Page 1

XM670-XM679 Controllers for

Multiplexed Cabinets Installation and

Operation Manual

026-1218 Rev 4

Page 2

Page 3

Emerson Commercial and Residential Solutions

1065 Big Shanty Road NW, Suite 100

Kennesaw, GA 30144 USA

770-425-2724 • 1-800-829-2724

www.emerson.com

Page 4

Page 5

Contents

1 INTRODUCTION.......................................................................................................................................................... 1

1.1. G

ENERAL WARNING ..................................................................................................................................................... 1

2 OVERVIEW ................................................................................................................................................................... 1

2.1. G

ENERAL DESCRIPTION................................................................................................................................................ 1

2.2. O

RDERING CODES......................................................................................................................................................... 2

3 USER INTERFACE ...................................................................................................................................................... 2

3.1. K

EYS AND FUNCTIONS ................................................................................................................................................. 2

3.2. U

SE OF LEDS ............................................................................................................................................................... 3

3.3. H

OW TO ENTER THE FAST ACCESS MENU ................................................................................................................... 3

3.4. H

OW TO SEE THE MAX AND MIN TEMPERATURE RECORDED ................................................................................... 3

3.5. H

OW TO SEE AND MODIFY THE SETPOINT................................................................................................................... 3

3.6. H

OW TO START A MANUAL DEFROST.......................................................................................................................... 3

3.7. H

OW TO ENTER THE PARAMETERS LIST PR1 .............................................................................................................. 3

3.8. H

OW TO ENTER THE PARAMETERS LIST PR2 .............................................................................................................. 4

3.9. H

OW TO ASSIGN A MODBUS ADDRESS ..................................................................................................................... 4

3.10. H

3.11. ON/OFF F

4 FAST ACCESS MENU ................................................................................................................................................. 5

OW TO CHANGE THE PARAMETER VALUE............................................................................................................... 4

UNCTION.................................................................................................................................................... 4

5 SECTION MENU .......................................................................................................................................................... 6

5.1. T

O SET ENERGY SAVING TIMES................................................................................................................................... 6

5.2. T

O SET TIMED DEFROST PARAMETERS ........................................................................................................................ 6

6 ELECTRONIC EXPANSION VALVE MENU (FOR MODEL XM679 ONLY).................................................... 7

7 CONTROLLING LOADS ............................................................................................................................................ 7

7.1. S

OLENOID VALVE ......................................................................................................................................................... 7

7.2. S

TANDARDS REGULATION AND CONTINUOUS REGULATION ....................................................................................... 7

7.2.1. First Kind of Regulation: Standard Regulation.................................................................................................... 8

7.2.2. Second Kind of Regulation: Continuous Regulation (For Model XM679 Only).................................................. 8

7.3. D

EFROST ....................................................................................................................................................................... 8

7.3.1. Defrost starting..................................................................................................................................................... 8

7.3.2. Defrost Ending...................................................................................................................................................... 8

7.4. F

ANS ............................................................................................................................................................................. 9

7.4.1. Control With Relay................................................................................................................................................ 9

7.4.2. Control With Analog Output (If Present).............................................................................................................. 9

7.5. A

NTI-SWEAT HEATERS (IF PRESENT)........................................................................................................................... 9

7.6. A

UXILIARY OUTPUT ..................................................................................................................................................... 9

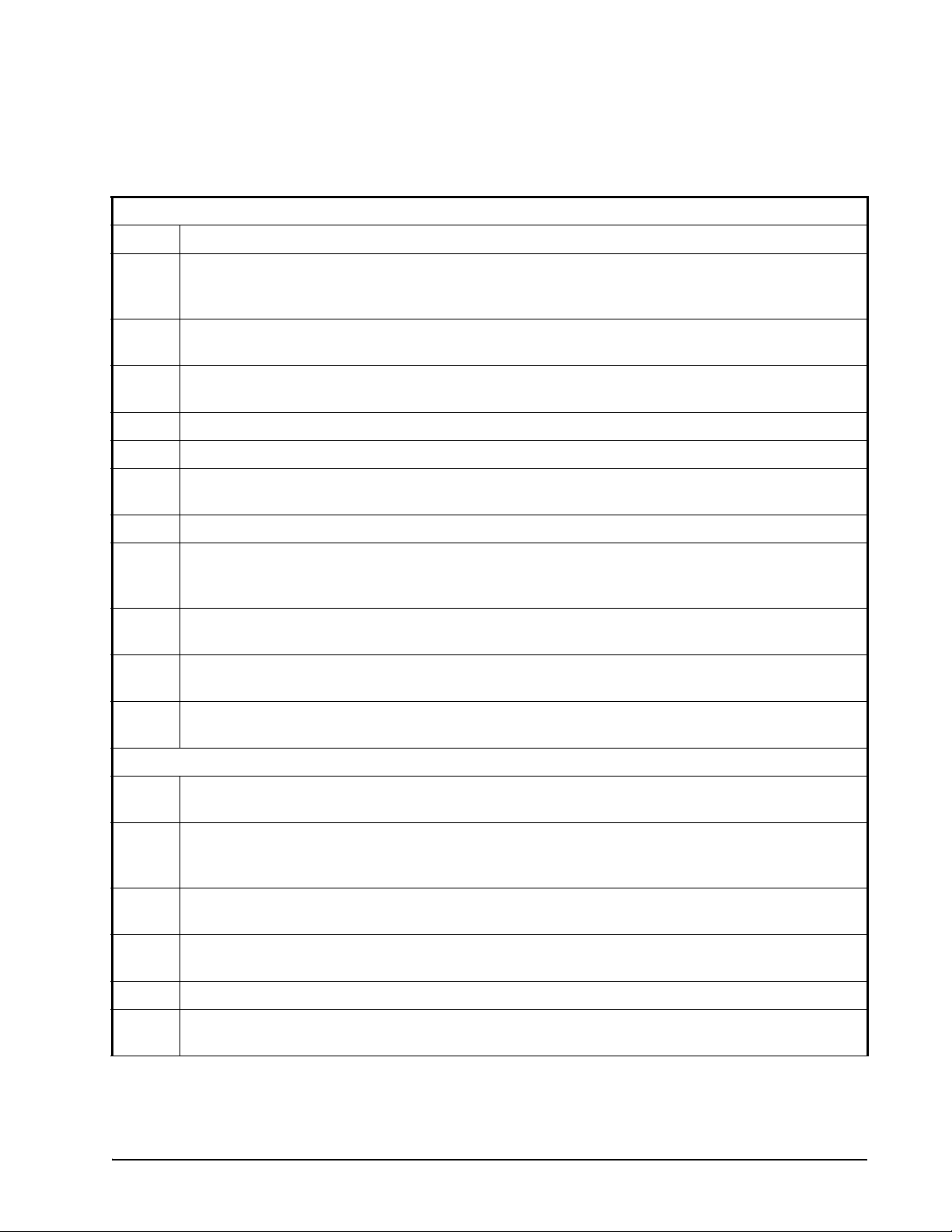

8 PARAMETERS LIST.................................................................................................................................................. 10

9 DIGITAL INPUTS....................................................................................................................................................... 19

9.1. G

ENERIC ALARM (EAL)............................................................................................................................................. 19

9.2. S

ERIOUS ALARM MODE (BAL)................................................................................................................................... 19

9.3. P

RESSURE SWITCH (PAL) .......................................................................................................................................... 19

9.4. D

OOR SWITCH INPUT (DOR) ....................................................................................................................................... 19

9.5. S

TART DEFROST (DEF)............................................................................................................................................... 19

9.6. R

ELAY AUX ACTUATION (AUS) ................................................................................................................................ 19

Table of Contents • 5

Page 6

9.7. RELAY LIGHT ACTUATION (LIG) ............................................................................................................................... 19

9.8. R

EMOTE ON/OFF (ONF) ............................................................................................................................................ 19

9.9. K

IND OF ACTION (HTR) .............................................................................................................................................. 19

9.10. FHU (N

9.11. E

9.12. C

9.13. D

OT USED) ..................................................................................................................................................... 19

NERGY SAVING INPUT (ES).................................................................................................................................... 19

ONFIGURABLE INPUT - HOLIDAY FUNCTION (HDY).............................................................................................. 20

IGITAL INPUTS POLARITY....................................................................................................................................... 20

10 INSTALLATION AND MOUNTING...................................................................................................................... 20

11 ELECTRICAL CONNECTIONS............................................................................................................................. 21

11.1. P

ROBE CONNECTIONS ............................................................................................................................................... 21

12 RS485 SERIAL LINE ................................................................................................................................................ 21

13 HOW TO USE THE HOT KEY ............................................................................................................................... 21

13.1. D

13.2. U

OWNLOAD (FROM THE HOTKEY TO THE DEVICE).................................................................................................. 21

PLOAD (FROM THE DEVICE TO THE HOTKEY) ....................................................................................................... 22

14 ALARM SIGNALS ................................................................................................................................................... 23

14.1. EE A

14.2. A

LARM................................................................................................................................................................ 24

LARM RECOVERY ................................................................................................................................................... 24

15 TECHNICAL DATA ................................................................................................................................................. 25

16 UL RATINGS ............................................................................................................................................................. 26

17 CONNECTIONS ........................................................................................................................................................ 27

17.1. E2

TO XM DEVICE COMMUNICATION RECOMMENDATIONS .................................................................................... 27

17.1.1. Wiring Guidelines ............................................................................................................................................. 27

17.2. XM670 - W

17.3. XM679 - 230VAC V

17.4. XM679 - 24VAC V

IRING DIAGRAM..................................................................................................................................... 27

ALVES/WIRING DIAGRAM....................................................................................................... 28

ALVES/WIRING DIAGRAM ......................................................................................................... 28

18 E2 MODBUS NETWORK WIRING ....................................................................................................................... 29

19 WIRING LAYOUT FOR SHARING A PRESSURE TRANSDUCER ON A LAN ............................................ 30

20 PRESSURE TRANSDUCER SETUP (XM679 ONLY) ......................................................................................... 31

20.1. RS485 N

ET MONITORING TEMPERATURES ............................................................................................................. 31

20.1.1. RS485 Connection............................................................................................................................................. 31

20.2. H

OW TO ENABLE A PRESSURE PROBE TO SHARE ACROSS THE LAN ...................................................................... 32

21 WIRING CONNECTION TO SITE SUPERVISOR.............................................................................................. 33

22 ECT MODBUS NETWORKING TO E2S............................................................................................................... 34

22.1. COM P

22.2. COM P

22.3. E2 S

ORT ASSOCIATIONS - E2 VERSIONS 3.XX AND BELOW ................................................................................ 34

ORT ASSOCIATIONS - E2 VERSIONS 4.0 AND ABOVE ................................................................................... 34

ETUP OF DEVICES .............................................................................................................................................. 35

22.3.1. Set Up Network Ports........................................................................................................................................ 35

22.3.2. Add and Connect the Device..................................................... ..................................... ................................... 35

22.4. W

22.5. MODBUS T

IRING TYPES .......................................................................................................................................................... 37

ERMINATION BLOCKS ........................................................................................................................... 37

23 DEFAULT SETTING VALUES............................................................................................................................... 38

TABLE 23-1 APPENDIX A - ALTERNATE MODBUS COM WIRING METHOD FOR E2, XR, XM, AND XEV

DEVICES ........................................................................................................................................................................... 45

6 • XM679K I&O Manual 026-1218 Rev 4

Page 7

1 Introduction

2Overview

1.1. General Warning

Please read the following safety precautions and

warnings before using this manual:

CAUTION!

• This manual is part of the product and

should be kept near the device for easy and

quick reference.

• The device should not be used for purposes

different from those described in this manual. It

cannot be used as a safety device.

• Check the application limits before proceeding.

SAFETY PRECAUTIONS AND

WARNINGS!

• Check that the supply voltage is correct

before connecting the device.

• Do not expose to water or moisture: use the

controller only within the operating limits and avoid

sudden temperature changes with high atmospheric

humidity to prevent condensation from forming.

• Warning! Disconnect all electrical connections

before performing any kind of maintenance.

