Emerson XL281, XL131, XL221, XL426, XL681 Installation, Operation & Maintenance Instructions Manual

...

Installation Operation & Maintenance Instructions

Hytork XL

MAC050515 EN Rev. C

May 2016

www.Hytork.com

Table 1 Applicable Models:

XL 26 XL 281 XL 2586

XL 71 XL 426 XL 4581

XL 131 XL 681

XL 186

XL 1127

XL 221 XL 1372

1 Important Safety Procedures

Installation, adjustment, putting into service, use, assembly, disas-

sembly and maintenance of the Actuator is strictly reserved to quali-

ed personnel.

Before installation, operation and maintenance, read the relevant

sections of:

- This manual

- Quick Reference Guide: DOC.QRG.XL

Caution: Always disconnect the Air and Electrical supplies before

carrying out any form of maintenance on an Actuator.

Caution: When removing any ball valve or plug valve assemblies

from a pipe system, isolate the piping system on which the Actuator

is installed and relieve any media pressure that may be trapped in

the valve cavities before removing the Actuator for maintenance.

Caution: Always contain the Spring tension with HYTORK Retrac-

tor Rods as explained in Section 9 (Disassembly procedure). Follow

instructions for using the Retractor Rod carefully. Only HYTORK

manufactured or approved Retractor Rods are to be used for Spring

removal. As with any threaded tool that is frequently used Retractor

Rods should be checked to ensure that the threads are not worn or

damaged in any way and greased regularly. Any damaged or worn

Rods must not be used and must be destroyed.

Never attempt to ‘BLOW OUT’ the Pistons or the End caps from the

Actuator Body by using air pressure.

Never turn the stop screws completely out when the actuator is

under pressure

Numbers in brackets (#) refer to parts on the exploded view drawing

(Fig. 5).

All HYTORK XL Spares Kits are supplied with SAFEKEY assemblies

(13/14) cut to an exact length which will t the circumference of the

End Cap (21) when fully assembled into the Actuator. Any shortened

SAFEKEY must not be used. If in doubt contact Emerson Process

Management or your local HYTORK Stocking Distributor.

Read the relevant sections carefully before continuing.

1.1 Warehouse storage

HYTORK Actuators should be stored in a clean, dry warehouse, free

from excessive vibration and rapid temperature changes.

Actuators should not be stored on any oor surface.

1.2 On site storage

HYTORK actuators should be stored in a clean, dry warehouse, free

from excessive vibration and rapid temperature changes.

Prevent moisture or dirt entering the actuator. Plug or seal both air

connection ports.

Important! Failure to follow proper storage guidelines will void war-

ranty

1.3 Lifting instructions

• Use lifting equipement as required by national or local legislation.

• Use lifting straps to lift the assembly of actuator and valve.

• Do not attach lifting straps to only the actuator, to lift the assem-

bly of actuator and valve.

