Page 1

Bulletin 74.2:Y695A

Y695A Series Vapor Recovery Regulators

January 2010

W7381

Figure 1. Y695A Series Vapor Recovery Regulators

Features

• Precision Control—Large diaphragm area

provides very accurate throttling control at low

pressure settings.

• Easy Conversion—Changes easily from the

Type Y695A to the Type Y695AM with two O-rings

and a machine screw.

• Rugged Construction—Heavy duty casings and

internal parts are designed to reduce vibration and

shock and give this regulator the ability to

withstand 150 psig (10,3 bar) inlet pressure with

no internal parts damage.

• Simplicity—Direct-operated, straightforward stem

and lever design minimizes the number of parts

while providing excellent regulation of pressure.

Introduction

The Y695A Series are direct-operated vapor recovery

regulators. These regulators are used to sense an

increase in vessel pressure and vent excessive internal

tank pressure to an appropriate vapor recovery disposal

or reclamation system. They may also be used as

backpressure regulators or relief valves.

www.sherregulators.com

D102595X012

Page 2

Bulletin 74.2:Y695A

Specications

Available Congurations

Type Y695A: Direct-operated vapor

recovery regulator.

Type Y695AM: Direct-operated vapor recovery

regulator equipped with a blocked throat and O-ring

stem seal. The lower diaphragm casing is tapped

1/2 NPT for control line connection.

Body Sizes

NPS 3/4 or 1 (DN 20 or 25)

End Connection Styles

See Table 1

Maximum Allowable Inlet (Casing) Pressure

(1)

150 psig (10,3 bar)

Maximum Outlet Pressure

(1)

150 psig (10,3 bar)

Maximum Emergency Inlet Pressure to Avoid

Internal Parts Damage

150 psig (10,3 bar)

Control Pressure Ranges

(1)

See Table 2

Flow Coefcients with Fully Open Disk

Cg: 120, CV: 3.43, C1: 35

Flow Capacities

See Table 4

Orice Size

7/16-inch (11 mm)

Construction Materials

See Table 3

Material Temperature Capabilities

Nitrile:

-20° to 180°F (-29° to 82°C)

Fluorocarbon (FKM):

40° to 300°F (4° to 149°C)

Peruoroelastomer (FFKM):

-20° to 300°F (-29° to 149°C)

Ethylenepropylene (EPDM):

-20° to 300°F (-29° to 149°C)

Pressure Setting Adjustment

Adjusting Screw

Spring Case Vent Connection

1/4 NPT

Diaphragm Case Connection

1/2 NPT

Approximate Weight

19 pounds (9 kg)

(1)

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation should not be exceeded.

