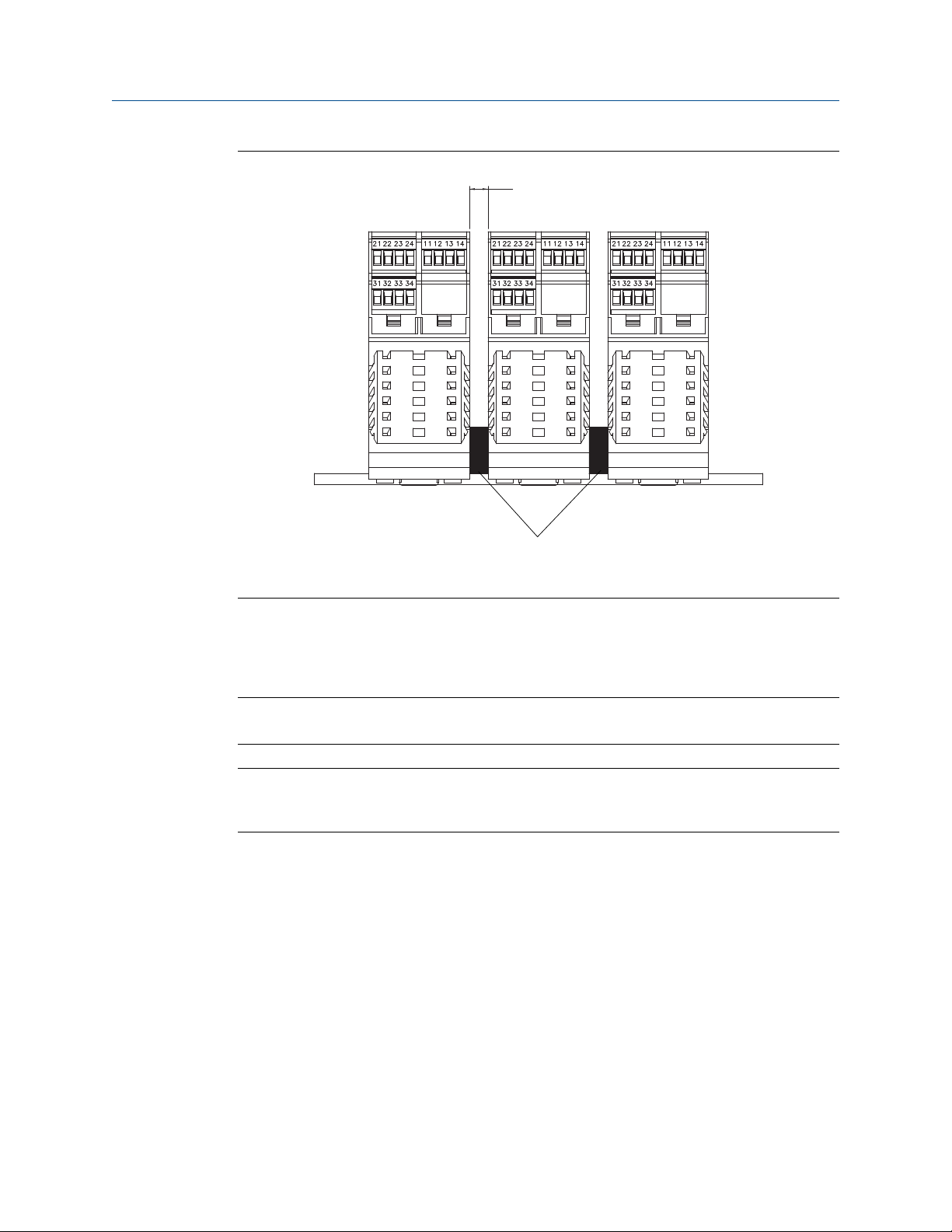

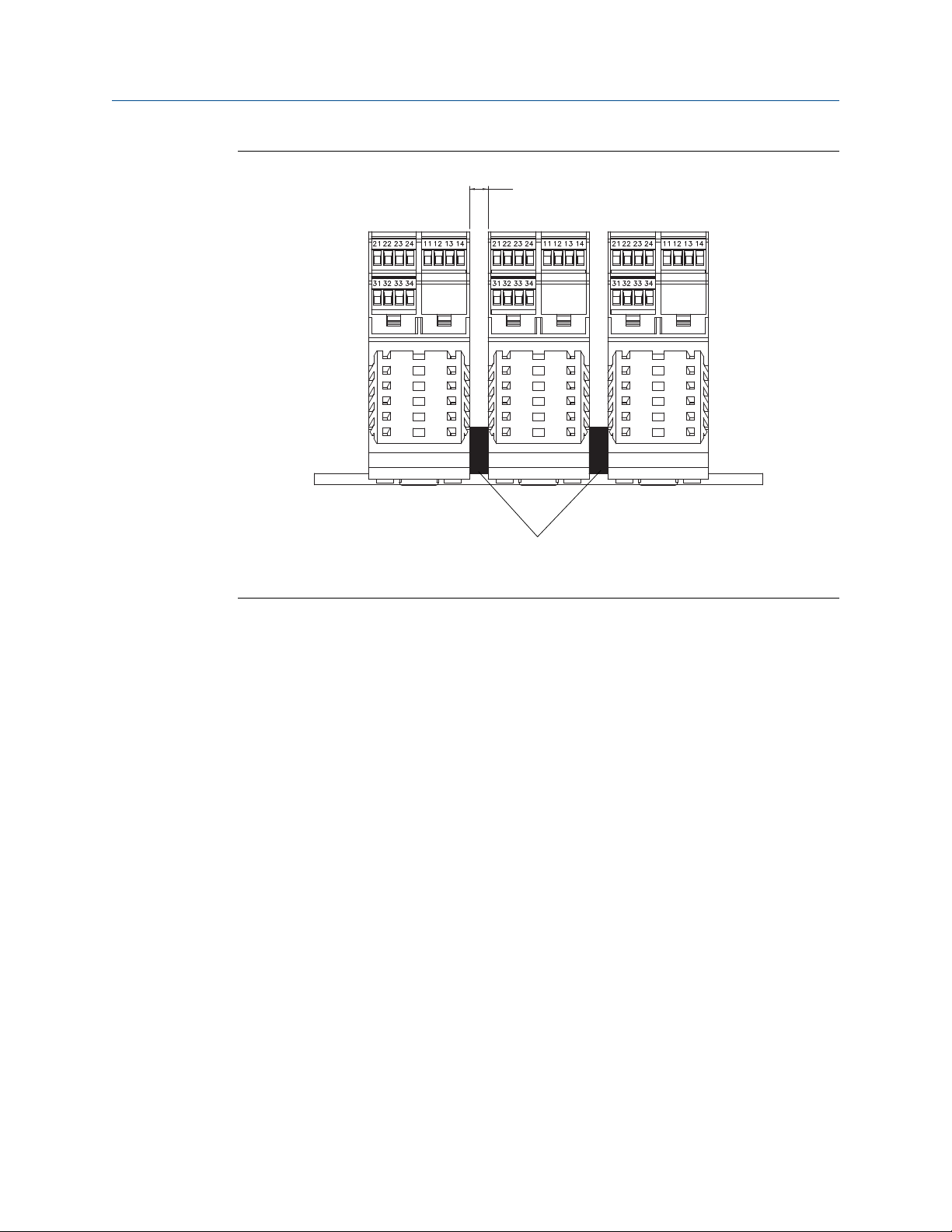

Mounting multiple transmitters

If the ambient temperature is above 113 °F (45 °C) and you are mounting multiple

transmitters, mount the transmitters so they are at least 0.33 in (8.5 mm) apart.

