Emerson Yarway 9200 Series, Yarway ARC 9200 Series Installation And Maintenance Instructions Manual

YARWAY 9200 SERIES ARC® VALVES 2", 3" AND 4"

InstallatIon and maIntenance InstructIons

Before installation these instructions must be fully read and understood

OPERATION

Flow through the check valve overcomes the

spring force to open the main check valve

element. When the disc lifts in response to

an increase in main flow, the bypass flow is

decreased as the port openings in the disc stem

begin to close. Conversely, as the pump flow is

reduced, the check disc moves downward and

at a designated point starts to uncover the disc

stem ports allowing bypass flow to begin.

The sizing of the main check/trim is such that

the bypass flow starts before the main flow

drops below the minimum pump flow specified.

The combined main and bypass flows provide

a total greater than the minimum pump flow

requirement.

GENERAL

These sizes in the 9200 ARC® (Automatic

Recirculation Control) valve series are designed

to provide protection for low to moderate

pressure (ASME/ANSI 150 and 300 Class)

centrifugal pumps against overheating and

possible unstable operation during low load

periods. The valve functions simultaneously

as (1) a check valve - to prevent reverse flow

through the pump and as (2) a bypass control

valve - to maintain the minimum required

pump flow and provide pressure letdown.

Bypass flow enters the disc stem passage

through the slots and the round ports and

around the annulus in the bypass bushing. It

then continues through the bypass where the

helix element conditions the flow at the valve

bypass outlet. The recirculation flow rate is

controlled by the disc slot sizing. Occasionally

higher pressure applications may require the

use of a Back Pressure Regulator (BPR) in the

bypass line for proper pressure letdown.

Engineering doc. #972562 Rev. A

© 2017 Emerson. All Rights Reserved.valves.emerson.com VCIOM-03341-EN 17/05

YARWAY 9200 SERIES ARC® VALVES 2", 3" AND 4"

InstallatIon and maIntenance InstructIons

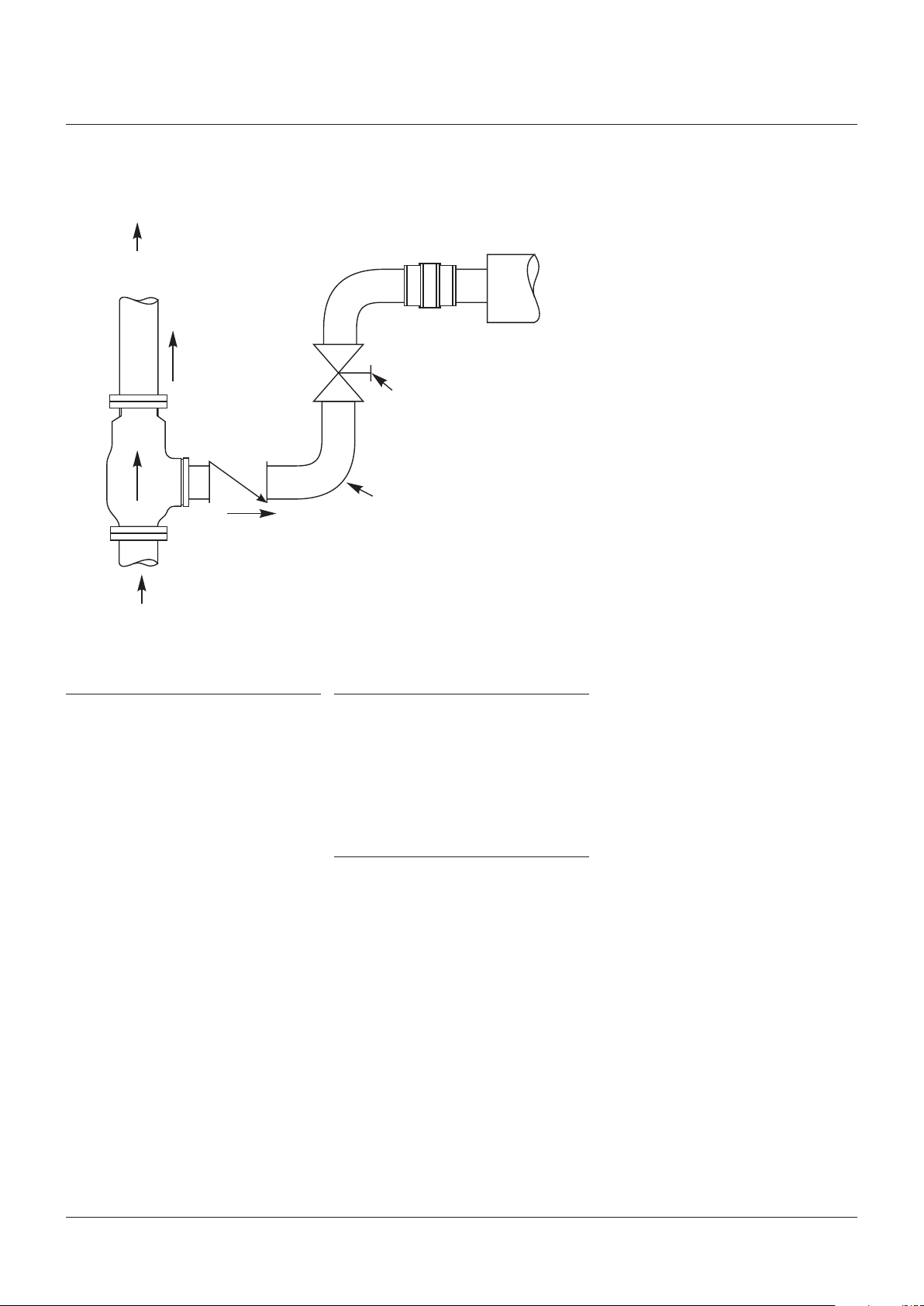

FIGURE 1

3 diameters straight pipe

minimum recommended

atvalve outlet

BPR

if required

To process

Main flow

Shut off valve

Optional

checkvalve

Long radius pipe

Bypass flow

bends typical

Receiver vessel

5 diameters straight pipe minimum

recommended at valve inlet

From pump

INSTALLATION (REFER TO FIGURE 1)

The 9200 Series valve is sized and configured

based on specifications provided by the user.

Make certain that these conditions are still

applicable. Changes in pressure, temperature,

normal main flow and minimum flow

requirements could result in unsatisfactory

performance. If operating conditions have

changed, contact Yarway; modifications

mayberequired prior to installation.

Remove all packing material. Place the valve

on wooden blocks with the flow arrow pointed

down. Push the disc from its seat and flush

away any packing materials with compressed

air or high pressure water. The disc should

move freely (against the spring load) through

the entire stroke length until contacting the

upper stop. This may not be practical on

larger sizes.

The valve may be installed with the main flow

direction either horizontal or vertically up.

Thedirection of bypass flow may be selected

tosuit the installation.

OPERATIONAL CHECK

When the valve is properly installed the

combined main and bypass flows should equal

or exceed that of the specified minimum pump

flow. If operational checks indicate a deviation

from the original specifications and field

adjustments are necessary, contact Yarway

for additional information.

VALVE MAINTENANCE

Except for periodic operational checks the

valve requires little maintenance. The disc

assembly, spring, bypass bushing and flow

conditioner should be inspected coincident

withother annual inspections. Make certain

that all pressure is relieved and the pipeline

is securedagainst pressurization before

attempting disassembly for inspection

purposes.

2

Loading...

Loading...