• Fit the probe where it is not accessible by the end

user. The device must not be opened.

• In case of failure or faulty operation, send the

device back to the distributor or to Emerson (see

address) with a detailed description of the fault.

• Verify the maximum current that can be applied

to each relay (see Section 15, Technical Data).

• Ensure that the wires for probes, loads, and the

power supply are separated and far enough from each

other without crossing or intertwining.

• In case of applications in industrial

environments, the use of main filters in parallel with

inductive loads could be useful.

2.1. How to Check the Software Release of the XM679K

1. Check the software release of the

XM679K printed on the label of the

controller.

Figure 2-1 - XM679K Software Release

2.2. General Description

Models XM670-XM679 are high level

microprocessor based controllers for multiplexed

cabinets, suitable for applications on medium or low

temperature. It can be inserted in a Local Area

Connection (LAN) of up to eight (8) different sections

that can operate depending on the programming, as

stand alone controllers or by following the commands

coming from the other sections.

XM670/XM679 controllers can have six (6) relay

outputs to control the solenoid valve, defrost that can

be either electrical or hot gas, evaporator fans, lights,

auxiliary output, alarm output and an output to drive

pulsed electronic expansion valves (applicable for

XM679 only).

The controllers can also have up to four (4) probe

inputs: the first one for temperature control, the

second for defrost end temperature control of the

evaporator, the third for the display, and the fourth

probe input can be used for applications with virtual

probe or for inlet/outlet air temperature measurement.

Model XM679 can exclusively have two (2) other

probes that can be used for superheat measurement

and regulation. Both XM670 and XM679 controllers

General Warning Introduction • 1

Page 8

are also equipped with three digital inputs (free

contact) that are fully configurable through

parameters.

The Hot Key connector allows simple programming

of the controllers.

Direct serial output RS485

MODBUS-RTU compatible permits a simple XWEB

interfacing. Depending on the model, the Hot Key

connector can also be used to connect X-REP display.

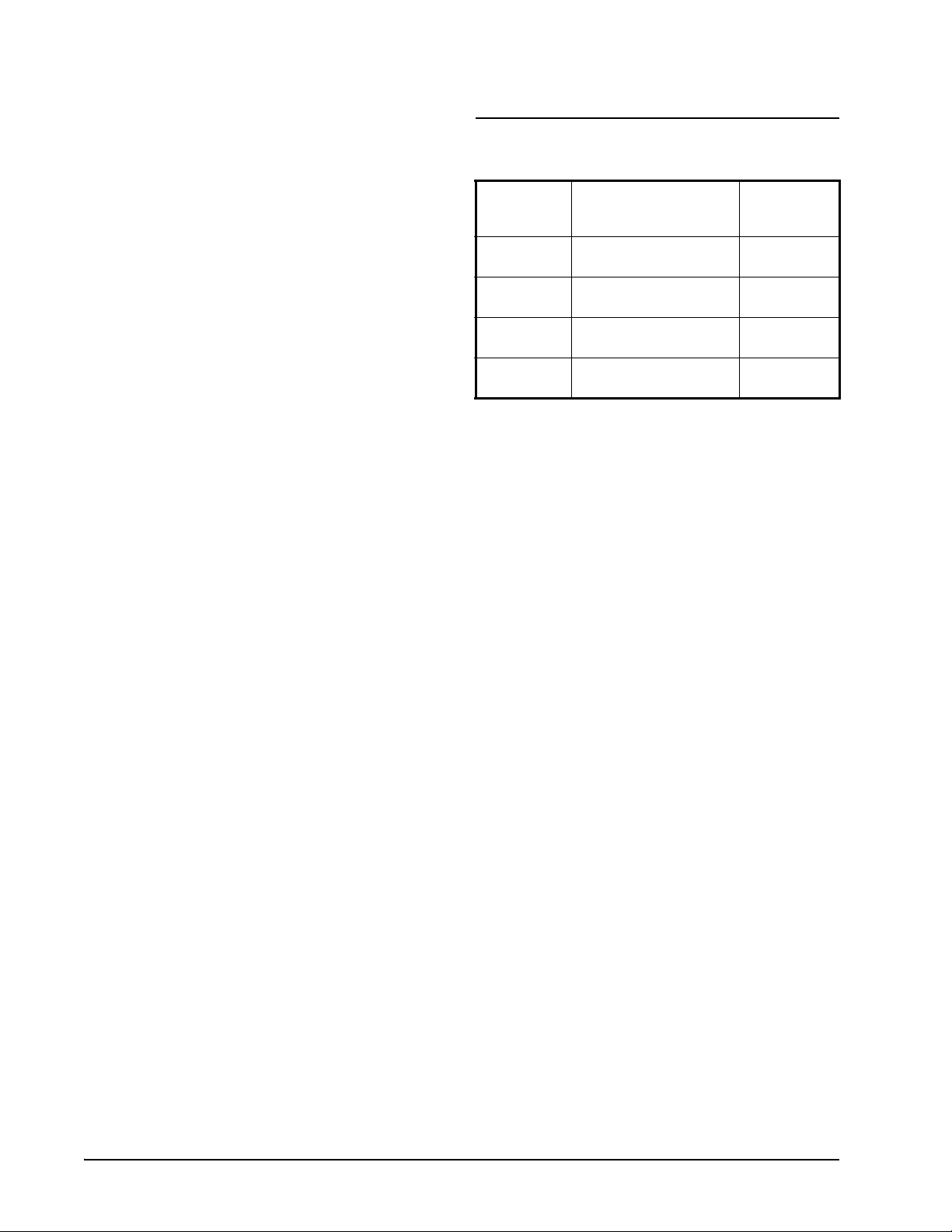

2.3. Ordering Codes

Device

Name

XM670

XM670

XM679

XM679

Table 2-1 - Product Ordering Codes

Description

Solenoid Case Control

Solenoid Case Control

11

5V

23

0V

Pulse Case Control

11

5V

Pulse Case Control

23

0V

Emerson

Part

Number

318-6520

318-6521

318-6700

318-6701

2 • XM679K I&O Manual 026-1218 Rev 4

Page 9

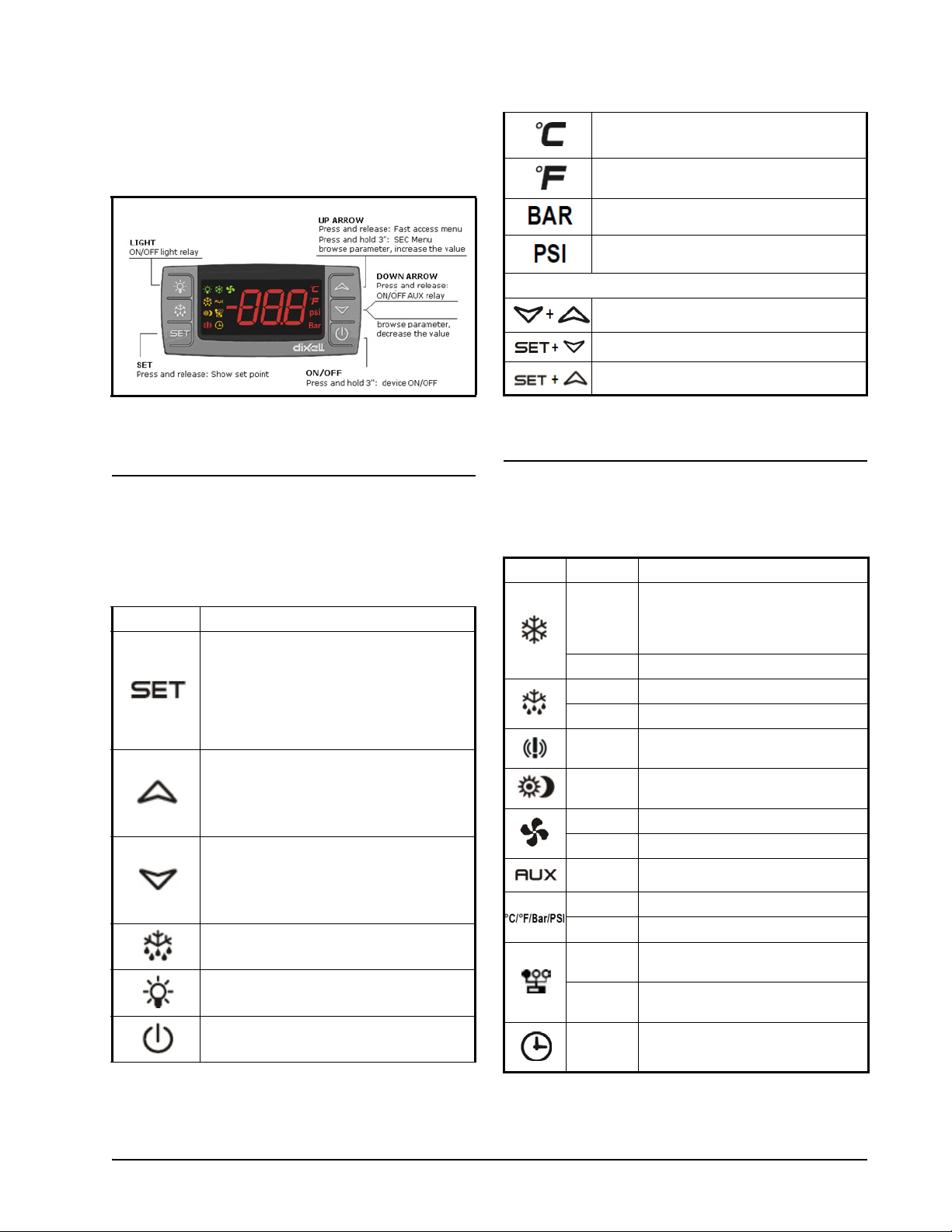

3 User Interface

Measurement unit

Measurement unit

Measurement unit

Measurement unit

Key Combinations

Locks/Unlocks the keyboard

Switches mode to programming mode

Exits the programming mode

Figure 3-1 - XM670 - XM679 Front Panel

3.1. Keys and Functions

Table 3-1 lists the keys that are found on the front

panel of XM670-XM679 controllers and the function

of each:

.

Key Function

Press to display the target setpoint, to

select a parameter in programming mode,

or to confirm an operation. Pressing this

key for three (3) seconds while the

minimum or maximum temperature is

displayed will erase the temperature

currently displayed.

Press this key to browse the parameter

codes in programming mode or increases

the displayed value. Pressing this key for

three (3) seconds will give you access to

the Section menu.

Press this key to access the fast access

menu, browse the parameter codes in

programming mode, decrease the

displayed value, or activate or deactivate

an auxiliary output.

Starts a defrost when pressed for three (3)

seconds.

Switches the room light ON and OFF.

Press for three (3) seconds to switch the

device ON and OFF.

Table 3-1 - XM670/XM679 Front Panel Keys and Functions

(Continued)

3.2. Use of LEDS

Each LED function is described in Table 3-2:

LED Mode Function

Compressor and valve regulation

ON

Flashing Anti-short cycle delay enabled

ON Defrost enabled

Flashing Drip time in progress

ON An alarm is occurring

ON Energy saving enabled

ON Fans enabled (fans are running)

Flashing Door opened or delay after defrost

ON Auxiliary relay ON

ON Measurement unit

Flashing Programming phase

ON

Flashing

Flashing

enabled.

percentage, enter the fast access

menu.

The controller is

ALL mode

The controller is

remote virtual display mode

During the CLOCK modification

(if clock is presen

To see the valve opening

working in

working in

t)

Table 3-1 - XM670

Keys and Functions User Interface • 3

/XM679 Front Panel Keys and Functions

Table 3-2 - LEDs

Page 10

3.3. How to Enter the Fast

Access Menu

1. Press and release the UP button.

2. The First Label will be displayed. Press the UP or

DOWN button to navigate the menu.

1. Enter the programming mode by pressing the SET

and DOWN buttons for a few seconds (wait for the

measurement unit to start blinking).

2. The controller will show the first parameter present

in Pr1.

