Page 1

Bulletin 74.2:Y696

Type Y696 Vapor Recovery Regulator

January 2010

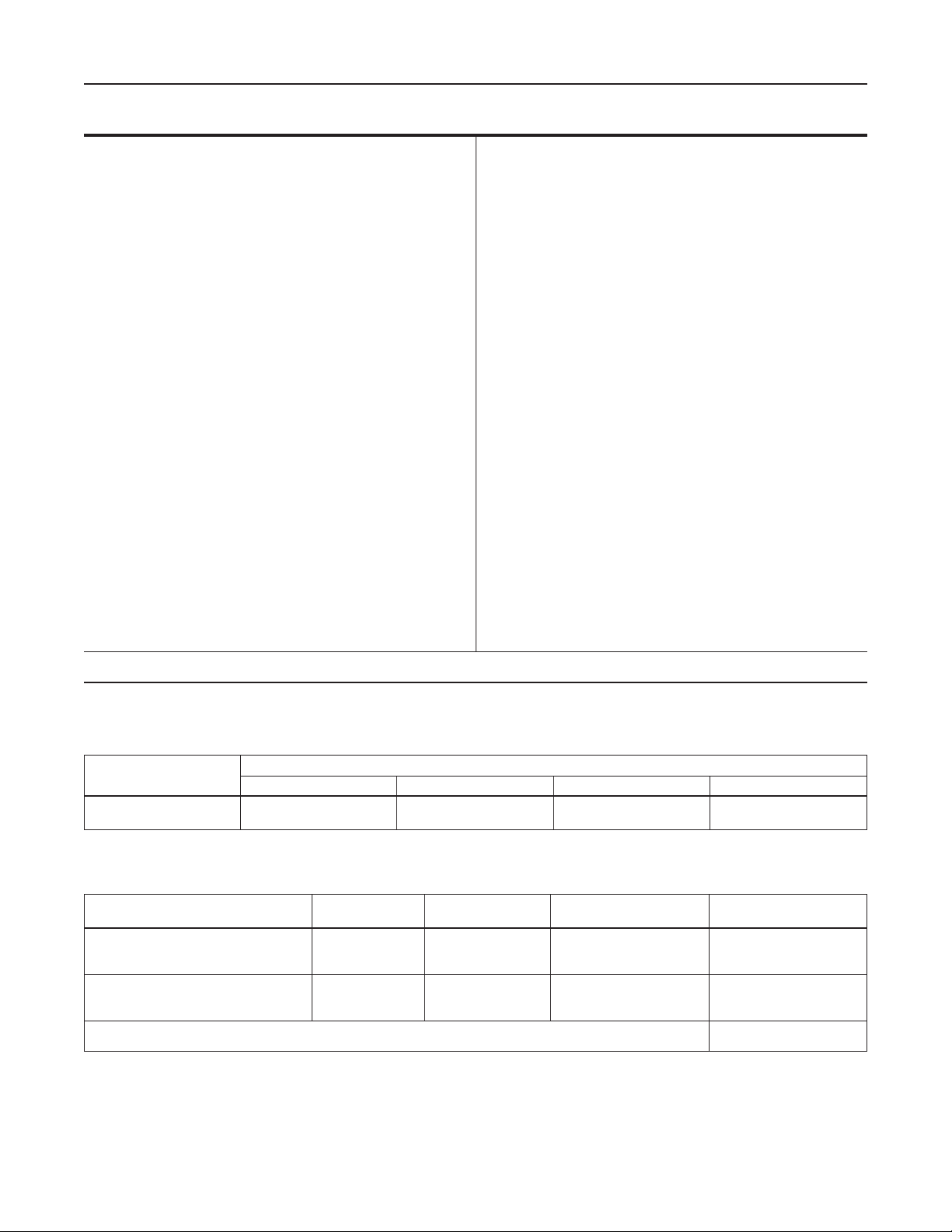

W5996

Figure 1. Type Y696 Vapor Recovery Regulator

Features

• Simplicity—Direct-operated, straight forward stem and

lever design minimizes the number of parts while

providing excellent regulation of pressure.

