Page 1

1. GENERAL WARNING

XJ200

4. INSTALLATION AND ASSEMBLY

4.1 PACKAGE CONTENTS

1.1 TO BE READ BEFORE USING THIS MANUAL.

This manual forms an integral part of the product and must be kept near the device

for easy and quick consultation.

The device must not be used for purposes different than those described below and

particularly, it cannot be used as a safety device.

Verify the limits of application before proceeding.

1.2

Verify that the connections comply with the instructions in this manual before

Do not expose the unit to water or humidity: use the device only within the

Caution: disconnect the electrical connections of the device before any

The module must never be opened.

If the device is faulty or malfunctions, return it to the retailer or to "DIXELL s.r.l."

SAFETY PRECAUTIONS

connecting the device.

stipulated working limits, avoiding sudden changes in temperature and high

atmospheric humidity in order to prevent condensation from forming.

maintenance.

(refer to address) with a precise description of the fault.

2. GENERAL DESCRIPTION

The wireless communication modules of the XJ200 range are a radio communication

system for Dixell monitoring systems.

The iCOOLL range consists of the XJ200 radio module and its power supplier PW-200J.

XJ200 can cover a variety of functions within the monitoring network:

a. Master: when it is connected to the X-WEB monitoring system.

b. Slave/Repeater: when it is connected to the subnets of devices equipped

with RS485.

c. Repeater: when it is assigned the function as a simple bridge towards other

subnets that cannot be reached directly by the master.

The XJ200 modules enable 2-way communication between Dixell devices/modules

equipped with an RS485 output that are appropriately connected to each other and the

monitoring unit of the X-WEB ranges, thereby replacing the connection via an RS485

cable.

Up to 200 devices can be connected to the same XJ200 (communication between the

module and the devices is via RS485), thereby covering several workstations with the

same communication module.

The maximum distance possible between the XJ200 modules in an open space (with no

obstacles) is 200 metres. This distance can be remarkably reduced in the presence of

interference such as radio emitters, generators of electrical or magnetic fields that can

affect the proper communication between the XJ200 modules.

The range of serial addresses allowed on the instruments connected to the iCOOLL

modules is from 1 to 244.

N.B. In order to work with the iCOOLL modules, the instruments must be equipped with

an RS485 serial port and use ModBUS-RTU communication protocol.