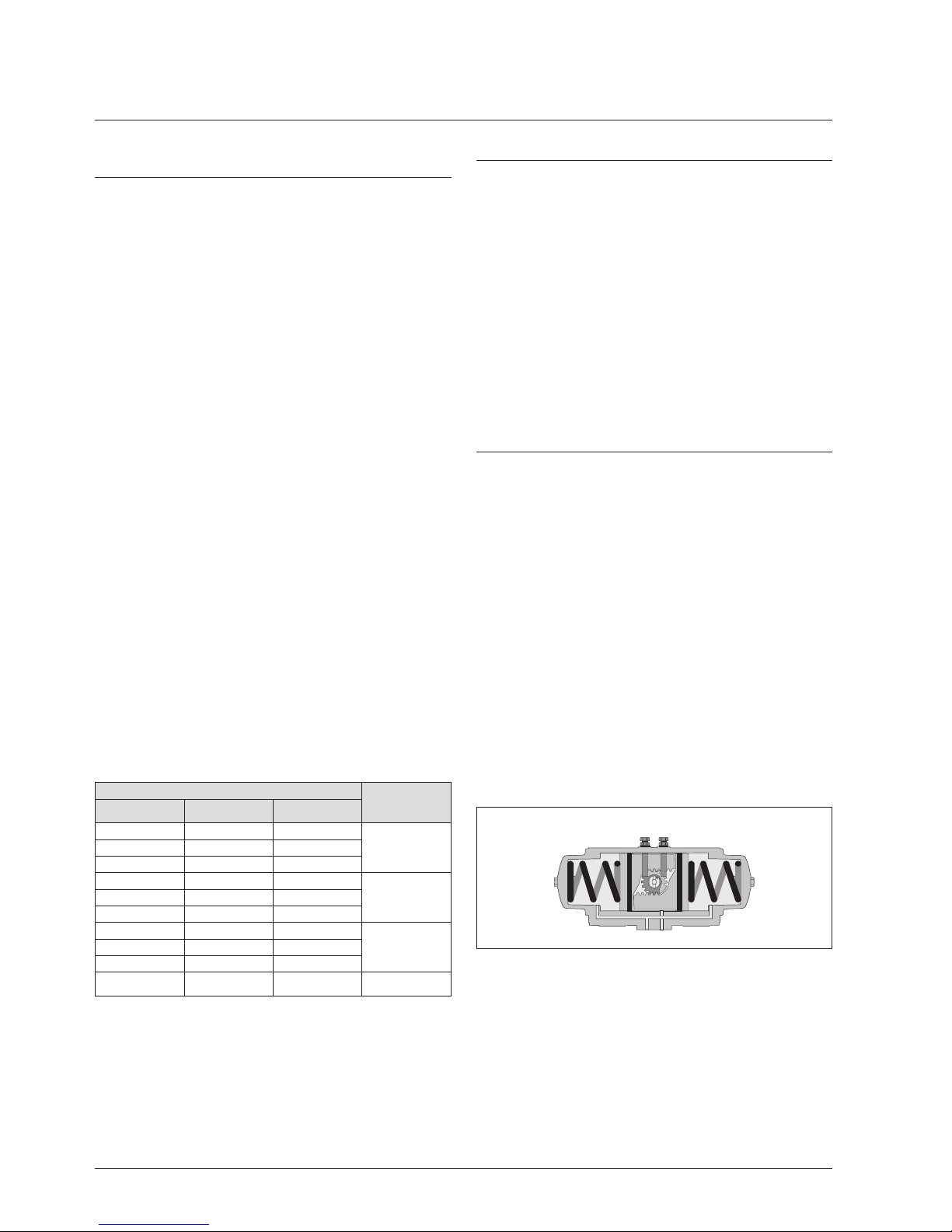

Table 2 Weight of Actuators

Model

Double Acting

Spring Return with S80

Springs

Kg Lbs Kg Lbs

XL26 1.39 3.06 1.53 3.37

XL71 2.39 5.27 2.78 6.13

XL131 3.90 8.60 4.76 10.49

XL186 4.77 10.52 5.45 12.02

XL221 6.19 13.65 7.76 17.11

XL281 7.02 15.47 9.90 21.83

XL426 7.30 16.10 12.50 27.56

XL681 8.80 19.40 22.50 49.60

XL1127 22.00 48.50 36.00 79.37

XL1372 27.00 59.52 46.60 102.73

XL2586 46.00 101.41 79.00 174.16

XL4581 83.00 182.98 142.00 313.05

Page 2

Hytork XL

Installation Operation & Maintenance Instructions

MAC050515 EN Rev. C

May 2016

2 ATEX instructions for use in (potential)

explosive areas

2.1 Intended use

The Hytork XL series pneumatic actuators are a Group II category

2 equipment and intended for use in areas in which explosive

atmospheres caused by mixtures of air and gases, vapours, mists or

by air/dusts are likely to occur. Therefore it may be used in (ATEX)

classied Zones 1, 2 (Gasses) and/or 21, 22 (Dust).