6 Micro Motion® Model 1500 and Model 2500

Page 11

A

Mounting and sensor wiring for 4-wire remote installations

Mounting multiple transmittersFigure 2-2:

2.2

A. 0.33 in or greater (8.5 mm or greater)

B. End bracket or end stop; 0.33 in (8.5 mm) minimum spacing

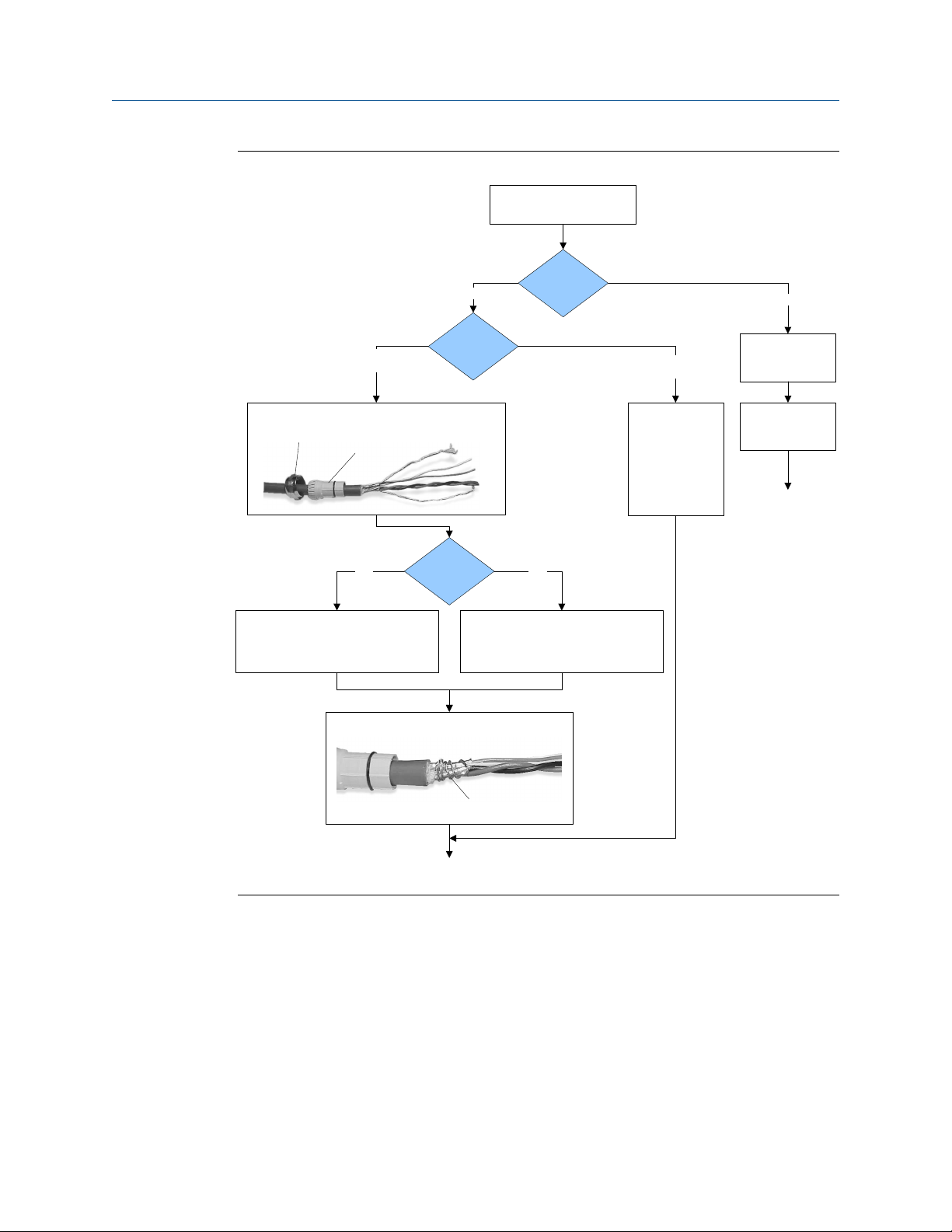

Prepare the 4-wire cable

Important

For user-supplied cable glands, the gland must be capable of terminating the drain wires.

Note

If you are installing unshielded cable in continuous metallic conduit with 360º termination shielding,

you only need to prepare the cable – you do not need to perform the shielding procedure.

Installation Manual 7

Page 12

Mounting and sensor wiring for 4-wire remote installations

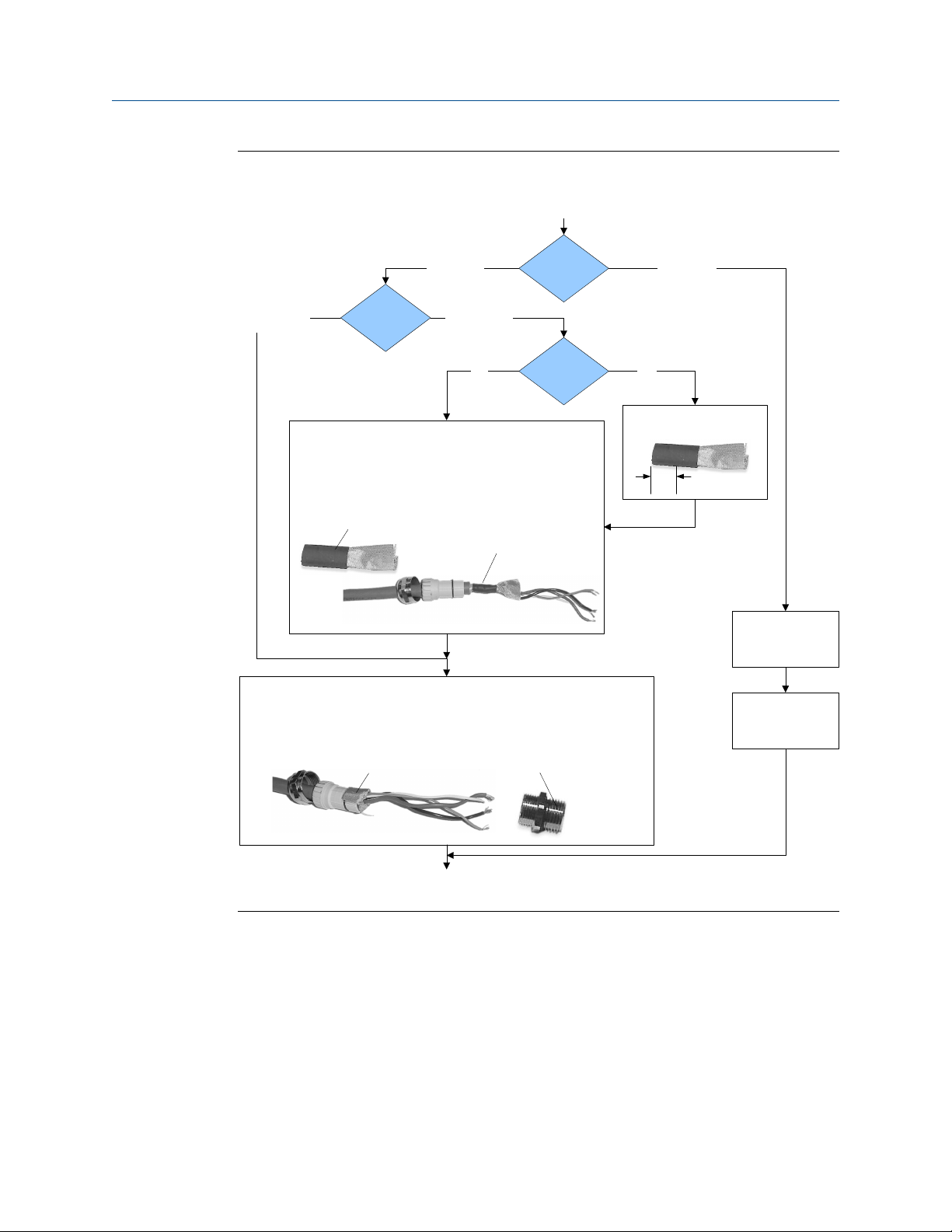

4-wire cable preparationFigure 2-3:

Remove the core processor

cover

Cable glands

Micro Motion

cable gland

Pass the wires through the gland nut and clamping insert.

Gland nut

1. Strip 4-1/2 inch (115 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 3/4 inch (19 mm) of shielding.

Clamping

insert

NPT

Wrap the drain wires twice around the shield and cut off

Gland supplier

Gland type

the excess drain wires.

Cable layout

through the gland.

Terminate the drain

wires inside the

M20

1. Strip 4-1/4 inch (108 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 1/2 inch (12 mm) of shielding.

User-supplied

cable gland

Pass the wires

gland.

Metal conduit

Run conduit to

sensor

Lay cable in conduit

Done

(do not perform the

shielding procedure)

Drain wires

wrapped around

shield

Go to the shielding

procedure

8 Micro Motion® Model 1500 and Model 2500

Page 13

Mounting and sensor wiring for 4-wire remote installations

4-wire cable shieldingFigure 2-4:

From the preparation

procedure

Micro Motion

cable gland

Braided

(armored cable)

Apply the Heat Shrink

1. Slide the shielded heat shrink over the drain wires. Ensure that the

wires are completely covered.

2. Apply heat (250 °F or 120 °C) to shrink the tubing. Do not burn the

cable.

3. Position the clamping insert so the interior end is flush with the braid

of the heat shrink.

Assemble the Gland

1. Fold the shield or braid back over the clamping insert and 1/8 inch

(3 mm) past the O-ring.