• Precision Control—Large diaphragm area provides very

accurate throttling control at low set pressures.

• Rugged Construction—Heavy duty castings and

internal parts are designed to lessen vibration and shock.

• Ease of Inspection and Maintenance—The union nut

connection permits maintenance or inspection of critical

parts without removing the body from the line.

• Variety of Construction Materials—Body and lower

casing are available in cast iron, steel, stainless steel,

or Hastelloy® C. Spring case is available in cast iron,

steel, or stainless steel. Trim is available in stainless

steel or Hastelloy® C.

Introduction

The Accu-Pressure™ Type Y696 is a direct-operated vapor

recovery regulator with internal registration, requiring no

downstream control line. This regulator is used to sense

an increase vessel pressure and vent excessive internal

tank pressure to an appropriate vapor recovery disposal

or reclamation system. However, inlet pressures, outlet

pressures, and other performance characteristics vary

according to construction.

Hastelloy® C is a mark owned by Haynes Internatio nal, Inc.

D102054X012

www.sherregulators.com

Page 2

Bulletin 74.2:Y696

Specications

Body Size and End Connection Style

(1)

See Table 1

Maximum Allowable Inlet and Outlet Pressure

15 psig (1,0 bar)

Orice Diameter

1-inch (25 mm)

Control Pressure Ranges

See Table 2

Flow Capacities

See Table 7

Wide-Open Flow Coefcients

CV: 14.7

Cg: 515

C1: 35

Pressure Registration

Internal

Vent Connections

1/4 NPT

Spring Case Connection

1/4 NPT

Common Services and Material Compatibility

See Tables 3 and 4

Temperature Capabilities

Nitrile (NBR): -20° to 180°F (-29° to 82°C)

(2)

Fluorocarbon (FKM): 40° to 300°F (4° to 149°C)

Peruoroelastomer (FFKM): 0° to 300°F (-18ۜ° to 149°C)

(2)

Ethylenepropylene (EPDM): -20° to 275°F (-29° to 135°C)

Approximate Weight

Cast iron: 45 pounds (20 kg)

Steel and Stainless Steel: 57 pounds (26 kg)

Construction Materials

Body and Union Nut: Cast iron, Steel,

CF8M Stainless steel, or Hastelloy® C

Spring Case: Cast iron, Steel, or CF8M Stainless steel

Diaphragm Case Assembly: Cast iron, Steel,

CF8M Stainless steel, or Hastelloy® C

Control Spring, Control Spring Seat, and

Diaphragm Plate: Plated Steel

Diaphragm: Nitrile (NBR) (standard),

Fluorocarbon (FKM), or Ethylenepropylene (EPDM)

Disk Assembly: 303 Stainless steel disk holder

with Nitrile (NBR) or Ethylenepropylene (EDPM) disk;

316 Stainless steel disk holder with Nitrile (NBR),

Fluorocarbon (FKM), Peruoroelastormer (FFKM), or

Polytetrauoroethylene (PTFE) disk; or Hastelloy® C

disk holder with PTFE disk

Orice, Pusher Post, Lever Assembly, Stem,

and Cotter Pin: 303 Stainless steel,

316 Stainless steel, or Hastelloy® C

Gaskets: Composition

1. End connections for other than U.S. standard can usually be provided, consult your local Sales Ofce.

2. The pressure/temperature limits in this Bulletin or any applicable standard limitation should not be exceeded.

Table 1. Body Sizes and End Connection Style

BODY SIZE,

NPS (DN)

1-1/2 and 2 (40 and 50) NPT

Cast Iron Steel Stainless Steel Hastelloy® C

NPT, SWE, CL150 RF,

CL300 RF, PN 16/25/40

BODY MATERIAL

NPT, SWE, CL150 RF,

CL300 RF, PN 16/25/40

Table 2. Control Pressure Ranges

CONTROL PRESSURE RANGE

2 to 5-inches w.c.

