Emerson XJAM-030Z-TFC-022, XJAL-050Z-TFC-012, XJAL-050Z-CFV-022, XJAM-030Z-TFC-012, XJAL-020Z-CFV-022 User Manual

...Page 1

© 2017 Emerson Climate Technologies, Inc.

1

TABLE OF CONTENTS

Safety Instructions ..................................................... 2

Safety Icon Explanation

.......................................... 2

Instructions Pertaining to Risk of Electrical Shock,

Fire, or Injury to Persons .......................................... 3

Safety Statements

................................................... 3

1. Introduction ......................................................... 4

2. Nomenclature/Features ...................................... 4

3. Understanding Actual vs. Standard Airflow .... 4

4. Performance Data ............................................... 4

5. Electrical / Physical Data ................................... 4

6. Generator Requirements ................................... 4

7. Physical Dimensions .......................................... 5

8. Installation / Piping Instructions ....................... 5

9. Condensing Unit Operational Control .............. 5

10. Control Features ............................................ 5

10.1. Fresh Start Program .................................... 5

10.2. Stop Program ............................................... 5

10.3. Automatic Liquid Injection (Medium

temperature units only) ............................................. 5

10.4. Compressor Phase Reversal ....................... 5

10.5. Loss of Phase Protection ............................. 6

10.6. Motor Current Overload ................................ 6

10.7. Non-Adjustable High Pressure Control ........ 6