3. FRONT PANEL

LED: the module has a few LED signals

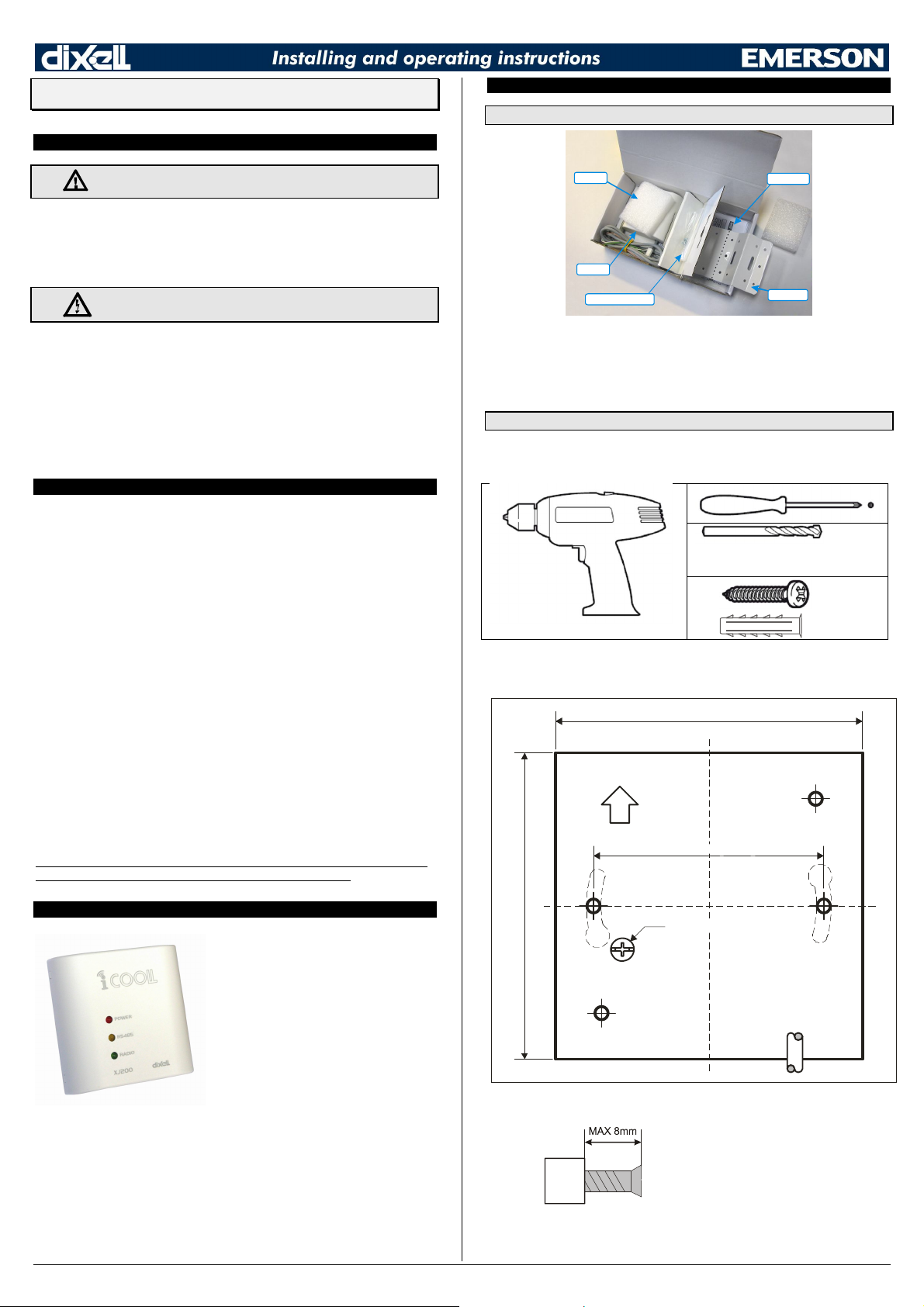

Sponge

1. Xj200

2. Screws

Each XJ200 package contains the following components:

1. XJ200 radio device

2. 2 self-tapping screws 3.9x6.5T to fix the XJ200 to the fixing bracket

3. Wall fixing bracket

4. Instructions manual

4.2 TOOLS TO FIX THE XJ200

4.2.1 DIRECT FIXING TO THE WALL

Parts required for assembly (not supplied)

2 x

2 x Ø 5 mm

1. To fix the module directly to the wall, use the cut out below to make the 2 holes

“B” at the distance indicated in fig. 1.

80.00mm (3.15”)

4. Manual

3. Bracket

Ø 5 mm

M5

TOP

A

60.00mm (2.36”)

B B

Ø MAX 6mm (0.2”)

80.00mm (3.15”)

A

POWER Green - Flashing with a frequency of 1 Hz: the module is ON and running

RS485 Yellow - Data is being transmitted/received via RS485 by the module

RADIO Green -The module is transmitting via radio

1592010320 XJ200 GB r1.0 14.03.2011 XJ200 1 / 3

2.

3. Fix the XJ200 to the head of the screws by rotating the container appropriately

Fig. 1

Insert the dowels and fix the screws with

a maximum distance of 8 mm from the

head to the wall

CABLE

Page 2

4.2.2 FIXING WITH THE USE OF A BRACKET

A suitable fastening bracket is included in every package to be used to:

a. shelves mount fitting;

b. pipemount fitting with appropriate retaining clamps (not supplied)

c. wall mount fittin

as shown in the following pictures:

!!!!!ATTENTION!!!!!

Set the XJ200 in the desired place in a VERTICAL POSITION.

Avoid horizontal or slanting positions.

RIGHT FIXING MODE RIGHT FIXING MODE

a. Remove the cover of the XJ200.

b. Close the jumper found inside the XJ200 by inserting the micro switch as

shown in the picture below.

Parts required for assembly (not supplied)

1. Fix the XJ200 to the fixing bracket using the 2 screws in the package

2. The 2 screws are to be entered in holes “A” as shown in Fig. 1.

3. The bracket can be bent and fixed so that the XJ200 is installed in a vertical

position.

4.3 RECOMMENDATIONS FOR PROPER INSTALLATION

If possible, place the module high up in order to guarantee enhanced data

transmission/reception.

If possible, avoid intermediate obstacles such as barriers, walls, floors and

counters between the modules.

If necessary, pass through the obstacle using the cable and install the module on

the opposite side in order to have it in direct view with the master module

connected to the X-WEB.

The maximum distance possible between the XJ200 modules in an open space

(with no obstacles) is 200 metres.

If the installation spans over a number of floors, try to position all the modules on

the same floor and connect the devices via cable in order to prevent

communication problems due to obstacles caused by the floor/ceiling.

The allowed temperature range for correct functioning is between 0 and 60 °C.

