Page 1

Reference Manual

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

Section 3 Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

Safety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-4

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . page 3-4

Mechanical Considerations . . . . . . . . . . . . . . . . . . . . . . . . page 3-5

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-11

Failure Mode and Security Jumpers . . . . . . . . . . . . . . . . . page 3-13

Zero and Span Adjustments . . . . . . . . . . . . . . . . . . . . . . . page 3-15

OVERVIEW This section is designed to guide you through a successful Rosemount 2088,

2090F, or 2090P Transmitter installation. Starting with an installation

flowchart, this section contains information on installation considerations and

transmitter options. Dimensional drawings are also included in this section.

SAFETY MESSAGES Instructions and procedures in this section may require special precautions to

ensure the safety of the personnel performing the operations. Information that

raises potential safety issues is indicated by a warning symbol ( ). Please

refer to the following safety messages before performing an operation

preceded by this symbol.

www.rosemount.com

Page 2

Rosemount 2088 and 2090

Warnings

Explosions could result in death or serious injury:

• Do not remove the transmitter cover in explosive atmospheres

when the circuit is alive.

• Before connecting a HART-based communicator in an explosive atmosphere,

make sure the instruments in the loop are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both transmitter covers must be fully engaged to meet

explosion-proof requirements.

Failure to follow these installation guidelines could result in death or serious injury:

• Make sure only qualified personnel perform the installation.

Reference Manual

00809-0100-4690, Rev EA

March 2007

High voltage that may be present on leads could cause electrical shock:

• Avoid contact with leads and terminals.

Use appropriately rated sanitary clamps and gaskets during installation. The

maximum working pressure of the clamp and gasket must be greater than or equal to

the working pressure range of the transmitter. Failure to use proper clamps and

gaskets can cause process leaks and can result in death or serious injury.