10.8. Adjustable Low Pressure Switch .................. 6

10.9. Liquid Floodback Protection ......................... 6

10.10. Crankcase Heater ..................................... 6

10.11. Condenser Fan Speed Control ................. 6

10.12. Enhanced Vapor Injection (EVI) Control

(Low temperature units only) .................................... 6

11. Electronic Expansion Value (EXV) ................ 7

12. TXV selection .................................................. 7

13. Other Inputs to the Control Board ................ 7

13.1. Customer Supplied Control (Thermostat)..... 7

14. Other Outputs from the Control Board ........ 7

14.1. Defrost Control Board for Units Produced

Prior to Mid- 2013 ..................................................... 7

15. Updated Defrost Control Module .................. 8

16. Evaporator Fan Control ................................. 8

17. Diagnostic Display Board .............................. 8

APPENDIXES

Appendix 1 - Electronic Defrost Control

Appendix 2 - Defrost Quickstart

Appendix 3 - XWeb Instructions

Appendix 4- E2 Instructions

TABLE OF FIGURES

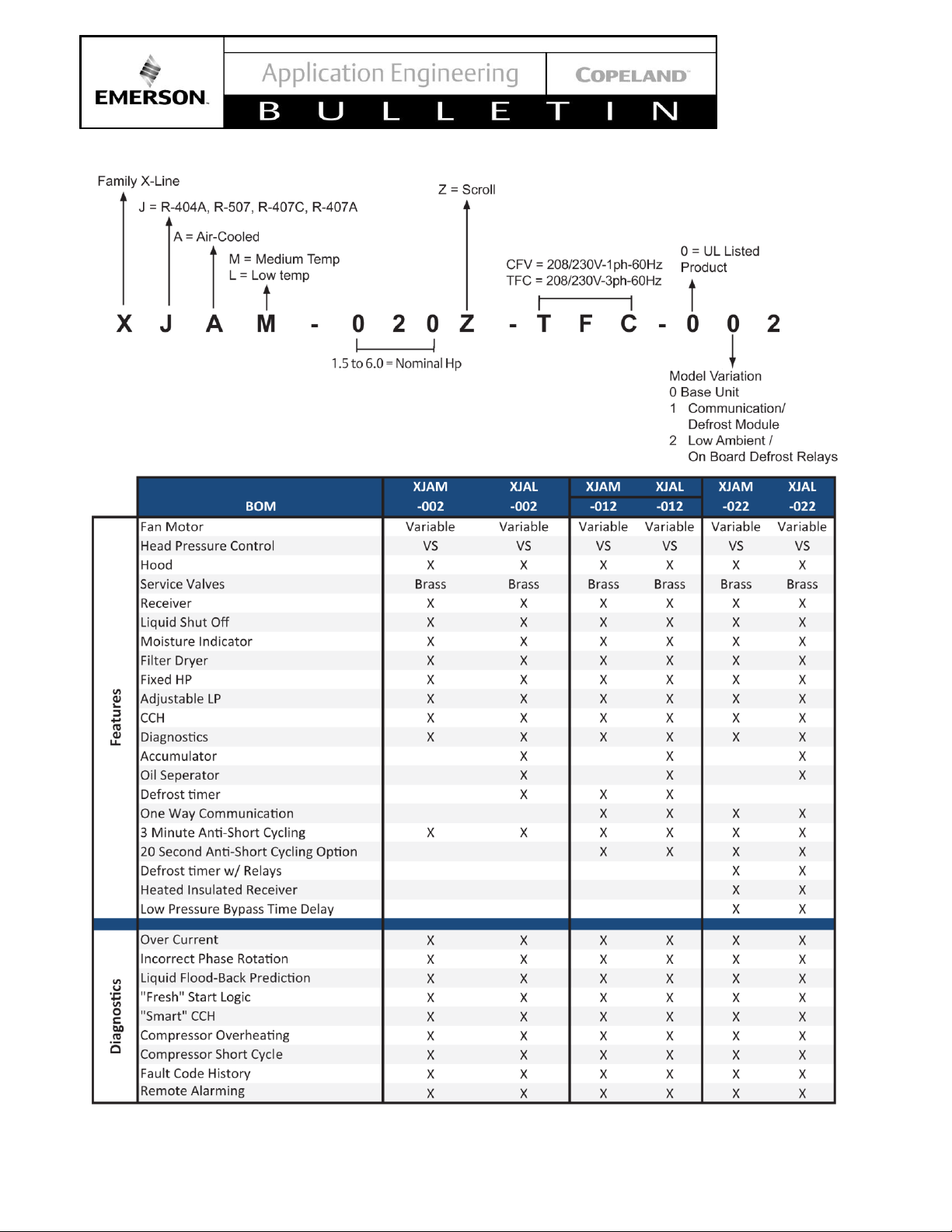

Figure 1 - Nomenclature and Features ........................ 9

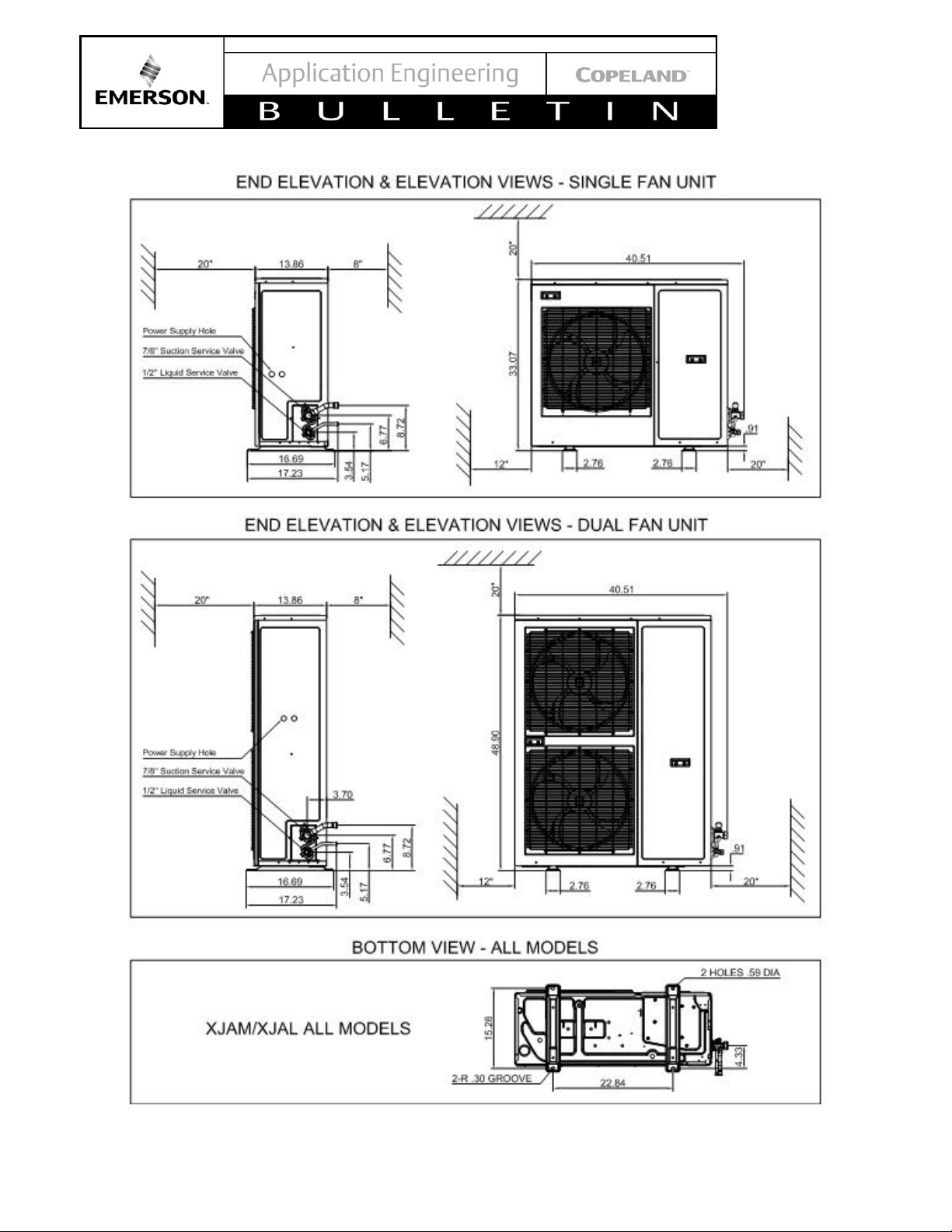

Figure 2 - Physical and Installation Requirements .... 10

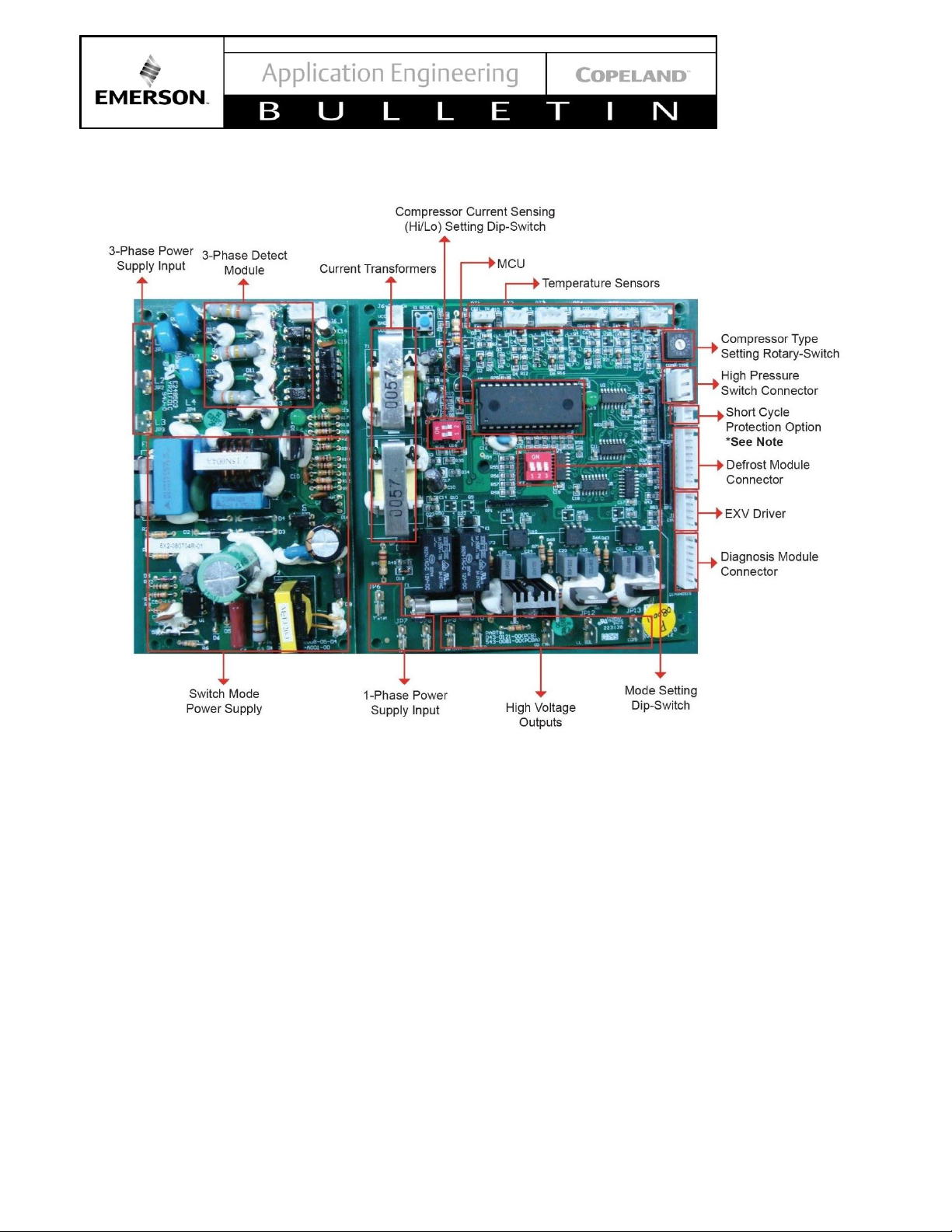

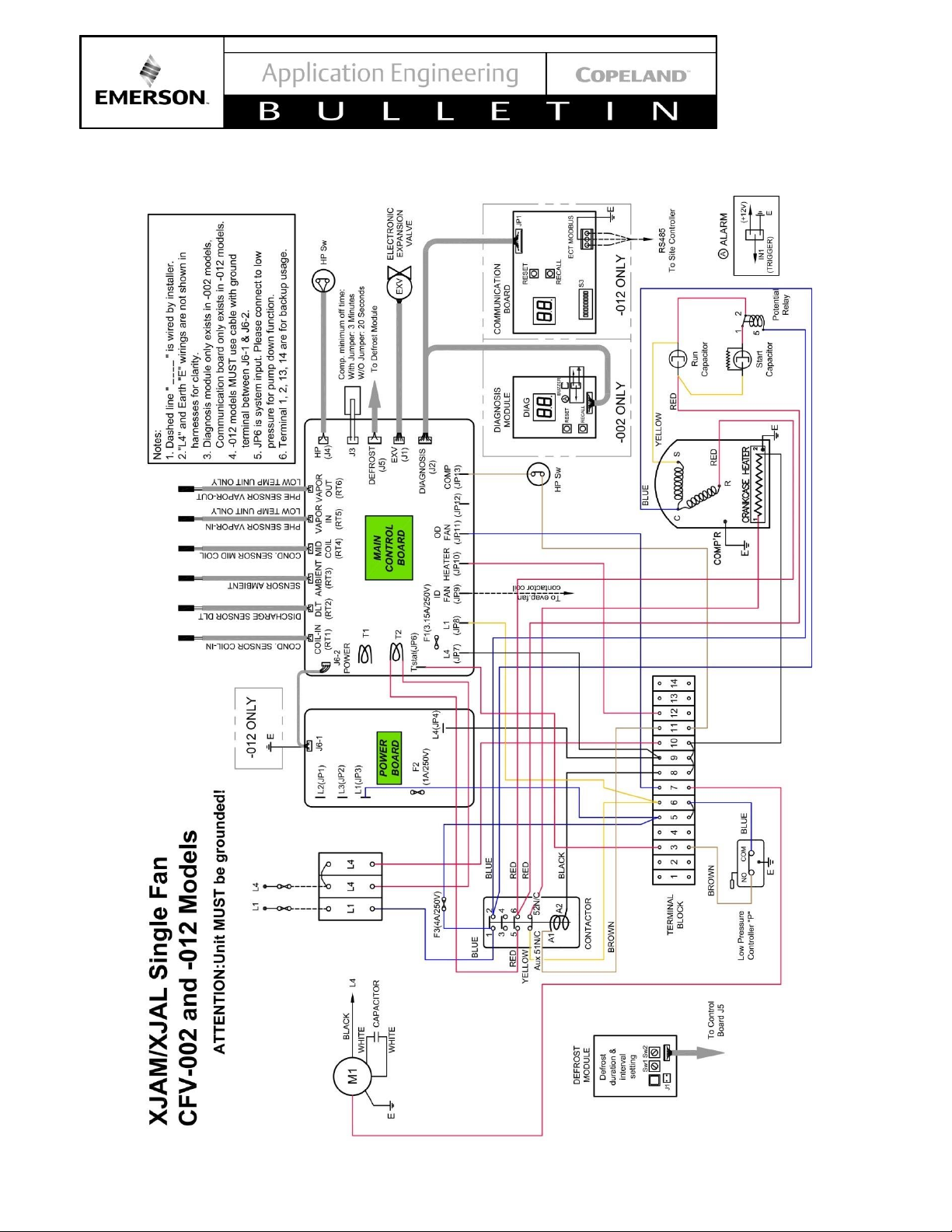

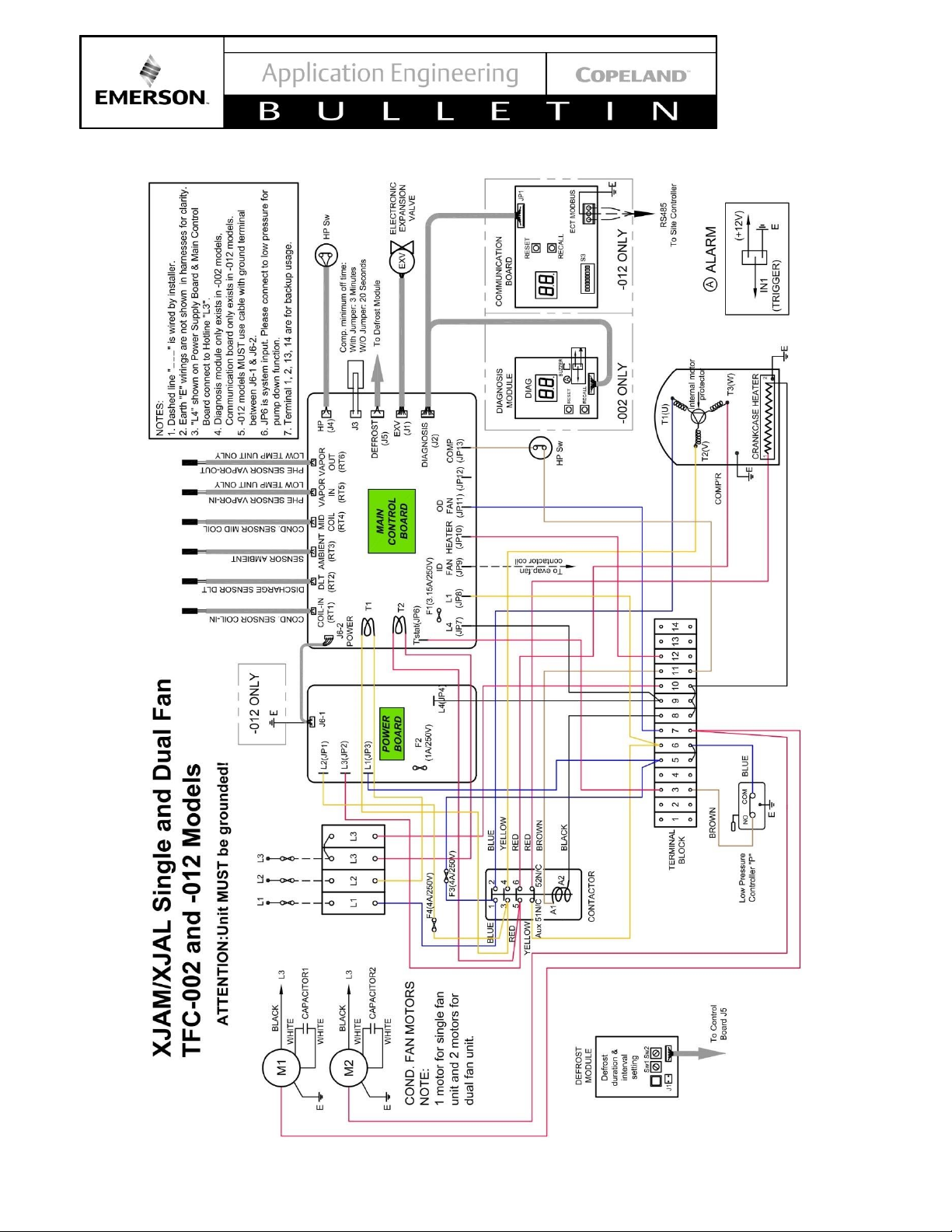

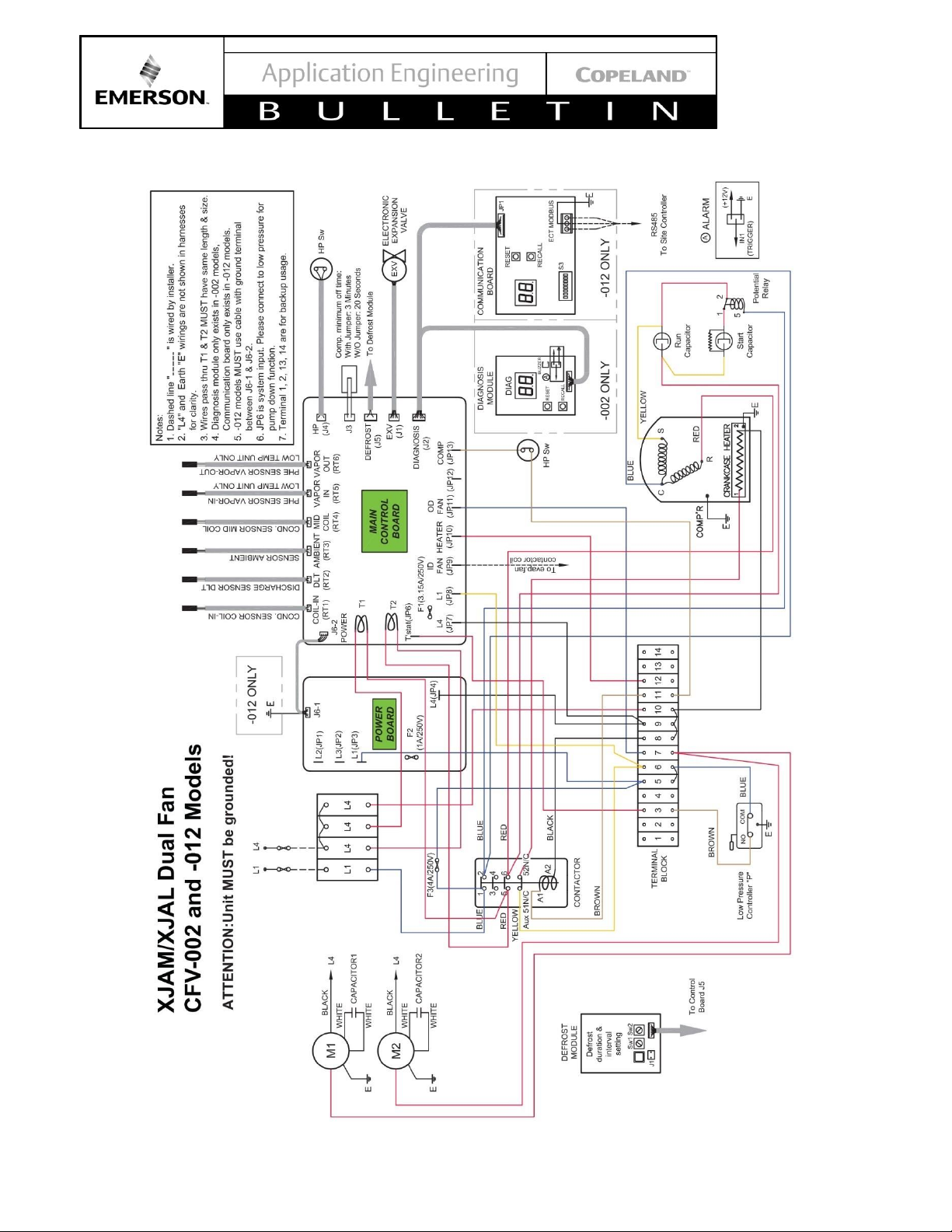

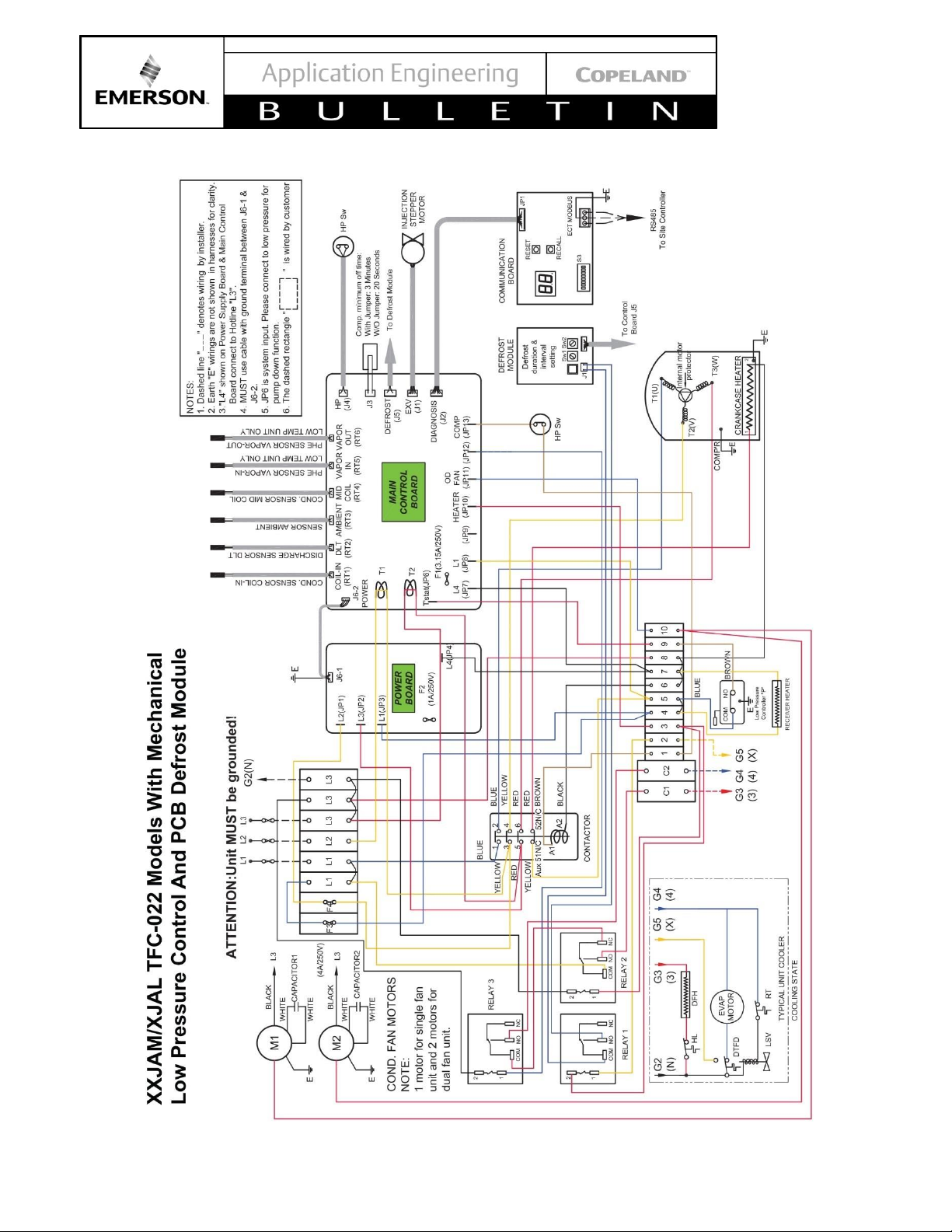

Figure 3 - Power Board / Control Board .................... 11

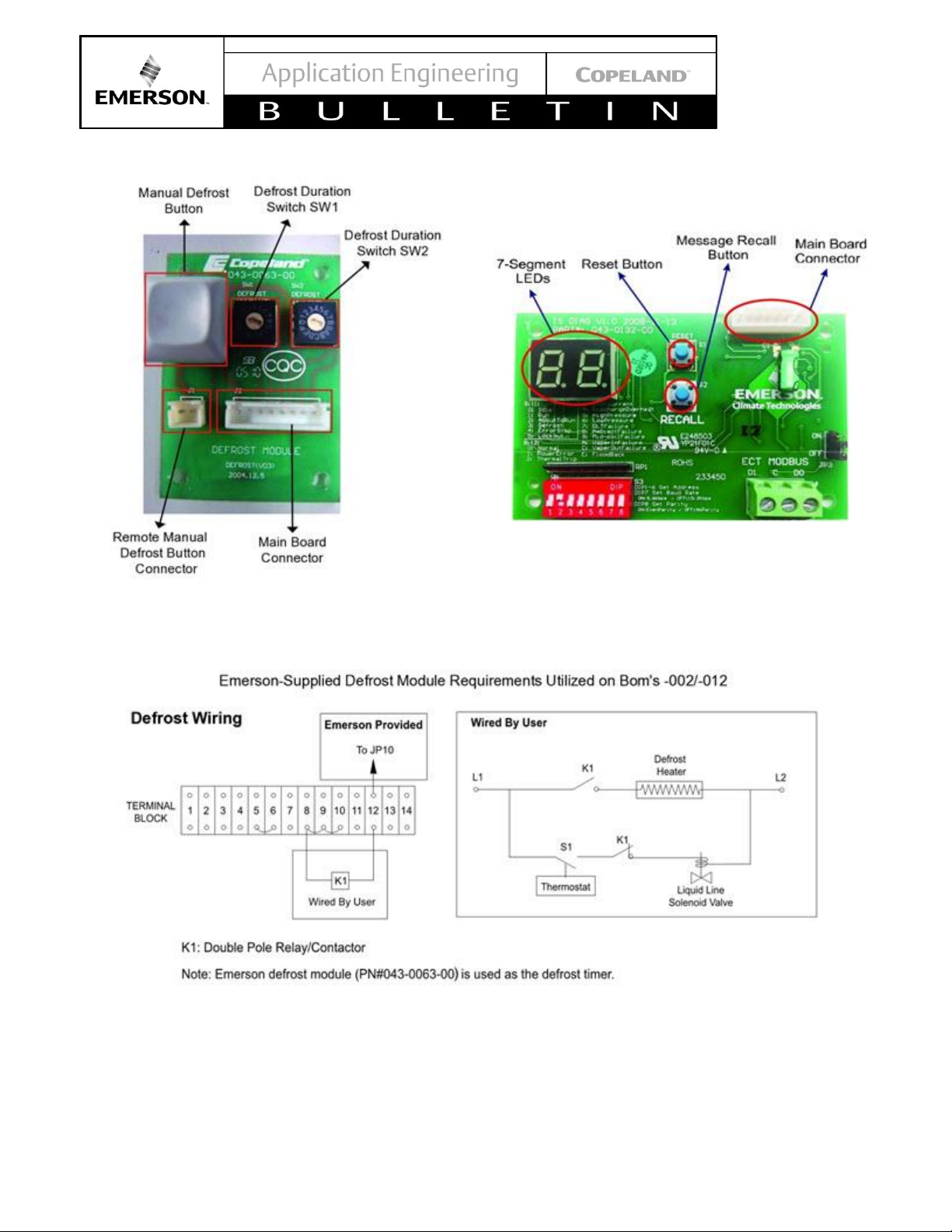

Figure 4 - Defrost Control Module.............................. 12

Figure 5 - Communication Board ............................... 12