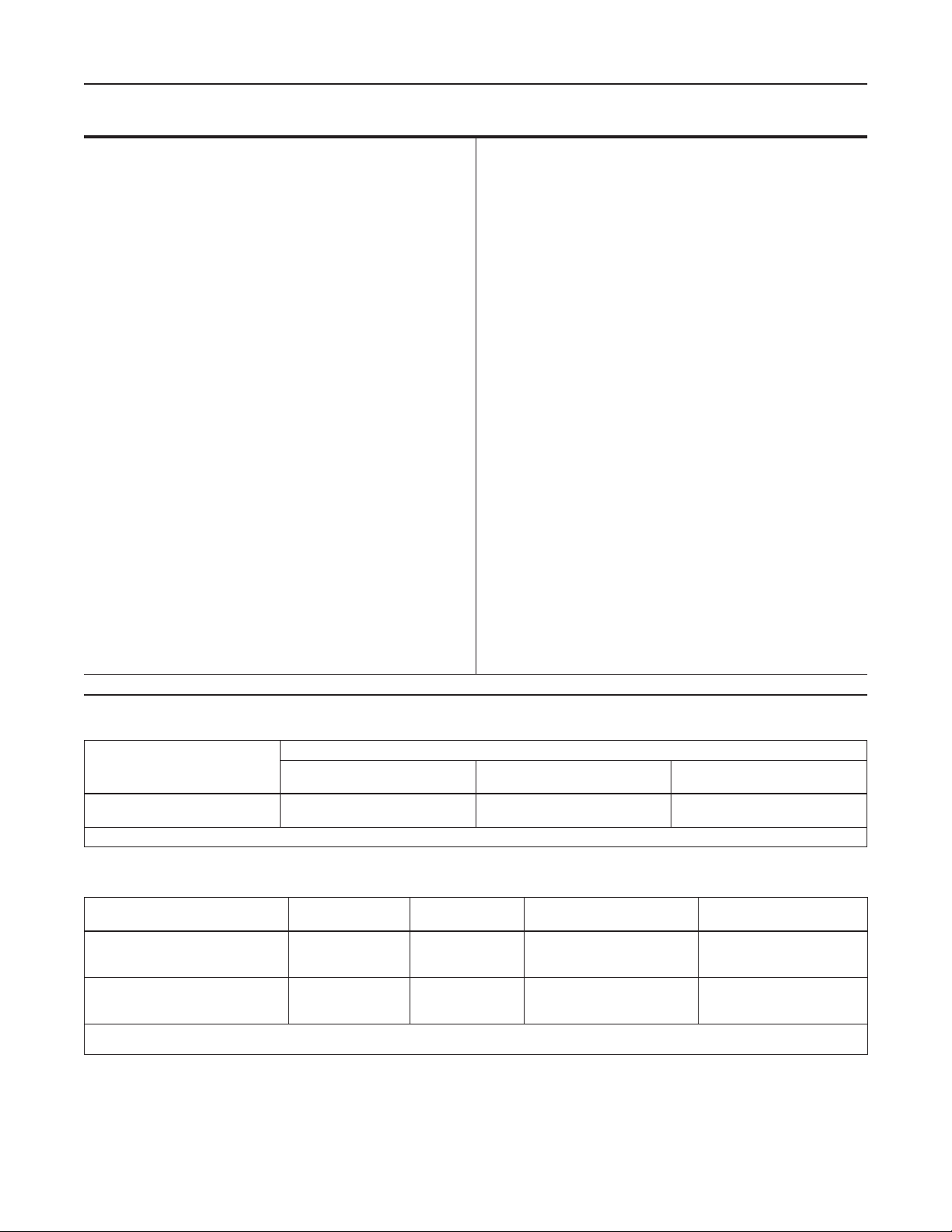

Table 1. End Connection Styles

BODY SIZES,

NPS (DN)

3/4 or 1 (20 or 25) NPT

1. All anges have 14-inches (356 mm) face-to-face.

Ductile Iron

END CONNECTION STYLES

CF8M

Stainless Steel

NPT, ANSI Class 150 RF,

ANSI Class 300 RF, or PN 16/25/40

(1)

Table 2. Control Pressure Ranges

RELIEF SET PRESSURE RANGE

2 to 7-inches w.c.

3 to 13-inches w.c.

10 to 26-inches w.c.

0.9 to 2.5 psig

1.3 to 4.5 psig

3.8 to 7 psig

1. Spring ranges based on spring case installed pointed down. When installed pointing up, the spring ranges increase by 2-inches w.c. (5 mbar).

2. Do not use Fluorocarbon (FKM) diaphragm with these springs at diaphragm temperatures lower than 60°F (16°C).

(5 to 17 mbar)

(7 to 32 mbar)

(25 to 65 mbar)

(0,06 to 0,17 bar)

(0,09 to 0,31 bar)

(0,26 to 0,48 bar)

(1)(2)

(1)(2)

SPRING PART

NUMBER

1B653827052

1B653927022

1B537027052

1B537127022

1B537227022

1B537327052

SPRING COLOR SPRING WIRE DIAMETER FREE LENGTH

Red

Olive drab

Yellow

Light green

Light blue

Black

0.085-inch

0.105-inch

0.114-inch

0.156-inch

0.187-inch

0.218-inch

(2,2 mm)