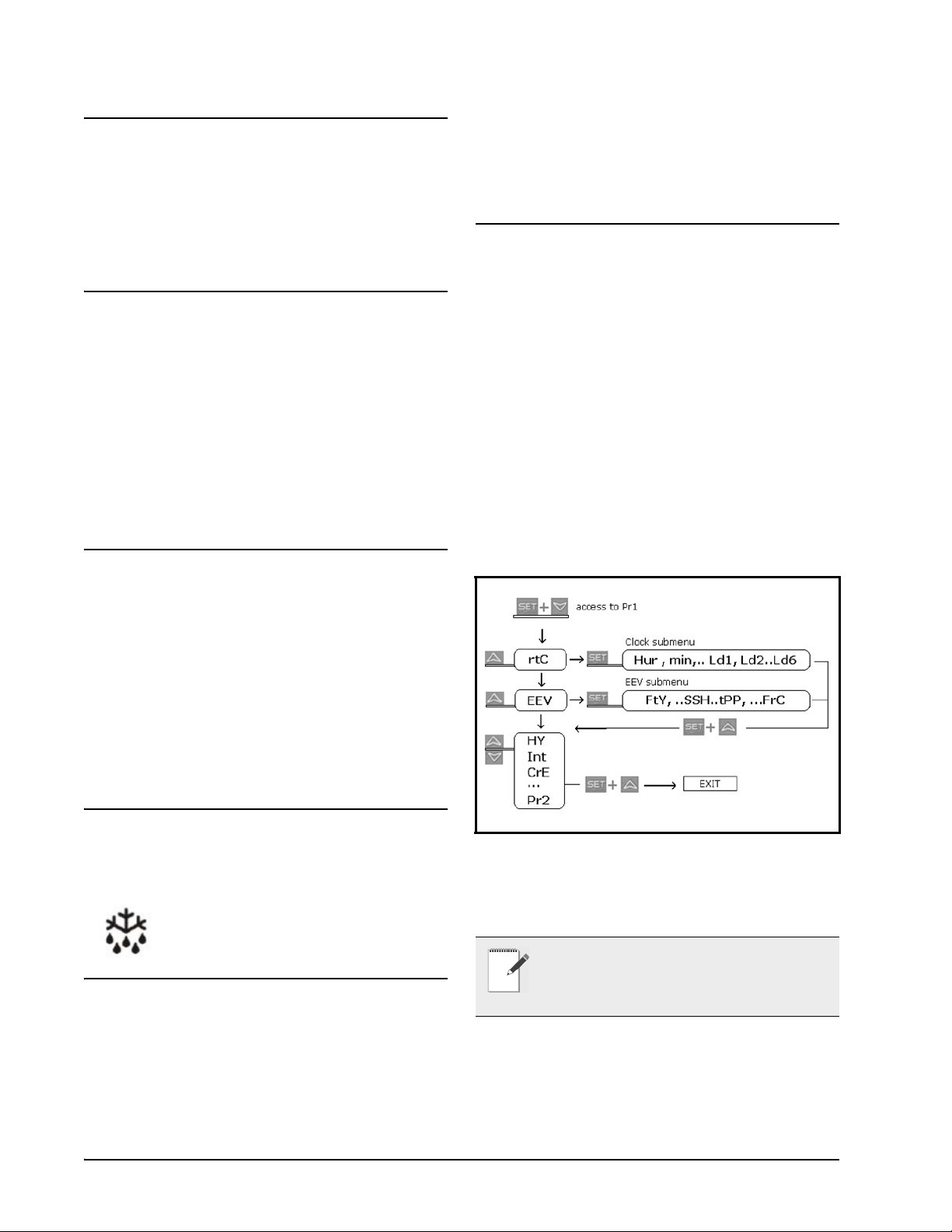

3.8. How to Enter the Parameters List PR2

3.4. How to See the MAX and MIN Temperature Recorded

1. Press and release the UP button.

2. The First Label will be displayed. Press the UP or

DOWN button to navigate the menu. Search the L°t

label and press SET to see minimum temperature;

search the H°t label and press SET to see maximum

temperature.

3.5. How to See and Modify the Setpoint

1. Press the SET button for three (3) seconds to show

the setpoint value.

2. The measurement unit starts blinking.

3. To change the setpoint value, press the UP or

DOWN button for 10 seconds.

4. To store the new setpoint value, press the SET key

again or wait 10 seconds.

To access the parameter list in Pr2:

1. Enter the Pr1 lev el . F ol lo w t he st ep s i n Section 3.7.,

How to Enter the Parameters List PR1.

2. Select Pr2 parameter and press the SET key.

3. The PAS flashing message will display, followed

shortly by “0 --” with a flashing zero.

4. Use the UP or DOWN button to input the security

code in the flashing digit. Confirm the security code

by pressing SET. The security code is 321.

5. If the security code is correct, the access to Pr2 is

enabled by pressing SET on the last digit.

3.6. How to Start a Manual Defrost

Press the DEF key for more than three

(3) seconds to start a manual defrost.

3.7. How to Enter the

Figure 3-2 - Parameters List 2

Another way to enter the programming mode is by

pressing the SET and DOWN buttons for 30 seconds

immediately after switching the controller ON.

NOTE: Each parameter in Pr2 can be removed

or put into Pr1 (user level) by pressing SET +

DOWN buttons. When a parameter is present

in Pr1, the Alarm LED will be display.

Parameters List PR1

To enter the parameter list in Pr1 (user accessible

parameters):

4 • XM679K I&O Manual 026-1218 Rev 4

Page 11

3.9. How to Assign a MODBUS Address

1. To enter the programming mode, press and hold the

SET and DOWN buttons together until the

temperature measurements start blinking.

2. Scroll through the parameters using the UP or

DOWN button until Adr is displayed.

3. Press and hold SET to select Adr.

4. Use the arrow keys to choose the address number of

the device.

5. Press and hold SET again to select the desired

number and save.

6. To exit, press the SET and UP arrow keys together.

3.10.How to Change the Parameter Value

1. Enter the programming mode.

2. Select the required parameter using the UP or

DOWN button.

3. Press the SET key to display the parameter value

(measurement unit starts blinking).

4. Use the UP or DOWN button to change the value.

5. Press SET to store the new value and move to the

next parameter.

6. To exit, press SET + UP keys or wait 15 seconds

without pressing a key.

NOTE: During the OFF status, the Light and

AUX buttons are active.

NOTE: The set value is stored even when the

time-out expires and ends the procedure.

3.11.ON/OFF Function

By pressing the ON/OFF key, the

controller shows OFF. During the OFF

status, all the relays are switched OFF

and the regulations are stopped; if a

monitoring system is connected, it does not record the

controller data and alarms.

How to Assign a MODBUS Address User Interface • 5

Page 12

4 Fast Access Menu

This menu contains the lists probes and some values that are automatically evacuated by the board, such as the

superheat and the percentage of valve opening. The values below stands for:

• nP or noP - probe not present or value not evacuate

• Err - value out of range, probe damaged, not connected or incorrectly configured

FAST ACESS MENU

HM Fast Access Menu to Clock Settings (If present)

An

SH Superheat Shows the actual superheat value (Only XM679)

oPP Valve opening percentage Shows the actual opening percentage of the valve (Only XM679)

dP1 Probe 1 value displaying Shows the temperature measured by probe 1

dP2 Probe 2 value displaying Shows the temperature measured by probe 2

dP3 Probe 3 value displaying Shows the temperature measured by probe 3

dP4 Probe 4 value displaying Shows the temperature measured by probe 4

dP5 Probe 5 value displaying Shows the temperature measured by probe 5

dP6 Probe 6 value displaying Shows the temperature measured by probe 6

dPP Pressure probe value

rPP Remote pressure probe value

L°t Minimum measured temperature Shows the minimum temperature read by the regulation probe

H°t Maximum measured temperature Shows the maximum temperature read by the regulation probe

dPr Virtual regulation probe value Shows the value measured by the virtual regulation probe

dPd Virtual defrost probe value Shows the value measured by the virtual defrost probe

dPF Virtual fans probe value Shows the value measured by virtual fan probe

rSE Real setpoint

Fast Access to Analog Output

Reading

(If present)

Shows the value of pressure measured by pressure transducer

(Only XM679)

Shows the value of pressure received by remote pressure probe

connected to other XM600 device (Only XM679)

Shows the setpoint used during the energy saving cycle or during

the continuous cycle

Table 4-1 - Fast Access Menu

6 • XM679K I&O Manual 026-1218 Rev 4

Page 13

5 Section Menu

This menu allows the user to access to a particular

feature of the XM series related to the LAN (Local

Area Network) of controllers. Depending on the

programming of this menu, a single keyboard can

control either the module of the local section of the

LAN or ALL. The possibilities are: LOC: the

keyboard controls and display the value, the status,

and the alarms of the local section of the LAN; and

ALL: the command given by the keyboard are

effective on all the sections of the LAN.

1. Press the UP key for more than three (3) seconds.

2. The label corresponding to the section controlled by

the keyboard will be displayed.

3. Using the UP or DOWN key, select the section you

want to control.

4. Press the SET key to confirm and exit.

5.1. To Set Energy Saving Times

ILE Energy Saving cycle

dLE Energy Saving cycle

ISE Energy Saving cycle

dSE Energy Saving cycle

HES Temperature

Table 5-1 - Energy Saving Times Parameters

start during

workdays

l

ength during

workdays

start on ho

l

ength on holidays

increase during the

Ener

lidays

gy Saving cycle

(0 to 23 h 50 min)

During the Energy

Saving cycle, the

setpoint is increased by

the value in HES so

that the operation

setpoint is SET + HES.

(0 to 24 h 00 min) Sets

the duration of the

Energy Saving cycle on

workdays.

(0 to 23h 50 min)

(0 o 24h 00 min)

(-54 to 54°F/ -30 to

°C) Sets the

30

increasing value of the

setpoint during the

Energy Saving cycle.

5.2. To Set Timed Defrost Parameters

Ld1

Workday

to

defrost start

Ld6

Sd1

Holiday

to

defrost start

Sd

6

Table 5-2 - Timed Defrost Parameters

NOTE: To disable a defrost cycle, set it to nu

(not used). For example, if Ld6=nu, the sixth

defrost cycle is disabled.

(0 to 23h 50 min) These

parameters set the beginning of

the eight programmable defrost

cycles during workdays. For

example, when Ld2=12.4, the

second defrost starts at 12.40

during workdays.

(0 to 23h 50 min) These

parameters set the beginning of

the eight programmable defrost

cycles during holidays. For

example, when Sd2=3.4, the

second defrost starts at 3.40 on

holidays.

To Set Energy Saving Times Section Menu • 7

Page 14

6 Electronic

Expansion Valve

Menu (For Model

XM679 Only)

1. Enter the programming mode by pressing the SET

and DOWN buttons for a few seconds

(measurement unit starts blinking).

2. Press the UP or DOWN key until the controller

displays the EEU label.

3. Press SET. You are now in EEV function menu.

7 Controlling Loads

7.1. Solenoid Valve

The regulation is performed based on the temperature

measured by the thermostat probe that can be a

physical probe or a virtual probe obtained by a

weighted average between the two probes (see

Section 8, Parameters List) with a positive

differential from the setpoint. If the temperature

increases and reaches setpoint plus the differential,

the solenoid valve is opened and then it is closed

when the temperature reaches the setpoint value

again.

In case of fault in the thermostat probe, the opening

and closing time of the solenoid valve are configured

by Con and CoF parameters.

7.2. Standards Regulation and Continuous Regulation

The regulation can be performed in two ways:

• Standard regulation is reaching the best superheat

via a classic temperature regulation obtained using

hysteresis.

• Continuous regulation permits the use of the valve

to realize a high performance temperature regulation

with a good factor of superheat precision. This only

can be used only in centralized plants and it is

available only with electronic expansion valve by

selecting the CrE=Y parameter.

In any case, the regulation is performed via the PI

regulator that gives the opening percentage to the

valve via PWM modulation explained as follows:

Opening Percentage is obtained from the average of

the Opening Time with respect to the CyP time period

Figure 7-1).

