Page 1

CC7.8.17/0220/E 1/22

Date of last update: Feb-20

Ref: CC7.8.17/0220/E

Application Engineering Europe

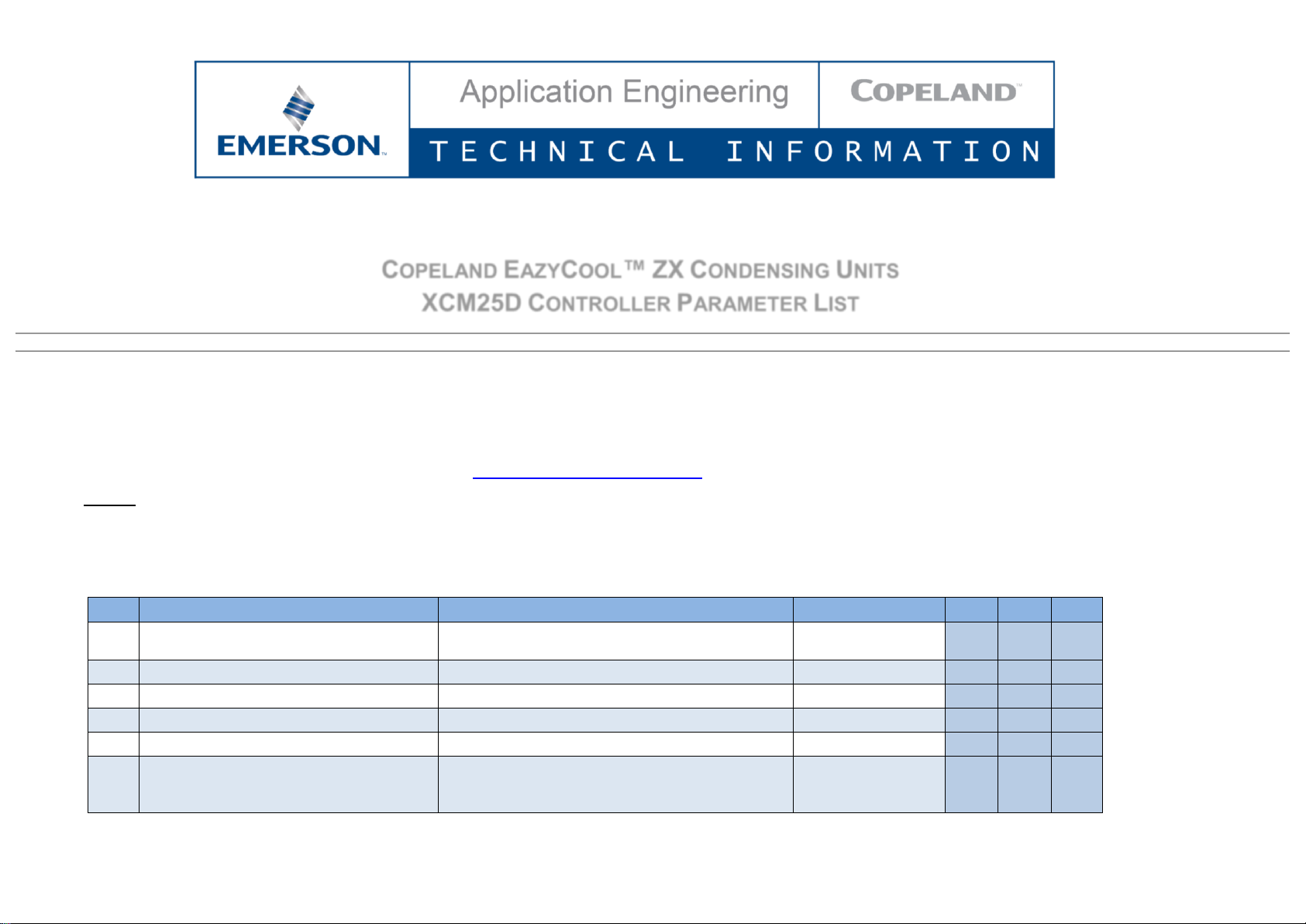

COPELAND EAZYCOOL™ ZX CONDENSING UNITS

XCM25D CONTROLLER PARAMETER LIST

Copeland EazyCool™ ZX Condensing Units are equipped with an XCM25D electronic controller from Dixell. The controller design allows the installer to start

and operate the system with minimum effort in terms of controller adjustments. The most important controller settings are described in the application

guidelines and most likely there is no need to change those settings.

In case of special applications additional parameters might have to be adjusted according to those special needs. This document contains the full list of

available parameters in the XCM25D controller. It is not a user’s manual. For questions about how to handle the controller and for functionality description

please refer to the dedicated documentation available at www.climate.emerson.com/en-gb.

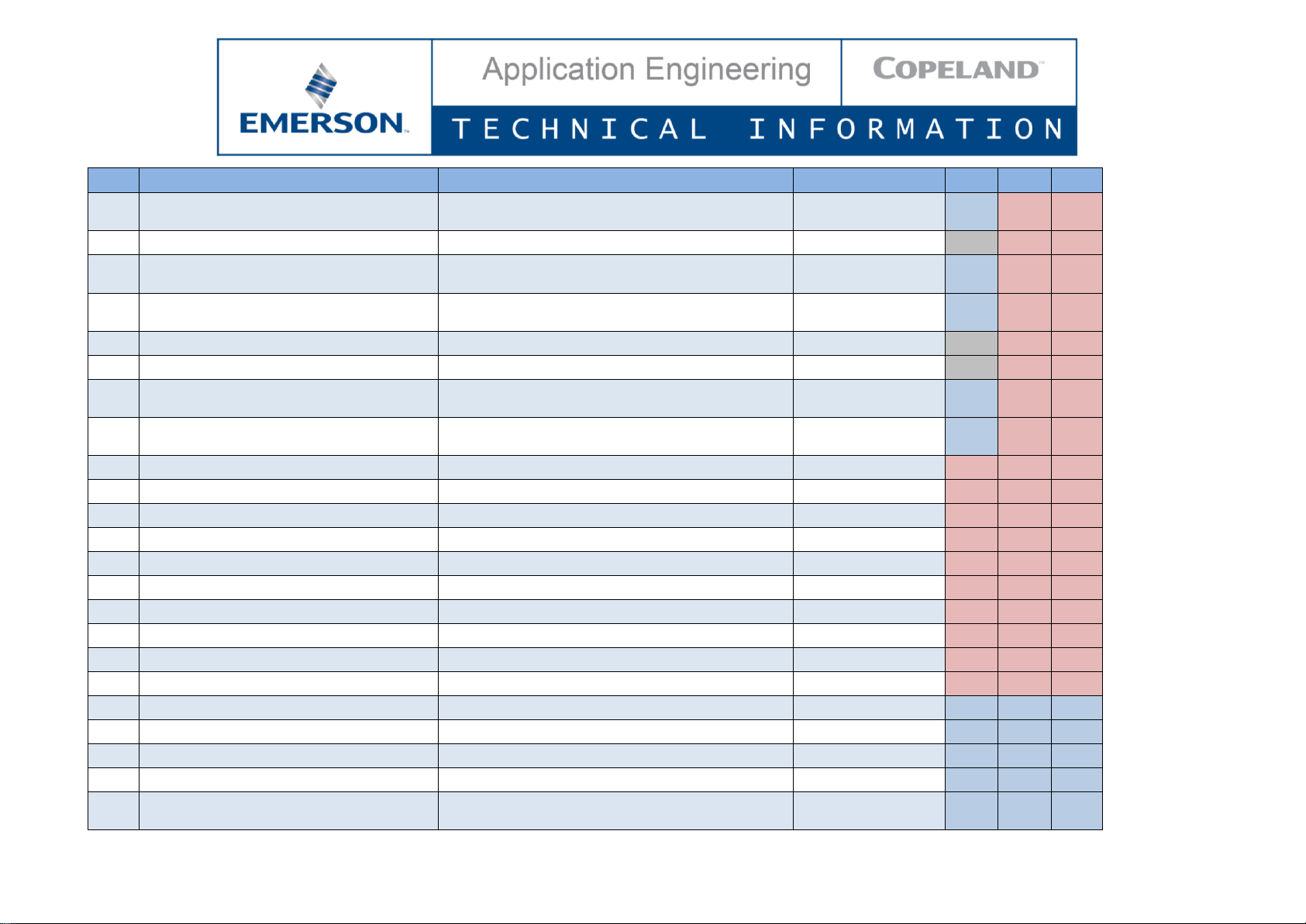

Legend

L1 = Parameter in level 1 (without password)

L2 = Parameter in level 2 (with password = 3 2 1)

N.V. = Parameter not accessible

NOTE: When changing parameters C01 (Cin), C02 (CoU) and C05 (CPb) a reset of the controller (interruption of power supply) is required.

