Page 1

Reference Manual

300530EN, Rev BA

September 2012

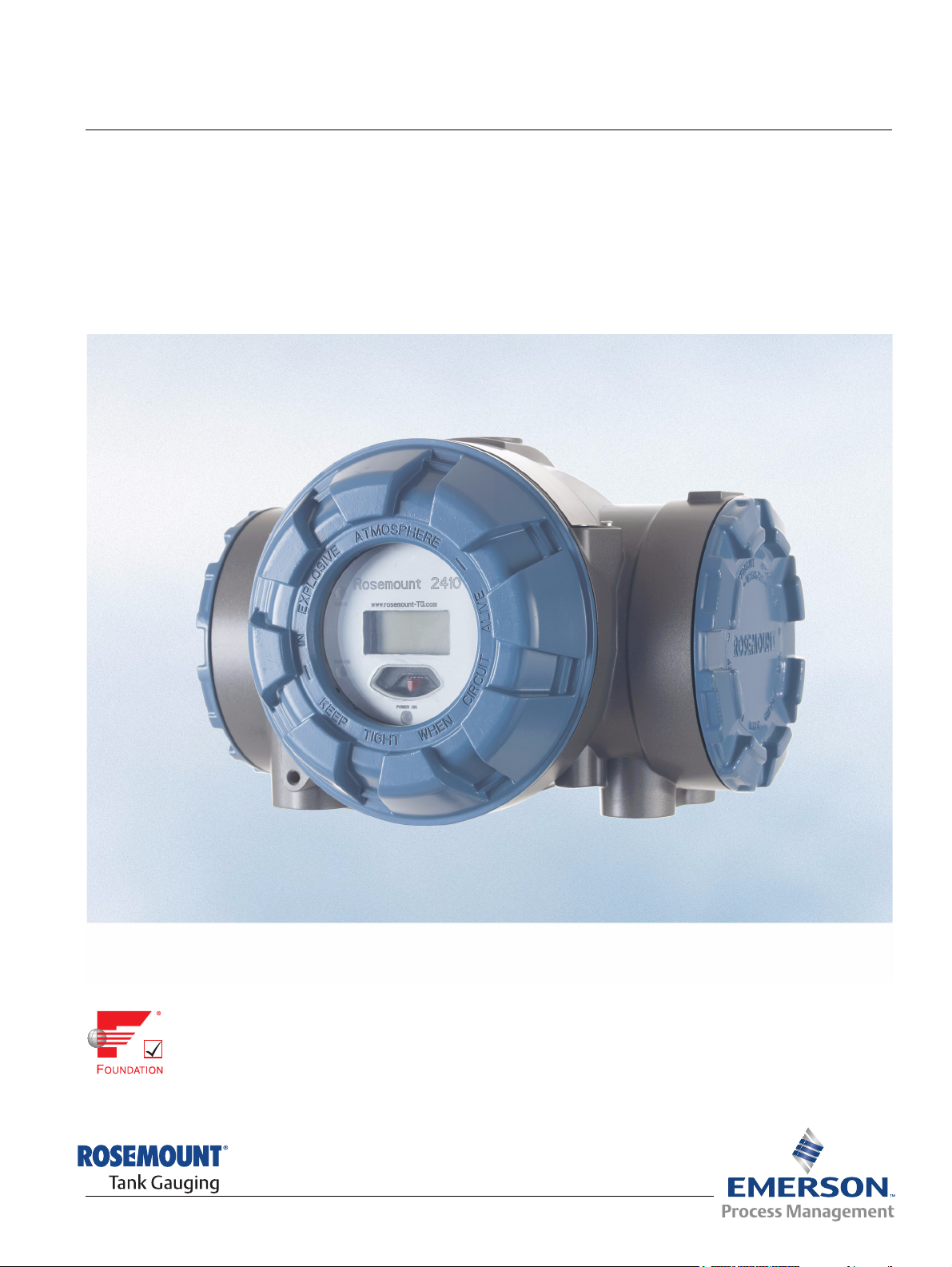

Rosemount 2410

Tank Hub

www.rosemount-tg.com

Page 2

Page 3

Reference Manual

NOTICE

300530EN, Rev BA

September 2012

Rosemount 2410

Rosemount 2410

Tank Hub

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

For equipment service or support needs, contact your local Emerson Process

Management/Rosemount Tank Gauging representative.

Spare Parts

Any substitution of non-recognized spare parts may jeopardize safety. Repair, e.g.

substitution of components etc, may also jeopardize safety and is under no circumstances

allowed.

Rosemount Tank Radar AB will not take any responsibility for faults, accidents, etc caused

by non-recognized spare parts or any repair which is not made by

Rosemount Tank Radar AB.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware

or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

Cover Photo: 2410_coverfoto.tif

www.rosemount-tg.com

Page 4

Page 5

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

Table of Contents

SECTION 1

Introduction

SECTION 2

Overview

SECTION 3

Installation

1.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Manual Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Technical Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Service Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6 Product Recycling/Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7 Packing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7.1 Reuse and Recycling . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7.2 Energy recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.4 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

3.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Pipe Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.1 Cable Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4.3 Cable Selection for Power Supply . . . . . . . . . . . . . . . 3-5

3.4.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4.5 Cable Selection for the Tankbus . . . . . . . . . . . . . . . . 3-6

3.4.6 Power Budget. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4.7 Tankbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4.8 Typical Installations . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.4.9 Cabling for the TRL2/RS485 Bus. . . . . . . . . . . . . . . 3-21

3.4.10 Non-IS Connection. . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3.4.11 Non-IS Terminal Block . . . . . . . . . . . . . . . . . . . . . . . 3-25

3.4.12 IS Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3.4.13 Intrinsically Safe Terminal Block . . . . . . . . . . . . . . . 3-29

3.4.14 Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

SECTION 4

Configuration

www.rosemount-tg.com

4.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.3 Configuration Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4 Basic Configuration of a Rosemount 2410 . . . . . . . . . . . . . . . . 4-3

4.5 Advanced Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6 Configuration Using TankMaster WinSetup . . . . . . . . . . . . . . . 4-4

Page 6

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

4.6.1 Installation Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6.2 Advanced Configuration. . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6.3 FCU 2160 Configuration . . . . . . . . . . . . . . . . . . . . . . 4-6

SECTION 5

Operation

SECTION 6

Service and

Troubleshooting

5.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Integral Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Start-up Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.5 LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.1 LED Start-Up Information. . . . . . . . . . . . . . . . . . . . . . 5-6

5.5.2 Error LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.6 Specifying Display Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

6.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2.1 Viewing Input and Holding Registers . . . . . . . . . . . . . 6-2

6.2.2 Editing Holding Registers. . . . . . . . . . . . . . . . . . . . . . 6-3

6.2.3 Device Live List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

6.2.4 Configuration Backup. . . . . . . . . . . . . . . . . . . . . . . . . 6-5

6.2.5 Configuration Recovery . . . . . . . . . . . . . . . . . . . . . . . 6-6

6.2.6 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

6.2.7 Device Software Upgrade . . . . . . . . . . . . . . . . . . . . . 6-8

6.2.8 Write Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

6.2.9 Write Protection Switch . . . . . . . . . . . . . . . . . . . . . . 6-11

6.2.10 Simulation Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

6.2.11 Testing the Relays . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6.2.12 Relay Output Configuration . . . . . . . . . . . . . . . . . . . 6-15

6.2.13 Loading the Default Database . . . . . . . . . . . . . . . . . 6-16

6.2.14 Logging Measurement Data . . . . . . . . . . . . . . . . . . . 6-17

6.3 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

6.3.1 Device Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

6.3.2 Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

6.3.3 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

APPENDIX A

Reference Data

APPENDIX B

Product Certifications

APPENDIX C

Advanced Configuration

TOC-2

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Dimensional drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.3 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

B.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2 EU Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

B.3 Hazardous Locations Certifications . . . . . . . . . . . . . . . . . . . . . . B-3

B.3.1 Factory Mutual US Approvals . . . . . . . . . . . . . . . . . . B-3

B.3.2 Factory Mutual Canadian Approvals . . . . . . . . . . . . . B-5

B.3.3 European ATEX Directive Information . . . . . . . . . . . .B-7

B.3.4 IECEx Approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

B.4 Approval Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

C.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

C.2 Advanced Configuration in Winsetup . . . . . . . . . . . . . . . . . . . .C-3

C.3 Primary Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

C.4 Secondary Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Table of Contents

Page 7

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

C.5 Relay Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

C.6 Hybrid Density Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

C.6.1 Hybrid Density Configuration . . . . . . . . . . . . . . . . . .C-12

C.7 Volume Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

C.8 Arithmetic Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-17

C.8.1 Delta Level Calculation . . . . . . . . . . . . . . . . . . . . . .C-19

Table of Contents

TOC-3

Page 8

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

TOC-4

Table of Contents

Page 9

Reference Manual

300530EN, Rev BA

September 2012

Section 1 Introduction

1.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-1

1.2 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2

1.3 Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-3

1.4 Technical Documentation . . . . . . . . . . . . . . . . . . . . page 1-4

1.5 Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

1.6 Product Recycling/Disposal . . . . . . . . . . . . . . . . . . page 1-5

1.7 Packing Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-5

Rosemount 2410

1.1 SAFETY MESSAGES

Procedures and instructions in this manual may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Refer to

the safety messages listed at the beginning of each section before performing

an operation preceded by this symbol.

Failure to follow these installation guidelines could result in death or serious

injury:

• Make sure only qualified personnel perform the installation.

• Use the equipment only as specified in this manual. Failure to do so may

impair the protection provided by the equipment.

Explosions could result in death or serious injury:

• Verify that the operating environment of the device is consistent with the

appropriate hazardous locations certifications.

• Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

• Do not remove the gauge cover in explosive atmospheres when the circuit is

alive.

Electrical shock could cause death or serious injury.

• Use extreme caution when making contact with the leads and terminals.

www.rosemount-tg.com

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution

of components etc., may also jeopardize safety and is under no circumstances allowed.

Page 10

Rosemount 2410

1.2 SYMBOLS

Reference Manual

300530EN, Rev BA

September 2012

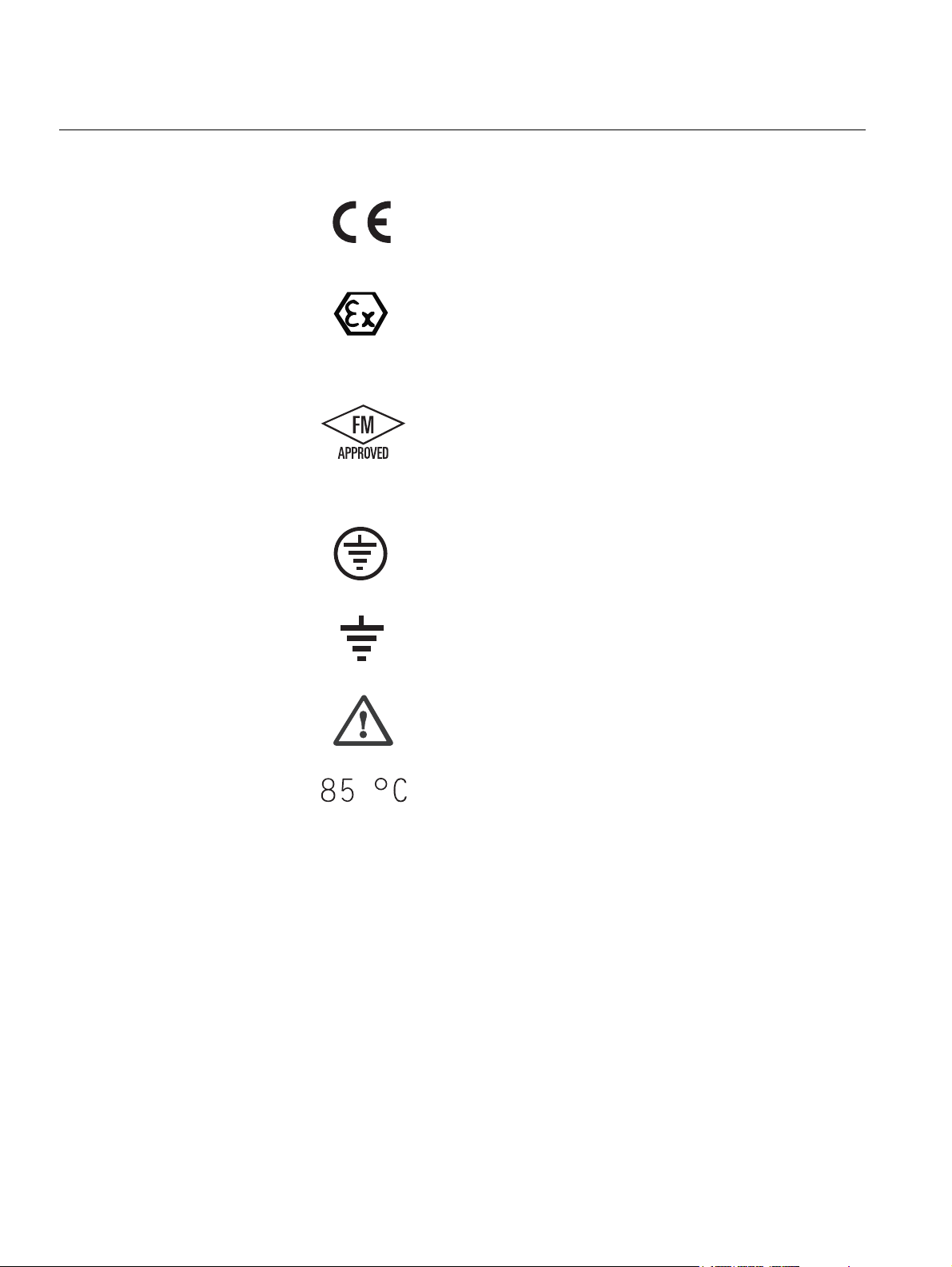

The CE marking symbolises the conformity

of the product with the applicable European

Community Directives.

