Page 1

Control Getting Started

Guide

Unidrive M700

Unidrive M701

Unidrive HS70

Unidrive HS71

Universal Variable Speed AC drive for

induction and permanent magnet motors

Part Number: 0478-0239-02

Issue: 2

Page 2

Contents

1 Safety information .......................................................................................3

2 Introduction ..................................................................................................6

2.1 Operating modes ......................................................................................................6

3 Control connections ....................................................................................8

3.1 Position feedback connections .................................................................................8

3.2 Communications connections ................................................................................10

3.3 Shield connections .................................................................................................11

3.4 Control connections ...............................................................................................12

4 Getting started ...........................................................................................13

4.1 Quick start commissioning / start-up using Unidrive M Connect

4.2 (V02.00.00.00 onwards) .........................................................................................13

4.3 Keypad / display .....................................................................................................16

4.4 Keypad operation ...................................................................................................17

4.5 Menu 0 ...................................................................................................................18

4.6 Menu structure .......................................................................................................18

4.7 Advanced menus ...................................................................................................19

4.8 Changing the operating mode ................................................................................20

4.9 Saving parameters .................................................................................................21

4.10 Restoring parameter defaults .................................................................................21

4.11 Displaying parameters with non-default values only ..............................................21

4.12 Displaying destination parameters only ................................................................. 21

4.13 Parameter access level and security .....................................................................22

4.14 NV Media Card operation .......................................................................................22

4.15 Transferring data ....................................................................................................25

5 Basic parameters (Menu 0) .......................................................................26

5.1 Parameter descriptions .......................................................................................... 29

6 Running the motor .....................................................................................34

6.1 Quick start Connections .........................................................................................34

6.2 Quick Start / start-up .............................................................................................36

7 Further information ...................................................................................46

7.1 Diagnostics .............................................................................................................46

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 3

1 Safety information

WARNING

CAUT ION

NOTE

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive. Specific warnings

are given at the relevant places in this guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a

system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy, and is used

to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid hazards either

in normal operation or in the event of equipment malfunction. System design, installation,

commissioning/start-up and maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this User Guide carefully.

The STOP and SAFE TORQUE OFF functions of the drive do not isolate dangerous voltages from

the output of the drive or from any external option unit. The supply must be disconnected by an

approved electrical isolation device before gaining access to the electrical connections.

With the sole exception of the SAFE TORQUE OFF function, none of the drive functions must

be used to ensure safety of personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a hazard,

either through their intended behavior or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or allow damage, loss or injury, a

risk analysis must be carried out, and where necessary, further measures taken to reduce the risk for example, an over-speed protection device in case of failure of the speed control, or a fail-safe

mechanical brake in case of loss of motor braking.

The SAFE TORQUE OFF function may be used in a safety-related application. The system designer

is responsible for ensuring that the complete system is safe and designed correctly according to the

relevant safety standards.

Safety information

Introduction Control connections Getting started

Basic parameters

(Menu 0)

Running the motor Further information

1.4 Environmental limits

Instructions in this guide regarding transport, storage, installation and use of the drive must be

complied with, including the specified environmental limits. Drives must not be subjected to

excessive physical force.

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 3

Issue Number: 2

Page 4

1.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the

place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must be provided.

For further information, refer to the Drive User Guide.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring

regulations, accident prevention regulations and electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective ground (earth) connections.

This guide contains instruction for achieving compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used must comply with the

following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations. Ensure the

motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is intended to

use the capability of the drive to run a motor at speeds above its designed maximum, it is strongly

recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less effective. The

motor should be installed with a protection thermistor. If necessary, an electric forced vent fan should

be used.

The values of the motor parameters set in the drive affect the protection of the motor. The default

values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 motor rated current. This affects the

thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated operation of an external brake

with the drive. While both hardware and software are designed to high standards of quality and

robustness, they are not intended for use as safety functions, i.e. where a fault or failure would result

in a risk of injury. In any application where the incorrect operation of the brake release mechanism

could result in injury, independent protection devices of proven integrity must also be incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

4 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 5

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric shock and may be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply

has been disconnected. If the drive has been energized, the AC supply must be isolated at least ten

minutes before work may continue.

Safety information

Introduction Control connections Getting started

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 5

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 6

2Introduction

This guide covers the Unidrive M700/HS70 and Unidrive M701/HS71 products.

Unidrive M700/HS70 / Unidrive M701/HS71 features

• Analog and digital I/O with single channel SAFE TORQUE OFF input

• NV Media Card for parameter copying and data storage

• Universal high performance drive for induction, servo, permanent magnet and linear motors

• Flexibility with speed and position measurement, supporting multiple devices and all common

interfaces

• Ethernet fieldbus communication (Unidrive M700/HS70)

• Provides an equivalent for Unidrive SP (Unidrive M701/HS71)

• 485 serial communication interface (Unidrive M701/HS71)

2.1 Operating modes

The drive is designed to operate in any of the following modes:

1. Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Quadratic V/F mode (V/Hz)

2. RFC - A

With position feedback sensor

Without position feedback sensor (Sensorless)

3. RFC - S

With position feedback sensor

Without position feedback sensor (Sensorless)

2.1.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of

the output frequency of the drive and slip due to the mechanical load. The drive can improve the

speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where

the drive uses motor parameters to apply the correct voltage to keep the flux constant under varying

load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a

voltage boost is provided which is set by the user. This mode can be used for multi-motor

applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Quadratic V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low

speed where a voltage boost is provided which is set by the user. This mode can be used for running

fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

6 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 7

2.1.2 RFC-A mode

Rotor Flux Control for Asynchronous (induction) motors (RFC-A) encompasses closed loop vector

control with a position feedback device

With position feedback

For use with induction motors with a feedback device installed. The drive directly controls the speed

of the motor using the feedback device to ensure the rotor speed exactly as demanded. Motor flux is

accurately controlled at all times to provide full torque all the way down to zero speed.

Without position feedback (Sensorless)

Sensorless mode provides closed loop control without the need for position feedback by using

current, voltages and key motor parameters to estimate the motor speed. It can eliminate instability

traditionally associated with open loop control such as operating large motors with light loads at low

frequencies.

2.1.3 RFC- S

Rotor Flux Control for Synchronous (permanent magnet brushless) motors (RFC-S) provides closed

loop control with position feedback device.

With position feedback

For use with permanent magnet brushless motors with a feedback device installed.

The drive directly controls the speed of the motor using the feedback device to ensure the rotor

speed is exactly as demanded. Flux control is not required because the motor is self excited by the

permanent magnets which form part of the rotor.

Absolute position information is required from the feedback device to ensure the output voltage is

accurately matched to the back EMF of the motor. Full torque is available all the way down to zero

speed.

Without position feedback

For use with permanent magnet brushless motors without a feedback device installed.

Flux control is not required because the motor is self excited by the permanent magnets which form

part of the rotor.

Full torque is available all the way down to zero speed, with salient motors.

Introduction

Introduction

Control connections Getting started

Basic parameters

(Menu 0)

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 7

Issue Number: 2

Running the motor Further information

Page 8

3 Control connections

NOTE

5

10

15

1

6

11

Drive encoder connector

Female 15-way D-type

Front view

End view

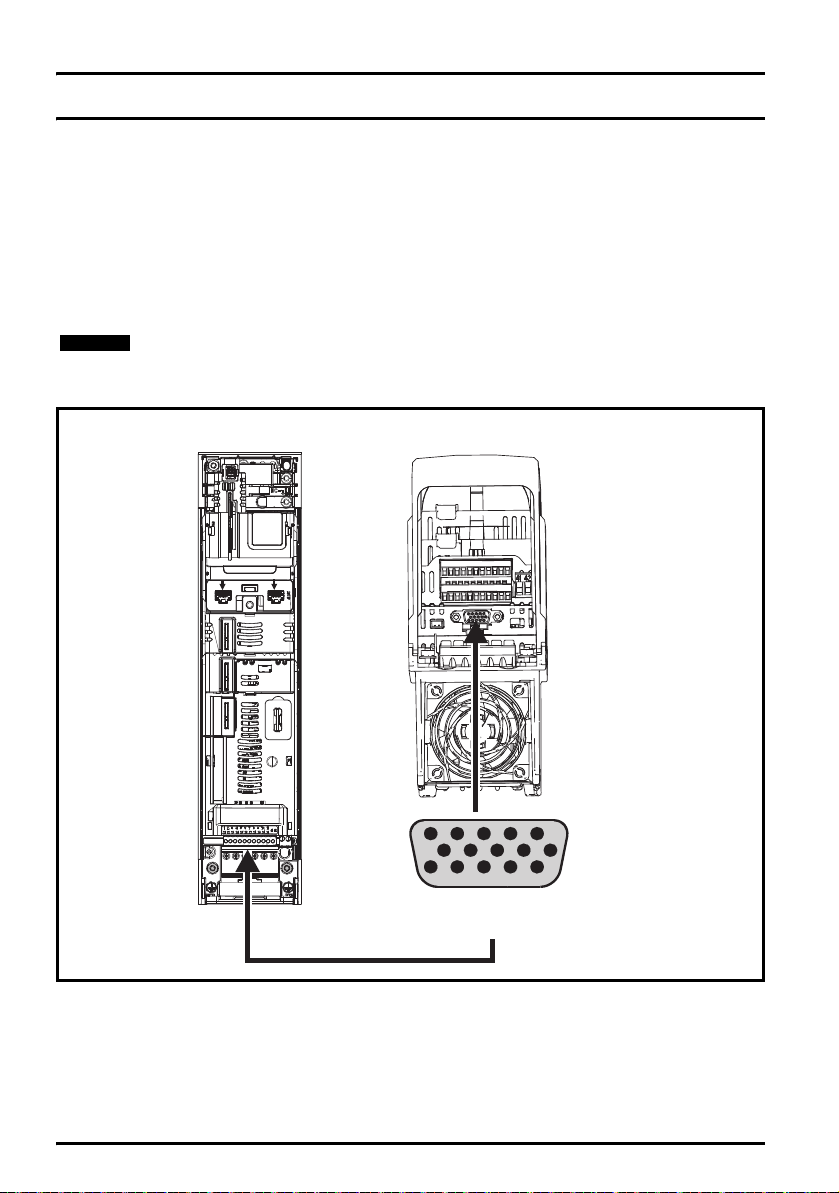

3.1 Position feedback connections

The following functions are provided via the 15-way high density D-type connector on the drive:

• Two position feedback interfaces (P1 and P2).

