Page 1

Bulletin 71.3:Y690VB

Y690VB Series Vacuum Breakers

February 2010

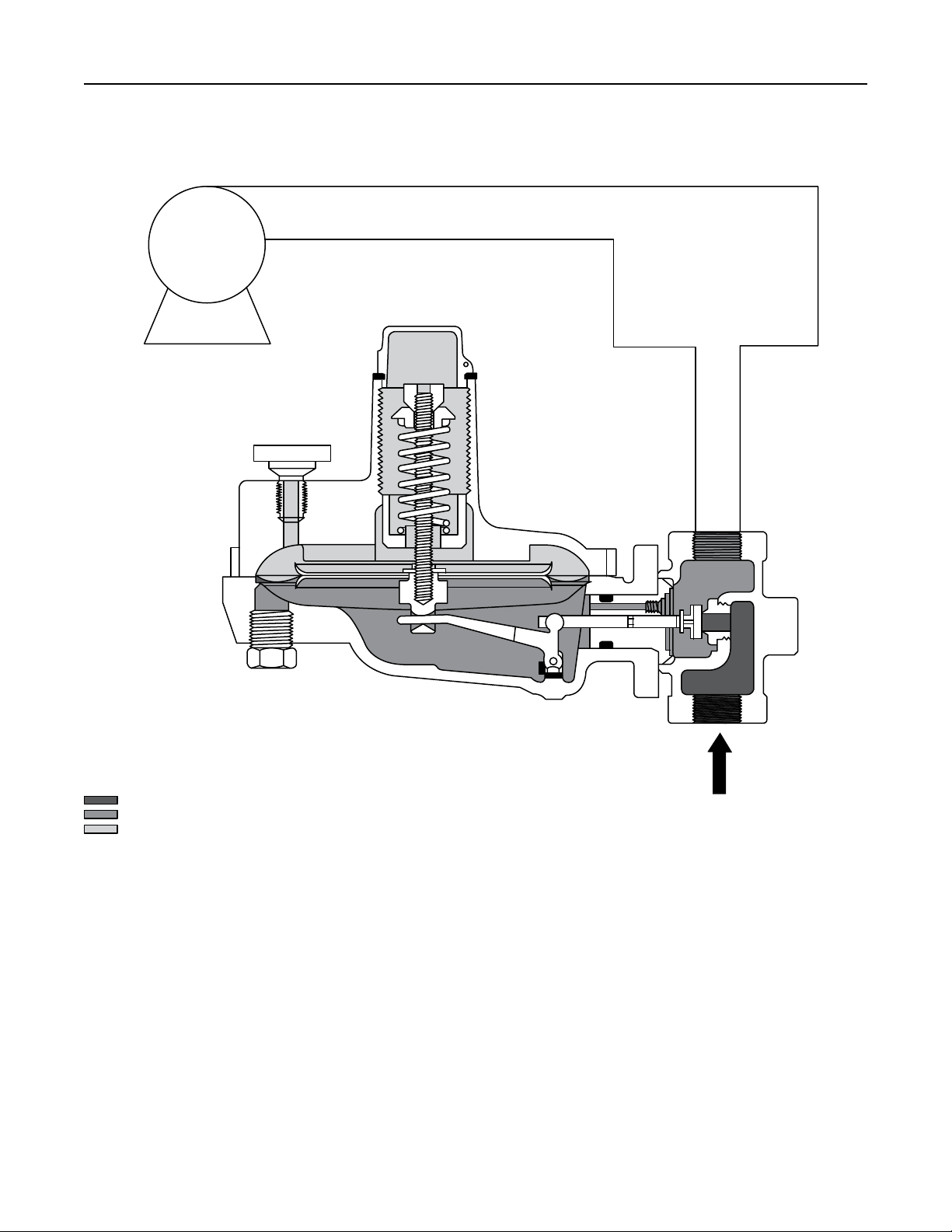

W7292

Figure 1. Type Y690VB Vacuum Breaker

Features

• Common Spare Parts:

The Types Y690VB and Y690VBM have common

spare parts with the other Y690A Series products.