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

A01

Probe P1 configuration

Not used (0-NU)

Suction pressure (0-5V)(1-SUP)

Suction pressure

(0-5V)

L2

L2

L2

A02

Start of scaling for probe 1 (0-5V)

0-5V: -1.5 bar to P1E; -21 PSI to P1E

0

L2

L2

L2

A03

End of scaling for probe 1 (0-5V)

0-5V: P1i to 99.9 bar; P1i to 999 PSI

15

L2

L2

L2

A04

Probe P1 calibration

0-5V: -12.0 to 12.0 bar; -12.0 to12.0 PSI

0

L2

L2

L2

A05

Probe P1 reading error delay (P1C = 0-5V)

0 to 255 min

5

L2

L2

L2

A06

Probe P2 configuration

Not used (0-NU)

Mid-coil temperature (NTC10K)(1-MCT)

Mid-coil pressure (0-5V)(2-MCP)

Mid-coil pressure

(0-5V)

L2

L2

L2

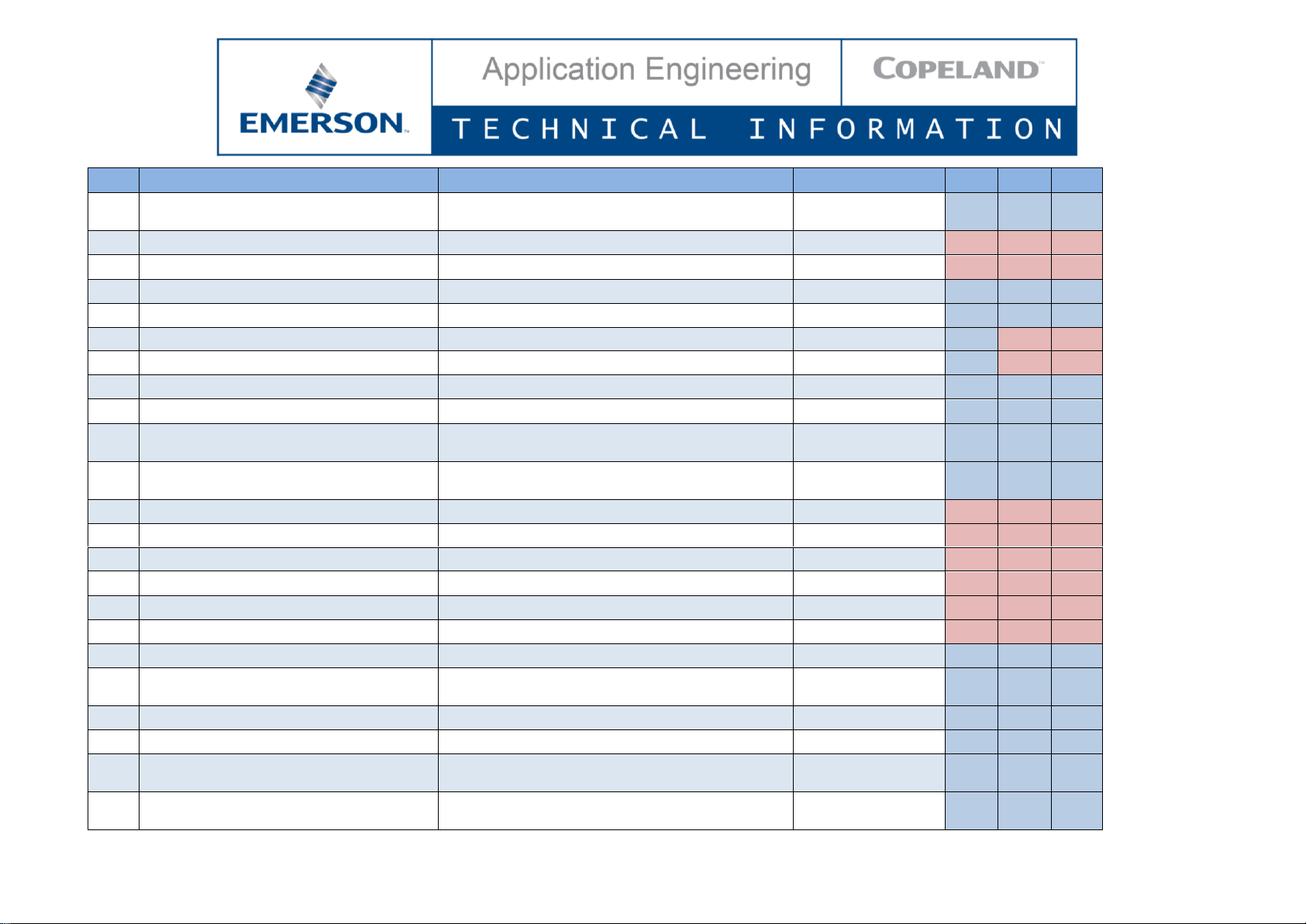

Page 2

CC7.8.17/0220/E 2/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

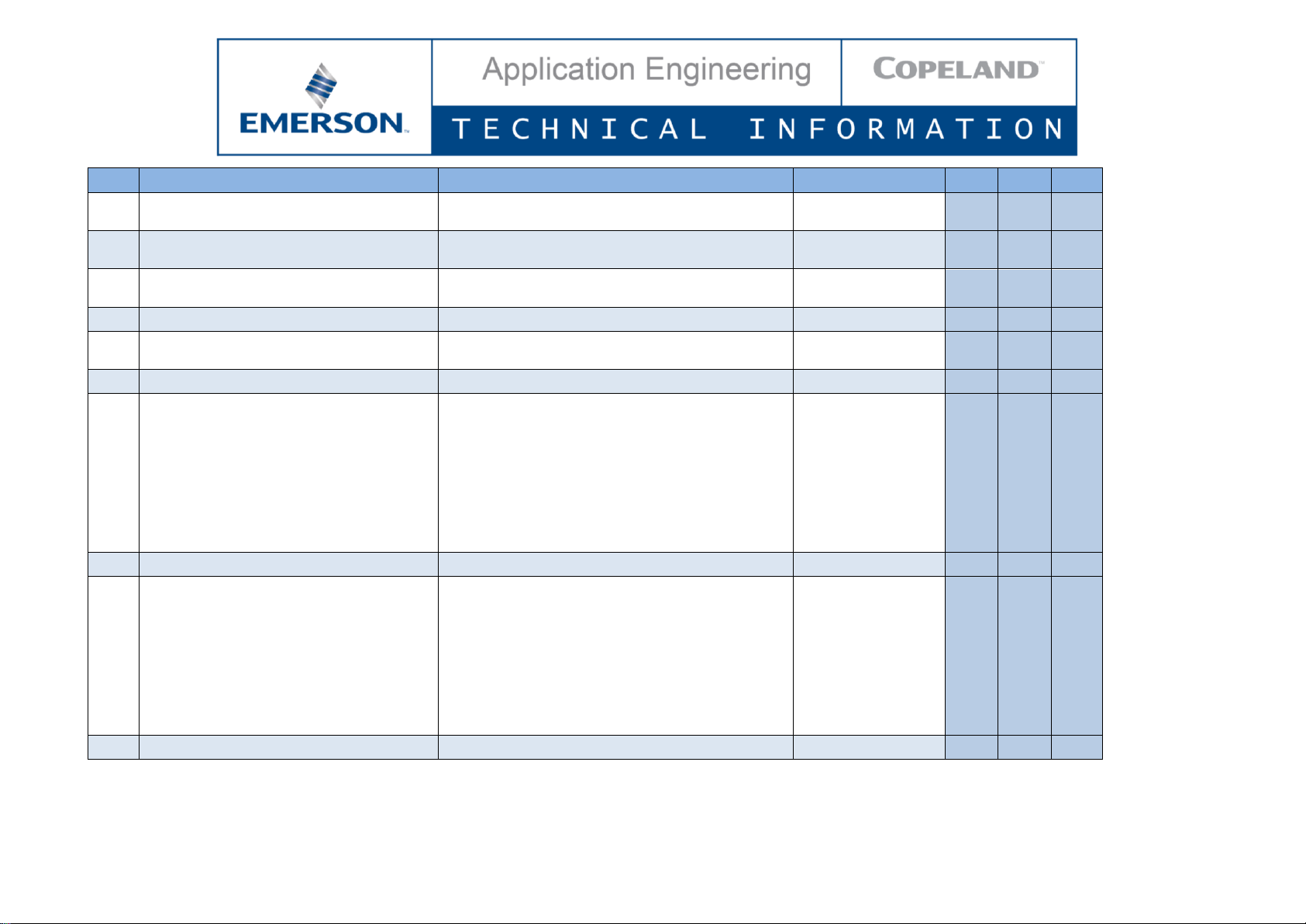

A07

Start of scaling for probe 2

0-5V: -1.5 bar to P2E; -21 PSI to P2E

NTC10K: -40°C to P2E

0

L2

L2

L2

A08

End of scaling for probe 2

0-5V: P2i to 99.9 bar; P2i to 999 PSI

NTC10K: P2i to 110°C

35

L2

L2

L2

A09

Probe P2 calibration

0-5V: -12.0 to 12.0 bar; -12.0 to 12.0 PSI

NTC10K: -12°C to 12°C

0

L2

L2

L2

A10

Probe P2 reading error delay (P2C=0-5V)

0 to 255 min

0

L2

L2

L2

A11

Probe P3 configuration

Not used (0-NU)

Discharge line temperature (1-DLT)

Discharge line

temperature

L2

L2

L2

A12

Probe P3 calibration

-12°C to 12°C

0

L2

L2

L2

A13

Probe P4 configuration

Not used (0-NU)