Avoid places subject to heavy vibrations, corrosive gas, excessive filth or

humidity.

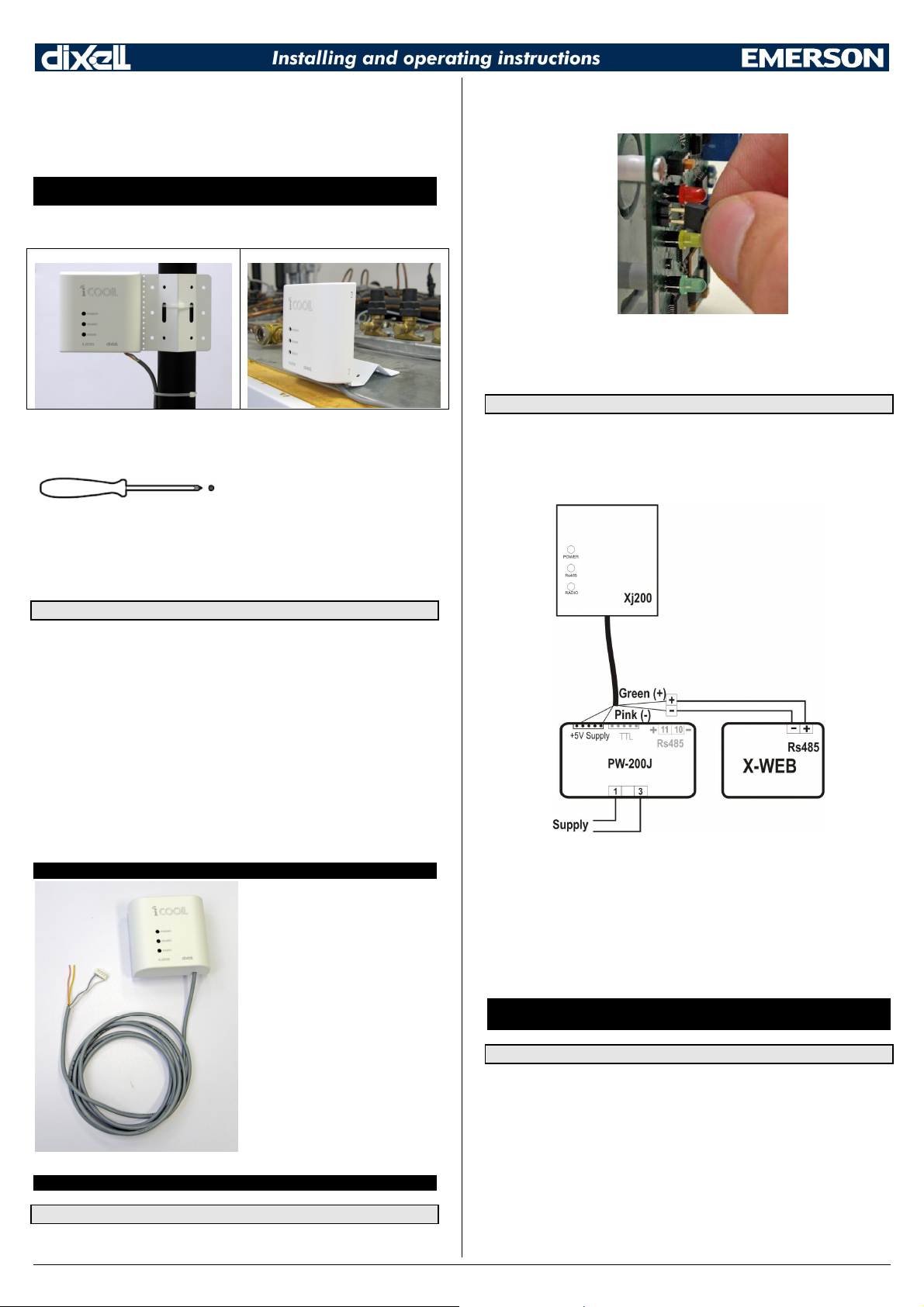

5. CONNECTIONS

Each module is supplied complete with

a 1.5-metre cable to connect the serial

communication line and the power line.

The XJ200 is powered by the PW-200J

power supplier and therefore, it is

connected to the RS485 serial line. The

following types of connection are

possible.

c. Close the cover of the XJ200 once again.

d. Connect the XJ200, PW200J and the X-WEB as shown in the connection

6.2 XJ200 –X-WEB CONNECTION

XJ200 and PW-200J connection

a. Disconnect the power supply from the PW200J

b. Connect the GREEN wire to the RS485 “+” terminal of the PW-200J

c. Connect the PINK wire to the RS485 “-” terminal of the PW-200J

d. Connect the white connector to the "+5V supply" connector of the PW-200J

XJ200 and X-WEB connection

Use the disconnecting terminal supplied with the PW-200J as a bridge of the RS485

line.