3-2

Page 3

Reference Manual

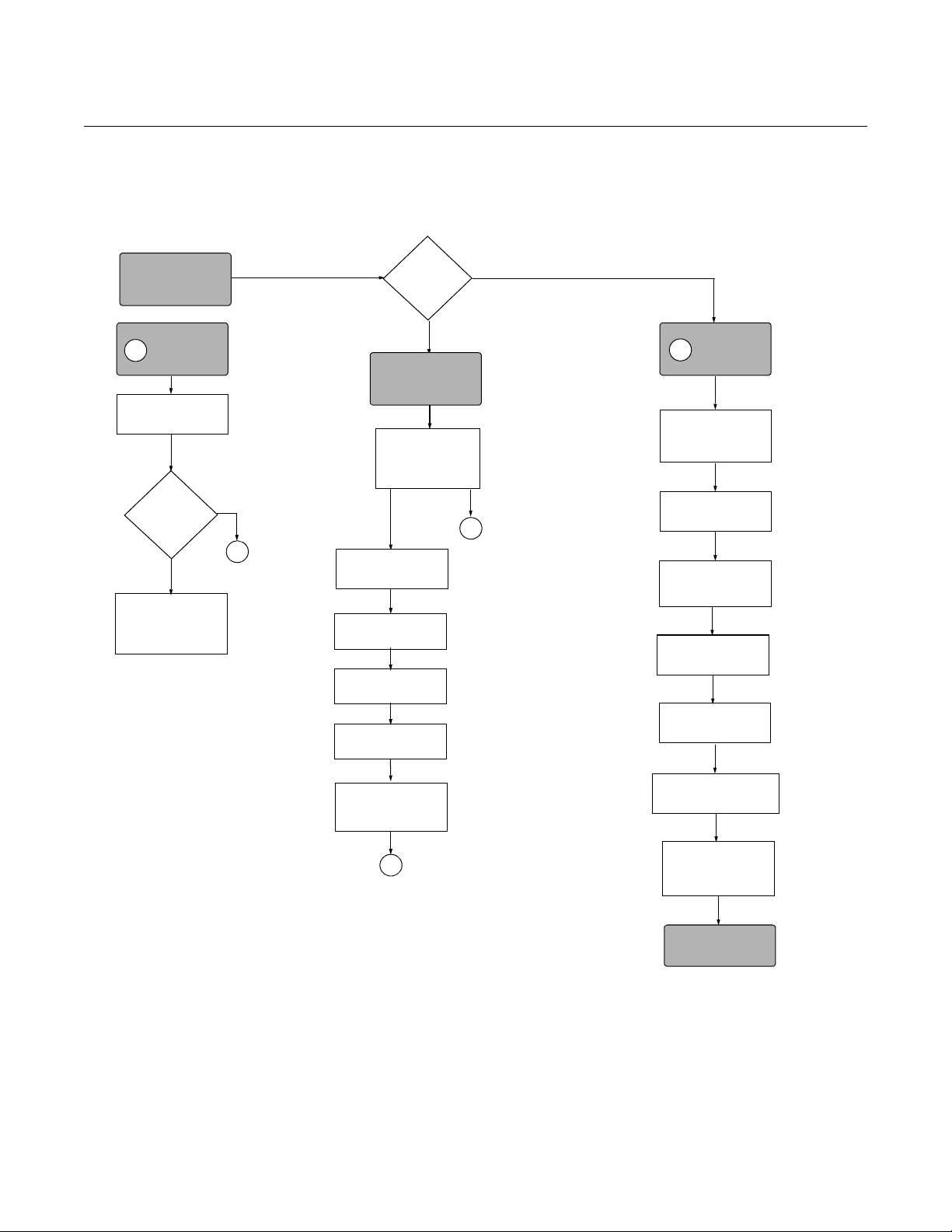

Check for Leaks

(Process

Connections)

Zero Trim

Transmitter for

Mounting Effects

Check Jumper

or Switches

Wire

Transmitter

Power

Transmitter

DONE

Mount

Transmitter

Apply Pressure

Refer to

Troubleshooting

Section

Within

Specifications?

VERIFY

START HERE

Bench

Calibration?

FIELD

INSTALL

Set Output Type

Check

Configuration

(See Chapter XX)

Set Range Points

Set Units

(See Chapter XX)

Set Damping

Confirm Transmitter

Configuration

Within

Specifications?

Perform

Sensor and/or

Output Trim

NO

YES

A

NO

NO

YES

YES

A

B

B

A

00809-0100-4690, Rev EA

March 2007

Figure 3-1. Installation

Flowchart.

Rosemount 2088 and 2090

3-3

Page 4

Rosemount 2088 and 2090

Electronics

Housing

Process

Connection

Reference Manual

00809-0100-4690, Rev EA

March 2007

GENERAL

CONSIDERATIONS

ENVIRONMENTAL

CONSIDERATIONS

The accuracy of the pressure measurement depends on proper installation of

the transmitter and impulse piping. The piping between the process and

transmitter must accurately transmit pressure to the transmitter. Mount the

transmitter close to the process and use a minimum of impulse piping to

achieve the best accuracy. Keep in mind, however, the need for convenient

access, safety of personnel, practical field calibration, and a suitable

transmitter environment. In general, install the transmitter to minimize

vibration, shock, and temperature fluctuations.

