Page 1

Instruction Manual

Form 5465

December 2009

Y690VB Series Vacuum Breakers

Introduction

Scope of the Manual

This manual describes and provides instructions

and parts lists for Types Y690VB and Y690VBM

vacuum breakers. Instructions and parts lists for other

equipment used with these breakers are found in

separate manuals.

Product Description

The Y690VB Series vacuum breakers are used for

precise control of small capacity, low-pressure service

applications where an increase in vacuum must be

limited. These direct-operated vacuum breakers come

in NPS 3/4 and 1 (DN 20 and 25) body sizes and

have an 1/4 or 1/2-inch (6,4 or 13 mm) orice. The

individual products are described as follows:

Type Y690VB

W7292

Figure 1. Type Y690VB Vacuum Breaker

Y690VB Series

The Type Y690VB is a vacuum breaker with internal

pressure registration requiring no downstream

control line.

Type Y690VBM

The Type Y690VBM is a vacuum breaker with a

control line connection and a throat seal for external

pressure registration.

Specications

Specications section gives some general ratings

and specications for the Y690VB Series vacuum

breakers. Individual breakers come from the factory

with the specic data stamped on the nameplate.

Installation

Warning

!

Personal injury, property damage,

equipment damage, or leakage due

to escaping gas or bursting of

pressure-containing parts may result if

this equipment is overpressured or is

installed where service conditions could

exceed the limits given in Specications

section, or where conditions exceed any

ratings of the adjacent piping or piping

connections. To avoid such injury or

damage, provide pressure-relieving or

pressure-limiting devices (as required

by the appropriate code, regulation,

or standard) to prevent service

conditions from exceeding those limits.

Additionally, physical damage to this

equipment could cause personal injury

or property damage due to escaping

gas. To avoid such injury or damage,

install the equipment in a safe and well

ventilated location.

Equipment operation within ratings does not preclude

the possibility of damage from debris in the lines

or from external sources. This equipment should

be inspected for damage periodically and after any

overpressure condition.

www.sherregulators.com

D102594X012

Page 2

Y690VB Series

Specications

Body Sizes

NPS 3/4 or 1 (DN 20 or 25)

End Connection Styles

(1)

See Table 2

Maximum Allowable Inlet (Positive) Pressure

(2)

150 psig (10,3 bar)

Vacuum Control Pressure Ranges

(2)

See Table 1

Maximum Outlet (Casing) Pressure

(2)

Full Vacuum

Maximum Emergency Outlet Pressure to Avoid

Internal Parts Damage

(2)

150 psig (10,3 bar)

Spring Case Connection

1/4 NPT

Orice Size

Change in Vacuum Control Pressure

to Wide-Open

(2)

See Table 1

Pressure Registration

Type Y690VB: Internal

Type Y690VBM: External

Temperature Capabilities

Nitrile (NBR):

-20° to 180°F (-29° to 82°C)

Fluorocarbon (FKM):

40° to 300°F (4° to 149°C)

Ethylenepropylene (EPDM):

-20° to 275°F (-29° to 135°C)

Peruoroelastomer (FFKM):

-20° to 300°F (-29° to 149°C)

Approximate Weight

19 pounds (9 kg)

1/4 or 1/2-inch (6,4 or 13 mm)

1. End connections for other than U.S. standards can usually be provided; consult the local Sales Ofce.

2. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

(2)