The EC-Type Examination Certificate is a

statement of a Notified Certification Body

declaring that this product meets the

Essential Health and Safety Requirements

of the ATEX directive

The FM APPROVED Mark indicates that the

equipment is approved by FM Approvals

according to applicable Approval Standards

and is applicable for installation in

hazardous locations

Protective Earth

Ground

Caution - see reference manual

Use wiring rated for maximum

ambient temperature + 15 °C

Examples:

For connections in ambient temperatures up

to 70 °C use wiring rated 85 °C minimum.

For connections in ambient temperatures up

to 60 °C use wiring rated 75 °C minimum.

For connections in ambient temperatures up

to 50 °C use wiring rated 65 °C minimum.

1-2

Section 1. Introduction

Page 11

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

1.3 MANUAL OVERVIEW

This manual provides information on installation, configuration and

maintenance of the Rosemount 2410 Tank Hub.

Section 2: Overview

• System architecture

• Installation procedure

Section 3: Installation

• Mounting considerations

• Mechanical installation

• Electrical installation

Section 4: Configuration

• Configuration tools

• Basic configuration

• Advanced configuration

• Configuration using TankMaster

Section 5: Operation

• Display description

• Error messages

• Specifying display variables

Section 6: Service and Troubleshooting

• Troubleshooting

• Error and Warning messages

• Device status

Appendix A: Reference Data

• Specifications

• Ordering Information

Appendix B: Product Certifications

• European ATEX Directive information

• FM approvals

• Labels

•Drawings

Appendix C: Advanced Configuration

• Advanced configuration in WinSetup

• Primary and Secondary Bus

• Relay Output

• Hybrid Density Calculation

• Volume Configuration

• Arithmetic Operations

Section 1. Introduction

1-3

Page 12

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

1.4 TECHNICAL DOCUMENTATION

The Raptor Tank Gauging System includes the following documentation:

• Raptor Technical Description (704010EN)

• Rosemount 5900S Reference Manual (300520EN)

• Rosemount 2410 Reference Manual (300530EN)

• Rosemount 2240S Reference Manual (300550EN)

• Rosemount 2230 Reference Manual (300560EN)

• Raptor System Configuration Manual (300510EN)

• Rosemount 5300 Product Data Sheet (00813-0100-4530)

• Rosemount 5400 Product Data Sheet (00813-0100-4026)

• Rosemount 5300 Series Reference Manual (00809-0100-4530)

• Rosemount 5400 Series Reference Manual (00809-0100-4026)

• Rosemount TankMaster WinOpi Reference Manual (303028EN)

• Rosemount Raptor Installation Drawings

1-4

Section 1. Introduction

Page 13

Reference Manual

300530EN, Rev BA

September 2012

1.5 SERVICE SUPPORT For service support contact the nearest Emerson Process

Management/Rosemount Tank Gauging representative. Contact information

can be found on the web site www.rosemount-tg.com.

1.6 PRODUCT RECYCLING/DISPOSAL

Recycling of equipment and packaging should be taken into consideration

and disposed of in accordance with local and national legislation/regulations.

The label below is put on Rosemount Tank Gauging products as a

recommendation to customers if scrapping is considered.

Recycling or disposal should be done following instructions for correct

separation of materials when breaking up the units.

Figure 1-1. A green label is

placed on the housing of the

2410 Tank Hub

R

A

A

T

P

E

E

S

Rosemount 2410

1.7 PACKING MATERIAL

1.7.1 Reuse and

Recycling

S

T

E

E

L

&

Rosemount Tank Radar AB is fully certified according to ISO 14001

environmental standards. By recycling the corrugated paperboard, or wooden

boxes, used for shipping our products you can contribute to take care of the

environment.

Experience has shown that wooden boxes can be used several times for

various purposes. After careful disassembly the wooden parts may be reused.

Metal waste may be converted.

C

I

T

S

A

L

P

1.7.2 Energy recovery Products which have served their time may be divided into wood and metal

components and the wood can be used as fuel in sufficient ovens.

Due to its low moisture content (approximately 7%) this fuel has a higher

calorific value than ordinary wood fuel (moisture content approximately 20%).

When burning interior plywood the nitrogen in the adhesives may increase

emissions of nitrogen oxides to the air 3-4 times more than when burning bark

and splinter.

NOTE!

Landfill is not a recycling option and should be avoided.

Section 1. Introduction

1-5

Page 14

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

1-6

Section 1. Introduction

Page 15

Reference Manual

TankMaster

2410 Tank Hub

Modem

FCU 2160 Field

Communication Unit

Relay Outputs

Secondary Bus

(Non-IS)

Primary Bus

Tan k b u s

2240S Temperature

Transmitter

2230 Display

Group Bus

Zone 1

Zone 0

5900S Radar

Level Gauge

Secondary bus (IS)

300530EN, Rev BA

September 2012

Rosemount 2410

Section 2 Overview

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1

2.2 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-5

2.3 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-6

2.4 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . page 2-12

2.1 INTRODUCTION The Rosemount 2410 Tank Hub collects measurement data and status

information from field devices designed for the Rosemount Raptor system via

the intrinsically safe 2-wire Tankbus

transmission and power supply (see also “Tankbus” on page 3-8).

The Rosemount 2410 is designed for use in hazardous area Zone 1 (Class 1,

Division 1) and communicates with field devices in Zone 1 via the intrinsically

safe Tankbus.

The 2410 is available in two versions for single tanks or multiple tanks. The

multiple tanks version supports up to 10 tanks and 16 devices.

(1)

. The Tankbus carries both data

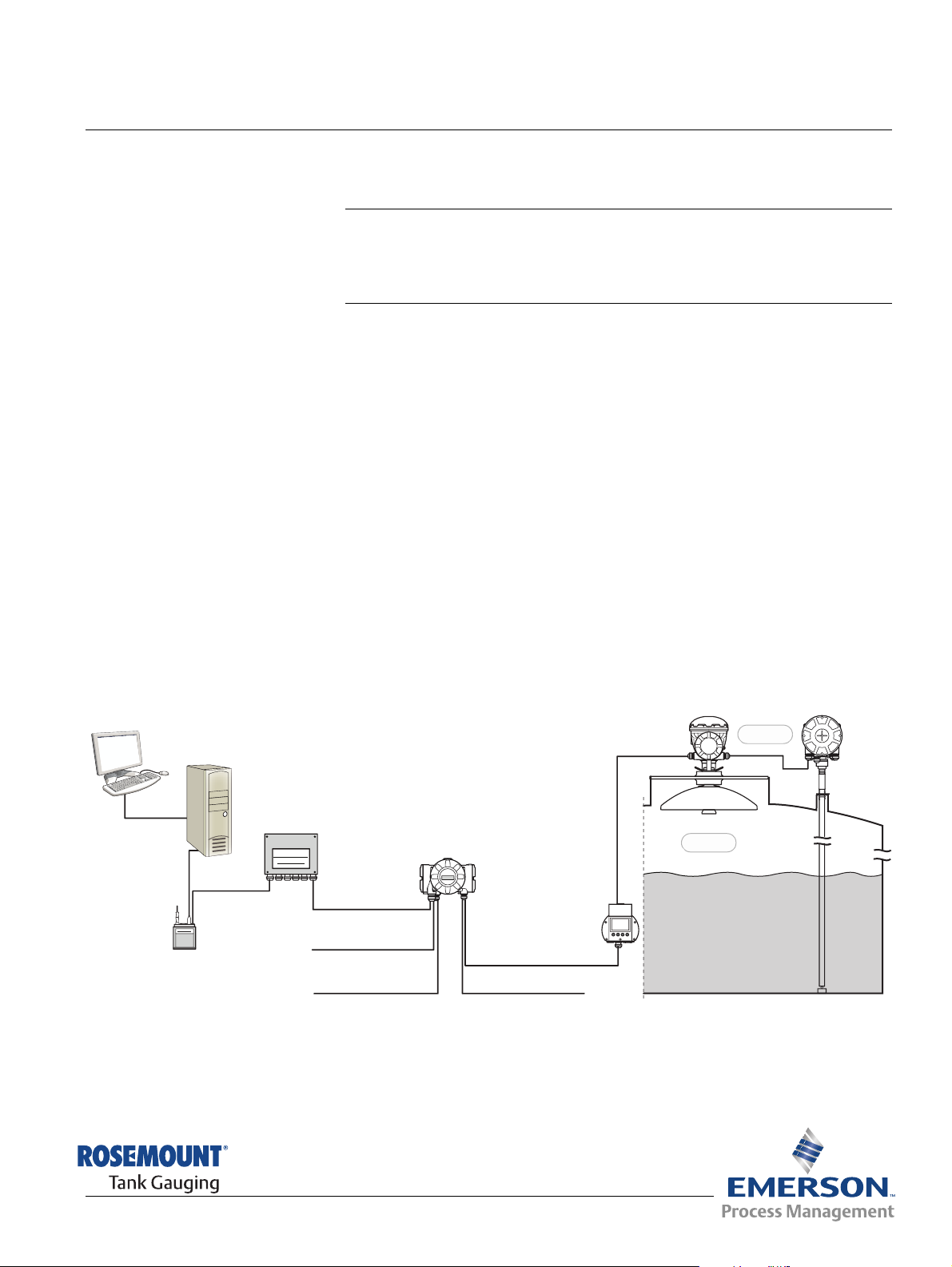

Figure 2-1. System integration

Measurement data and status information from one or more tanks is

distributed via the Primary Bus to a Rosemount 2160 Field Communication

Unit (FCU). Data is buffered by the 2160 and distributed to a TankMaster PC,

or a host system, whenever the FCU receives a request for data. In case no

FCU is included in the system, the 2410 can communicate directly with a host

computer.

www.rosemount-tg.com

(1) The intrinsically safe Tankbus complies with the FISCO FOUNDATION™ fieldbus standard.

Page 16

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

The Rosemount 2410 has two external buses for communication with host

systems. The Primary Bus is typically used with the TRL2 Modbus or RS-485

Modbus protocol for communication with a 2160 Field Communication Unit. If

there is no 2160 included, the Primary bus can communicate directly, or via a

modem, with the TankMaster PC.

The Secondary Bus supports various protocols such as TRL2 Modbus,

Enraf, and Varec which allows you to connect to other systems as well.

The 2410 is equipped with two solid state relays that allows controlling

external devices such as valves and pumps.

An integral display (optional) presents measurement data and device status

such as warnings and error messages. At start-up, communication settings

and optional hardware configuration is presented as well as whether it is a

Single tank or Multiple tank version of the 2410 Tank Hub.

Using the input from a Rosemount 5900S Radar Level Gauge and one or two

pressure sensors, the 2410 can be configured for online presentation of

Observed Density to a host computer. The 2410 also calculates Average

Temperature and strapping table based Volume.

Rosemount 2410 can be equipped with two relays which can be configured to

control level, temperature, and water level. The output can be connected to

an external system for alarm indication or process control. The relays are user

configurable for normally open or closed operation.

The 2410 can be configured with up to ten “virtual” relay functions. This

allows you to specify several different source variables to trigger a relay.

The Rosemount 2410 Tank Hub supports the Emerson’s Smart Wireless

solution, which is based on WirelessHART the emerging industry standard

for wireless field networks. By connecting to a Smart Wireless THUM™

Adapter, the Rosemount 2410 can be integrated in a wireless network to

provide measurement data at greatly reduced field wiring costs.