(see

8 • XM679K I&O Manual 026-1218 Rev 4

Page 15

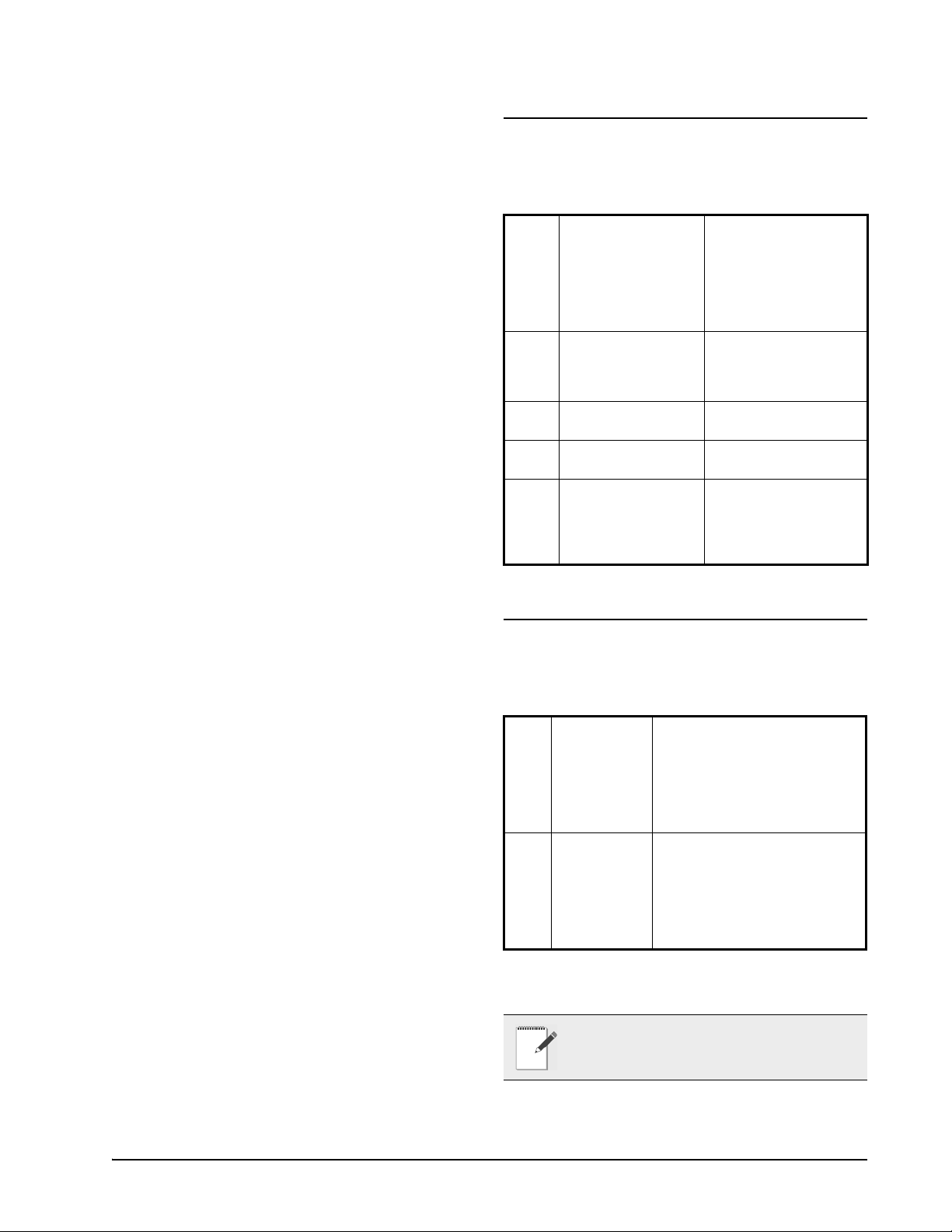

Figure 7-1 - Regulation via PI Regulator

Opening percentage is the percentage of the cycle

period where the valve is open. For example, if

CyP=6s (standard value) and the valve is opened at

50%, this means that the valve is opened for three (3)

seconds during the cycle period.

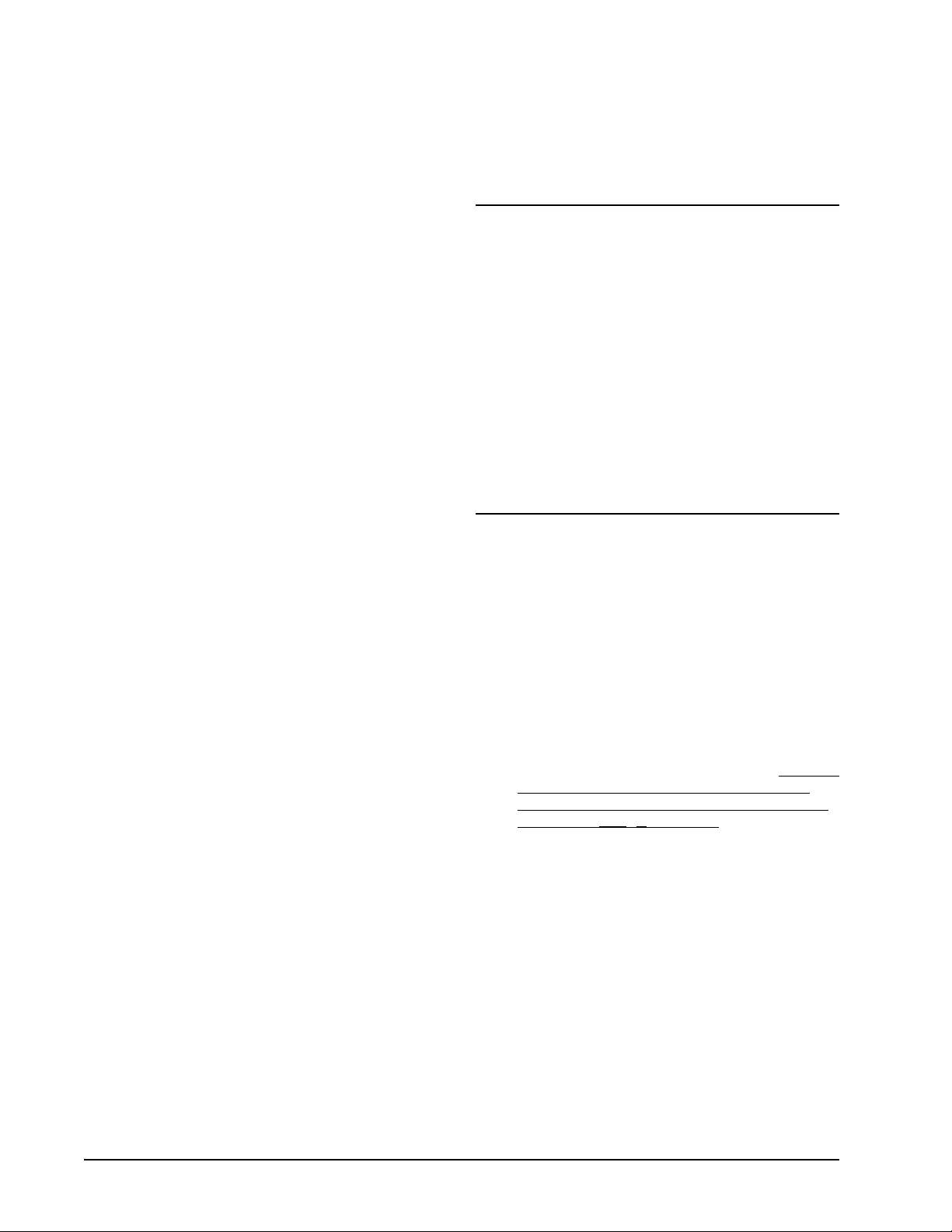

7.2.1. First Kind of Regulation: Standard Regulation

In this case, the Hy parameter is the differential for

the standard ON/OFF regulation. In this case, the int

parameter is neglected. The regulation follows the

diagram shown in

Figure 7-2 - First Kind of Regulation

Figure 7-2:

7.2.2. Second Kind of Regulation:

Continuous Regulation

(For Model XM679 Only)

In this case, the Hy parameter is the proportional band

of PI in charge of room temperature regulation. It is

advisable to use at least Hy=10°F/ 5.0°C.

The int parameter is the integral time of the same PI

regulator. Increasing the int parameter will cause the

PI regulator to react more slowly, and is true vice

versa. To disable the integral part of regulation, set

int=0.

Figure 7-3 - Second Kind of Regulation

7.3. Defrost

7.3.1. Defrost starting

In any case, the device checks the temperature that is

read by the configured defrost probe before starting

defrost procedure. After that:

• Starting defrost cycles can be operated locally

(manual activation by means of the keyboard or

digital input or end of interval time) or the command

can come from the Master defrost unit of the LAN.

In this case, the controller will operate the defrost

cycle following the parameters it has programmed,

but at the end of the drip time it will wait until all the

other LAN controllers finish their defrost cycle

before the normal regulation of the temperature is

restarted according to the dEM parameter.

• Every time any of the LAN controllers begin a

defrost cycle, it issues the command to the network

making all the other controllers start their own cycle.

This allows a perfect synchronization of the defrost

in the whole multiplexed cabinet according to LMd

parameter.

• By selecting the dPA and dPb probes and changing

the dtP and ddP parameters, defrost can be started

when the difference between the dPA and dPb

probes is lower than dtP for all ddP time. This is

useful to start defrost when a low thermal exchange

is detected. If ddP=0, this function is disabled.

7.3.2. Defrost Ending

•If dPA and dPb are present and d2P=y, the

controller stops the defrost procedure when dPA is

higher than the dtE temperature and dPb is higher

than the dtS temperature.

At the end of defrost, the drip time is controlled

through the Fdt parameter.

Defrost Controlling Loads • 9

Page 16

7.4. Fans

7.5. Anti-Sweat Heaters

7.4.1. Control With Relay

The fan control mode is selected by means of the FnC

parameter:

• C-n = running with the solenoid valve, OFF during

defrost

• C-y = running with th1e solenoid valve, ON during

defrost

• O-n = continuous mode, OFF during defrost

• O-y = continuous mode, ON during defrost

An additional parameter FSt provides the setting of

temperature, detected by the evaporator probe, above

which the fans are always OFF. This ensures that air

is circulated only if the temperature is lower than set

in FSt.