(2,7 mm)

(2,9 mm)

(4,0 mm)

(4,8 mm)

(5,5 mm)

Hastelloy® C

ANSI Class 150 RF

3.625-inches

3.75-inches

4.188-inches

4.060-inches

3.938-inches

3.980-inches

(92,1 mm)

(95,2 mm)

(106 mm)

(103 mm)

(100 mm)

(101 mm)

2

Page 3

Bulletin 74.2:Y695A

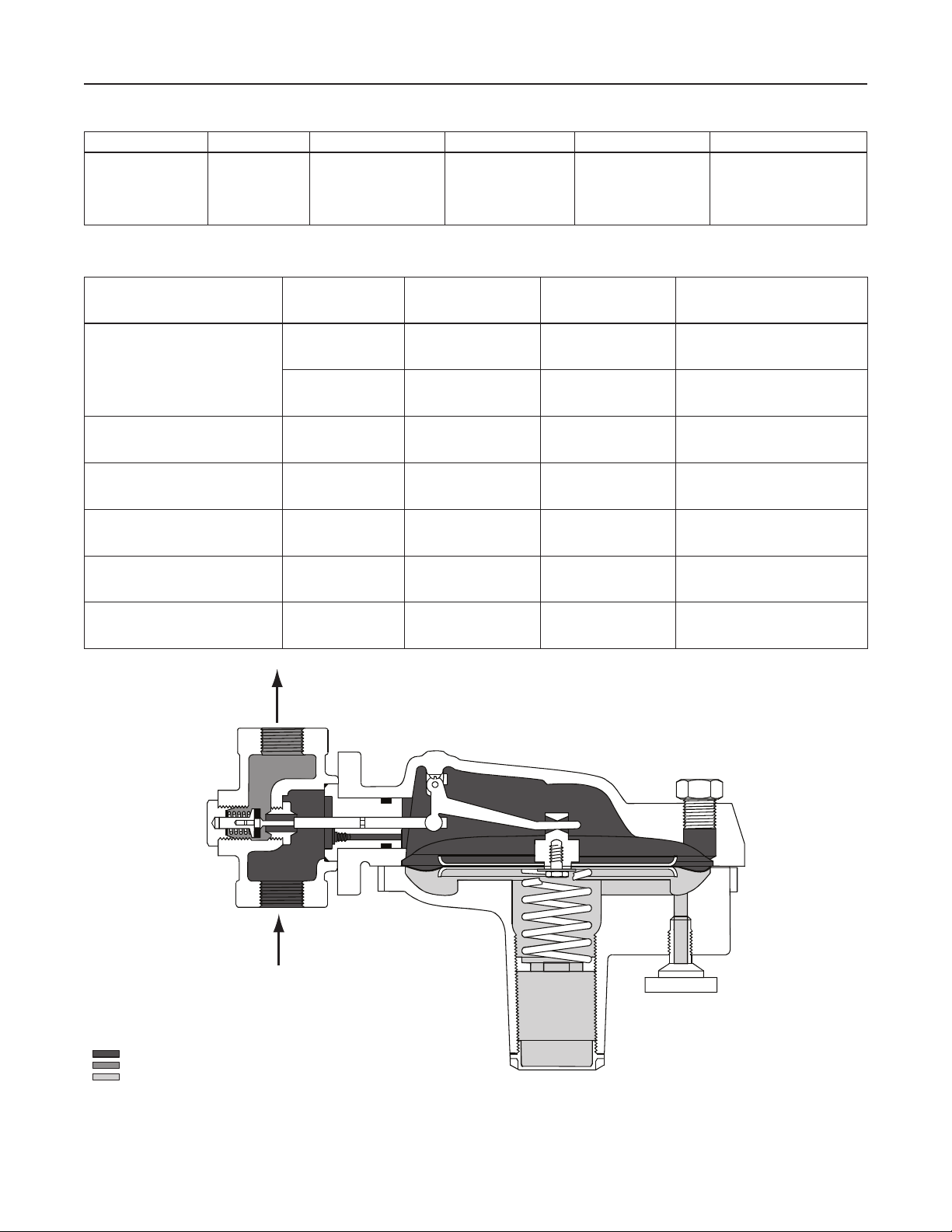

Type Y695A

Type Y695A

MXXXX

January 2010

Type Y695A

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Table 3. Construction Materials