• Tamper–Resistant Adjustment:

Closing cap and spring case on many types allow

installation of sealing wire to discourage or detect

unauthorized adjustment of pressure setting.

• Easy Conversion:

The Type Y690VB converts easily to the

Type Y690VBM.

• Precision Control of Low-Pressure Settings:

Large diaphragm areas provide more accurate

control at low-pressure settings.

• Corrosion Resistance:

Constructions are available in a variety of materials

for compatibility with corrosive process gases.

Introduction

The Y690VB Series direct-operated vacuum breakers

are used for precise control of small capacity and

low-pressure service applications where an increase

in vacuum must be limited. The Type Y690VB has

internal pressure registration. The Type Y690VBM has

a control line connection and an O-ring stem seal for

external pressure registration.

www.sherregulators.com

D102593X012

Page 2

Bulletin 71.3:Y690VB

Specications

Available Congurations

Type Y690VB: Direct-operated vacuum breaker

with internal registration.

Type Y690VBM: Direct-operated vacuum breaker

equipped with a blocked throat and control line

connection for external pressure registration.

Body Sizes

NPS 3/4 or 1 (DN 20 or DN 25)

End Connection Styles

See Table 1

Maximum Allowable Inlet Pressure

(1)

150 psig (10,3 bar)

Maximum Outlet (Casing) Pressure

(1)

Full Vacuum

Maximum Emergency Outlet Pressure to Avoid

Internal Parts Damage

(1)

150 psig (10,3 bar)

Vacuum Control Pressure Ranges

(1)

See Table 4

Construction Materials

See Table 3

Temperature Capabilities

(1)

Nitrile (NBR):

-20° to 180°F (-29° to 82°C)

Fluorocarbon (FKM):

40° to 300°F (4° to 149°C)

Ethylenepropylene (EPDM):

-20° to 300°F (-29° to 149°C)

Peruoroelastomer (FFKM):

-20° to 300°F (-29° to 149°C)

Pressure Registration

Type Y690VB: Internal

Type Y690VBM: External

Orice Size

1/4-inch (6,3 mm)

1/2-inch (13 mm)

Pressure Setting Adjustment

Adjusting Nut

Spring Case Connection

1/4 NPT

Flow Coefcients

See Table 2

Flow Capacities

See Table 6

1. The pressure/temperature limits in this Bulletin and any applicable standard or code limitation should not be exceeded.

Table 1. End Connection Styles

BODY SIZE,

NPS (DN)

3/4 (20)

1 (25)

1. All ange dimensions are 14-inches (356 mm) face-to-face.

END CONNECTION STYLE

Ductile Iron Stainless Steel

NPT

NPT, SWE, or ASME

(1)

CL150 RF

Diaphragm Case Connection

1/2 NPT

Approximate Weight

19 pounds (9 kg)

Table 2. Flow Coefcients

ORIFICE SIZE

INCHES (mm)