2-2

Section 2. Overview

Page 17

Reference Manual

Modem

TankMaster

FCU 2160

RS232

USB / RS232

Primary bus:

TRL2 Modbus,

RS485 Modbus

Field devices

TRL2 Modbus

RS485 Modbus

Rosemount 2410

Tan kbus

DCS

Secondary bus:

Enraf and others,

HART 4-20 mA

analog output/input

Modem

USB / RS232

Tan kbus

Field devices

Rosemount 2410

Primary bus:

TRL2 Modbus,

RS485 Modbus

TankMaster

Secondary bus:

Enraf and others,

HART 4-20 mA

analog output/input

300530EN, Rev BA

September 2012

Rosemount 2410

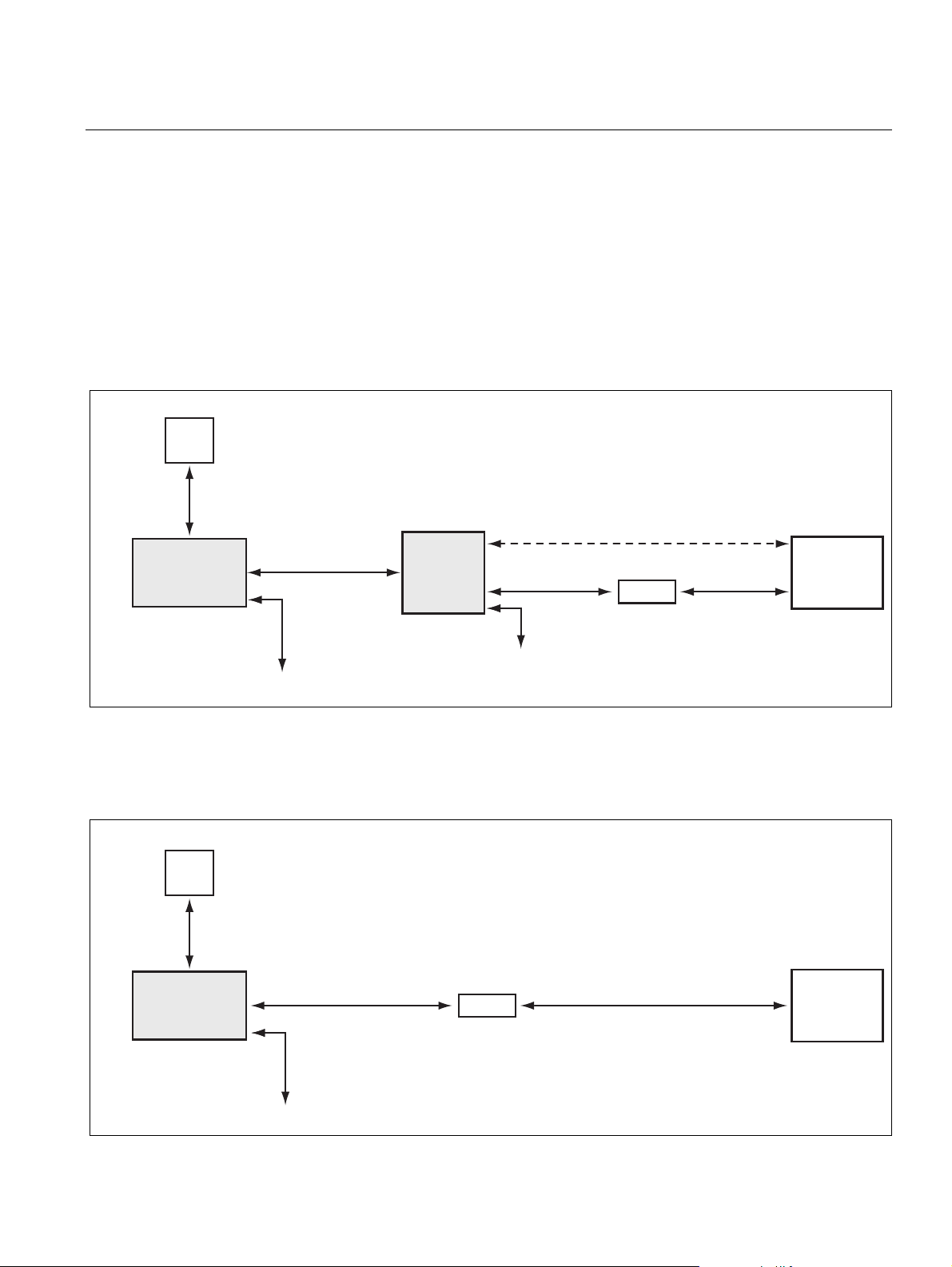

2.1.1 Communication The Raptor system supports various communication interfaces between a

Rosemount 2410 and a TankMaster PC or other host computers as illustrated

in Figure 2-2 to Figure 2-4.

Both the Primary bus and the Secondary bus can be used for either TRL2

Modbus (standard) or RS485 Modbus communication.

On the Secondary bus you may use other communication protocols as well,

such as Enraf, Varec etc.

Figure 2-2. Typical configuration

of a Rosemount 2410 and 2160

FCU connected to PC/Host

Figure 2-3. Typical configuration

of a Rosemount 2410 connected

to PC/Host

Section 2. Overview

2-3

Page 18

Rosemount 2410

Tan kbu s

Field devices

Rosemount 2410

Primary bus:

TRL2 Modbus

RS485 Modbus

TankMaster

Smart Wireless

THUM™Adapter

Smart Wireless

Gateway

Secondary bus

(1)

(Non-IS):

Enraf and others

HART 4-20 mA analog output/input

Secondary bus (IS):

Wireless HART

Reference Manual

300530EN, Rev BA

September 2012

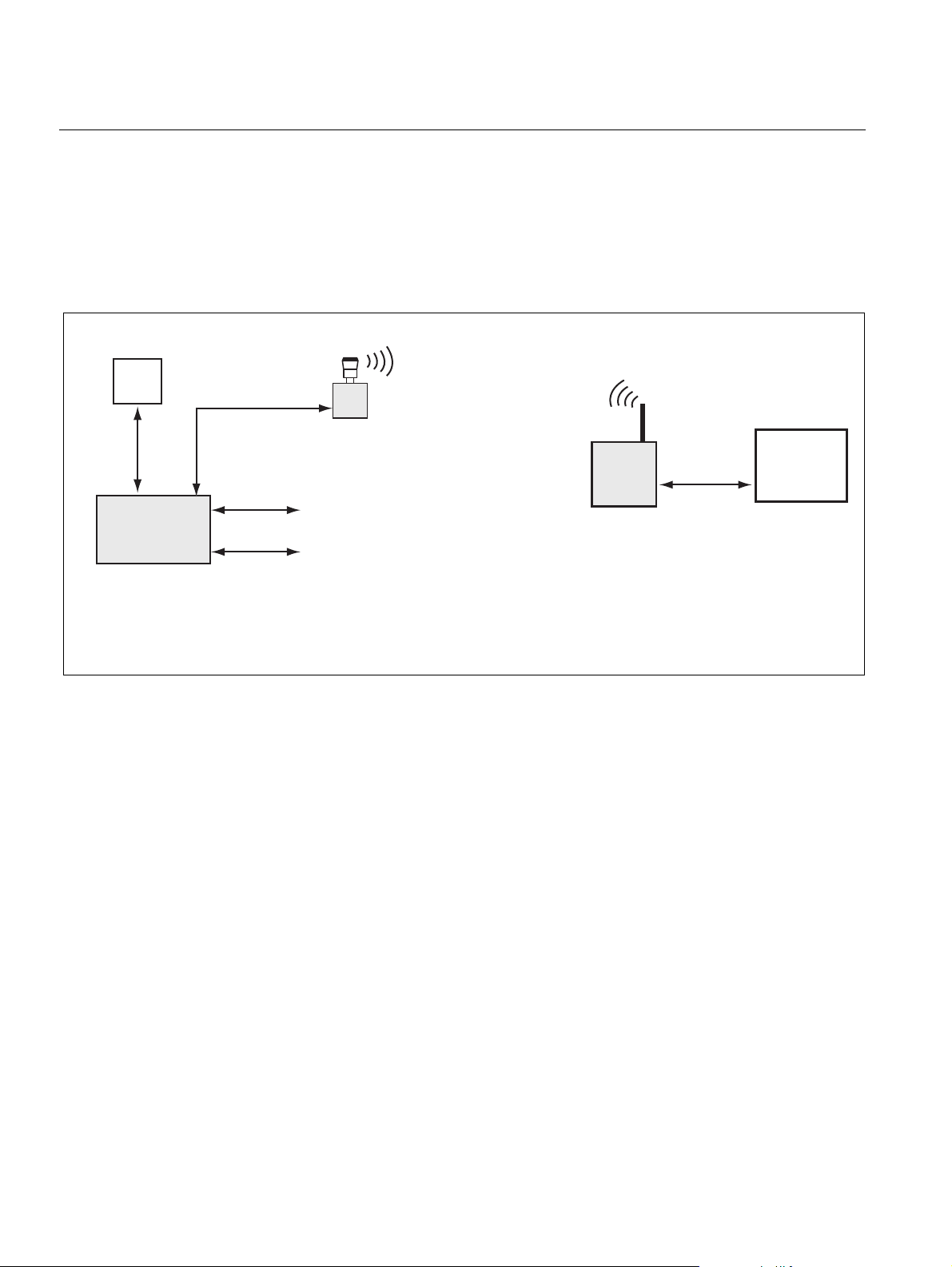

Figure 2-4. Typical configuration

of a Rosemount 2410 with

wireless connection to Smart

Wireless Gateway and PC/Host

A THUM Adapter, connected to the Intrinsically Safe Secondary

(1)

bus, allows

wireless communication between a 2410 Tank Hub and a Smart Wireless

Gateway.

2-4

(1) The Non-IS Secondary Bus can not be used simultaneously with the IS HART 4-20 mA Sec-

ondary Bus.

Section 2. Overview

Page 19

Reference Manual

2

1

3

4

576 5

56

300530EN, Rev BA

September 2012

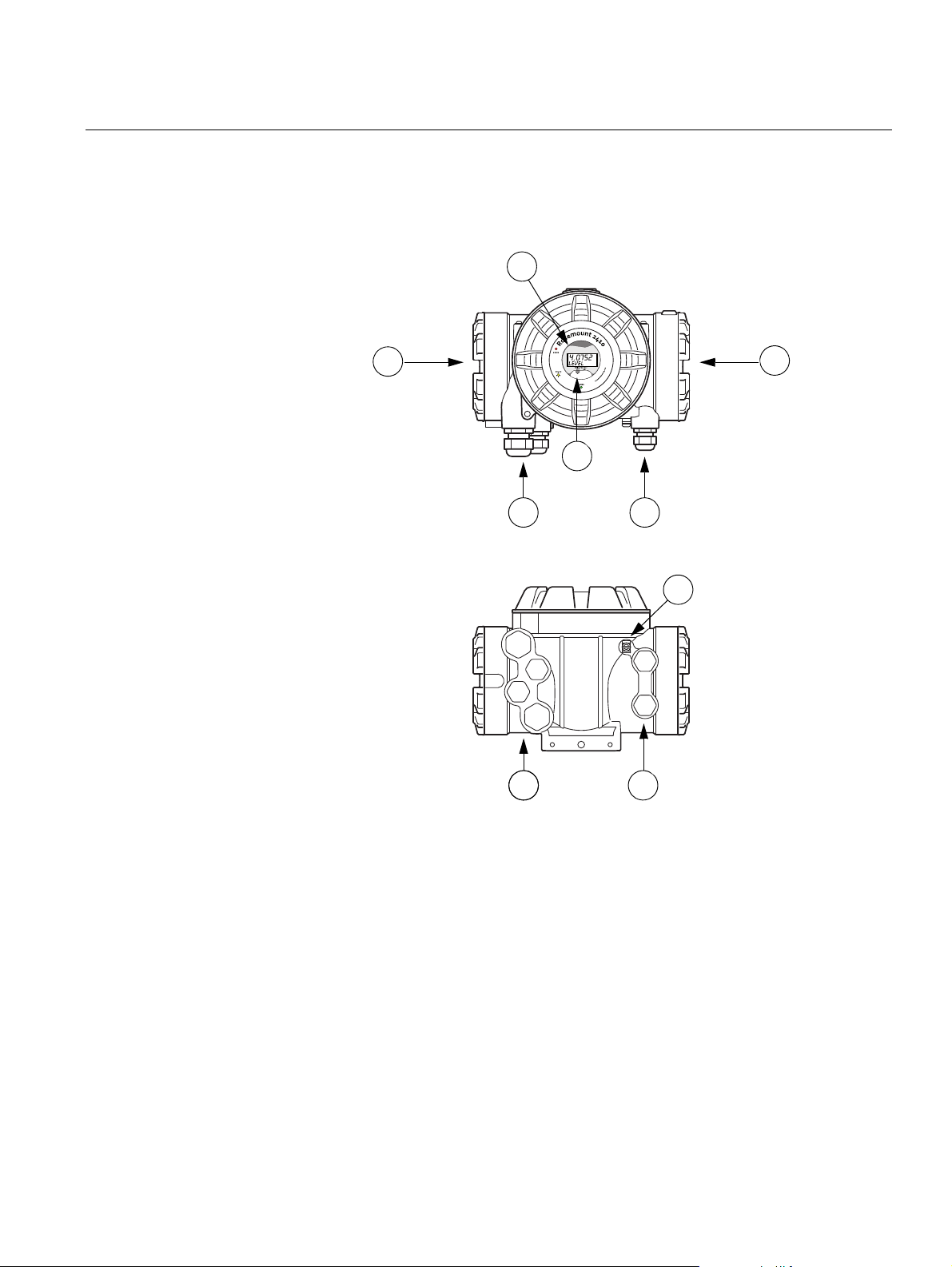

2.2 COMPONENTS

Figure 2-5. Rosemount 2410

components

Rosemount 2410

1. Intrinsically safe terminal compartment

2. Non-intrinsically safe terminal compartment

3. Integral display (optional)

4. Write protection switch

5. Cable entries for IS connection (two ½ - 14 NPT)

6. Cable entries for Non-IS connection (two ½ - 14 NPT, two ¾ - 14 NPT)

7. Grounding terminal

Section 2. Overview

2-5

Page 20

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

2.3 SYSTEM OVERVIEW

Raptor is a state-of-the art inventory and custody transfer radar tank level

gauging system. It is developed for a wide range of applications at refineries,

tank farms and fuel depots, and fulfills the highest requirements on

performance and safety.