• One encoder simulation output.

• Two freeze trigger inputs (marker inputs).

• One thermistor input.

The P1 position interface is always available but the availability of the P2 position interface and the

encoder simulation output depends on the position feedback device used on the P1 position interface.

Refer to the Drive User Guide for information regarding the supported feedback devices

on the P1 and P2 position interface and the encoder stimulation output.

Figure 3-1 Location of position feedback connection

8 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 9

3.1.1 Position feedback connection details

NOTE

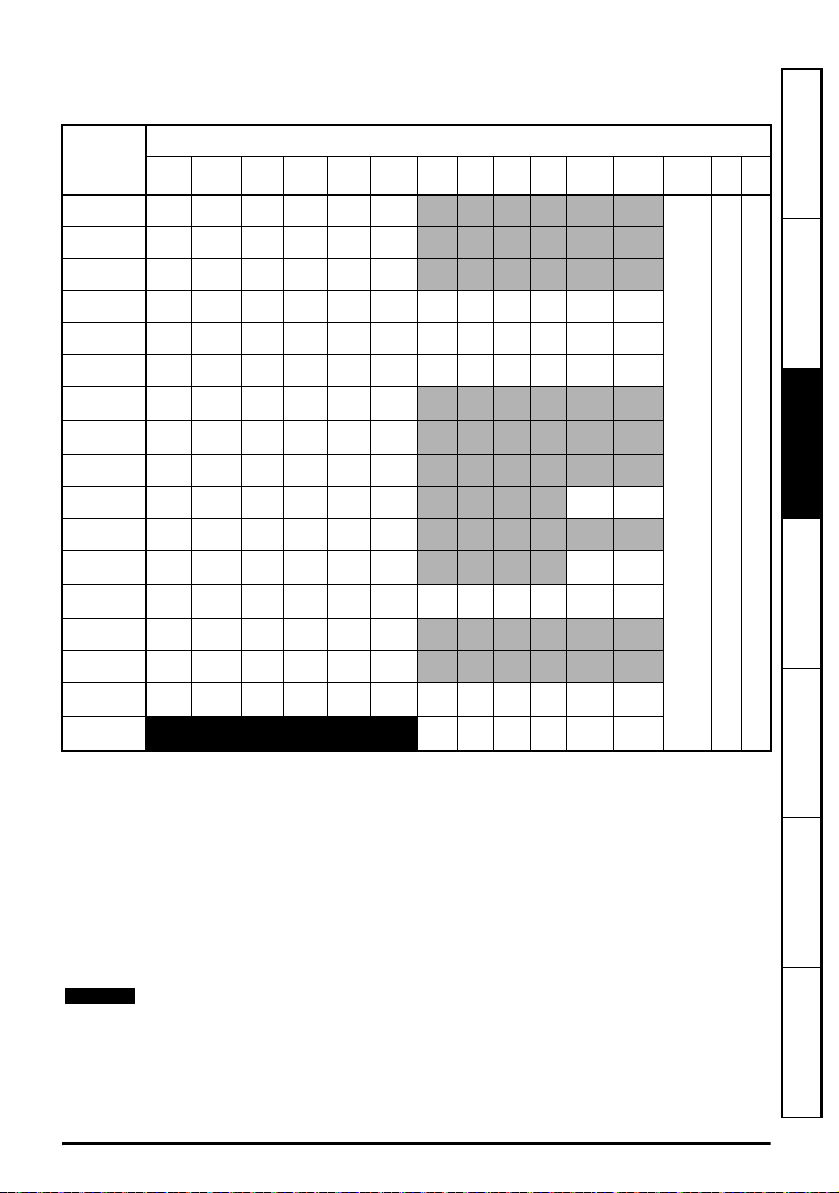

Table 3-1 P1 position feedback connection details

P1 Position

feedback

interface

Pr 03.038

AB (0) A A\ B B\ Z Z\

FD (1) F F\ D D\ Z Z\

FR (2) F F\ R R\ Z Z\

AB Servo (3) A A\ B B\ Z Z\ U U\ V V\ W W\

FD Servo (4) F F\ D D\ Z Z\ U U\ V V\ W W\

FR Servo (5) F F\ R R\ Z Z\ U U\ V V\ W W\

SC (6)

SC

Hiperface (7)

EnDat (8) DATA DATA\ CLK CLK\

SC EnDat (9) A A\ B B\ DATA DATA\ CLK CLK\

SSI (10) DATA DATA\ CLK CLK\

SC SSI (11)

SC Servo

(12)

BiSS (13) DATA DATA\ CLK CLK\

Resolver (14) Cos H Cos L Sin H Sin L Ref H Ref L

SC SC (15)

Commutation

Only (16)

1

- One sine wave per revolution

*

2

*

- One cosine wave per revolution

3

*

- Freeze inputs are shown in the table above as ‘Frz’.

4

- The encoder power supply is selectable through parameter configuration to 5 Vdc, 8 Vdc and

*

123456789101112131415

A

(Cos)A\(Cos\)B(Sin)B\(Sin\)

Cos Cosref Sin Sinref DATA DATA\

A

(Cos)A\(Cos\)B(Sin)B\(Sin\)

A

(Cos)A\(Cos\)B(Sin)B\(Sin\)

A

(Cos)A\(Cos\)B(Sin)B\(Sin\)

ZZ\

Frz*3Frz\*

Frz*3Frz\*

DATA DATA\ CLK CLK\

ZZ\UU\VV\WW\

Frz*3Frz\*

ZZ\

15 Vdc.

Th - Thermistor input.

Greyed cells are for P2 position feedback connections or simulated encoder outputs. Refer to the

Drive User Guide for further information.

Connections

3

3

3

C*1C\*1D*2D\*2Frz2*3Frz2\*

UU\VV\ W W\

*4

0 V Th

+V

3

Control connections Introduction

Control connections

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Frz and Frz\ on terminals 5 and 6 are for Freeze input 1. Frz2 and Frz2\ on terminals 11

and 12 are for Freeze input 2.

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 9

Issue Number: 2

Page 10

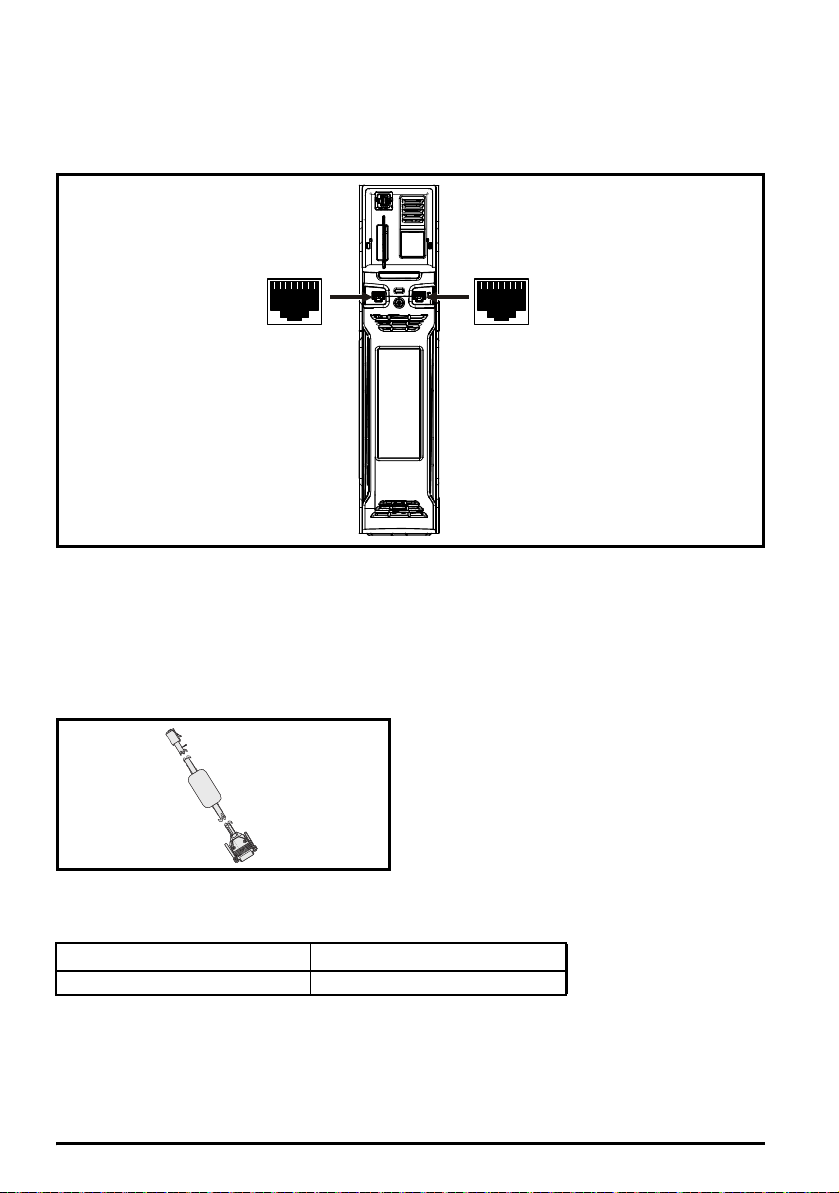

3.2 Communications connections

1 1

8

8

The Unidrive M700/HS70 product offers Ethernet fieldbus communications and the Unidrive M701/

HS71 offers a 2 wire 485 serial interface. This enables the drive set-up, operation and monitoring to

be carried out with a PC or controller if required.

