Emerson unidrive m300 Quick Start Manual

Quick Start Guide

Unidrive M300

Frame sizes 1 to 4

Enhance throughput with

Machine Safety

Part Number: 0478-0039-05

Issue: 5

This guide is intended to provide basic information required in order to set-up a drive to run a motor.

WARNING

CAUT ION

NOTE

WARNING

For more detailed installation information, please refer to the Unidrive M300 User Guide which is

available to download from:

www.controltechniques.com/userguides or www.emersonindustrial.com/en-EN/leroy-somer-motorsdrives/downloads/Pages/manuals.aspx

Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

This guide does not include safety information. Incorrect installation or operation of the

drive, could cause personnel injury or equipment damage. For essential safety

information, please refer to the Unidrive M300 User Guide or the safety booklet supplied

with the drive.

Copyright © July 2014

Issue Number: 5

Contents

1 Product information ....................................................................................7

1.1 Ratings .................................................................................................................... 7

2 Options .........................................................................................................8

3 Mechanical installation ...............................................................................9

4 Electrical installation .................................................................................11

4.1 AC supply requirements ........................................................................................11

4.2 External braking resistor ........................................................................................ 11

4.3 Ground leakage ..................................................................................................... 12

4.4 Control terminal configurations and wiring ............................................................. 14

4.5 EMC ....................................................................................................................... 20

4.6 SAFE TORQUE OFF (STO) .................................................................................. 21

5 Keypad and display ...................................................................................22

5.1 Saving parameters ................................................................................................ 23

5.2 Restoring parameter defaults ................................................................................ 23

6 Basic parameters (Menu 0) ....................................................................... 24

6.1 Menu 0: Basic parameters ..................................................................................... 24

7 Running the motor .................................................................................... 30

8 NV Media Card Operation .........................................................................31

9 UL listing information ...............................................................................32

9.1 General ..................................................................................................................32

9.2 Mounting ................................................................................................................ 32

9.3 Environment .......................................................................................................... 32

9.4 Electrical ratings .................................................................................................... 32

9.5 Opening of branch circuit .......................................................................................32

9.6 Electrical installation .............................................................................................. 32

9.7 cUL requirements for frame size 4 ......................................................................... 33

9.8 Motor overload protection ......................................................................................33

9.9 Motor overspeed protection ................................................................................... 33

9.10 Thermal memory retention ..................................................................................... 33

9.11 Group installation ................................................................................................... 34

9.12 UL listed accessories ............................................................................................. 34

Unidrive M300 Quick Start Guide

Issue Number: 5

Declaration of Conformity

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration applies to Unidrive M variable speed drive products, comprising models numbers as shown below:

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

Maaa-bbcddddd Valid characters:

aaa 100, 101, 200, 201, 300, 400

bb

c 1, 2, 4, 5 or 6

ddddd

01, 02, 03, 04, 05, 06, 07, 08

00017, 00024, 00033, 00042

00013, 00018, 00023, 00024, 00032, 00033, 00041, 00042, 00056, 00075

00056, 00073, 00094, 00100

00133, 00135, 00170, 00176

00030, 00040, 00069, 00250, 00270, 00300

00100, 00150, 00190, 00230, 00290, 00330, 00350, 00420, 00440, 00470

00190, 00240, 00290, 00380, 00440, 00540, 00550, 00610, 00660, 00750, 00770, 00830,

01000

00630, 00860, 01160, 01320, 01340, 01570

The AC variable speed drive products listed above have been designed and manufactured in accordance with the

following European harmonized standards:

EN 61800-5-1:2007

EN 61800-3:2004

EN 61000-6-2:2005

EN 61000-6-4:2007

EN 61000-3-2:2006

EN 61000-3-3:2008

Adjustable speed electrical power drive systems - safety requirements electrical, thermal and energy

Adjustable speed electrical power drive systems. EMC product standard

including specific test methods

Electromagnetic compatibility (EMC). Generic standards. Immunity

standard for industrial environments

Electromagnetic compatibility (EMC). Generic standards. Emission

standard for industrial environments

Electromagnetic compatibility (EMC), Limits, Limits for harmonic current

emissions (equipment input current <16 A per phase)

Electromagnetic compatibility (EMC), Limits, Limitation of voltage

fluctuations and flicker in low-voltage supply systems for equipment with

rated current <16 A

EN 61000-3-2:2006 Applicable where input current <16 A. No limits apply for professional equipment where input

power >1 kW.