Figure 6 - Emerson Supplied Defrost (-002/-012 Models

Only) ........................................................................... 12

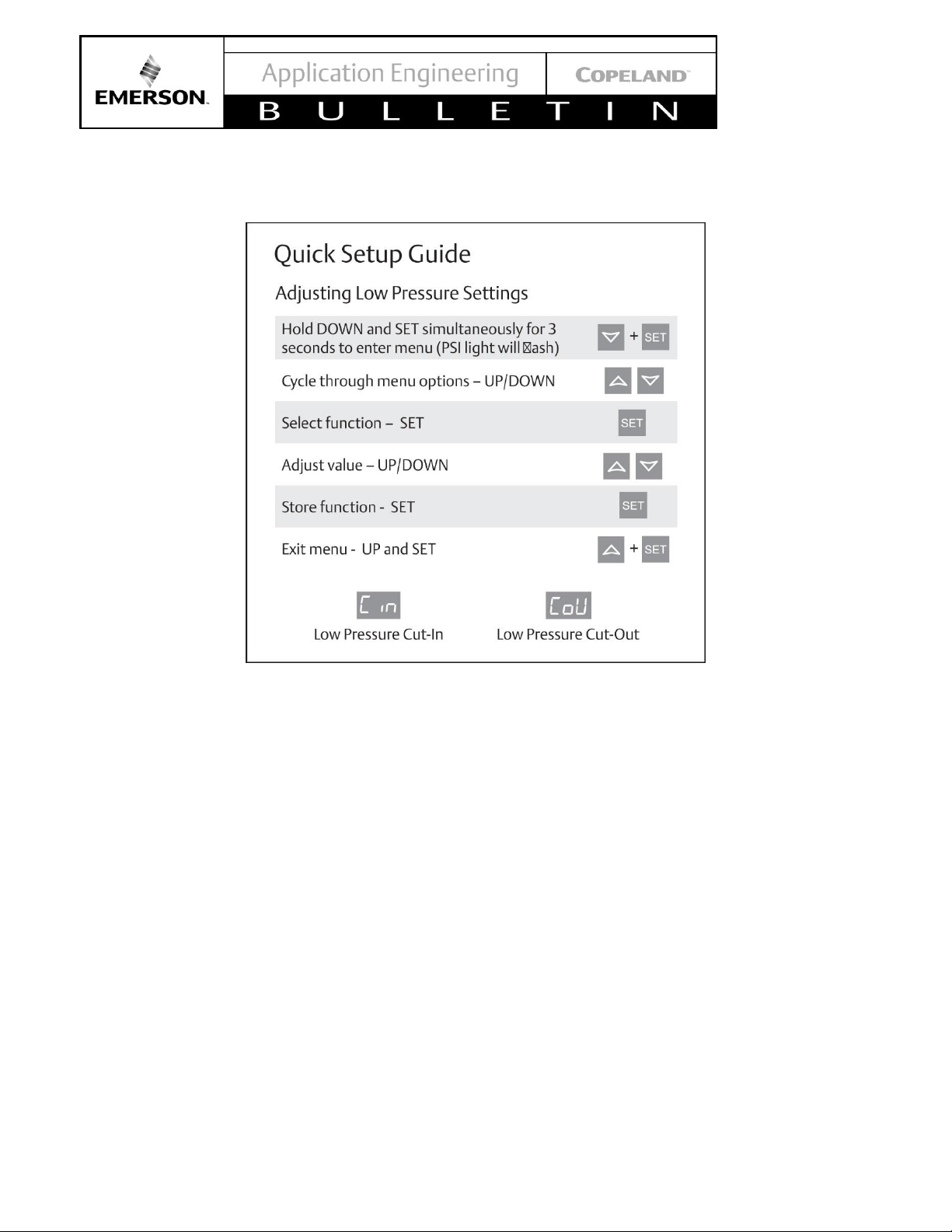

Figure 7 - Quick Setup Guide for Electronic Low

Pressure Control ......................................................... 13

Figure 8 - Diagnostics Module Start Up Information .. 27

TABLES

Table 1 - Temperature Conversion Factors ................. 4

Table 2 - Altitude Conversion Factors (A2) .................. 4

Table 3 - Medium Temp Performance Criteria for R-

404A ........................................................................... 24

Table 4 - Low Temp Performance Criteria for R-404A

................................................................................... 24

Table 5 - Mechanical/Electrical Specifications ........... 25

Table 6 - Emerson Supplied Defrost Set Points ........ 25

Table 7 - Main Control Board Settings ....................... 26

Table 8 - Diagnostics Module Display ....................... 27

Table 9 - Refrigerant Liquid Temperature Valve

Capacity Multiplier Correction Factors ....................... 28

Table 10 - Pressure Control Settings for SJAL/M Units

.................................................................................... 28

Table 11 - System Diagnostic Information ................. 29

Table 12 - Sensor Information .................................... 33

AE5-1377 R3

June 2013

Copeland Scroll™ Outdoor Refrigeration Unit

Page 2

© 2017 Emerson Climate Technologies, Inc.

2

AE5-1377 R3

Safety Instructions

Copeland Scroll™ compressors are manufactured according to the latest U.S. and European Safety Standards.