The field devices on the tank communicate over the intrinsically safe Tankbus.

The Tankbus is based on a standardized fieldbus, the FISCO

fieldbus, and allows integration of any device supporting that protocol. By

utilizing a bus powered 2-wire intrinsically safe fieldbus the power

consumption is minimized. The standardized fieldbus also enables integration

of other vendors’ equipment on the tank.

The Raptor product portfolio includes a wide range of components to build

small or large customized tank gauging systems. The system includes various

devices, such as radar level gauges, temperature transmitters, and pressure

transmitters for complete inventory control. Such systems are easily

expanded thanks to the modular design.

Raptor is a versatile system that is compatible with and can emulate all major

tank gauging systems. Moreover, the well-proven emulation capability

enables step-by-step modernization of a tank farm, from level gauges to

control room solutions.

It is possible to replace old mechanical or servo gauges with modern Raptor

gauges, without replacing the control system or field cabling. It is further

possible to replace old HMI/SCADA-systems and field communication

devices without replacing the old gauges.

(1)

FOUNDATION™

There is a distributed intelligence in the various system units which

continuously collect and process measurement data and status information.

When a request for information is received an immediate response is sent

with updated information.

The flexible Raptor system supports several combinations to achieve

redundancy, from control room to the different field devices. Redundant

network configuration can be achieved at all levels by doubling each unit and

using multiple control room work stations.

2-6

(1) See documents IEC 61158-2 and IEC/TS 60079-27

Section 2. Overview

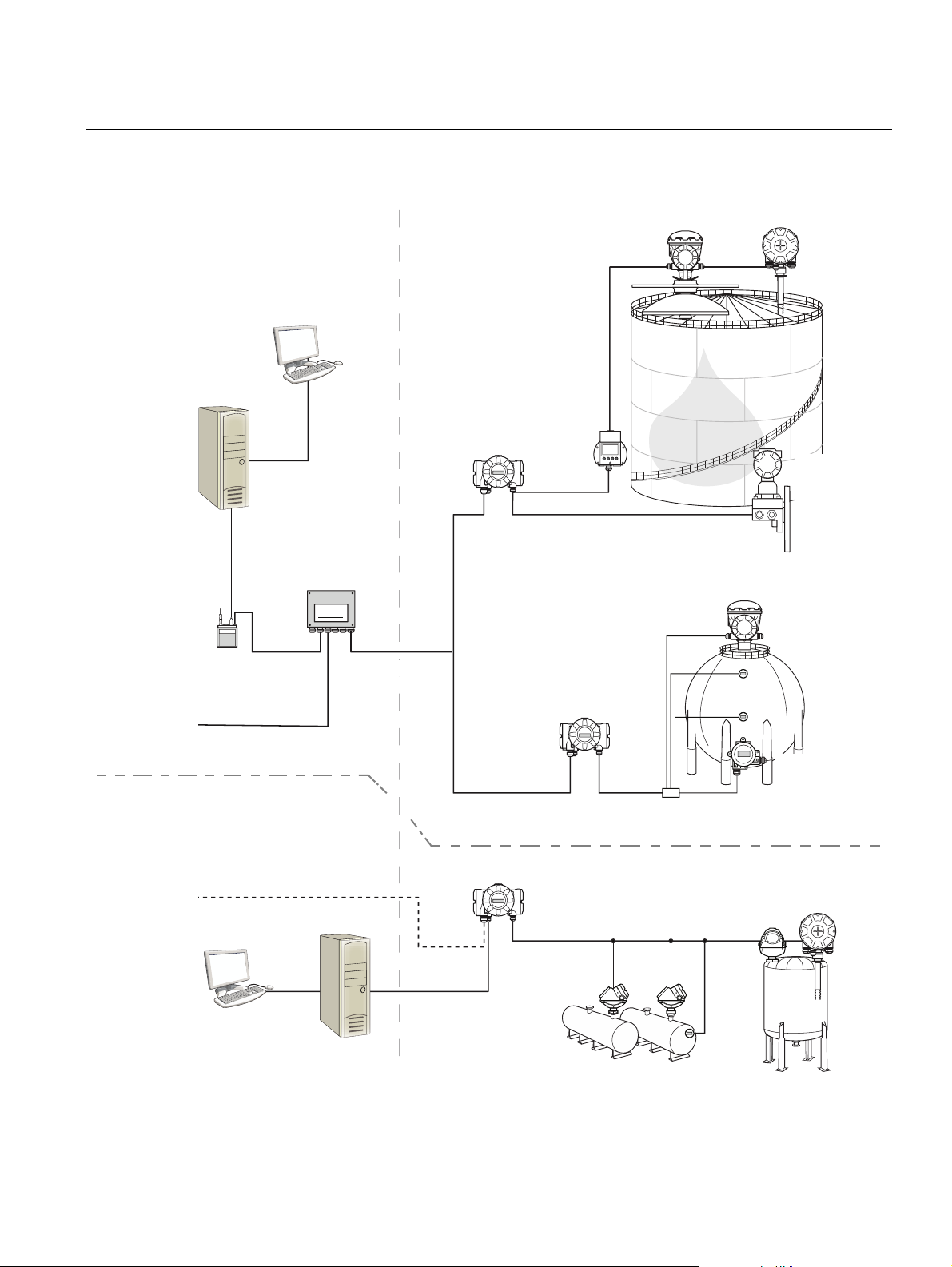

Page 21

Reference Manual

2230 Display

2240S Temperature

Transmitter

5900S Radar

Level Gauge

2410 Tank Hub

Tan kbus

5300 Level

Transmitter

5400 Level

Transmitter

3051S

Pressure

Transmitter

TRL2 Modbus

Group bus

2180 Field

Bus Modem

2160 Field

Communication Unit

TankMaste r PC

Plant Host Computer

2410 Tank Hub

644

644

644

644Temperature

Transmitter

TankMaster PC

Plant Host Computer

NON-HAZARDOUS AREA HAZARDOUS AREA

2240S Temperature

Transmitter

2410 Tank Hub

5900S Radar

Level Gauge

Tan kbus

Segment coupler

CUSTODY TRANSFER / INVENTORY TANK GAUGINGOPERATIONAL CONTROL

300530EN, Rev BA

September 2012

Figure 2-6. Raptor system

architecture

Rosemount 2410

Section 2. Overview

2-7

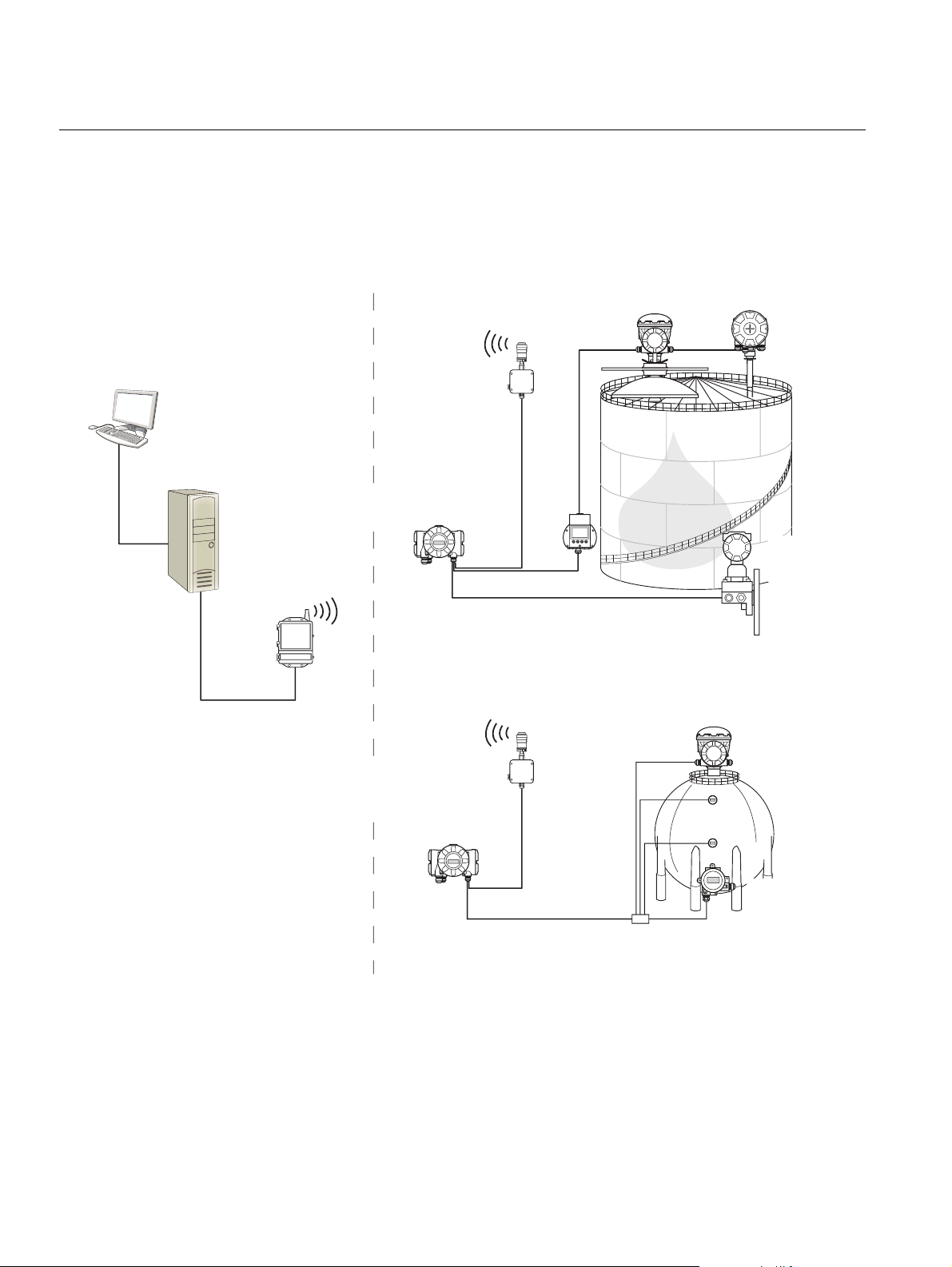

Page 22

Rosemount 2410

2230

Display

2240S Temperature

Transmitter

5900S Radar

Level Gauge

2410 Tank Hub

3051S

Pressure

Transmitter

Smart Wireless

Gateway

TankMaster PC

644

644

644Temperature

Transmitter

NON-HAZARDOUS AREA HAZARDOUS AREA

2410 Tank Hub

5900S Radar

Level Gauge

Tankbus

Segment coupler

THUM

THUM

Figure 2-7. Raptor system

architecture for wireless

systems

Reference Manual

300530EN, Rev BA

September 2012

2-8

Section 2. Overview

Page 23

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

TankMaster HMI Software

TankMaster is a powerful Windows-based Human Machine Interface (HMI) for

complete tank inventory management. It provides configuration, service,

set-up, inventory, and custody transfer functions for Raptor systems and other

supported instruments.

TankMaster is designed to be used in the Microsoft Windows XP and Vista

environment providing easy access to measurement data from your Local

Area Network (LAN).

The TankMaster WinOpi program lets the operator monitor measured tank

data. It includes alarm handling, batch reports, automatic report handling,

historical data sampling as well as inventory calculations such as Volume,

Observed Density and other parameters. A plant host computer can be

connected for further processing of data.