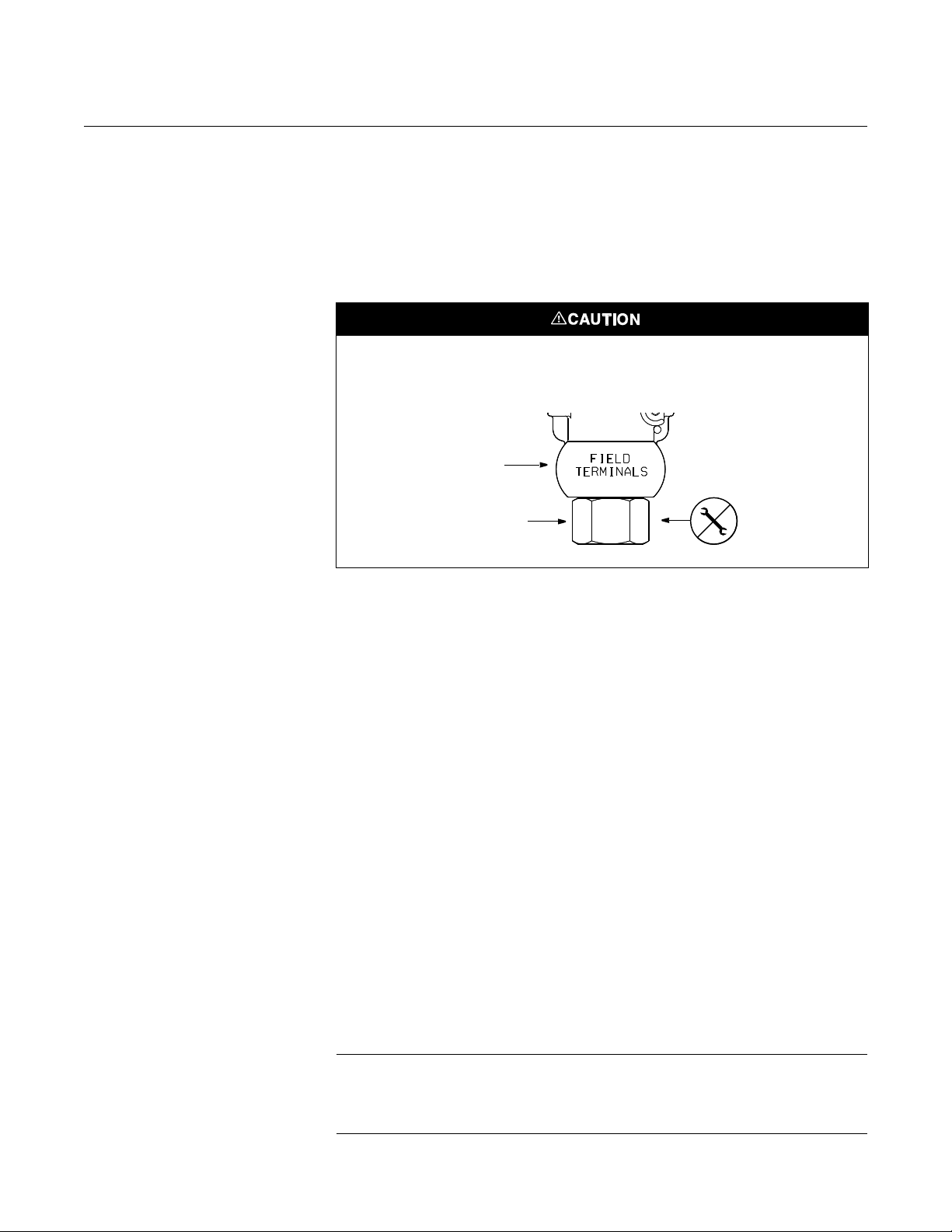

Do not apply torque directly to the electronics housing. Rotation between the electronics

housing and the process connection can damage the electronics. To avoid damage, apply

torque only to the hex-shaped process connection. Use a backup wrench on Process

Connection when installing an adapter.

Temperature

Mount the transmitter in a manner that minimizes variations in ambient

temperature.

Moisture and Corrosives The transmitter is designed to resist attack by moisture and corrosives. The

electronics module is fully encapsulated and mounted in a compartment that

is sealed from the power-side conduit entries. O-ring seals protect both

compartments when the covers are installed.

In humid environments, it is possible for moisture to accumulate in the conduit

lines and reach the terminal compartment of the transmitter housing. To

prevent moisture from entering the terminal compartment, mount the

transmitter at a high point in the conduit run, if possible. Also, remove the

terminal compartment cover periodically and inspect the terminals for

moisture and corrosion.

Hazardous Locations

Installations

Rosemount 2088, 2090P, and 2090F transmitters are designed with

explosion-proof electronics enclosures and circuitry that complies with

intrinsic safety requirements and non-incendive operation. Individual

transmitters are clearly tagged with approvals. Refer to Section 5:

Specifications and Reference Data for a complete list of available approvals.

To maintain certified ratings for installed transmitters, install with applicable

installation codes and approval drawings.

NOTE

Once a device labeled with multiple approval types is installed, it should not

be reinstalled using any other approval types. Permanently mark the approval

label to distinguish it from unused approval types.