Ambient temperature (NTC10K)(1-AMT)

Thermostat temperature (NTC10K)(2-TMT)

Vapour inlet temperature (NTC10K)(3-UIT)

Vapour outlet temperature (NTC10K)(4-UOT)

Evaporator temperature (NTC10K)(5-EPT)

Liquid temperature (NTC10K)(6-LLT)

Suction line temperature (7-SLT)

Coil temperature (8-COT)

Not used

L2

L2

L2

A14

Probe P4 calibration

-12°C to 12°C

0

L2

L2

L2

A15

Probe P5 configuration

Not used (0-NU)

Ambient temperature (NTC10K)(1-AMT)

Thermostat temperature (NTC10K)(2-TMT)

Vapour inlet temperature (NTC10K)(3-UIT)

Vapour outlet temperature (NTC10K)(4-UOT)

Evaporator temperature (NTC10K)(5-EPT)

Liquid temperature (NTC10K)(6-LLT)

Suction line temperature (7-SLT)

Coil temperature (8-COT)

Not used

L2

L2

L2

A16

Probe P5 calibration

-12°C to 12°C

0

L2

L2

L2

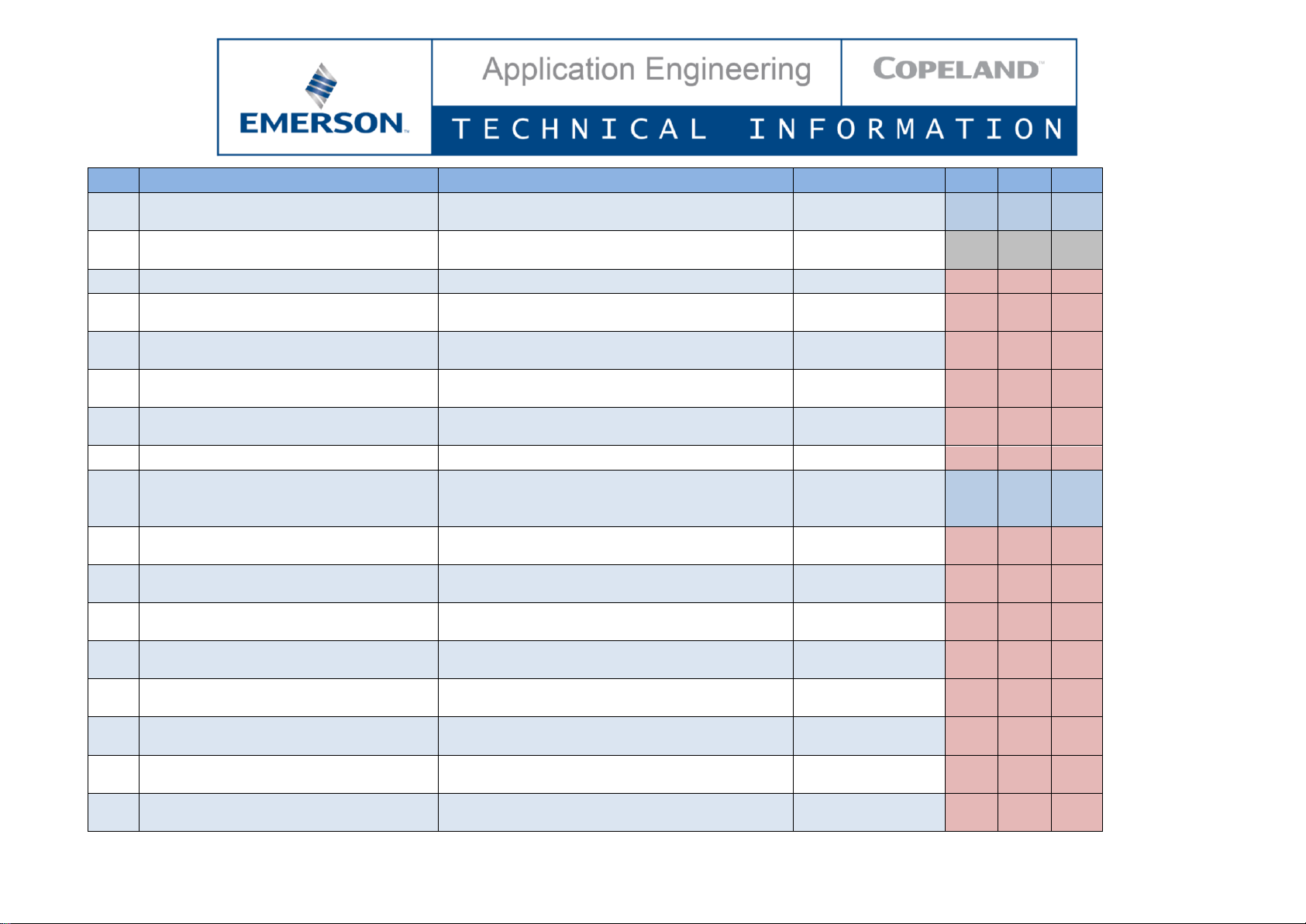

Page 3

CC7.8.17/0220/E 3/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

A17

Probe P6 configuration

Not used (0-NU)

Ambient temperature (NTC10K)(1-AMT)

Thermostat temperature (NTC10K)(2-TMT)

Vapour inlet temperature (NTC10K)(3-UIT)

Vapour outlet temperature (NTC10K)(4-UOT)

Evaporator temperature (NTC10K)(5-EPT)

Liquid temperature (NTC10K)(6-LLT)

Suction line temperature (7-SLT)

Coil temperature (8-COT)

Ambient temperature

(NTC10K)

L2

L2

L2

A18

Probe P6 calibration

-12°C to 12°C

0.0

L2

L2

L2

A19

Probe P7 configuration

Not used (0-NU)

Ambient temperature (NTC10K)(1-AMT)

Thermostat temperature (NTC10K)(2-TMT)

Vapour inlet temperature (NTC10K)(3-UIT)

Vapour outlet temperature (NTC10K)(4-UOT)

Evaporator temperature (NTC10K)(5-EPT)

Liquid temperature (NTC10K)(6-LLT)

Suction line temperature (7-SLT)

Coil temperature (8-COT)

Not used

L2

L2

L2

A20

Probe P7 calibration

-12°C to 12°C

0

L2

L2

L2

A21

Delay before activating probe error

0 to 255 sec

0

L2

L2

L2

B01

Measurement unit for pressure

Bar (0-BAR) – PSI (1-PSI) – KPA (2-TPA)

bar

L2

L2

L2

B02

Measurement unit for temperature

°C (0-C)

°C

L2

L2

L2

B03

Remote display visualization

P1 (0-P1) - P2 (1-P2) - P3 (2-P3) P4 (3-P4) - P5 (4-P5) - P6 (5-P6) P7 (6-P7) – Per (7-PER) – Aou (8-AOU)

P1

L2

L2

L2

B04

Filter enabling for probe reading

n (0-NO) - Y (1-YES)

YES

N.V.

N.V.

N.V.

B05

Coefficient for probe reading filter (0 =

max,100 = disable)

0 to 100, mEd (101)

50

N.V.

N.V.

N.V.

C01

Compressor cut-in pressure setpoint

CoU to US

4

N.V.