5 to 15-inches w.c.

8-inches w.c. to 1 psig

1 to 2.8 psig

2 to 3.5 psig

4 to 7 psig

1. Spring ranges based on spring case installed pointed down. When installed pointed up, spring range increases 2-inches w.c. (5 mbar).

2. Do not use Fluorocarbon (FKM) diaphragm with these springs at diaphragm temperatures lower than 60°F (16°C).

(5 to 12 mbar)

(12 to 37 mbar)

(20 to 69 mbar)

(69 mbar to 0,19 bar)

(0,14 to 0,24 bar)

(0,28 to 0,48 bar)

(1)(2)

(1)(2)

SPRING PART

NUMBER

1A200127022

1B766627062

0B019427052

0A081127202

0Y066427022

1H802427032

SPRING COLOR

Red

Gray

Dark Green

Orange

Green stripe

Red

SPRING WIRE DIAMETER,

INCHES (mm)

0.135 (3,43)

0.156 (3,96)

0.187 (4,75)

0.250 (6,35)

0.363 (9,22)

0.406 (10,3)

CL150 RF

SPRING FREE LENGTH,

INCHES (mm)

5.38 (137)

6.63 (168)

6.00 (152)

6.00 (152)

6.00 (152)

6.00 (152)

2

Page 3

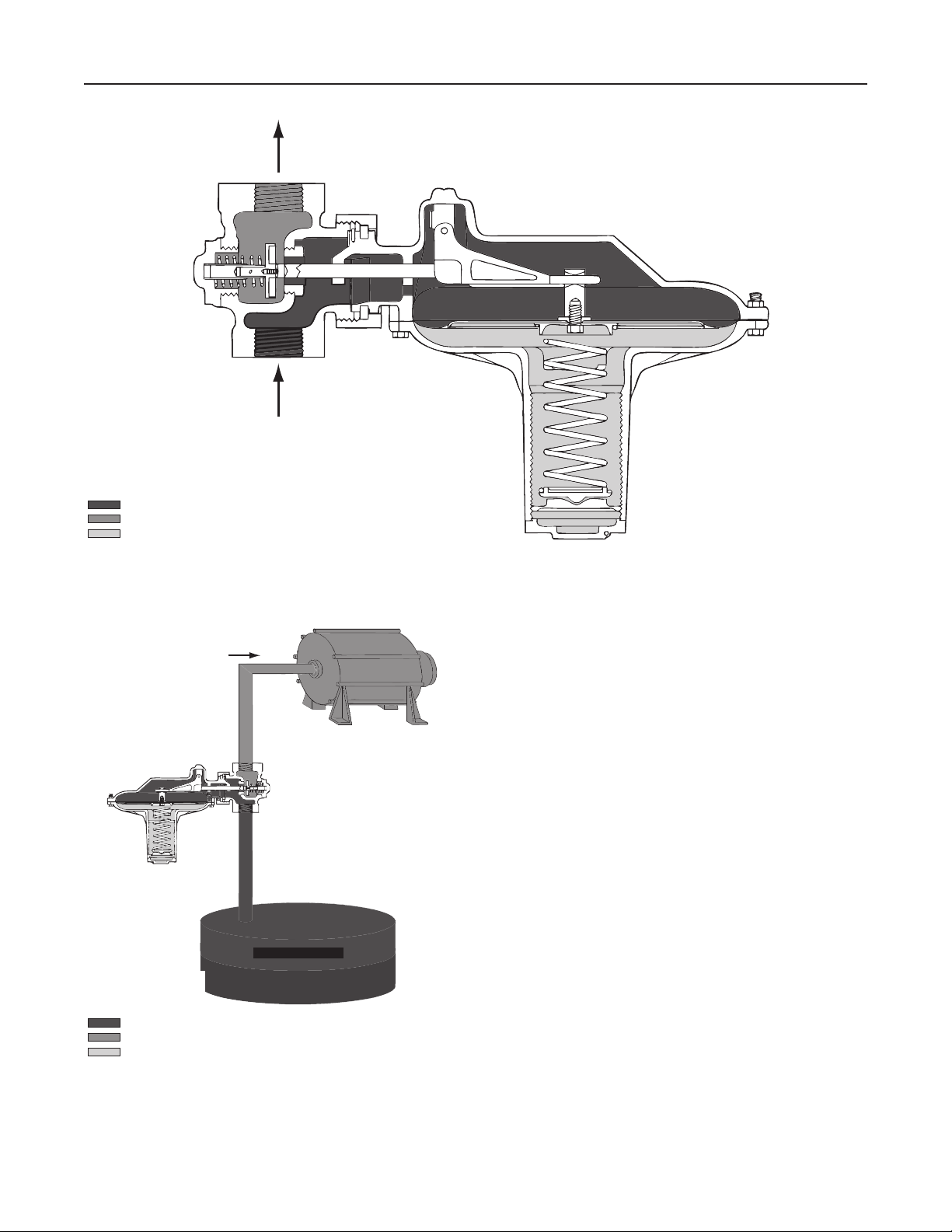

E0751

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Bulletin 74.2:Y696

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Operational Schematic

VAPOR RECOVERY

VACUUM SOURCE

VAPOR PRESSURE

LIQUID

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 3. Principal of Operational Schematic

Principle of Operation

The Type Y696 vapor recovery regulator is used to maintain

a constant blanket (inlet) pressure or vessel pressure with

the outlet owing to a system whose pressure is lower than

that at the inlet.

When vessel pressure increases above the setpoint of the

regulator due to pumping in or thermal heating, the force

of the control spring is overcome by pressure acting on the

diaphragm. This moves the disk away from the orice allowing