4 Unidrive M300 Quick Start Guide

Issue Number: 5

These products comply with the Low Voltage Directive 2006/95/EC, the Electromagnetic Compatibility Directive

T. Alexander

VP Technology

Date: 29th May 2014

Place: Newtown, Powys. UK

2004/108/EC.

These electronic drive products are intended to be used with appropriate motors, controllers,

electrical protection components and other equipment to form complete end products or

systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters. The drives must be

installed only by professional assemblers who are familiar with requirements for safety and

EMC. The assembler is responsible for ensuring that the end product or system complies

with all the relevant laws in the country where it is to be used. Refer to the User Guide. An

EMC Data Sheet is also available giving detailed EMC information.

Declaration of Conformity (including 2006 Machinery Directive)

This declaration applies to Unidrive M variable speed drive products, comprising models numbers as shown below:

Maaa-bbbbbbbbb Valid characters:

aaa 300, 400

01100017A, 01100024A, 01200017A, 01200024A, 01200033A, 01200042

02100042A, 02100056A, 02200024A, 02200033A, 02200042A, 02200056A, 02200075A,

02400013A, 02400018A, 02400023A,

02400032A, 02400041A

03200100A, 03400056A, 03400073A, 03400094A

04200133A, 04200176A, 04400135A, 04400170A

bbbbbbbbb

This declaration relates to these products when used as a safety component of a machine. Only the SAFE

TORQUE OFF function may be used for a safety function of a machine. None of the other functions of the

drive may be used to carry out a safety function.

These products fulfil all the relevant provisions of Directive 2006/42/EC (The Machinery Directive).

EC type-examination has been carried out by the following notified body:

TÜV Rheinland Industrie Service GmbH

Alboinstraße 56

12103 Berlin, Germany

05200250A, 05400270A, 05400300A, 05500030A, 05500040A, 05500069A

06200330A, 06200440A, 06400350A, 06400420A, 06400470A, 06500100A, 06500150A,

06500190A, 06500230A, 06500290A,

06500350A

07200610A, 07200750A, 07200830A, 07400660A, 07400770A, 07401000A, 07500440A,

07500550A, 07600190A, 07600240A,

07600290A, 07600380A, 07600440A, 07600540A

08201160A, 08201320A, 08401340A, 08401570A, 08500630A, 08500860A, 08600630A,

08600860A

Notified Body identification number: 0035

EC type-examination certificate number: 01/205/5383.00/14 and 01/205/5387.00/14

Unidrive M300 Quick Start Guide 5

Issue Number: 5

The harmonised standards used are shown below:

T. Alexander

VP Technology

Date: 9th April 2014

Place: Newtown, Powys. UK

EN 61800-5-1:2007

EN 61800-5-2:2007 Adjustable speed electrical power drive systems. Safety requirements. Functional

EN ISO 13849-1:2008

EN ISO 13849-2:2008 Safety of machinery. Safety-related parts of control systems. Validation

EN 62061:2005

Person authorised to compile the technical file:

C Hargis

Chief Engineer

Newtown, Powys. UK

IMPORTANT NOTICE

These drive products are intended to be used with appropriate motors, sensors, electrical protection

components and other equipment to form complete systems. It is the responsibility of the installer to

ensure that the design of the complete machine, including its safety-related control system, is carried out

in accordance with the requirements of the Machinery Directive and any other relevant legislation. The use

of a safety-related drive in itself does not ensure the safety of the machine.

Compliance with safety and EMC regulations depends upon installing and configuring inverters correctly.

The inverters must be installed only by professional assemblers who are familiar with requirements for

safety and EMC. The assembler is responsible for ensuring that the end product or system complies with

all the relevant laws in the country where it is to be used. Refer to the User Guide.