The TankMaster WinSetup program is a graphical user interface for

installation, configuration and service of the different devices in the Raptor

system.

Rosemount 2160 Field Communication Unit

The 2160 Field Communication Unit (FCU) is a data concentrator that

continuously polls and stores data from field devices such as radar level

gauges and temperature transmitters in a buffer memory. Whenever a request

for data is received, the FCU can immediately send data from a group of tanks

from the updated buffer memory.

Rosemount 2410 Tank Hub

The Rosemount 2410 Tank Hub acts as a power supply to the connected field

devices in the hazardous area using the intrinsically safe Tankbus.

The 2410 collects measurement data and status information from field

devices on a tank. It has two external buses for communication with various

host systems.

There are two versions of the 2410 for single tank or multiple tanks operation.

The 2410 multiple tanks version supports up to 10 tanks and 16 devices. With

the Rosemount 5300 and 5400 level transmitters the 2410 supports up to 5

tanks.

The 2410 is equipped with two relays which support configuration of up to 10

“virtual” relay functions allowing you to specify several source signals for each

relay.

The 2410 supports Intrinsically Safe (IS) and Non-Intrinsically Safe (Non-IS)

analog 4-20 mA inputs/outputs. By connecting a Smart Wireless THUM

Adapter to the IS HART 4-20 mA output, the 2410 is capable of wireless

communication with a Smart Wireless Gateway in a WirelessHART network.

Section 2. Overview

Rosemount 5900S Radar Level Gauge

The Rosemount 5900S Radar Level Gauge is an intelligent instrument for

measuring the product level inside a tank. Different antennas can be used in

order to meet the requirements of different applications. The 5900S can

measure the level of almost any product, including bitumen, crude oil, refined

products, aggressive chemicals, LPG and LNG.

2-9

Page 24

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

The Rosemount 5900S sends microwaves towards the surface of the product

in the tank. The level is calculated based on the echo from the surface. No

part of the 5900S is in actual contact with the product in the tank, and the

antenna is the only part of the gauge that is exposed to the tank atmosphere.

The 2-in-1 version of the 5900S Radar Level Gauge has two radar modules in

the same transmitter housing allowing two independent level measurements

using one antenna.

Rosemount 5300 Guided Wave Radar

The Rosemount 5300 is a premium 2-wire guided wave radar for level

measurements on liquids, to be used in a wide range of medium accuracy

applications under various tank conditions. Rosemount 5300 includes the

5301 for liquid level measurements and the 5302 for liquid level and interface

measurements.

Rosemount 5400 Radar Level Transmitter

The Rosemount 5400 is a reliable 2-wire non-contact radar level transmitter

for liquids, to be used in a wide range of medium accuracy applications under

various tank conditions.

Rosemount 2240S Multi-Input Temperature Transmitter

The Rosemount 2240S Multi-input Temperature Transmitter can connect up

to 16 temperature spot sensors and an integrated water level sensor.

Rosemount 2230 Graphical Field Display

The Rosemount 2230 Graphical Field Display presents inventory tank

gauging data such as level, temperature, and pressure. The four softkeys

allow you to navigate through the different menus to provide all tank data,

directly in the field. The Rosemount 2230 supports up to 10 tanks. Up to three

2230 displays can be used on a single tank.

Rosemount 644 Temperature Transmitter

The Rosemount 644 is used with single spot temperature sensors.

Rosemount 3051S Pressure Transmitter

The 3051S series consists of transmitters and flanges suitable for all kinds of

applications, including crude oil tanks, pressurized tanks and tanks with /

without floating roofs.

By using a 3051S Pressure Transmitter near the bottom of the tank as a

complement to a 5900S Radar Level Gauge, the density of the product can be

calculated and presented. One or more pressure transmitters with different

scalings can be used on the same tank to measure vapor and liquid pressure.

Rosemount 2180 Field Bus Modem

2-10

The Rosemount 2180 field bus modem (FBM) is used for connecting a

TankMaster PC to the TRL2 communication bus. The 2180 is connected to

the PC using either the RS232 or the USB interface.

Section 2. Overview

Page 25

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

Rosemount Smart Wireless Gateway and Rosemount Smart Wireless

THUM Adapter

A THUM Adapter allows wireless communication between a 2410 Tank Hub

and a Smart Wireless Gateway. The gateway is the network manager that

provides an interface between field devices and the TankMaster inventory

software or host / DCS systems.

See the Raptor Technical Description (Document no. 704010en) for more

information on the various devices and options.

Section 2. Overview

2-11

Page 26

Rosemount 2410

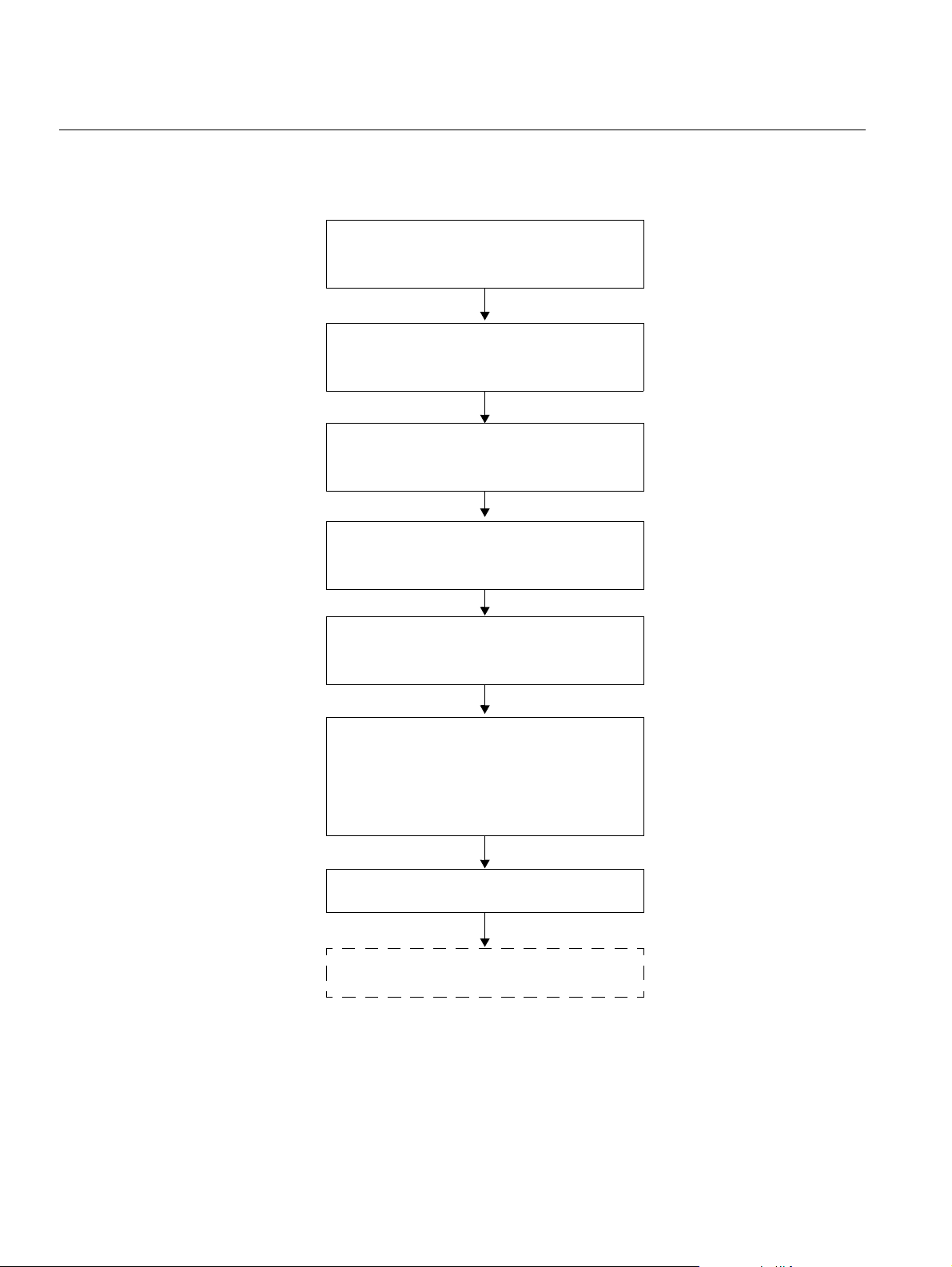

Review Mounting Considerations.

See “Installation Considerations”

on page 3-2.

Mount the 2410.

See “Mechanical

Installation” on page 3-3.

Wire the 2410.

See “Electrical Installation” on

page 3-5.

Make sure covers

and cable/conduit

connections are tight

Power up the 2410

Configure the 2410 (Section 4: Configuration):

- tank database

- tags

- integral display

- Primary/Secondary Bus

- Relay output

- Hybrid density

Verify operation

Enable the Write Protection

switch if required

Reference Manual

300530EN, Rev BA

September 2012

2.4 INSTALLATION PROCEDURE

Follow these steps for a proper installation:

2-12

Section 2. Overview

Page 27

Reference Manual

300530EN, Rev BA

September 2012

Section 3 Installation

3.1 Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

3.2 Installation Considerations . . . . . . . . . . . . . . . . . . . page 3-2

3.3 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . page 3-3

3.4 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . page 3-5

Rosemount 2410

3.1 SAFETY MESSAGES

Procedures and instructions in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

Failure to follow safe installation and servicing guidelines could result in death or

serious injury:

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Do not perform any service other than those contained in this manual unless you are

qualified.

Explosions could result in death or serious injury:

Verify that the operating environment of the device is consistent with the appropriate

hazardous locations certifications.

Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Do not remove the gauge cover in explosive atmospheres when the circuit is alive.

To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

www.rosemount-tg.com

High voltage that may be present on leads could cause electrical shock:

Avoid contact with leads and terminals.

Make sure the main power to the 2410 Tank Hub is off and the lines to any other

external power source are disconnected or not powered while wiring the gauge.

Page 28

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

3.2 INSTALLATION CONSIDERATIONS

The Rosemount 2410 Tank Hub may be installed on various locations at the

plant. Mounting at the tank foot may be convenient when you would like to

have easy access to measuring data, diagnostics and other information on

the 2410 optional integral display.

The 2410 can also be mounted on the tank roof if this is the preferred location.

In case the 2410 is exposed to long periods of sunshine, a sunshade should

be used to prevent the 2410 Tank Hub from being heated to temperatures

above the maximum operating temperature.

Ensure that environmental conditions are within specified limits as listed in

Appendix A: Reference Data.

Ensure that the Rosemount 2410 is installed such that it is not exposed to

higher pressure and temperature than specified in Appendix A: Reference

Data.

The multi-tank version of the Rosemount 2410 Tank Hub is able to serve

several tanks. In that case the 2410 may be placed at a suitable location

further away from the tanks.

The 2410 is designed with two Tankbus terminals and several cable entries

which allows alternative cable routings to suit various requirements.

Do not install the Rosemount 2410 in non-intended applications, for example

environments where it may be exposed to extremely intense magnetic fields

or extreme weather conditions.

It’s a good idea to plan the installation in order ensure that all components in

the system are properly specified. The planning stage should include the

following tasks:

• make a plan of the site and specify suitable locations for the devices

• consider power budget

• specify cabling and connections (for example whether devices will be

“daisy-chained” or not)

• specify cable glands that will be needed for the various devices

• specify location of terminators on the Tankbus

• make a note of identification codes such as Unit ID/Device ID of each

device

• assign Modbus adresses for level gauges and other tank devices to be

used in the Tank Database of the 2410 and the Slave Database of the

2160 Field Communication Unit (see the Raptor System Configuration

manual, document no. 300510 for more information)

3-2

See “Electrical Installation” on page 3-5 for more information on cables and

glands.

IMPORTANT

Check the 2410 Tank Hub for any signs of damage prior to installation. Ensure

that the glass on the integral display is undamaged, and O-rings and gaskets

are in good condition.