gas to ow from the vessel to the vapor recovery system.

As vessel pressure is reduced, the force of the control

spring causes the disk to move toward the orice

decreasing the ow of gas out of the vessel. As vessel

pressure drops below the setpoint of the regulator, the disk

will seat against the orice shutting off the ow of gas.

Sizing Vapor Recovery Systems

To determine the capacity required, you must consider the

amount of blanketing gas that must be displaced from the

tank when either lling the vessel with liquid (pump-in) or the

expansion of tank vapors during atmospheric thermal heating.

Using the established procedures from American Petroleum

Institute Standard 2000 (API 2000), determine the required

ow rate for outbreathing.

3

Page 4

Bulletin 74.2:Y696

Table 3. Fluid Compatibility of Metals

FLUID

Acetaldehyde

Acetic Acid, Air Free

Acetic Acid, Aerated

Acetic Acid Vapors

Acetone

Acetylene

Alcohols

Aluminum Sulfate

Ammonia

Ammonium Chloride

Ammonium Nitrate

Ammonium Phosphate

Ammonium Sulfate

Ammonium Sulte

Aniline

Asphalt

Beer

Benzene (Benzol)

Benzoic Acid

Boric Acid

Butane

Calcium Chloride (Alkaline)

Calcium Hypochlorite

Carbolic Acid

Carbon Dioxide, Dry

Carbon Dioxide, Wet

Carbon Disulde

Carbon Tetrachloride

Carbonic Acid

Chlorine Gas, Dry

Chlorine Gas, Wet

Chlorine, Liquid

Chromic Acid

Citric Acid

Coke Oven Gas

Copper Sulfate

Cottonseed Oil

Creosote

Ethane

Ether

Ethyl Chloride

Ethylene

Ethylene Glycol

Ferric Chloride

Formaldehyde

Formic Acid

Freon, Wet

Freon, Dry

Furfural

Gasoline, Rened

Glucose

A - Recommended

B - Minor to moderate effect. Proceed with caution.