L1

L1

C02

Compressor cut-out pressure setpoint

LS to Cin

2

L2

L1

L1

C03

Minimum setpoint for suction

pressure/temperature

P1i to US; -50.0°C to US

0.6

L2

L2

L2

Page 4

CC7.8.17/0220/E 4/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

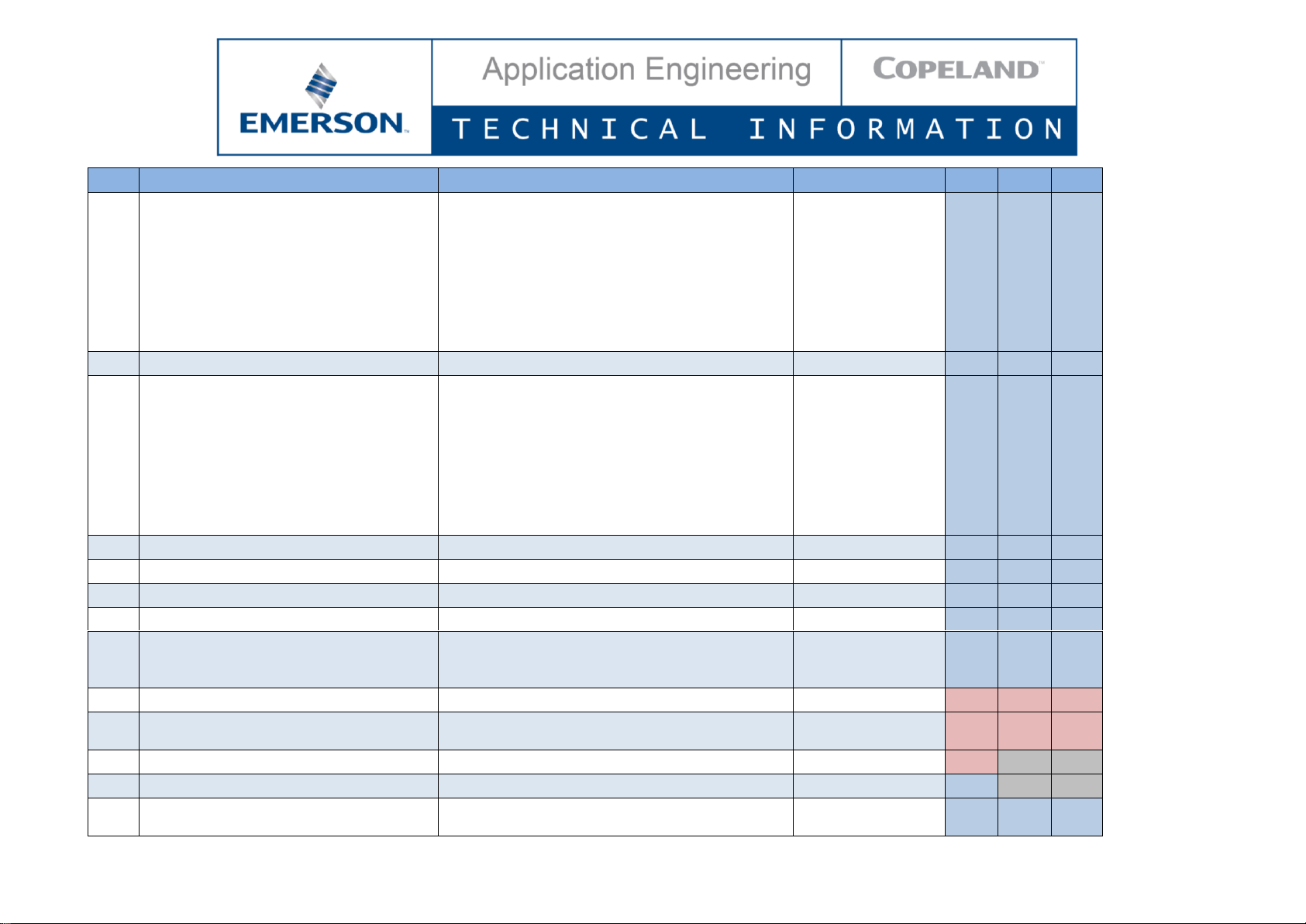

C04

Maximum setpoint for suction

pressure/temperature

LS to P1E; LS to 60.0°C

7.2

L2

L2

L2

C05

Compressor regulation probe selection

NU (0-NU)

Suction pressure probe (1-SUP)

Case temperature (2-CST)

Suction pressure switch (3-dIS)

Suction pressure

probe

L2

L2

L2

C06

EXV closing time before compressor off

0 to 999 sec

0

L2

L2

L2

C07

Refrigerant selection for regulation

R404A (0-404) - R507 (1-507)

R134a (2-134) - R22 (3-R22)

R407C (4-07C) - R407A (5-07A)

R407F (6-07F) - R448A (7-48A)

R449A (8-49A)

R404A

L1

L1

L1

C08

Setpoint offset

NU (0-NU)

Small offset (1-SOF)

Medium offset (2-MOF)

Large offset (3-LOF)

LAO (4-FOF)

Not used

L2

L2

L2

C09

Ambient temperature operation setpoint

-40°C to 110°C

-20

L2

L2

L2

C10

Pressure/Temperature operation for ambient

differential

0.0 to 9.9 bar; 0.0 PSI to 99.9 PSI

0.0°C to 25.5°C

1

L2

L2

L2

C11

Ambient temperature recover differential

0.1°C to 25.5°C

5

L2

L2

L2

C12

Ambient temperature threshold for low

ambient operation

-40°C to 110°C

-10

L2

L2

L2

C13

Temperature/Pressure to end low ambient

timer and resume normal operation

-40°C to 110°C

-1.5 to 99.9 bar; -21 to 999 PSI

10

L2

L2

L2

C14

Compressor minimum on time in low ambient

operation

0 to 255 sec

10

L2

L2

L2

C15

Pressure to end low ambient timer and shut

off the compressor

-1.5 to 99.9 bar; -21.0 to 999 PSI

0.5

L2

L2

L2

C16

Digital compressor setpoint

LS to US

3.3

L1

N.V.

N.V.

C17

Proportional band for compressor regulation

0.1 to 9.9 bar; 0.1 to 99.9 PSI; 0.1°C to 25.5°C

2

L1

N.V.

N.V.

C18

Band offset for compressor regulation

0 to 9.9 bar; 0 to 99.9 PSI; 0.0°C to 25.5°C

0

L2

N.V.

N.V.

C19

Integral time

0 to 999 sec

250

L2

L2

N.V.

Page 5

CC7.8.17/0220/E 5/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

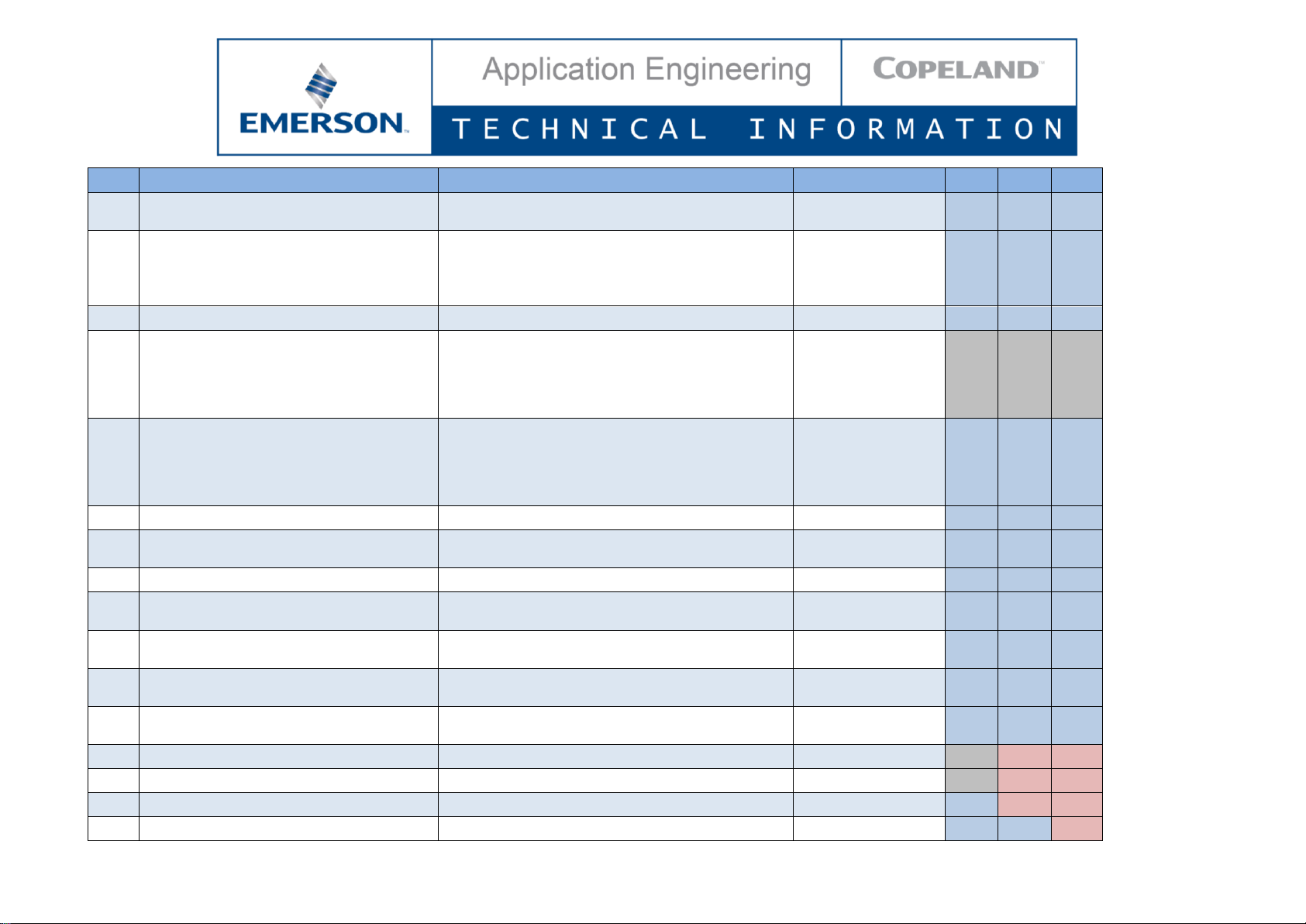

C20

Start-up time: interval time with digital valve

energized before regulation starts

0.0 to 10.0 sec

10

L2

N.V.

N.V.

C21

Cycle time for digital compressor

10 to 40 sec

20

L1

N.V.

N.V.

C22

Safety value for PI regulator (in case of probe

error)

0 to 100%

50

L2

N.V.

N.V.

C23

Number of active compressor when probe

error

0 (0) – 1 (1) – 2 (2)

0

L2

N.V.

N.V.

C24

Minimum capacity for digital compressor

0 to PMA

20

L1

N.V.

N.V.

C25

Maximum capacity for digital compressor

PMi to 100

100

L1

N.V.

N.V.

C26

Time with DGS at PMA before starting another

load

0 to 255 sec

0

L2

N.V.

N.V.