Section 3. Installation

Page 29

Reference Manual

Bracket

4 nuts and

washers

1 - 2 inches

Bracket

300530EN, Rev BA

September 2012

Rosemount 2410

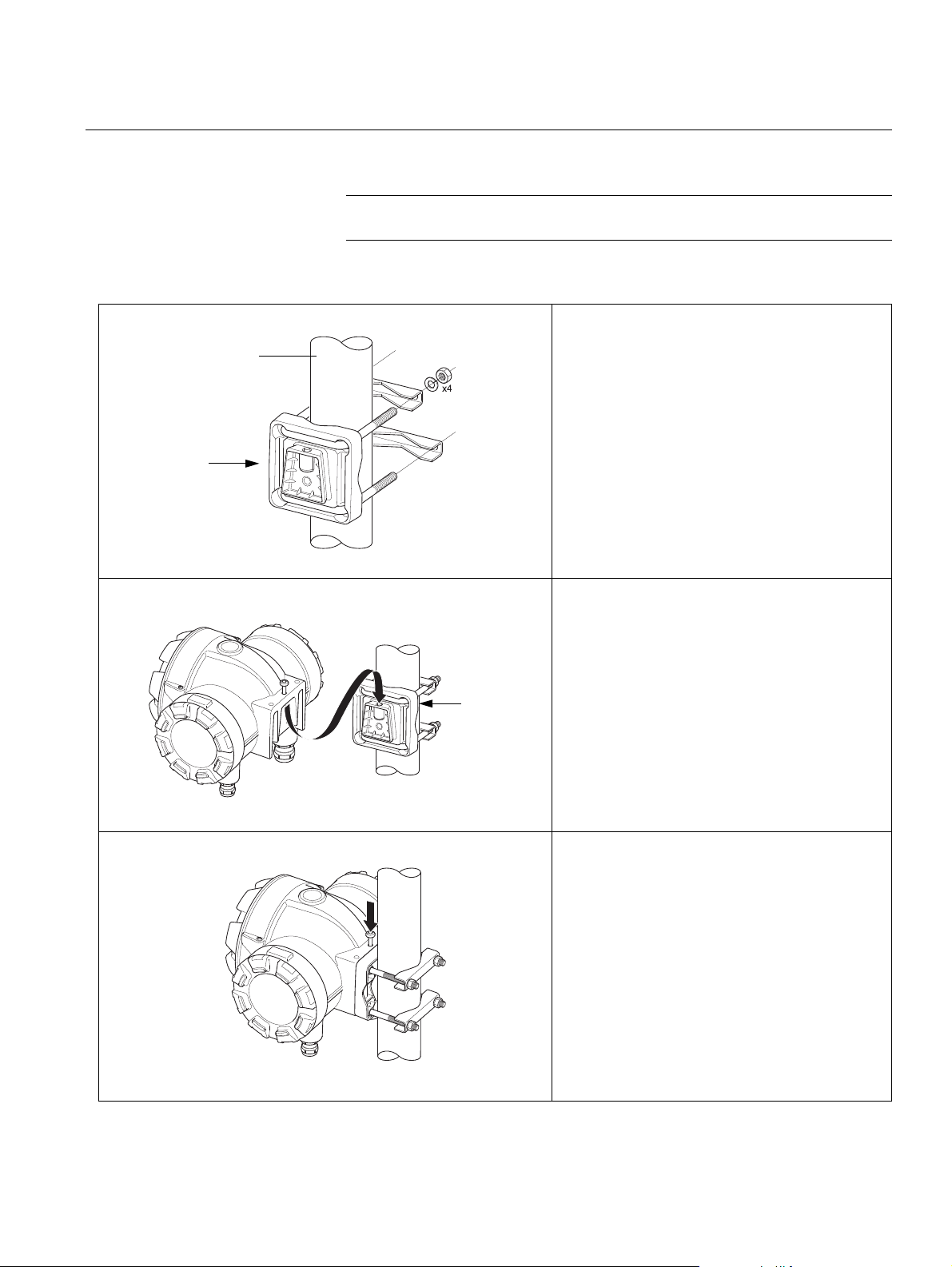

3.3 MECHANICAL INSTALLATION

3.3.1 Pipe Mounting

The Rosemount 2410 is designed for mounting on a pipe stand or on a wall.

NOTE!

Ensure that the 2410 is installed to minimize vibration and mechanical shock.

1. Attach the bracket to the pipe.

2. Ensure that the 2410 is placed in a

direction so that the display is clearly

visible and wiring can be properly

connected.

3. Tighten the nuts. Use moderate torque

to ensure that the bracket does not

break.

4. Attach the 2410 to the bracket by sliding

it from the top downwards.

Section 3. Installation

5. Secure the 2410 to the bracket by

tightening the screw.

3-3

Page 30

Rosemount 2410

70 mm

70 mm

94 mm

94 mm

Ø 9 mm

Screw

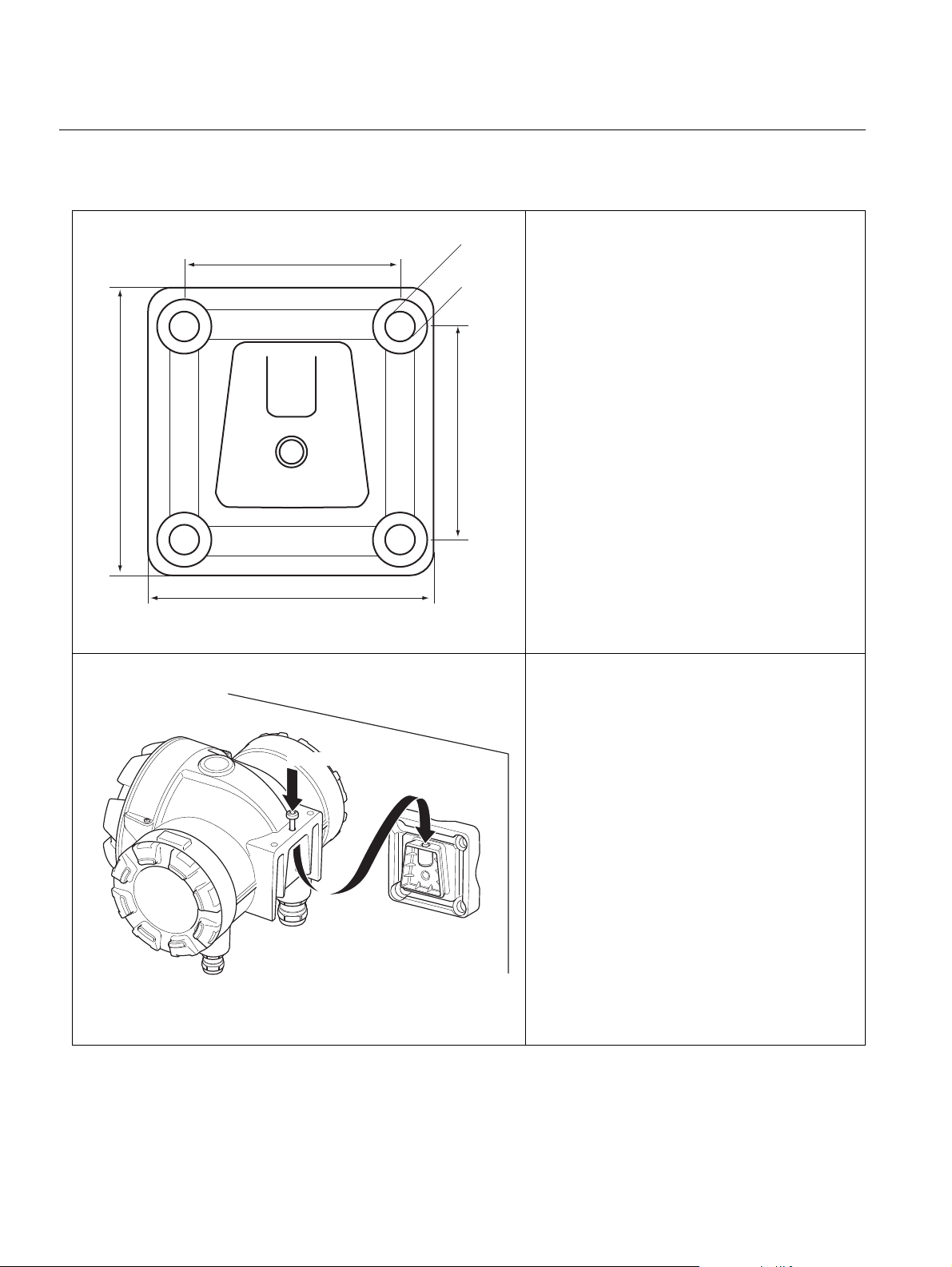

3.3.2 Wall Mounting

Reference Manual

300530EN, Rev BA

September 2012

1. Mount the bracket on the wall by using

four M8 screws and flat washers.

Note! Countersunk screws are not

suitable.

2. Attach the 2410 to the bracket and

tighten the screw.

3-4

Section 3. Installation

Page 31

Reference Manual

The NPT threaded gland leaves a

number of threads outside the housing

300530EN, Rev BA

September 2012

Rosemount 2410

3.4 ELECTRICAL INSTALLATION

3.4.1 Cable Entries The Rosemount 2410 electronics housing has four ½ - 14 NPT and two

¾ - 14 NPT entries. The connections must be made in accordance with local

or plant electrical codes.

Make sure that unused ports are properly sealed to prevent moisture or other

contamination from entering the terminal block compartment of the electronics

housing.

NOTE!

Use the enclosed metal plugs to seal unused ports. The plastic plugs

mounted at delivery are not sufficient as seal!

NOTE!

It is recommended that a sealant of type PTFE is used to prevent water

ingress and to enable future removal of the plug/gland.

NPT is a standard for tapered threads. Engage the gland with 5 to 6 threads.

Note that there will be a number of thvbreads left outside the housing as

illustrated below.

Figure 3-1. Cable entry with

NPT threaded gland

Glands must meet the following requirements for the Non-IS cable entries:

• Ex de explosion protection

• IP class 66 and 67

• material: metal (recommended)

3.4.2 Power Supply The Rosemount 2410 Tank Hub accepts supply voltage 48 - 240 Vac

(50/60 Hz) and 24 - 48 Vdc The 2410 provides intrinsically safe power to all

devices connected to the Tankbus (see “Tankbus” on page 3-8).

3.4.3 Cable Selection for Power Supply

Cables must be suitable for the supply voltage and approved for use in

hazardous areas, where applicable. For instance, in the U.S., explosion-proof

conduits must be used in the vicinity of the vessel.

Suitable conduits with sealing device or flame proof cable glands must be

used depending on local requirements.

Section 3. Installation

Appropriate cross sectional area of wires must be used in order to prevent a

too high voltage drop to the connected device. Use 0.75 mm

(18 AWG to 13 AWG) in order to minimize the voltage drop.

2

to 2.5 mm2

3-5

Page 32

Reference Manual

Rosemount 2410

300530EN, Rev BA

September 2012

3.4.4 Grounding The housing should always be grounded in accordance with national and

local electrical codes. Failure to do so may impair the protection provided by

the equipment. The most effective grounding method is direct connection to

earth ground with minimal impedance. There are grounding screw

connections inside the terminal compartments which are identified by ground

symbols: / . There is also a grounding screw on the housing.

NOTE!

Grounding the device via threaded conduit connection may not provide

sufficient ground.

Grounding - Foundation Fieldbus

Signal wiring of the fieldbus segment (Tankbus) can not be grounded.

Grounding one of the signal wires may shut down the entire fieldbus segment.

Shield Wire Ground

To protect the fieldbus segment (Tankbus) from noise, grounding techniques

for shield wire usually require a single grounding point for shield wire to avoid

creating a ground loop. The ground point is typically at the power supply.

3.4.5 Cable Selection for the Tankbus

Table 3-1. FISCO cable

parameters

The Raptor devices are designed for “daisy-chain” connection of shield wiring

in order to enable a continuous shield throughout the Tankbus network.

Use shielded twisted pair wiring for the Rosemount 2410 Series in order to

comply with FISCO

(1)

requirements and EMC regulations. The preferred cable

is referred to as type “A” fieldbus cable. The cables must be suitable for the

supply voltage and approved for use in hazardous areas, where applicable. In

the U.S. explosion-proof conduits may be used in the vicinity of the vessel.

We recommend cable size 1.0 mm

However, cables within the range 0.5 to 1.5 mm

2

or 18 AWG in order to facilitate wiring.

2

or 20 to 16 AWG can be

used.

The FISCO F

OUNDATION™ fieldbus specification requires that cables for the

Tankbus comply with the following parameters:

Parameter

Loop resistance 15 to 150 /km

Loop inductance 0.4 to 1 mH/km

Capacitance 45 to 200 nF/km

Maximum length of each spur

Maximum length of each trunk

(1) For further information see requirements of the IEC 61158-2 standard, and safety requirements in

(2) A spur is an unterminated part of the network.

(3) A trunk is the longest cable path between two devices on the fieldbus network, and is the part of the

(1)

(2)

cable

(3)

cable

IEC/TS 60079-27:2002.

network which has terminations at both ends. In the Raptor system, a trunk is typically located

between the 2410 Tank Hub and a splitter or the last device in a daisy-chain configuration.

Value

60 m in apparatus class IIC and IIB

1000 m in apparatus class IIC and 1900 m in

apparatus class IIB

3-6

(1) See IEC 61158-2 and IEC/TS 60079-27:2002.