3-4

Page 5

Reference Manual

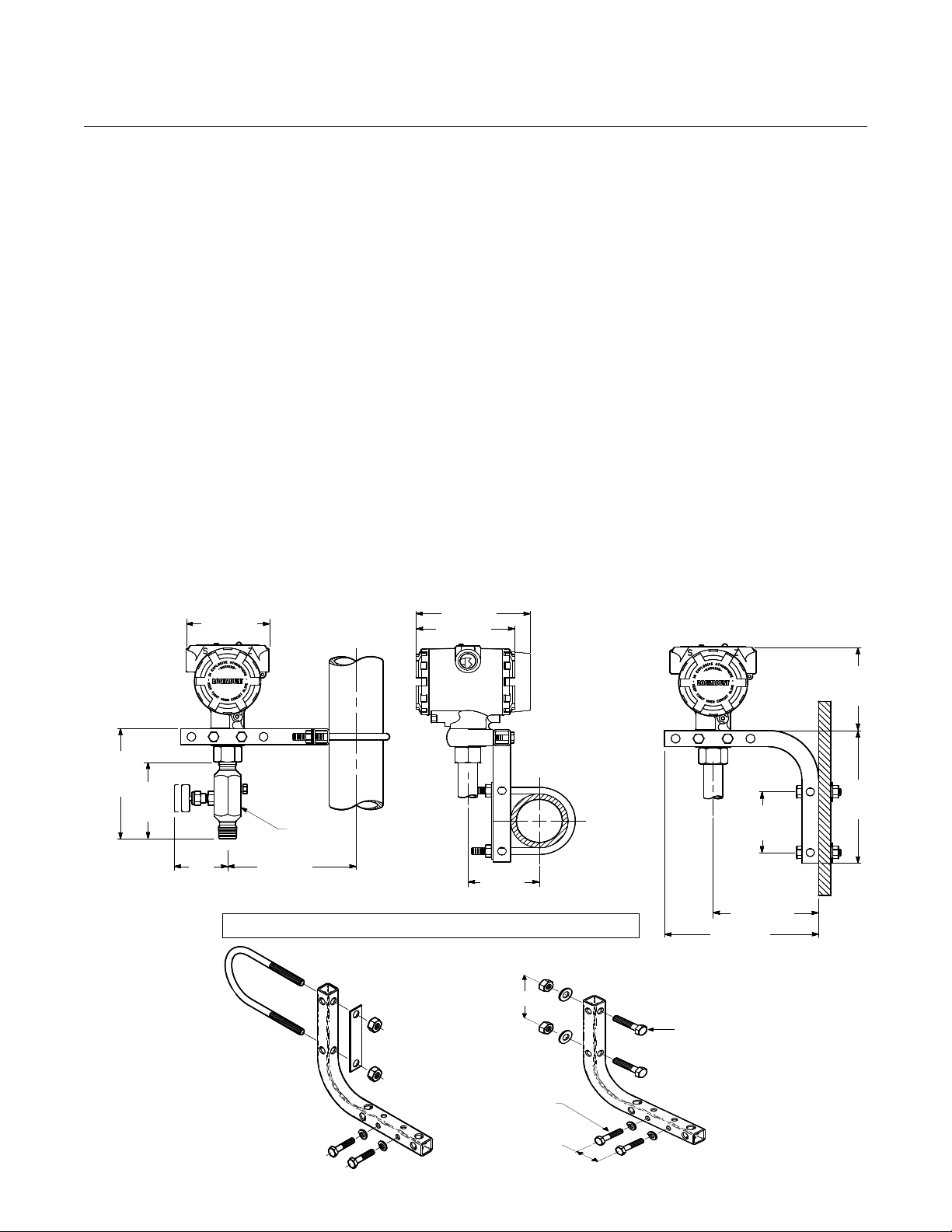

2-inch U-Bolt

for Pipe Mounting

NOTE

Dimensions are in. (mm).

1.30 (33)

2.81 (71)

PIPE MOUNTING

PANEL MOUNTING

Mounting bracket ordering code B4, and optional block and bleed valve.

5

/16 × 1½ Bolts

for Panel Mounting

(not supplied)

5

/16× 1½ Bolts

for Panel Mounting

(not supplied)

3.9 (100)

5.0 (125)

4.3 (110)

6.0 (150)

2.5

(63)

3.6

(90)

5.0

(139)

1.25 (32)

HEX

3.0 (80)

3.9

(100)

6.2

(160)

2.8

(70)

4.75 (120)

7.0 (175)

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

MECHANICAL CONSIDERATIONS

Mounting

Rosemount 2088 The Rosemount 2088 Smart Transmitter weighs approximately 2.44 lb.

(1,11 kg). The 2088 Analog Transmitter weighs approximately 1.9 lb.

(0,86 kg). In many cases, its compact size and light weight makes it possible

to mount the 2088 directly to the impulse line without using an additional

mounting bracket. When this is not desirable, mount directly to a wall, panel,

or two-inch pipe using the optional mounting bracket (see Figure 3-3).

The 2088 also offers several process connections. Use your plant-approved

thread sealant to ensure a leak-proof connection.

Rosemount 2090P The Rosemount 2090P is designed to be mounted directly to the process pipe

using a weld spud (see Figure 3-7). Mount the transmitter using an existing

weld spud, or install a new one using the instructions on page -9.

Rosemount 2090F The Rosemount 2090F is designed to be mounted directly to the process pipe

using a standard sanitary fitting (see Figure 3-8). The transmitter is available

with either a 1.5- or 2-inch Tri-Clamp

®

connection.

Figure 3-2. Transmitter

Mounting Configurations with

Optional Bracket.

3-5

Page 6

Reference Manual

GAS

SERVICE

LIQUID OR STEAM

SERVICE

GAS OR LIQUID

SERVICE

00809-0100-4690, Rev EA

Rosemount 2088 and 2090

March 2007

Impulse Piping Impulse piping configurations depend on specific measurement conditions.