Particular emphasis has been placed on the user's safety. Safety icons are explained below and safety instructions

applicable to the products in this bulletin are grouped on Page 3. These instructions should be retained throughout

the lifetime of the compressor. You are strongly advised to follow these safety instructions.

Safety Icon Explanation

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE is used to address practices not related to personal injury.

CAUTION, without the safety alert symbol, is used to address practices not related to

personal injury.

FLAMMABLE, Fire hazard! Sparking in a potentially explosive atmosphere! Explosion

hazard!

WARNING

CAUTION

NOTICE

DANGER

CAUTION

Page 3

© 2017 Emerson Climate Technologies, Inc.

3

AE5-1377 R3

Instructions Pertaining to Risk of Electrical Shock, Fire, or Injury to Persons

ELECTRICAL SHOCK HAZARD

• Disconnect and lock out power before servicing.

• Discharge all capacitors before servicing.

• Use compressor with grounded system only.

• Molded electrical plug must be used when required.

• Refer to original equipment wiring diagrams.

• Electrical connections must be made by qualified electrical personnel.

• Failure to follow these warnings could result in serious personal injury.

PRESSURIZED SYSTEM HAZARD

• System contains refrigerant and oil under pressure.

• Remove refrigerant from both the high and low compressor side before

removing compressor.

• Never install a system and leave it unattended when it has no charge, a

holding charge, or with the service valves closed without electrically locking

out the system.

• Use only approved refrigerants and refrigeration oils.

• Personal safety equipment must be used.

•

Failure to follow these warnings could result in serious personal injury.

BURN HAZARD

• Do not touch the compressor until it has cooled down.

• Ensure that materials and wiring do not touch high temperature areas of the

compressor.

• Use caution when brazing system components.

• Personal safety equipment must be used.

•

Failure to follow these warnings could result in serious personal injury or

property damage.

COMPRESSOR HANDLING

• Use the appropriate lifting devices to move compressors.

• Personal safety equipment must be used.

•

Failure to follow these warnings could result in personal injury or property

damage.

Safety Statements

• Refrigerant compressors must be employed only for their intended use.

• Only qualified and authorized HVAC or refrigeration personnel are permitted to install commission and

maintain this equipment.

• Electrical connections must be made by qualified electrical personnel.

• All valid standards and codes for installing, servicing, and maintaining electrical and refrigeration equipment

must be observed.

CAUTION

WARNING

WARNING

WARNING

Page 4

© 2017 Emerson Climate Technologies, Inc.

4

AE5-1377 R3

1. Introduction

Copeland Scroll™ Outdoor Refrigeration Units provide

the many benefits of scroll compressor technology,

coupled with advanced diagnostic controls, to ensure

reliable performance and operation in foodservice

applications. Electronics are used extensively in its

protection and diagnostic features. These features are

controlled by an electronic integrated control board. The

control board provides base control functions related to

temperature controller, defrost, evaporator fan control,

compressor protection e.g. current overload, phase

reversal, liquid/ vapor injection control, self diagnostics

and warnings. These error codes can be seen by an

LED display for easy and rapid troubleshooting and

maintenance.

A complete product offering for medium and low

temperature units is being offered in single and three

phase 208/230 volts. The -002 and -012 BOM product

is approved for operation in ambients from 120°F to 10°F.

XJAM/XJAL -022 models come factory equipped with a

heated and insulated receiver (thermostat controlled), a

check valve installed between the condenser outlet and

receiver inlet, and a 6 second low pressure control time

delay function.

XJAM/XJAL -022 models are approved to operate in

ambient temperatures below -10°F (-24°C). Laboratory

testing has confirmed successful operation at -30°F (34°C) with the factory supplied low ambient

components. At low ambient conditions, a unit may

recycle on low pressure several times during a restart.

This is normal behavior.

2. Nomenclature/Features

See Figure 1 at the end of this bulletin.

3. Understanding Actual vs. Standard Airflow

To choose the proper coil for your application, the

density of the incoming air needs to be known to

calculate the actual capacity and performance of the

system.

A coil’s required capacity can be calculated using the

thermodynamic equation

Q = M x Delta hr

Q = Heat transfer to or from the air (Btuh)

M = Mass flow rate of air (lb/hr)

Delta h ] Difference between the entering and leaving air

enthalpy or total heat (Btu/lb)

The mass flow rate is equal to the density of air times

the face area of the coil times the velocity of the air at

the coil or face velocity.

M = P x A x V

P = Density (lb/cubic ft.)

A =Face area of coil (square ft.)~Fin height x fin length

V = Air Velocity (ft./min.)

For temperature conversions

(𝑨𝟏)

=

𝟓𝟑𝟎

𝑻+𝟒𝟔𝟎

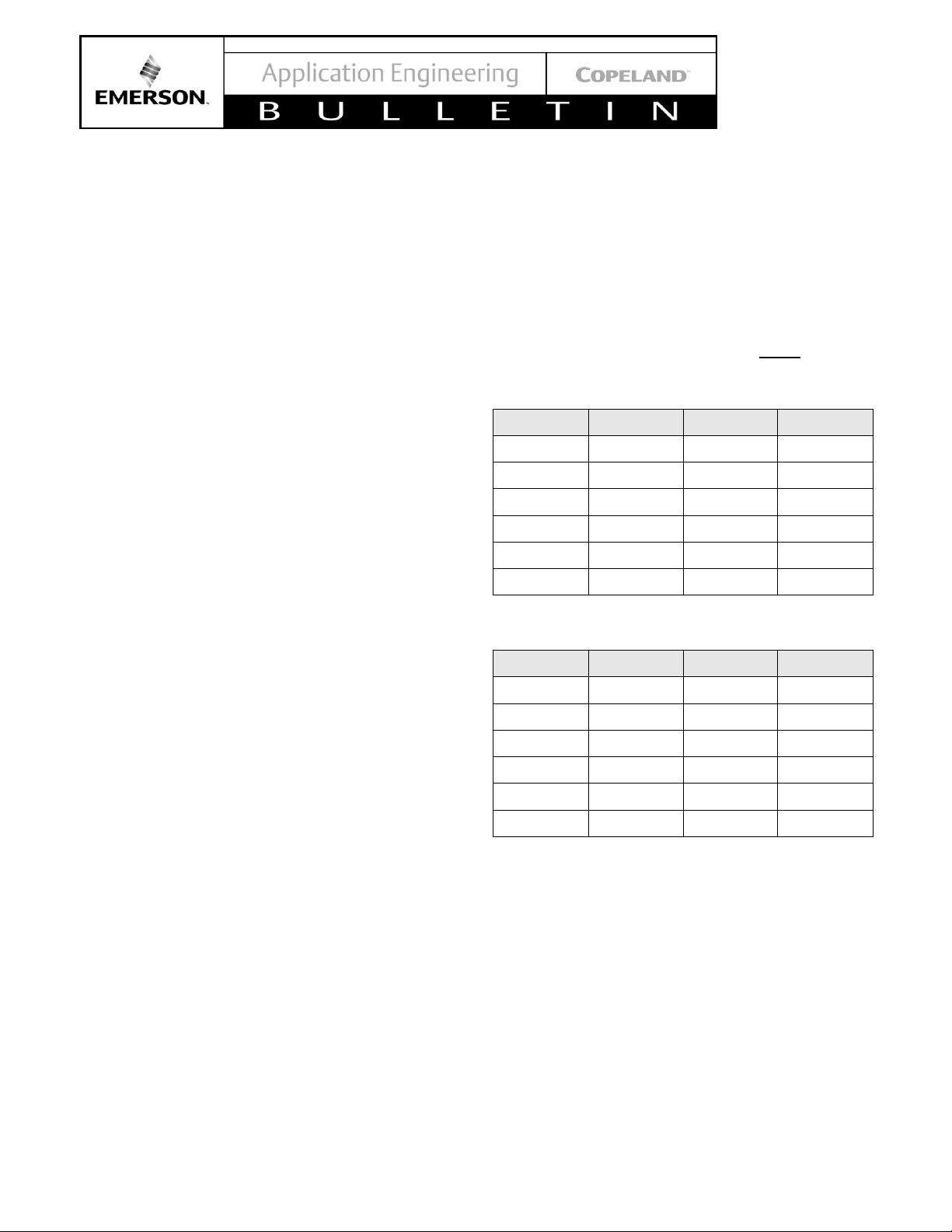

Table 1 - Temperature Conversion Factors

Temp (°F)

Factor A1

Temp (°F)

Factor A1

0

1.15

60

1.02

10

1.13

70

1.00

20

1.10

80

.98

30

1.08

90

.96

40

1.06

100

.95

50

1.04

110

.93

Table 2 - Altitude Conversion Factors (A2)

Alt (ft.)

Factor A2

Alt (ft.)

Factor A2

0

1.00

3000

.895

500

.982

4000

.864

1000

.965

5000

.832

1500

.947

6000

.802

2000

.930

7000

.771

2500

.912

8000

.743

SCFM= CFM X A1 X A2

Note: all calculations and ratings are based on standard

air at 70°F dry bulb temp and 29.92 Hg atmospheric

pressure (sea level). These tables convert non standard

cfm to standard cfm.

4. Performance Data

See Table 3 and Table 4 at the end of this bulletin.

5. Electrical / Physical Data

See Table 5.

6. Generator Requirements

In situations or locations were an electrical power

generator could be applied in the event of a power

outage, the Copeland Scroll™ outdoor condensing unit

will operate providing the generator will provide a supply

Page 5

© 2017 Emerson Climate Technologies, Inc.

5

AE5-1377 R3

voltage range of 180-260 VAC along with a frequency of

47-63 Hz. The electronics control along with the power

board will function properly providing the range of

operating limits is in compliance!

7. Physical Dimensions

See Figure 2.

8. Installation / Piping Instructions

See Figure 2 for overall dimensions of the units. It is

recommended that a clearance of 8 inches from the wall

(or the next unit) be maintained from the unit’s left and

rear panel whereas a clearance of 20 inches is to be

maintained from the unit's right, top and front panels.

Both service access and airflow have been considered

in making these recommendations. Where multiple units

are to be installed in the same location, careful

consideration for proper clearance needs to be given to

each individual unit.

Ideally, the unit should be mounted level on a solid

concrete slab with rubber strips between unit feet and

concrete. However, these units have been designed for

mounting on suitable brackets for wall mounting. In this

case it is equally important that the spatial guidelines

given above are followed, and additional consideration

needs to be given for possible air recycling if units are

stacked above and below each other. In general terms,

air by-pass around each condenser and between each

unit should be avoided at all times.

Pipe sizing should not only be of sufficient size to ensure

optimum performance and good oil return, but it also

needs to take into account the full capacity range

through which this particular unit will need to operate.

Follow the ASHRAE guidelines for proper piping

practices.

9. Condensing Unit Operational Control

The Digital Control electronic control board controls the

operation of the condensing unit. Whenever there is a

control input asking to start or stop the condensing unit,

the control board will execute a set of pre-programmed

procedures to do so. It also monitors the compressor

operating parameters, so as to protect the system from

unsafe operating parameters. See Figure 3.

For example, when the low temperature unit

experiences an extreme temperature day, the control

board decides to switch from vapor-injectionoptimization to discharge gas temperature control to

allow the compressor to run safely and pass the extreme

weather hours.

10. Control Features

The base control function is for the following standard

features. See Figure 3 for additional input options and

output options of the control board.

10.1. Fresh Start Program

This Fresh Start Program is a bump start procedure that

will energize and start the compressor for 3 seconds and

then will be followed by a 20 second off cycle time. This

will occur for 3 cycles, and then continuous power will

be supplied to the compressor for normal operation.

The Fresh Start Program will be executed on initial start

up or any time power is reapplied when the ambient

temperature is lower than 95°F. In addition, the Fresh

Start Program will be executed for any start when the

unit has been cycled off for more than an hour when the

ambient temperature is lower than 95°F.

10.2. Stop Program

When the unit is satisfied, or there is any error which

requires the unit to be shut down, the controller will

execute a Stop Program. The compressor and the

condenser fans will cycle off and the injection valves will

close.

For low temperature units only, when the unit is satisfied

the EXV will start closing immediately, but the

compressor will delay 5 seconds before shut down to

prevent reverse rotation of the compressor.

10.3. Automatic Liquid Injection (Medium

temperature units only)

Automatic Liquid Injection ensures that the scroll

compressor operates within a safe temperature limit.