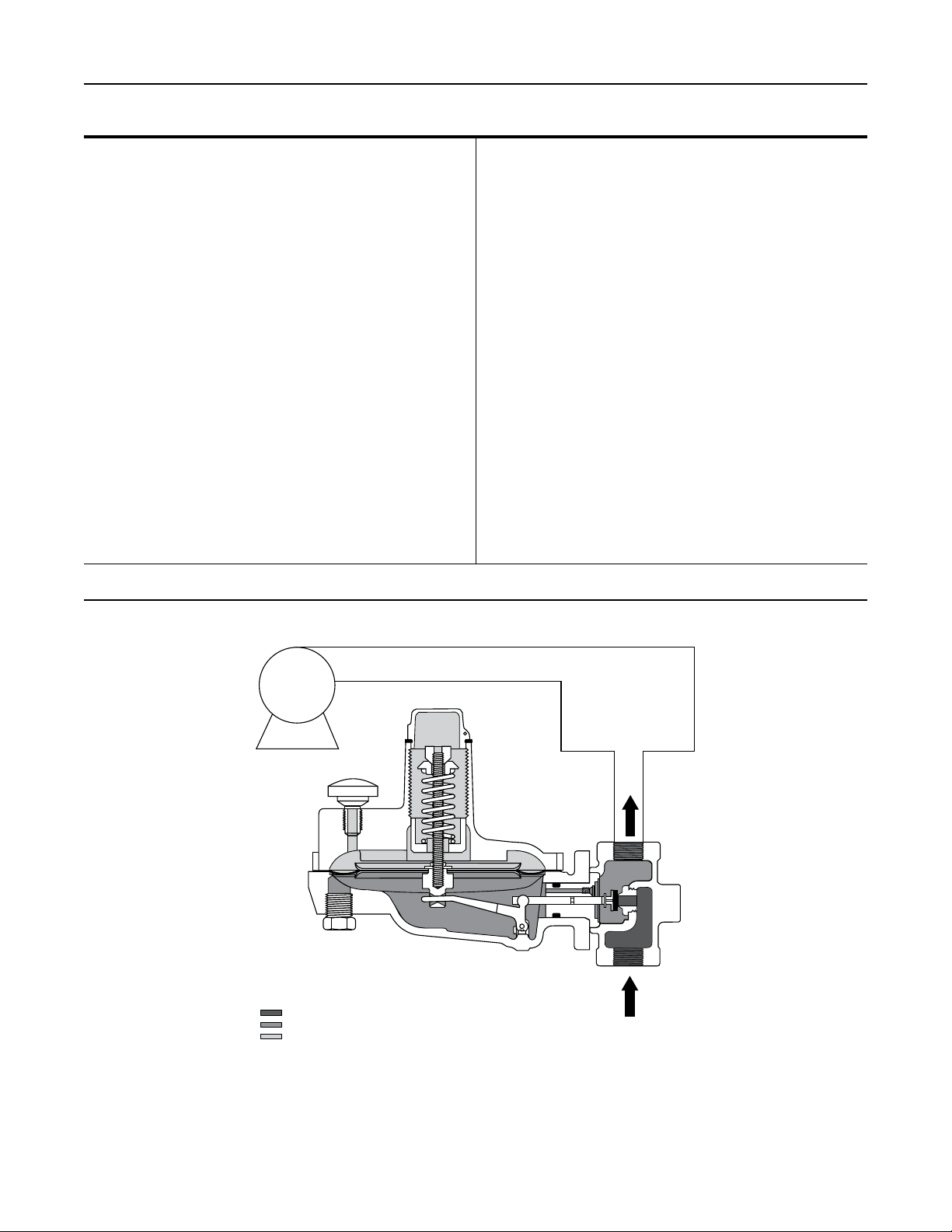

B2672

VACUUM

PUMP

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type Y690VB Operational Schematic