Adjustable speed electrical power drive systems. Safety requirements. Electrical,

thermal and energy

Safety of machinery. Safety-related parts of control systems. General principles for

design

Safety of machinery. Functional safety of safety related electrical, electronic and

programmable electronic control systems

6 Unidrive M300 Quick Start Guide

Issue Number: 5

1 Product information

NOTE

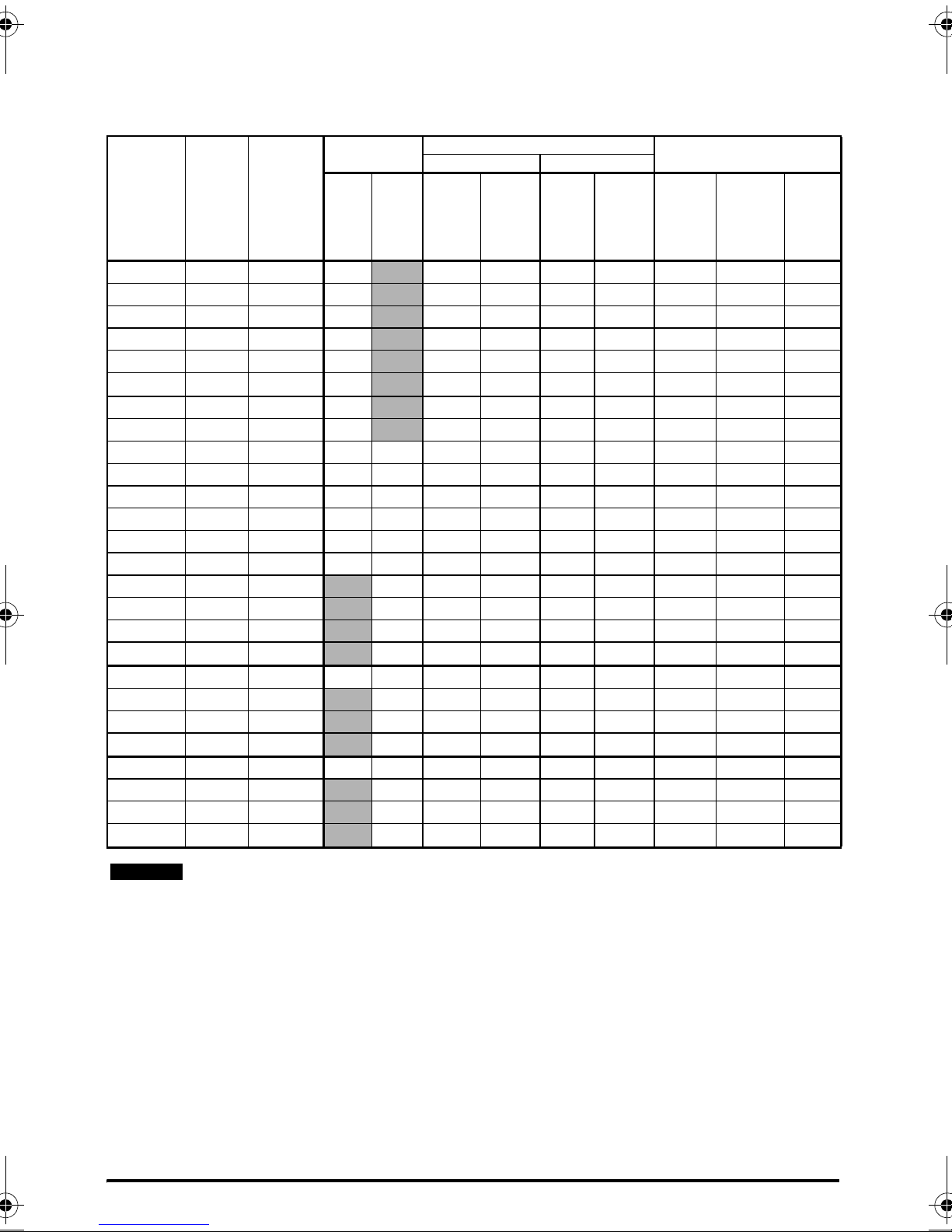

1.1 Ratings

Max input

Max.