1/4 (6,3) 50 1.4 35

1/2 (13) 200 5.7 35

FLOW COEFFICIENT

C

g

C

v

C

1

2

Page 3

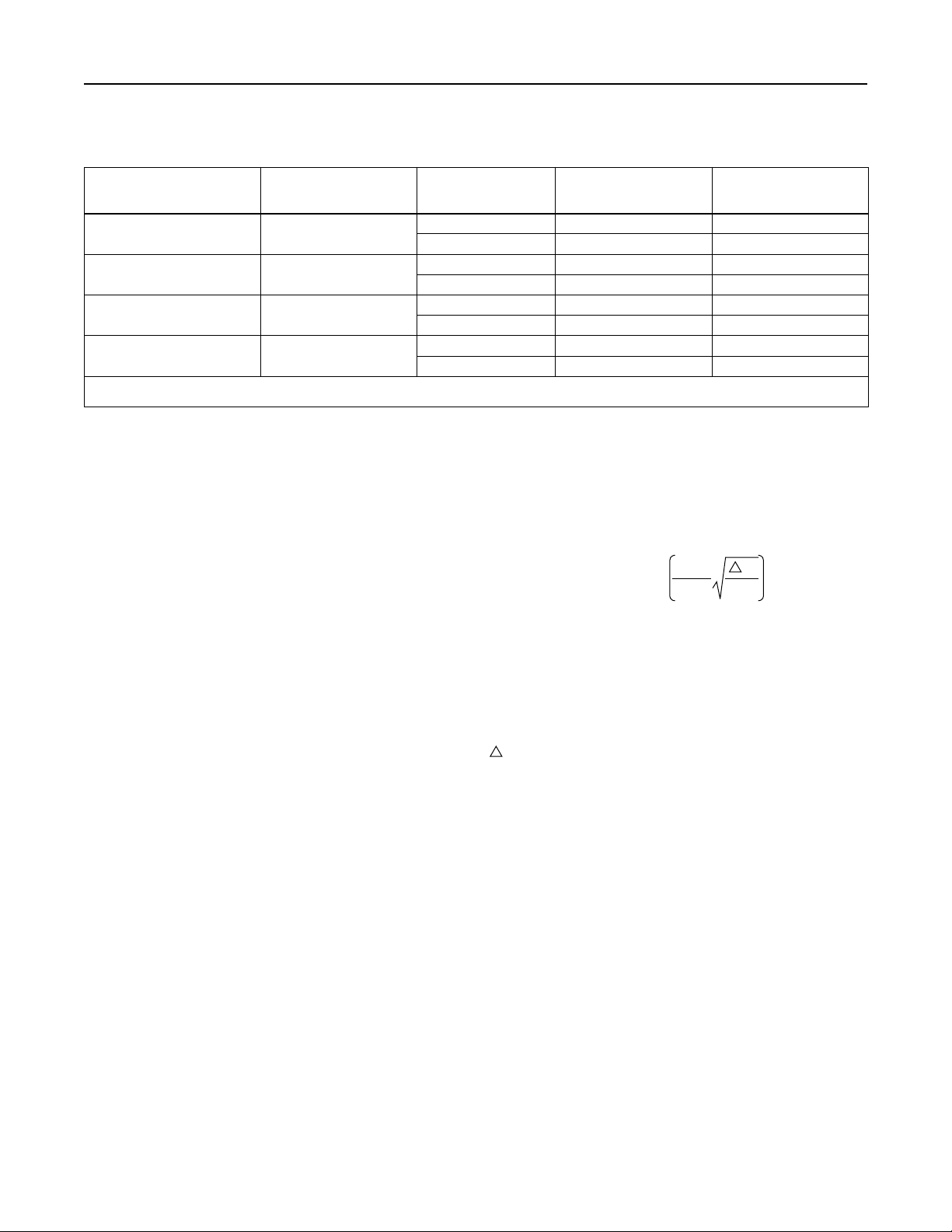

VACUUM PUMP

Type Y692

July 2007

Type Y692

Bulletin 71.3:Y690VB

VACUUM BEING LIMITED

INLET PRESSURE

CONTROL PRESSURE (VACUUM)

INLET PRESSURE

CONTROL PRESSURE (OUTLET PRESSURE)

ATMOSPHERIC PRESSURE

ATMOSPHERIC PRESSURE

B2672

Figure 2. Y690VB Series Operational Schematic

POSITIVE PRESSURE OR ATMOSPHERE, OR A

LESSER VACUUM THAN THE ONE BEING LIMITED

3

Page 4

Bulletin 71.3:Y690VB

Table 3. Construction Materials

BODY SPRING CASE DIAPHRAGM CASE TRIM DIAPHRAGM DISK

Ductile iron or CF8M

Stainless steel

Table 4. Vacuum Control Pressure Ranges

Ductile iron or

CF8M Stainless steel

CF8M Stainless steel

Ductile iron or

S303 Stainless steel

Nitrile (NBR) or

Fluorocarbon (FKM)

Nitrile (NBR) or

Fluorocarbon (FKM)

VACUUM

CONTROL

PRESSURE

(1)(2)

RANGE

0 to 4-inches w.c.