Use the following information and Figure 3-3 as a guideline when installing

impulse piping.

Liquids: Make the line tap on the side of the pipe to prevent sediment

deposits from plugging the impulse line or transmitter. Mount the transmitter

level with or below the tap so gases vent into the process line.

Gases: Make line taps on either the top or the side of the process line. Mount

the transmitter level with or above the line tap so liquids drain into the process

line.

Steam: Make line taps in the side of the process line. Mount the transmitter

below the line tap to ensure that the impulse line remains filled with

condensate.

NOTE

Installing a “T”-connection with a shut-off valve in the impulse line between

the transmitter and the valve to the process line will allow you to vent the

transmitter to atmosphere, thereby enabling calibration without removing the

transmitter.

Figure 3-3. Transmitter

Mounting Configurations for

Liquids, Gases, and Steam

3-6

NOTE

In steam or other high-temperature services, the temperature at the process

connection must not exceed the process temperature limit of the transmitter,

which is 250 °F (121 °C).

In steam service above 250 °F (121 °C), fill impulse lines with water to prevent

steam from contacting the transmitter. Condensate chambers are not

necessary since the volumetric displacement of the Rosemount 2088

is negligible.

Page 7

Reference Manual

* M20 1.5 Female (CM20), PG 13.5, and G

1

/2 Female (PF 1/2) also available as options.

†

DIN 16288 G

1

/2 Male, RC 1/2 Female (PT 1/2), and M20 1.5 Male (CM20) also available.

2 ½–14 NPT*

Conduit

Connection

Terminal

Connections

5.0 (125)

Optional Meter Cover

Transmitter Circuitry

Certifications Tag

2 ¼–20 UNC-2B

Mounting Holes

½–14 NPT

Female† Process Connection

4.3 (110) Max.

3.9 (100)

0.75 (20)

Clearance for

Cover Removal

4.7

(120)

5.75

(146)

Rosemount 2088

2.38

(60)

5.0 (125)

Optional Meter Cover

Transmitter Circuitry

Terminal

Connections

M44 1.25

Weld Spud

2

1

/4–20 UNC–2BX

Depth 0.60

Mounting Holes

4.7

(120)

3.9 (100)

0.82

(21)

Weld Spud

Certification Tag

4.3 (110)

Rosemount 2090P (1.5-in.)

Vessel Wall

NOTE: Dimensions are in. (mm).

5.1(130)

Typical

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

Access Requirements When choosing a mounting location and position, take into account the need

for access to the transmitter.

Make wiring terminations through the conduit openings at the top of the

electronics housing. The field terminal side of the transmitter is clearly marked

on the transmitter neck. Test terminals are incorporated on the terminal block;

you do not need access to the electronics compartment to perform calibration

procedures.

The transmitter electronics compartment contains the electronics module with

failure mode and security jumpers, and the optional LCD meter. Consider the

need for access to both compartments when installing the transmitter. Refer

to Figure 3-5 for transmitter dimensional drawings.

Figure 3-4. Smart Transmitter Dimensional Drawings.

3-7

Page 8

Rosemount 2088 and 2090

Nameplate

3.9

(100)

2X

1

/4–20 UNC–2BX 0.60 Deep

Mounting Bracket Holes

4.7 (140)

Terminal

Connections

Transmitter Circuitry Side

Optional Meter Cover

5.0 (125)

Weld Spud

1.0 (25.4)

Vessel Wall

4.3 (110)

1.05 (26.6)

1.32 (33,4)

5.75 (146)

3X

5

/16–18 UNC

Mounting Holes for

Rotational Mounting

0.7 (17,8)

O-ring (Viton

®

standard)

External Zero/Span (under Nameplate)

1.03 (26.2)

Rosemount 2090P Compatible with 1-in. PMC® Process Connection

11/2 or 2-in. Tri-Clamp Connection

2

1

/4–20 UNC–2BX 0.60

Deep Mounting Holes

4.7

(120)

3.9 (100)

* M20 1.5 Female (M20) and PG 13.5 also available.

NOTE: Dimensions are in inches (millimeters).

Optional Meter Cover

Transmitter Circuitry Side

Terminal

Connections

5.0 (125)

4.3 (110)

Certifications Tag

Rosemount 2090F

Reference Manual

00809-0100-4690, Rev EA

March 2007

3-8

Page 9

Reference Manual

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

Rosemount 2090P Installing the Rosemount 2090P transmitter involves attaching a weld spud to

the tapped process vessel, attaching the transmitter to the weld spud, and

making electrical connections. If you intend to use an existing weld spud,

proceed to the transmitter section of this installation procedure.