2.2 Safety instructions

a Assembly, disassembly and maintenance, is only allowed at the

actuator, when, at the time of the activity, there is not an explosive mixture.

b Prevent entry of explosive mixtures into the actuator. We suggest

utilizing a solenoid with a “breather” function on spring return

actuators when used in potentially explosive atmospheres.

c The plastic position indicator caps are approved for ATEX gas

group IIB areas. In areas where ATEX gas group IIC requirements apply, do not use the plastic position indicator cap of sizes

XL426 up to XL4581, to avoid build up of static electricity.

d In order to avoid increasing dust explosion risk, periodically clean

dust deposits from all equipment.

e When equipment is installed in a hazardous area location (po-

tentially explosive atmosphere), prevent sparks by proper tool

selection and avoiding other types of impact energy.

f Proper care must be taken to avoid generation of static electricity

on the non-conductive external surfaces of the equipment (e.g.

rubbing of surfaces, etc.).

g HYTORK XL actuators do not have an inherent ignition source

due to electro-static discharge, but explosion hazard may be

present due to the discharge of static electricity from other valve

assembly components.

– To avoid personal injury or property damage, make sure that

the valve is grounded to the pipeline before placing the valve

assembly into service.

– Use and maintain alternate shaft-to-valve body bonding, such

as a shaft-to-body bonding strap assembly.

2.3 Maximum temperatures

Temperature

Valid for actuator

model

Ambient range ATEX class

TX (ATEX surface

temperature)

-20..75°C T6 T85°C (185°F)

Standard Tem-

perature models

-20..80°C T5 T90°C (194°F)

-20..80°C T1...T4 T90°C (194°F)

-20..75°C T6 T85°C (185°F)

High Temperature

models

-20..90°C T5 T100°C (212°F)

-20..120°C T1...T4 T130°C (266°F)

-40..75°C T6 T85°C (185°F)

Low Temperature

models

-40..80°C T5 T90°C (194°F)

-40..80°C T1...T4 T90°C (194°F)

-20..250°C for

2 hours

T2 T260°C 500°F)

Tunnel

application models

Note:

a The actual maximum surface temperature depends not on the

equipment itself, but mainly on operating conditions like e.g. the

temperature of the supply media.

b The specied values are valid with the following conditions:

- Maximum working frequency of the actuator is 1Hz at a maximum of 50 cycles per hour and at maximum load.

3 Operating Media, Pressures and Temperatures

3.1 Operating media

a Use clean, dry or lubricated air or inert gas.

b Maximum pressure : 8 barg / 116PSI

Note:

On applications where the spring stroke of single acting actuators

is pneumatically operated, the maximum pressure is 6.5 bar /

95PSI

c Dew point 10 K below operating temperature.

d For subzero applications take appro priate measures.

3.2 Operating Temperature range

a Using standard seals and greases the operating temperature

range is -20°C to + 100°C (-4°F to +212°F) as is indicated on the

product label.

b Other medias and temperatures may be used but consult your

local Hytork supplier for conrmation as to suitability.

4 Actuator to Valve Installation

The Pinion drive, coupling device and Valve Stem should be cen-

tered and concentric to prevent any side loading to the Pinion Radial

Bearing and Valve Stem Seat area. Ensure that the coupling shaft to

be operated is a tight but free sliding t into the female drive in the

Actuator Pinion (19).

4.1 Bi-directional Travel Stops

Hytork XL actuators have two travel stops (22, 23 and 24) for setting

acurately the travel and the open and closed positions. XL2586 and

XL4581 can be tted with the optional Bottom Stop Block for setting

the travel.

The actuator has a factory set stroke of 90°. The adjustable stroke

range of the actuator is :

- at closed (0°) position : -3° to +7°

- at open (90°) position : -83° to +93°

REMARK:

- If the actuator is assembled for reverse operation, instead of

standard operation, Stop “1” will adjust the “open” position

and stop “2” the “closed” position.