(0 to 10 mbar)

0 to 1.0 psig

(0 to 0,07 bar)

0 to 2.1 psig

(0 to 0,15 bar)

0 to 5 psig

(0 to 0,35 bar)

1. Spring ranges based on atmospheric inlet pressure.

2. To convert to inches Hg, multiply psig value by 2.04.

CHANGE IN VACUUM TO WIDE-OPEN

1/4-inch

(6,3 mm) Orice

0.6-inches w.c.

(1,5 mbar)

10-inches w.c.

(25 mbar)

1.2 psig

(0,08 bar)

3.2 psig

(0,22 bar)

1/2-inch

(13 mm) Orice

1.3-inches w.c.

(3 mbar)

0.7 psig

(0,05 bar)

2.4 psig

(0,17 bar)

6.3 psig

(0,43 bar)

Table 5. Maximum Setpoints for Achieving Wide-Open Flow

SPRING RANGE,

PART NUMBER,

AND COLOR

0 to 4-inches w.c.

(0 to 10 mbar)

0N039427222

Unpainted

0 to 1.0 psig

(0 to 0,07 bar)

0N086127022

Unpainted

0 to 2.1 psig

(0 to 0,14 bar)

0N004327022

Yellow

0 to 5 psig

(0 to 0,34 bar)

1D141827012

Dark blue

1. Spring ranges based on atmospheric inlet pressure.

2. To convert to inches Hg, multiply psig value by 2.04.

(1)(2)

ORIFICE SIZE

INCHES (mm)

1/4 (6,3)

1/2 (13)

1/4 (6,3)

1/2 (13)

1/4 (6,3)

1/2 (13)

1/4 (6,3)

1/2 (13)

MAXIMUM

ALLOWED

VACUUM

5.1 psig

(0,35 bar)

6.0 psig

(0,41 bar)

7.1 psig

(0,49 bar)

12.0 psig

(0,83 bar)

MAXIMUM SETPOINTS FOR ACHIEVING WIDE-OPEN FLOW AT SPECIFIC INLET PRESSURES

0 Psi (0 bar) 25 Psi (1,7 bar) 50 Psi (3,4 bar) 75 Psi (5,2 bar) 100 Psi (6,9 bar) 125 Psi (8,6 bar)

4-inches w.c.

(10 mbar)

4-inches w.c.

(10 mbar)

1 psig

(0,07 bar)

1 psig

(0,07 bar)

2.1 psig

(0,14 bar)

2.1 psig

(0,14 bar)

5.0 psig

(0,34 bar)

5.0 psig

(0,34 bar)

1 psig

2.1 psig

5.0 psig

5.0 psig

SPRING WIRE

DIAMETER

INCHES (mm)

2.5-inches w.c.

(6,2 mbar)

0-inches w.c.

(0 mbar)

0.96 psig

(0,07 bar)

0.8 psig

(0,05 bar)

2.05 psig

(0,14 bar)

1.92 psig

(0,13 bar)

5.0 psig

(0,34 bar)

5.0 psig

(0,34 bar)

SPRING

PART NUMBER

0N039427222 Unpainted 0.062 (1,6) 3.06 (77)

0N086127022 Unpainted 0.125 (3,2) 2.50 (63)

0N004327022 Yellow 0.172 (4,4) 2.50 (63)

1D1418227012 Dark blue 0.207 (5,3) 2.50 (63)

4-inches w.c.

(10 mbar)

3-inches w.c.

(7,5 mbar)

1 psig

(0,07 bar)

0.95 psig

(0,07 bar)

2.1 psig

(0,14 bar)

2.1 psig

(0,14 bar)

5.0 psig

(0,34 bar)

5.0 psig

(0,34 bar)

SPRING COLOR

3.5-inches w.c.