Section 3. Installation

Page 33

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

3.4.6 Power Budget The Rosemount 2410 Tank Hub delivers 250 mA to the Tankbus. In Smart

Wireless systems a 2410 Tank Hub equipped with active analog

inputs/outputs may deliver 200 mA. The number of tanks served by the 2410

Table 3-2. Power consumption

for various Raptor devices

depends on the type of connected field devices and their power

consumption

below:

Field device Power consumption

5900S Radar Level Gauge

5900S Radar Level Gauge,

2-in-1 solution

5300 or 5400 Series Radar Level

Gauge

Rosemount 2230 Graphical Field

Display

Rosemount 2240S Multi-input

Temperature Transmitter

Rosemount 644 Temperature

Transmitter

Rosemount 3051S and Rosemount

2051 Pressure Transmitters

(1)

. Power consumption per field device is listed in Table 3-2

50 mA

100 mA

21 mA

30 mA

30 mA including MST and WLS

11 m A

18 mA

The Rosemount 2410 Tank Hub is available in a single tank version as well as

a multiple tank version which supports up to 10 tanks

(2)

.

Section 3. Installation

(1) May be fewer than the 16 devices per segment, stated in the FOUNDATION™ fieldbus stan-

dard.

(2) Maximum five Rosemount 5300 or 5400 level transmitters.

3-7

Page 34

Reference Manual

Rosemount 2410

300530EN, Rev BA

September 2012

3.4.7 Tankbus The Raptor system is easy to install and wire. Devices can be “daisy-chained”

thus reducing the number of external junction boxes.

In a Raptor system the field devices communicate with a Rosemount 2410

Tank Hub via the intrinsically safe Tankbus. The Tankbus complies with the

FISCO

power supply to the field devices on the Tankbus.

The Rosemount 2410 is designed for use in hazardous area Zone 1 (Class 1,

Division 1) and communicates with field devices via the intrinsically safe

Tankbus.

Termination

(1)

FOUNDATION fieldbus standard with the Rosemount 2410 acting as a

A terminator is needed at each end of the trunk in a F

OUNDATION fieldbus

network. A trunk is defined as the longest cable path between two devices on

the fieldbus network. In the Raptor system, a trunk is typically located

between the 2410 Tank Hub and a splitter or the last device in a daisy-chain

configuration. Generally, one terminator is placed in the fieldbus power

supply, and the other one in the last device in the fieldbus network as

illustrated in Figure 3-7.

NOTE!

Ensure that there are two terminators on the fieldbus.

In a Raptor system the Rosemount 2410 Tank Hub acts as a power supply.

Since the 2410 normally is the first device in the fieldbus segment, the built-in

termination is enabled at factory.

Other Raptor devices such as the Rosemount 5900S Radar Level Gauge, the

Rosemount 2230 Graphical Field Display, and the Rosemount 2240S

Multi-input Temperature Transmitter also have built-in terminators which can

easily be enabled by inserting a jumper in the terminal block when necessary.

When adding new devices at the end of an existing F

OUNDATION fieldbus

network, the termination is moved to the farthest field device in order to fulfill

the requirement on locating the terminator at the end of the trunk. However, in

case a field device is added to the network with a short cable, this rule may be

slightly bent by leaving the terminator in its original position.

3-8

Fieldbus Segment Design

When designing a FISCO fieldbus segment you will have to make sure that

cabling complies with FISCO requirements as described in “Cable Selection

for the Tankbus” on page 3-6.

You will also have to ensure that the total operating current of the connected

field devices is within the output capability of the Rosemount 2410 Tank Hub.

The 2410 is able to deliver 250 mA. Consequently, the total number of field

devices has to be considered so that the total current consumption is less

than 250 mA, see “Power Budget” on page 3-7.

(1) FISCO=Fieldbus Intrinsically Safe Concept

Section 3. Installation

Page 35

Reference Manual

300530EN, Rev BA

September 2012

Table 3-3. Typical

characteristics of

instrumentation cable

Rosemount 2410

Since the field devices on the Tankbus must have at least a 9 V input voltage

at their terminals, you will have to take into account the voltage drop in the

fieldbus cables. Distances are normally quite short between the Rosemount

2410 Tank Hub and field devices on the tank. In many cases you can use

existing cables as long as the FISCO requirements are fulfilled (see “Cable

Selection for the Tankbus” on page 3-6). Typical characteristics for such a

cable is:

Parameter Value

Loop resistance 42 /km

Inductance 0.65 mH/km

Capacitance 115 nF/km

Cross-sectional area 0.75 mm2 (18 AWG)

The Rosemount 2410 outputs 12.5 Vdc. Considering the minimum voltage

supply of 9 V on the field device terminals, a maximum voltage drop of 3.5 V

on the Tankbus can be allowed. At a maximum current consumption of

250 mA (12.5 Vdc) with all field devices located at the far end of the Tankbus,

a total “worst case” cable resistance of approximately 14 Ω (3.5 V/250 mA) is

allowed. This corresponds to a cable length of 333 m (1092 ft) in case typical

cable characteristics are assumed as specified in Table 3-3 on page 3-9.

Table 3-4. Maximum distance

from power source to field

devices on the tank for different

cable areas

However, normally the current consumption is less than 250 mA. A typical

Raptor configuration would include a tank supplied with a Rosemount 5900S

Radar Level Gauge, a Rosemount 2230 Graphical Field Display, a

Rosemount 2240S Multi-input Temperature Transmitter, and a Rosemount

3051S Pressure Transmitter. In this case the current consumption would be

128 mA allowing a cable length of 677 m (2221 ft) between the 2410 Tank

Hub and the field devices on the tank. With fewer devices on the Tankbus, an

even longer cable would be allowed.

Table 3-4 shows the maximum distance between a 2410 Tank Hub and the

field devices on a tank for different cable cross-sectional areas. The table

shows the maximum distance to a tank at a total current consumption of

250 mA as well as for a typical installation as outlined above.

Cable characteristics Maximum distance to tank (m/ft)

Cross-sectional area Typical loop

20 AWG (0.5 mm

18 AWG (0.75 mm2) 42 333 (1092) 651 (2136)

17 AWG (1.0 mm

16 AWG (1.5 mm2) 26 538 (1765) 1052 (3451)

resistance

/km)

2

) 66 212 (695) 414 (1358)

2

) 33 424 (1391) 829 (2720)

Maximum Current

consumption

(250 mA)

Typical installation

(128 mA)

Section 3. Installation

3-9

Page 36

Rosemount 2410

2410 Tank Hub with

intrinsically safe power

supply:12.5 V, 250 mA

5900S Radar

Level Gauge

2230 Display

300 m

Voltage drop=1.3 V

Tank bus

2240S Temperature

Transmitter

Figure 3-2. Example installation

with one tank

Reference Manual

300530EN, Rev BA

September 2012

Example 1

The example illustrated in Figure 3-2 includes a tank located 300 m away

from a Rosemount 2410 Tank Hub acting as power supply. In the calculations

below it is assumed that the cable length between the field devices on the

tank can be ignored.

The tank is equipped with the following field devices: a Rosemount 5900S

Radar Level Gauge, a Rosemount 2240S Multi-input Temperature

Transmitter, and a Rosemount 2230 Graphical Field Display. The total current

consumption of the three devices is 110 mA (see Table 3-2).

3-10

The total operating current of the connected field devices on the tank is

50+30+30 mA=110 mA. This is within the output capability of the Rosemount

2410 Tank Hub.

The voltage drop to the tank:

110 mA x 0.30 km x 42 /km=1.4 V.

Voltage at the tank =12.5 V - 1.4 V=11.1 V.

The input voltage of 11.1 V to the field devices is above the minimum

requirement of 9 V.

Section 3. Installation

Page 37

Reference Manual

2410 Tank Hub with

intrinsically safe power

supply:12.5 V, 250 mA

5400 Radar Level

Transmitter

644 Temperature

Transmitter

300 m

350 m

Voltage drop=0.80 V Voltage drop=0.47 V

Segment

coupler

Tan kbus

(Spur <60 m)

(Spur <60 m)

Segment

coupler

300530EN, Rev BA

September 2012

Figure 3-3. Example installation

with two tanks

Rosemount 2410

Example 2

The second example, illustrated in Figure 3-3, includes two tanks with a

Rosemount 2410 Tank Hub acting as power supply to the field devices on

both tanks.

The first tank is located 300 m away from the 2410 Tank Hub and the second

tank a further 350 m away.

Both tanks have two field devices: a Rosemount 5400 Radar Level

Transmitter and a Rosemount 644 Temperature Transmitter. The total current

consumption of the two devices is 32 mA (see Table 3-2).

Section 3. Installation

The total operating current of the connected field devices on the two tanks is

32+32 mA=64 mA. This is within the output capability of the Rosemount 2410

Tank Hub.

Voltage drop to the first tank:

64 mA x 0.30 km x 42 /km=0.80 V.

Voltage at first tank =12.5 V - 0.80 V=11.70 V.

Voltage drop between first and second tank:

32 mA x 0.35 km x 42 /km=0.47 V.

Voltage at second tank =12.5 V - 0.80 V - 0.47 V=11.23 V.

For both tanks the input voltage to the field devices is above the minimum

requirement of 9 V.

The field devices may be connected to the Tankbus via segment couplers as

illustrated in Figure 3-3. The spur length must not exceed 60 m according to

the FISCO standard. In the example above, it is assumed that the voltage

drop between the segment coupler and the devices can be ignored.

3-11

Page 38

Rosemount 2410

122

64

36

45

173.5

185.5

207

Reference Manual

300530EN, Rev BA

September 2012

Tankbus Segment Coupler

Figure 3-4. Dimensions (mm)

In case “daisy-chain” connection is not suitable, a Tankbus Segment

Coupler

(1)

can be used to connect the various devices to the Raptor Tankbus.

Features:

• Entity and FISCO compliant

• adjustable short-circuit limit

• robust die-cast aluminium housing

• protection degree IP67

• integrated bus terminating resistor (switch integrated inside the

housing)

• cable shielding: capacitive or direct connection to housing potential

selectable via switch

NOTE!

Sufficient equipotential bonding of the installation must be ensured. The

device is connected via the bolt on the housing to the system’s potentializer.

3-12

(1) Part no. 6853511-493. Contact Emerson Process Management/Rosemount Tank Gauging

for more information.

Section 3. Installation

Page 39

Reference Manual

1

2

3

4

1. Switch for capacitive or direct

connection between shield and housing

potential

2. Switch for activating terminating

resistor

3. Current limitation for all ports via a

rotary switch; 30, 35, 45, or 60 mA

4. Connection of housing potential

5. LED power on indication

6. LED short-circuit indication

6

5

Trunk IN Trunk OUT

Spur

Spur

Spur

Spur

Spur

Spur

Case ground

300530EN, Rev BA

September 2012

Figure 3-5. Segment coupler

Rosemount 2410

In case there are different device types connected to the segment coupler, set

the current limitation switch (3) to the closest value above the largest current

consumption of the connected devices. See “Power Budget” on page 3-7 for

information on current consumption for various Raptor devices.

Examples

Rosemount 5900S; set the switch to 60mA.

Rosemount 5300 and 5400; set the switch to 30 mA.

Rosemount 2230; set the switch to 35 mA.

Section 3. Installation

3-13

Page 40

Rosemount 2410

Tankbus (trunk)

(Spur<60 m)

(Spur<60 m)

2410 Tank Hub

5400 Level

Transmitter

644 Temperature

Trans mitter

Segment coupler

2240S Temperature

Transmitter

2230 Display

Tankbus (trunk)

Segment coupler with active

terminator (end of trunk)

Figure 3-6. Example of Raptor

system with field devices

connected to the Tankbus via

segment couplers

Reference Manual

300530EN, Rev BA

September 2012

3-14

Section 3. Installation

Page 41

Reference Manual

5900S Radar

Level Gauge

2240S Multi-input Temperature

Trans mitter

Built-in

terminator

enabled on the

last device

2230 Display

2410 Tank Hub with

intrinsically safe power

supply, integrated power

conditioner, and built-in

terminator

Tankbus length up to 1000 meter depending

on number of devices and cable type

Tan kbu s

300530EN, Rev BA

September 2012

Rosemount 2410

3.4.8 Typical Installations

Figure 3-7. Example of a Raptor

system with single tank

The example below (Figure 3-7) illustrates a Raptor system with

daisy-chained field devices on a single tank. Terminators are installed at both

ends of the fieldbus segment as required in a F

OUNDATION fieldbus system. In

this example the terminators are enabled in the Rosemount 2410 Tank Hub

and a Raptor field device (Rosemount 2240S) the end of the network

segment.

Section 3. Installation

The maximum distance between the 2410 Tank Hub and the field devices

depends on the number of devices connected to the Tankbus and the cable

type.