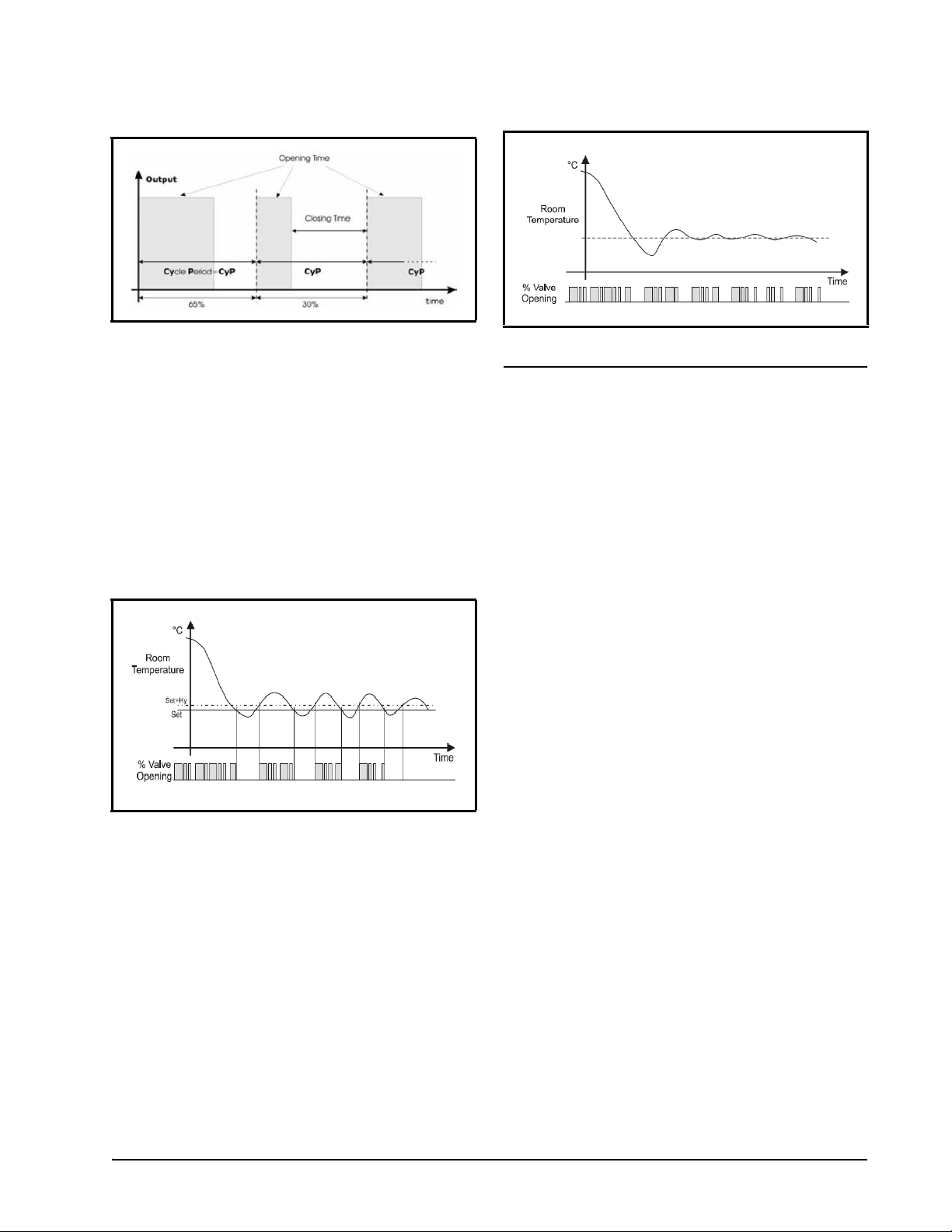

7.4.2. Control With Analog Output (If Present)

The modulating output (trA=rEG) works in a

proportional manner (excluding the first AMt

seconds where the fans speed is the maximum). The

regulation setpoint is relative to the regulation

setpoint and is indicated by the parameter ASr, the

proportional band is always located above the

SET+ASr value and its value is PbA. The fans are at

minimum speed (AMi) when the temperature read by

the fan probe is SET+ASr and the fans are at

maximum speed (AMA) when the temperature is

SET+ASr+PbA.

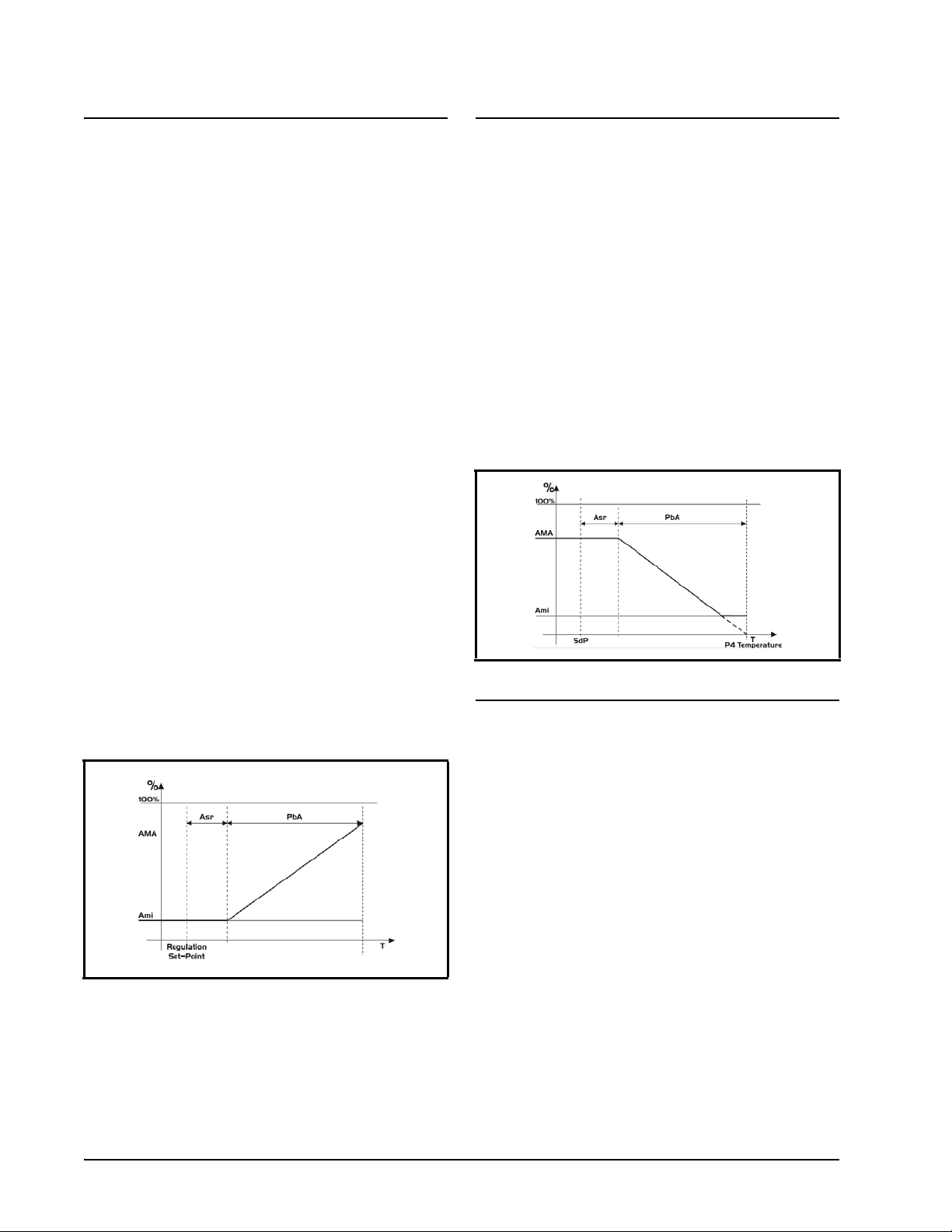

(If Present)

This control is performed when trA=AC. In this case,

there are two ways to control the anti-sweat heaters:

• Without real dewpoint information: in this case, the

default value for dewpoint is used (SdP parameter).

• Dewpoint received from the XWEB5000 system:

the SdP parameter is overwritten when the valid

value for dewpoint is received from XWEB.

The P4 probe is used to perform the regulation and it

should be placed on the showcase glass. In case of P4

error or if P4 is absent, the output is at AMA value for

the AMt time then the output is at 0 value for the time

255-AMt time performing a simple PWM

modulation.

Figure 7-5 - Anti-Sweat Heaters

7.6. Auxiliary Output

The auxiliary output is switched ON and OFF by

means of the corresponding digital input or by

pressing and releasing the DOWN key.

Figure 7-4 - Control with Analog Output

10 • XM679K I&O Manual 026-1218 Rev 4

Page 17

8 Parameters List

EEU Access to EEV submenu (only XM679)

Differential: (1 to 45°F; 0.1 to 25.5°C) This is the intervention differential for setpoint, this value is always

Hy

positive. Solenoid valve Cut IN is Setpoint Plus Differential (Hy). Solenoid valve Cut OUT is when the

temperature reaches the setpoint.

REGULATION

Int

CrE

LS Minimum setpoint limit: (-67°F to SET; -55.0°C to SET) Sets the minimum acceptable value for the setpoint.

US Maximum setpoint limit: (SET to 302°F; SET to 150°C) Set the maximum acceptable value for setpoint.

OdS

AC Anti-short cycle delay: (0 to 60 min) The interval between the solenoid valve stop and the following restart.

CCt

CCS

Con

CoF

Integral time for room temperature regulation (Only XM679): (0 to 255 s) This is the integral time for room

temperature PI regulator. 0= no integral action.

Continuous regulation activation (Only XM679): (n to Y) n= standard regulation; Y= continuous regulation.

Use it only in centralized plants.

Outputs activation delay at start up: (0 to 255 min) This function is enabled at the initial start up of the device

and inhibits any output activation for the time set in the parameter. (AUX and Light can work)

Compressor ON time during continuous cycle: (0.0 to 24.0h; resolution 10min) Allows to set the length of

the continuous cycle: compressor stays on without interruption for the CCt time. Can be used, for instance,

when the room is filled with new products.

Setpoint for continuous cycle: (-67 to 302°F / -55 to 150°C) it sets the setpoint used during the continuous

cycle.

Solenoid valve ON time with faulty probe: (0 to 255 min) The time during which the solenoid valve is active

in case of faulty thermostat probe. With COn=0 solenoid valve is always OFF.

Solenoid valve OFF time with faulty probe: (0 to 255 min) time during which the solenoid valve is off in case

of faulty thermostat probe. With COF=0 solenoid valve is always active.

DISPLAY

CF

PrU

PMU

PMd

rES Resolution (for °C): (in = 1°C; dE = 0.1 °C) allows decimal point display

Lod

Table 8-1 - XM670 to XM679 Parameters List

Auxiliary Output Parameters List • 11

Temperature measurement unit: °C = Celsius; °F = Fahrenheit. CAUTION! When the measurement unit is

changed the parameters with temperature values have to be checked.

Pressure mode: (rEL or AbS) defines the mode to use the pressure. CAUTION! the setting of PrU is used for

all the pressure parameters. If PrU = rEL all pressure parameters are in relative pressure unit, if PrU = AbS

all pressure parameters are in absolute pressure unit. (Only XM679)

Pressure measurement unit: (bAr - PSI - MPA) it selects the pressure measurement units. MPA= the value of

pressure measured by kPA*10. (Only XM679)

Way of displaying pressure: (tEM - PrE) it permits showing the value measured by pressure probe with

tEM= temperature or by PrE= pressure (Only XM679)

Device display: (nP; P1; P2, P3, P4, P5, P6, tEr, dEF) it selects which probe is displayed by the device. P1,

P2, P3, P4, P5, P6, tEr= virtual probe for thermostat, dEF= virtual probe for defrost.

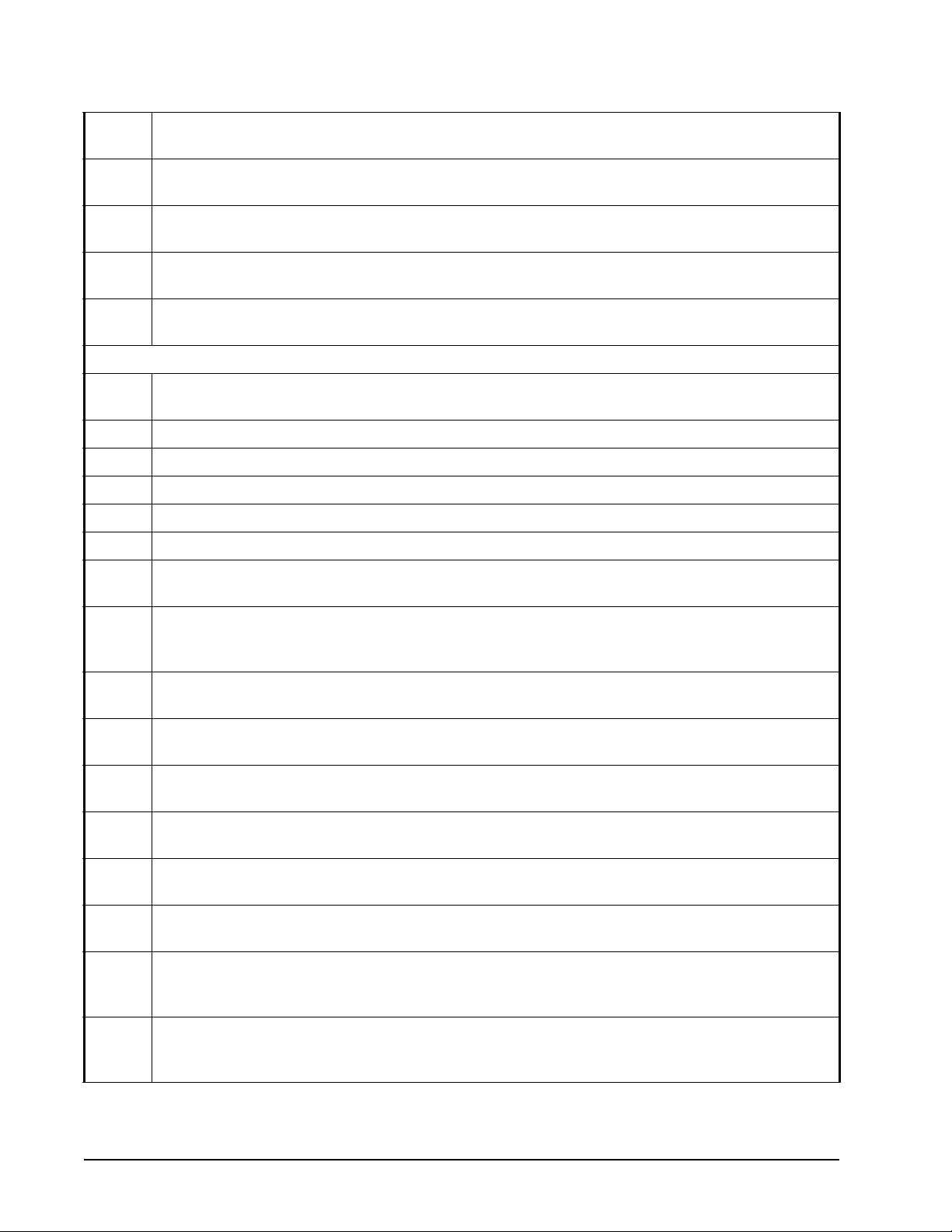

Page 18

red

Remote display: (nP; P1; P2, P3, P4, P5, P6, tEr, dEF) it selects which probe is displayed by the X-REP. P1,