(8,7 mbar)

1.5-inches w.c.

(3,7 mbar)

1 psig

(0,07 bar)

0.9 psig

(0,06 bar)

2.1 psig

(0,14 bar)

2.05 psig

(0,14 bar)

5.0 psig

(0,34 bar)

5.0 psig

(0,34 bar)

3-inches w.c.

(7,5 mbar)

0-inches w.c.

(0 mbar)

(0,07 bar)

0.85 psig

(0,06 bar)

(0,14 bar)

1.98 psig

(0,14 bar)

(0,34 bar)

(0,34 bar)

SPRING FREE

LENGTH

INCHES (mm)

2-inches w.c.

(5 mbar)

0-inches w.c.

(0 mbar)

0.92 psig

(0,06 bar)

0.75 psig

(0,05 bar)

2.0 psig

(0,14 bar)

1.86 psig

(0,13 bar)

5.0 psig

(0,34 bar)

5.0 psig

(0,34 bar)

4

Page 5

Table 6. Type Y690VB Capacities

Bulletin 71.3:Y690VB

SPRING RANGE,

PART NUMBER, AND COLOR

0 to 4-inches w.c. (0 to 10 mbar)

0N039427222 Unpainted

0 to 1.0 psig (0 to 0,07 bar)

0N086127022 Unpainted

0 to 2.1 psig (0 to 0,14 bar)

0N004327022 Yellow

0 to 5 psig (0 to 0,34 mbar)

1D141827012 Dark blue

1. Spring ranges based on atmospheric inlet pressure.

2. To convert to inches Hg, multiply psig value by 2.04.

(1)

VACUUM

CONTROL SETTING

2-inches w.c. (5 mbar)

0.5 psig (0,03 bar)

2 psig (0,14 bar)

4 psig (0,28 bar)

(2)

ORIFICE SIZE

INCHES (mm)

Principle of Operation

An increase in vacuum (decrease in absolute

pressure) beyond a setpoint registers on the

diaphragm, opening the disk. This permits

atmosphere, positive, or an upstream vacuum that

has higher absolute pressure than the downstream

vacuum, to enter the system and restore the controlled

vacuum to the setpoint. On the Type Y690VB,

the pressure registers internally underneath the

diaphragm. The Type Y690VBM has a control line

connecting the diaphragm casing to the vacuum line

and a throat seal allowing for registration only through

the control line connection.

Installation

CHANGE IN VACUUM

TO WIDE-OPEN

1/4 (6,3) 0.6-inches w.c. (1,5 mbar) 110 (2,95)

1/2 (13) 1.3-inches w.c. (3 mbar) 486 (13,0)

1/4 (6,3) 10-inches w.c. (25 mbar) 293 (7,85)

1/2 (13) 0.7 psig (0,05 bar) 1382 (37,0)

1/4 (6,3) 1.2 psig (0,08 bar) 524 (14,0)

1/2 (13) 2.4 psig (0,17 bar) 2353 (63,1)

1/4 (6,3) 3.2 psig (0,22 bar) 682 (18,3)

1/2 (13) 6.3 psig (0,43 bar) 2910 (78,0)

CAPACITIES IN SCFH

(Nm³/h) OF 1.0 SPECIFIC

GRAVITY AIR

Capacity Information

To determine ow capacities for the Y690VB Series

vacuum breakers, use the following formula:

3415

Q = P

SIN

1abs Cg

C

where,

Q = ow capacity in SCFH (60°F and 14.7 psia) of air

P

= absolute inlet pressure in psia

1abs

(P1 gauge + 14.7)

Cg = ow coefcient (from Table 3)