2. Install the gland body into the conduit opening on the core processor housing.

3. Insert the wires through gland body and tighten the gland nut onto the gland body.

Cable shield

type

Shielded heat

shrink

Foil

(shielded cable)

NPT

Gland supplier

Gland type M20

After heat applied

User-supplied

cable gland

Trim 7 mm from the shielded

heat shrink

Trim

Terminate the shield

and drain wires in the

Assemble the gland

according to vendor

gland

instructions

Shield folded back

Done

Gland body

2.2.1 4-wire cable types and usage

Micro Motion offers two types of 4-wire cable: shielded and armored. Both types contain

shield drain wires.

The 4-wire cable supplied by Micro Motion consists of one pair of red and black 18 AWG

(0.75 mm2) wires for the VDC connection, and one pair of white and green 22 AWG

(0.35 mm2) wires for the RS-485 connection.

User-supplied 4-wire cable must meet the following requirements:

Installation Manual 9

Page 14

RS-485B

RS-485A

VDC–

VDC+

Mounting and sensor wiring for 4-wire remote installations

• Twisted pair construction.

• Applicable hazardous area requirements, if the core processor is installed in a

hazardous area.

• Wire gauge appropriate for the cable length between the core processor and the

transmitter.

Wire gaugeTable 2-1:

Wire gauge Maximum cable length

VDC 22 AWG (0.35 mm2) 300 ft (90 m)

VDC 20 AWG (0.5 mm2) 500 ft (150 m)

VDC 18 AWG (0.8 mm2) 1000 ft (300 m)

RS-485 22 AWG (0.35 mm2) or larger 1000 ft (300 m)

2.3 Wire the transmitter to the sensor

1. Connect the cable to the core processor as described in the sensor documentation.

2. Connect the four wires from the core processor to terminals 1–4 on the transmitter.

Important

Do not ground the shield, braid, or drain wires at the transmitter.

Terminal connections for 4-wire cableFigure 2-5:

2.4 Ground the flowmeter components

In 4-wire remote installations, the transmitter and sensor are grounded separately.

10 Micro Motion® Model 1500 and Model 2500

Page 15

Mounting and sensor wiring for 4-wire remote installations

CAUTION!

Improper grounding could cause inaccurate measurements or flow meter failure. Failure to

comply with requirements for intrinsic safety in a hazardous area could result in an explosion.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

• Use copper wire, 14 AWG (2.5 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

1. Ground the sensor according to the instructions in the sensor documentation.

2. Ground the DIN rail.

The rail clip in the base of the transmitter housing grounds the transmitter to the

DIN rail.

Installation Manual 11

Page 16

A

B

C

Mounting and sensor wiring for remote core processor with remote sensor installations

3 Mounting and sensor wiring for

remote core processor with remote

sensor installations

Topics covered in this chapter:

Mounting the transmitter to a DIN rail

•

Mount the remote core processor

•

Prepare the 4-wire cable

•

Wire the transmitter to the remote core processor

•

Prepare the 9-wire cable

•

Wire the remote core processor to the sensor using jacketed cable

•

Wire the remote core processor to the sensor using shielded or armored cable

•

Ground the flowmeter components

•

3.1 Mounting the transmitter to a DIN rail

The transmitter is designed to be mounted on a 35 mm DIN rail. The DIN rail must be

grounded.

Mounting the transmitterFigure 3-1:

A. Spring clamp

B. DIN rail

C. Spring clamp release loop

3.1.1

Mounting multiple transmitters

If the ambient temperature is above 113 °F (45 °C) and you are mounting multiple

transmitters, mount the transmitters so they are at least 0.33 in (8.5 mm) apart.

12 Micro Motion® Model 1500 and Model 2500

Page 17

A

Mounting and sensor wiring for remote core processor with remote sensor installations

Mounting multiple transmittersFigure 3-2:

3.2

A. 0.33 in or greater (8.5 mm or greater)

B. End bracket or end stop; 0.33 in (8.5 mm) minimum spacing

Mount the remote core processor

This procedure is required only for remote core processor with remote transmitter

installations.

For mounting the remote core processor to a wall:

• Use four 5/16-inch diameter (or M8) bolts and nuts that can withstand the process

environment. Micro Motion does not supply bolts or nuts (appropriate bolts and

nuts are available as an option).

• Ensure that the surface is flat and rigid, does not vibrate, or move excessively.

For mounting the remote core processor to an instrument pole:

• Use two 5/16-inch U-bolts for 2-inch pipe, and four matching nuts, that can

withstand the process environment. Micro Motion does not supply U-bolts or nuts.

• Ensure the instrument pole extends at least 12 inches (305 mm) from a rigid base,

and is no more than 2 inches (50.8 mm) in diameter.

1. If desired, reorient the core processor housing on the bracket.

a. Loosen each of the four cap screws (4 mm).

b. Rotate the bracket so that the core processor is oriented as desired.

c. Tighten the cap screws, torquing to 30 to 38 in-lbs (3 to 4 N-m).

Installation Manual 13

Page 18

A

B

Mounting and sensor wiring for remote core processor with remote sensor installations

Components of a remote core processorFigure 3-3:

A. Mounting bracket

B. Cap screws

2. Attach the mounting bracket to an instrument pole or wall.

3.3 Prepare the 4-wire cable

Important

For user-supplied cable glands, the gland must be capable of terminating the drain wires.

Note

If you are installing unshielded cable in continuous metallic conduit with 360º termination shielding,

you only need to prepare the cable – you do not need to perform the shielding procedure.

14 Micro Motion® Model 1500 and Model 2500

Page 19

Mounting and sensor wiring for remote core processor with remote sensor installations

4-wire cable preparationFigure 3-4:

Remove the core processor

cover

Cable glands

Micro Motion

cable gland

Pass the wires through the gland nut and clamping insert.

Gland nut

1. Strip 4-1/2 inch (115 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 3/4 inch (19 mm) of shielding.

Clamping

insert

NPT

Wrap the drain wires twice around the shield and cut off

Gland supplier

Gland type

the excess drain wires.

Cable layout

through the gland.

Terminate the drain

wires inside the

M20

1. Strip 4-1/4 inch (108 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Strip all but 1/2 inch (12 mm) of shielding.

User-supplied

cable gland

Pass the wires

gland.

Metal conduit

Run conduit to

sensor

Lay cable in conduit

Done

(do not perform the

shielding procedure)

Drain wires

wrapped around

shield

Go to the shielding

procedure

Installation Manual 15

Page 20

Mounting and sensor wiring for remote core processor with remote sensor installations

4-wire cable shieldingFigure 3-5:

From the preparation

procedure

Micro Motion

cable gland

Braided

(armored cable)

Apply the Heat Shrink

1. Slide the shielded heat shrink over the drain wires. Ensure that the

wires are completely covered.

2. Apply heat (250 °F or 120 °C) to shrink the tubing. Do not burn the

cable.

3. Position the clamping insert so the interior end is flush with the braid

of the heat shrink.

Assemble the Gland

1. Fold the shield or braid back over the clamping insert and 1/8 inch

(3 mm) past the O-ring.

2. Install the gland body into the conduit opening on the core processor housing.

3. Insert the wires through gland body and tighten the gland nut onto the gland body.

Cable shield

type

Shielded heat

shrink

Foil

(shielded cable)

NPT

Gland supplier

Gland type M20

After heat applied

User-supplied

cable gland

Trim 7 mm from the shielded

heat shrink

Trim

Terminate the shield

and drain wires in the

Assemble the gland

according to vendor

gland

instructions

Shield folded back

Done

Gland body

3.3.1 4-wire cable types and usage

Micro Motion offers two types of 4-wire cable: shielded and armored. Both types contain

shield drain wires.

The 4-wire cable supplied by Micro Motion consists of one pair of red and black 18 AWG

(0.75 mm2) wires for the VDC connection, and one pair of white and green 22 AWG

(0.35 mm2) wires for the RS-485 connection.

User-supplied 4-wire cable must meet the following requirements:

16 Micro Motion® Model 1500 and Model 2500

Page 21

A

Mounting and sensor wiring for remote core processor with remote sensor installations

• Twisted pair construction.

• Applicable hazardous area requirements, if the core processor is installed in a

hazardous area.

• Wire gauge appropriate for the cable length between the core processor and the

transmitter.

Wire gaugeTable 3-1:

Wire gauge Maximum cable length

VDC 22 AWG (0.35 mm2) 300 ft (90 m)

VDC 20 AWG (0.5 mm2) 500 ft (150 m)

VDC 18 AWG (0.8 mm2) 1000 ft (300 m)

RS-485 22 AWG (0.35 mm2) or larger 1000 ft (300 m)

3.4 Wire the transmitter to the remote core processor

1. If you are installing a Micro Motion-supplied cable gland at the core processor

housing, identify the cable gland to use for the 4-wire cable conduit opening.