Figure 3-2 Location of the communication connectors

3.2.1 Ethernet Fieldbus communications (Unidrive M700/HS70 only)

The Unidrive M700/HS70 provides two RJ45 connections with an Ethernet switch for easy network

creation.

3.2.2 485 Serial communications (Unidrive M701/HS71 only)

The Unidrive M701/HS71 provides two parallel RJ45 connectors allowing easy daisy chaining. The

drive supports the Modbus RTU protocol. See Table 3-3 for the connection details.

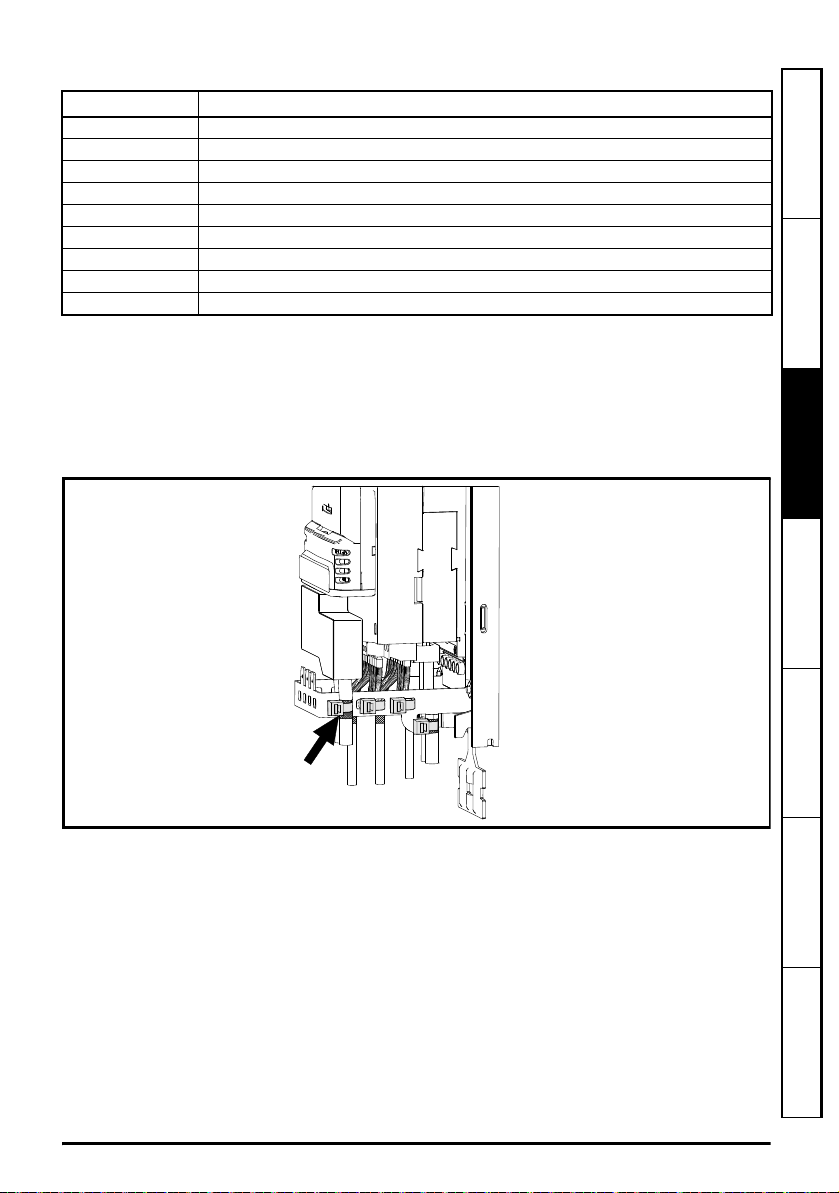

Figure 3-3 CT Comms cable

An isolated serial communications lead has been designed to connect the drive to IT equipment

(such as laptop computers), and is available from the supplier of the drive. See below for details:

Table 3-2 Isolated serial comms lead details

Part number Description

4500-0096 CT USB Comms cable

The “isolated serial communications” lead has reinforced insulation as defined in IEC60950 for

altitudes up to 3,000 m.

10 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 11

Table 3-3 Serial communication port pin-outs

Pin Function

1 120 Ω Termination resistor

2RX TX

3 Isolated 0 V

4 +24 V (100 mA)

5 Isolated 0 V

6 TX enable

7RX\ TX\

8

RX\ TX\ (if termination resistors are required, link to pin 1)

Shell Isolated 0 V

3.3 Shield connections

The following guidelines should be followed to ensure suppression of radio-frequency

emission and good noise immunity. It is particularly recommended that the guidelines for the

encoder cable be followed closely in order to avoid disturbance to the encoder operation from

electrical noise. Use the grounding bracket and grounding clamp supplied with the drive to terminate

the shields at the drive.

Figure 3-4 Grounding of signal cable shields using the grounding bracket

Control connections Introduction

Control connections

Getting started

Motor cable: Use a motor cable with an overall shield. Connect the shield of the motor cable to the

ground terminal of the motor frame using a link that is as short as possible and not exceeding 50 mm

(2 in) long. A full 360 ° termination of the shield to the terminal housing of the motor is beneficial.

Encoder cable: For best shielding use cable with an overall shield and individual shields on twisted

pairs, connect the cable as illustrated in Figure 3-5. Clamp the overall shield to grounded metallic

surfaces at both the encoder and the drive.

Brake resistor cable: The optional braking resistor should also be wired with shielded cable. If

unshielded wire is required refer to the Drive User Guide for guidance.

Control cables: If the control wiring is to leave the enclosure, it must be shielded and the shield(s)

clamped to the drive using the grounding bracket. Remove the outer insulating cover of the cable to

ensure the shield(s) make contact with the bracket, but keep the shield(s) intact until as close as

possible to the terminals.

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 11

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 12

Figure 3-5 Feedback cable shield connections

Cable

Cable

shield

Twis ted

pair

shield

Cable

shield

Twis ted

pair

shield

Connection

at motor

Connection

at drive

Ground clamp

on shield

Shield

connection

to 0V

Shield

connection

to 0V

3.4 Control connections

For information on control connections, refer to the back cover of this guide.

12 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 13

4 Getting started

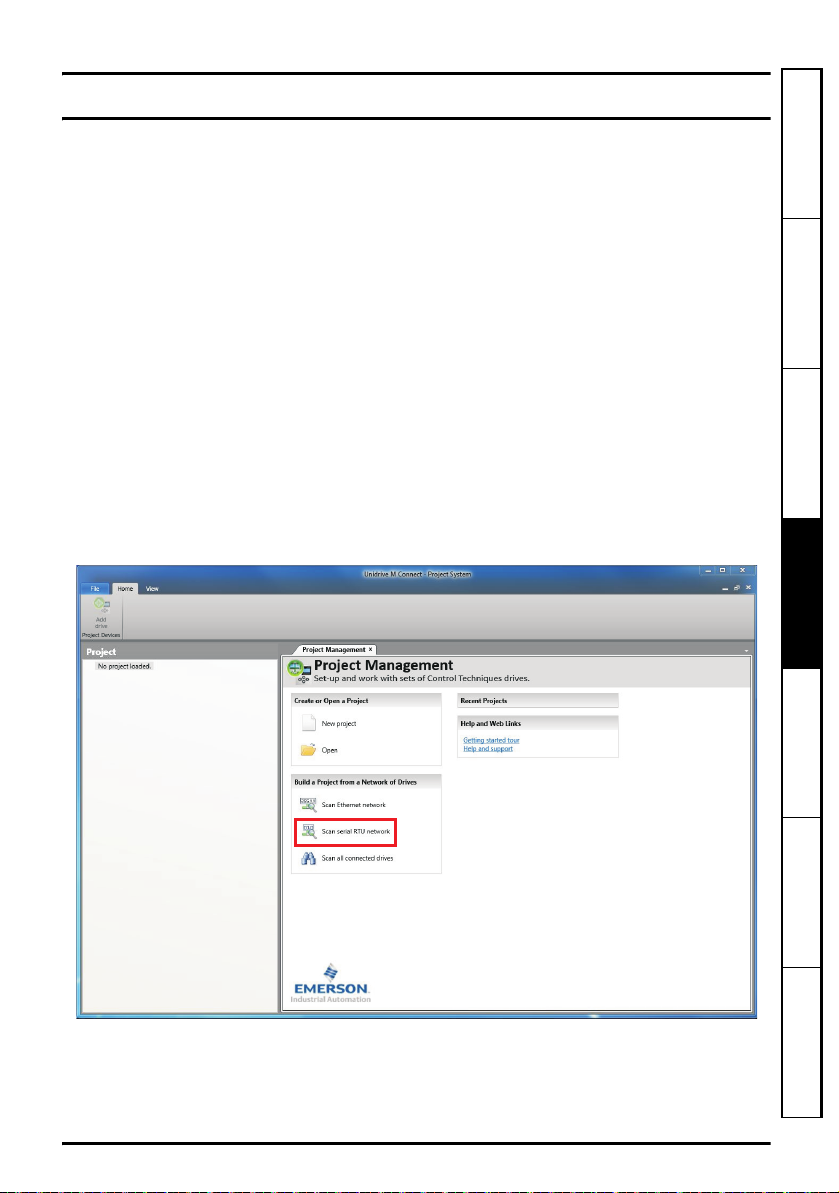

4.1 Quick start commissioning / start-up using Unidrive M Connect (V02.00.00.00 onwards)

Unidrive M Connect is a Windows™ based software commissioning / start-up tool for Unidrive M/HS.