Input

Model

01100017 1 8.7 10 1 1 16 16 1.7 0.25 0.33

01100024 1 11.1 16

01200017 1 4.5 6

01200024 1 5.3 6

01200033 1 8.3 10

01200042 1 10.4 16

02100042 1 18.8 20

02100056 1 24 25

02200024 1 / 3 5.3/4.1 6 6 1 1 16 16 2.4 0.37 0.5

02200033 1 / 3 8.3/6.7 10 10 1 1 16 16 3.3 0.55 0.75

02200042 1 / 3 10.4/7.5 16 10 1 1 16 16 4.2 0.75 1

02200056 1 / 3 14.9/11.3 20 15 2.5/1.5 1 12/14 16 5.6 1.1 1.5

02200075 1 / 3 18.1/13.5 20 15 2.5 1 12 16 7.5 1.5 2

02400013 3 2.4 6 1 1 16 16 1.3 0.37 0.5

02400018 3 2.9

02400023 3 3.5

02400032 3 5.1

02400041 3 6.2

03200100 1 / 3 23.9/17.7 25 20 4 1.5 10/12 14 10 2.2 3

03400056 3 8.7

03400073 3 12.2

03400094 3 14.8

04200133 1 / 3 23.7/16.9 25 20 4/2.5 2.5 10 12 13.3 3 3

04200176 3 21.3

04400135 3 16.3

04400170 3 20.7

phases

ph A A A

cont

input

current

fuse rating

1 Ph 3 Ph Input Output Input Output

6 1 1 16 16 1.8 0.55 0.75

6 1 1 16 16 2.3 0.75 1

61 116163.21.11.5

10 1 1 16 16 4.1 1.5 2

10 1 1 14 16 5.6 2.2 3

16 1.5 1 12 16 7.3 3 3

16 2.5 1.5 12 14 9.4 4 5

25 4 2.5 10 12 17.6 4 5

20 2.5 2.5 10 12 13.5 5.5 7.5

25 4 2.5 10 12 17 7.5 10

Nominal cable size

European USA

2

mm

1 1 14 16 2.4 0.37 0.5

1 1 16 16 1.7 0.25 0.33

1 1 16 16 2.4 0.37 0.5

1 1 16 16 3.3 0.55 0.75

1 1 16 16 4.2 0.75 1

2.5 1 12 16 4.2 0.75 1

4 1 10 16 5.6 1.1 1.5

mm

2

AWG AWG A kW hp

Output current

Max.

cont

output

current

Nominal

power

Motor

power

The nominal cable sizes shown in the table above, are provided as a guide only. Ensure

that the cables used conform to the local wiring regulations.

Unidrive M300 Quick Start Guide 7

Issue Number: 4

Figure 1-1 Model number structure

Product line:

Frame size:

Current Rating :

Heavy Duty current rating x10

Drive Format :

A – AC in AC out

Voltage rating

:

1 - 100 V (100 - 120 10 %)±

2 - 200 V (200 - 240 10 %)±

4 - 400 V (380 - 480 10 %)±

5 - 575 V (500 - 575 10 %)±

6 - 690 V (500 - 690 10 %)±

Derivative

Electrical Specifications

M300 - 03 4 00073 A

2Options

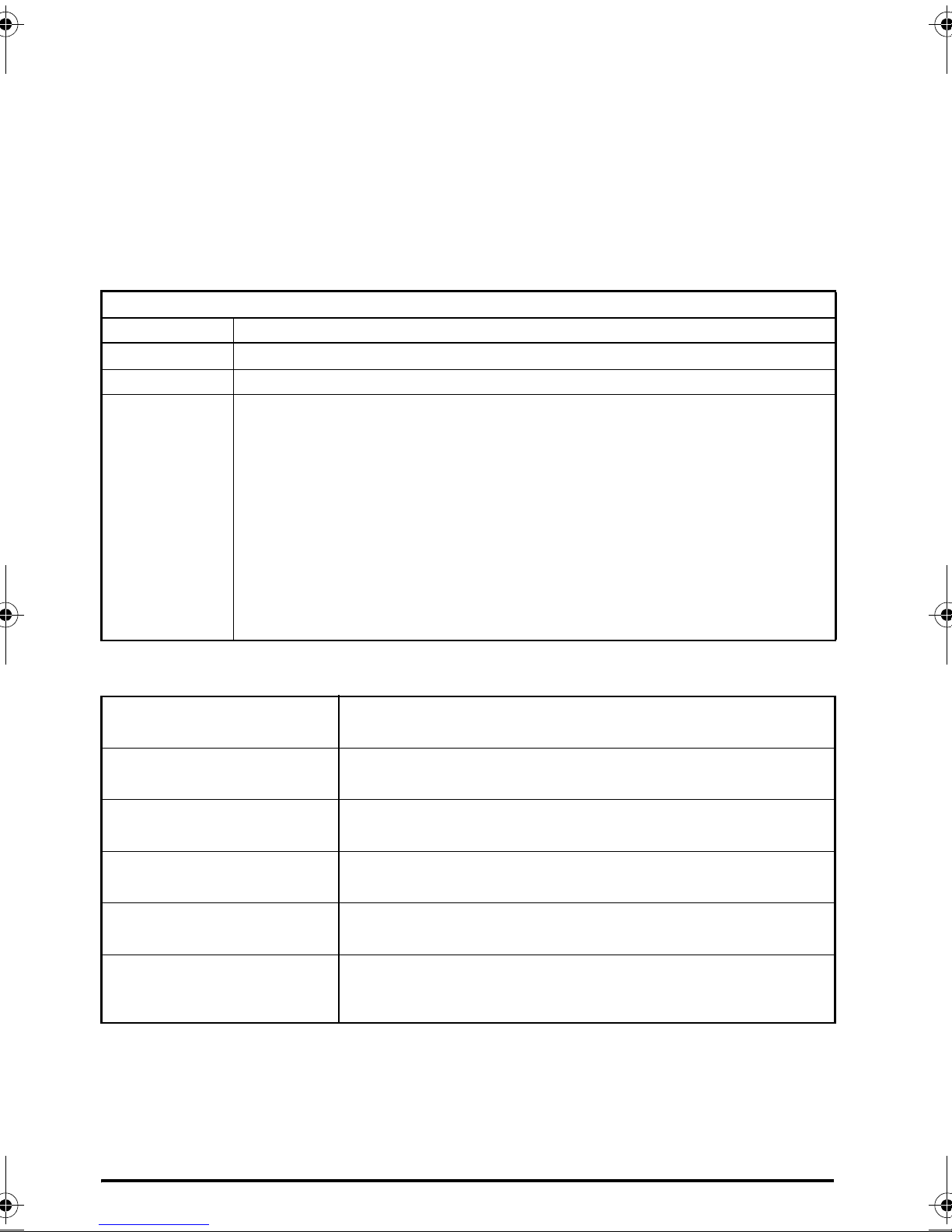

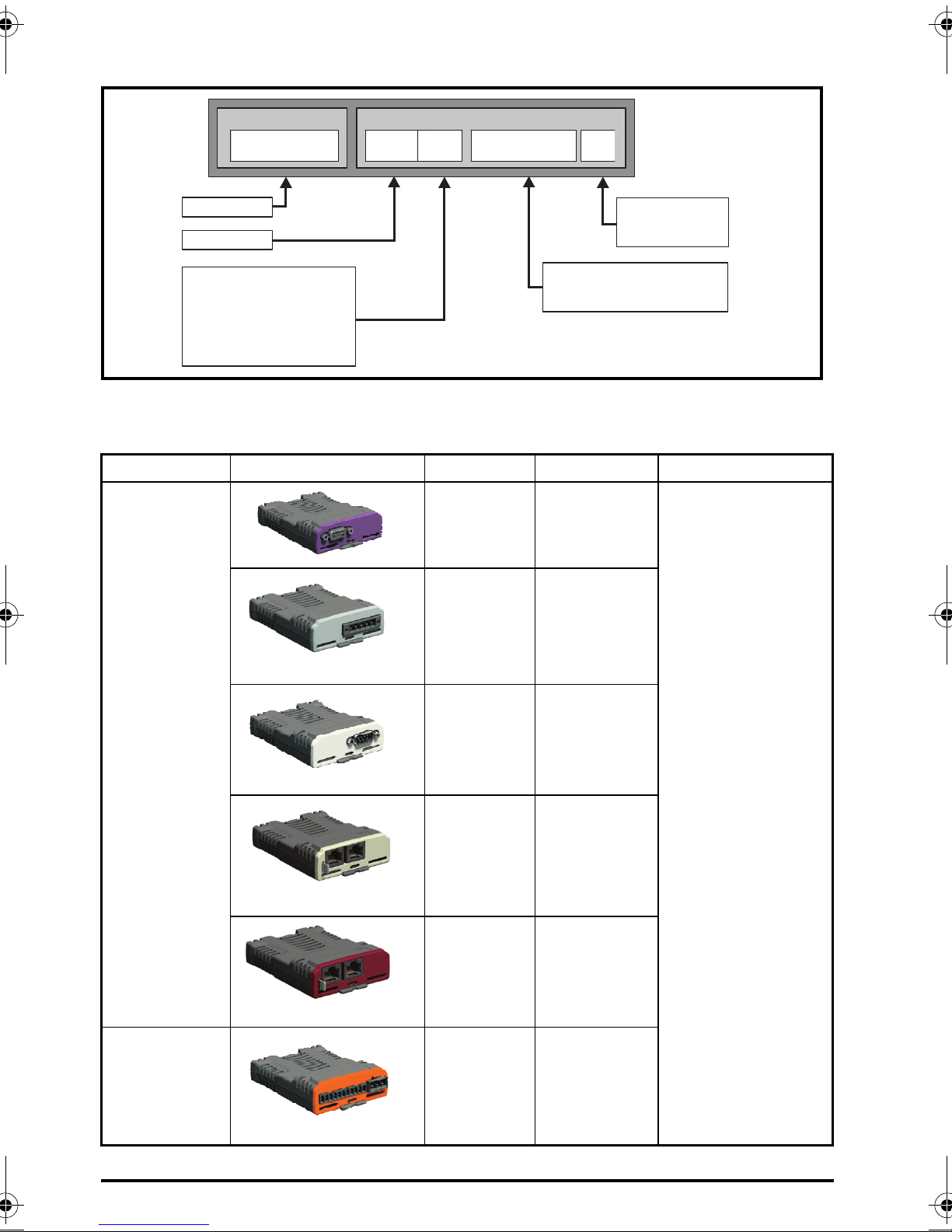

Table 2-1 System Integration (SI) option module identification

Type Option module Color Name Further details

Purple SI-PROFIBUS

Fieldbus

Medium

Grey

Light Grey SI-CANopen

Beige SI-Ethernet

Brown Red SI-EtherCAT

SI-DeviceNet

See relevant option

module User Guide

Automation

(I/O expansion)