NOTE

The Rosemount 2090P Isolating Diaphragm can be mounted flush with the

inside diameter of any vessel larger than three inches in diameter.

Installation of the weld spud should be performed by a skilled welder using a TIG welder.

Improper installation may result in weld spud distortion.

Weld Spud

1. Using the appropriate size hole saw, cut a hole in the process vessel

to accept the weld spud. The diameter for a weld spud with heat

isolator groove is 2.37 inch (60 mm); when compatible with 1-in.

®

PMC

process connection style spud, diameter is 1.32 in. (33,4 mm).

The hole should produce a tight, uniform fit when coupled with the

weld spud.

2. Bevel the edge of the vessel hole to accept filler material (see Figure

3-5).

®

3. Remove the weld spud from the transmitter and remove the Teflon

gasket from the weld spud.

Excessive heat will distort the weld spud. Weld in sections, as shown in Figure 3-5,

cooling each section with a wet cloth. Allow adequate cooling between passes.

To reduce the chances of distorting the weld spud (for 1.5-in. connection), use a heat

sink—Rosemount Part Number 02088-0196-0001.

4. Position the weld spud in the vessel hole, place heat sink and tack

spud in place using the welding sequence shown in Figure 3-5. Cool

each section with a wet cloth before proceeding to the next section.

5. Weld the spud in place using 0.030 to 0.045 in. (0,762 to 1,143 mm)

stainless steel rod as filler in the bevelled area. Using between 100

and 125 amps., adjust the amperage for 0.080 in. (2,032 mm)

penetration.

Transmitter

1. After the weld spud has cooled, remove the heat sink and install the

Teflon gasket into the weld spud. Ensure that the gasket is properly

positioned within the weld spud; improper placement could cause a

process leak (see Figure 3-6).

2. Position the transmitter into the spud and begin to engage the

threads. Rotate the transmitter prior to seating the threads completely

to enable access to the housing compartments, the conduit entry, and

the local indicator.

3-9

Page 10

Rosemount 2088 and 2090

PREPARING THE VESSEL HOLE

4

6

8

1

3

5

7

2

Process

Vessel

Bevelled

Edge

Weld Spud

100–125 Amps

recommended

308L SST

2.37 (60)

Code “C” in Model Structure or

P/N 02088-0295-0003

WELDING SEQUENCE

Heat Isolation

Grooves

Teflon Gasket

Nameplate

2 ¼–20

UNC–2BX

Depth 0.60

Mounting

Holes

Bevelled Edge

Vessel

Wall

Weld Spud

DETAIL OF WELD SPUD

Vessel Wall

100–125 Amps

recommended

Weld Spud

Reference Manual

00809-0100-4690, Rev EA

March 2007

Figure 3-5. Installing the Weld Spud.

3. Hand tighten the transmitter using the knurled retaining ring, then

snug an additional

1

/8 turn with adjustable pliers.

IMPORTANT

Do not over-tighten the retaining ring. A spanner wrench (P/N

02088-0193-0001) hole is located on the knurled portion of the retaining ring

to assist in transmitter removal if it is over-tightened.

Figure 3-6. Teflon Gasket Placement.

Figure 3-7. Rosemount 2090P Mounting Configuration Using a Weld Spud.

3-10

Page 11

Reference Manual

Nameplate

1.5- or 2-in.

Tri-Clamp

Connection

1.1 (28)

Typical

User Supplied

Gasket and

Clamp

B

A

DETAIL OF SANITARY

CONNECTION

STANDARD SANITARY CLAMP MODELS

Clamp Model

psi @ 70 °F

(kPa @ 21 °C)

psi @ 250 °F

(kPa @ 121 °C)

Recommended

Torque

13 MHHM 1.5-inch

13 MHHM 2-inch

450 (3 103)

500 (3 448)

250 (1 724)

250 (1 724)

25 in-lb (2.8 N•m)

13 MHHS 1.5-inch

13 MHHS 2-inch

600 (4 138)

550 (3 793)

300 (2 069)

275 (1 896)

25 in-lb (2.8 N•m)

13 MHP 1.5-inch

13 MHP 2-inch

1500 (10 345)

1000 (6 896)

1200 (8 276)

800 (5 517)

20 ft-lb (27 N•m)

CONNECTION SIZE

* Dimensions are in inches (millimeters)

Connection

Size*

A B

1.50 (38) 1.99 (50) 1.71 (43)

2.00 (51) 2.52 (64) 2.22 (56)

Mounting

Hole

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

Rosemount 2090F The Rosemount 2090F sanitary pressure transmitter is designed to be

installed directly to a sanitary fitting. The transmitter is available with either a

1.5- or 2-inch clamp connection.