VACUUM

BEing

LIMITED

POSITIVE PRESSURE OR ATMOSPHERE OR A

LESSER VACUUM THAN THE ONE BEING LIMITED

2

Page 3

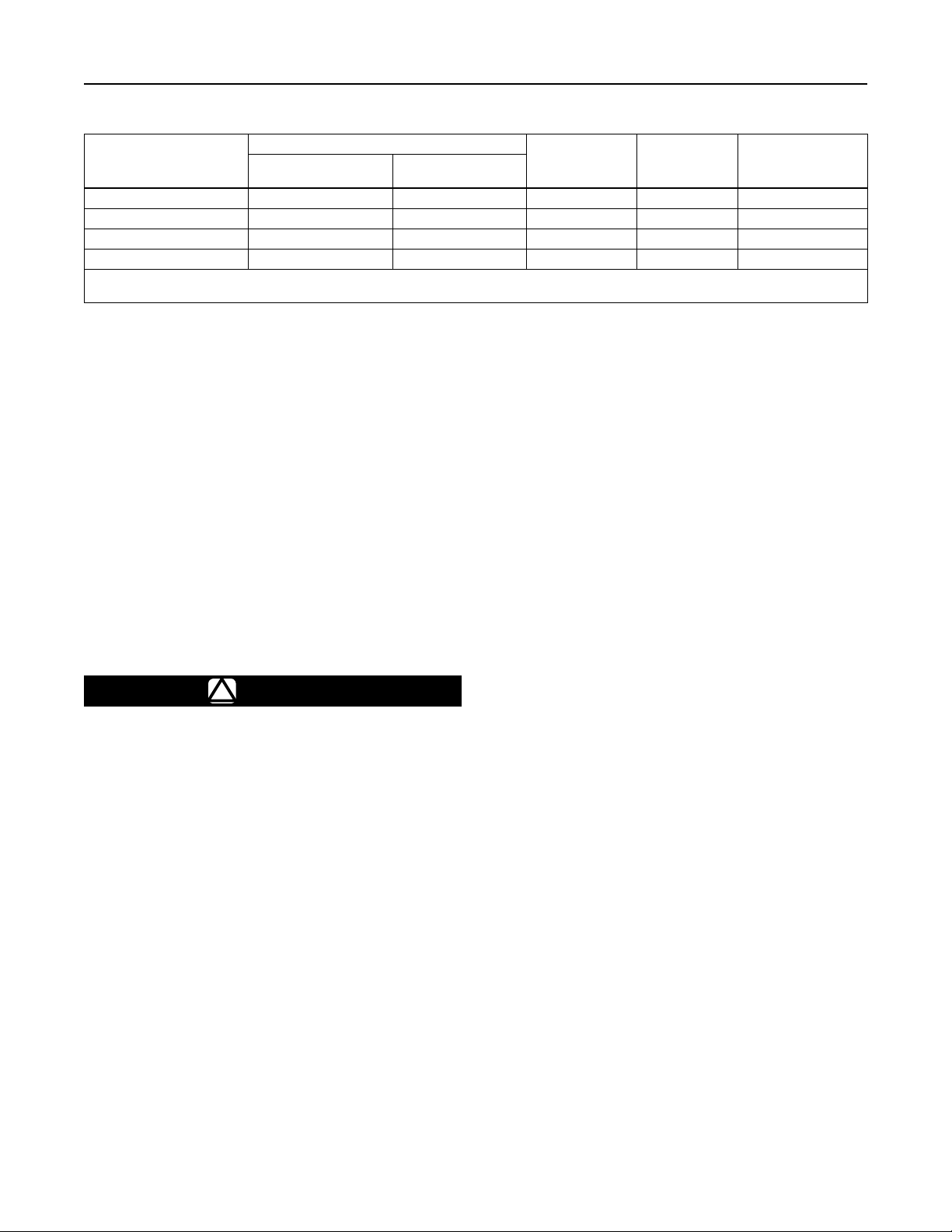

Table 1. Vacuum Pressure Information

Y690VB Series

VACUUM CONTROL

PRESSURE RANGE

0 to 4-inches w.c. (0 to 10 mbar) 0.6-inches w.c. (1,5 mbar) 1.3-inches w.c. (3 mbar) 0N039427222 Unpainted 0.062-inches (1,6 mm)

0 to 1.0 psig (0 to 0,07 bar) 10-inches w.c. (25 mbar) 0.7 psig (0,05 bar) 0N086127022 Unpainted 0.125-inches (3,2 mm)