P2, P3, P4, P5, P6, tEr= virtual probe for thermostat, dEF= virtual probe for defrost.

dLy

rPA

rPb

rPE

Display delay: (0 to 24.0 m; resolution 10s) when the temperature increases, the display is updated of

1 °F/1°C after this time.

Regulation probe A: (nP; P1; P2, P3, P4, P5) first probe used to regulate room temperature. If rPA = nP the

regulation is performed with real value of rPb.

Regulation probe B: (nP; P1; P2, P3, P4, P5) second probe used to regulate room temperature. If rPb = nP

the regulation is performed with real value of rPA

Regulation virtual probe percentage: (0 to 100%) it defines the percentage of the rPA respect to rPb. The value

used to regulate room temperature is obtained by: value_for_room = (rPA*rPE + rPb*(100-rPE))/100

ELECTRONIC EXPANSION VALVE SUBMENU (Only XM679)

FtY

Kind of gas (R22, 134, 404, 407, 410, 507,CO2): Type of gas used by plant. Fundamental parameter for

correct functioning of all system.

SSH Superheat setpoint: [1°F to 45°F] [0.1°C to 25.5°C] This is the value used to regulate superheat.

CyP Cycle Period: (1 to 15s) Allows to set cycle time

Pb Proportional band: (1 to 108°F / 0.1 to 60.0) PI proportional band

rS Band Offset: (-21 to 21°F / -12.0 to 12.0°C) PI band offset

inC Integration time: (0 to 255s) PI integration time

PEO

Probe Error opening percentage: (0 to 100%) if a temporary probe error occurs, valve opening percentage is

PEo until PEd time is elapsed.

Probe Error delay before stopping regulation: (0 to 239 sec. - On = unlimited) if probe error duration is bigger

PEd

than PEd then valve totally closes. Pf message displays. If PEd = On valve opening is PEo until probe error

finishes.

OPE

SFd

OPd

Pdd

MnF

dCL

Start opening Percentage: (0 to 100%) Valve opening percentage when start function is active. This phase

duration is SFd time.

Start Function duration: (0.0 to 42.0 min: resolution 10s) Sets start function duration and post-defrost

duration. During this phase the alarms are neglected.

Opening Percentage after defrost phase: (0 to 100%) Opening valve percentage when after defrost function

is active. This phase duration is Pdd time.

Post Defrost Function duration: (0.0 to 42.0 min: resolution 10s) Sets start function duration and post-defrost

duration. During this phase the alarms are neglected.

Maximum opening percentage at normal Functioning: (0 to 100%) during regulation it sets the maximum

valve opening percentage.

Delay before stopping valve regulation: (0 to 255s) When the cooling request goes off, the electronic valve

regulation can go on for the dCL time in order to prevent uncontrolled superheat variation.

Forced opening percentage: (0 to 100% - nu) it permits to force the valve opening to the specified value. This

Fot

value overwrites the value calculated by PID algorithm. CAUTION! To obtain the correct superheat

regulation you have to set Fot = nu.

Type of Pressure Transducer: (PP - LAn) it sets type of pressure transducer to use: PP= 4 to 20mA pressure

tPP

transducer or ratiometric transducer 0 to 5V depending on P5C parameter, LAn= the pressure signal arrives

from another XM600. Referred to Pb5

Table 8-1 - XM670 to XM679 Parameters List

12 • XM679K I&O Manual 026-1218 Rev 4

Page 19

PA4

Probe value At 4mA or At 0V: (-1.0 to P20 bar / -14 to PSI / -10 to P20 kPA*10) pressure value measured by

probe at 4mA or at 0V (related to PrM parameter) Referred to Pb5

P20

Probe value 20mA or At 5V: (PA4 to 50.0 bar / 725 psi / 500 kPA*10) pressure value measured by probe at

20mA or at 5V (related to PrM parameter) Referred to Pb5

Lower Pressure Limit for superheat regulation: (PA4 to P20 bar / psi / kPA*10) when suction pressure comes

LPL

down to LPL the regulation is performed with a LPL fixed value for pressure, when pressure comes back to

LPL the normal pressure value is used. (related to PrM parameter)

MOP

LOP

Maximum Operating Pressure threshold: (PA4 to P20 bar / psi / kPA*10) if suction pressure exceeds

maximum operating pressure value, device signals situation with MOP alarm. (related to PrM parameter)

Lowest Operating Pressure threshold: (PA4 to P20 bar / psi / kPA*10) If the suction pressure comes down to

this value, a low pressure alarm is signaled with LOP alarm. (related to PrM parameter)

delta MOP-LOP: (0 to 100%) When a MOP alarm occurs, the valve will close of the dML percentage every

dML

cycle period until MOP alarm is active. When LOP occurs, the valve will open of the dML percentage every

cycle period until LOP alarm is active.

MSH

LSH

Maximum Superheat alarm: (LSH to 144°F / LSH to 80.0°C) When the superheat exceeds this value, a high

superheat alarm is signaled after interval SHd.

Lowest Superheat alarm: (0 to MSH °F / 0.0 to MSH °C) When the superheat goes down to this value, a low

superheat alarm is signaled after interval SHd.

SHy Superheat alarm Hysteresis: (1 to 45°F / 0.1 to 25.5°C) Hysteresis for superheat alarm deactivation.

SHd

FrC

Superheat alarm activation delay: (0.0 to 42.0 min: resolution 10s) When a superheat alarm occurs, the time

SHd have to pass before signaling the alarm.

Fast-recovery Constant: (0 to 100 s) permits to increase integral time when SH is below the setpoint. If FrC=0

fast recovery function is disabled.

DEFROST

dPA

dPb

dPE

defrost Probe A: (nP; P1; P2, P3, P4, P5) first probe used for defrost. If rPA = nP the regulation is performed

with real value of dPb.

defrost Probe B: (nP; P1; P2, P3, P4, P5) second probe used for defrost. If rPB = nP the regulation is

performed with real value of dPA.

defrost virtual probe percentage: (0 to 100%) it defines the percentage of the dPA respect to dPb. The value

used to regulate room temperature is obtained by: value_for_defrost= (dPA*dPE + dPb*(100-dPE))/100.

tdF Defrost type: (EL - in) EL = electrical heater; in = hot gas.

EdF Defrost mode: (in) In= interval defrost activation with idf.

Srt

Heater setpoint during defrost: (-67 to 302°F; -55.0 to 150.0°C) if tdF=EL during the defrost the defrost relay

perform an ON/OFF regulation with Srt as setpoint.

Hyr Differential for heater: (1°F to 45°F, 0.1°C to 25.5°C) the differential for heater

Time out for heater: 0 to 255 (min.) if the defrost probe temperature is bigger than Srt for all tod time the

tod

defrost ends although the defrost probe temperature is lower than dtE or dtS. It permits to reduce defrost

duration.

dtP

Minimum temperature difference to start defrost: [1°F to 90°F] [0.1°C to 50.0°C] if the difference between

the two defrost probes stays lower than dtP for all ddP time the defrost is activated.

ddP Delay before starting defrost (related to dtP): (0 to 60 min) delay related to dtP.

Table 8-1 - XM670 to XM679 Parameters List

Auxiliary Output Parameters List • 13

Page 20

d2P

dtE

dtS

Defrost with two probes: (n - Y) n= only the dPA probe is used to defrost management; Y= defrost is managed

with dPA probe and dPb probe. Defrost can performed only if both probe value are lower than dtE for dPA

probe and dtS for dPb probe.

Defrost termination temperature (Probe A): (-67 to 122°F; -55.0 to 50.0°C) (Enabled only when the

evaporator probe is present) sets the temperature measured by the evaporator probe dPA which causes the

end of defrost.

Defrost termination temperature (Probe B): (-67 to 122°F; -55.0 to 50.0°C) (Enabled only when the

evaporator probe is present) sets the temperature measured by the evaporator probe dPb which causes the end

of defrost.

IdF

MdF

dSd

dFd

dAd

Interval between defrosts: (0 to 120h) Determines the time interval between the beginning of two defrost

cycles.

Maximum duration of defrost: (0 to 255 min) When dPA and dPb aren't present, it sets the defrost duration,

otherwise it sets the maximum duration for defrost.

Start defrost delay: (0 to 255 min) This is useful when different defrost start times are necessary to avoid

overloading the plant.

Display during defrost: rt = real temperature; it = temperature reading at the defrost start; Set = setpoint;

dEF = “dEF” label.

Defrost display time out: (0 to 255 min) Sets the maximum time between the end of defrost and the restarting

of the real room temperature display.

Drain down time: (0 to 255 min.) time interval between reaching defrost termination temperature and the

Fdt

restoring of the control's normal operation. This time allows the evaporator to eliminate water drops that

might have formed due to defrost.

dPo First defrost after start-up: y = Immediately; n = after the IdF time

dAF

Defrost delay after continuous cycle: (0 to 23.5h) time interval between the end of the fast freezing cycle and

the following defrost related to it.

FAN

FPA

FPB

Fan probe A: (nP; P1; P2, P3, P4, P5) first probe used for fan. If FPA = nP the regulation is performed with

real value of FPB.

Fan probe B: (nP; P1; P2, P3, P4, P5) second probe used for defrost. If FPB = nP the regulation is performed

with real value of FPB.

FPE

Fan virtual probe percentage: (0 to 100%) Defines the percentage of the FPA with respect to FPb. The value

used to regulate room temperature is obtained by: value_for_defrost= (FPA*FPE + FPb*(100-FPE))/100.

Fan operating mode: C-n = running with the solenoid valve, OFF during the defrost; C-y = running with the

FnC

solenoid valve, ON during the defrost; O-n = continuous mode, OFF during the defrost; O-y = continuous

mode, ON during the defrost.

Fnd Fan delay after defrost: (0 to 255 min) The time interval between the defrost end and evaporator fans start.

Temperature differential avoiding short cycles of fans (0°F to 90°F; 0.0°C to 50.0°C) If the difference of

FCt

temperature between the evaporator and the room probes is more than the value of the Fct parameter, the fans

are switched on.

FSt

Table 8-1 - XM670 to XM679 Parameters List

14 • XM679K I&O Manual 026-1218 Rev 4

Fan stop temperature: (-58 to 230°F; -50 to 110°C) setting of temperature, detected by evaporator probe,

above which the fan is always OFF.