C - Unsatisfactory

IL - Information lacking

Carbon

Steel

A

C

C

C

A

A

A

C

A

C

A

C

C

C

C

A

B

A

C

C

A

B

C

B

A

C

A

B

C

A

C

C

C

IL

A

C

A

A

A

B

C

A

A

C

B

IL

B

B

A

A

A

Cast

Iron

A

C

C

C

A

A

A

C

A

C

C

C

C

C

C

A

B

A

C

C

A

B

C

B

A

C

A

B

C

A

C

C

C

C

A

C

A

A

A

B

C

A

A

C

B

C

B

B

A

A

A

MATERIAL

316

Stainless

Steel

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

B

B

A

A

A

A

B

B

B

C

C

B

A

A

B

A

A

A

A

A

A

A

C

A

B

A

A

A

A

A

Hastelloy® C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

A

A

A

A

IL

B

A

A

A

A

A

A

A

FLUID

Hydrochloric Acid, Aerated

Hydrochloric Acid, Air free

Hydrouoric Acid, Aerated

Hydrouoric Acid, Air free

Hydrogen

Hydrogen Peroxide

Hydrogen Sulde, Liquid

Magnesium Hydroxide

Mercury

Methanol

Methyl Ethyl Ketone

Milk

Natural Gas

Nitric Acid

Oleic Acid

Oxalic Acid

Oxygen

Petroleum Oils, Rened

Phosphoric Acid, Aerated

Phosphoric Acid, Air Free

Phosphoric Acid Vapors

Picric Acid

Potassium Chloride

Potassium Hydroxide

Propane

Rosin

Silver Nitrate

Sodium Acetate

Sodium Carbonate

Sodium Chloride

Sodium Chromate

Sodium Hydroxide

Sodium Hypochloride

Sodium Thiosulfate

Stannous Chloride

Stearic Acid

Sulfate Liquor (Black)

Sulfur

Sulfur Dioxide, Dry

Sulfur Trioxide, Dry

Sulfuric Acid (Aerated)

Sulfuric Acid (Air Free)

Sulfurous Acid

Trichloroethylene

Turpentine

Vinegar

Water, Boiler Feed

Water, Distilled

Water, Sea

Zinc Chloride

Zinc Sulfateilled

Carbon

Steel

C

C

B

A

A

IL

C

A

A

A

A

C

A

C

C

C

A

A

C

C

C

C

B

B

A

B

C

A

A

C

A

A

C

C

B

A

A

A

A

A

C

C

C

B

B

C

B

A

B

C

C

Cast

Iron

C

C

C

C

A

A

C

A

A

A

A

C

A

C

C

C

A

A

C

C

C

C

B

B

A

B

C

A

A

C

A

A

C

C

B

C

A

A

A

A

C

C

C

B

B

C

C

A

B

C

C

MATERIAL

316

Stainless

Steel

C

C

B

B

A

A

A

A

A

A

A

A

A

B

A

B

A

A

A

A

B

A

A

A

A

A

A

A

A

B

A

A

C

A

A

A

A

A

A

A

C

C

B

A

A

A

A

A

B

C

A

Hastelloy® C

B

B

A

A

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

IL

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

1. Determine the ow rate of blanketing gas displaced when

liquid is being pumped in (see Table 6).

2. Determine the gas ow rate due to “outbreathing”

caused by atmospheric thermal heating (see Table 5).

3. Add the requirements of 1 and 2 and select a vapor

recovery regulator size based on total capacity required

from Table 7.

4

Sample sizing problem:

Vessel Capacity . . . . . . . . . 168 000 gallons (636 000 liters)

Pump In Capacity . . . . . . . . . . . . . . . . . 50 GPM (189 l/min)

Desired Vapor Recovery . . . . . . . . . 2-inches w.c. (5 mbar)

Vapor Recovery Vacuum Source . . . . . . . . . . . . 5-inches Hg

1. From Table 6 the desired air ow rate due to pump in

equals 50 GPM (189 l/min) x 8.01 = 400 SCFH

(10,7 Nm3/h) air.