BODY SPRING CASE DIAPHRAGM CASE DISK HOLDER DIAPHRAGM DISK

Ductile iron,

CF8M Stainless steel,

or Hastelloy C

Ductile iron or

CF8M Stainless

steel

Table 4. Y695A Series Capacities

SPRING RANGE,

PART NUMBER, AND COLOR

2 to 7-inches w.c. (5 to 17 mbar)

1B653827052

Red

3 to 13-inches w.c. (7 to 32 mbar)

10 to 26-inches w.c. (25 to 65 mbar)

1B653927022

Olive drab

1B537027052

Yellow

0.9 to 2.5 psig (0,06 to 0,17 bar)

1B537127022

Light green

1.3 to 4.5 psig (0,09 to 0,31 bar)

1B537227022

Light blue

3.8 to 7 psig (0,26 to 0,48 bar)

1B537327052

Black

Ductile iron,

CF8M Stainless steel, or

Hastelloy C

SET PRESSURE

2-inches w.c.

(5 mbar)

4-inches w.c.

(10 mbar)

10-inches w.c.

(25 mbar)

15-inches w.c.

(37 mbar)

1 psig

(0,07 bar)

2 psig

(0,14 bar)

5 psig

(0,34 bar)

316 Stainless steel

or Hastelloy C

MINIMUM BUILDUP TO

WIDE-OPEN

1.5-inches w.c.

(3,7 mbar)

1.5-inches w.c.

(3,7 mbar)

2.3-inches w.c.

(5,7 mbar)

3.4-inches w.c.

(8,5 mbar)

0.40 psig

(0,03 bar)

0.88 psig

(0,06 bar)

1.66 psig

(0,11 bar)

VACUUM OUTLET

Nitrile (NBR),

Fluorocarbon (FKM), or

Nitrile (NBR) with bonded

Teon (PTFE)

PRESSURE

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

0 psig

(0 bar)

2.5 psig

(0,17 bar)

5 psig

(0,34 bar)

SPECIFIC GRAVITY NITROGEN

Nitrile (NBR),

Fluorocarbon (FKM),

Peruoroelastomer (FFKM),

Teon (PTFE), or

Ethylenepropylene (EPDM)

CAPACITIES IN

SCFH (Nm3/h) OF 0.97

280

(7,50)

1180

(31,6)

1520

(40,7)

350

(9,38)

1200

(32,2)

1530

(41,0)

520

(13,9)

1250

(33,5)

1570

(42,1)

640

(17,2)

1300

(34,8)

1600

(42,9)

940

(25,2)

1450

(38,9)

1720

(46,1)

1360

(36,4)

1730

(46,4)

1940

(52,0)

2110

(56,5)

2330

(62,4)

2470

(66,2)

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

B2648

Figure 2. Y695A Series Operational Schematic

3

Page 4

Bulletin 74.2:Y695A

Table 5. Materials Compatibility

Material

CORROSION INFORMATION

Material

Fluid

Cast or

Ductile Iron

Carbon Steel

Acetic Acid (Air Free)

Acetic Acid Vapors

Acetone

Acetylene

Alcohols

Aluminum Sulfate

Ammonia

Ammonium Chloride

Ammonium Nitrate

Ammonium Sulfate

Ammonium Sulte

Beer

Benzene (Benzol)

Benzoic Acid

Boric Acid

Butane

Calcium Chloride (Alkaline)

Carbon Dioxide (Dry)

Carbon Dioxide (Wet)