8 Unidrive M300 Quick Start Guide

Orange SI-I/O

Issue Number: 4

Table 2-2 Adaptor Interface (AI) option module identification

A

W

M2

M2

B

D

B

A

HM1

Cover

release

Type Option module Name Further Details

Communications AI-485 Adaptor

See Drive User Guide

Backup AI-Backup Adaptor

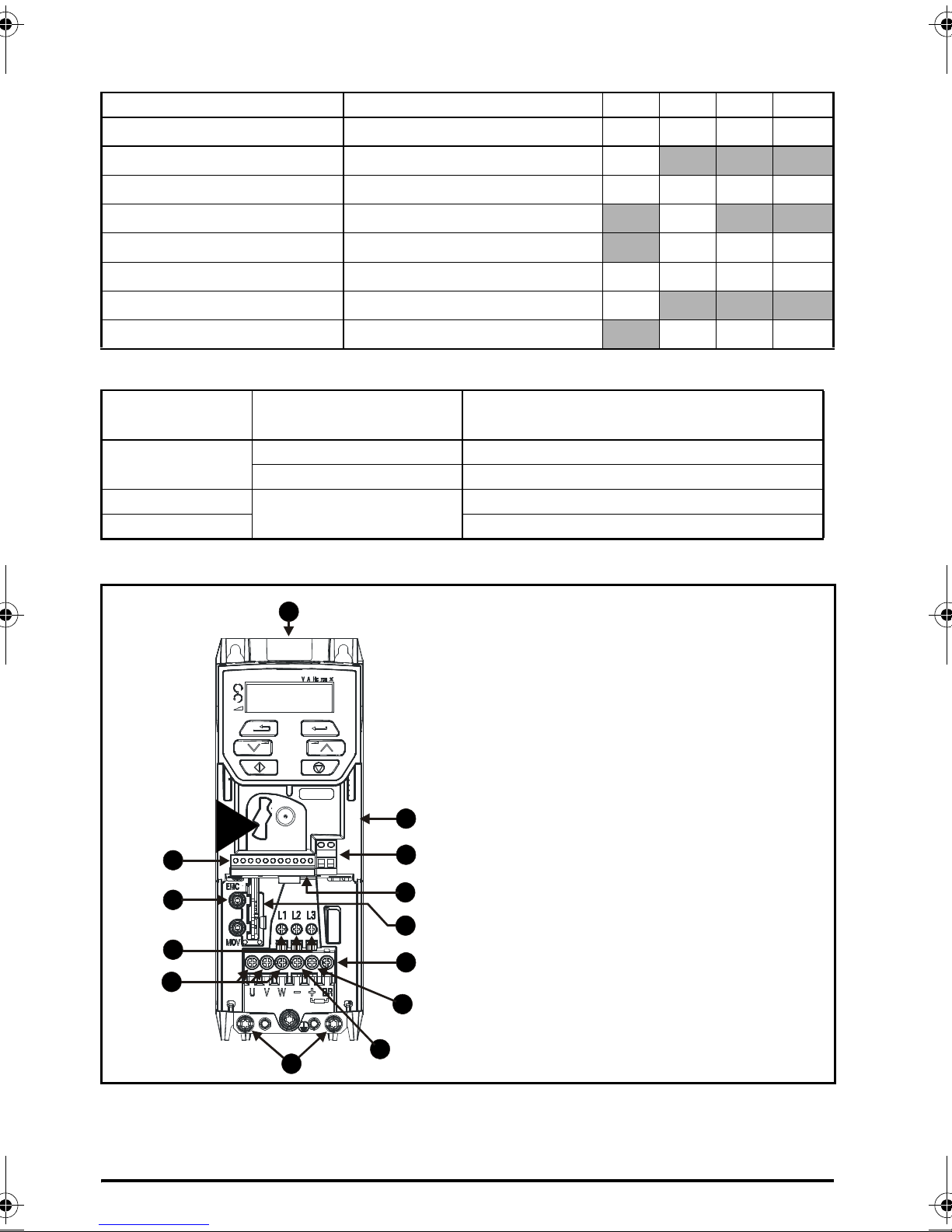

3 Mechanical installation

The drives can be panel mounted with 0 mm space between the drives. For further information on

mechanical installation refer to the Drive User Guide.

To remove the terminal cover, use a flat bladed screwdriver to rotate the terminal cover locating clip

by approximately 30° in a counter clockwise direction, and then slide the cover down.