Page 5

Table 4. Fluid Compatibility of Elastomers

FLUID

Acetic Acid (30%)

Acetone

Air, Ambient

Air, Hot [200°F (93°C)]

Alcohol (Ethyl)

Alcohol (Methyl)

Ammonia (Anhydrous)(Cold)

Ammonia (Gas, Hot)

Beer

Benzene

Brine (Calcium Chloride)

Butadiene Gas

Butane (Gas)

Butane (Liquid)

Carbon Tetrachloride

Chlorine (Dry)

Chlorine (Wet)

Coke Oven Gas

Ethyl Acetate

Ethylene Glycol

Freon 11

Freon 12

Freon 22

Freon 114

Gasoline (Automotive)

Hydrogen Gas

Hydrogen Sulde (Dry)

Hydrogen Sulde (Wet)

Jet Fuel (JP-4)

Methyl Ethyl Ketone (MEK)

MTBE

Natural Gas

Nitric Acid (50 to 100%)

Nitrogen

Oil (Fuel)

Propane

Sulfur Dioxide

Sulfuric Acid (up to 50%)

Sulfuric Acid (50 to 100%)

Water (Ambient)

Water [at 200°F (93°C)]

1. Performance worsens with hot temperatures.

A - Recommended

B - Minor to moderate effect. Proceed with caution.

C - Unsatisfactory

N/A - Information not available

Neoprene (CR) Nitrile (NBR) Fluorocarbon (FKM) Ethylenepropylene (EPDM) Peruoroelastomer (FFKM)

B

C

A

C

A

A

A

B

A

C

A

C

A

C

C

C

C

C

C

A

C

A

A

A

C

A

A

B

B

C

C

A

C

A

C

B

A

B

C

A

C

Bulletin 74.2:Y696

MATERIAL

C

C

A

B

C

A

A

C

A

C

A

C

A

A

C

C

C

C

C

A

B

A

C

A

B

A

(1)

A

C

A

C

C

A

C

A

A

A

C

C

C

A

B

C

C

A

A

C

C

C

C

A

B

B

B

A

A

A

A

B

A

C

A

A

B

C

B

A

A

C

C

A

C

C

A

B

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

B

A

C

A

C

C

C

C

C

C

C

B

A

C

B

A

A

C

A

A

A

C

A

C

C

C

A

C

C

A

B

B

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

2. From Table 5 the desired air ow rate = 4000 SCFH

(107 Nm3/h) air due to thermal heating.

3. Total required ow rate = 4400 SCFH (118 Nm3/h) air.

4400 SCFH (118 Nm3/h) converts to 4500 SCFH

(121 Nm3/h) nitrogen.

4. From Table 7, with a 2-inches w.c. (5 mbar), and an outlet

pressure of 5-inches Hg, an NPS 1-1/2 or 2 (DN 40 or 50)

body size would ow 5130 SCFH (137 Nm3/h) nitrogen.

This would satisfy the desired ow rate of 4500 SCFH

(121 Nm3/h) nitrogen.

Capacity Information

Table 7 gives typical nitrogen regulating capacities at

selected inlet pressures and outlet pressure settings. Flows

are in SCFH (at 60°F and 14.7 psia) and Nm3/h (at 0°C and

1,01325 bar) of 0.97 specic gravity nitrogen. For gases of

other specic gravities, multiply the given SCFH capacity

of nitrogen by 0.985, and divide by the square root of the

appropriate specic gravity of the gas required. Then, if

capacity is desired in Nm3/h, multiply SCFH by 0.0268.

5

Page 6

Bulletin 74.2:Y696

Table 5. Gas Flow Required for Thermal Heating (Outbreathing) per API 2000 (Interpolate for Intermediate Sizes)