Page 21

FHy

Differential to restart fan: (1°F to 45°F) (0.1°C to 25.5°C) when stopped, fan restarts when fan probe reaches

FSt-FHy temperature.

Fod Fan activation time after defrost: (0 to 255 min.) it forces fan activation for indicated time.

Fan ON time: (0 to 15 min) with Fnc = C_n or C_y, (fan activated in parallel with compressor). Sets the

Fon

evaporator fan ON cycling time when the compressor is off. With Fon =0 and FoF =0 the fan are always off,

with Fon=0 and FoF =0 the fan are always off.

Fan OFF time: (0 to 15 min) with Fnc = C_n or C_y, (fan activated in parallel with compressor). Sets the

FoF

evaporator fan off cycling time when the compressor is off. With Fon =0 and FoF =0 the fans are always off,

with Fon=0 and FoF =0 the fans are always off.

MODULATING OUTPUT (AnOUT) If Present

Kind of regulation with PWM output: (UAL - rEG - AC) it selects the functioning for the PWM output if

trA

CoM is not equal to OA7. UAL= the output is at FSA value; rEG= the output is regulated with fan algorithm

described in fan section; AC= anti-sweat heaters control (require the XWEB5000 system).

SOA Fixed value for analog output: (0 to 100%) value for the output if trA = UAL.

SdP

ASr

Default value for Dew point: (-67 to 122°F; -55.0 to 50.0°C) default value of dew point used when there is

no supervising system (XWEB5000). Used only when trA=AC.

Dew-point offset (trA=AC) / Differential for modulating fan regulation (trA=rEG): (-45°F to 45°F)

(-25.5°C to 25.5°C).

PbA Differential for anti-sweat heaters: (1°F to 45°F) (0.1°C to 25.5°C)

AMi Minimum value for analog output: (0 to AMA)

AMA Maximum value for analog output: (Ami to 100)

AMt

Anti-sweat heaters cycle period (trA=AC)/ Time with fan at maximum speed (trA=rEG): (0 to 255 s) when

the fan starts, during this time the fan is at maximum speed.

ALARMS

rAL

ALC

ALU

ALL

AHy

Probe for temperature alarm: (nP - P1 - P2 - P3 - P4 - P5 - tEr) Selects the probe used to signal alarm

temperature.

Temperature alarm configuration: rE = High and Low alarms related to Setpoint; Ab = High and low alarms

related to the absolute temperature.

High temperature alarm setting: (ALC= rE, 0 to 90°F or 50°C / ALC= Ab, ALL to 302°F or 150°C) when

this temperature is reached and after the ALd delay time the HA alarm is enabled.

Low temperature alarm setting: (ALC = rE, 0 to 90°F or 50 °C / ALC = Ab, - 67°F or - 55°C to ALU) when

this temperature is reached and after the ALd delay time, the LA alarm is enabled.

Differential for temperature alarm: (1°F to 45°F / 0.1°C to 25.5°C) Intervention differential for recovery of

temperature alarm.

ALd

dLU

dLL

Table 8-1 - XM670 to XM679 Parameters List

Auxiliary Output Parameters List • 15

Temperature alarm delay: (0 to 255 min) The time interval between the detection of an alarm condition and

the corresponding alarm signaling.

High temperature alarm (defrost probe): (ALC= rE, 0 to 90°F or 50°C / ALC= Ab, ALL to 302°F or 150°C)

When this temperature is reached and after the ddA delay time, the HAd alarm is enabled.

Low temperature alarm (defrost probe): (ALC = rE, 0 to 90°F or 50 ° C / ALC = Ab, - 67°F or - 55°C to ALU)

when this temperature is reached and after the ALd delay time, the LAd alarm is enabled.

Page 22

dAH

Differential for temperature alarm (defrost probe): (1°F to 45°F / 0.1°C to 25.5°C) Intervention differential

for recovery of temperature alarm.

ddA

FLU

FLL

FAH

FAd

dAO

EdA

Temperature alarm delay (defrost probe): (0 to 255 min) time interval between the detection of an alarm

condition and the corresponding alarm signaling.

High temperature alarm (defrost probe): (ALC= rE, 0 to 90°F or 50°C / ALC= Ab, ALL to 302°F or 150°C)

when this temperature is reached and after the FAd delay time the HAF alarm is enabled.

Low temperature alarm (defrost probe): (ALC = rE, 0 to 90°F or 50°C / ALC = Ab, - 67°F or - 55°C to ALU)

when this temperature is reached and after the FAd delay time, the LAF alarm is enabled.

Differential for temperature alarm (defrost probe): (1°F to 45°F / 0.1°C to 25.5°C) Intervention differential

for recovery of temperature alarm.

Temperature alarm delay (defrost probe): (0 to 255 min) time interval between the detection of an alarm

condition and the corresponding alarm signaling.

Delay of temperature alarm at start-up: (0min to 23h 50min) The time interval between the detection of the

temperature alarm condition after the device power on and the alarm signaling.

Alarm delay at the end of defrost: (0 to 255 min) Time interval between the detection of the temperature alarm

condition at the end of defrost and the alarm signaling.

dot Temperature alarm exclusion after door open

Sti

Std

Stop regulation interval (Only XM679): (0.0 to 24.0 hours: tens of minutes) After regulating continuously for

Sti time, the valve closes for Std time to prevent ice from forming.

Stop duration (Only XM679): (0 to 60 min.) Defines the stop regulation time after Sti. During this stop

display shows StP message.

Sixth relay configuration (CPr-dEF-Fan-ALr-LiG-AUS-db-OnF): CPr= relay works as a compressor or

OA6

solenoid valve relay; dEF= relay works as defrost relay; Fan= relay works as a Fan relay; ALr= activation

with alarm conditions; LiG= light activation; AUS= auxiliary relay, it can be switched ON/OFF also by key;

db= deadband regulation (not compatible with CrE = y); OnF= ON/OFF functioning.

OPTIONAL OUTPUT (AnOUT) If Present

Modulating output configuration (if CoM=0A7): (CPr - dEF - FAn - ALr - LiG - AUS - db) it selects the

OA7

functioning of the modulating output in case of CoM=OA7: CPr= compressor; dEF= defrost; FAn= Fan;

Alr= Alarm; LiG= Light; AUS= auxiliary; db= neutral zone (not available with CrE=Y)

Type of functioning modulating output:

CoM

For models with PWM / O.C. output -> PM5= PWM 50Hz; PM6= PWM 60Hz; OA7= two state, it can be

used as an open collector output

For models with 4 to 20mA / 0 to 10V output -> Cur= 4 to 20mA current output; tEn= 0 to 10V voltage output

AOP Alarm relay polarity: cL= normally closed; oP= normally opened

iAU

Auxiliary output is unrelated to ON/OFF device status: n= if the device is switched off also the auxiliary

output is switched off; Y= the auxiliary output state is unrelated to the ON/OFF device status.

DIGITAL INPUTS

i1P

Table 8-1 - XM670 to XM679 Parameters List

Digital input 1 polarity: (cL - oP) CL: the digital input is activated by closing the contact; OP: the digital input

is activated by opening the contact.

16 • XM679K I&O Manual 026-1218 Rev 4

Page 23

i1F

d1d

Digital input 1 function: (EAL - bAL - PAL - dor - dEF - AUS - LiG - OnF - Htr - FHU - ES - Hdy) EAL=

external alarm; bAL= serious external alarm; PAL= pressure switch activation; dor= door open; dEF= defrost

activation; AUS= auxiliary activation; LiG= light activation; OnF= switch on/off the device; Htr= change

type of action; FHU= not used; ES= activate energy saving; Hdy= activate holiday function

Time interval/delay for digital input alarm: (0 to 255 min.) Time interval to calculate the number of the

pressure switch activation when i1F=PAL. If I1F=EAL or bAL (external alarms), “d1d” parameter defines

the time delay between the detection and the successive signaling of the alarm. If i1F=dor this is the delay to

activate door open alarm.

i2P

i2F

d2d

i3P

i3F

d3d

nPS

Digital input 2 polarity: (cL - oP) CL: the digital input is activated by closing the contact; OP: the digital input

is activated by opening the contact.

Digital input 2 function: (EAL - bAL - PAL - dor - dEF - AUS - LiG - OnF - Htr - FHU - ES - Hdy) EAL=

external alarm; bAL= serious external alarm; PAL= pressure switch activation; dor= door open; dEF= defrost

activation; AUS= auxiliary activation; LiG= light activation; OnF= switch on/off the device; Htr= change

type of action; FHU= not used; ES= activate energy saving; Hdy= activate holiday function

Time interval/delay for digital input alarm: (0 to 255 min.) Time interval to calculate the number of the

pressure switch activation when i2F=PAL. If I2F=EAL or bAL (external alarms), “d2d”parameter defines the

time delay between the detection and the successive signaling of the alarm. If i2F=dor this is the delay to

activate door open alarm.

Digital input 3 polarity: (cL - oP) CL: the digital input is activated by closing the contact; OP: the digital input

is activated by opening the contact.

Digital input 3 function: (EAL - bAL - PAL - dor - dEF - AUS - LiG - OnF - Htr - FHU - ES - Hdy) EAL=

external alarm; bAL= serious external alarm; PAL= pressure switch activation; dor= door open; dEF= defrost

activation; AUS= auxiliary activation; LiG= light activation; OnF= switch on/off the device; Htr= change

type of action; FHU= not used; ES= activate energy saving; Hdy= activate holiday function

Time interval/delay for digital input alarm: (0 to 255 min.) Time interval to calculate the number of the

pressure switch activation when i3F=PAL. If i3F=EAL or bAL (external alarms), “d3d” parameter defines

the time delay between the detection and the successive signaling of the alarm. If i3F=dor this is the delay to

activate door open alarm.

Pressure switch number: (0 to 15) Number of activation of the pressure switch, during the “d#d” interval,

before signaling the alarm event (I2F= PAL). If the nPS activation in the did time is reached, switch off and

on the device to restart normal regulation.

odc

Compressor and fan status when open door: no = normal; Fan = Fan OFF; CPr = Compressor OFF; F_C =

Compressor and fan OFF.

rrd Outputs restart after door open alarm.

ENERGY SAVING

ESP Energy saving probe selection: (nP - P1 - P2 - P3 - P4 - P5 - tEr).

HES

PEL

Temperature increase during the Energy Saving cycle: (-54 to 54°F / -30 to 30°C) sets the increasing value

of the setpoint during the Energy Saving cycle.

Energy saving activation when light is switched off: (n to Y) n= function disabled; Y= energy saving is

activated when the light is switched off and vice versa.

LAN MANAGEMENT

LMd

Table 8-1 - XM670 to XM679 Parameters List

Auxiliary Output Parameters List • 17

Defrost synchronization: y= the section send a command to start defrost to other controllers, n= the section

don't send a global defrost command

Page 24

dEM Type of end defrost: n= the of the LAN defrost are independent; y= the end of the defrost are synchronized

LSP

LdS

LOF

LLi

LAU

LES

LSd

LPP

L.A.N. set-point synchronization: y= the section set-point, when modified, is updated to the same value on

all the other sections; n= the set-point value is modified only in the local section

L.A.N. display synchronization: y= the value displayed by the section is sent to all the other sections; n= the

set-point value is modified only in the local section

L.A.N. On/Off synchronization this parameter states if the On/Off command of the section will act on all the

other ones too: y= the On/Off command is sent to all the other sections; n= the On/Off command acts only in

the local section

L.A.N. light synchronization this parameter states if the light command of the section will act on all the other

ones too: y= the light command is sent to all the other sections; n= the light command acts only in the local

section

L.A.N. AUX output synchronization this parameter states if the AUX command of the section will act on all

the other ones too: y= the light command is sent to all the other sections; n= the light command acts only in

the local section

L.A.N. energy saving synchronization this parameter states if the energy saving command of the section will

act on all the other ones too: y= the Energy Saving command is sent to all the other sections; n= the Energy

Saving command acts only in the local section

Remote probe display: this parameter states if the section has to display the local probe value or the value

coming from another section: y= the displayed value is the one coming from another section (which has

parameter LdS = y); n= the displayed value is the local probe one.