C27

Time with DGS at PMi before switching off

another load

0 to 255 sec

0

L2

N.V.

N.V.

C28

R404A Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C29

R507 Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C30

R134a Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C31

R22 Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C32

R407C Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C33

R407A Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C34

R407F Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C35

R448A Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C36

R449A Enable function

Disable (0-NO) - Enable (1-YES)

Enable

N.V.

N.V.

N.V.

C37

R410A Enable function

Disable (0-NO) - Enable (1-YES)

Disable

N.V.

N.V.

N.V.

C38

Compressor regulation control signal

Pressure (0-PRS) - temperature (1-TMP)

Pressure

L2

L2

L2

D01

Output delay at start-up

0 to 255 sec

5

L2

L2

L2

D02

Compressor On time with faulty probe

0 to 255 min

0

L2

L2

L2

D03

Compressor Off time with faulty probe

0 to 255 min

0

L2

L2

L2

D04

Minimum time between two starts (same

compressor)

0 to 15 min

4

L2

L2

L2

Page 6

CC7.8.17/0220/E 6/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

D05

Delay between compressor switch-off and

start-up (same compressor)

1 to 900 sec

120

L2

L2

L2

D06

Delay between two different loads start-up

[0÷99.5] min, resolution 10 sec

10

N.V.

N.V.

N.V.

D07

Delay between two different loads switch-off

[0÷99.5] min, resolution 10 sec

10

N.V.

N.V.

N.V.

D08

Minimum time a stage stays switched on

[0÷99.5] min, resolution 10 sec

0

L2

L2

L2

D09

Maximum time a stage stays switched on

[0.00÷24.00] hours, resolution 10 min

0

L2

L2

L2

D10

don delay enabled also for the first request

No (0-NO) - Yes (1-YES)

NO

L2

N.V.

N.V.

D11

doF delay enable also for the first switching off

No (0-NO) - Yes (1-YES)

NO

L2

N.V.

N.V.

D12

Low suction pressure alarm delay

0 to 999 sec

0

L2

L2

L2

D13

Low suction pressure error signal enabling

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

D14

Compressor minimum off time for highpressure switch protection

0 to 15 min

5

L2

L2

L2

D15

Number of high-pressure switch activations

before compressor lockout

0 to 15

7

L2

L2

L2

D16

Bump start enable

No (0-NO) - Yes (1-YES)

NO

N.V.

N.V.

N.V.

D17

Bump start ambient threshold

-40°C to 110°C

0

N.V.

N.V.

N.V.

D18

Compressor stop time for next bump start

0 hour to 23 hours and 50 minutes

1 hour

N.V.

N.V.

N.V.

D19

Compressor on time during bump function

1 to 15 sec

2

N.V.

N.V.

N.V.

D20

Compressor off time during bump function

1 to 15 sec

15

N.V.

N.V.

N.V.

D21

Number of cycles during bump start

1 to 15

3

N.V.

N.V.

N.V.

D22

DLT alarm temperature to stop compressor

-40°C to 180°C

140

L2

L2

L2

D23

DLT alarm recover temperature to turn on

compressor

-40°C to 180°C

90

L2

L2

L2

D24

DLT alarm activation delay

0 to 255 sec

30

L2

L2

L2

D25

Compressor minimum off time for DLT Alarm

0 to 255 min

5

L2

L2

L2

D26

Number of DLT alarm activations before

compressor lockout

0 to 15

10

L2

L2

L2

D27

Time to ignore low DLT sensor error at startup

0 to 255 min

5

L2

L2

L2

Page 7

CC7.8.17/0220/E 7/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

D28

Compressor minimum off time for lowpressure switch protection

0 to 15 min

3

L2

L2

L2

D29

Low-pressure alarm value (from serial number

16EZ08855M onwards)

0 to 15 bar

0.5

L1

L1

L1

D30

Cold start enable

Disable (0) - Enable (1)

Disable

N.V.

N.V.

N.V.

D31

DLT temperature threshold to trip during cold

start

-40 to 180°C

60

N.V.

N.V.

N.V.

D32

Suction pressure threshold to trip during cold

start

-1.5 to 99.9 bar

0.5

N.V.

N.V.

N.V.

D33

Allowed number of cycles of DLT temperature

trips during cold start

1 to 15

4

N.V.

N.V.

N.V.

D34

Allowed number of cycles of low-pressure trips

during cold start

1 to 15

4

N.V.

N.V.

N.V.

D35

Compressor stop time during cold start

1 to 999 sec

180

N.V.

N.V.

N.V.

E01

Condenser fan motor modulation type

Not used (0-NU)

Fan cycling (1-CYC)

Modulated fan (2-MOD)

Modulated fan

L2

L2

L2

E02

Low setpoint for condenser fan map 1 (for

R404A, R507)

-40°C to HT1

10

N.V.

N.V.

N.V.

E03

Lower suction pressure point for condenser

fan map 1 (for R404A, R507)

-1.5 bar to HP1; -21 PSI to HP1

3.3

N.V.

N.V.

N.V.

E04

High setpoint for condenser fan map 1 (for

R404)

LT1 to 110°C

30

N.V.

N.V.

N.V.

E05

High suction pressure point for condenser fan

map 1 (for R404A, R507)

LP1 to 99.9 bar; LP1 to 999 PSI

7.2

N.V.

N.V.

N.V.

E06

Low setpoint for condenser fan map 2 (for

R134)

-40°C to HT2

25

N.V.

N.V.

N.V.

E07

Lower suction pressure point for condenser

fan map 2 (for R404)

-1.5 bar to HP2; -21 PSI to HP2

2.5

N.V.

N.V.

N.V.

E08

High setpoint for condenser fan map 2 (for

R134)

LT2 to 110°C

40

N.V.

N.V.

N.V.

E09

High suction pressure point for condenser fan

map 2 (for R404)

LP2 to 99.9 bar; LP2 to 999 PSI

3.9

N.V.

N.V.

N.V.

Page 8

CC7.8.17/0220/E 8/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

E10

Low setpoint for condenser fan map 3 (for

R22)

-40°C to HT3

20

N.V.

N.V.

N.V.

E11

Low suction pressure point for condenser fan

map 3 (for R22)

-1.5 bar to HP3; -21PSI to HP3

5.2

N.V.

N.V.

N.V.

E12

High setpoint for condenser fan map 3 (for

R22)

LT3 to 110°C

30

N.V.

N.V.

N.V.

E13

High suction pressure point for condenser fan

map 3 (for R22)

LP3 to 99.9 bar; LP3 to 999 PSI

6.4

N.V.

N.V.

N.V.

E14

Low setpoint for condenser fan map 4 (for

R407C)

-40°C to HT4

10

N.V.

N.V.

N.V.

E15

Lower suction pressure point for condenser

fan map 4 (for R404)

-1.5 bar to HP4; -21 PSI to HP4

1.3

N.V.

N.V.

N.V.

E16

High setpoint for condenser fan map 4 (for

R407C)

LT4 to 110°C

38

N.V.

N.V.

N.V.

E17

High suction pressure point for condenser fan

map 4 (for R404)

LP4 to 99.9 bar; LP4 to 999 PSI

5.4

N.V.

N.V.

N.V.

E18

Low setpoint for condenser fan map 5 (for

R407A)

-40°C to HT5

10

N.V.

N.V.

N.V.

E19

Low suction pressure point for condenser fan

map 5 (for R407A)

-1.5 bar to HP5; -21 PSI to HP5

2.5

N.V.

N.V.

N.V.

E20

High setpoint for condenser fan map 5 (for

R407A)

LT5 to 110°C

27

N.V.

N.V.

N.V.

E21

High suction pressure point for condenser fan

map 5 (for R407A)

LP5 to 99.9 bar; LP5 to 999 PSI

5.3

N.V.

N.V.

N.V.

E22

Low setpoint for condenser fan map 6 (for

R407F)

-40°C to HT6

10

N.V.

N.V.

N.V.

E23

Low suction pressure point for condenser fan

map 6 (for R407F)

-1.5 bar to HP6; -21 PSI to HP6

1.7

N.V.

N.V.

N.V.

E24

High setpoint for condenser fan map 6 (for

R407F)

LT6 to 110°C

38

N.V.

N.V.

N.V.

E25

High suction pressure point for condenser fan

map 6 (for R407F)

LP6 to 99.9 bar; LP6 to 999 PSI

6.3

N.V.

N.V.

N.V.

E26

Low setpoint for condenser fan map 7 (for

R448A)

-40°C to HT7

10

N.V.

N.V.

N.V.

Page 9

CC7.8.17/0220/E 9/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

E27

Low suction pressure point for condenser fan

map 7 (for R448A)

-1.5 bar to HP7; -21 PSI to HP7

3.3

N.V.

N.V.

N.V.

E28

High setpoint for condenser fan map 7 (for

R448A)

LT7 to 110°C

30

N.V.

N.V.

N.V.

E29

High suction pressure point for condenser fan

map 7 (for R448A)

LP7 to 99.9 bar; LP7 to 999 PSI

7.2

N.V.

N.V.

N.V.

E30

Low setpoint for condenser fan map 8 (for

R449A)

-40°C to HT8

10

N.V.

N.V.

N.V.