This unit employs a patented liquid injection system

which injects a saturated refrigerant into the suction line

at the compressor. Activation of the liquid injection valve

is in response to a thermistor which is attached to the

compressor discharge line. A signal is sent to the

stepper motor of the injection valve, opening the valve

in response to increasing discharge temperatures and

injecting saturated refrigerant to reduce the discharge

temperature.

10.4. Compressor Phase Reversal

Compressor Phase Reversal senses for the correct

phase sequence on three phase applications. Reset is

automatic once the correct phase sequence is sensed.

An error message will be shown on the diagnostic LED.

Page 6

© 2017 Emerson Climate Technologies, Inc.

6

AE5-1377 R3

10.5. Loss of Phase Protection

If three phase supply is incorrectly connected to the

contactor terminals, or if a missing phase is sensed, an

error message will be shown on the diagnostic LED.

Reset is automatic once the correct phasing is sensed.

10.6. Motor Current Overload

• All scroll compressors used in these condensing

units have an internal inherit motor protector.

• The Copeland Scroll Outdoor Condensing Unit is

also equipped with two current sensors (CT1, CT2)

to monitor the electrical current of the condensing

unit. If the condensing unit current exceeds a predefined current limit, the controller will take the

following actions:

➢ Stop the compressor for 3 minutes

➢ LED signal will display an Over Current Error for 3

minutes

➢ After a 3 minute delay the compressor will go

through a normal start

➢ The system will lock out after 6 over current trips

within an hour

For this function to operate, two of the power leads are

routed through the current sensing coils (CT1, CT2),

prior to the contactor, from the factory. See Figure 3.

10.7. Non-Adjustable High Pressure Control

This pressure sensing device is a nonadjustable, low

voltage pressure switch that will open at 435psig and

reset at 348psig in the event of high discharge pressure.

Its signal is monitored by the control board.

➢ In the event of a high pressure trip, the unit will stop

and then restart after a 3-minute delay.

➢ After 6 successive HP cut-outs within 1 hour, the

unit will lock-out.

➢ The lockout feature can be reset by disconnecting

the power source and then cycling power to the unit.

10.8. Adjustable Low Pressure Switch

An adjustable low pressure switch is provided as

standard equipment on both the medium and low

temperature condensing units. This control can be used

for a pump-down cycle if so desired. See Table 10 -

Pressure Control Settings for SJAL/M Units.

Units introduced in mid-2013 include an electronic low

pressure control. The electronic low pressure control

provides more accurate cut-in and cut-out pressure

settings and maintains these settings without drifting

over time. See Figure 7 for setup procedure.

10.9. Liquid Floodback Protection

• Liquid refrigerant entering the compressor during

the run cycle, in excessive quantities, can damage

the compressor by diluting the lubricant, as well as

excessive stress on several components in the

compressor. Proper control of liquid refrigerant

within the system is an application issue and is

beyond control of this controller. However, the

controller can perform checks and alert the user that

liquid refrigerant floodback may be occurring and

immediate field service is required. This is only a

warning signal and will not terminate the operation

of the unit. See Table 6.

• Liquid Floodback Protection is acquired by

monitoring the compressor discharge temperature.

When the discharge line temperature falls below a

specified point, low suction line superheat may be

the cause.

10.10. Crankcase Heater

The crankcase heater is wired through a normally

closed contact of the compressor contactor which is

energized whenever the compressor cycles off.

10.11. Condenser Fan Speed Control

The Condenser Fan Speed Control will vary the speed

of the condenser fan motor for head pressure control

under low ambient conditions. There are two thermistor

type sensors that are connected to the control board.

These sensors monitor the condenser mid coil

temperatures and ambient air temperatures to control

the fan speed.

10.12. Enhanced Vapor Injection (EVI) Control

(Low temperature units only)

The EVI system improves low temperature operational

efficiency and provides a reliable low temperature

envelope. It is used to optimize performance and to

prevent the scroll set from overheating. This is done by

controlling the discharge line temperature (DLT) and

vapor injection superheat (VISH).

Enhanced vapor injection is accomplished by utilizing a

subcooling circuit. A heat exchanger is used to subcool

the liquid refrigerant before it enters the evaporator. As

a result of the subcooling done by the heat exchanger,

refrigerant will also be evaporated. This evaporated

refrigerant is then injected into the mid compression

cycle of the scroll compressor for overheat temperature

control.

Page 7

© 2017 Emerson Climate Technologies, Inc.

7

AE5-1377 R3

There are two thermistors sensing the discharge line

temperature, one is located at the discharge line of the

compressor and the second one is placed at the inlet of

the condenser coil. In order to have a higher

temperature resolution, the discharge line thermistor

and condenser coil inlet sensor cooperate to sense a

temperature range from 50°F to 329°F. The discharge

line thermistor has a sensing range from 163°F to 329°F

and the condenser coil will sense temperature from 50°F

to 176°F. The EVI system will keep the discharge line

temperature below 230°F to ensure the safety of the

compressor.

It is important to insulate the system liquid line from the

condensing unit to the evaporator. The recommended

insulation thickness is a minimum of ½ inch. Also the

lower liquid temperature can increase the evaporator

expansion valve capacities. Please follow the valve

manufactures recommended liquid temperature

correction factors for proper selection of the evaporator

expansion valve.

11. Electronic Expansion Value (EXV)

The Electronic Expansion Value (EXV) is a key part of

the EVI system. It will regulate vapor injection flow to

optimize the performance of system and cool the scroll

set. Every second, the control chip will collect the

thermistors reading and do a four second averaging.

The EXV opening will be changed every 20 seconds and

the variation is calculated by different ways based on

different purposes.

12. TXV selection

For EVI, Emerson recommends a balanced port TXV

because it offers a wider operating range for floating

liquid temperatures.

See Table 9 for specifics regarding balanced port sizing

recommendations. Applied with the low temp units it is

recommended that a balanced port expansion valve be

used along with a complete review of the the distributor

& nozzle (orifice) that is supplied with the Evaporator coil

being matched with the applicable condensing unit.

Typically nozzles are selected for standard TXV sizing

using 100°F liquid, with the XJAL those typical

selections could be grossly oversized. See Table 9 for

the liquid correction safety factors when selecting those

components.

13. Other Inputs to the Control Board

13.1. Customer Supplied Control (Thermostat)

The control board will accept a normal 220 volt AC input

ON/OFF signal such as the switching action of a normal

commercial thermostat and relay. If the system is

controlled by low pressure control for a multiple

evaporator system and/or pump down system, the

control board will accept the signal directly from the

control. See Wiring Diagrams, for proper installation.

14. Other Outputs from the Control Board

14.1. Defrost Control Board for Units Produced

Prior to Mid- 2013

(using the control module shown in Figure 4.) The

defrost control board is a basic time initiated module

which is standard on both low and medium temperature

units. The defrost control board can control either offcycle or electric defrost.

The defrost control board will control the liquid line

solenoid valve. When defrost is initiated the liquid line

solenoid valve will close and the unit will go into a

pumpdown cycle. When the suction pressure equals the

setting of the low pressure control, the compressor will

cycle off. After the defrost time has expired, the liquid

line solenoid valve opens and then

the low pressure control will allow the compressor to

restart.

On -002 and -012 models only, due to heater amperage

loads, electric defrost requires an additional relay or

contactor to energize the defrost heater. Relays capable

of 30 amp loads are supplied on the -022 models

The defrost cycle can be executed either automatically

or manually. There are two rotary dip switches by which

the user can set up the defrost cycle, see Figure 4. One

rotary dipswitch sets the defrost duration (SW1) and the

second rotary dipswitch sets the time interval between

defrost cycles (SW2). For automatic defrost set SW1

and SW2 as desired. See Table 6 for time settings. The

defrost control board also incorporates a manual defrost

button that enables a manual defrost as an override to

the rotary switch setting the defrost interval. Upon the

completion of a manual defrost, the system will reset to

the refrigeration cycle with the same procedures as

automatic defrost and then the automatic defrost timer

will reset.

For setting manual defrost only set SW1 as desired and

set SW2 to “0”. Whenever the manual defrost button is

pressed, one defrost cycle will be executed and the

duration of defrost will be determined by the setting of

the rotary dipswitch SW1.

Note: There is no method to terminate a defrost cycle

without resetting the control board.

Table 6 lists rotary dip switch settings for the Defrost

Control Board.

An ON/OFF output connection is provided on the control

board (JP10) for direct connection of a customer

Page 8

© 2017 Emerson Climate Technologies, Inc.

8

AE5-1377 R3

supplied contactor coil/relay when the defrost option is

used. Terminals are male spade type. Coil voltage rating

should be 220VAC and current ratings, 30VA (hold) and

330VA (inrush). See Figure 6.

For customers using their existing defrost timer, remove

the defrost cable connecting the defrost control board to

the unit control board. Also on the unit control board

change the mode setting dip-switch bit 2 to ON and

proceed to standard defrost wiring. See Table 7.

15. Updated Defrost Control Module

Models produced after mid 2013 include an updated

electronic control module that allows for both interval

based defrost or real time based defrost. See Figure 7

for quick setup guide. See Appendix 2, Defrost

Quickstart, for detailed information.

16. Evaporator Fan Control

An ON/OFF output connection is also provided on the

control board (JP9) for direct connection of a customer

supplied contactor coil controlling the evaporator fans.

Terminals are the male spade type. Coil voltage rating

is to be 220VAC and a maximum power rating of 30VA

(hold) and 330VA (inrush). See Figure 6.

17. Diagnostic Display Board

Each condensing unit is supplied with a one-way

communications and diagnostic display board, see

Figure 5. A two character display will make up the

diagnostic/error code. The first character will display the

unit status as shown in Table 8. The second character

will display the error/warning code as shown in Table 8.

See Figure 5 for a detailed view of the diagnostics

board assembly.

The Main Board Connector terminal will accept the

cable connecting the display board to the main control

board. The Reset Button will reset the diagnostic display

board only. The Message Recall Button will display the

last error signal received by the display board. See

Figure 5.

Page 9

© 2017 Emerson Climate Technologies, Inc.

9

AE5-1377 R3

Figure 1 - Nomenclature and Features

Page 10

© 2017 Emerson Climate Technologies, Inc.

10

AE5-1377 R3

Figure 2 - Physical and Installation Requirements

Page 11

© 2017 Emerson Climate Technologies, Inc.

11

AE5-1377 R3

Figure 3 - Power Board / Control Board

* Note: Short Cycle Protection Option

a. Factory Jumper Intalled Three Minute Time Delay

b. Remove Jumper Twenty Second Time Delay

Page 12

© 2017 Emerson Climate Technologies, Inc.

12

AE5-1377 R3

Figure 4 - Defrost Control Module

Figure 5 - Communication Board

Figure 6 - Emerson Supplied Defrost (-002/-012 Models Only)

Page 13

© 2017 Emerson Climate Technologies, Inc.

13

AE5-1377 R3

Figure 7 - Quick Setup Guide for Electronic Low Pressure Control

Page 14

© 2017 Emerson Climate Technologies, Inc.

14

AE5-1377 R3

Drawings

Page 15

© 2017 Emerson Climate Technologies, Inc.

15

AE5-1377 R3

Page 16

© 2017 Emerson Climate Technologies, Inc.

16

AE5-1377 R3

Page 17

© 2017 Emerson Climate Technologies, Inc.

17

AE5-1377 R3

Page 18

© 2017 Emerson Climate Technologies, Inc.

18

AE5-1377 R3

Page 19

© 2017 Emerson Climate Technologies, Inc.

19

AE5-1377 R3

Page 20

© 2017 Emerson Climate Technologies, Inc.

20

AE5-1377 R3

Page 21

© 2017 Emerson Climate Technologies, Inc.

21

AE5-1377 R3

Page 22

© 2017 Emerson Climate Technologies, Inc.

22

AE5-1377 R3

Page 23

© 2017 Emerson Climate Technologies, Inc.

23

AE5-1377 R3

Page 24

© 2017 Emerson Climate Technologies, Inc.

24

AE5-1377 R3

Table 3 - Medium Temp Performance Criteria for R-404A

For other approved refrigerant performance data, visit Online Product Information at Emerson.com/OPI

H.P.