0 to 2.1 psig (0 to 0,14 bar) 1.2 psig (0,08 bar) 2.4 psig (0,17 bar) 0N004327022 Yellow 0.172-inches (4,4 mm)

0 to 5 psig (0 to 0,34 bar) 3.2 psig (0,22 bar) 6.3 psig (0,43 bar) 1D141827012 Dark blue 0.207-inches (5,3 mm)

1. Spring ranges based on atmospheric inlet pressure.

2. To convert to inches Hg, multiply psig value by 2.04.

(1)(2)

If this equipment is shipped mounted on

another unit, install that unit according

to the appropriate instruction manual.

1. Only personnel qualied through training and

experience should install, operate, and maintain

this equipment. For Y690VB Series equipment

CHANGE IN VACUUM TO WIDE-OPEN

1/4-inch (6,4 mm) Orice

Note

1/2-inch (13 mm)

Orice

downstream vacuum, to enter the system and restore

the controlled vacuum to its original pressure setting.

A Type Y690VB (Figure 3) direct-operated vacuum

breaker is self-contained and requires no control

line. A Type Y690VBM (Figure 4) vacuum breaker

requires a control line from the 1/2 NPT tapping in

the diaphragm case assembly to the point where the

vacuum needs to be controlled.

Spring

PART NUMBER

SPRING COLOR

Spring WirE

DIAMETER

that is shipped separately, make sure that there is

no damage to or foreign material in it. Also ensure

that all tubing and piping have been blown free.

2. This equipment may be installed in any position

as long as the ow through the body is in the

direction indicated by the arrow attached to the

body. If continuous operation is required during

inspection or maintenance, install a three-way

bypass valve around the equipment.

Startup and Adjustment

All Y690VB Series equipment can be placed in

operation by slowly introducing inlet vacuum or

pressure. This equipment takes control when vacuum

is established. This equipment is suitable for the

pressure range stamped on the nameplate (key 46),

and listed in Table 1. To adjust the pressure setting,

remove the closing cap (key 22) and turn the adjusting

Warning

!

This equipment may vent some gas

to the atmosphere. In hazardous or

ammable gas service, vented gas may

nut (key 20) clockwise to increase the pressure setting

or counterclockwise to decrease the setting. Replace

the cap after making this adjustment. If desired, the

closing cap may be wired to the hole provided in the

spring case (key 3) to discourage tampering.

accumulate and cause personal injury,

death, or property damage due to re or

explosion. Vent equipment in hazardous

gas service to a remote, safe location

away from air intakes or any hazardous

area. The vent line or stack opening

must be protected against condensation

or clogging.

Shutdown

First close the nearest upstream shutoff valve and then

close the nearest downstream shutoff valve to vent

the equipment properly. Next, open the vent valve

between the equipment and the downstream shutoff

valve nearest to it. All pressure between these shutoff

valves is released through the open vent valve.

Principle of Operation

The Y690VB Series vacuum breakers (Figure 2) are

used in applications where an increase in vacuum

must be limited. An increase in vacuum (decrease

in absolute pressure) is transmitted to the lower side

of the diaphragm, opening the disk assembly. This

permits positive pressure, atmosphere, or an upstream

vacuum that has higher absolute pressure than the

Maintenance

Equipment parts are subject to normal wear and

must be inspected and replaced as necessary. The

frequency of inspection and replacement of parts

depends on the severity of service conditions and

upon applicable codes and government regulations.

3

Page 4

Y690VB Series

Warning

!

To avoid personal injury, property

damage, or equipment damage caused

by sudden release of pressure or

explosion of accumulated gas, do not

attempt any maintenance or disassembly

without rst isolating the regulator from

system pressure and relieving all internal

pressure from the equipment.

Body Area

These procedures are for gaining access to the disk

assembly, orice, and body O-ring. All pressure must

be released from the diaphragm case before the

following steps can be performed.