E31

Low suction pressure point for condenser fan

map 8 (for R449A)

-1.5 bar to HP8; -21 PSI to HP8

3.3

N.V.

N.V.

N.V.

E32

High setpoint for condenser fan map 8 (for

R449A)

LT8 to 110°C

30

N.V.

N.V.

N.V.

E33

High suction pressure point for condenser fan

map 8 (for R449A)

LP8 to 99.9 bar; LP8 to 999 PSI

7.2

N.V.

N.V.

N.V.

E34

Low setpoint for condenser fan map 9 (for

R410A)

-40°C to HT9

10

N.V.

N.V.

N.V.

E35

Low suction pressure point for condenser fan

map 9 (for R410A)

-1.5 bar to HP9; -21 PSI to HP9

3.3

N.V.

N.V.

N.V.

E36

High setpoint for condenser fan map 9 (for

R410A)

LT9 to 110°C

30

N.V.

N.V.

N.V.

E37

High suction pressure point for condenser fan

map 9 (for R410A)

LP9 to 99.9 bar; LP9 to 999 PSI

7.2

N.V.

N.V.

N.V.

E38

Fan setpoint modulation enabling

No (0-NO) - Yes (1-YES)

NO

L2

L2

L2

E39

Condenser temperature setpoint when fan

setpoint modulation is disabled

-40°C to 110°C

27

L1

L1

L1

E40

Minimum condenser temperature setpoint

-40°C to 110°C

10

L2

L2

L2

E41

High ambient fan motor override enabled

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

E42

High ambient fan motor override differential

0.1°C to 25.5°C

5

L2

L2

L2

E43

High DLT fan motor override enabled

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

E44

High DLT fan motor override differential

-40°C to 180°C

120

L2

L2

L2

E45

Minimum fan motor speed

0 to 100%

40

N.V.

N.V.

N.V.

Page 10

CC7.8.17/0220/E 10/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

E46

Regulation band of variable fan

0.1°C to 25.5°C

10

L1

L1

L1

E47

Integration time for fan

0 to 999 sec

500

L2

L2

L2

E48

Fan full speed duration at fan start-up

0 to 255 sec

0

L2

L2

L2

E49

Fan minimum on time

0 to 255 sec

5

L2

L2

L2

E50

Fan minimum off time

0 to 255 sec

10

L2

L2

L2

E51

Fixed condenser fan setpoint

-40°C to 110°C

23

L2

L2

L2

E52

Fan 1 differential

0.1°C to 25.5°C

7

L2

L2

L2

E53

Fan 1 to fan 2 differential

0.1°C to 25.5°C

10

L2

L2

L2

E54

Fan 2 differential

0.1°C to 25.5°C

7

L2

L2

L2

E55

Fan control with ambient sensor - Min ambient

-40°C to E56

0

L2

L2

L2

E56

Fan control with ambient sensor - Max

ambient

E55 to 110°C

20

L2

L2

L2

E57

Fan speed control with ambient sensor

0 to 100%

60

L2

L2

L2

E58

Condenser temperature/pressure threshold for

high alarm

-40°C to 110°C

-1.5 to 99.9 bar; -21 to 999 PSI

27.8

L2

L2

L2

E59

High condenser temperature alarm delay

0 to 255 min

0

L2

L2

L2

E60

High condenser temperature alarm with

compressor off

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

E61

Condenser temperature/pressure threshold for

alarm recovery

-40°C to E58°C

-1.5 to E58 bar; -21 to E58 PSI

23

L2

L2

L2

F01

Liquid injection setpoint

-40°C to 180°C

130

N.V.

L2

L2

F02

Max DLT temperature before full open

injection

LIS°C to 180°C

137

N.V.

L2

L2

F03

Min DLT temperature before close injection

-40°C to LIS°C

40

N.V.

L2

L2

F04

Mid-coil limp-along for DLT failure - Mid-coil 1

LA2 to 110°C

60

N.V.

L2

N.V.

F05

Mid-coil limp-along for DLT failure - Mid-coil 2

LA3 to LA1

50

N.V.

L2

N.V.

F06

Mid-coil limp-along for DLT failure - Mid-coil 3

LA4 to LA2

40

N.V.

L2

N.V.

F07

Mid-coil limp-along for DLT failure - Mid-coil 4

LA5 to LA3

30

N.V.

L2

N.V.

F08

Mid-coil limp-along for DLT failure - Mid-coil 5

-40°C to LA4

20

N.V.

L2

N.V.

Page 11

CC7.8.17/0220/E 11/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

F09

Mid-coil limp-along for DLT failure - Valve

opening 1

LE2 to 100%

100

N.V.

L2

N.V.

F10

Mid-coil limp-along for DLT failure - Valve

opening 2

LE3 to LE1%

80

N.V.

L2

N.V.

F11

Mid-coil limp-along for DLT failure - Valve

opening 3

LE4 to LE2%

60

N.V.

L2

N.V.

F12

Mid-coil limp-along for DLT failure - Valve

opening 4

LE5 to LE3%

35

N.V.

L2

N.V.

F13

Mid-coil limp-along for DLT failure - Valve

opening 5

0 to LE4%

15

N.V.

L2

N.V.

F14

Ambient limp-along for DLT and mid-coil

failure - Temperature 1

MA2 to 110°C

30

N.V.

L2

N.V.

F15

Ambient limp-along for DLT and mid-coil

failure - Temperature 2

-40°C to MA1

20

N.V.

L2

N.V.

F16

Ambient limp-along for DLT and mid-coil

failure - Valve opening 1

ME2 to 100%

80

N.V.

L2

N.V.

F17

Ambient limp-along for DLT and mid-coil

failure - Valve opening 2

0 to ME1%

35

N.V.

L2

N.V.

F18

EVI EXV initial opening – Ambient 1

EA2 to 110°C

35

N.V.

N.V.

L2

F19

EVI EXV initial opening – Ambient 2

EA3 to EA1

30

N.V.

N.V.

L2

F20

EVI EXV initial opening – Ambient 3

EA4 to EA2

25

N.V.

N.V.

L2

F21

EVI EXV initial opening – Ambient 4

-40.0°C to EA3

15

N.V.

N.V.

L2

F22

EVI EXV initial opening – Valve opening 1

EO2 to 100%

60

N.V.

N.V.

L2

F23

EVI EXV initial opening – Valve opening 2

EO3 to EO1%

40

N.V.

N.V.

L2

F24

EVI EXV initial opening – Valve opening 3

EO4 to EO2%

30

N.V.

N.V.

L2

F25

EVI EXV initial opening – Valve opening 4

EO5 to EO3%

20

N.V.

N.V.

L2

F26

EVI EXV initial opening – Valve opening 5

0 to EO4%

10

N.V.

N.V.

L2

F27

EVI EXV initial opening with sensor failure

0 to 100%

40

N.V.

N.V.

L2

F28

Differential between the vapour inlet and the

vapour outlet temperature for R404A

0.0 to 25.5°C

8

N.V.

N.V.

L2

Page 12

CC7.8.17/0220/E 12/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

F29

Differential between the vapour inlet and the

vapour outlet temperature for R507

0.0 to 25.5°C

8

N.V.

N.V.

L2

F30

Differential between the vapour inlet and the

vapour outlet temperature for R134a

0.0 to 25.5°C

8

N.V.

N.V.

N.V.

F31

Differential between the vapour inlet and the

vapour outlet temperature for R22

0.0 to 25.5°C

8

N.V.

N.V.

L2

F32

Differential between the vapour inlet and the

vapour outlet temperature for R407C

0.0 to 25.5°C

13

N.V.

N.V.

L2

F33

Differential between the vapour inlet and the

vapour outlet temperature for R407A

0.0 to 25.5°C

13

N.V.

N.V.

L2

F34

Differential between the vapour inlet and the

vapour outlet temperature for R407F

0.0 to 25.5°C

13

N.V.

N.V.

L2

F35

Differential between the vapour inlet and the

vapour outlet temperature for R448A

0.0 to 25.5°C

13

N.V.

N.V.

L2

F36

Differential between the vapour inlet and the

vapour outlet temperature for R449A

0.0 to 25.5°C

13

N.V.

N.V.

L2

F37

Differential between the vapour inlet and the

vapour outlet temperature for R410A

0.0 to 25.5°C

8

N.V.

N.V.

N.V.

F38

Max DLT temperature before changing from

vapour to liquid injection control

-40°C to 180°C

133

N.V.

N.V.

L2

F39

Differential before resuming vapour injection

0.0°C to 25.5°C

10

N.V.

N.V.

L2

F40

Max open EXV warning time

0 to 255 min

2

L2

L2

L2

F41

Delta between setpoint and shortage of

refrigerant error during max open warning

0.0°C to 25.5°C

8

L2

L2

L2

F42

Constant liquid temperature mode enabled for

low ambient EVI injection

No (0-NO) - Yes (1-YES)

NO

N.V.

N.V.

L2

F43

Constant liquid temperature setpoint

-40°C to 110°C

0

N.V.

N.V.

L2

F44

Constant liquid temperature enable

temperature

-40°C to 110°C

-20

N.V.

N.V.