When installing the transmitter to the sanitary fitting it is important to use the

proper sanitary clamp and gasket (user-supplied). Check the clamp and

gasket specifications before installing. Refer to Standard Sanitary Clamp

Models in Figure 3-8 for a list of standard sanitary clamps, their respective

maximum pressure ranges, and the recommended torque to be applied when

mounting.

Figure 3-8. Rosemount 2090F Mounting Configuration Using a Sanitary Fitting.

ELECTRICAL

CONSIDERATIONS

Power Supply The dc power supply should provide power to the transmitter with less than

The wiring terminations on the Rosemount 2088, 2090P, and 2090F are

located in the side of the transmitter housing marked “FIELD TERMINALS.”

Access to these terminations is required during installation and may be

necessary during periodic calibration of the transmitter.

one percent ripple. The total loop resistance load is the sum of the resistance

of the signal wires and the resistance load of the controller, indicator, and

other pieces of equipment in the loop. Note that the resistance of intrinsic

safety barriers, if used, must be included. Figure 3-9 shows the transmitter

power supply load limitations.

3-11

Page 12

Reference Manual

(1) For CENLEC EX ia Approval, power supply must not exceed 30 volts.

NOTE

Minimum load impedance for Output Code N is 100 kilohms.

Operating

Region

Max. Load = 45.4 (Power Supply Voltage) –10.5

10.5 15 20 25 30

(1)

36

POWER SUPPLY (DC VOLTS)

LOAD (OHMS)

1158

1000

800

600

400

200

0

00809-0100-4690, Rev EA

Rosemount 2088 and 2090

March 2007

Figure 3-9. Transmitter

Load Limitations

Field Wiring All power to the transmitter is supplied over the signal wiring. Signal wiring

need not be shielded, but use twisted pairs for best results. Do not run

unshielded signal wiring in conduit or open trays with power wiring, or near

heavy electrical equipment. For high EMI/RFI environments, shielded twisted

pair cable should be used. To power the transmitter, connect the positive

power lead to the terminal marked “PWR/COMM+” and the negative power

lead to the terminal marked “–” (see Figure 3-10). Tighten the terminal screws

to ensure that proper contact is made. Avoid contact with the leads and the

terminals. No additional power wiring is required for transmitters with

4-20 mA output. For low power transmitters, connect positive signal lead to

“test +” and negative signal lead to terminal marked “-.”

3-12

To connect test equipment for monitoring the output of the Rosemount 2088

Smart during maintenance procedures, connect one lead to the terminal

labeled “TEST+” and the other lead to the terminal labeled “–” (see Figure

3-10). Avoid contact with the leads and the terminals.

Signal wiring may be grounded at any one point on the measurement loop, or

it may be left ungrounded. The negative side of the power supply is a

recommended grounding point. The transmitter case may be grounded or left

ungrounded.

Conduit connections at the transmitter should be sealed to prevent moisture

accumulating in the field terminal side of the transmitter housing. Also, install

wiring with a drip loop with the bottom of the drip loop lower than the conduit

connection of the transmitter housing.

Page 13

Reference Manual

Positive

Negative

Tes t

00809-0100-4690, Rev EA

March 2007

Figure 3-10. Rosemount 2088

Smart Signal Wiring Terminals.

FAILURE MODE AND

SECURITY JUMPERS

Rosemount 2088 and 2090

Failure Mode

As part of normal operation, the Rosemount 2088/2090 Smart Pressure

Transmitter continuously monitors its own operation. This automatic

diagnostic routine is a timed series of checks repeated continuously. If the

diagnostic routine detects a failure in the transmitter, the transmitter drives its

output either below or above specific values depending on the position of the

failure mode jumper or switch.

The values to which 4–20 mA transmitters drive their output in failure mode

depend on whether they are factory-configured to standard or

NAMUR-compliant operation. The values for each are as follows:

Standard Operation

Linear output: 3.9 ≤ I ≤ 20.8 mA

Fail low: I ≤ 3.75 mA

Fail high: I ≥ 21.75 mA

NAMUR-Compliant Operation (Option Code C4)

Linear output: 3.8 ≤ I ≤ 20.8 mA

Fail low: I ≤ 3.6 mA

Fail high: 21.0 ≤ I ≤ 23.0 mA

To determine the failure mode configuration of your transmitter, review the

failure mode options using a 275 HART Communicator.

