Emerson YARWAY B, YARWAY C Installation, Operation And Maintenance Instructions

YARWAY SEATLESS BLOW-OFF VALVES

Type b and Type c

Installation, operation and maintenance instructions

PRINCIPLE OF OPERATION

The seatles blow-off valve is a manually

operated sliding primarily for boiler blow-off

service where high temperature fluid,

containing dirt, sediment and scale, is

encountered.

When the valve is open (Fig. 2) the controlled

fluid passes through the ports in the plunger

(8) and lower gland (5) and discharges to the

valve outlet via the center of the plunger

assembly. In the closed position the shoulder

of the plunger assembly contacts the upper

gland (6). This feature provides additional

loading from the handwheel to compress the

packing rings (3) (4) and assure leak-tight

shut-off. Any packing relaxation during service

is accommodated by the heavy compression

springs (14) which provide a constant packing

load.

VALVE OPERATION

Open the valve quickly and fully. Never use this

valve to throttle the flow in the partly open

condition as this will reduce the packing life.

Close the valve in the same manner. Apply a

hard turn at the end of the valve travel. This

will assure that the plunger seats against the

upper gland which, in turn, will recompress

the packing rings.

In operating Yarway seatless valves in tandem,

the valve next to the boiler should be used as

the blowing valve, opened last and closed first.

The outside or sealing valve should be opened

first and closed last.

If a Yarway double tghtening valve is used in

tandem with a Yarway seatless valve, the

double tighteningvalve is placed next to the

boiler and is opened first and closed last. The

Seatless or outside valve is the blowing valve

and is opened last and closed first.

WARNING

Hot discharge from this product may cause severe

burns. Discharge must be piped away or directed

so that persons in the vicinity are not endangered.

This product must be isolated, vented and cool to

the touch before repairing or inspecting.

© 2018 Emerson. All Rights Reserved.Emerson.com/FinalControl VCIOM-03114 EN 18/10

YARWAY SEATLESS BLOW-OFF VALVES

Type b and Type c

MAINTENANCE AND ADJUSTMENT

Packing ring adjusment

Yoke nuts (15A) should be tightened at regular

intervals. The yoke springs (14) will maintain a

constant load on the packing. Packing rings

will relax slightly during use and an adjustment

may be required. To adjust the packing,

back the plunger off slightly by turning the

handwheel (do not allow flow to occur) and then

tighten the yoke nuts. Approximately ¼ to ½

turn should be sufficient. Reseat the plunger

against the upper gland.

NOTE:

If the valve has not been operated for a long period, the

packing nuts should be adjusted prior to blowing down

the boiler.

Lubrication

A fitting (2A) is provided on the yoke for

lubricating the ball thrust bearing (11) and the

stem collar. This fitting is compatible with an

Alemite No. 7585 gun. A high temperature

grease equivalent to Texaco Regal AFB2

should be used to lubricate this area. Stem

threads should be kept well lubricated. A good

grade of antiseize compound similar to NeverSeez NS165 should be used. Both of these

areas should be lubricated every six months.

Installation of packing rings

WARNING

This procedure should not be attempted unless all

pressure has been vented from the valve, and its

connecting lines, and the temperature of the valve

is at or near ambient.

Remove the stopscrew (10) then remove the

yoke nuts and springs. Turn the handwheel to

open the valve. This will raise the plunger. Turn

the handwheel to close the valve. This will raise

the yoke. Turn the yoke so that the holes and

studs are out of line and turn the handwheel to

open the valve. The plunger is thus withdrawn

from the valve.

Next, remove the glands and the old packing.

This can be done by using a Yarway gland and

packing puller or similar tool (Fig. 3) in the

following manner: Insert the tool until the

pawls engage the ports in the lower gland.

Tighten the nut on the top of the puller to draw

out the lower gland, upper packing and upper

gland. The lower packing can then be removed

using a hook tool. Care should be exercised,

however, so that the lower packing groove is

not damaged. Install new packing rings, (Fig. 4

or 5) glands and stopscrew in the body and

replace the yoke, with the plunger screwed all

the way up on the stem, in place and using the

yoke nuts pull down the yoke assembly. Next,

place the springs under the nuts and adjust as

previously described.