Carbon Disulde

Carbon Tetrachloride

Carbonic Acid

Chlorine Gas (Dry)

Chlorine Gas (Wet)

Chlorine (Liquid)

Chromic Acid

Citric Acid

Coke Oven Gas

Copper Sulfate

Ether

Ethyl Chloride

Ethylene

Ethylene Glycol

Formaldehyde

Formic Acid

Freon (Wet)

Freon (Dry)

Gasoline (Rened)

Glucose

Hydrochloric Acid (Aerated)

1. Monel is a trademark of International Nickel Co.

2. Hastelloy is a trademark of Stelite Div., Cabot Corp.

I.L.

I.L.

C

C

C

C

A

A

A

A

A

A

C

C

A

A

C

C

A

C

C

C

C

C

B

B

A

A

C

C

C

C

A

A

B

B

A

A

C

C

A

A

B

B

C

C

A

A

C

C

C

C

C

C

C

A

A

C

C

B

B

C

C

A

A

A

A

B

B

C

B

B

B

B

A

A

A

A

C

C

S41600

Stainless Steel

Stainless Steel

CF8M or S31600

S30200 or S30400

B

B

A

A

A

A

A

A

B

A

B

A

A

A

A

A

A

C

A

A

A

B

B

B

C

C

C

B

A

B

A

A

A

A

A

B

B

A

A

A

C

C

A

C

A

A

A

A

A

A

A

C

A

A

B

C

A

C

A

C

A

B

A

B

A

A

A

A

A

B

A

A

B

C

A

A

A

A

A

B

B

C

B

A

B

C

C

C

C

C

B

C

A

B

A

A

B

A

A

A

A

B

A

A

A

A

A

A

B

C

A

I.L.

A

I.L.

A

A

A

A

C

C

(2)

C

(1)

®

®

Monel

Stainless Steel

Hastelloy

B

A

A

A

A

A

A

A

A

A

B

A

A

A

B

A

C

A

A

A

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

A

A

A

C

B

C

A

A

A

B

A

B

A

C

A

A

A

A

A

A

A

A

I.L.

A

A

A

A

A

A

A

A

A

A

A

A

C

B

Fluid

Cast or

Carbon Steel

Hydrochloric Acid (Air free)

Hydrogen

Hydrogen Peroxide

Hydrogen Sulde (Liquid)

Magnesium Hydroxide

Methanol

Methyl Ethyl Ketone

Natural Gas

Nitric Acid

Petroleum Oils (Rened)

Phosphoric Acid (Air Free)

Phosphoric Acid Vapors

Potassium Chloride

Potassium Hydroxide

Propane

Silver Nitrate

Sodium Acetate

Sodium Carbonate

Sodium Chloride

Sodium Chromate

Sodium Hydroxide

Stearic Acid

Sulfur

Sulfur Dioxide (Dry)

Sulfur Trioxide (Dry)

Sulfuric Acid (Aerated)

Sulfuric Acid (Air Free)

Sulfurous Acid

Trichloroethylene

Water (Boiler Feed)

Water (Distilled)

Water (Sea)

Zinc Chloride

Zinc Sulfate

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

A+--Best possible selection

A--Recommended

B--Minor to moderate effect. Proceed with caution.

C--Unsatisfactory

I.L.--Information lacking

I.L.

C

C

A

A

A

C

C

A

A

A

A

A

A

A

A

C

C

A

A

C

C

C

C

B

B

B

B

A

A

C

C

A

A

A

A

C

C

A

A

A

A

A

C

A

A

A

A

A

A

C

C

C

C

C

C

B

B

B

C

A

A

B

B

C

C

C

C

Ductile Iron

Stainless Steel

CF8M or S31600

S30200 or S30400

C

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

A

A

A

A

B

A

A

A

A

B

A

A

A

A

B

A

A

A

B

B

A

A

A

A

A

A

A

A

A

A

A

A

C

C

C

C

B

B

B

A

A

A

A

A

B

B

C

C

A

A

®(1)

S41600

Monel

Stainless Steel

Stainless Steel

C

C

A

A

B

A

C

C

A

A

A

A

A

A

A

A

C

C

A

A

C

B

C

C

C

B

B

A

A

A

B

C

A

A

B

A

B

A

A

A

B

A

B

B

A

A

B

A

B

A

C

C

C

B

C

C

B

A

B

A

B

A

C

A

C

C

B

A

(2)

C

®

Hastelloy

B

A

B

A

A

A

A

A

B

A

A

I.L.