TANK CAPACITY,

BARRELS

60

100

500

1000

2000

3000

4000

5000

10 000

15 000

20 000

25 000

30 000

35 000

40 000

45 000

50 000

60 000

70 000

80 000

90 000

100 000

120 000

140 000

160 000

180 000

TANK CAPACITY,

GALLONS

2500

4200

21 000

42 000

84 000

126 000

168 000

210 000

420 000

630 000

840 000

1 050 000

1 260 000

1 470 000

1 680 000

1 890 000

2 100 000

2 520 000

2 940 000

3 360 000

3 780 000

4 200 000

5 040 000

5 880 000

6 720 000

7 560 000

OUTBREATHING (FLASH POINT

< 100°F OR NORMAL BOILING POINT

< 300°F), SCFH AIR

60

100

500

1000

2000

3000

4000

5000

10 000

15 000

20 000

24 000

28 000

31 000

34 000

37 000

40 000

44 000

48 000

52 000

56 000

60 000

68 000

75 000

82 000

90 000

TANK CAPACITY,

3

m

10

20

100

200

300

500

700

1000

1500

2000

3000

3180

4000

5000

6000

7000

8000

9000

10 000

12 000

14 000

16 000

18 000

20 000

25 000

30 000

OUTBREATHING (FLASH POINT

< 38°C OR NORMAL BOILING POINT

< 149°C), Nm3/h AIR

1,6

2,7

13,4

26,8

53,6

80,4

107

134

268

402

536

643

750

831

911

992

1072

1179

1286

1394

1501

1608

1822

2010

2198

2412

Table 6. Flow Rate Conversion

MULTIPLY MAXIMUM PUMP RATE OUT: BY TO OBTAIN

U.S. GPM

U.S. GPH

m3/hr

Barrels/hour

Barrels/day

1. Gas ow of blanketing gas to replace liquid pumped out.

(1)

8.021

0.1337

1.01

5.615

0.2340

Table 7. Capacities

OUTLET PRESSURE RANGE,

SPRING PART NUMBER,

AND COLOR

2 to 5-inches w.c.

(5 to 12 mbar)

1A200127022, Red

5 to 15-inches w.c.

(12 to 37 mbar)

1B766627062, Gray

8-inches w.c. to 1 psig

(20 to 69 mbar)

0B019427052, Dark Green

1 to 2.8 psig

(69 mbar to 0,19 bar)

0A081127202, Orange

2 to 3.5 psig

(0,14 to 0,24 bar)

0Y066427022, Green Stripe

4 to 7 psig

(0,28 to 0,48 bar)

1H802427032, Red

SET PRESSURE

2-inches w.c.

(5 mbar)

4-inches w.c.

(10 mbar)

15-inches w.c.

(37 mbar)

21-inches w.c.

(52 mbar)

2 psig

(0,14 bar)

3 psig

(0,21 bar)

5 psig

(0,34 bar)

BUILDUP TO OBTAIN

WIDE-OPEN TRAVEL

2.6-inches w.c.

(6 mbar)

2.6-inches w.c.

(6 mbar)

3.9-inches w.c.

(10 mbar)

7.7-inches w.c.

(19 mbar)

23-inches w.c.

(57 mbar)

3.2 psig

(0,22 bar)

5.87 psig

(0,41 bar)

OUTLET PRESSURE

VACUUM

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

0 psig (0 bar)

2.5 psig (0,17 bar)

5 psig (0,34 bar)

(1)

:

SCFH

SCFH

Nm3/h

SCFH

SCFH

CAPACITIES IN SCFH (Nm3/h)

OF 0.97 SPECIFIC GRAVITY

NITROGEN

1420 (38,1)

5130 (137)

6560 (176)

1680 (45,0)

5200 (139)

6600 (177)

2810 (75,3)

5580 (150)

6850 (184)

3510 (94,1)

5950 (159)

7160 (192)

5820 (156)

7410 (199)

8340 (224)

8790 (236)

10 400 (279)

9770 (262)

12 000 (322)

12 700 (340)

13 100 (351)

6

Page 7

17.44

(443)

10.38

(264)

2.25

(57)

Bulletin 74.2:Y696

7.06

(179)

GAUGE TAP

1/4 NPT

TYPE Y602

VENT

CAST IRON

1/4 NPT VENT

CONNECTION

Figure 4. Dimensions

STEEL OR STAINLESS STEEL

3/4 NPT VENT

To determine regulating capacities at pressure settings not

given or to determine wide-open ow capacities, use the

following formula:

520

Q = CgP1SIN

GT

3417

)