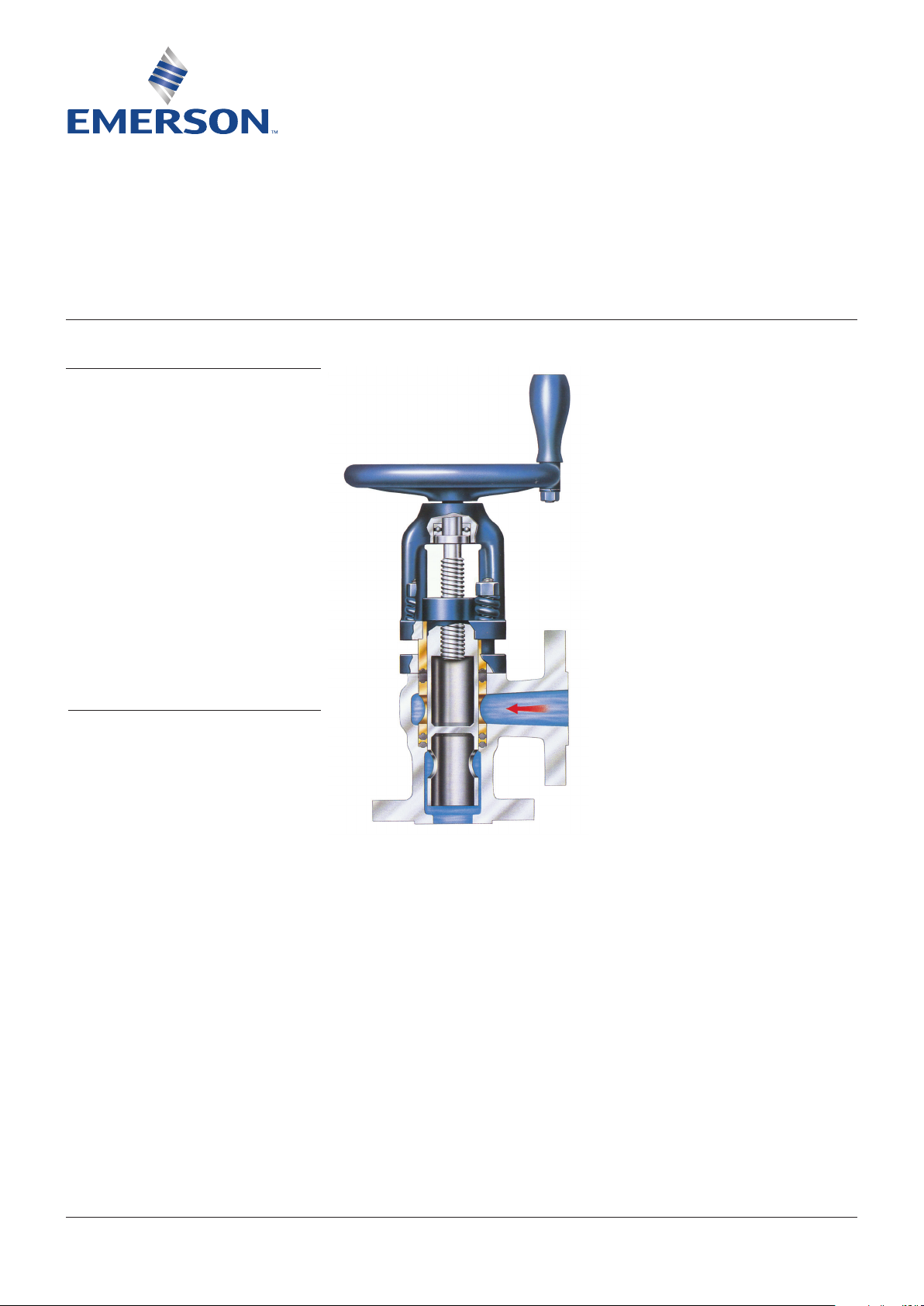

FIGURE 2

Type C angle valve

9A

12

11

2

9

6

4

5

10,10A

3

8

1

TYPE C ANGLE VALVE

Item Description

1 Body

2 Yoke

2A Lubrication fitting

3 Lower packing ring assembly

4 Upper packing ring assembly

5 Lower gland

6 Upper gland

8 Plunger assembly

9 Stem

9A Stem nut

10 Stop screw

10A Stop screw gasket

11 Rail thrust bearing (2 Type C; 1 Type B)

12 Handwheel

13 Extension lever (Type C only)

14 Yoke springs (4 per set)

15 Yoke studs (4 per set)

15A Yoke stud nuts (4 per set)

NOTE:

When ordering parts, use parts numbers and names

shown in table, specify size and type of valve, figure

number and operating pressure (see nameplate on

valve). Maintenance kits for Type B valves include

the following: cast iron valve, 250 psi: upper & lower

glands, packing set, springs, studs, nuts, stop screw,

stop screw gasket, cast steel valve, 300 psi & 400

psi: upper and lower glands, packing set, stem, ball

bearing, springs, studs, nuts, stop screw gasket.

2A

15

15A

14

2

Loading...

Loading...