Cable gland identificationFigure 3-6:

A. Cable gland used with 4-wire conduit opening

B. 3/4"–14 NPT cable gland used with 9-wire conduit opening

2. Connect the cable to the core processor as described in the sensor documentation.

3. Connect the four wires from the core processor to terminals 1–4 on the transmitter.

Important

Do not ground the shield, braid, or drain wires at the transmitter.

Installation Manual 17

Page 22

RS-485B

RS-485A

VDC–

VDC+

Mounting and sensor wiring for remote core processor with remote sensor installations

Terminal connections for 4-wire cableFigure 3-7:

3.5 Prepare the 9-wire cable

Micro Motion supplies three types of 9-wire cable: jacketed, shielded, and armored. The

type of cable you are using determines how you will prepare the cable.

Perform the cable preparation procedure appropriate for your cable type.

18 Micro Motion® Model 1500 and Model 2500

Page 23

Mounting and sensor wiring for remote core processor with remote sensor installations

Preparing jacketed cableFigure 3-8:

Prepare jacketed

cable at the sensor

end

1. Trim 4 ½ inches (115 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Remove the foil that is around the insulated wires

and separate them.

Trim cable jacket

4. Identify the drain wires in the cable. Clip off each

drain wire as close as possible to the cable jacket.

Drain wires clipped

5. Slide the 1 ½ inch (40 mm) heat-shrink tubing over

the wires and cable jacket. The tubing should

completely cover the clipped ends of the drain wires.

Prepare jacketed

cable at the

transmitter end

1. Trim 4 inches (100 mm) of cable jacket.

2. Remove the clear wrap and filler material.

3. Remove the foil that is around the insulated wires

and separate them.

Trim cable jacket

4. Identify the drain wires in the cable and bring them

together. Fan the other wires to the outside of the

cable. Twist the drain wires together.

5. Slide the 3-inch (75 mm) heat-shrink tubing over

the drain wires. Push the tubing as close as possible

to the cable jacket.

6. Slide the 1 ½ inch (40 mm) long heat-shrink tubing

over the cable jacket. The tubing should

completely cover all portions of the drain wires that

remain exposed next to the cable jacket.

Heat-shrink

tubing

6. Without burning the cable, apply heat to shrink all

tubing. Recommended temperature is 250 °F (121

°C).

7. Allow the cable to cool, then strip ¼ inch (5 mm) of

insulation from each wire.

Heat-shrink tubing over

cable jacket

Heat-shrink tubing over drain

wires

7. Without burning the cable, apply heat to shrink all

tubing. Recommended temperature is 250 °F (121

°C).

8. Allow the cable to cool, then strip ¼ inch (5 mm) of

insulation from each wire.

Installation Manual 19

Page 24

Mounting and sensor wiring for remote core processor with remote sensor installations

Preparing shielded or armored cableFigure 3-9:

Prepare shielded or

armored cable at the

sensor end

1. Without cutting the shield, strip 7 inches (175 mm)

of outer jacket.

2. Strip 6 ½ inches (165 mm) of braided shield, so ½

inch (10 mm) of shield remains exposed.

3. Remove the foil shield that is between the braided

shield and inner jacket.

4. Strip 4 ½ inches (115 mm) of inner jacket.

Trim outer jacket

Trim braided shield

Trim inner jacket

5. Remove the clear wrap and filler material.

6. Remove the foil that is around the insulated wires

and separate them.

7. Identify the drain wires in the cable. Clip each drain

wire as close as possible to the cable jacket.

Drain wires clipped

8. Slide the 1 ½ inch (40 mm) long heat-shrink tubing

over the cable jacket. The tubing should completely

cover the clipped ends of the drain wires.

Prepare shielded or

armored cable at the

transmitter end

1. Without cutting the shield, strip 9 inches (225 mm) of

cable jacket.

2. Strip 8 ½ inches (215 mm) of braided shield, so ½

inch (10 mm) of shield remains exposed.

3. Remove the foil shield that is between the braided

shield and inner jacket.

4. Strip 4 inches (100 mm) of inner jacket.

Trim outer jacket

Trim braided shield

Trim inner jacket

5. Remove the clear wrap and filler material.

6. Remove the foil that is around the insulated wires and

separate them.

7. Identify the drain wires in the cable and bring them

together. Fan the other wires to the outside of the

cable. Twist the drain wires together.

8. Slide the 3-inch (75 mm) long heat-shrink tubing over

the drain wires. Push the tubing as close as possible to

the inner jacket.

9. Slide the 1 ½ inch (40 mm) long heat-shrink tubing

over the cable jacket. The tubing should completely

cover all portions of the drain wires that remain

exposed next to the cable jacket.

Heat-shrink tubing

9. Without burning the cable, apply heat to shrink all

tubing. Recommended temperature is 250 °F (121

°C).

10. Allow the cable to cool, then strip ¼ inch (5 mm) of

insulation from each wire.

Heat-shrink tubing over cable

Heat-shrink tubing over drain wires

10. Without burning the cable, apply heat to shrink all

tubing. Recommended temperature is 250 °F (121

°C).

11. Allow the cable to cool, then strip ¼ inch (5 mm) of

insulation from each wire.

jacket

3.5.1 9-wire cable types and usage

20 Micro Motion® Model 1500 and Model 2500

Page 25

Mounting and sensor wiring for remote core processor with remote sensor installations

Cable types

Micro Motion supplies three types of 9-wire cable: jacketed, shielded, and armored. Note

the following differences between the cable types:

• Armored cable provides mechanical protection for the cable wires.

• Jacketed cable has a smaller bend radius than shielded or armored cable.

• If ATEX compliance is required, the different cable types have different installation

requirements.

Cable jacket types

All cable types can be ordered with a PVC jacket or Teflon® FEP jacket. Teflon FEP is

required for the following installation types:

• All installations that include a T-series sensor.

• All installations with a cable length of 250 ft (75 m) or greater, a nominal flow less

than 20 percent, and ambient temperature changes greater than +68 °F (+20 °C).

Cable jacket material and temperature rangesTable 3-2:

Handling temperature Operating temperature

Cable jacket material Low limit High limit Low limit High limit

PVC –4 °F (–20 °C) +194 °F (+90 °C) –40 °F (–40 °C) +221 °F (+105 °C)

Teflon FEP –40 °F (–40 °C) +194 °F (+90 °C) –76 °F (–60 °C) +302 °F (+150 °C)

Cable bend radii

Bend radii of jacketed cableTable 3-3:

Jacket material Outside diameter Minimum bend radii

Static (no load) condition Under dynamic load

PVC 0.415 inches (10 mm) 3–1/8 inches (80 mm) 6–1/4 inches (159 mm)

Teflon FEP 0.340 inches (9 mm) 2–5/8 inches (67 mm) 5–1/8 inches (131 mm)

Bend radii of shielded cableTable 3-4:

Jacket material Outside diameter Minimum bend radii

Static (no load) condition Under dynamic load

PVC 0.2 inches (14 mm) 4–1/4 inches (108 mm) 8–1/2 inches (216 mm)

Teflon FEP 0.425 inches (11 mm) 3–1/4 inches (83 mm) 6–3/8 inches (162 mm)

Installation Manual 21

Page 26

A

C (4)

B (4)

D (5)

Mounting and sensor wiring for remote core processor with remote sensor installations

Bend radii of armored cableTable 3-5:

Jacket material Outside diameter Minimum bend radii

Static (no load) condition Under dynamic load

PVC 0.525 inches (14 mm) 4–1/4 inches (108 mm) 8–1/2 inches (216 mm)

Teflon FEP 0.340 inches (9 mm) 3–1/4 inches (83 mm) 6–3/8 inches (162 mm)

Cable illustrations

Cross-section view of jacketed cableFigure 3-10:

A. Outer jacket

B. Drain wire (4 total)

C. Foil shield (4 total)

D. Filler (5 total)

22 Micro Motion® Model 1500 and Model 2500

Page 27

A

C (1)

B

D

E (4)

F (4)

G (5)

A

C (1)

B

D

E (4)

F (4)

G (5)

Mounting and sensor wiring for remote core processor with remote sensor installations

Cross-section view of shielded cableFigure 3-11:

A. Outer jacket

B. Tin-plated copper braided shield

C. Foil shield (1 total)

D. Inner jacket

E. Drain wire (4 total)

F. Foil shield (4 total)

G. Filler (5 total)

Cross-section view of armored cableFigure 3-12:

A. Outer jacket

B. Stainless steel braided shield

C. Foil shield (1 total)

D. Inner jacket

E. Drain wire (4 total)

F. Foil shield (4 total)

G. Filler (5 total)

Installation Manual 23

Page 28

Mounting and sensor wiring for remote core processor with remote sensor installations

3.6 Wire the remote core processor to the sensor using jacketed cable

For ATEX installations, the jacketed cable must be installed inside a user-supplied sealed

metallic conduit that provides 360° termination shielding for the enclosed cable.