Unidrive M Connect can be used for commissioning / start-up and monitoring, drive parameters can be

uploaded, downloaded and compared and simple or custom menu listings can be created. Drive menus can

be displayed in standard list format or as live block diagrams. Unidrive M Connect is able to communicate

with a single drive or a network. Unidrive M Connect can be downloaded from www.controltechniques.com

(file size approximately 100 MB).

Unidrive M Connect system requirements

• Windows 8, Windows 7 SP1, Windows Vista SP2, Windows XP SP3

• Minimum of 1280 x 1024 screen resolution with 256 colours

• Microsoft.Net Frameworks 4.0 (this is provided in the downloaded file)

• Note that you must have administrator rights to install Unidrive M Connect

Any previous copy of Unidrive M Connect should be uninstalled before proceeding with the installation

(existing projects will not be lost). Included within Unidrive M Connect is the Parameter Reference Guide for

Unidrive M700/701 and Unidrive HS70/HS71.

4.1.1 Power-up the drive

1. Start Unidrive M Connect, and on the ‘Project Management’ screen select 'Scan serial RTU network' or

'Scan all connected drives’.

Safety information Introduction Control connections

Getting started

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 13

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 14

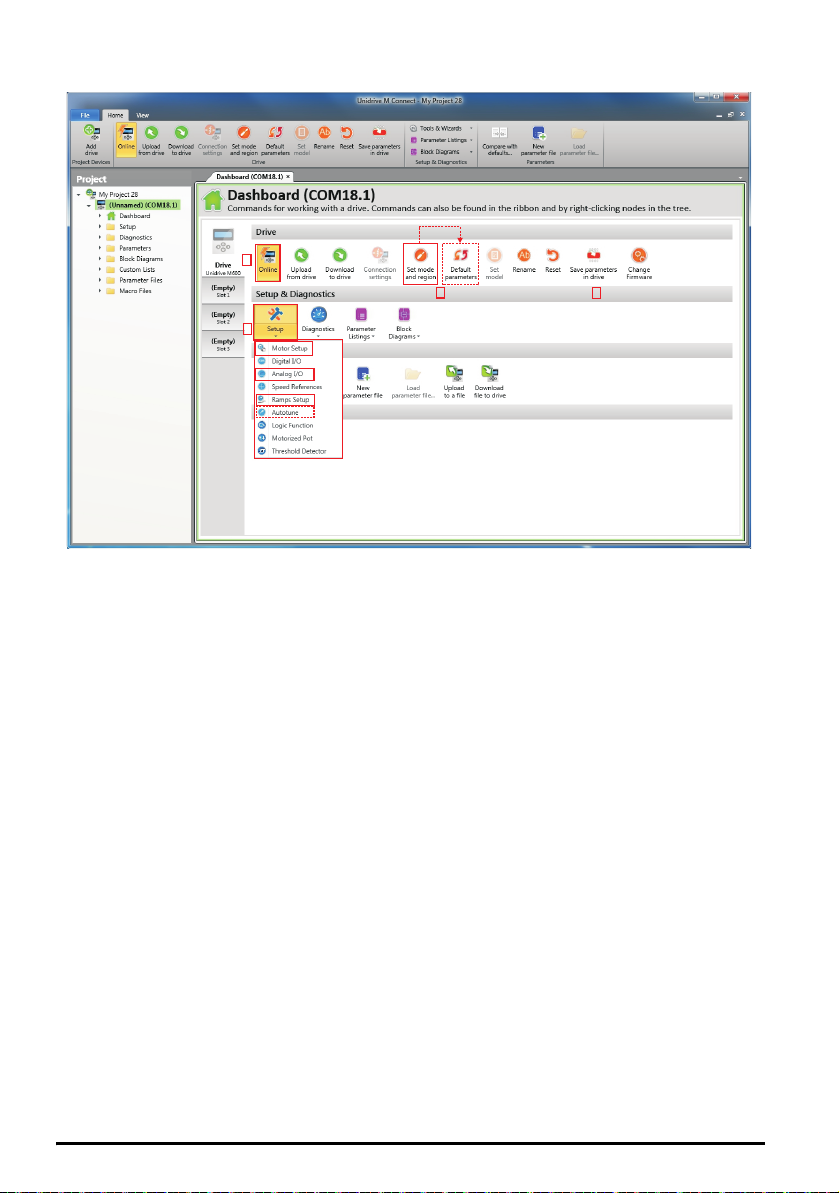

Select the discovered drive.

1

2

4

3

1. Select the ‘Online’ icon to connect with the drive. When a successful connection is made the icon will

be highlighted orange.

2. Select ‘Set mode and region’.

If the required control mode is highlighted in the ‘Drive Settings’ dialog, then:

• Change the supply frequency, if required and select ‘Apply’, otherwise select ‘Cancel’.

• Select ‘Default parameters‘ from the Dashboard and in the ‘Default Parameters’ dialogue, select ‘Apply’

If the required control mode is not highlighted in the ‘Drive Settings’ dialog then:

• Select the required mode and supply frequency.

• Select ‘Apply’.

3. Select ‘Setup’ and perform the steps highlighted (dotted lines indicate a step which may not need to be

performed (see below):

14 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 15

Action Detail

NOTE

Setting the encoder voltage supply too high for the encoder could result in

damage to the feedback device.

CAUT ION

Unidrive M Connect contains a database for induction motors and permanent magnet motors.

Motor Setup

Motor Feedback

Setup

Analog I/O

Provision is also made to enter motor nameplate data.

The next section describes the use of the motor database for a Leroy Somer LSRPM motor

used in RFC-S Sensorless mode.

This only needs to be performed in RFC-A (with feedback) mode

Set Pr 03.024 = Feedback (0)

Enter:

• Encoder power supply in Pr. 03.036 = 5 V (0), 8 V (1) or 15 V (2). *

• Drive encoder Lines Per Revolution (LPR) in Pr 03.034 (set according to encoder) *

• Drive encoder termination resistor setting in Pr 03.039: *

* mm is dependant on the slot into which the SI-Encoder module is installed (15 =Slot 1, 16 =

Slot 2, 17 = Slot 3).

The motor thermistor can be selected in Pr 07.015. Refer to the parameter help for Pr 07.015

for further information.

If output voltage from the encoder is >5 V, then the termination resistors must be

disabled Pr 03.039 to 0. *

0 = A-A\, B-B\ termination resistors disabled

1 = A-A\, B-B\, termination resistors enabled

Safety information Introduction Control connections

Enter the required Acceleration rate and Deceleration rate

Ramps Setup

Autotune

Note: If a braking resistor is installed, set 'Ramp mode' to 'Fast'. Also ensure Pr 10.030 and

Pr 10.031 and Pr 10.061 are set correctly, otherwise premature 'Brake R Too Hot' trips may

be seen).

Not required when using data from the motor database for a Leroy Somer LSRPM motor used

in RFC-S Sensorless mode.

4. Select 'Save parameters in drive' to perform a parameter save.

The drive is now ready to run.

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 15

Issue Number: 2

Page 16

4.2 Keypad / display

NOTE

4.2.1 Understanding the display

The keypad can only be mounted on the drive.

4.2.2 KI-Keypad

The KI-Keypad display consists of two rows of text. The upper row shows the drive status or the

menu and parameter number currently being viewed. The lower row of the display line shows the

parameter value or the specific trip type. The last two characters on the first row may display special

indications. If more than one of these indications is active then the indications are prioritized as

shown in Table 4-1 .

When the drive is powered up the lower row will show the power up parameter defined by Parameter

Displayed At Power-up (11.022).

Figure 4-1 KI-Keypad

1. Escape button

2. Start reverse (Auxiliary button)

3. Start forward

4. Navigation keys (x4)

5. Stop / Reset (red) button

6. Enter button

The red stop button is also used to reset the drive.

Table 4-1 Active action icon

Active action icon Description

Accessing non-volatile media card 1 1

Alarm active 1 2

Keypad real-time clock battery low 1 3

or

Drive security active and locked or

unlocked

Motor map 2 active 2 1

User program running 3 1

Keypad reference active 4 1

Row

(1=top)

14

16 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Priority

in row

Page 17

4.3 Keypad operation

To enter Edit Mode,

press key

Status

Mode

(Display

not

flashing)

Parameter

Mode

(Upper row

display flashing)

Edit Mode

(Character to be edited in lower line of displa y flashing)

Change parameter values

using keys.

When returning

to Parameter

Mode use the

keys to select

another parameter

to change, if

required

To enter Parameter

Mode, press key or

Tem por ar y

Parameter

Mode

(Upper display

flashing)

T

imeout

T

imeout

To return to Status Mode,

RO

parameter

is displayed

R/W

parameter

To select parameter

Press

To return to Parameter Mode,

Press key to keep the new parameter value

Press key to ignore the new parameter value and ret urn

the parameter to the pre-edite d value

Press key

Timeo ut

or

Press key

4.3.1 Control buttons

The keypad consists of:

• Navigation Keys - Used to navigate the parameter structure and change parameter values.

• Enter / Mode button - Used to toggle between parameter edit and view mode.

• Escape / Exit button - Used to exit from parameter edit or view mode. In parameter edit mode, if

parameter values are edited and the exit button pressed the parameter value will be restored to

the value it had on entry to edit mode.

• Start forward button - Use to provide a 'Run' command if keypad mode is selected.

• Start reverse button - Used to control the drive if keypad mode is selected and the reverse button

is activated.

• Stop / Reset button - Used to reset the drive. In keypad mode can be used for 'Stop'.