Remote pressure probe: n= the value of pressure probe is read from local probe; Y= the value of pressure

probe is sent via LAN.

StM

Solenoid activation via LAN: n= not used; Y= a generic cooling requests from LAN activate the solenoid

valve connected to compressor relay.

PROBE CONFIGURATION

P1C Probe 1 configuration: (nP - Ptc - ntc - PtM) nP= not present; PtC= Ptc; ntc= Ptc; PtM= Pt1000

Ot Probe 1 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offset of the thermostat probe.

P2C Probe 2 configuration: (nP - Ptc - ntc - PtM) nP= not present; PtC= Ptc; ntc= Ptc; PtM= Pt1000

OE Probe 2 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offsets of the evaporator probe.

P3C Probe 3 configuration: (nP - Ptc - ntc - PtM) nP= not present; PtC= Ptc; ntc= Ptc; PtM= Pt1000

o3 Probe 3 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offset of the probe 3.

P4C Probe 4 configuration: (nP - Ptc - ntc - PtM) nP= not present; PtC= Ptc; ntc= Ptc; PtM= Pt1000

o4 Probe 4 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offset of the probe 4.

P5C

o5

P6C

o6

Probe 5 configuration: (nP - Ptc - ntc - PtM - 420 - 5Vr) nP= not present; PtM= Pt1000; 420= 4 to 20mA;

5Vr= 0 to 5V ratiometric; (Only XM679)

Probe 5 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offset of the probe 5.

(Only XM679)

Probe 6 configuration: (nP - Ptc - ntc - PtM) nP= not present; PtC= Ptc; ntc= Ptc; PtM= Pt1000;

(Only XM679)

Probe 6 calibration: (-21 to 21°F/ -12.0 to 12.0°C) allows to adjust possible offset of the probe 6.

(Only XM679)

Table 8-1 - XM670 to XM679 Parameters List

18 • XM679K I&O Manual 026-1218 Rev 4

Page 25

SERVICE - READ ONLY

CLt Cooling time percentage: it shows the effective cooling time calculated by XM600 during regulation

tMd Time to next defrost: it shows time before the next defrost if interval defrost is selected

LSn L.A.N. section number (1 to 5) Shows the number of sections available in the L.A.N.

Lan

Adr

L.A.N. serial address (1 to LSn) Identifies the device address inside local network of multiplexed cabinet

controller.

RS485 serial address (1 to 247): Identifies the device address when connected to a MODBUS compatible

monitoring system.

Rel Release software: (read only) Software version of the microprocessor.

Ptb Parameter table: (read only) it shows the original code of the dIXEL parameter map.

Pr2 Access to the protected parameter list (read only)

Table 8-1 - XM670 to XM679 Parameters List

Auxiliary Output Parameters List • 19

Page 26

9 Digital Inputs

The XM600 series of controllers can support up to

three (3) configurable digital inputs that are free of

voltage contact (depending on the models). They are

configurable via i#F parameter.

1. The terminals [30] to

[33] are free of voltage.

2. Use shielded cable for

distances higher than

one meter.

For each input, the following

has to be configured: the

polarity of activation, the

function of the input, and the

delay of signaling. The

parameters to perform this

configuration are i1P, i1F,

i1d respectively for polarity,

functioning, and delay.

9.4. Door Switch Input (dor)

This input signals the door status and the

corresponding relay output status through the odc

parameter: no = normal (any change); Fan = Fan

OFF; CPr = Compressor OFF; F_C = Compressor

and fan OFF. Since the door is opened, after the delay

time set through parameter d#d, the door alarm is

enabled, the display shows the message dA, and the

regulation restarts after rrd time. The alarm stops as

soon as the external digital input is disabled again.

With the door open, the high and low temperature

alarms are disabled.

9.5. Start Defrost (dEF)

A defrost will start if the right conditions exist. After

the defrost is finished, normal regulation will restart

only if the digital input is disabled; otherwise, the

controller will wait until the MdF safety time is

expired.

9.1. Generic Alarm (EAL)

As soon as the digital input is activated, the controller

will wait for the did time delay before signaling the

EAL alarm message. The outputs status don’t change.

The alarm will stop as soon as the digital input is

deactivated.

9.2. Serious Alarm Mode (bAL)

When the digital input is activated, the controller will

wait for the did time delay before signaling the bAL

alarm message. The relay outputs are switched OFF.

The alarm will stop as soon as the digital input is

deactivated.

9.3. Pressure Switch (PAL)

If the pressure switch has reached the number of

activation of the nPS parameter during the interval

time set by the d#d parameter, the CA pressure alarm

message will be displayed. The compressor and the

regulation are stopped. When the digital input is ON

the compressor is always OFF.

in the d#d time is reached, switch the controller OFF

and ON to restart normal regulation.

If the nPS activation

9.6. Relay Aux Actuation (AUS)

This function enables the auxiliary relay to be turned

ON and OFF by using the digital input as external

switch.

9.7. Relay Light Actuation (LiG)

This function enables the light relay to be turned ON

and OFF by using the digital input as external switch.

9.8. Remote ON/OFF (OnF)

This function switches the controller ON and OFF.

9.9. Kind of Action (Htr)

This function enables the change in the kind of

regulation: from cooling to heating and vice versa.

20 • XM679K I&O Manual 026-1218 Rev 4

Page 27

9.10.FHU (Not Used)

This function enables the change in the kind of

regulation: from cooling to heating and vice versa.

9.11.Energy Saving Input (ES)

The Energy Saving function allows you to change the

setpoint value as the result of the SET+ HES

(parameter) sum. This function is enabled until the

digital input is activated.

9.12.Configurable Input Holiday Function (HDY)

In Holiday function, the Energy Saving and defrost

cycles follow holiday times (Sd1…Sd6).

10 Installation and

Mounting

The XM679 can operate without any user interface,

but normal application is with the CX660 keyboard.

The CX660 keyboard should be mounted on a vertical

panel, in a 29 mm x 71 mm hole, and secured using

the special bracket supplied.

9.13.Digital Inputs Polarity

The digital inputs polarity depends on the I#P

parameters: CL (the digital input is activated by

closing the contact) and OP (the digital input is

activated by opening the contact).

Figure 10-1 - Installation and Mounting of CX660 Keyboard

The temperature range allowed for correct operation

is 0 to 60°C. Avoid places subject to strong

vibrations, corrosive gases, excessive dirt, or

humidity. The same recommendations apply to

probes. Allow air to circulate through the cooling

holes.

Figure 10-2 - CX660 Keyboard Dimensions

FHU (Not Used) Installation and Mounting • 21

Page 28

11 Electrical

13 How to Use the

Connections

The XM670/XM679 controllers come with a screw

terminal block to connect cables with a cross section

up to 1.6 mm

RS485, the LAN, the probes, the digital inputs, and

the keyboard. Other inputs, power supply, and relay

connections are provided with a Faston connection

(5.0 mm). Heat-resistant cables have to be used.

Before connecting cables, verify that the power

supply complies with the controller’s requirements.

Separate the probe cables from the power supply

cables, from the outputs and the power connections.

Do not exceed the maximum current allowed on each

relay; in case of heavier loads, use a suitable external

relay.

2

for all the low voltage connections: the

NOTE: Maximum current allowed for all the

load is 16A.

11.1.Probe Connections

The probes should be mounted with the bulb upwards

to prevent damages due to casual liquid infiltration. It

is recommended that the thermostat probe be placed

away from air streams to measure the average room

temperature correctly. Place the defrost termination

probe among the evaporator fans in the coldest place,

(where most ice is formed) and far from heaters or

from the warmest place during defrost to prevent

premature defrost termination.

12 RS485 Serial Line

Each XM670/XM679 controller has a direct RS485

connection that enables the controller to be linked to

a network line that is MODBUS-RTU compatible

with all monitoring systems.

Hot Key

XM controllers can download or upload the

parameter list from its own non-volatile internal

memory to the Hot Key and vice-versa through a

5-pin connector. The Hot Key will not change the

Adr.

13.1.Download (From the Hotkey to the Device)

1. Turn OFF the controller by pressing the on/off

button for five (5) seconds. OFF will display.

Insert the Hot Key into the 5-pin connector

labeled HOT-KEY, and then turn the controller

back ON by pressing the on/off button again for

five (5) seconds. The normal temperature value

will display to indicate the controller is ON.

2. The parameter list of the Hot Key is downloaded

into the controller memory automatically and

doL will display. After 10 seconds, the controller

will start working with the new parameters.

3. End will display at the end of the data transfer

phase if the controller is programmed correctly.

Err will display if there is an error or failure in

programming.

• End = correct programming. This means the

controller will start regularly with the new

programming.

• Err = failed programming. In this case, turn the

controller OFF and then ON if you want to restart

the download again or remove the Hot Key to abort

the operation.

4. Remove the Hot Key.

Note: The procedure may fail if the firmware version

and the controller models are different.

22 • XM679K I&O Manual 026-1218 Rev 4

Page 29

13.2.Upload (From the Device to the Hotkey)

1. When the XM controller is ON, insert the Hot

Key into the 5-pin connector labeled HOT-KEY.

2. Press and release the up arrow button.

3. The upload will begin, and UPL will blink on the

display. End will display at the end of the data

transfer phase if a successful upload has

occurred. Err will display if there is an error or

failure in programming.

• End = correct programming.

• Err = failed programming. In this case, press the

SET key if you want to restart the programming

again or remove the unprogrammed Hot Key.

4. Remove the Hot Key.

Note: The upload procedure will overwrite everything

previously uploaded from the last Hot Key upload.

Upload (From the Device to the Hotkey) How to Use the Hot Key • 23

Page 30

14 Alarm Signals

Message Cause Outputs

KEYBOARD

No display: the keyboard is trying to

nod

PON Keyboard enabled Outputs unchanged

POF Keyboard locked Outputs unchanged

rst Alarm reset Alarm relay reset

nOP, nP, nA Probe not present Compressor output according to parameter Con and COF

noL

P1 First probe failure Compressor output according to parameters Con and COF

P2 Second probe failure Defrost end is timed

P3 Third probe failure Outputs unchanged

P4 Fourth probe failure Outputs unchanged

P5 Fifth probe failure Outputs unchanged

P6 Sixth probe failure Outputs unchanged

PPF

CPF

HA Maximum temperature alarm Outputs unchanged

LA Minimum temperature alarm Outputs unchanged

HAd Defrost high temperature Outputs unchanged

LAd Defrost low temperature Outputs unchanged

FAd Defrost low temperature Outputs unchanged

HAF Fan high temperature Outputs unchanged

LAF Fan high temperature Outputs unchanged

StP

PAL Lock due to pressure switch All outputs OFF

dA Door open Compressor and fans restarts according to rrd and odc

EA External alarm Outputs unchanged

CA Serious external alarm (i1F=bAL) All outputs OFF

LOP Minimum operating pressure reached According to dML

MOP Maximum operating pressure reached According to dML

work with another board that is not

working or not present.

They keyboard is not able to

communicate with the XM679K.

ALARM FROM PROBE INPUT

PPF is displayed by slaves of pressure

that don’t receive the value of pressure.

CPF is displayed when the remote

probe 4 is not working,

TEMPERATURE ALARM

Stop due to regulation pauses

(Sti and Std parameters)

DIGITAL INPUT ALARM

ELECTRONIC VALVE ALARM

Press the UP arrow for three (3) seconds. Enter the SEC

menu, and select LOC entry.

Verify the connection. Call the service.

The percentage of the valve opening is fixed at PEO value.

The percentage of the valve opening is fixed at PEO value.

Compressor and valve OFF

Table 14-1 - Alarm Signals

24 • XM679K I&O Manual 026-1218 Rev 4

Page 31

LSH Minimum superheat alarm Valve closed

MSH Maximum superheat alarm Outputs unchanged

HSH Minimum superheat alarm Outputs changed.

CLOCK ALARM

rtC Clock settings lost.

Defrost will be performed with ldF until the settings of

RTC has been restored.

rtF Clock damaged. Defrost will be performed with ldF.