C

∆P

DEG

)

P

1

1

where:

Q = gas ow rate, SCFH

C

P

G = specic gravity of the gas

= gas sizing coefcient

g

= absolute inlet pressure, psia

1

T = absolute temperature of gas at inlet, °Rankine

C

∆P = pressure drop across the regulator, psi

= ow coefcient

1

7.00

14.00

(356)

(178)

8.94

(227)

5.19

(132)

2.94

(75)

5.88

(149)

Ordering Guide

Body Size (Select One)

NPS 1-1/2 (DN 40)

NPS 2 (DN 50)

Body Material and End Connection Style (Select One)

Cast Iron Hastelloy® C

NPT*** NPT*

CL150 RF*

CL300 RF*

WCC Steel CF8M Stainless Steel

NPT*** NPT**

CL150 RF** CL150 RF**

CL300 RF** CL300 RF**

PN 16/25/40* PN 16/25/40*

11.88

(302)

INCHES

(mm)

Installation

Install the regulator using a straight run of pipe the same

size as or larger than the regulator body. Flow through the

regulator body is indicated by the ow arrow cast, stamped

or riveted on the body. If a block valve is required, install

a full ow valve between the regulator and the blanketed

vessel. For proper operation at low setpoint ranges, the

Type Y696 regulators should be installed with the spring

case barrel pointed down.

Ordering Information

Carefully review each specication and complete the

Ordering Guide. To ensure ordering accuracy, please

complete the Specications Worksheet on the last page.

Spring Case Material (Select One)

Cast iron***

WCC Steel***

CF8M Stainless steel**

Diaphragm Case Material (Select One)

Cast iron***

WCC Steel***

CF8M Stainless steel**

Hastelloy® C*

Trim Material (Select One)

303 Stainless steel***

316 Stainless steel (not available with

Ethylenepropylene (EPDM))**

Hastelloy® C (only available with PTFE)*

- continued -

7

Page 8

Bulletin 74.2:Y696

Ordering Guide (continued)

Diaphragm Material (Select One)

Nitrile (NBR) (standard)***

Fluorocarbon (FKM)**

Nitrile (NBR) with PTFE Protector**

Disk Material (Select One)

Nitrile (NBR) (standard)***

Fluorocarbon (FKM)***

Peruoroelastomer (FFKM)*

Ethylenepropylene (EPDM)*

PTFE*

Outlet Pressure Range (Select One)

2 to 5-inches w.c. (5 to 12 mbar) Red***

5 to 15-inches w.c. (12 to 37 mbar) Gray***

8-inches w.c. to 1 psig (20 to 69 mbar) Dark Green***

1 to 2.8 psig (69 mbar to 0,19 bar) Orange***

2 to 3.5 psig (0,14 to 0,24 bar) Green Stripe***

4 to 7 psig (0,28 to 0,48 bar) Red***

Regulators Quick Order Guide

* * * Standard - Readily Available for Shipment

* * Non-Standard - Allow Additional Time for Shipment

Special Order, Constructed from Non-Stocked Parts.

*

Consult your local Sales Ofce for Availability.

Availability of the product being ordered is determined by the component with the

longest shipping time for the requested construction.

Replacement Parts Kit (Optional)

Yes, send one parts kit to match this order.

Vapor Recovery Specication Worksheet

Application Specications:

Tank Size

Pump In Rate

Pump Out Rate

Blanketing Gas (Type and Specic Gravity)

Pressure Requirements:

Control Pressure Setting

Downstream Pressure

Maximum Flow (Q

max

)

Build-up Limitations:

0.25-inches w.c. (0,6 mbar)

1-inch w.c. (2 mbar)

0.5-inches w.c. (1 mbar)

2-inches w.c. (5 mbar)

Others

Other Specications:

Is a tank blanketing regulator required?

Special Material Requirements:

Ductile Iron

Stainless Steel Hastelloy® C

Yes No

Other

Other Requirements:

Steel

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 2001, 2010; All Rights Reserved

Loading...

Loading...