Key numbers are referenced in Figures 3 and 4.

1. To inspect and replace the disk assembly (key 13)

or orice (key 5), remove the cap screws

(key 2), and separate the diaphragm casing

(key 4) from the body (key 1).

2. Remove and inspect the body seal O-ring (key 11)

and the backup ring (key 50).

3. Inspect and replace the orice (key 5) if

necessary. Lubricate the threads of the

replacement orice with a good grade of light

grease and tighten using 29 to 37 foot-pounds

(39 to 50 N•m) of torque.

4. Remove the cotter pin (key 15) if it is necessary

to replace the disk holder assembly (key 13).

For a Type Y690VBM, also inspect the throat

seal O-ring (key 31) by removing the machine

screw (key 33). Replace if necessary. To install

a throat seal, place the O-ring on the machine

screw and thread into guide insert (key 18) to seal.

Note

The disk holder assembly (key 13) is

comprised of the disk and disk holder.

5. Install the disk holder assembly (key 13) and

secure it to the valve stem (key 14) with the cotter

pin (key 15).

6. Install the backup ring (key 48) and body seal O-ring

(key 11) into the body (key 1).

7. Replace the diaphragm casing (key 4) on the body

(key 1) and secure with the cap screws (key 2).

Diaphragm and Spring Case Area

These procedures are for gaining access to the

control spring, diaphragm assembly, valve stem, and

stem O-ring. All pressure must be released from the

diaphragm case before these steps can be performed.

Type Y690VB

Key numbers are referenced in Figure 3.

1. Remove the closing cap (key 22) and turn the

adjusting nut (key 20) counterclockwise until all

compression is removed from the control spring

(key 6). If the only further maintenance is to change

the control spring (key 6), skip to step 11.

2. Remove the spring case cap screws (key 24) and

hex nuts (key 23, not shown) and lift off the spring

case assembly (key 3).

3. Remove the diaphragm (key 10) and attached

parts by tilting it so that the pusher post (key 8)

slips off the lever assembly (key 16). To separate

the diaphragm from the attached parts, unscrew

the diaphragm hex nut (key 21). If the only further

maintenance is to replace the diaphragm parts, skip

to step 8.

4. To replace the lever assembly (key 16), remove

the machine screws (key 17) .

5. To replace the valve stem (key 14) also perform body

area maintenance procedure steps 1 through 4 and

pull the valve stem (key 14) out of the guide insert

(key 18).

6. Install the valve stem (key 14) into the guide

insert (key 18) and perform body area

maintenance procedure steps 5 through 7.

7. Install the lever assembly (key 16) into the valve

stem (key 14) and secure the lever assembly

(key 16) with the machine screws (key 17).

8. Reassemble the diaphragm assembly in the

following order:

Pusher post (key 8)

Diaphragm head gasket (key 45)

Diaphragm head (key 7)

Diaphragm (key 10)

Diaphragm head (key 7)

Washer (key 36)

Diaphragm nut (key 38)

Secure with 5 to 6 foot-pounds (7 to 8 N•m) of torque.

9. Install the pusher post (key 8) plus attached

diaphragm parts onto the lever assembly (key 16).

4

Page 5

Y690VB Series

10. Install the spring case assembly (key 3) and

control spring (key 6) on the diaphragm casing

(key 4) so that the vent assembly is correctly

oriented, and secure them with the spring case

cap screws (key 24) and hex nuts (key 23, not

shown) to nger tightness only.

11. Install the upper spring seat (key 19) and the

adjusting nut (key 20) turning clockwise until

there is enough control spring (key 6) force to

provide proper slack to the diaphragm (key 10)

and attached parts. Using a crisscross pattern,

nish tightening the spring case cap screws

(key 24) and hex nuts (key 23) to 160 to 190

inch-pounds (18 to 21 N•m) of torque. Then

nish turning the adjusting nut to the desired

outlet pressure setting.