“2” “1”

Stop marked Stop marked

View from above

Fig. 1 Travel stops

Installation Operation & Maintenance Instructions

Hytork XL

Page 3

MAC050515 EN Rev. C

May 2016

4.2 Travel Stop Adjustments

1 Operate valve/actuator assembly to the open position.

2 Remove air supply.

3 Slacken locknut (24) on the “closed” stop (marked “2”).

4 Turn the “closed” stop clockwise to reduce or counter clockwise

to increase the travel.

5 Tighten the lock nut.

6 Connect air and check that the position is correct. If not repeat

from 2.

7 Operate valve/actuator assembly to the “closed” position.

8 Remove air supply.

9 Adjust “open” travel stop (marked “1”) as from step 3 to 6.

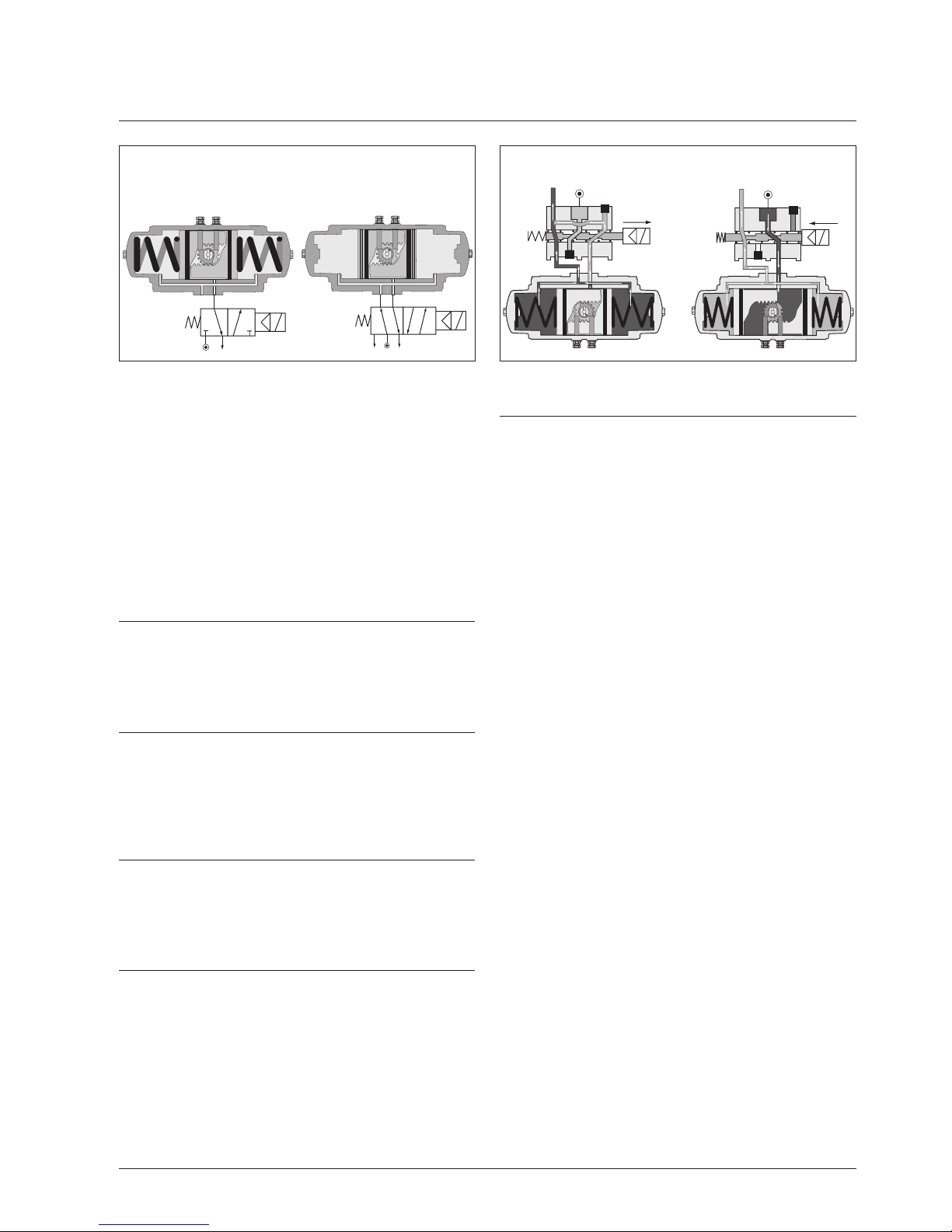

5 Piping Instructions

(See Fig. 2) All Actuators can be either piped with solid or exible

tubing with the solenoid valve mounted remotely from the actuator or

by mounting a NAMUR designed solenoid valve DIRECTLY onto the

NAMUR mounting pad on the side of the actuator.

6 Solenoid Valves on Spring Return Actuators

(See Fig. 3) It is recommended that on Spring Return Actuators,

the HYTORK “CATS” Solenoid Valves are used. These Valves are

specially designed to prevent contamination of the internals of the

Actuator by dirt from the atmosphere. This increases the working life

of the Actuator which reduces down time and maintenance periods.

7 Position feedback

All position feedback or positioning accesories, that comply to the

VDI/VDE 3845 (NAMUR) standard, can be mounted easily on top of

Hytork XL actuators. To access the pinion top, remove the position

indicator.

8 Spares Recommendations

When disassembling and carrying out maintenance work on the

XL Actuator, a HYTORK Spares Kit must be used to replace all ‘O’

Rings, DURASTRIP Bearings, Washers etc. This Kit is available

from Emerson Process Management or its Stocking Distributors.

9 Disassembly procedure

9.1 End cap and springs dis-assembly on Spring

Return actuators

1 Release Locking Nuts (24) and remove both Travel Stops (22)

and Thread Seals (23) or ‘O’-rings (23a).