NOTE

The failure mode configuration, whether standard or NAMUR-compliant, is

configured at the factory and can not be changed in the field.

Jumper Locations Without a meter installed

The failure mode alarm jumper is located on the front side of the electronics

module just inside the electronics housing cover and is labeled ALARM (See

Figure 3-11). Do not remove the transmitter cover in explosive atmospheres

when the circuit is alive. Both covers must be fully engaged to meet

explosion-proof requirements.

3-13

Page 14

Reference Manual

Alarm

Security

Alarm

2088A05A, 2088A05B

Security

Alarm

Security

Alarm

Security

2088A05, 2088A05C

00809-0100-4690, Rev EA

Rosemount 2088 and 2090

March 2007

With a meter installed

The failure mode alarm jumper is located on the LCD faceplate in the

electronics module side of the transmitter housing and is labeled ALARM

(See Figure 3-11). Do not remove the transmitter cover in explosive

atmospheres when the circuit is alive. Both covers must be fully engaged to

meet explosion proof requirements.

Transmitter Security After commissioning the transmitter, you may wish to protect the configuration

data from unwarranted changes. The transmitter is equipped with a security

jumper that can be positioned to prevent changes to the configuration data

(see Figure 3-11). The circuit board is electrostatically sensitive. Observe

handling precautions for static-sensitive components to avoid circuit board

damage.

When the transmitter security jumper is in the “ON” position, the transmitter

will not accept any “writes” to its memory. This means that configuration

changes (such as digital trim and reranging) cannot take place when the

transmitter security is on. To reposition the jumper, use the following

procedure.

1. If the transmitter is installed, secure the loop, and remove power.

2. Remove the housing cover opposite the field terminal side. Do not

remove the instrument cover in explosive atmospheres when the

circuit is alive.

3. Reposition the jumper. Avoid contact with the leads and the terminals.

Refer to Figure 3-11 for the location of the jumper and the ON and

OFF positions.

4. Reattach the transmitter cover. The cover must be fully engaged to

comply with explosion-proof requirements.

Figure 3-11. Transmitter Alarm

and Security Jumper Locations

Without LCD Meter Low Power without LCD Display

With LCD Meter Low Power with LCD Display

.

3-14

Page 15

Reference Manual

Span and Zero Adjustment Buttons

00809-0100-4690, Rev EA

March 2007

Rosemount 2088 and 2090

NOTE

If either the alarm or security jumper is dislodged or removed from its position

the transmitter reverts to default alarm or security settings of: Alarm: Output

high; Security: Off

ZERO AND SPAN

ADJUSTMENTS

The smart Rosemount 2088 is equipped with local zero and span adjustment

buttons. The buttons are located on the top of the transmitter beneath the

certifications label. Use the zero and span adjustments to set the 4 and 20 mA

output points.

Rerange Procedure To rerange the transmitter using the span and zero buttons, perform the

following procedure.

1. Loosen the screw holding the nameplate on top of the transmitter

housing and rotate the nameplate to expose the zero and span

buttons (see Figure 3-12).

2. Using a pressure source with an accuracy three to ten times the

desired calibrated accuracy, apply a pressure equivalent to the lower

range value.

3. To set the 4 mA point, press and hold the zero button for at least two

seconds, then verify that the output is 4 mA. If a meter is installed, it

will display ZERO PASS.

4. Apply a pressure equivalent to the upper range value.

5. To set the 20 mA point, press and hold the span button for at least two

seconds, then verify that the output is 20 mA. If a meter is installed, it

will display SPAN PASS.

NOTE

If the transmitter security jumper is in the “ON” position, or if the local zero and

span adjustments are disabled through the software, you will not be able to

make adjustments to the zero and span using the local buttons. Refer to

Figure 3-11 on page -14 for the proper placement of the transmitter security

jumper.

Figure 3-12. Local Zero

and Span Adjustments

3-15

Page 16

Rosemount 2088 and 2090

Disabling the Zero

and Span Adjustments

After you rerange the transmitter using the span and zero adjustments, you

may wish to disable the adjustments to prevent further reranging. To disable

the span and zero adjustments, activate the transmitter security jumper (see

“Transmitter Security” on page -14).

NOTE

The transmitter security jumper prevents any changes to the transmitter

configuration data. The software lockout sequence only disables the local

span and zero adjustment buttons.

Reference Manual

00809-0100-4690, Rev EA

March 2007

3-16

Loading...

Loading...