L2

Page 13

CC7.8.17/0220/E 13/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

G01

Case temperature probe selection

NU (0-NU)

Mid-coil temperature (1-MCT)

Discharge line temperature (2-DLT)

Ambient temperature (3-AMT)

Thermostat temperature (4-TMT)

Evaporator temperature (5-EPT)

Vapour inlet temperature (6-UIT)

Vapour outlet temperature (7-UOT)

Liquid temperature (8-LLT)

Suction line temperature (9-SLT)

Coil temperature (10-COT)

Not used

L2

L2

L2

G02

Case temperature setpoint

CLS to CUS

2

L2

L2

L2

G03

Case temperature differential

0.1°C to 25.5°C

1

L2

L2

L2

G04

Case temperature low range

-40°C to CUS

-10

L2

L2

L2

G05

Case temperature high range

CLS to 110°C

15

L2

L2

L2

G06

Case probe failure limp-along on time

0 to 255 min

2

L2

L2

L2

G07

Case probe failure limp-along off time

0 to 255 min

1

L2

L2

L2

G08

Compressor and fan status when open door

>> no = normal operation; Fn = Fans off;

cP = Compressor off; Fc = Compr. & fans off

no (0-NO)

Fn (1-FAN)

cP (2-CPR)

Fc (3-F-C)

NO

L2

L2

L2

G09

Regulation with open door

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

G10

Liquid/vapour injection switch based on SH

activation

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

G11

Maximum pump-down time

0 to 255 min

3

L2

L2

L2

Page 14

CC7.8.17/0220/E 14/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

G12

Defrost probe selection

nu (0-NU)

Mid-coil temperature (1-MCT)

Discharge Line temperature (2-DLT)

Ambient temperature (3-AMT)

Thermostat temperature (4-TMT)

Evaporator temperature (5-EPT)

Vapour inlet temperature (6-UIT)

Vapour outlet temperature (7-UOT)

Liquid temperature (8-LLT)

Suction line temperature (9-SLT)

Coil temperature (10-COT)

Not used

L2

L2

L2

G13

Defrost in probe selection

Not used

L2

L2

L2

G14

Defrost out probe selection

Not used

L2

L2

L2

G15

Threshold percentage to enable intelligent

defrost

0 to 100

40

L2

L2

L2

G16

Duration to calculate the average difference

between the diP and doP

0 to 100 min

5

L2

L2

L2

G17

Defrost type

EL (0-EL)

in (1-IN)

Pulse (2-PLS)

EL

L2

L2

L2

G18

Interval between defrost cycles

0 to 120 h

4

L2

L2

L2

G19

Maximum length for defrost

0 to 255 min

20

L2

L2

L2

G20

Duration of pulse defrost

0 to G19

15

L2

L2

L2

G21

Defrost termination temperature

-40°C to 110°C

10

L2

L2

L2

G22

Defrost delay time

0 to 255 min

0

L2

L2

L2

G23

Defrost interval mode

nu (0-NU)

in (1-IN)

rtC (2-rtC)

Intelligent (3-INT)

Not used

L2

L2

L2

G24

Display during defrost

dEF = Defrost;

Set = Setpoint case temp;

it = Case temp;

rt = Display in standard operation

dEF (0-DEF)

Set (1-SET)

it (2-IT)

rt (3-RT)

dEF

L2

L2

L2

G25

Maximum display delay after defrost

0 to 255 min

0

L2

L2

L2

G26

Drip time

0 to 120 min

1

L2

L2

L2

Page 15

CC7.8.17/0220/E 15/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

G27

Defrost at power-on

No (0-NO) - Yes (1-YES)

NO

L2

L2

L2

G28

Workday defrost start 1

00:00 – 23:50; nu

0:00

L2

L2

L2

G29

Workday defrost start 2

00:00 – 23:50; nu

4:00

L2

L2

L2

G30

Workday defrost start 3

00:00 – 23:50; nu

8:00

L2

L2

L2

G31

Workday defrost start 4

00:00 – 23:50; nu

12:00

L2

L2

L2

G32

Workday defrost start 5

00:00 – 23:50; nu

16:00

L2

L2

L2

G33

Workday defrost start 6

00:00 – 23:50; nu

20:00

L2

L2

L2

G34

Holiday defrost start 1

00:00 – 23:50; nu

0:00

L2

L2

L2

G35

Holiday defrost start 2

00:00 – 23:50; nu

4:00

L2

L2

L2

G36

Holiday defrost start 3

00:00 – 23:50; nu

8:00

L2

L2

L2

G37

Holiday defrost start 4

00:00 – 23:50; nu

12:00

L2

L2

L2

G38

Holiday defrost start 5

00:00 – 23:50; nu

16:00

L2

L2

L2

G39

Holiday defrost start 6

00:00 – 23:50; nu

20:00

L2

L2

L2

G40

First weekly holiday

SUN (0-SUN)

MON (1-MON)

TUE (2-TUE)

WED (3-WED)

THU (4-THU)

FRI (5-FRI)

SAT (6-SAT)

nu (7-NU)

SUN

L2

L2

L2

G41

Second weekly holiday

SUN

L2

L2

L2

G42

Fans operating mode

cn = Parallel to compressor, off during defrost;

on = Fans always on, only off during defrost;

cy = Parallel to compressor, on during defrost;

oy = Fans permanently in operation

cn (0-CN)

on (1-ON)

cy (2-CY)

oy (3-OY);

cn

L2

L2

L2

G43

Fans stop temperature

-40°C to 110°C

0

L2

L2

L2

G44

Temperature differential avoiding short cycles

of fans

0 to 59°C

2

L2

L2

L2

G45

Fan On time

0 to 255 min

1

L2

L2

L2

G46

Fan Off time

0 to 255 min

1

L2

L2

L2

Page 16

CC7.8.17/0220/E 16/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

G47

Room probe selection for evaporator fan

management

NU (0-NU)

Mid-coil temperature (1-MCT)

Discharge line temperature (2-DLT)

Ambient temperature (3-AMT)

Thermostat temperature (4-TMT)

Not used

L2

L2

L2

G48

Maximum case temperature alarm threshold

G49 to 110°C

10

L2

L2

L2

G49

Minimum case temperature alarm threshold

-40°C to G48

-25

L2

L2

L2

G50

Case temperature alarm restart differential

0.1°C to 25.5°C

3

L2

L2

L2

G51

Case temperature alarm delay

0 to 255 sec

60

L2

L2

L2

G52

Exclusion of temperature alarm at start-up

0 to 255 min

20

L2

L2

L2

G53

Maximum door open time before alarm

0 to 255 min

3

L2

L2

L2

G54

Maximum length for light when door switch is

closed

0 to 255 min

1

L2

L2

L2

G55

Fan delay after defrost

0 to 255 min

1

L2

L2

L2

G56

Use the liquid line solenoid

no; yes

NO

L2

L2

L2

H01

Current sensing 1

no; yes

YES

L2

L2

L2

H02

Current sensing 2

no; yes

YES

L2

L2

L2

H03

Voltage sensing 1

no; yes

NO

L2

L2

L2

H04

Voltage sensing 2

no; yes

NO

L2

L2

L2

H05

Voltage sensing 3

no; yes

NO

L2

L2

L2

H06

Voltage and current protection enabled

no; yes

YES

L2

L2

L2

H07

Maximum continuous current limit

3PE = 0: 0.0 to 70.0 A

3PE = 1: 0.0 to 35.0 A

Unit dependent

L2

L2

L2

H08

Voltage/current sensing trip minimum off time

0 to 255 min

5

L2

L2

L2

H09

Adjustable current limit before trip

0.0 to MCC Ampere

9.5

L2

L2

L2

H10

Ignore current sensing duration at start-up

duration

0 to 255 sec

3

L2

L2

L2

H11

Number of over current trips before lockout

0 to 15

5

L2

L2

L2

H12

Number of loss of phase trips before lockout

0 to 15

5

L2

L2

L2

Page 17

CC7.8.17/0220/E 17/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

H13

Minimum voltage to trip compressor

0 to 400V

360

N.V.

N.V.

N.V.

H14

Maximum voltage to trip compressor

0 to 800V

480

N.V.

N.V.

N.V.

H15

Over or under voltage minimum time

0 to 255 sec

60

L2

L2

L2

H16

Compressor minimum off time because of

voltage error

0 to 255 min

3

L2

L2

L2

H17

Number of compressor trips before lockout

because of voltage

0 to 15

5

L2

L2

L2

H18

Adjustable under average voltage percentage

0 to 100%

90

L2

L2

L2

H19

Generate warning or shut down compressor

when phase imbalance

0: Generate warning (0-ARN)

1: Unit off(1-Off)

Unit off

L2

L2

L2

H20

Missing current duration before warning

0 to 255 sec

10

L2

L2

L2

H21

Minimum high side superheat

-40 to 110°C

10

L2

L2

L2

H22

Amount of time allowed in an interval to check

for floodback

0 to H23 min

30

L2

L2

L2

H23

Interval to check for floodback

H22 to 120 min

45

N.V.

N.V.

L2

H24

Duration of checking anti-floodback alarm

reset condition

1 to 255 min

20

N.V.

N.V.