CAUTION!

Sensor wiring is intrinsically safe. To keep sensor wiring intrinsically safe, keep the sensor

wiring separated from power supply wiring and output wiring.

CAUTION!

Keep cable away from devices such as transformers, motors, and power lines, which produce

large magnetic fields. Improper installation of cable, cable gland, or conduit could cause

inaccurate measurements or flow meter failure.

CAUTION!

Improperly sealed housings can expose electronics to moisture, which can cause measurement

error or flowmeter failure. Install drip legs in conduit and cable, if necessary. Inspect and

grease all gaskets and O-rings. Fully close and tighten all housing covers and conduit openings.

1. Run the cable through the conduit. Do not install 9-wire cable and power cable in

the same conduit.

2. To prevent conduit connectors from seizing in the threads of the conduit openings,

apply a conductive anti-galling compound to the threads, or wrap threads with PTFE

tape two to three layers deep.

Wrap the tape in the opposite direction that the male threads will turn when

inserted into the female conduit opening.

3. Remove the junction box cover and core processor end-cap.

4. At both the sensor and transmitter, do the following:

a. Connect a male conduit connector and waterproof seal to the conduit opening

for 9-wire.

b. Pass the cable through the conduit opening for the 9-wire cable.

c. Insert the stripped end of each wire into the corresponding terminal at the

sensor and transmitter ends, matching by color. No bare wires should remain

exposed.

Sensor and remote core processor terminal designationsTable 3-6:

Wire color Sensor terminal Remote core processor terminal Function

Black No connection Ground screw (see note) Drain wires

Brown 1 1 Drive +

Red 2 2 Drive –

24 Micro Motion® Model 1500 and Model 2500

Page 29

Mounting and sensor wiring for remote core processor with remote sensor installations

Table 3-6:

Wire color Sensor terminal Remote core processor terminal Function

Orange 3 3 Temperature –

Yellow 4 4 Temperature return

Green 5 5 Left pickoff +

Blue 6 6 Right pickoff +

Violet 7 7 Temperature +

Gray 8 8 Right pickoff –

White 9 9 Left pickoff –

Note

Ground the shield drain wires (the black wire) only on the core processor end, by

connecting it to the ground screw inside the lower conduit ring. Never ground to the core

processor’s mounting screw. Never ground the cable at the sensor junction box.

Sensor and remote core processor terminal designations

(continued)

d. Tighten the screws to hold the wire in place.

e. Ensure integrity of gaskets, grease all O-rings, then replace the junction-box and

transmitter housing covers and tighten all screws, as required.

3.6.1

Sensor and remote core processor terminals

Installation Manual 25

Page 30

D

I

H

F

E

A

B

C

G

Mounting and sensor wiring for remote core processor with remote sensor installations

ELITE, H-Series, T-Series, and some F-Series sensor terminalsFigure 3-13:

A. Violet

B. Yellow

C. Orange

D. Brown

E. White

F. Green

G. Red

H. Gray

I. Blue

F-Series, Model D, and Model DL sensor terminalsFigure 3-14:

26 Micro Motion® Model 1500 and Model 2500

Page 31

1

9

8

7

6

5

4

3

2

A

A

B

C

D

E

F

G

H

I

J

K

Mounting and sensor wiring for remote core processor with remote sensor installations

Figure 3-15:

Model DT sensor terminals (user-supplied metal junction box with

terminal block)

A. Earth ground

Remote core processor terminalsFigure 3-16:

A. Brown

B. Violet

C. Yellow

D. Orange

E. Gray

F. Blue

G. White

H. Green

I. Red

J. Mounting screw

K. Ground screw (black)

Installation Manual 27

Page 32

A

B

C

D

E

F

G

H

I

Mounting and sensor wiring for remote core processor with remote sensor installations

3.7 Wire the remote core processor to the sensor using shielded or armored cable

For ATEX installations, shielded or armored cable must be installed with cable glands, at

both the sensor and remote core processor ends. Cable glands that meet ATEX

requirements can be purchased from Micro Motion. Cable glands from other vendors can

be used.

CAUTION!

Keep cable away from devices such as transformers, motors, and power lines, which produce

large magnetic fields. Improper installation of cable, cable gland, or conduit could cause

inaccurate measurements or flow meter failure.

CAUTION!

Install cable glands in the 9-wire conduit opening in the transmitter housing and the sensor

junction box. Ensure that the cable drain wires and shields do not make contact with the

junction box or the transmitter housing. Improper installation of cable or cable glands could

cause inaccurate measurements or flow meter failure.

CAUTION!

Improperly sealed housings can expose electronics to moisture, which can cause measurement

error or flowmeter failure. Install drip legs in conduit and cable, if necessary. Inspect and

grease all gaskets and O-rings. Fully close and tighten all housing covers and conduit openings.

1. Identify the components of the cable gland and cable.

Cable gland and cable (exploded view)Figure 3-17:

A. Cable

B. Sealing nut

C. Compression nut

D. Brass compression ring

E. Braided shield

F. Cable

G. Tape or heat-shrink tubing

H. Clamp seat (shown as integral to nipple)

I. Nipple

2. Unscrew the nipple from the compression nut.

28 Micro Motion® Model 1500 and Model 2500

Page 33

A

B

C

D

E F

G

A

Mounting and sensor wiring for remote core processor with remote sensor installations

3. Screw the nipple into the conduit opening for the 9-wire cable. Tighten it to one turn

past hand-tight.

4. Slide the compression ring, compression nut, and sealing nut onto the cable. Make

sure the compression ring is oriented so the taper will mate properly with the

tapered end of the nipple.

5. Pass the cable end through the nipple so the braided shield slides over the tapered

end of the nipple.

6. Slide the compression ring over the braided shield.

7. Screw the compression nut onto the nipple. Tighten the sealing nut and

compression nut by hand to ensure that the compression ring traps the braided

shield.

8. Use a 25-mm (1-inch) wrench to tighten the sealing nut and compression nut to

20–25 foot-pounds (27–34 N-m) of torque.

Cross-section of assembled cable gland with cableFigure 3-18:

A. Cable

B. Sealing nut

C. Seal

D. Compression nut

E. Braided shield

F. Brass compression ring

G. Nipple

9. Remove the junction box cover and remote core processor end-cap.

10. At both the sensor and remote core processor, connect the cable according to the

following procedure:

a. Insert the stripped end of each wire into the corresponding terminal at the

sensor and remote core processor ends, matching by color. No bare wires should

remain exposed.

Installation Manual 29

Page 34

Mounting and sensor wiring for remote core processor with remote sensor installations

Sensor and remote core processor terminal designationsTable 3-7:

Wire color Sensor terminal Remote core processor terminal Function

Black No connection Ground screw (see notes) Drain wires

Brown 1 1 Drive +

Red 2 2 Drive –

Orange 3 3 Temperature –

Yellow 4 4 Temperature return

Green 5 5 Left pickoff +

Blue 6 6 Right pickoff +

Violet 7 7 Temperature +

Gray 8 8 Right pickoff –

White 9 9 Left pickoff –

Notes

• Ground the shield drain wires (the black wire) only on the remote core processor end,

by connecting it to the ground screw inside the lower conduit ring. Never ground to

the core processor’s mounting screw. Never ground the cable at the sensor junction

box.

• Ground the cable braid on both ends, by terminating it inside the cable glands.

3.7.1

b. Tighten the screws to hold the wires in place.

c. Ensure integrity of gaskets, grease all O-rings, then replace the junction box

cover and remote core processor end-cap and tighten all screws, as required.