The connection between the XJ200 and X-WEB is then implemented as follows:

Connect the GREEN wire of the XJ200 to the RS485 “+” terminal of the X-WEB

Connect the PINK wire of the XJ200 to the RS485 “-” terminal of the X-WEB

Power the X-WEB and the PW200J once again.

diagram below.

7. XJ200 CONNECTION AND DEVICES EQUIPPED WITH A SERIAL

OUTPUT

7.1 DEVICE EQUIPPED WITH AN RS485 SERIAL OUTPUT

7.1.1 Device with an RS485 output but not able to power the

XJ200.

E.G. Ranges: XR100C; XR500C; XR75CX and XR77CX.

XJ200 and PW-200J connection

6. X-WEB - XJ200 MASTER CONNECTION

6.1 TRANSFORM THE XJ200 TO MASTER

The XJ200 connected to the X-WEB must be configured as Master.

To do so:

1592010320 XJ200 GB r1.0 14.03.2011 XJ200 2 / 3

Connect the white connector to the "+5V supply" connector of the PW-200J.

Connect the other devices to the RS485 serial line in compliance with the polarity.

Use the disconnecting terminal supplied with the PW-200J as a bridge of the RS485 line

with the XJ200 as follows:

Connect the GREEN wire of the XJ200 to the RS485 “+” terminal.

Connect the PINK wire of the XJ200 to the RS485 “-” terminal.

Page 3

7.2 DEVICE EQUIPPED WITH A TTL SERIAL OUTPUT

7.2.1 Device with a TTL output but not able to power the XJ200.

E.G. Ranges: Prime CX, Wing Basic New, XC400C and XC600C

XJ200 and PW-200J connection

Connect the GREEN wire to the RS485 “+” terminal of the PW-200J.

Connect the PINK wire to the RS485 “-” terminal of the PW-200J.

Connect the white connector to the "+5V supply" connector of the PW-200J.

Controller connection with TTL and PW-200J

Connect the other devices to the RS485 serial line in compliance with the polarity.

Connect the 2 TTL outputs of the PW200J and the device.

Then connect the RS485 line to the PW200J, in compliance with the polarity.

Power Supply:

XJ200 +5Vdc (from the controller or from the PW-200J module)

Note: the PW200J feeder or any Dixell controllers that can power the XJ200 are SELVtype. Max Power <18VA, DC current < 8A.

Power Consumption: 0.30 VA max.

Operating Temperature: from 0 to 60 °C

Storage Temperature: -25 to 60

Relative Humidity: 20 - 85% (no condensation)

The XJ200 -0000 is compliant with the following standards:

ETSI EN 300 220-2 V2.1.2 (2007-06)

ETSI EN 301 489-3 V1.4.1 (2002-08)

CEI EN 60950-1 (2007-02)

It therefore meets the essential requirements of the following Directives:

Radio and telecommunications terminal equipment 99/5/EC

Electromagnetic compatibility 2004/108/EC

Low Voltage equipment 2006/95/EC

The XJ200 -1000 (922MHz) is compliant with the following standards and rules:

AS/NZS 4268: 2008:

Classification: Schedule 1: Item 45

FCC 15.247

The complete Declaration of Conformity can be found at:

www.dixell.com

8. CHECK OF GOOD CONNECTION QUALITY BETWEEN THE XJ200

MASTER AND THE OTHER XJ200 OF THE NETWORK

The following must be implemented in order to verify good connection quality between

an XJ200 and the master connected to the X-WEB:

1. Connect and power the XJ200 Master to the X-WEB

2. Set the XJ200 in place where it is to be installed

3. Power the XJ200 and press the LED Power button for a couple of seconds

4. A test cycle begins and lasts a few minutes

5. At the end of the cycle, the following remains on:

a. Good communication: the GREEN “RADIO” LED is on

b. Insufficient communication: the YELLOW “RS485” LED is on; in this case,

try installing the XJ200 in a better position or connect another XJ200

between the Master and the XJ200 being tested.

9. TECHNICAL DATA

Operating Frequency:

Container: Self-extinguishing ABS

Format: Front panel 80 x 80 mm; depth 5 mm

1592010320 XJ200 GB r1.0 14.03.2011 XJ200 3 / 3

Europe version: XJ200 -00000: 869.4 - 869.650 MHz

AUS and USA version: XJ200 -10000: 922 MHz

Loading...

Loading...