Figure 4-2 Display modes

Safety information Introduction Control connections

Getting started

Basic parameters

(Menu 0)

The navigation keys can only be used to move between menus if Pr 00.049 has been set to show 'All

Menus'

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 17

Issue Number: 2

Running the motor Further information

Page 18

Figure 4-3 Mode examples

12

34

WARNING

NOTE

NOTE

Menu 0

....MM.000....

00.050

00.049

00.048

00.047

00.046

00.001

00.002

00.003

00.004

00.005

Moves

between

parameters

Menu 41

Menu 1

Menu 2

Moves between Menus

41.029

41.028

41.027

41.026

41.025

41.001

41.002

41.003

41.004

41.005

01.001

01.002

01.003

01.004

01.005

01.050

01.049

01.048

01.047

01.046

Option module menus (S.mm.ppp)*

Do not change parameter values without careful consideration; incorrect values may

cause damage or a safety hazard.

When changing the values of parameters, make a note of the new values in case they

need to be entered again.

For new parameter-values to apply after the AC supply to the drive is interrupted, new

values must be saved. Refer to section 4.8 Saving parameters on page 21.

4.4 Menu 0

Menu 0 is used to bring together various commonly used parameters for basic easy set up of the

drive. Appropriate parameters are copied from the advanced menus into menu 0 and thus exist in

both locations. For further information, refer to Chapter 5 Basic parameters (Menu 0) on page 26.

4.5 Menu structure

The drive parameter structure consists of menus and parameters. The drive initially powers up so

that only Menu 0 can be viewed. The up and down arrow buttons are used to navigate between

parameters and once Pr 00.049 has been set to 'All Menus' the left and right buttons are used to

navigate between menus. For further information, refer to section 4.12 Parameter access level and

security on page 22.

Figure 4-4 Menu structure

The menus and parameters roll over in both

directions. i.e. if the last parameter is

displayed, a further press will cause the

display to rollover and show the first

parameter.

When changing between menus the drive

remembers which parameter was last

viewed in a particular menu and thus

displays that parameter.

* The option module menus (S.mm.ppp) are

only displayed if option modules are

installed. Where S signifies the option

module slot number and the mm.ppp

signifies the menu and the parameter

number of the option module's internal

menus and parameter.

18 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 19

4.6 Advanced menus

The advanced menus consist of groups or parameters appropriate to a specific function or feature of

the drive. Menus 0 to 41 can be viewed on the KI-Keypad.

Table 4-2 Advanced menu descriptions

Menu Description

0 Commonly used basic set-up parameters for quick / easy programming

1 Frequency / speed reference

2Ramps

3 Frequency slaving, speed feedback and speed control

4 Torque and current control

5 Motor control

6 Sequencer and clock

7 Analog I/O, Temperature monitoring

8 Digital I/O

9 Programmable logic, motorized pot, binary sum, timers and scope

10 Status and trips

11 Drive set-up and identification, serial communications

12 Threshold detectors and variable selectors

13 Standard motion control

14 User PID controller

15 Option module slot 1 set-up menu

16 Option module slot 2 set-up menu

17 Option module slot 3 set-up menu

18 General option module application menu 1

19 General option module application menu 2

20 General option module application menu 3

21 Second motor parameters

22 Menu 0 set-up

23 Not allocated

24 Ethernet module (slot 4) set-up menu*

25 Option module slot 1 application parameters

26 Option module slot 2 application parameters

27 Option module slot 3 application parameters

28 Option module slot 4 application parameters

29 Reserved menu

30 Onboard user programming application menu

31-41 Advanced motion controller setup parameters

Slot 1 Slot 1 option menus**

Slot 2 Slot 2 option menus**

Slot 3 Slot 3 option menus**

Slot 4 Ethernet menus*

* Only applicable to Unidrive M700/HS70.

** Only displayed when the option modules are installed.

Safety information Introduction Control connections

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 19

Issue Number: 2

Page 20

4.7 Changing the operating mode

NOTE

Changing the operating mode returns all parameters to their default value, including the motor

parameters. User security status (00.049) and User security code (00.034) are not affected by this

procedure).

Procedure

Use the following procedure only if a different operating mode is required:

1. Ensure the drive is not enabled, i.e. terminal 31 is open or Pr 06.015 is OFF (0)

2. Enter either of the following values in Pr mm.000, as appropriate:

1253 (50Hz AC supply frequency)

1254 (60Hz AC supply frequency)

3. Change the setting of Pr 00.048 as follows:

Pr 00.048 setting Operating mode

1

2

(Induction motor with or without position feedback)

3

(Permanent magnet motor with or without position

The figures in the second column apply when serial communications are used.

4. Either:

• Press the red reset button

• Toggle the reset digital input

• Carry out a drive reset through serial communications by setting Pr 10.038 to 100.

Entering 1253 or 1254 in Pr mm.000 will only load defaults if the setting of Pr 00.048 has

been changed.

Open-loop

(Induction motor)

RFC-A

RFC-S

feedback)

20 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 21

4.8 Saving parameters

When changing a parameter in Menu 0, the new value is saved when pressing the Enter

button to return to parameter view mode from parameter edit mode.

If parameters have been changed in the advanced menus, then the change will not be saved

automatically. A save function must be carried out.

Procedure

1. Select ‘Save Parameters'* in Pr mm.000 (alternatively enter a value of 1000* in Pr mm.000)

2. Either:

• Press the red reset button

• Toggle the reset digital input, or

• Carry out a drive reset through serial communications by setting Pr 10.038 to 100

* If the drive is in the under voltage state (i.e. when the control terminal 1 & 2 are being supplied from

a low voltage DC supply) a value of 1001 must be entered into Pr

mm.000

to perform a save function.

4.9 Restoring parameter defaults

Restoring parameter defaults by this method saves the default values in the drives memory. User

security status (00.049) and User security code (00.034) are not affected by this procedure).

Procedure

1. Ensure the drive is not enabled, i.e. terminal 31 is open or Pr 06.015 is OFF (0)

2. Select 'Reset 50 Hz Defs' or 'Reset 60 Hz Defs' in Pr mm.000. (alternatively, enter 1233 (50 Hz

settings) or 1244 (60 Hz settings) in Pr mm.000).

3. Either:

• Press the red reset button

• Toggle the reset digital input

• Carry out a drive reset through serial communications by setting Pr 10.038 to 100

4.10 Displaying parameters with non-default values only

By selecting 'Show non-default' in Pr mm.000 (Alternatively, enter 12000 in Pr mm.000), the only

parameters that will be visible to the user will be those containing a non-default value. This function

does not require a drive reset to become active. In order to deactivate this function, return to

Pr mm.000 and select 'No action' (alternatively enter a value of 0). Please note that this function can

be affected by the access level enabled, refer to section 4.9 Restoring parameter defaults on

page 21 for further information regarding access level.

4.11 Displaying destination parameters only

By selecting 'Destinations' in Pr mm.000 (Alternatively enter 12001 in Pr mm.000), the only

parameters that will be visible to the user will be destination parameters. This function does not

require a drive reset to become active. In order to deactivate this function, return to Pr mm.000 and

select 'No action' (alternatively enter a value of 0).

Please note that this function can be affected by the access level enabled, refer to section

4.12 Parameter access level and security on page 22 for further information regarding access level.

Safety information Introduction Control connections

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 21

Issue Number: 2

Page 22

4.12 Parameter access level and security

The parameter access level determines whether the user has access to Menu 0 only or to all the

advanced menus (Menus 1 to 41) in addition to Menu 0. The User Security determines whether the

access to the user is read only or read write. Both the User Security and Parameter Access Level

can operate independently of each other as shown in Table 4-3.

Table 4-3 Parameter access level and security

User security

status (11.044)

0 Menu 0

1 All Menus

2 Read-only Menu 0

3 Read-only

4 Status only

5 No access

The default settings of the drive are Parameter Access Level Menu 0 and User Security Open i.e.

read / write access to Menu 0 with the advanced menus not visible.

Access level User security Menu 0 status

Open RW Not visible

Closed RO Not visible

Open RW RW

Closed RO RO

Open RO Not visible

Closed RO Not visible

Open RO RO

Closed RO RO

Open Not visible Not visible

Closed Not visible Not visible

Open Not visible Not visible

Closed Not visible Not visible

Advanced menu

status

4.13 NV Media Card operation

4.13.1 Introduction

The Non-Volatile Media Card feature enables simple configuration of parameters, parameter back-up

and drive cloning using a SMARTCARD or SD card. The drive offers backward compatibility for a

Unidrive SP SMARTCARD.

The NV Media Card can be used for:

• Parameter copying between drives

• Saving drive parameter sets

• Saving a program

The NV Media Card is located at the top of the module under the drive display (if installed) on the lefthand side.

Ensure NV Media Card is inserted with the contacts facing the left-hand side of the drive.

The drive only communicates with the NV Media Card when commanded to read or write, meaning

the card may be "hot swapped".

22 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 23

Figure 4-5 Installation of the NV Media Card

Safety information Introduction Control connections

1. Installing the NV Media Card

2. NV Media Card installed

NV Media Card Part number

SD Card Adaptor (memory card not included) 3130-1212-03

8 kB SMARTCARD 2214-4246-03

64 kB SMARTCARD 2214-1006-03

4.13.2 NV Media Card support

The NV Media Card can be used to store drive parameters and / or PLC programs set from the

Unidrive M/HS in data blocks 001 to 499.

The Unidrive M/HS is compatible with a Unidrive SP SMARTCARD and is able to read and translate

the Unidrive SP parameter set into a compatible parameter set for Unidrive M/HS. This is only

possible if the Unidrive SP parameter set was transferred to the SMARTCARD using the difference

from defaults transfer method (i.e. 4yyy transfer). The Unidrive M/HS is not able to read any other

type of Unidrive SP data block on the card. Although it is possible to transfer difference from default

data blocks from a Unidrive SP into the Unidrive M/HS, the following should be noted:

1. If a parameter from the source drive does not exist in the target drive then no data is transferred

for that parameter.