12. Install a replacement closing cap gasket (key 25)

if necessary, and then install the closing cap

(key 22).

Type Y690VBM

Key numbers are referenced in Figure 4.

1. Remove the closing cap (key 22) and turn the

adjusting nut (key 20) counterclockwise until all

compression is removed from the control spring

(key 6). If the only further maintenance is to

change the control spring, skip to step 11.

2. Remove the spring case cap screws (key 24) and

hex nuts (key 23, not shown) and lift off the spring

case assembly (key 3).

3. Remove the diaphragm (key 10) and attached

parts by tilting it so that the pusher post (key 8)

slips off the lever assembly (key 16). To separate

the diaphragm (key 10) from the attached parts,

unscrew the diaphragm hex nut (key 21). If

the only further maintenance is to replace the

diaphragm parts, skip to step 8.

7. Install the lever assembly (key 16) into the valve

stem (key 14) and secure the lever assembly

(key 16) with the machine screws (key 17).

8. Reassemble the diaphragm assembly in the

following order:

Pusher post (key 8)

Diaphragm head gasket (key 45)

Diaphragm head (key 7)

Diaphragm (key 10)

Diaphragm head (key 7)

Washer (key 36)

Diaphragm nut (key 38)

Secure with 5 to 6 foot-pounds (7 to 8 N•m) of torque.

9. Install the pusher post (key 8) plus attached

diaphragm parts onto the lever assembly (key 16).

10. Install the spring case assembly (key 3) and control

spring (key 6) on the diaphragm casing (key 4)

so that the vent assembly (key 26) is correctly

oriented, and secure them with the spring case

cap screws (key 24) and hex nuts (key 23, not

shown) to nger tightness only.

11. Install the upper spring seat (key 19) and adjusting

nut (key 20). Turn adjusting nut clockwise until

there is enough control spring (key 6) force to

provide proper slack to the diaphragm (key 10)

and attached parts. Using a crisscross pattern,

nish tightening the spring case cap screws

(key 24) and hex nuts (key 23, not shown) to 160

to 190 inch-pounds (18 to 21 N•m) of torque. Then

nish turning the adjusting nut to the desired outlet

pressure setting.

12. Install a replacement closing cap gasket (key 25)

if necessary, and then install the closing cap (key 22).

To Convert Constructions

4. To replace the lever assembly (key 16), remove

the machine screws (key 17).

5. To replace the valve stem (key 14) or stem seal

O-ring (key 30) perform body area maintenance

procedure steps 1 through 4 and pull the valve

stem out of the guide insert (key 18).

6. Lightly grease the replacement stem seal

O-ring (key 30) and install on the valve stem

(key 14). Install the valve stem by pushing it

into the guide insert (key 18) and perform body

area maintenance procedure steps 5 through 7.

Type Y690VB to Type Y690VBM:

New parts required: keys 30, 31, and 33

1. Remove pipe plug (key 27) from the diaphragm

casing (key 4).

2. Refer to steps 1 and 3 in the Body area

maintenance section.

3. Insert the throat seal O-ring (key 31, Figure 4) and

one machine screw (key 33).

5

Page 6

Y690VB Series

Table 2. Body Materials and Part Numbers (Key 1)

BODY MATERIAL END CONNECTION STYLE

Ductile iron NPT 17B5351X012 17B5351X022

Stainless steel

Stainless steel with

Carbon steel anges

NPT 17B5351X032 17B5351X042

CL150 RF 17B9733X072 17B9733X082

CL150 RF 17B9733X012 17B9733X022

4. Insert the stem seal O-ring (key 30) by

following steps 1 through 7 and 9 through

12 in the Diaphragm and Spring Case Area

Maintenance section

Type Y690VBM to Type Y690VB:

New parts required: key 27

1. Insert pipe plug (key 27) in the diaphragm

casing (key 4).