Drive

Size

1 160 6.30 75 2.95 130 5.12 143 5.70 53 2.08 5 0.2

2 205 8.07 78 3.07 150 5.91 194 7.63 55 2.17 5 0.2

3 226 8.90 90 3.54 160 6.30 215 8.46 70.7 2.80 5 0.2

4 277 10.91 115 4.53 175 6.89 265 10.43 86 3.40 6 0.23

Unidrive M300 Quick Start Guide 9

Issue Number: 4

HWD M1M2∅ AB

mm in mm in mm in mm in mm in mm in mm in mm in

0.00 0.00 100 3.93

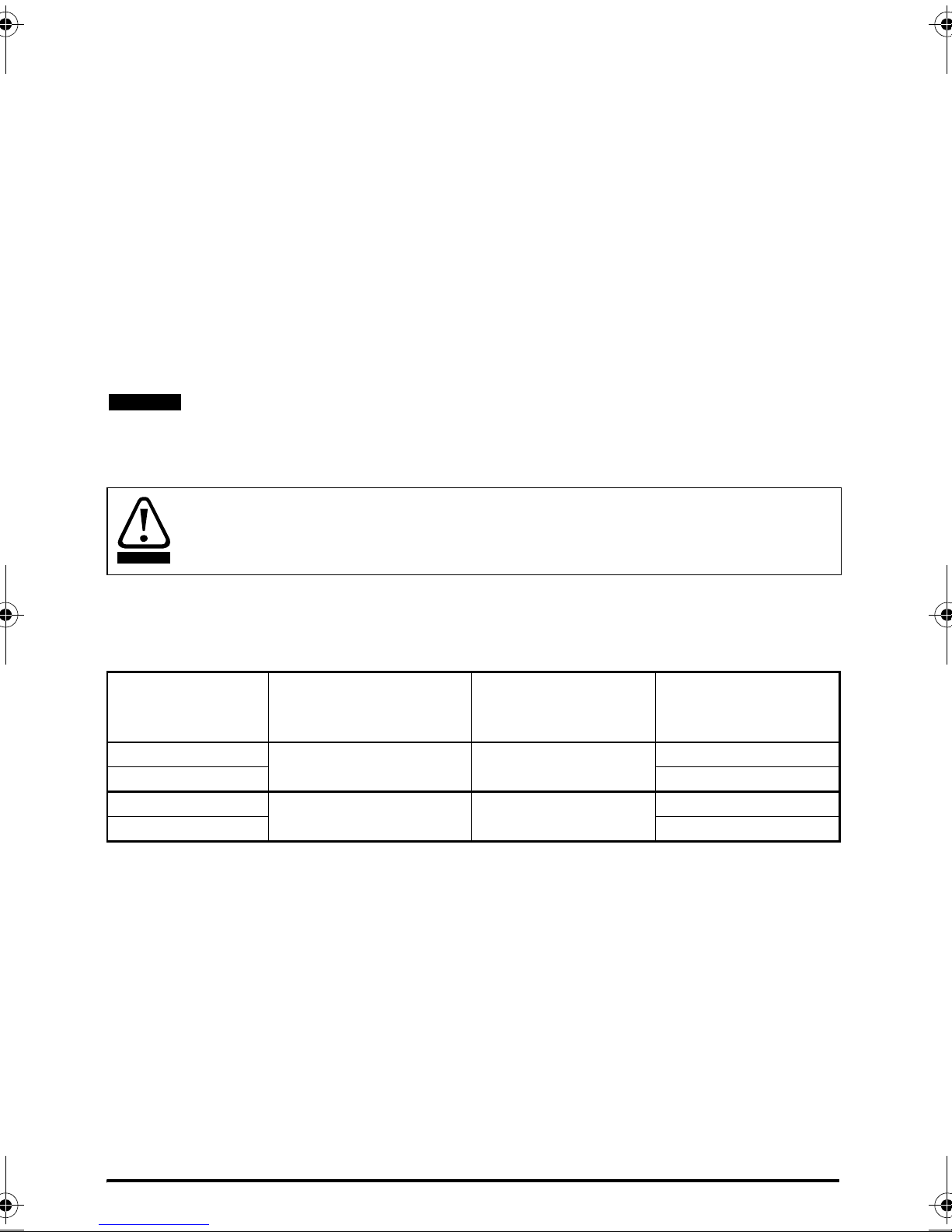

Table 3-1 Tools required

6

8

9

5

7

12

4

1

3

2

11

10

2

13

3

Key

1. Rating label (On side of drive)

2. Identification label

3. Option module connection

4. Relay connections

5. Control connections

6. Braking terminal

7. Internal EMC filter screw

8. DC bus +

9. DC bus -

10. Motor connections

11. AC supply connections

12. Ground connections

13. SAFE TORQUE OFF connections

Tool Location Size 1 Size 2 Size 3 Size 4

Small terminal screwdriver Control, relay and STO terminals

3mm Flat-bladed screwdriver Power terminals

5mm Flat-bladed screwdriver Terminal cover

Pozidrive 1 screwdriver AC power terminals

Pozidrive 2 screwdriver Power terminals

Torx 10 driver EMC & MOV screws

Torx 15 driver Fan screw

Torx 20 driver Fan screw

Table 3-2 Recommended torque settings

Model size

All

1

2, 3, 4 1.4 N m (1.03 Ib ft)

Figure 3-1 Feature diagram (size 2 shown)

Terminal block

description

Control terminals 0.2 N m (0.15 Ib ft)

Relay terminals 0.5 N m (0.37 Ib ft)

Power terminals

9999

9

9999

9

999

9999

9

999

Torque settings

0.5 N m (0.37 Ib ft)

10 Unidrive M300 Quick Start Guide

Issue Number: 4

4 Electrical installation

NOTE

WARNING

An overlay of the electrical connections / terminals is included on the back page of this manual.

4.1 AC supply requirements

Voltage:

100 V drive: 100 V to 120 V ±10 %

200 V drive: 200 V to 240 V ±10 %

400 V drive: 380 V to 480 V ±10 %

Number of phases: 3

Maximum supply imbalance: 2 % negative phase sequence (equivalent to 3 % voltage imbalance

between phases).

Frequency range: 48 to 62 Hz

For UL compliance only, the maximum supply symmetrical fault current must be limited to 100 kA.

On the size 2 110 V drives or when connecting single phase to a dual rated 200 V unit, the

supply should be connected to L1 and L3.

4.2 External braking resistor

Overload protection

When an external braking resistor is used, it is essential that an overload protection device

is incorporated in the braking resistor circuit; as shown in the electrical diagram on the

back cover.

4.2.1 Minimum resistance values and peak power rating for the braking resistor

at 40 °C (104 °F)

Table 4-1 Braking resistor resistance and power rating (100 V)

Minimum

Model

01100017

01100024 0.37

02100042

02100056 1.1

resistance*

Ω

130 1.2

68 2.2

Instantaneous

power rating

kW

Continuous

power rating

kW

0.25

0.75

Unidrive M300 Quick Start Guide 11

Issue Number: 4

Loading...

Loading...