2. If the data for the parameter in the target drive is out of range then the data is limited to the range

of the target parameter.

3. If the target drive has a different rating to the source drive then the normal rules for this type of

transfer apply.

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 23

Issue Number: 2

Page 24

Figure 4-6 Basic NV Media Card operation

Pr = Read +00.030

Drive reads all

parameters from

the NV Media Card

Pr = Program +00.030

Programs all drive

parameters to the

NV Media Card

NOTE

Overwrites any

data already in

data block 1

Pr = Auto +00.030

Auto

Save

Drive automatically

writes to the

when a parameter

save is performed

Media Card

Pr = Boot +00.030

Boot

Auto Save

Drive boots from the

NV Media Card on

power up and

automatically writes

to the

when a parameter

save is performed

Media Card

The whole card may be protected from writing or erasing by setting the read-only flag, refer to the

Drive User Guide for further information.

The card should not be removed during data transfer, as the drive will produce a trip. If this occurs

then either the transfer should be reattempted or in the case of a card to drive transfer, default

parameters should be loaded.

24 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 25

4.14 Transferring data

Data transfer, erasing and protecting the information is performed by entering a code in Pr mm.000

and then resetting the drive as shown in Table 4-4.

Table 4-4 SMARTCARD and SD card codes

Code Operation SMARTCARD SD card

2001

4yyy

5yyy

6yyy

7yyy Erase file yyy. 99

8yyy

9555 Clear the warning suppression flag 99

9666 Set the warning suppression flag 99

9777 Clear the read-only flag 99

9888 Set the read-only flag 99

9999 Erase and format the NV media card 99

15yyy

16yyy As 15yyy, but for slot 2 9

17yyy As 15yyy, but for slot 3 9

18yyy

19yyy As 18yyy, but for slot 2

20yyy As 18yyy, but for slot 3 9

21yyy As 15yyy, but for slot 4

22yyy As 18yyy, but for slot 4

40yyy

60yyy

Transfer the drive parameters to parameter file 001 and

sets the block as bootable. This will include the parameters

from attached option modules.

Transfer the drive parameters to parameter file yyy. This

will include the parameters from attached option modules.

Transfer the onboard user program to onboard user

program file yyy.

Load the drive parameters from parameter file yyy or the

onboard user program from onboard user program file yyy.

Compare the data in the drive with file yyy. If the files are

the same then Pr mm.000 (mm.000) is simply reset to 0

when the compare is complete. If the files are different a

‘Card Compare’ trip is initiated. All other NV media card

trips also apply.

Transfer a program from an option module in slot 1 to an

option module applications file

Load a program to the option module in slot 1 from an

option module applications file

Backup all drive data (parameter differences from defaults,

an onboard user program, applications programs and

miscellaneous option data), including the drive name; the

store will occur to the </MCDF/driveyyy/> folder; if it does

not exist, it will be created. Because the name is stored, this

is a backup, rather than a clone. The command code will be

cleared when all drive and option data have been saved.

Load all drive data (parameter differences from defaults, an

onboard user program, applications programs and

miscellaneous option data); the load will come from the

</MCDF/driveyyy/> folder. The command code will not be

cleared until the drive and all option data have been

loaded.

99

99

99

99

99

9

9

9

9

9

9

9

Safety information Introduction Control connections

Getting started

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 25

Issue Number: 2

Page 26

5 Basic parameters (Menu 0)

Parameter

00.001 Minimum Reference Clamp ±VM_NEGATIVE_REF_CLAMP1 Hz / rpm 0.0 Hz

00.002 Maximum Reference Clamp ±VM_POSITIVE_REF_CLAMP Hz / rpm

00.003 Acceleration Rate 1

00.004 Deceleration Rate 1

00.005 Reference Selector

00.006 Symmetrical Current Limit ±VM_MOTOR1_CURRENT_LIMIT % 0.0 %

Open-loop Control Mode

00.007

Speed Controller

Proportional Gain Kp1

Low Frequency Voltage

Boost

00.008

Speed Controller Integral

Gain Ki1

Dynamic V to F Select Off (0) or On (1) OFF (0)

00.009

Speed Controller Differential

Feedback Gain Kd 1

Motor Rpm ±180000 rpm 0 rpm

00.010

Speed Feedback

Output Frequency

00.011

P1 Position 0 to 65535

00.012 Current Magnitude ±VM_DRIVE_CURRENT_UNIPOLAR A

00.013 Torque Producing Current ±VM_DRIVE_CURRENT A

00.014 Torque Mode Selector 0 or 1 0 to 5 0

00.015 Ramp Mode Select

00.016 Ramp Enable OFF (0) or On (1) On (1)

Digital Input 6 Destination 00.000 to 30.999 06.031

00.017

Current Reference Filter

Time Constant

OL RFC-A RFC-S OL RFC-A RFC-S

±VM_ACCEL_R

ATE s /100 Hz

±VM_ACCEL_R

ATE s /100 Hz

A1 A2 (0), A1 Preset (1), A2 Preset (2),

Preset (3), Keypad (4), Precision (5),

Ur S (0), Ur (1),

Fixed (2),

Ur Auto (3),

Ur I (4),

Square (5),

Current 1P (6)

0.0 to 25.0 %

±VM_SPEED_FREQ_REF Hz

Fast (0),

Standard (1),

Std boost (2)

Range Default

50Hz

default:

50.0 Hz

60Hz

default:

60.0 Hz

±VM_ACCEL_RATE

s /1000 rpm

±VM_ACCEL_RATE

s /1000 rpm

Keypad Ref (6)

0.0000 to 200.000 s/rad

0.00 to 655.35 s2/rad

0.00000 to 0.65535 1/rad 0.00000 1/rad

±VM_SPEED rpm

Fast (0), Standard (1) Standard (1)

0.0 to 25.0 ms 0.0 ms

5.0

s/100 Hz

10.0

s/100 Hz

Ur I (4)

Size 3 to

6: 3.0 %

Size 7 &

8: 2.0 %

Size 9≥:

1.0 %

50Hz

default:

1500.0 rpm

60Hz

default:

1800.0 rpm

2.000

s/1000 rpm

2.000

s/1000 rpm

A1 A2 (0)

0.0300

s/rad

0.10

s2/rad

0.0 rpm

3000.0

rpm

0.200

s/1000

0.200

s/1000

0.0100

s/rad

1.00

s2/rad

Typ e

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RO

RO

RO

RO

RO

RW

RW

RW

RW

RW

1

26 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 27

Parameter

00.019 Analog Input 2 Mode

00.020 Analog Input 2 Destination 00.000 to 30.999 01.037

00.021 Analog Input 3 Mode

00.022 Bipolar Reference Enable Off (0) or On (1) OFF(0)

00.023 Jog Reference 0.0 to 400.0 Hz

00.024 Preset Reference 1 ±VM_SPEED_FREQ_REF rpm 0.0

00.025 Preset Reference 2 ±VM_SPEED_FREQ_REF rpm 0.0

Preset Reference 3

Uni M: Overspeed

00.026

Threshold

Uni HS: Overspeed

Threshold

Preset Reference 4

00.027

P1 Rotary Lines Per

Revolution

00.028 Enable Auxiliary Key 0 to 2 0

NV Media Card Data

00.029

Previously Loaded

00.030 Parameter copying

00.031 Drive Rated Voltage

Maximum Heavy Duty

00.032

Rating

Catch A Spinning Motor

00.033

Motor Parameter Adaptive

Control

00.034 User Security Code

00.035 Serial Mode*

00.036 Serial Baud Rate*

00.037 Serial Address* 1 to 247 1

00.037 Active IP Address** 000.000.000.000 to 255.255.255.255

00.038 Current Controller Kp Gain 0 to 30000 20 150

00.039 Current Controller Ki Gain 0 to 30000 40 2000

00.040 Auto-tune 0 to 2 0 to 3 0 to 4 0

Maximum Switching

00.041

Frequency

00.042 Number Of Motor Poles Automatic (0) to 480 Poles (240) Automatic (0)

OL RFC-A RFC-S OL RFC-A RFC-S

4-20 mA Low (-4), 20-4 mA Low (-3),

4-20 mA Hold (-2), 20-4 mA Hold (-1),

0-20 mA (0), 20-0 mA (1), 4-20 mA Trip (2),

20-4 mA Trip (3), 4-20 mA (4), 20-4 mA (5),

Volt (6), Therm Short Cct (7), Thermistor (8),

±VM_SPEED_

FREQ_REF Hz

±VM_SPEED_

FREQ_REF Hz

None (0), Read (1), Program (2),

200 V (0), 400 V (1), 575 V (2),

Disable (0),

Enable (1), Fwd

Only (2), Rev

Only (3)

8 2 NP (0), 8 1 NP (1), 8 1 EP (2), 8 1 OP (3),

8 2 NP M (4), 8 1 NP M (5), 8 1 EP M (6),

8 1 OP M (7), 7 2 NP (8), 7 1 NP (9),

7 1 EP (10), 7 1 OP (11), 7 2 NP M (12),

7 1 NP M (13), 7 1 EP M (14), 7 1 OP M (15)

300 (0), 600 (1), 1200 (2), 2400 (3), 4800 (4),

9600 (5), 19200 (6), 38400 (7), 57600 (8),

2 kHz (0), 3 kHz (1), 4 kHz (2), 6 kHz (3),

8 kHz (4), 12 kHz (5), 16 kHz (6)

Range Default

Volt (6)

Therm No Trip (9)

0.0 to 4000.0 rpm

0 to 40000 rpm

0 to 50000 rpm

1 to 100000 1024 4096

0 to 999

Auto (3), Boot (4)

690 V (3)

0.000 to 99999.999 A

Disable

0 to 2 0

0 to 231-1

76800 (9), 115200 (10)

Volt ( 6)

Volt ( 6)

0.0

0.0

0.0

0.0

None (0)

(0)

0

8 2 NP (0)

19200 (6)

3 kHz (1) 6 kHz (3)

6 Poles

(3)

Typ e

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RW

RO

RW

RO

RO

RW

RW

RW

RW

RW

RW

RO

RW

RW

RW

RW

RW

Safety information Introduction Control connections Getting started

1

Basic parameters

(Menu 0)

Running the motor Further information

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 27

Issue Number: 2

Page 28

Parameter

Rated Power Factor 0.000 to 1.000 0.850

00.043

Position Feedback Phase

Angle

00.044 Rated Voltage ±VM_AC_VOLTAGE_SET

Uni M: Rated Speed

00.045

Uni HS: Rated Speed

Motor Thermal Time

Constant 1

00.046 Rated Current ±VM_RATED_CURRENT

Uni M: Rated Frequency 0.0 to 550.0 Hz

00.047

Uni HS: Rated Frequency 0.0 to 3000 Hz

00.048 Drive Mode

00.049 User Security Status

00.050 Software Version 0 to 99999999

00.051 Action On Trip Detection 0 to 31 0

Reset Serial

00.052

Communications*

1

RW = Read Write, RO = Read Only.