Sensor and remote core processor terminals

30 Micro Motion® Model 1500 and Model 2500

Page 35

D

I

H

F

E

A

B

C

G

A. Violet

B. Yellow

C. Orange

D. Brown

E. White

F. Green

G. Red

H. Gray

I. Blue

Mounting and sensor wiring for remote core processor with remote sensor installations

ELITE, H-Series, T-Series, and some F-Series sensor terminalsFigure 3-19:

F-Series, Model D, and Model DL sensor terminalsFigure 3-20:

Installation Manual 31

Page 36

1

9

8

7

6

5

4

3

2

A

A

B

C

D

E

F

G

H

I

J

K

Mounting and sensor wiring for remote core processor with remote sensor installations

Figure 3-21:

Model DT sensor terminals (user-supplied metal junction box with

terminal block)

A. Earth ground

Remote core processor terminalsFigure 3-22:

A. Brown

B. Violet

C. Yellow

D. Orange

E. Gray

F. Blue

G. White

H. Green

I. Red

J. Mounting screw

K. Ground screw (black)

32 Micro Motion® Model 1500 and Model 2500

Page 37

Mounting and sensor wiring for remote core processor with remote sensor installations

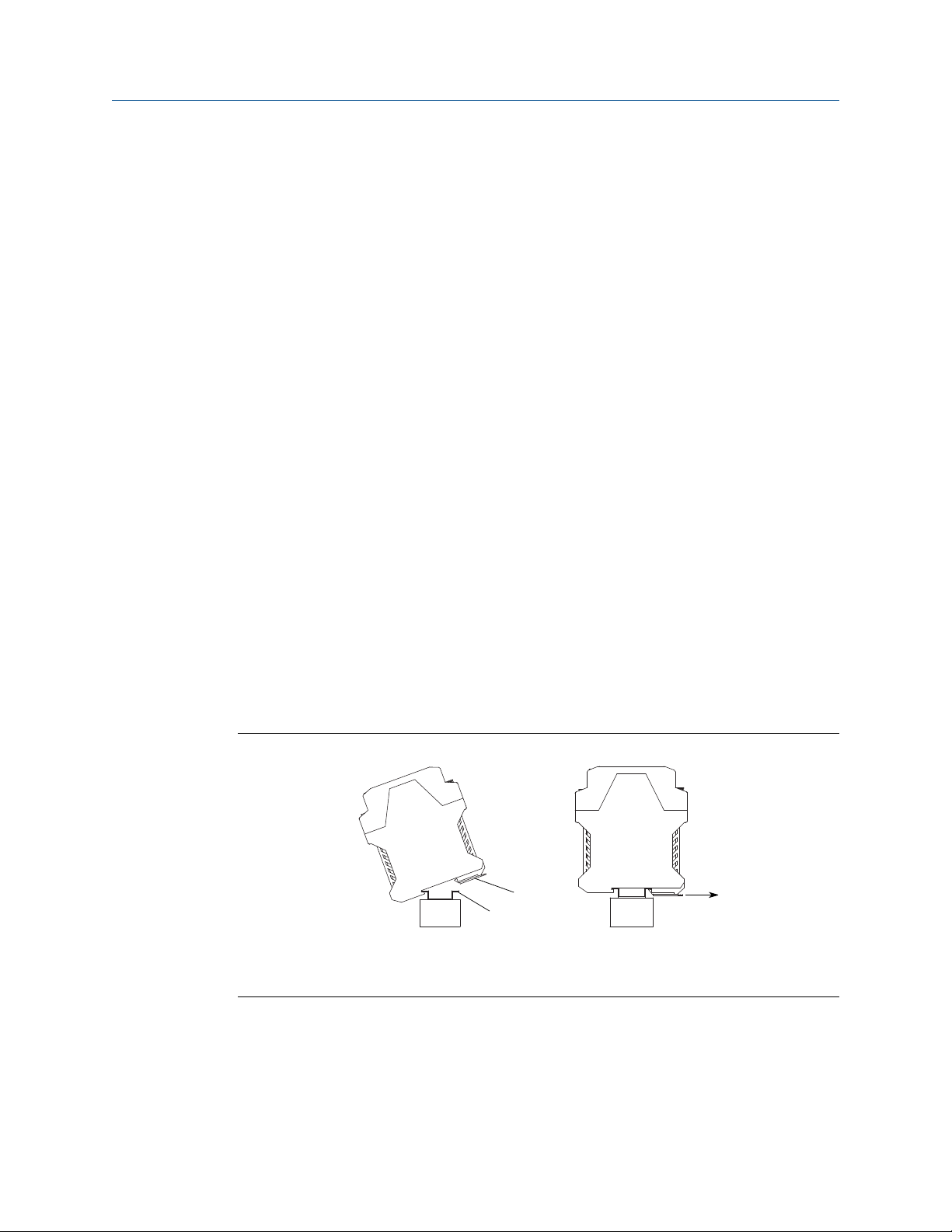

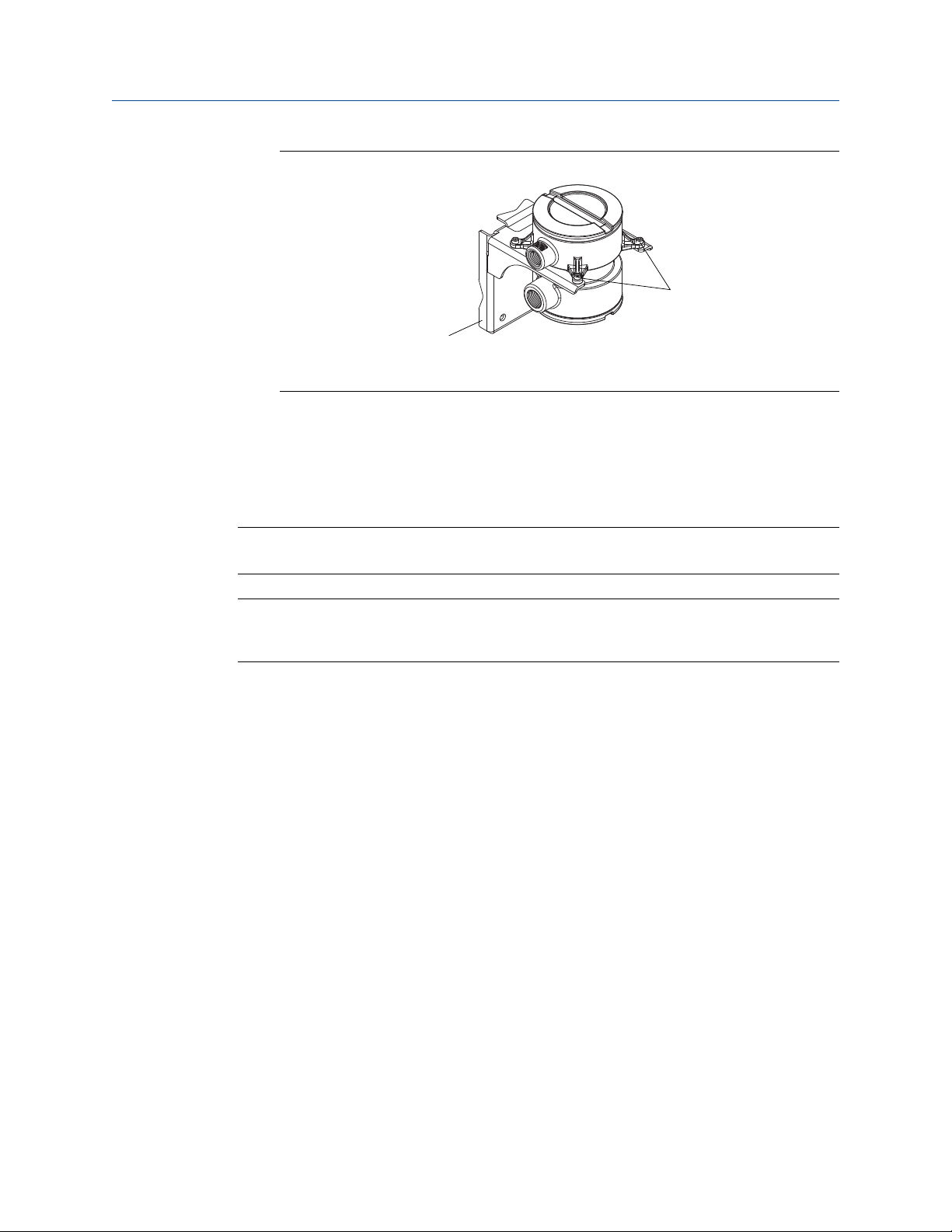

3.8 Ground the flowmeter components

In a remote core processor with remote sensor installation, the transmitter, remote core

processor, and sensor are all grounded separately.

CAUTION!

Improper grounding could cause inaccurate measurements or flow meter failure. Failure to

comply with requirements for intrinsic safety in a hazardous area could result in an explosion.

Note

For hazardous area installations in Europe, refer to standard EN 60079-14 or national standards.

If national standards are not in effect, adhere to the following guidelines for grounding:

• Use copper wire, 14 AWG (2.5 mm2) or larger wire size.

• Keep all ground leads as short as possible, less than 1 Ω impedance.

• Connect ground leads directly to earth, or follow plant standards.