2. Follow steps 1 through 7 and 9 through 12 in

the Diaphragm and Spring Case Area Maintenance

section to remove the stem seal O-ring (key 30,

Figure 4). Follow steps 1 through 7 of Body Area

Maintenance to remove the throat seal (key 31)

and machine screw (key 33).

Parts Ordering

When corresponding with the local Sales Ofce about

this regulator, include the type number and all other

pertinent information stamped on the nameplate

(key 46). Specify the eleven-character part number

when ordering new parts from the following parts list.

Parts List

Key Description Part Number

Spare Parts Kit (Stainless steel/Nitrile Construction)

Included are keys 10, 11, 12, 13, 15,

25, 30, 31, 33, and 45 RY690AX0012

1 Body See Table 2

2 Cap Screw

Ductile iron 1C856228992

Stainless steel 18B3456X012

3 Spring Case Assembly

Ductile iron 17B8946X012

Stainless steel 17B8946X022

4 Diaphragm Casing

Ductile iron 47B3063X012

Stainless steel 47B3064X012

5 Orice

303 Stainless steel

1/4-inch (6,4 mm) 1B815135032

1/2-inch (13 mm) 1A928835032

6 Spring See Table 1

*Recommended spare part

PART NUMBER

NPS 3/4 (DN 20) Body NPS 1 (DN 25) Body

Key Description Part Number

7 Diaphragm Head (2 required)

Stainless steel 17B9723X032

8 Pusher Post Assembly

Stainless steel 17B9742X012

10* Diaphragm

Nitrile (NBR) 37B9720X012

Fluorocarbon (FKM) 23B0101X052

11* Body Seal O-Ring

Nitrile (NBR) 1H993806992

Fluorocarbon (FKM) 1H9938X0012

12* Insert Seal

Nitrile (NBR) 1B885506992

Fluorocarbon (FKM) 1B8855X0012

13* Disk Assembly

303 Stainless steel with

Nitrile (NBR) 1C4248X0202

Fluorocarbon (FKM) 1C4248X0052

14 Stem 17B3423X012

15* Cotter Pin

Stainless steel 1A866537022

16 Lever Assembly

Stainless steel 1B5375000B2

17 Machine Screw (2 required)

Stainless steel 19A7151X022

18 Guide Insert

Stainless steel 27B4028X022

19 Upper Spring Seat 1A201824092

20 Adjusting Nut 17B9740X012

21 Hex Nut 1A345724122

22 Closing Cap

Standard 1B541644012

Steel 1E422724092

23 Hex Nut, not shown (8 required)

Ductile iron 1A352724122

Stainless steel 1E9440X0302

24 Diaphragm Case Cap Screw (8 required)

Ductile iron 1A352524052

Stainless steel 18B3455X012

25* Closing Cap Gasket 1P753306992

26 Vent Assembly

Spring Case Up (standard) 17A6570X012

Spring Case Down 17A6571X012

27 Pipe Plug

Ductile iron 1A369224492

Stainless steel 1A369235072

30* Stem Seal (Type Y690VBM only)

Nitrile (NBR) 1H2926G0012

Fluorocarbon (FKM) 1H2926X0022

31* Throat Seal (Type Y690VBM only)

Nitrile (NBR) 1D682506992

Fluorocarbon (FKM) 1D6825X0012

33 Machine Screw (Type Y690VBM only) 18A0703X022

36 Washer 18B3440X012

45* Lower Head Gasket 18B3450X012

46 Nameplate - - - - - - - - - - 47 Drive Screw (2 required) 1A368228982

50 Backup Ring 18B3446X012

6

Page 7

Y690VB Series

B2674_2

B2674_1

Figure 3. Type Y690VB Assembly

7

Page 8

Y690VB Series

B2675

Figure 4. Type Y690VBM Assembly

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1999, 2009; All Rights Reserved

Loading...

Loading...