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

- continued -

Principle of Operation

Y695A Series vapor recovery regulators are used to

maintain a constant blanket (inlet) pressure or vessel

pressure with the outlet owing to a system whose

pressure is lower than the inlet (see Figure 2).

4

When vessel pressure increases above the setpoint

of the regulator due to pumping in or thermal heating,

the force of the control spring is overcome by pressure

acting on the diaphragm. This moves the disk away

from the orice, allowing gas to ow from the vessel

to the vapor recovery system. As vessel pressure is

Page 5

Table 5. Materials Compatibility (continued)

Fluid

Acetic Acid (30%)

Acetone

Alcohol (Ethyl)

Alcohol (Methyl)

Ammonia (Anhydrous)

Ammonia (Gas, Hot)

Benzene

Brine (Calcium Chloride)

Butadiene Gas

Butane (Gas)

Butane (Liquid)

Carbon Tetrachloride

Chlorine (Dry)

Chlorine (Wet)

Coke Oven Gas

Ethyl Acetate

Ethylene Glycol

Freon 11

Freon 12

Freon 22

Freon 114

Gasoline

Hydrogen Gas

Hydrogen Sulde (Dry)

Hydrogen Sulde (Wet)

Jet Fuel (JP-4)

Natural Gas

Natural Gas + H2S (Sour Gas)

Nitric Acid (20%)

Nitric Acid (50 to 100%)

Nitrogen

Oil (Fuel)

Propane

Sulfur Dioxide

Sulfuric Acid (to 50%)

Sulfuric Acid (50 to 100%)

Water (Ambient)

Water [at 200°F (93°C)]

Water (Sea)

A+--Best possible selection

A--Recommended

B--Minor to moderate effect. Proceed with caution.

C--Unsatisfactory

I.L.--Information lacking

Neoprene

(CR)

C

B

A

A+

A

B

C

A

B

A

B

C

C

C

C

C

A

B

A+

A+

A

B

A

A

B

C

A

A

B

C

A

B

A

B

A

B

C

A

C

FLUID INFORMATION

Nitrile

(NBR)

B

C

A

A

C

C

C

A

C

A+

A

C

C

C

B

C

A

A

A

C

A

A+

A

C

C

A

A+

B

C

C

A

A+

A

A

C

C

C

A

B

Material

Fluorocarbon

(FKM)

B

C

B

C

C

C

A

B

B

A

A

A

A

A

A+

C

A

A+

B

C

B

A

A

C

C

A

A

C

A

A

A

A

A

A

A

A

A

A

B

Bulletin 74.2:Y695A

Peruoroelastomer

(FFKM)

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Ethylenepropylene

(EPDM)

A

A

A

A

A

B

C

A

C

C

C

C

C

C

C

B

A

C

B

A

A

C

A

A

A

I.L.

C

C

C

C

A

C

C

A

A

B

B

A

A

reduced, the force of the back disk spring causes the

disk to move toward the orice, decreasing the ow of

gas out of the vessel. As vessel pressure drops below

the setpoint of the regulator, the disk will seat against

the orice, shutting off the ow of gas.

Sizing Vapor Recovery Systems

To determine the capacity required, you must consider

the amount of blanketing gas that must be displaced

from the tank when either lling the vessel with liquid

(pump-in) or the expansion of tank vapors during

atmospheric thermal heating.

Using the established procedures from American

Petroleum Institute Standard 2000 (API 2000),

determine the required ow rate for outbreathing.