1. Ground the sensor according to the instructions in the sensor documentation.

2. Ground the DIN rail.

The rail clip in the base of the transmitter housing grounds the transmitter to the

DIN rail.

3. Ground the remote core processor according to applicable local standards, using

the remote core processor’s internal ground screw.

Remote core processor internal ground screwFigure 3-23:

Installation Manual 33

Page 38

A

B

Wiring the power supply

4 Wiring the power supply

4.1 Wire the power supply

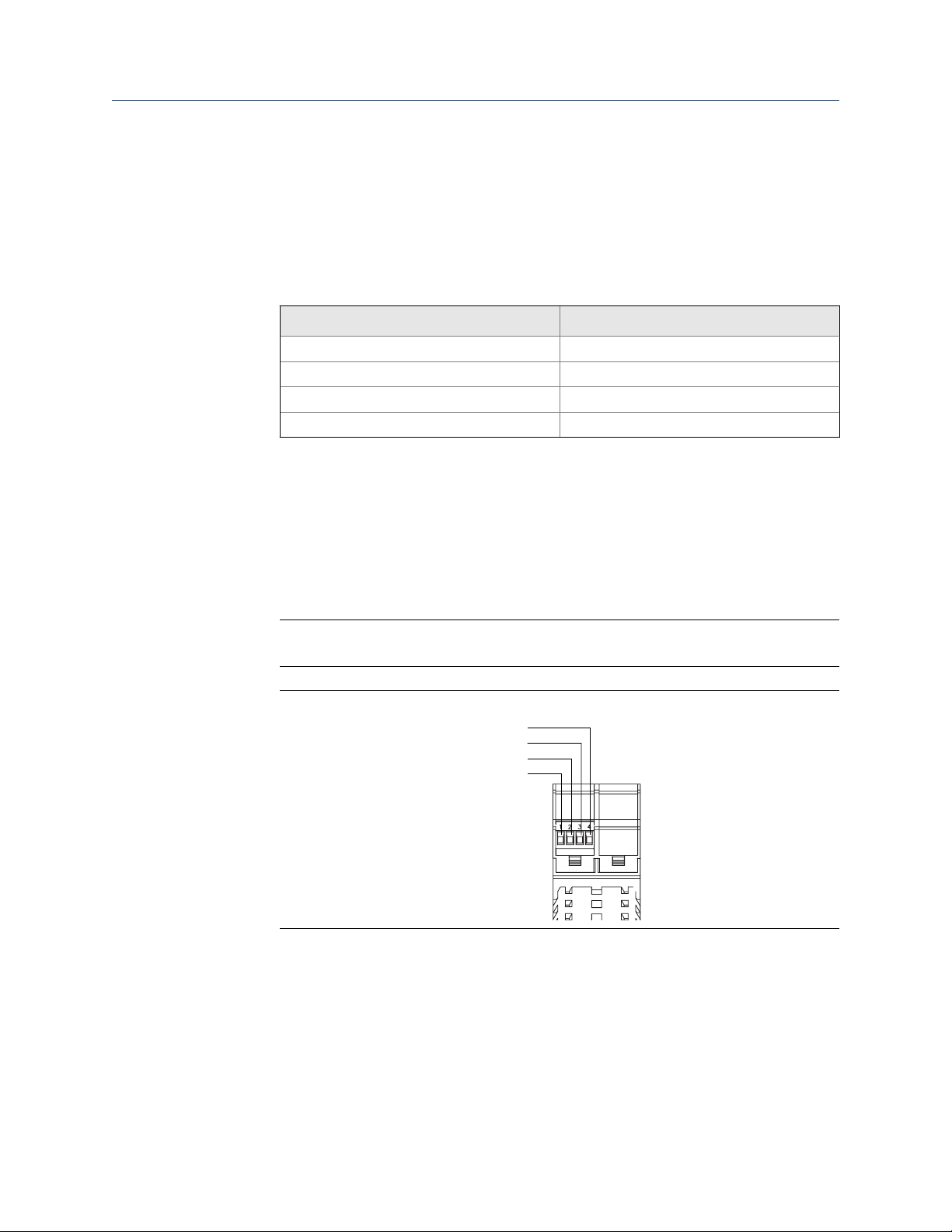

Connect the power supply to terminals 11 and 12. Terminals 13 and 14 are used to jumper

power to another Model 1500 or Model 2500 transmitter. A maximum of five transmitters

can be jumpered together.

Power terminalsFigure 4-1:

A. Primary power supply (VDC)

B. Power supply jumper to 1–4 additional Model 1500 or Model 2500 transmitters

34 Micro Motion® Model 1500 and Model 2500

Page 39

5 I/O wiring for Model 1500

A

transmitters

Topics covered in this chapter:

Basic analog wiring

•

HART/analog single loop wiring

•

HART multidrop wiring

•

5.1 Basic analog wiring

Model 1500 basic analog wiringFigure 5-1:

I/O wiring for Model 1500 transmitters

A. Terminals 21 and 22 to mA receiving device; 820 Ω maximum loop resistance

5.2

Installation Manual 35

HART/analog single loop wiring

Note

For HART communications:

600 Ω maximum loop resistance

•

250 Ω minimum loop resistance

•

Page 40

A

B

A

B

C

D

E

F

I/O wiring for Model 1500 transmitters

HART/analog single loop wiringFigure 5-2:

820 Ω maximum loop resistance

A.

B. HART-compatible host or controller

5.3 HART multidrop wiring

Tip

For optimum HART communication, single-point ground the output loop to an instrument-grade

ground.

HART multidrop wiringFigure 5-3:

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitters

D. Model 1500 or Model 2500 transmitter

E. SMART FAMILY™ transmitters

F. 24 VDC loop power supply required for passive transmitters

36 Micro Motion® Model 1500 and Model 2500

Page 41

6 I/O wiring for Model 2500

A B

transmitters

Topics covered in this chapter:

mA/HART wiring

•

Frequency output wiring

•

Discrete output wiring

•

Discrete input wiring

•

6.1 mA/HART wiring

I/O wiring for Model 2500 transmitters

6.1.1 Basic analog wiring

Model 2500 basic analog wiringFigure 6-1:

A. Channel A – Terminals 21 and 22 to mA receiving device; 820 Ω maximum loop resistance

B. Channel B – Terminals 23 and 24 to mA receiving device; 420 Ω maximum loop resistance

6.1.2

HART/analog single loop wiring

Note

For HART communications:

600 Ω maximum loop resistance

•

250 Ω minimum loop resistance

•

Installation Manual 37

Page 42

A

B

A

B

C

D

E

F

I/O wiring for Model 2500 transmitters

HART/analog single loop wiringFigure 6-2:

820 Ω maximum loop resistance

A.

B. HART-compatible host or controller

6.1.3 HART multidrop wiring

Tip

For optimum HART communication, single-point ground the output loop to an instrument-grade

ground.

HART multidrop wiringFigure 6-3:

A. 250–600 Ω resistance

B. HART-compatible host or controller

C. HART-compatible transmitters

D. Model 1500 or Model 2500 transmitter

E. SMART FAMILY™ transmitters

F. 24 VDC loop power supply required for passive transmitters

38 Micro Motion® Model 1500 and Model 2500

Page 43

A

B

C

A

I/O wiring for Model 2500 transmitters

6.2 Frequency output wiring

6.2.1 Internally powered frequency output wiring

Internally powered frequency output wiringFigure 6-4:

A. Counter

B. Channel B – Terminals 23 and 24

C. Channel C – Terminals 31 and 32

Installation Manual 39

Page 44

Open circuit output voltage = 15 VDC ±3%

Load resistance (Ohms)

High level output voltage (Volts)

I/O wiring for Model 2500 transmitters

16

14

12

10

8

6

High level output voltage (Volts)

4

2

Output voltage versus load resistance (Channel B)Figure 6-5:

Maximum output voltage = 15 VDC ± 3%

0

0 500 1000 1500 2000 2500

Load resistance (Ohms)

Output voltage versus load resistance (Channel C)Figure 6-6:

40 Micro Motion® Model 1500 and Model 2500

Page 45

A

A

B

C

D

D

E

I/O wiring for Model 2500 transmitters

6.2.2 Externally powered frequency output wiring

Externally powered frequency output wiringFigure 6-7:

A. Counter

B. Channel B – Terminals 23 and 24

C. Channel C – Terminals 31 and 32

D. 3–30 VDC

E. Pull-up reisistor

CAUTION!

Exceeding 30 VDC can damage the transmitter. Terminal current must be less than 500 mA.