OL RFC-A RFC-S OL RFC-A RFC-S

0 to

33,000 rpm

0 to

180,000 rpm

Read-only Menu 0 (2), Read-only (3),

Range Default

0.0 to 359.9 °

50 Hz default 400 V drive: 400 V

60 Hz default 400 V drive: 460 V

0.00 to

33,000.00

rpm

0 to

50,000 rpm

1.0 to

3000.0 s

0.0 to

1667 Hz

Open-loop (1), RFC-A (2),

RFC-S (3), Regen (4)

Menu 0 (0), All Menus (1),

Status Only (4), No Access (5)

Off (0) or On (1) Off (0)

50Hz

default:

1500 rpm

60Hz

default:

1800rpm

Maximum Heavy Duty Rating

50Hz default: 50.0 Hz

60Hz default: 60.0 Hz

Open-loop

200 V drive: 230 V

575 V drive: 575 V

690 V drive: 690 V

(1)

Menu 0 (0)

* Only applicable to Unidrive M701/HS71.

** Only applicable to Unidrive M700/HS70.

50Hz

default:

1450 rpm

60Hz

default:

1750rpm

(11.032)

RFC-A

(2)

89.0 s

RFC-S

(3)

Typ e

RW

RW

RW

RW

RW

RW

RW

RW

RW

RO

RW

RW

1

28 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 29

5.1 Parameter descriptions

5.1.1 Pr mm.000

Pr mm.000 is available in all menus, commonly used functions are provided as text strings in

Pr mm.000 shown in Table 5-1. The functions in Table 5-1 can also be selected by entering the

appropriate numeric values (as shown in Table 5-2) in Pr mm.000. For example, enter 7001 in

Pr mm.000 to erase the file in NV media card location 001.

Table 5-1 Commonly used functions in Pr mm.000

String Action

Save parameters

Load file 1 Load the drive parameters or user program file from NV media card file 001

Save to file 1 Transfer the drive parameters to parameter file 001

Load file 2 Load the drive parameters or user program file from NV media card file 002

Save to file 2 Transfer the drive parameters to parameter file 002

Load file 3 Load the drive parameters or user program file from NV media card file 003

Save to file 3 Transfer the drive parameters to parameter file 003

Show non-default Displays parameters that are different from defaults

Destinations Displays parameters that are set

Reset 50 Hz Defs Load parameters with standard (50 Hz) defaults

Reset 60 Hz Defs Load parameters with US (60 Hz) defaults

Reset modules Reset all option modules

Read Enc.NP P1 Transfer electronic nameplate motor parameters to the drive from the P1 encoder

Read Enc.NP P2 Transfer electronic nameplate motor parameters to the drive from the P2 encoder

Save parameters when under voltage is not active and low voltage threshold is not

active

Safety information Introduction Control connections Getting started

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 29

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 30

Table 5-2 Functions in Pr mm.000

Value Action

Save parameters when Under Voltage Active (Pr 10.016) is not active and Low Under Voltage

1000

Threshold Select mode (Pr 06.067 = Off) is not active.

1001 Save parameter under all conditions

1070 Reset all option modules

1233 Load standard (50 Hz) defaults

1234 Load standard (50 Hz) defaults to all menus except option module menus (i.e 15 to 20 and 24 to 28)

1244 Load US (60 Hz) defaults

1245 Load US (60 Hz) defaults to all menus except option module menus (i.e 15 to 20 and 24 to 28)

1253 Change drive mode and load standard (50 Hz) defaults

1254 Change drive mode and load US (60 Hz) defaults

1255 Change drive mode and load standard (50 Hz) defaults except for menus 15 to 20 and 24 to 28

1256 Change drive mode and load US (60 Hz) defaults except for menus 15 to 20 and 24 to 28

1299 Reset {Stored HF} trip.

Create a boot file on a non-volatile media card based on the present drive parameters including all

2001*

Menu 20 parameters

4yyy* NV media card: Transfer the drive parameters to parameter file xxx

5yyy* NV media card: Transfer the onboard user program to onboard user program file xxx

NV media card: Load the drive parameters from parameter file xxx or the onboard user program from

6yyy*

onboard user program file xxx

7yyy* NV media card: Erase file xxx

8yyy* NV Media card: Compare the data in the drive with file xxx

9555* NV media card: Clear the warning suppression flag

9666* NV media card: Set the warning suppression flag

9777* NV media card: Clear the read-only flag

9888* NV media card: Set the read-only flag

9999* NV media card: Erase and format the NV media card

Transfer electronic nameplate motor object parameters from the drive to an encoder connected to the

110 S0

drive or an option module.

Transfer electronic nameplate motor objects parameters from an encoder connected to the drive or

110 S1

option module to the drive parameters.

110S2 As 110S0, but for performance object 1

110S3 As 110S1, but for performance object 1

110S4 As 110S0, but for performance object 2

110S5 As 110S1, but for performance object 2

Transfer electronic nameplate motor object parameters from the drive to an encoder connected to the

110 S6

drive or an option module in the Unidrive SP format.

12000**

12001**

Only display parameters that are different from their default value. This action does not require a drive

reset.

Only display parameters that are used to set-up destinations (i.e. DE format bit is 1). This action does

not require a drive reset.

15xxx*

Transfer the user program in an option module installed in slot 1 to a non-volatile media card file xxx

16xxx*

Transfer the user program in an option module installed in slot 2 to a non-volatile media card file xxx

17xxx*

Transfer the user program in an option module installed in slot 3 to a non-volatile media card file xxx

18xxx*

Transfer the user program from file xxx in a non-volatile media card to an option module installed in slot 1.

19xxx*

Transfer the user program from file xxx in a non-volatile media card to an option module installed in slot 2.

20xxx*

Transfer the user program from file xxx in a non-volatile media card to an option module installed in slot 3.

21xxx*

Transfer the user program in an option module installed in slot 4 to a non-volatile media card file xxx.

22xxx*

Transfer the user program from file xxx in a non-volatile media card to an option module installed in slot 4.

* See section 4.13 NV Media Card operation on page 22 for more information on these functions.

** These functions do not require a drive reset to become active. All other functions require a drive

reset to initiate the function.

30 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 31

Safety information Introduction Control connections Getting started

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 31

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 32

Figure 5-1 Menu 0 logic diagram

Analog

Input 2

Mode

00.019

5

6

7

Analog reference

Keypad reference

00.XXX

00.XXX

Key

Read-write

(RW)

parameter

Read-only

(RO)

parameter

Input

terminals

Output

terminals

X

X

X

X

The parameters are all shown in their default settings

00.024

00.025

00.026

00.027

Preset

Frequency 1

Preset

Frequency 2

Preset

Frequency 3

Preset

Frequency 4

Preset frequency

reference

Analog

Reference 2

+

+

00.020

??.??

Any

unprotected

variable

parameter

??.??

01.037

Analog

Input 2

Destination

00.013

28

29

0

1

2

3

4

5

Precision reference

Analog

Input 2

Offset Trim

Open Loop only

00.024

Bipolar

Reference

Select

00.028

Enable Forward /

Reverse Key

00.023

Jog Reference

A1.A2

A1.Preset

A2.Preset

Preset

Keypad

Precision

6

01.015

01.050

Pr

set

01.050

>1

Keypad Ref

32 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 33

Safety information Introduction Control connections Getting started

OL> FREQUENCY

SPEED

TORQUE

Motor

control

Speed-Loop

Proportional

Gain

OL> Catch A

Spinning Motor

RFC-A, RFC-S

> Motor Full

Load Rated Speed

Autotune

Motor

Speed

00.033

00.006

00.007

Speed-Loop

Integral

Gain

00.008

Speed-Loop

Derivative

Gain

00.009

00.010

9 10

15 way sub-D

connector

24

AT ZERO SPEED

Current

Limit

Number Of Poles

PowerFactor

RatedVoltage

Rated Speed

Rated Current

Rated Frequency

00.042 ~ 00.047

Motor

parameters

Power stage

VoltageMode

Selector

Dynamic

V/f

Select

00.007

Boost Voltage

00.008

00.009

OL>

Motor-voltage control

Estimated

Motor

Speed

00.010

_

+

L1 L2 L3

_

+

U V W

Resistor

optional

Drive

RUN

FORWARD

RUN

REVERSE

RESET

Minimum

Frequency/

Speed

Clamp

00.001

00.002

26 27

25

Ramps

Acceleration

Rate

Deceleration

Rate

Ramp Mode

Selector

00.003

00.004

00.015

RFC-A, RFC-S modes only

000.16

Maximum

Frequency/

Speed

Clamp

Ramp

Enable

Analog outputs Digital output

00.027

00.026

Drive Encoder

PPR

Overspeed

Threshold

00.041

00.011

Maximum Switching

Frequency

Output Frequency

SV> Motor Thermal

Time Constant

00.014

Torque Mode

Selector

00.017

Current Demand

Filter Time

Constant

RFC-A,

RFC-S>

00.013

00.012

RFC-A

RFC-S

Torque

Producing

Current

Current

Magnitude

Magnetising

Current

+ BR

_

RFC-A,

RFC-S

RFC-A, RFC-S>

Speed

Estimator

RFC-A}

RFC-S}

Sensorless

00.027

00.026

RFC-A / S,

RFC-A / S - Sensorless

Speed loop gains

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 33

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor Further information

Page 34

6 Running the motor

WARNING

CAUT ION

CAUT ION

WARNING

This chapter takes the new user through all the essential steps to running a motor for the first time, in

each of the possible operating modes.