For liquids with a ash point below 100°F (38°C) or a

normal boiling point below 300°F (149°C), multiply the

calculated outbreathing requirements in Table 6 by 2.0

as indicated in footnote 1 from Table 6.

5

Page 6

Bulletin 74.2:Y695A

Table 6. Flow Rate Conversions (Gas ow required to displace

blanketing gas with pump-in of liquid.)

MULTIPLY MAXIMUM

PUMP RATE IN

U.S. GPM

U.S. GPH

Barrels/hour

Barrels/day

1. For liquids with a ash point below 100°F (38°C) or normal boiling point below 300°F

(149°C), multiply the above calculated outbreathing requirement by 2.0.

2. To convert to Nm³/h multiply SCFH by 0.0268.

BY TO OBTAIN

8.021

0.1337

5.615

0.2340

SCFH air

required

(1)(2)

1. Determine the ow rate of blanketing gas displaced

when liquid is being pumped in (see Table 6).

2. Determine the gas ow rate due to “outbreathing”

caused by atmospheric thermal heating (see

Table 7).

3. Add the requirements of steps 1 and 2 and select

a vapor recovery regulator size based on total

capacity required from Table 4.

Sample sizing problem for vapor

recovery applications:

Vessel capacity . . . . . . 1000 barrels (42,000 gal)(159 000 liters)

Pump in capacity . . . . . . . . . . . . . . . . . 20 GPM (75,7 l/min)

Inlet pressure source . . . . . . . . 60 psig (4,14 bar) nitrogen

Desired blanket setpoint . . . . . . . . 0.5-inches w.c. (1 mbar)

Desired vapor recovery setpoint . . . 2-inches w.c. (5 mbar)

Vapor recovery vacuum source . . . 5-inches Hg (169 mbar)

Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hexane

Boiling point . . . . . . . . . . . . . . . . . . . . . . . . . . 155°F (68°C)

1. From Table 6 the desired air ow rate due to pump

in equals 20 GPM (75,7 l/min) x 8.021 x 2 = 321

SCFH (8,60 Nm3/h) air.

Table 7. Gas Flow Required for Thermal Heating (Outbreathing)

per API 2000 (Interpolate for intermediate sizes.)

VESSEL CAPACITY

Barrels Gallons Liters

60

100

500

1000

2000

3000

4000

5000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

60,000

70,000

80,000

90,000

100,000

120,000

140,000

160,000

180,000 7,560,000 28 616 000 54,000 (1447) 90,000 (2412)

2500

4200

21,000

42,000

84,000

126,000

168,000

210,000

420,000

630,000

840,000

1,050,000

1,260,000

1,470,000

1,680,000

1,890,000

2,100,000

2,520,000

2,940,000

3,360,000

3,780,000

4,200,000

5,040,000

5,880,000

6,720,000

9500

15 000

79 500

159 000

318 000

477 000

636 000

795 000

1 590 000

2 385 000

3 180 000

3 975 000

4 769 000

5 564 000

6 359 000

7 154 000

7 949 000

9 539 000

11 129 000

12 718 000

14 308 000

15 898 000

19 078 000

22 257 000

25 437 000

SCFH (Nm³/h) AIR FLOW

RATE REQUIRED

Flash point is equal

to or above 100°F

(38°C) or normal

boiling point is

equal to or above

300°F (149°C)

40 (1,07)

60 (1,61)

300 (8,04)

600 (16,1)

1200 (32,2)

1800 (48,2)

2400 (64,3)

3000 (80,4)

6000 (161)

9000 (241)

12,000 (322)

15,000 (402)

17,000 (456)

19,000 (509)

21,000 (563)

23,000 (616)

24,000 (643)

27,000 (724)

29,000 (777)

31,000 (831)

34,000 (911)

36,000 (965)

41,000 (1099)

45,000 (1206)

50,000 (1340)

Flash point is

below 100°F

(38°C) or

normal boiling

point is below

300°F (149°C)