Medium Temperature

Model Number

Btu/hr @ +25°F Sat. Suction

Temp / 90°F Ambient

Btu/hr @ +25°F Sat. Suction

Temp / 100°F Ambient

Refrigerant/

Oil Type

1.5 XJAM-015Z-CFV

14600

13600

R404A / POE

2 XJAM-020Z-CFV

19600

17900

R404A / POE

2 XJAM-020Z-TFC

19600

17900

R404A / POE

3 XJAM-030Z-CFV

28500

25900

R404A / POE

3 XJAM-030Z-TFC

28500

25900

R404A / POE

4 XJAM-040Z-CFV

38600

35300

R404A / POE

4 XJAM-040Z-TFC

38600

35300

R404A / POE

5 XJAM-050Z-CFV

47100

43800

R404A / POE

5 XJAM-050Z-TFC

47100

43800

R404A / POE

6 XJAM-060Z-TFC

54600

50200

R404A / POE

Table 4 - Low Temp Performance Criteria for R-404A

For other approved refrigerant performance data, visit Online Product Information at Emerson.com/OPI

H.P.

Low Temperature

Model Number

Btu/hr @ -10°F Sat. Suction

Temp / 90°F Ambient

Btu/hr @ -10°F Sat. Suction

Temp / 100°F Ambient

Refrigerant/

Oil Type

2 XJAL-020Z-CFV

13100

12700

R404A / POE

2 XJAL-020Z-TFC

13100

12700

R404A / POE

3 XJAL-030Z- TFC

17200

16400

R404A / POE

3 XJAL-035Z- CFV

19700

18100

R404A / POE

4 XJAL-040Z-CFV

24700

23700

R404A / POE

4 XJAL-040Z-TFC

24700

23700

R404A / POE

5 XJAL-050Z-CFV

27600

25700

R404A / POE

5 XJAL-050Z-TFC

27600

25700

R404A / POE

6 XJAL-060Z-TFC

34700

32700

R404A / POE

Page 25

© 2017 Emerson Climate Technologies, Inc.

25

AE5-1377 R3

Table 5 - Mechanical/Electrical Specifications

Unit Model

Compressor

H.P.

Dimensions (in)

Connection Lines

#

of

Fans

Min Circuit Ampacity/

Max Fuse (Amps)

Pump

Down

Capacity

(lbs)

Unit

Weight

(lbs)

dba *

L W H Suction

Liquid

208/230V

1ph-60hz

208/230V

3ph-60hz

XJAM-015Z

ZS11KAE

1.5 16.7 40.5 33

3/4"

Pre mid-2013

7/8"

Post mid-2013

1/2 " 1 15.2 / 20

N/A 7.5 180 55

XJAM-020Z

ZX15KCE

2 16.7 40.5 33

3/4"

Pre mid-2013

7/8"

Post mid-2013

1/2 " 1 18.7 / 30

11.1 / 15

7.5 182 55

XJAM-030Z

ZX21KCE

3 16.7 40.5 33

3/4"

Pre mid-2013

7/8"

Post mid-2013

1/2 " 1 24.3 / 40

14.7 / 25

7.5 194 55

XJAM-040Z

ZX30KCE

4 16.7 40.5 49 7/8 "

1/2 " 2 32.1 / 50

19.7 / 30

11

250 56

XJAM-050Z

ZX38KCE

5 16.7 40.5 49 7/8 "

1/2 " 2 36.6 / 60

29.0 / 50

11

258 56

XJAM-060Z

ZX45KCE

6 16.7 40.5 49 7/8 "

1/2 " 2 N/A

28.1 / 45

11

270 56

XJAL-020Z

ZXI06KCE

2 16.7 40.5 33

3/4"

Pre mid-2013

7/8"

Post mid-2013

1/2 " 1 19.4 / 30

14.7 / 25

7.5 188 50

XJAL-030Z

ZXI09KCE

3 16.7 40.5 33

3/4"

Pre mid-2013

7/8"

Post mid-2013

1/2 " 1 N/A

15.4 / 25

7.5 192 50

XJAL-035Z

ZXI11KCE

3.5 16.7 40.5 33 7/8 "

1/2 " 1 30.7 / 50

N/A 7.5 213 50

XJAL-040Z

ZXI14KCE

4 16.7 40.5 49 7/8 "

1/2 " 2 36.1 / 60

24.5 / 40

11

251 58

XJAL-050Z

ZXI15KCE

5 16.7 40.5 49 7/8 "

1/2 " 2 N/A

26.1 / 45

11

267 58

XJAL-050Z

ZXI16KCE

5 16.7 40.5 49 7/8 "

1/2 " 2 40.4 / 70

N/A 11 287 58

XJAL-060Z

ZXI18KCE

6 16.7 40.5 49 7/8 "

1/2 " 2 N/A

30.7 / 50

11

291 58

Assume Each Fan @ .75 Amps

*Estimated sound pressure values are 10 feet from the unit at 25F evap for MT and -10 evap for LT at 90 ambient. A sound reduction of up to 3

dBA will occur in ambient temperatures below 70F. This data is typical of ‘free field’ conditions for horizontal air cooled condensing units and

may vary depending on the condensing unit installation. There are many factors that affect the sound reading of a condensing unit such as unit

mounting, reflecting walls, background noise and operating condition.

Table 6 - Emerson Supplied Defrost Set Points

For Models with Mechanical Low Pressure Control and PCB Defrost Module

Switch 1

Defrost duration (minutes)

Switch 2

Time interval between defrost

0

No defrost (manual defrost only)

0

No defrost (manual defrost only)

1

5 minutes

1

1 hour

2

10 minutes

2

2 hours

3

15 minutes

3

3 hours

4

20 minutes

4

4 hours

5

25 minutes

5

5 hours

6

30 minutes

6

6 hours

7

35 minutes

7

7 hours

Page 26

© 2017 Emerson Climate Technologies, Inc.

26

AE5-1377 R3

Table 7 - Main Control Board Settings

XJAM

Unit Model

Compressor

Name**

Rotary

Switch

2bit Dip-

Switch

3bit Dip Switch

Control Board

Default Setting

0

ON/ON

Bit1: To set evaporator fan control mode

"OFF": Evaporator Fan On/Off Logic Same As

Compressor

"ON": Evaporator fan will be ON all the time no matter

whether compressor is ON/OFF or defrosting

Bit2: To set defrost mode

"OFF": default setting, using Emerson defrost module

"ON": Using Customer defrost module

Bit3: Not Used Yet

XJAM-015Z-CFV

ZS11KAE-PFV

A

ON/ON

XJAM-020Z-TFC

ZX15KCE-TF5

1

ON/ON

XJAM-020Z-CFV

ZX15KCE-PFV

2

ON/ON

XJAM-030Z-TFC

ZX21KCE-TF5

3

ON/ON

XJAM-030Z-CFV

ZX21KCE-PFV

4

OFF/OFF

XJAM-040Z-TFC

ZX30KCE-TF5

5

ON/ON

XJAM-040Z-CFV

ZX30KCE-PFV

6

OFF/OFF

XJAM-050Z-TFC

ZX38KCE-TF5

7

OFF/OFF

XJAM-050Z-CFV

ZX38KCE-PFV

8

OFF/OFF

XJAM-060Z-TFC

ZX45KCE-TF5

9

OFF/OFF

XJAL

Unit Model

Compressor

Name**

Rotary

Switch

2bit Dip-

Switch

3bit Dip Switch

Control Board

Default Setting

0

ON/ON

Bit1: To set evaporator fan control mode

"OFF": Evaporator Fan On/Off Logic Same As

Compressor

"ON": Evaporator fan will be ON all the time no matter

whether compressor is ON/OFF or defrosting

Bit2: To set defrost mode

"OFF": default setting, using Emerson defrost module

"ON": Using Customer defrost module

Bit3: Not Used Yet

XJXL-020Z-TFC

ZXI06KCE-TF5

1

ON/ON

XJXL-020Z-CFV

ZXI06KCE-PFV

2

ON/ON

XJXL-030Z-TFC

ZXI09KCE-TF5

3

ON/ON

XJXL-035Z-CFV

ZXI11KCE-PFV

4

OFF/OFF

XJXL-040Z-TFC

ZXI14KCE-TF5

5

OFF/OFF

XJXL-040Z-CFV

ZXI14KCE-PFV

6

ON/ON

XJXL-050Z-TFC

ZXI15KCE-TF5

7

OFF/OFF

XJAM-050Z-TFC

ZX38KCE-TF5

7

OFF/OFF

XJAM-050Z-CFV

ZX38KCE-PFV

8

OFF/OFF

XJAM-060Z-TFC

ZX45KCE-TF5

9

OFF/OFF

**Please set the switches to the correct position according to compressor model.

Page 27

© 2017 Emerson Climate Technologies, Inc.

27

AE5-1377 R3

Table 8 - Diagnostics Module Display

LED1 – Unit Status

Display

Status

Idle (Set Point or Low Pressure Cut-Out Rached)

Run

About to Start1

Defrost

Unit Trip

Unit Lockout

LED1 – Unit Status

Display

Status

No error/warnings

Compressor Phase Error (Wrong Phase Sequence/Loss of

Phase)

Compressor Inside Internal Motor Protector Trip

Compressor Over Current

Discharge Gas Overheat (High Discharge Temperature)

Compressor High Pressure Cut Out

Not Used

DLT Thermistors Failure

Ambient Temperature Sensor Failure

Mid-coil Temperature Sensor Failure

PHE Vapor In Temperature Sensor Failure or over range2

PHE Vapor Out Temperature Sensor Failure or over range2

System Liquid Flood Back Warning

Notes:

1

This signal is for Fresh Start, Normal Start Program and any start request delay.

2

PHE Vapor In/Out Temperature Sensor is not applicable in XJAM condensing unit (MT units).

All error/warning messages are priority-ranked from highest to lowest. If unit is initially powered on, the diagnosis

module will show signal similar to the below example:

Figure 8 - Diagnostics Module Start Up Information

Page 28

© 2017 Emerson Climate Technologies, Inc.

28

AE5-1377 R3

Table 9 - Refrigerant Liquid Temperature Valve Capacity Multiplier Correction Factors

Refrigerant Liquid Temperature °F

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

R-12

Correction Factor

1.60

1.54

1.48

1.42

1.36

1.30

1.24

1.18

1.12

1.06

1.00

0.94

0.88

0.82

0.75

R-134a

Correction Factor

1.70

1.63

1.56

1.49

1.42

1.36

1.29

1.21

1.14

1.07

1.00

0.93

0.85

0.78

0.71

R-22

Correction Factor

1.56

1.51

1.45

1.40

1.34

1.29

1.23

1.17

1.12

1.06

1.00

0.94

0.88

0.82

0.76

R-404A/R-507

Correction Factor

2.00

1.90

1.80

1.70

1.60

1.50

1.40

1.30

1.20

1.10

1.00

0.90

0.80

0.70

0.50

These factors include corrections for liquid refrigerant density and net refrigerating effect and are based on an

average evaporator temperature of 0°F. However, they may be used for any evaporator temperature from - 40°F to

+ 40°F since the variation in the actual Factors across this range is insignificant.

Table 10 - Pressure Control Settings for SJAL/M Units

Application

Control

R-404A/R-507

R-407A

R-407C

XJAL(Low Temp)

Low Pressure

0 PSIG min.

N/A

N/A

XJAM(Medium

Temp)

Low Pressure

17 PSIG min.

26.9 PSIG min.

9.4 PSIG min.

Page 29

© 2017 Emerson Climate Technologies, Inc.

29

AE5-1377 R3

Table 11 - System Diagnostic Information

Code

Character

1

Code

Character

2

Fault Type

Trip to Set Point

Control Board

Actions

Auto

Resets

Possible Error and Solution

0

0

Low Pressure

Cutout

Loss of Low

Pressure Control

Signal

- Stop the Unit

Auto Start

Suction Pressure below Cutout Set

Point, normal operation for pump down

system control. Unit in standby mode of

operation

1

0

No Fault

No Fault

No Action

Run

No Fault, Unit Running

1

2

Electrical

Failure

Compressor intends

to start but current

transducers on main

control board sense

no current

-Display compressor

protector trip on

diagnostic

-Auto Start When

protector resets

Auto Start

-Verify proper system voltage at the

compressor

-Verify start component operation ( if

single phase )

-Verify all phases are present, ( three

phase ) verify operation of the unit

contactor.

1

7

Discharge

Line And Coil

in Temp

Sensors

Failure

(See Table

12)

-Actual DLT>320°F

~DLT Sensor Fails

and actual DLT>

176°F

-Both coil-in and DLT

sensors fail (short

circuit)

-Coil Sensor fails

(open) and actual

DLT is <163°F

-Display DLT sensor

failure on diagnostic

-Continue to run the

unit on default mode

Run

-Verify proper connection at the main

control board

-Verify the resistance of the two

sensers See Table 12

1

8

Ambient

Temperature

Sensor Failure

(See Table

12)

Ambient sensor

reads < -22°F or

>145°F

-Display ambient temp

sensors failure on

diagnostic

-Continue to run the

unit on default mode.