Ensure that no damage or safety hazard could arise from the motor starting unexpectedly.

The values of the motor parameters affect the protection of the motor.

The default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 Rated Current. This affects the

thermal protection of the motor.

If the drive is started using the keypad it will run to the speed defined by the Keypad

Control Mode Reference (01.017). This may not be acceptable depending on the

application. The user must check in Pr 01.017 and ensure that the keypad reference has

been set to 0.

If the intended maximum speed affects the safety of the machinery, additional

independent over-speed protection must be used.

6.1 Quick start Connections

6.1.1 Basic requirements

This section shows the basic connections which must be made for the drive to run in the required

mode. For minimal parameter settings to run in each mode please see the relevant part of the Drive

User Guide.

Table 6-1 Minimum control connection requirements for each control mode

Drive control method Requirements

Drive enable

Terminal mode

Keypad mode Drive enable

Communications

Speed / Torque reference

Run forward / Run reverse

Drive enable

Communications link

Table 6-2 Minimum control connection requirements for each mode of operation

Operating mode Requirements

Open loop mode Induction motor

RFC-A mode (with position feedback) Induction motor with position feedback

RFC-S mode (with position feedback) Permanent magnet motor with position feedback

34 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 35

Figure 6-1 Minimum connections to get the motor running in any operating mode (size 4

AA

BB

UU

VV

WW

ZZ

1

AA

BB

ZZ

1

E E

Induction

motor

RFC-S

1

2

Marker pulse optional

Thermal overload for braking resistor

to protect against fire risk.

This must be

wired to interrupt the

AC supply in the

event of a fault.This is not required if the

optional internal braking resistor is used

T

e

r

m

i

n

a

l

M

o

d

e

K

e

y

p

a

d

M

o

d

e

Communications

port*

Keypad

Optional item, must

be installed

for keypad mode

L1 L2 L3

Fuses

L1 L2 L3UVW

UVW

Servo motor

(permanent

magnet)

2

!

+

_

BR

Braking resistor

(optional)

Position feedback

connector 15 way D-type**

5

10

15

1

6

11

UVW

RFC-A

Open loop

10

11

8

9

6

7

4

5

3

Speed

reference

input

RUN FWD

RUN REV

24V

0V

+10V

2

1

30

31

28

29

26

27

24

25

23

21

22

SAFE TORQUE OFF

(drive enable)

4

RFC-A

Sensorless

RFC-S

Sensorless

illustrated)

Safety information Introduction Control connections Getting started

* Ethernet fieldbus communication ports on Unidrive M700/HS70 and 485 serial communication ports

on Unidrive M701.

** Position feedback port (refer to Table 3-1 P1 position feedback connection details on page 9).

Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide 35

Issue Number: 2

Basic parameters

(Menu 0)

Running the motor

Further information

Page 36

6.2 Quick Start / start-up

Mot X XXXXXXXXX

No XXXXXXXXXX kg

IP55 I.cl F C 40 s S1

°

VHzmin-1kW cosφA

230

400

50 1445 2.20 0.80 8.50

4.90

CN = 14.5Nm

240

415

50 1445 2.20 0.76 8.50

4.90

CN = 14.4Nm

CTP- VEN 1PHASE 1=0,46A P=110W R.F 32MN

I.E.C 34 1(87)

0.02

t

100Hz

0.03

t

0.04

A rotating autotune will cause the motor to accelerate up to 2/3

base speed in the direction selected regardless of the

reference provided. Once complete the motor will coast to a

stop. The enable signal must be removed before the drive can

be made to run at the required reference.

WARNING

cos

∅

σ

L

S

R

S

6.2.1 Open loop

Action Detail

Before

power-up

Ensure:

• The drive enable signal is not given (terminal 31)

• Run signal is not given

• Motor is connected

Power-up

the drive

Enter motor

nameplate

details

Set max

frequency

Set accel. /

decel. rates

Motor

thermistor

set-up

Autotune

Save

parameters

Verify that Open Loop mode is displayed as the drive powers up.

Ensure: Drive displays ‘Inhibit’

Enter:

• Motor rated frequency in Pr 00.047 (Hz)

• Motor rated current in Pr 00.046 (A)

• Motor rated speed in Pr 00.045 (rpm)

• Motor rated voltage in Pr 00.044 (V) - check if or connection

Enter:

• Maximum frequency in Pr 00.002 (Hz)

• Acceleration rate in Pr 00.003 (s /100 Hz)

• Deceleration rate in Pr 00.004 (s /100 Hz) (If braking resistor installed,

set Pr 00.015 = FAST. Also ensure Pr 10.030, Pr 10.031 and

Pr 10.061 are set correctly, otherwise premature ‘Brake R Too Hot’

trips may be seen).

If a thermistor is connected to terminal 8, then the Analog Input 3 Mode

(07.015) parameter must be set to Thermistor Short Cct (7), Thermistor

(8) or Therm No Trip (9).

The drive is able to perform either a stationary or a rotating autotune. The

motor must be at a standstill before an auto-tune is enabled. A rotating

autotune should be used whenever possible so the measured value of

power factor of the motor is used by the drive

To perform an autotune:

•Set Pr 00.040 = 1 for a stationary autotune or set Pr 00.040 = 2 for a

rotating autotune

• Close the Drive Enable signal (terminal 31). The drive will display

’Ready’.

• Close the run signal (terminal 26 or 27). The lower display will flash

’Autotune’ while the drive is performing the autotune.

• Wait for the drive to display ’Ready’ or ‘Inhibit’ and for the motor to

come to a standstill.

• Remove the drive enable and run signal from the drive.

Select 'Save Parameters' in Pr mm.000 (alternatively enter a value of

1000 in Pr mm.000) and press red reset button or toggle the reset

digital input.

Run Drive is now ready to run

36 Unidrive M700/M701 / Unidrive HS70/HS71 Control Getting Started Guide

Issue Number: 2

Page 37

6.2.2 RFC-A mode (with position feedback)

If output voltage from the encoder is >5 V, then the

termination resistors must be disabled Pr 03.039 to 0.

NOTE

Setting the encoder voltage supply too high for the encoder

could result in damage to the feedback device.

CAUT ION

The thermistor input will be disabled until Pr 07.015 is set to

one of the above.

NOTE

Mot X XXXXXXXXX

No XXXXXXXXXX kg

IP55 I.cl F C 40 s S1

°

VHzmin-1kW cosφA

230

400

50 1445 2.20 0.80 8.50

4.90

CN = 14.5Nm

240

415

50 14452.20 0.76 8.50

4.90

CN = 14.4Nm

CTP- VEN 1PHASE 1=0,46A P=110W R.F 32MN

I.E.C 34 1(87)

0.02

t

1000rpm

0.03

t

0.04

Induction motor with position feedback

For simplicity only an incremental quadrature encoder will be considered here. For information on

setting up one of the other supported speed feedback devices, refer to Setting up a feedback device

in the Drive User Guide.

Action Detail

Before

power-up

Power-up

the drive

Ensure:

• Drive Enable signal is not given (terminal 31)

• Run signal is not given

• Motor and feedback device are connected

• Verify that RFC-A mode is displayed as the drive powers up. If the

mode is incorrect see section 4.7 Changing the operating mode on

page 20.

Ensure: Drive displays ‘Inhibit’

Incremental encoder basic set-up

Enter:

• Drive encoder type in Pr 03.038 = AB (0): Quadrature encoder

• Encoder power supply in Pr. 03.036 = 5 V (0), 8 V (1) or 15 V (2).

Safety information Introduction Control connections Getting started

Set motor

feedback

parameters

Motor

thermistor

set-up

Enter motor

nameplate

details

Set max

speed

Set accel /

decel rates

• Drive encoder Lines Per Revolution (LPR) in Pr 03.034

• Drive encoder termination resistor setting in Pr 03.039:

0 = A-A\, B-B\, Z-Z\ termination resistors disabled

1 = A-A\, B-B\, termination resistors enabled, Z-Z\ termination

resistors disabled

2 = A-A\, B-B\, Z-Z\ termination resistors enabled

If a thermistor is connected to terminal 8, then the Analog Input 3 Mode

(07.015) parameter must be set to Thermistor Short Cct (7), Thermistor

(8) or Therm No Trip (9).

• Motor rated frequency in Pr 00.047 (Hz)

• Motor rated current in Pr 00.046 (A)

• Motor rated speed in Pr 00.045 (rpm)

• Motor rated voltage in Pr 00.044 (V) - check if or connection

Enter:

• Maximum speed in Pr 00.002 (rpm)

Enter:

• Acceleration rate in Pr 00.003 (s/1000 rpm)

• Deceleration rate in Pr 00.004 (s/1000 rpm) (If braking resistor