60 (1,61)

100 (2,68)

500 (13,4)

1000 (26,8)

2000 (53,6)

3000 (80,4)

4000 (107)

5000 (134)

10,000 (268)

15,000 (402)

20,000 (536)

24,000 (643)

28,000 (750)

31,000 (831)

34,000 (911)

37,000 (992)

40,000 (1072)

44,000 (1179)

48,000 (1286)

52,000 (1394)

56,000 (1501)

60,000 (1608)

68,000 (1822)

75,000 (2010)

82,000 (2198)

given capacity of nitrogen by 0.985, and divide by the

square root of the appropriate specic gravity of the

gas required. To determine regulating capacities at

pressure settings not given or to determine wide-open

ow capacities, use the following formula:

2. From Table 7 the desired air ow rate = 1000 SCFH

(26,8 Nm3/h) air due to thermal heating.

3. Total required ow rate = 1000 SCFH (26,8 Nm3/h)

air + 320 SCFH (8,58 Nm3/h) = 1320 SCFH

(35,4 Nm3/h) air. This converts to nitrogen

requirements of 1340 SCFH (35,9 Nm3/h).

Capacity Information

Table 4 gives typical nitrogen regulating capacities at

selected inlet pressures and outlet pressure settings.

Flows are in SCFH at 60°F and 14.7 psia and Nm³/h at

0°C and 1,01325 bar of 0.97 specic gravity nitrogen.

For gases of other specic gravities, multiply the

6

520

Q = CgP1SIN

GT

3417

C

∆P

Deg.

P

1

1

Where:

Cg = gas sizing coefcient from Specications

C1 = Cg/CV or 35 from Specications

G = gas specic gravity (air = 1.0)

P

= inlet pressure, psia (add 14.7 psi to gauge inlet

1abs

pressure to obtain absolute inlet pressure)

Q = ow rate, SCFH

T = absolute temperature in °Rankine of gas at inlet

(°Rankine = °F + 460)

∆P = Pressure differential across the valve,

psig (P1 - P2)

Page 7

Installation

Bulletin 74.2:Y695A

Install the regulator using a straight run of pipe the

same size or larger as the regulator body. Flow

through the regulator body is indicated by the ow

arrow on the body. If a block valve is required, install a

B

14

(356)

B2441

INCHES

(mm)

A

5.56

(141)

full ow valve between the regulator and the blanketed

vessel. For proper operation at low setpoint ranges,

the regulators should be installed with the spring case

pointed down.

G F

D

8.38

(213)

DIAMETER

DIMENSIONS, INCHES (mm)

BODY SIZE,

NPS (DN)

3/4,1 (20, 25) 4.0 (102) 4.12 (105) 2.12 (54) 2.25 (57) 6.19 (157) 6.19 (157) 10.38 (264) 10.38 (264) 1.69 (43) 1.69 (43)

A B D F G

Iron

Stainless

Steel or

Hastelloy® C

Ductile

Iron

Stainless

Steel or

Hastelloy® C

Ductile

Iron

Stainless

Steel or

Hastelloy® C

Ductile

Iron

Stainless

Steel or

Hastelloy® C

Ductile

Iron

Stainless

Steel or

Hastelloy® C

Figure 3. Dimensions

7

Page 8

Bulletin 74.2:Y695A

Ordering information

When ordering, specify:

Application

1. Type of gas being controlled (natural gas, air, etc.);

list any factors such as impurities in the gas that

may affect compatibility of gas with the regulator

trim parts.

2. Specic gravity of the gas.

3. Temperature of the gas.

4. Range of owing inlet pressures to regulator.

5. Flow rates

a) Minimum controlled ow

b) Normal ow

c) Maximum ow

6. Line size and end connection size of adjacent piping.

Regulator

Refer to the Specications table on page 2. Carefully

review the description of each specication and make

the desired selection wherever there is a choice.

Always specify the type number.

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1999, 2010; All Rights Reserved

Loading...

Loading...