Installation Manual 41

Page 46

I/O wiring for Model 2500 transmitters

4400

4000

3600

3200

2800

2400

2000

1600

External pull-up resistor range (Ohms)

1200

800

Recommended pull-up resistor versus supply voltageFigure 6-8:

0

5 10 15 20 25 30

Supply voltage (Volts)

6.3 Discrete output wiring

6.3.1 Internally powered discrete output wiring

42 Micro Motion® Model 1500 and Model 2500

Page 47

Internally powered discrete output wiringFigure 6-9:

A

A

B

C

A. Discrete output receiving device

B. Channel B (DO1) – Terminals 23 and 24

C. Channel C (DO2) – Terminals 31 and 32

I/O wiring for Model 2500 transmitters

Output voltage versus load resistance (Channel B)Figure 6-10:

Maximum output voltage = 15 VDC ± 3%

16

14

12

10

8

6

High level output voltage (Volts)

4

2

0

0 500 1000 1500 2000 2500

Load resistance (Ohms)

Installation Manual 43

Page 48

Open circuit output voltage = 15 VDC ±3%

Load resistance (Ohms)

High level output voltage (Volts)

A

A

B

C

D

D

I/O wiring for Model 2500 transmitters

Output voltage versus load resistance (Channel C)Figure 6-11:

6.3.2 Externally powered discrete output wiring

Externally powered discrete output wiringFigure 6-12:

A. 3–30 VDC

B. Channel B (DO1) – Terminals 23 and 24

C. Channel C (DO2) – Terminals 21 and 32

D. Pull-up register or DC relay

44 Micro Motion® Model 1500 and Model 2500

Page 49

I/O wiring for Model 2500 transmitters

CAUTION!

Exceeding 30 VDC can damage the transmitter. Terminal current must be less than 500 mA.

Recommended pull-up resistor versus supply voltageFigure 6-13:

4400

4000

3600

3200

2800

2400

2000

1600

External pull-up resistor range (Ohms)

1200

800

0

5 10 15 20 25 30

Supply voltage (Volts)

6.4 Discrete input wiring

6.4.1 Internally powered discrete input wiring

Internally powered discrete input wiringFigure 6-14:

Installation Manual 45

Page 50

A

B

C

I/O wiring for Model 2500 transmitters

6.4.2 Externally powered discrete input wiring

Externally powered discrete input wiringFigure 6-15:

A. PLC or other device

B. VDC

C. Direct DC input

Power is supplied by either a PLC/other device or by direct DC input.

Input voltage ranges for external powerTable 6-1:

VDC Range

3–30 High level

0–0.8 Low level

0.8–3 Undefined

46 Micro Motion® Model 1500 and Model 2500

Page 51

7 Specifications

Topics covered in this chapter:

Electrical connections

•

Input/output signals

•

Environmental limits

•

Physical specifications

•

7.1 Electrical connections

Electrical connectionsTable 7-1:

Type Descriptions

Input/output connections Three pairs of wiring terminals for transmitter outputs. Screw ter-

minals accept stranded or solid conductors, 24 to 12 AWG (0.40

to 3.5 mm2).

Power connections The transmitter has two pairs of terminals for the power connec-

tion:

• Either pair accepts DC power

• The remaining pair is used for making a jumper connection to

a second transmitter

Plug terminals accept solid or stranded conductors, 24 to

12 AWG (0.40 to 3.5 mm2).

Digital communications maintenance connections

Core processor connection The transmitter has two pairs of terminals for the 4-wire connec-

Two clips for temporary connection to the service port. One pair

of terminals supports Modbus/RS-485 signal or service port

mode. On device power-up, user has 10 seconds to connect in

service port mode. After 10 seconds, the terminals default to

Modbus/RS-485 mode.

tion to the core processor:

• One pair is used for the RS-485 connection to the core pro-

cessor

• One pair is used to supply power to the core processor

Plug terminals accept solid or stranded conductors, 24 to

12 AWG (0.40 to 3.5 mm2).

Specifications

7.2 Input/output signals

Installation Manual 47

Page 52

Specifications

Input/output signals – Model 1500Table 7-2:

Type Description

Output variables • Mass flow

• Volume flow

Inputs/outputs • One active 4–20 mA output

• One active frequency output

• Zero button, to initiate flowmeter zero calibration

HART Bell 202 signal is superimposed on the primary milliamp output

Input/output signals – Model 2500Table 7-3:

Type Description

Output variables • Mass & volume flow

• Net product content / flow

• Temperature

• Density

• Concentration

Inputs/outputs • One or two active 4–20 mA outputs

• One active or passive frequency output

• One or two discrete outputs

• One discrete input

• Zero button, to initiate flowmeter zero calibration

HART Bell 202 signal is superimposed on the primary milliamp output

7.3 Environmental limits

Environmental specificationsTable 7-4:

Type Value

Ambient temperature limits

(Operating)

Ambient temperature limits

(Storage)

Humidity limits 5 to 95% relative humidity, non-condensing at 140 °F (60 °C)

Vibration limits Meets IEC68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cy-

EMI effects Complies with EMC Directive 2004/108/EC per EN 61326 Indus-

Ambient temperature effect

(analog output option)

48 Micro Motion® Model 1500 and Model 2500

–40 to +131 °F (–40 to +55 °C)

–40 to +185 °F (–40 to +85 °C)

cles at 1.0 g

trial

Complies with NAMUR NE-21 (22.08.2007)

On mA output: ±0.005% of span per °C

Page 53

7.4 Physical specifications

3.90

(99)

4.41

(112)

1.78

(45)

Transmitter dimensionsFigure 7-1:

Specifications

Installation Manual 49

Page 54

2 13/16

(71)

2 13/16

(71)

4 × Ø3/8

(10)

6 3/16

(158)

2 1/4

(57)

4 9/16

(116)

wall mount

5 1/2 (140)

To centerline of 2" instrument pole

2 1/2

(64)

1/2"–14 NPT

or M20 × 1.5

2 3/8

(61)

1 11/16

(43)

3 5/16

(84)

3/4"–14 NPT

5 11/16

(144)

Ø4 3/8

(111)

Specifications

Remote core processor dimensionsFigure 7-2:

50 Micro Motion® Model 1500 and Model 2500

Page 55

Index

Index

4-wire cable

preparation 7, 14

types 9, 16

user-supplied 9, 16

9-wire cable

connecting to sensor 24, 28

preparation 18

types and usage 20–22

A

AC power, See Power

analog I/O

wiring 35, 37

C

cable

4-wire cable types 9, 16

4-wire preparation 7, 14

9-wire preparation 18

9-wire types and usage 20–22

cable lengths

maximum 3

configurable I/O

discrete input wiring 45, 46

discrete output wiring 42, 44

frequency output wiring 39, 41

customer service

contacting ii

F

flowmeter

components 1

frequency output

wiring 39, 41

G

grounding

4-wire remote installation 10

remote core with remote transmitter installation 33

H

HART

multidrop wiring 36, 38

single loop wiring 35, 37

hazardous area classifications

planning for 4

humidity

environmental limit 4

I

installation types

4-wire remote 1

9-wire remote 1

high-temperature flexible conduit 1

integral 1

remote core processor with remote transmitter 1

D

DC power, See Power

DIN rail

mountings 6, 12

discrete input

wiring 45, 46

discrete output

wiring 42, 44

E

environmental limits

humidity 4

temperature 4

vibration 4

M

mA output

wiring 35, 37

mounting

DIN rail 6, 12

multiple transmitters 6, 12

recommendation 6, 12

remote core processor 13

O

option board

identifying 3

Installation Manual 51

Page 56

Index

P

power

requirements 5

S

safety messages ii

T

temperature

environmental limit 4

terminals

remote core processor 25

sensor 25

Terminals

remote core processor 30

sensor 30

transmitter

installation types 1

transmitter type

identifying 3

V

vibration

environmental limit 4

W

wiring

4-wire remote to sensor 10

9-wire armored cable 28

9-wire jacketed cable 24

9-wire shielded cable 28

basic analog 35, 37

discrete input 45, 46

discrete output 42, 44

frequency output 39, 41

HART multidrop 36, 38

HART single loop 35, 37

terminal reference 25

to sensor 24, 28

transmitter to remote core processor 17

Wiring

terminal reference 30

wiring distances

maximum 3

52 Micro Motion® Model 1500 and Model 2500

Page 57

Page 58

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

T +1 800-522-6277

F +1 303-530-8459

www.micromotion.com

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 318 495 555

F +31 (0) 318 495 556

www.micromotion.nl

*20001685*

20001685

Rev DA

2012

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

©

2012 Micro Motion, Inc. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson

Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct

Connect marks are marks of one of the Emerson Process

Management family of companies. All other marks are property of

their respective owners.

Loading...

Loading...