2 Remove the Indicator (7) from the top of the Pinion (19) For XL26

to XL221 use an Allen key size 4mm. For the larger sizes the

Indicator can by pulled from the pinion top.

3 Remove both Sealing Bolts (28) and seals (29) from the End

Caps (21).

4 Place both the HYTORK Retractor Rods through the hole in the

End Caps and screw the Rods into :

- For XL 26 to XL 681 the Pistons (20)

- For XL 1127 to XL4581 the Retractor plate (20a, see also Fig

5) until travel is stopped (DO NOT OVERTIGHTEN) and take

care the nut and washer being free of the End Cap face.

5 Turn back the Rod 1/2 turn.

6 Screw the adjusting nut and washer by hand clockwise down

the Retractor Rod until they come up against the face of the End

Cap.

7 Prevent the “hold-nuts “ to rotate by one wrench. Use another

wrench, to screw both adjusting nuts half turn at a time (see Fig.

5) clockwise down the Rods until the end cap loosens (Maximum;

approximately two complete turns). This draws the;

- For XL 26 to XL681 the Pistons (20)

- For XL 1127 to XL4581 the Retractor plate (see also Fig 5) to

the end caps (21) and compresses the springs. This Spring-

compression, releases the Spring force and un-locks the

SAFEKEY for removal.

8 Rotate the Caps to ensure that the Springs are retracted; if the

Cap will not turn easily, a gentle tapping with a plastic hammer

against the endcap will loosen the end cap.

9 Unscrew the two slotted SAFEKEYS (13/14), and gently pull

each SAFEKEY from the Body. If the SAFEKEY resists removal,

gently tap the End Cap with a soft hammer to assist release.

10 When both SAFEKEYS have been removed, use a wrench to

rotate the Pinion, driving the pistons (20) apart until they partially

push the End Caps from the Body.

- For XL 26 to XL681 the Pistons (20), springs and end cap will

come out

- For XL 1127 to XL4581 the Retractor plate, springs and end

cap will come out.

Spring return actuator

operation

Double acting actuator

operation

Spring stroke operation Air stroke operation

Fig. 2 Solenoid operation

Fig. 3 HYTORK “CATS” Solenoid Valve

Loading...

Loading...