C1 = 35

P = pressure drop across vacuum breaker

P

deg

P

1

1abs

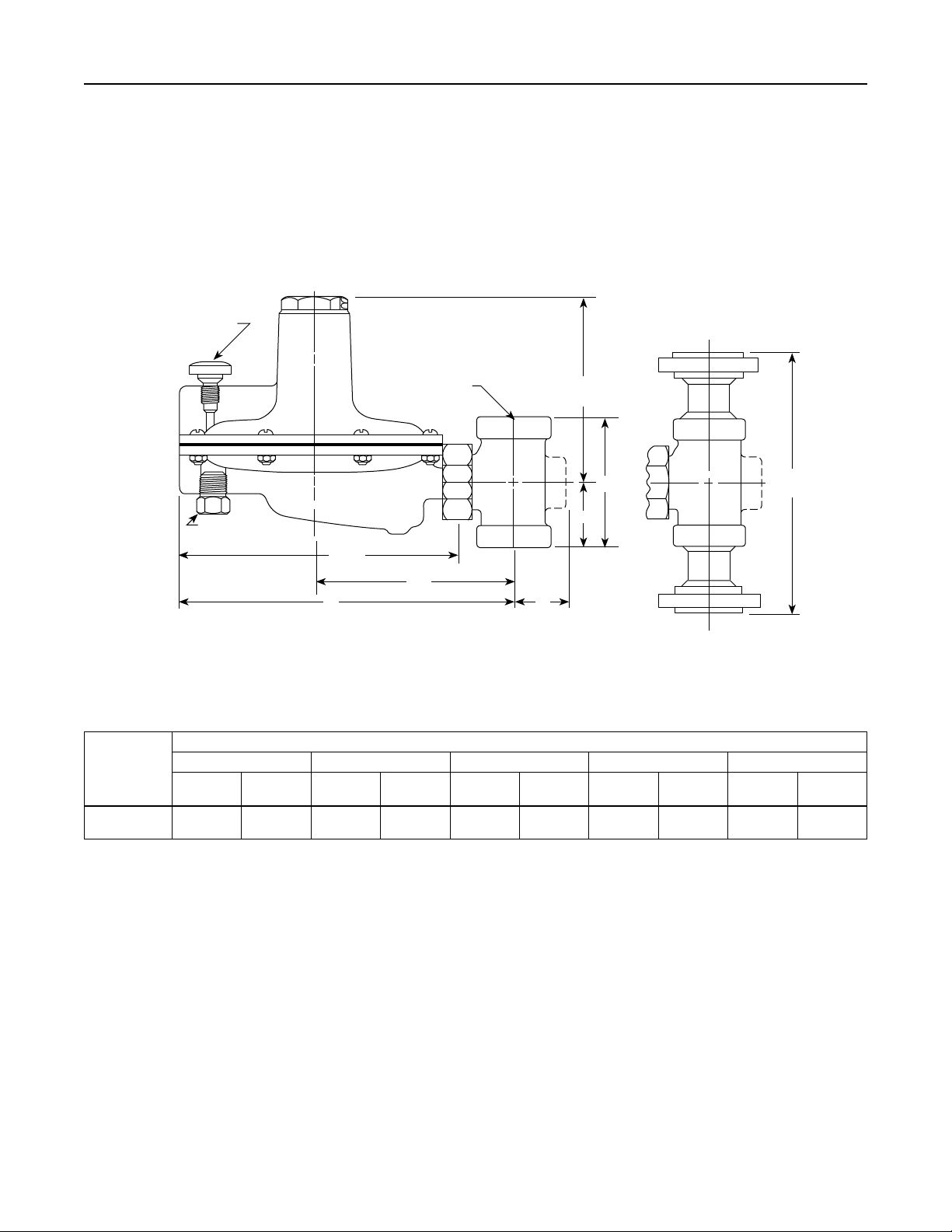

A Y690VB Series regulator may be installed in any

orientation as long as ow through it matches the

direction of the arrow on the body. Normal installation

is with the spring case vertical above or below the

diaphragm case. When exposed to the weather, the

vent should be protected by the optional umbrella

vent or pointed down to allow condensate to drain. If

used in hazardous gas service on indoor installations,

this connection should be piped outdoors. External

dimensions and connections are shown in Figure 3.