Run

-Verify proper connection at the main

control board

-Verify the resistance of the sensor.

See Table 12

1

9

Condensor

Mid-Coil

Sensor Failure

(See Table

12)

Mid-coil sensor

reads < -22°F or

>145°F

-Display mid-coil temp

sensors failure on

diagnostic

-Continue to run the

unit on default mode.

Run

-Verify proper connection at the main

control board

-Verify the resistance of the senser

See Table 12

1

A

PHE vapor in

sensor failure

(Only in XJAL

CDU)

(See Table

12)

-Vapor in sensor

reads <3.2°F or

>163°F

-Ambient temp reads

>50°F

-Display sensor error

on diagnostics

-Continue to run unit

on default mode

Run

-Check whether actual temperature is

out of range

-Check whether the sensor is

connected to the control board

-Check whether the sensor is mounted

at the right position

-Check whether the sensor is in the

heat isolation material

-Check whether the sensor has failed

Page 30

© 2017 Emerson Climate Technologies, Inc.

30

AE5-1377 R3

Code

Character

1

Code

Character

2

Fault Type

Trip to Set Point

Control Board

Actions

Auto

Resets

Possible Error and Solution

1

C

PHE vapor out

sensor failure

(Only in XJAL

CDU)

(See Table

12)

-Vapor out sensor

reads <3.2°F or

>163°F

-Ambient temp reads

>50°F

-Display sensor error

on diagnostics

-Continue to run unit

on default mode

Run

-Check whether actual temperature is

out of range

-Check whether the sensor is

connected to the control board

-Check whether the sensor is mounted

at the right position

-Check whether the sensor is in trhe

heat isolation material

-Check whether the sensor has failed

2

0

Compressor

Rapid Cycling

See Page 8.

Minimum off time

can be selected via

jumper setting

-Delay compressor

start, if minimum off

time is less than 3 min

-Display about to turn

on diagnostic

Auto Start

-Compressor start signal is active when

unit stops; the only thing needed to do

is wait until the unit starts

Fresh Start

Occurs on:

-initial unit start,

-When power is reset

<95°F ambient

Compressor is

cycled off > than 1

hour < than 95° F

ambient

-Compressor runs 3

sec and stops 20 sec

-After 3 cycles,

compressor runs

continously

-Display fresh start on

diagnostic

Auto Start

No faults detected, unit about to start.

2

1

Reverse

Phase/Loss of

phase

(3 phase only)

Incorrect phase

sequence

-Stop the unit

-Display the incorrect

phase

-Display waiting to

restart on diagnostic

-Check the phase

sequence after 3

minutes

Auto Start

Compressor Phase Reversal senses

for the correctphase sequence on three

phase applications. Reset is automatic

once the correct phase sequence is

sensed.An error message will be

shown on the diagnostic LED.

2

3

Over Current

Set based on

Compressor

-Stop the Unit

-Display over current

trip on diagnostic

-Display waiting to

restart on diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

in less than 12 hour

5 Auto

Starts in 1

Hour

* Check rotary switch, make sure it is

on the right position according to the

unit model, Reference Table 7

* Check system operating pressures

* Check voltage supply at the

compressor terminals, must be with in

the +/- 10% voltage tolerance of the

comprressor nameplate.

Page 31

© 2017 Emerson Climate Technologies, Inc.

31

AE5-1377 R3

Code

Character

1

Code

Character

2

Fault Type

Trip to Set Point

Control Board

Actions

Auto

Resets

Possible Error and Solution

2

4

Discharge Gas

Overheat

Discharge

Temperatures over

270°F

-Stop the Unit

-Display DLT trip on

diagnostic

-Display waiting to

restart on diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

within 1 hour

5 Auto

Starts in 1

hour

-Verify system operations to be with in

unit pressure / temperature envelope of

the unit

-Review return gas temperatures at the

compressor.

2

5

High Pressure

Trip

-Contact open at 435

psig ±22psig

-Contact Close at

348 psig ±22psig

-Stop the Unit

-Display HP trip on

diagnostic

-Display waiting to

restart on diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

within 1 hour

5 Auto

Starts in 1

Hour

-Check fan motor / blade operations,

verify wiring of the system.

-Blocked condenser, air re-circulation ,

Non Condensables

-Check liquid line solenoid valve, liquid

service valve, make sure they are open

2

7

Discharge

Line And Coil

in Temp

Sensors

Failure

(See Table

12)

-Actual DLT>320°F

~DLT Sensor Fails

and actual DLT>

176°F

-Both coil-in and DLT

sensors fail (short

circuit)

(Only in XJAL)

-Stop the unit

-Display DLT sensor

failure on the

diagnostic

-Display waiting to

restart on diagnostic

-Auto start the unit

after 3 minutes

Auto Start

-Verify proper connection at the main

control board

-Verify the resistance of the two

sensers See Table 12

4

1

Reverse

Phase/Loss of

phase

(3 phase only)

Incorrect Voltage

sequence

-Stop the unit

-Display the incorrect

phase

-Display waiting to

restart on diagnostic

-Check the phase

sequence after 3

minutes

Auto Start

-Check Voltage sequence of the Power

board, see wiring diagram for

applicable sequence. Verify voltage

sequence at line side of unit terminal

block. See wiring diagram

4

3

Over Current

Set based on

Compressor

-Stop the Unit

-Display over current

trip on diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

in less than 12 hour

5 Auto

Starts in 1

Hour

* Check rotary switch, make sure it is

on the right position according to the

unit model, Reference Table 7

* Check system operating pressures

* Check voltage supply at the

compressor terminals, must be with in

the +/- 10% voltage tolerance of the

compressor nameplate.

Page 32

© 2017 Emerson Climate Technologies, Inc.

32

AE5-1377 R3

Code

Character

1

Code

Character

2

Fault Type

Trip to Set Point

Control Board

Actions

Auto

Resets

Possible Error and Solution

4

4

Discharge Gas

Overheat

Discharge

Temperatures over

270°F

-Stop the Unit

-Display DLT trip on

diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

within 1 hour

5 Auto

Starts in 1

hour

-Check system operations, for example

condensing pressures, return gas

temperatures, envelope operations etc.

Verify operations and correct the

situation

4

5

High Pressure

Trip

-Contact open at 435

psig ±22psig

-Contact Close at

348 psig ±22psig

-Stop the Unit

-Display HP trip on

diagnostic

-Auto start the unit

after 3 minutes

-Lockout unit if 6 trips

within 1 hour

-Display HP lockout on

diagnostic

5 Auto

Starts in 1

Hour

-Verify condenser fan operation,

excessive air recirculation, excessive

ambient temperatures, incorrect

envelope operations

-Verify system component operations

5

3

Over Current

Set based on

Compressor

-Stop the Unit

-Display over current

trip on diagnostic

-Lockout unit if 6 trips

in less than 12 hour

-Display over current

lockout on diagnostic

Lockout

* Check rotary switch, make sure it is

on the right position according to the

unit model, Reference Table 7

* Check system operating pressures

* Check voltage supply at the

compressor terminals, must be with in

the +/- 10% voltage tolerance of the

compressor nameplate.

5

4

Discharge Gas

Overheat

(XJAM

Models)

Discharge

Temperatures over

270°F

-Stop the Unit

-Display DLT trip on

diagnostic

-Lockout unit if 6 trips

within 1 hour

-Display DLT overheat

lockout on diagnostic

Lockout

-Check system operations, for example

condensing pressures, return gas

temperatures, envelope operations etc.

Verify operations and correct the

situation

5

5

High Pressure

Trip

-Contact open at 435

psig ±22psig

-Contact Close at

348 psig ±22psig

-Stop the Unit

-Display HP trip on

diagnostic

-Lockout unit if 6 trips

within 1 hour

-Display HP lockout on

diagnostic

Lockout

-Verify condenser fan operation,

excessive air recirculation, excessive

ambient temperatures, incorrect

envelope operation

-Verify system component operations

Page 33

© 2017 Emerson Climate Technologies, Inc.

33

AE5-1377 R3

Table 12 - Sensor Information

In the event there is fault code referencing a possible issue with any one of the four unit control temperature sensors,

see this table to assess the fault code condition. If the resistance of the sensor in question does not compare to the

information provide in the table for the applicable sensor, then that sensor will need replaced.

DLT

Coil-in

Amb/Mid-Coil

VIT/VOT

Temp

Temp

R

Temp

Temp

R

Temp

Temp

R

Temp

Temp

R

140

60

22.99

50

10

207.6

-22

-30

121.9

5

-15

56.48

142

61

22.13

52

11

197.2

-20

-29

115.5

7

-14

53.78

144

62

21.31

54

12

187.5

-18

-28

109.5

9

-13

51.24

145

63

20.51

55

13

178.4

-17

-27

103.9

10

-12

48.84

147

64

19.78

57

14

169.7

-15

-26

98.54

12

-11

46.56

149

65

19.06

59

15

161.5

-13

-25

93.52

14

-10

44.4

151

66

18.36

61

16

153.7

-11

-24

88.78

16

-9

42.36

153

67

17.7

63

17

146.4

-9

-23

84.32

18

-8

40.42

154

68

17.06

64

18

139.4

-8

-22

80.1

19

-7

38.58

156

69

16.45

66

19

132.8

-6

-21

76.12

21

-6

36.84

158

70

15.87

68

20

126.6

-4

-20

72.38

23

-5

35.08

160

71

15.31

70

21

120.6

-2

-19

68.82

25

-4

33.62

162

72

14.78

72

22

115.1

0

-18

65.48

27

-3

32.12

163

73

14.26

73

23

109.8

1

-17

62.3

28

-2

30.7

165

74

13.77

75

24

104.7

3

-16

59.3

30

-1

29.36

167

75

13.29

77

25

100

5

-15

56.48

32 0 28.08

169

76

12.83

79

26

95.47

7

-14

53.78

34 1 26.86

171

77

12.39

81

27

91.19

9

-13

51.24

36 2 25.7

172

78

11.97

82

28

87.1

10

-12

48.84

37 3 24.6

174

79

11.57

84

29

83.24

12

-11

46.56

39 4 23.56

176

80

11.18

86

30

79.55

14

-10

44.4

41 5 22.46

178

81

10.8

88

31

76.05

16

-9

42.36

43 6 21.6

180

82

10.44

90

32

72.73

18

-8

40.42

45 7 20.7

181

83

10.1

91

33

35.12

19

-7

38.58

46 8 19.84

183

84

9.761

93

34

66.56

21

-6

36.84

48 9 19.02

185

85

9.443

95

35

63.7

23

-5

35.08

50

10

18.24

187

86

9.135

97

36

60.98

25

-4

33.62

52

11

17.49

189

87

8.836

99

37

58.4

27

-3

32.12

54

12

16.78

190

88

8.55

100

38

55.92

28

-2

30.7

55

13

16.11

192

89

8.275

102

39

53.59

30

-1

29.36

57

14

15.46

194

90

8.01

104

40

51.34

32 0 28.08

59

15

14.84

196

91

7.754

106

41

49.21

34 1 26.86

61

16

14.25

198

92

7.508

108

42

47.18

36 2 25.7

63

17

13.69

199

93

7.272

109

43

45.25

37 3 24.6

64

18

13.15

201

94

7.044

111

44

43.39

39 4 23.56

66

19

12.64

Page 34

© 2017 Emerson Climate Technologies, Inc.