L2

H25

Three-phase enable

no; yes

YES

L2

L2

L2

I01

Ambient temperature threshold to off

crankcase heater

-40°C to 180°C

10

L2

L2

L2

I02

Compressor minimum off time before turning

the crankcase heater on

0 to 255 min

5

L2

L2

L2

L01

Steps for initial regulation

SH2 to SH1 steps

15

L2

N.V.

L2

L02

Superheating setpoint

0.0°C to 25.5°C

5

L2

N.V.

L2

L03

Threshold of low superheating

0.0 to SH18°C

1

L2

N.V.

L2

L04

Threshold of high superheating

SH17 to 80.0°C

15

L2

N.V.

L2

L05

Extra % of valve close in case of low

superheating

0 to 100%

0

L2

N.V.

N.V.

L06

Delay high superheating

0 to 255 sec

30

L2

N.V.

N.V.

L07

Delay low superheating

0 to 255 sec

30

L2

N.V.

N.V.

Page 18

CC7.8.17/0220/E 18/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

L08

Threshold of MOP

SH23 to 60.0°C

35

L2

N.V.

N.V.

L09

Threshold of LOP

-50°C to SH22°C

-20

L2

N.V.

N.V.

L10

Activation delay MOP

0 to 255 sec

1

L2

N.V.

N.V.

L11

Activation delay LOP

0 to 255 sec

1

L2

N.V.

N.V.

L12

Steps close/open in case of MOP/LOP

0 to SH1 steps

20

L2

N.V.

N.V.

M01

Max step valve

SH2 to 800 steps

250

L2

L2

L2

M02

Min step valve

0 to SH1 steps

0

L2

L2

L2

M03

Extra steps of valve close

0 to 100 steps

20

L2

L2

L2

M04

Relax steps

0 to 100 steps

0

L2

L2

L2

M05

Step rate

10 to 100 steps

35

L2

L2

L2

M06

Regulation of the valve 0: automatic,

1: manual

Automatic (0-AUT)

Manual (1-MAN)

Automatic

L2

L2

L2

M07

Steps if manual regulation

SH2 to SH1 steps

15

L2

L2

L2

M08

Proportional band (if 0 the regulation is auto

adaptive)

0 to 50°C

0

L2

L2

L2

M09

Integral time

0 to 255 sec

20

L2

L2

L2

M10

Derivative

0 to 255 sec

0

L2

L2

L2

M11

Dead band

0 to10°C

1

L2

L2

L2

M12

Min % of the valve

0 to SH15

0

L2

L2

L2

M13

Max % of the valve

SH14 to 100

100

L2

L2

L2

M14

Filter on the pressure

1 to 255 sec

1

L2

L2

L2

M15

Interval of updating valve

1 to 255 sec

20

L2

L2

L2

M16

Filter on the temperature [1-100] sec

1 to 255 sec

1

L2

L2

L2

M17

Activation delay probe error

0 to 255 sec

1

L2

L2

L2

M18

% valve in case of probe error

0 to 100%

50

L2

L2

L2

M19

Time at initial steps at the start time

0 to 255 sec

30

L2

L2

L2

N01

Current minute

0 to 59

L1

L1

L1

Page 19

CC7.8.17/0220/E 19/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

N02

Current hour

0 to 23

L1

L1

L1

N03

Day of month

1 to 31

L1

L1

L1

N04

Month

1 to 12

L1

L1

L1

N05

Year

0 to 99

L1

L1

L1

P01

Compressor setpoint hysteresis in energy

saving mode

0.0 to 9.9 bar; 0. to 99.9 PSI;

0.0°C to 25.5°C

0

L2

L2

L2

P02

Condenser setpoint hysteresis in energy

saving mode

0.0°C to 25.5°C

0

L2

L2

L2

R01

Digital input 1 function

Not used (0-NU)

Suction pressure switch (1-SUS)

Thermostat input (2-DEF)

High-pressure input (3-HP)

Low-pressure input (4-LP)

Door switch (5-DOR)

Energy saving enable (6-ES)

On/Off (7-ONF)

Not used

L2

L2

L2

R02

Digital input 1 polarity

oP (0) - CL (1)

CL

L2

L2

L2

R03

Activation delay for digital input 1

0 to 255 min

0

L2

L2

L2

R04

Digital input 2 function

Not used (0-NU)

Suction pressure switch (1-SUS)

Thermostat input (2-DEF)

High-pressure input (3-HP)

Low-pressure input (4-LP)

Door switch (5-DOR)

Energy saving enable (6-ES)

On/Off (7-ONF)

High-pressure input

N.V.

N.V.

N.V.

R05

Digital input 2 polarity

oP (0) - CL (1)

oP

N.V.

N.V.

N.V.

R06

Activation delay for digital input 2

0 to 255 min

0

N.V.

N.V.

N.V.

Page 20

CC7.8.17/0220/E 20/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

R07

Digital input 3 function

Not used (0-NU)

Suction pressure switch (1-SUS)

Thermostat input (2-DEF)

High-pressure input (3-HP)

Low-pressure input (4-LP)

Door switch (5-DOR)

Energy saving enable (6-ES)

On/Off (7-ONF)

Not used

L2

L2

L2

R08

Digital input 3 polarity

oP (0) - CL (1)

CL

L2

L2

L2

R09

Activation delay for digital input 3

0 to 255 min

0

L2

L2

L2

S01

Alarm contact activation in a warning, alarm,

lockout

Warning (0-ARN) - Alarm (1-ALM) Lockout (2-LOC)

Alarm

L2

L2

L2

S02

Alarm relay deactivation

No (0-NO) - Yes (1-YES)

YES

L2

L2

L2

S03

Buzzer enabled

No (0-NO) - Yes (1-YES)

NO

L2

L2

L2

S04

Relay output 1 configuration

Not used (0-NU)

DGS compressor (1-DGS)

On-Off compressor (2-CPR)

Condenser fan 1 (3-CF1)

Condenser fan 2 (4-CF2)

Evaporator fan (5-EPF)

Defrost (6-DEF)

Liquid line solenoid (7-LLS)

Crankcase heater (8-HTR)

Alarm (9-ALM)

Light (10-LIG)

Crankcase heater

L2

L2

L2

S05

Relay output 2 configuration

Not used

L2

L2

L2

S06

Relay output 3 configuration

Digital Scroll

compressor

L2

L2

L2

S07

Relay output 4 configuration

Not used

L2

L2

L2

S08

Relay output 5 configuration

Alarm

L2

L2

L2

S09

Triac output 1 configuration

Not used (0-NU)

Digital solenoid (1-DGT)

Wave-form chopper for fan speed (2-PCF)

PWM fan speed (3-PEF)

0-10V (4-UEF)

Digital solenoid

L2

L2

L2

S10

Triac output 2 configuration

Not used (0-NU)

Digital solenoid (1-DGT)

Wave-form chopper for fan speed (2-PCF)

Wave-form chopper

for fan speed

L2

L2

L2

Page 21

CC7.8.17/0220/E 21/22

Code

Description

Range

Factory setting

ZXDE

ZXME

ZXLE

S11

EXV Configuration

Not used (0-NU)

Liquid injection EXV (1-LIN)

EVI EXV (2-UIN)

System EXV (3-SHT)

Not used

L2

L2

L2

S12

Output 1 polarity

oP (0) - CL (1)

CL

N.V.

N.V.

N.V.

S13

Output 2 polarity

oP (0) - CL (1)

CL

L2

L2

L2

T01

Serial address

1 to 247

1

L2

L2

L2

T02

Reset key configuration

nP (0-NU) - rSt (1-RST)

rSt

L2

L2

L2

T03

Period time of menu exit without pressing any

key

10 to 120 sec

30

N.V.

N.V.

N.V.

T04

Time for showing firmware version at start-up

0 to 60 sec

3

N.V.

N.V.

N.V.

T05

Time for showing program name at start-up

0 to 60 sec

3

N.V.

N.V.

N.V.

T06

P1 visualization

0 to 999

L2

L2

L2

T07

P2 visualization

0 to 999

L2

L2

L2

T08

P3 visualization

0 to 999

L2

L2

L2

T09

P4 visualization

0 to 999

L2

L2

L2

T10

P5 visualization

0 to 999

L2

L2

L2

T11

P6 visualization

0 to 999

L2

L2

L2

T12

P7 visualization

0 to 999

L2

L2

L2

T13

Firmware release: day

[1÷31] L2

L2

L2

T14

Firmware release: month

[1÷12] L2

L2

L2

T15

Firmware release: year

[0÷999]

L2

L2

L2

T16

Firmware release code

[0÷999]

L2

L2

L2

T17

EEPROM map identification

[0÷999]

6

L2

L2

L2

T18

Access PR2 level

[0÷999]

L1

L1

L1

Page 22

CC7.8.17/0220/E 22/22

DISCLAIMER

1. The contents of this publication are presented for informational purposes only and are not to be construed as warranties or guarantees, express or implied,

regarding the products or services described herein or their use or applicability.

2. Emerson Climate Technologies GmbH and/or its affiliates (collectively "Emerson"), as applicable, reserve the right to modify the design or specifications

of such products at any time without notice.

3. Emerson does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance

of any Emerson product remains solely with the purchaser or end user.

4. Emerson does not assume responsibility for possible typographic errors contained in this publication.

Loading...

Loading...