See “Cable Selection for the Tankbus” on page 3-6 and “Tankbus” on

page 3-8 for more information about cable selection and the Tankbus.

an example with a 2-in-1 version of the 5900S in a SIL safety installation. A

4-wire cable is used to connect the Primary and Secondary Tankbuses

through the same cable entry. The SIL alarm wire is connected through a

separate cable entry as illustrated in Figure 3-8.

A junction box is used to provide sufficient number of connections for the field

devices to the Primary and Secondary Tankbus.

3-15

Page 42

Rosemount 2410

5900S Radar

Level Gauge

2240S Multi-input

Temperature

Transmitter

Junction box

2230 Display

Pressure

transmitter

Pressure

transmitter

Terminators for Primary and

Secondary Tankbus

Primary 2410 Tank Hub

4-wire cable for connection of

Primary Tankbus and Secondary

Tankbus to 2-in-1 5900S

Primary Tank Hub is

connected to the

electronic unit of the

5900S 2-in-1 level

gauge which is used

for SIL overfill alarm

Secondary 2410 Tank Hub

Primary Tankbus Secondary Tankbus

2230 Display

Secondary Tank Hub

is connected to the

5900S electronic unit

used for level

measurements

Figure 3-8. Raptor SIL system

with a 5900S connected to

separate Tank buses

Reference Manual

300530EN, Rev BA

September 2012

Figure 3-8 illustrates an example with a 2-in-1 version of the 5900S in a SIL

safety installation. A 4-wire cable is used to connect the Primary and

Secondary Tankbuses through the same cable entry. The SIL alarm wire is

connected through a separate cable entry. A junction box is used to provide

sufficient number of connections for the field devices to the Primary and

Secondary Tankbus.

3-16

Section 3. Installation

Page 43

Reference Manual

2410 Tank Hub with

intrinsically safe power

supply, integrated power

conditioner, and built-in

terminator

(Trunk)

2240S Multi-input

Temperature

Transmitter

Field Communicator

Tan kbu s

5400 Level

Transmitter

(Spurs <60 m)

644 Temperature

Transmitter

2230 Display

Tankbus length up to 1000 meter

depending on number of devices

and cable type

Segment coupler with

integrated bus terminator

300530EN, Rev BA

September 2012

Figure 3-9. Example of a Raptor

system with a Rosemount 2410

connected to several tanks at

the end of the Tankbus (fieldbus

segment)

Rosemount 2410

Figure 3-9 illustrates an example with four tanks connected to a Rosemount

2410 Tank Hub (requires 2410 with multiple tanks option). The field devices

are connected to a segment coupler at the end of the Tankbus.

A separate bus terminator is not required if one of the Raptor field devices

with built-in terminator is connected at the end of the fieldbus segment. There

are other options available as well, for example using a separate terminator

plugged into the segment coupler, or a segment coupler with integrated bus

terminator.

Note that the total length of the Tankbus (fieldbus segment) must be within the

FISCO specifications and the spurs must not exceed 60 meter, see “Cable

Selection for the Tankbus” on page 3-6.

Section 3. Installation

3-17

Page 44

Rosemount 2410

Tan kbus

5400 Level

Transmitter

2230 Display

644 Temperature

Trans mitter

2410 Tank Hub with

intrinsically safe power

supply, integrated power

conditioner, and built-in

terminator

2230 Display with

built-in terminator

Tankbus length up to 1000 meter depending

on number of devices and cable type

Figure 3-10. Example of a

Raptor system with several

tanks daisy-chained to a

Rosemount 2410

Reference Manual

300530EN, Rev BA

September 2012

Figure 3-10 illustrates an example with a number of tanks daisy-chained to a

Rosemount 2410 Tank Hub (requires multiple tanks option).

If a Raptor field device is connected to the end of the Tankbus (fieldbus

segment), the built-in terminator can be used. A separate bus terminator may

be used instead.

3-18

Note that the total length of the Tankbus (fieldbus segment) must be within the

FISCO specifications, see “Cable Selection for the Tankbus” on page 3-6.

Section 3. Installation

Page 45

Reference Manual

Tan kbus

5400 Level

Transmitter

644 Temperature

Transmitter

(Spur <60 m)

2410 Tank Hub with

intrinsically safe power

supply, integrated power

conditioner, and built-in

terminator

Segment coupler

2230 Display with

built-in terminator

Tankbus length up to 1000 meter depending

on number of devices and cable type

Segment coupler Segment coupler

5400 Level

Transmitter

5400 Level

Transmitter

2230 Display

(Spur <60 m)

(Spur <60 m)

300530EN, Rev BA

September 2012

Figure 3-11. Raptor system with

three tanks connected to the

Tankbus via segment couplers

Rosemount 2410

Figure 3-11 illustrates an example with three tanks connected to a Rosemount

2410 Tank Hub (requires multiple tanks option). For each tank the field

devices are connected to the Tankbus via a segment coupler.

The fieldbus segment needs to be terminated at both ends. A terminator is

enabled in the Rosemount 2410 Tank Hub. At the end of the fieldbus segment

you may use the built-in terminator in one of the Raptor field devices, or an

external terminator plugged into one of the devices, or a segment coupler with

integrated bus terminator.

Section 3. Installation

Note that the total length of the Tankbus (fieldbus segment) must be within the

FISCO specifications and the spurs must not exceed 60 meter, see “Cable

Selection for the Tankbus” on page 3-6.

3-19

Page 46

Rosemount 2410

644 Temperature

Transmitter

External terminator

5400 Level

Transmitter

2410 Tank Hub with

intrinsically safe power

supply, integrated power

conditioner, and built-in

terminator

2230 Display

½ inch NPT

Red +

Black -

Reference Manual

300530EN, Rev BA

September 2012

Figure 3-12. Example of Raptor

system with external terminator

In case the last device on the Tankbus has no internal terminator, an external

terminator

(1)

according to FISCO model and Entity model can be used

instead. It can be screwed into a free cable gland on the device.

3-20

(1) Part no. 6853511-494. Contact Emerson Process Management/Rosemount Tank Gauging

for more information.

Section 3. Installation

Page 47

Reference Manual

300530EN, Rev BA

September 2012

Rosemount 2410

3.4.9 Cabling for the TRL2/RS485 Bus

Table 3-5. Minimum cable area

for the TRL2 bus

Figure 3-13. Individually

shielded pair cables minimizes

crosstalk

In a Raptor system a Rosemount 2410 Tank Hub communicates with a 2160

Field Communication Unit using the TRL2/RS485 Modbus protocol, see

Section 2: Overview.

TRL2 Bus

The TRL2 bus requires twisted and shielded pair wiring with a minimum

cross-sectional area of 0.50 mm

2

(AWG 20 or similar). The maximum length

of the TRL2 bus is approximately 4 km /13000 ft. The TRL2 field bus can

normally use existing cables in the tank area.

Cable cross-sectional area for the TRL2 wiring should follow the

recommendations in Table 3-5:

Maximum distance Minimum cross-sectional area

3 km 0.50 mm

4 km 0.75 mm2 (AWG 18)

2

(AWG 20)

NOTE!

Wherever two or more TRL2 buses run alongside each other, sharing the

same cable or conduit tube, use twisted and shielded wire and ensure that

each pair of bus wires is individually shielded in order to avoid crosstalk.

Table 3-6. Recommended cable

standards for the TRL2 bus

Section 3. Installation

Table 3-6 shows typical cable types that can be used for connecting the TRL2

bus. Other cables of similar type may also be used.

Typ e Manufacturing standard Core size

Signal BS 5308 part 1, type 1 1 mm

Signal (armoured) BS 5308 part 2, type 1 1 mm

2

2

RS485 Bus

The RS485 bus should meet the following requirements:

• twisted and shielded pair wiring

• characteristic impedance of 120

• maximum cable length 1200 m / 4000 ft.

3-21

Page 48

Rosemount 2410

Cable entries

Safety locking screw

Non-IS compartment

Terminal block

Ground screws

Ground screw

Wiring with drip loop

Reference Manual

300530EN, Rev BA

September 2012

3.4.10 Non-IS Connection

The non-IS explosion-proof/flameproof compartment has a terminal block for

connecting power supply, communication buses to host systems, relay

outputs, and HART 4-20 mA analog input and output.

1. Ensure that the power supply is switched off.

2. Loosen the safety locking screw.

3. Remove the cover on the non-IS terminal compartment.

4. Run the wires through the cable gland/conduit. Install wiring with a drip

loop in such a way that the lower part of the loop is under the

cable/conduit entry.

5. Connect wires to the terminal block. See Table 3-8 on page 3-25 for

information on the terminal block connections.

6. Use the enclosed metal plug to seal any unused port.

7. Tighten the conduits/cable glands.

8. Attach and tighten the cover. Ensure that it is fully engaged to meet

explosion-proof requirements and to prevent water from entering the

terminal compartment.

9. Tighten the safety locking screw.

NOTE!

Ensure that o-rings and seats are in good condition prior to mounting the

cover in order to maintain the specified level of ingress protection. The same

requirements apply for cable inlets and outlets (or plugs). Cables must be

properly attached to the cable glands.

Figure 3-14. Non-IS terminal

compartment

3-22

Section 3. Installation

Page 49

Reference Manual

Stripping length: 10 mm

Conductor cross-sectional area,

see Table 3-7

300530EN, Rev BA

September 2012

Figure 3-15. Conductor and

insulation requirements

Rosemount 2410

Conductor Recommendations

Ensure that you use cables suitable for the terminal block of the 2410. The

terminal block is designed for cables that meet the specifications as illustrated

below.

Table 3-7. Conductor

cross-sectional area

Conductor connection Cross-section (mm2)

Minimum Maximum

Solid 0.5 4

Flexible 0.5 2.5

Flexible, ferrule with plastic

collar

0.5 1.5

Section 3. Installation

3-23

Page 50

Rosemount 2410

Conductor

Terminal block

Figure 3-16. Use a screw driver

to connect the conductor to the

terminal block

Reference Manual

300530EN, Rev BA

September 2012

Use a screw driver to insert the conductor into the terminal block as illustrated

in Figure 3-16.

1

2

3-24

Section 3. Installation

Page 51

Reference Manual

Ground screws for

communication bus

shields

Ground screw

X1

XP/Exd/Exe

300530EN, Rev BA

September 2012

3.4.11 Non-IS Terminal Block

Figure 3-17. Terminal block in

the explosion-proof/flameproof

compartment

Rosemount 2410

Table 3-8. Terminal assignment

for non-intrinsically safe side

(XP/Exd/Exe)

Ter min al Designation Function

1 N / - Power, Neutral / DC 2 L / + Power, Line / DC +

3 K1 A Relay 1 output (optional). Hardware configurable NO/NC.

4 K1 com Relay 1 common

5 K2 A Relay 2 output (optional). Hardware configurable NO/NC.

6 K2 com Relay 2 common

7a/7b P Bus B

8a/8b P Bus A

9 S Pwr - Secondary power - (optional)

10 S Pwr + Secondary power +(optional)

11 S Bus B Secondary communication bus (optional)

12 S Bus A Secondary communication bus (optional)

PE PE Protective power supply ground

GND_1 GND_1 Housing chassis/shield Primary bus

GND_2 GND_2 Housing chassis/shield Secondary bus

Primary communication bus

Power Supply

The Rosemount 2410 accepts supply voltage 24-48 Vdc and 48-240 Vac

(50/60 Hz).

Primary Communication Bus

The Rosemount 2410 communicates with a host or a FCU 2160 via TRL2

Modbus or RS-485 Modbus protocol.

Section 3. Installation

Secondary Communication Bus

The secondary bus can be used for communication using a number of

protocols such as TRL2 Modbus, HART 4-20 mA, Enraf, Varec and L&J.

3-25

Page 52

Rosemount 2410

Table 3-9. Designation of relay

contact positions

Reference Manual

300530EN, Rev BA

September 2012

Relay Outputs

There are two optional relay outputs. You can choose Normally Open (NO) or

Normally Closed (NC) by setting a switch as described in “Relay Output

Configuration” on page 6-15.

NO and NC refers to the contact position when a relay is deenergized. This is

also referred to as the Alarm state. The terminology can be summarized as

follows:

Normally Closed (NC) Normally Open (NO)

Deenergized Energized Deenergized Energized

Closed Open Open Closed

Not active Active Not active Active

Alarm (Reset) Normal Alarm (Reset) Normal

NOTE!

Ensure that maximum current through the relays does not exceed the

specifications in Appendix A: Reference Data.

See “Relay Output” on page C-6 in Appendix C: Advanced Configuration for

information on how to configure the relay source signal, set points etc. for the

Rosemount 2410 Tank Hub.

3-26

Section 3. Installation

Page 53

Reference Manual

Ground screws

Ground screw

SIL Relay

XP/Exd/Exe

300530EN, Rev BA