34

AE5-1377 R3

Table 12 - Sensor Information Continued

DLT

Coil-in

Amb/Mid-Coil

VIT/VOT

Temp

Temp

R

Temp

Temp

R

Temp

Temp

R

Temp

Temp

R

203

95

6.823

113

45

41.64

41 5 22.46

68

20

12.15

205

96

6.612

115

46

39.95

43 6 21.6

70

21

11.68

207

97

6.406

117

47

38.36

45 7 20.7

72

22

11.23

208

98

6.209

118

48

36.82

46 8 19.84

73

23

10.8

210

99

6.019

120

49

35.36

48 9 19.02

75

24

10.39

212

100

5.834

122

50

33.96

50

10

18.24

77

25

10

214

101

5.658

124

51

32.62

52

11

17.49

79

26

9.624

216

102

5.487

126

52

31.35

54

12

16.78

81

27

9.266

217

103

5.321

127

53

30.14

55

13

16.11

82

28

8.922

219

104

5.164

129

54

28.97

57

14

15.46

84

29

8.592

221

105

5.01

131

55

27.86

59

15

14.84

86

30

8.276

223

106

4.862

133

56

26.8

61

16

14.25

88

31

7.974

225

107

4.717

135

57

25.78

63

17

13.69

90

32

7.686

226

108

4.578

136

58

24.81

64

18

13.15

91

33

7.408

228

109

4.445

138

59

23.87

66

19

12.64

93

34

7.142

230

110

4.316

140

60

22.99

68

20

12.15

95

35

6.886

232

111

4.192

142

61

22.13

70

21

11.68

97

36

6.642

234

112

4.07

144

62

21.31

72

22

11.23

99

37

6.408

235

113

3.954

145

63

20.51

73

23

10.8

100

38

6.182

237

114

3.841

147

64

19.78

75

24

10.39

102

39

5.966

239

115

3.733

149

65

19.06

77

25

10

104

40

5.76

241

116

3.626

151

66

18.36

79

26

9.624

106

41

5.56

243

117

3.524

153

67

17.7

81

27

9.266

108

42

5.368

244

118

3.427

154

68

17.06

82

28

8.922

109

43

5.186

246

119

3.331

156

69

16.45

84

29

8.592

111

44

5.008

248

120

3.239

158

70

15.87

86

30

8.276

113

45

4.84

250

121

3.149

160

71

15.31

88

31

7.974

115

46

4.676

252

122

3.062

162

72

14.78

90

32

7.686

117

47

4.52

253

123

2.978

163

73

14.26

91

33

7.408

118

48

4.37

255

124

2.897

165

74

13.77

93

34

7.142

120

49

4.224

257

125

2.819

167

75

13.29

95

35

6.886

122

50

4.086

259

126

2.742

169

76

12.83

97

36

6.642

124

51

3.952

261

127

2.668

171

77

12.39

99

37

6.408

126

52

3.822

262

128

2.598

172

78

11.97

100

38

6.182

127

53

3.698

264

129

2.529

174

79

11.57

102

39

5.966

129

54

3.58

266

130

2.462

176

80

11.18

104

40

5.76

131

55

3.464

268

131

2.396 106

41

5.56

133

56

3.354

270

132

2.333 108

42

5.368

135

57

3.246

271

133

2.272 109

43

5.186

136

58

3.144

270

132

2.333 108

42

5.368

135

57

3.246

271

133

2.272 109

43

5.186

136

58

3.144

Page 35

© 2017 Emerson Climate Technologies, Inc.

35

AE5-1377 R3

Table 12 - Sensor Information Continued

DLT

Amb/Mid-Coil

VIT/VOT

Temp

Temp

R

Temp

Temp

R

Temp

Temp

R

273

134

2.213 111

44

5.008

138

59

3.046

275

135

2.156 113

45

4.84

140

60

2.95

277

136

2.101 115

46

4.676

142

61

2.858

279

137

2.047 117

47

4.52

144

62

2.77

280

138

1.994 118

48

4.37

145

63

2.684

282

139

1.944 120

49

4.224

147

64

2.602

284

140

1.894 122

50

4.086

149

65

2.522

286

141

1.847 124

51

3.952

151

66

2.446

288

142

1.801 126

52

3.822

153

67

2.372

289

143

1.756 127

53

3.698

154

68

2.302

291

144

1.712 129

54

3.58

156

69

2.232

293

145

1.669 131

55

3.464

158

70

2.166

295

146

1.628 133

56

3.354

160

71

2.102

297

147

1.588 135

57

3.246

162

72

2.04

298

148

1.549 136

58

3.144

163

73

1.98

300

149

1.512 138

59

3.046 302

150

1.474 140

60

2.95

The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. Emerson Climate Technologies, Inc. and/or its affiliates

(collectively "Emerson"), as applicable, reserve the right to modify the design or specifications of such products at any time without notice. Emerson

does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Emerson product remains solely with the purchaser or end user.

Page 36

APPENDIX 1

Digital controller with off cycle defrost

XR30CX

CONTENTS

1. GENERAL WARNING ____________________________________________________ 1

2. GENERAL DESCRIPTION ________________________________________________ 1

3. CONTROLLING LOADS __________________________________________________ 1

4. FRONT PANEL COMMANDS ______________________________________________ 1

5. MAIN FUNCTIONS ______________________________________________________ 1

6. PARAMETERS _________________________________________________________ 2

7. DIGITAL INPUT_________________________________________________________ 2

8. TTL SERIAL LINE – FOR MONITORING SYSTEMS ___________________________ 2

9. INSTALLATION AND MOUNTING __________________________________________ 2

10. ELECTRICAL CONNECTIONS_____________________________________________ 2

11. HOW TO USE THE HOT KEY _____________________________________________ 2

12. TECHNICAL DATA ______________________________________________________ 2

13. CONNECTIONS ________________________________________________________ 2

14. DEFAULT SETTING VALUES _____________________________________________ 3

1. GENERAL WARNING

1.1 PLEASE READ BEFORE USING THIS MANUAL

This manual is part of the product and should be kept near the instrument for easy and

quick reference.

The instrument shall not be used for purposes different from those described hereunder. It

cannot be used as a safety device.

Check the application limits before proceeding.

Dixell Srl reserves the right to change the composition of its products, even without notice,

ensuring the same and unchanged functionality.

1.2

Check the supply voltage is correct before connecting the instrument.

Do not expose to water or moisture: use the controller only within the operating limits

Warning: disconnect all electrical connections before any kind of maintenance.

Fit the probe where it is not accessible by the End User. The instrument must not be

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell

Consider the maximum current which can be applied to each relay (see Technical Data).

Ensure that the wires for probes, loads and the power supply are separated and far

In case of applications in industrial environments, the use of mains filters (our mod. FT1)

2. GENERAL DESCRIPTION

Model XR30CX, format 32 x 74 mm, is a digital thermostat with off cycle defrost designed for

refrigeration applications at normal temperature. It provides two relay outputs, one for the

compressor, the other one can be used for defrost heater. The digital input operates to stop

defrost.

The HOT KEY output allows to connect the unit, by means of the external module XJ485-CX,

to a network line ModBUS-RTU compatible such as the dIXEL monitoring units of X-WEB

family. It allows to program the controller by means the HOT KEY programming keyboard.

The instrument is fully configurable through special parameters that can be easily programmed

through the keyboard.

3. CONTROLLING LOADS

3.1 COMPRESSOR

The compressor relay is always closed when the controller is powered except during defrost

and dripping time.

3.2 DEFROST

The defrost interval is controlled by means of parameter “EdF”:

- with EdF=in the defrost is made every “IdF” time,

- with EdF = “rtc”, the defrost is made in real time depending on the hours set in the

Other parameters are used to control defrost cycles: its maximum length (MdF)

4. FRONT PANEL COMMANDS

SAFETY PRECAUTIONS

avoiding sudden temperature changes with high atmospheric humidity to prevent

formation of condensation

opened.

S.s.l.” (see address) with a detailed description of the fault.

enough from each other, without crossing or intertwining.

in parallel with inductive loads could be useful.

parameters Ld1..Ld6 on workdays and in Sd1…Sd6 in holidays;

(UP): To see the max. stored temperature; in programming mode it browses the

parameter codes or increases the displayed value.

(DOWN) To see the min stored temperature; in programming mode it browses the

parameter codes or decreases the displayed value.

To switch the instrument off, if onF = oFF.

Not used

KEY COMBINATIONS:

+

+ To enter in programming mode.

+ To return to the room temperature display.

To lock & unlock the keyboard.

4.1 USE OF LEDS

Each LED function is described in the following table.

LED MODE FUNCTION

ON Compressor enabled

Flashing Anti-short cycle delay enabled

ON Defrost enabled

ON An alarm is occurring

°C/°F ON Measurement unit

°C/°F Flashing Programming phase

5. MAIN FUNCTIONS

5.1 CONTROLLER DISPLAY

The controller displays:

- “on” when is powered.

- “dEF” dring a defrost

- “oFF” when it is in stand by.

5.2 HOW TO START A MANUAL DEFROST

Push the DEF key for more than 2 seconds and a manual defrost will

start.

5.3 HOW TO CHANGE A PARAMETER VALUE

To change the parameter’s value operate as follows:

1. Enter the Programming mode by pressing the Set + n keys for 3s (the “°C” or “°F” LED

starts blinking).

2. Select the required parameter. Press the “SET” key to display its value

3. Use “UP” or “DOWN” to change its value.

4. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + UP or wait 15s without pressing a key.

NOTE: the set value is stored even when the procedure is exited by waiting the time-out to

expire.

5.4 THE HIDDEN MENU

The hidden menu Includes all the parameters of the instrument.

5.4.1 HOW TO ENTER THE HIDDEN MENU

1. Enter the Programming mode by pressing the Set + n keys for 3s (the “°C” or “°F” LED

starts blinking).

2. Released the keys, then push again the Set+n keys for more than 7s. The Pr2 label will be

displayed immediately followed from the HY parameter.

NOW YOU ARE IN THE HIDDEN MENU.

3. Select the required parameter.

4. Press the “SET” key to display its value

5. Use o or n to change its value.

6. Press “SET” to store the new value and move to the following parameter.

To exit: Press SET + o or wait 15s without pressing a key.

NOTE1: if none parameter is present in Pr1, after 3s the “noP” message is displayed. Keep the

keys pushed till the Pr2 message is displayed.

NOTE2: the set value is stored even when the procedure is exited by waiting the time-out to

expire.

5.4.2 HOW TO MOVE A PARAMETER FROM THE HIDDEN MENU TO

THE FIRST LEVEL AND VICEVERSA.

Each parameter present in the HIDDEN MENU can be removed or put into “THE FIRST LEVEL”

(user level) by pressing “SET + n”.

In HIDDEN MENU when a parameter is present in First Level the decimal point is on.

5.5 HOW TO LOCK THE KEYBOARD

1. Keep pressed for more than 3 s the UP + DOWN keys.

2. The “POF” message will be displayed and the keyboard will be locked. At this point it will

be possible only to see the set point or the MAX o Min temperature stored

3. If a key is pressed more than 3s the “POF” message will be displayed.

5.6 TO UNLOCK THE KEYBOARD

Keep pressed together for more than 3s the o and n keys, till the “Pon” message will be

(DEF) To start a manual defrost

1598030330 XR30CX MRS GB r2.0 23.05.2013.doc XR30CX 1/3

displayed.

Page 37

5.7 THE ON/OFF FUNCTION

WARNING: Loads connected to the normally closed contacts of the relays are always

supplied and under voltage, even if the instrument is in stand by mode.

With “onF = oFF”, pushing the ON/OFF key, the instrument is switched off. The

“OFF” message is displayed. In this configuration, the regulation is disabled.

To switch the instrument on, push again the ON/OFF key.

6. PARAMETERS

rtc Real time clock menu: to set the time and date and defrost start time.

DISPLAY

CF Temperature measurement unit: °C=Celsius; °F=Fahrenheit. WARNING: When the

measurement unit is changed the SET point and the values of the parameters Hy, LS,

US, Ot, ALU and ALL have to be checked and modified if necessary).

rES Resolution (for °C): (in = 1°C; dE = 0.1 °C) allows decimal point display.

DEFROST

EdF Defrost mode:

rtc = Real Time Clock mode. Defrost time follows Ld1÷Ld6 parameters on workdays

and Sd1÷Sd6 on holidays.

in = interval mode. The defrost starts when the time “Idf” is expired.

IdF Interval between defrost cycles: (0÷120h) Determines the time interval between the

beginning of two defrost cycles.

MdF (Maximum) length for defrost: (0÷255min) When P2P = n, (not evaporator probe: timed

defrost) it sets the defrost duration, when P2P = y (defrost end based on temperature) it

sets the maximum length for defrost.

dFd Temperature displayed during defrost: (rt = real temperature; it = temperature at

defrost start; SEt = set point; dEF = “dEF” label)

dAd MAX display delay after defrost: (0÷255min). Sets the maximum time between the end

of defrost and the restarting of the real room temperature display.

Fdt Drip time: (0120 min) time interval between reaching defrost termination temperature

and the restoring of the control’s normal operation. This time allows the evaporator to

eliminate water drops that might have formed due to defrost.

TO SET CURRENT TIME AND WEEKLY HOLIDAYS