Note

Downstream piping will vary with the

installation, but to obtain the calculated

characteristics, the pipe should be the

same size as the outlet and should be

straight for the rst 18 inches (457 mm).

Note

If the actual change in (control) pressure

(from the service conditions) is less than

the minimum change in (control) pressure

required to fully open the vacuum breaker

(Table 6), the Cg in the formula must

be reduced accordingly. To obtain the

correct reduced Cg, multiply the Cg from

Table 2 by the ratio of the actual change in

(control) pressure to the minimum change

in (control) pressure required to fully

open the vacuum breaker.

5

Page 6

Bulletin 71.3:Y690VB

Conversion Factors

To determine equivalent capacities for natural gas,

propane, butane, or nitrogen, multiply the calculated

capacity by the following appropriate conversion

factor: 1.29 for natural gas, 0.810 for propane, 0.707

for butane, or 1.018 for nitrogen. For gases of other

specic gravities, divide by the square root of the

appropriate specic gravity. Then, if capacity is

desired in normal cubic meters per hour at 0°C and

1.01325 bar, multiply SCFH by 0.0268.

Example Problem Using Formula

This example involves a Type Y690VB vacuum breaker

with its outlet connected to a vessel in which the vacuum

must be limited. This breaker has a 1/4-inch (6,4 mm)

orice and a control spring set to start opening and

admit atmospheric pressure whenever the vacuum

pump downstream from the vessel increases the vessel

vacuum to more than 4-inches w.c. (10 mbar). It is

desirable to nd the air ow by the time the pump has

increased the vessel vacuum to 9-inches w.c. (22 mbar)

and the breaker has opened more. To nd the air ow

through the breaker under these conditions:

1. Check whether the change in outlet (controlled)

pressure of 5-inches w.c. (12 mbar) is less than the

minimum change in outlet (controlled) pressure

required to fully open the vacuum breaker. Since

the minimum change in outlet (controlled) pressure

required to fully open the vacuum breaker with

a 1/4-inch (6,4 mm) orice and control spring is

0.6-inches w.c. (1,5 mbar) from Table 4, no

reduction in the regulating Cg of 50 (Table 2) need

be made.

2. Solve the problem by using the appropriate

values in the formula as follows, remembering

that the

9-inches w.c. (0.325 psig) (22 mbar):

=184 SCFH (4,93 Nm³/h) of Air

P across the vacuum breaker is

Q = 14.7(50) SIN DEG

3415350.325

14.7

Ordering Information

When ordering, specify:

Application

1. Composition and specic gravity of gas (including

chemical analysis if possible)

2. Range of temperatures, owing inlet pressures

(maximum, minimum, nominal), and

pressure drops

3. Desired pressure setting or range

4. Range of ow rates (minimum controlled,

maximum, normal)

5. Piping size(s)

Construction

Refer to the Specications section and to each

referenced table; specify the desired selection

whenever there is a choice to be made. Always

be sure to specify the type number and the spring

case orientation.

6

Page 7

1/4 NPT VENT

Bulletin 71.3:Y690VB

B2673

BODY SIZE,

NPS (DN)

3/4 (20),

1 (25)

NPT SWE

1/2 NPT

CONTROL LINE

CONNECTION

8.38

(213)

D

f G

DIMENSIONS, INCHES (mm)

A b D f G

Ductile

Iron NPT

Stainless

Steel NPT

Ductile

Iron

Stainless

Steel

Ductile

Iron

Stainless

Steel

4.00 (102) 4.12 (105) 2.12 (54) 2.25 (57) 6.18 (157) 6.18 (157)

6.04

(153)

b

A

Ductile

Iron

10.37

(263)

Stainless

Steel

10.37

(263)

14

(356)

INCHES

(mm)

Ductile

Iron

Stainless

Steel

1.53 (39) 1.53 (39)

Figure 3. Dimensions

7

Page 8

Bulletin 71.3:Y690VB

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1999, 2010; All Rights Reserved

Loading...

Loading...