Page 1

Installation Guide

Unidrive M /

Unidrive HS Modular

Model sizes 9 to 11

Universal Variable Speed AC drive

Modular Solutions for induction and

permanent magnet motors

Part Number: 0478-0141-05

Issue: 5

Page 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC

General information

This guide covers the basic information that is required to install the drive, in applications where a drive malfunction does not result in

a mechanical hazard. When the drive is used in a safety related application, i.e. where a malfunction might result in a hazard, it is

essential to refer to this guide and the Control User Guide. The Control User Guide is available for download from:

http://www.emersonindustrial.com/en-EN/controltechniques/downloads/userguidesandsoftware/Pages/downloads.aspx

or

www.emersonindustrial.com/en-EN/leroy-somer-motors-drives/downloads/Pages/manuals.aspx

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect installation or

adjustment of the optional operating parameters of the equipment or from mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous

development and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or

the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical

including photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Drive firmware version

This product is supplied with the latest firmware version. If this drive is to be connected to an existing system or machine, all drive

firmware versions should be verified to confirm the same functionality as drives of the same model already present. This may also

apply to drives returned from an Emerson Industrial Automation Service Centre or Repair Centre. If there is any doubt please contact

the supplier of the product.

The firmware version of the drive can be checked by looking at Pr 11.029

Environmental statement

Emerson Industrial Automation is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is certified to the

International Standard ISO 14001. Further information on the EMS, our Environmental Policy and other relevant information is

available on request, or can be found at:

http://www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/Pages/environment.aspx.

The electronic variable-speed drives manufactured by Emerson Industrial Automation have the potential to save energy and (through

increased machine/process efficiency) reduce raw material consumption and scrap throughout their long working lifetime. In typical

applications, these positive environmental effects far outweigh the negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should instead be

recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to dismantle into their major component

parts for efficient recycling. Many parts snap together and can be separated without the use of tools, while other parts are secured

with conventional fasteners. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller products come

in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these containers can be recycled.

Polythene, used on the protective film and bags for wrapping product, can be recycled in the same way. Emerson Industrial

Automation’s packaging strategy prefers easily-recyclable materials of low environmental impact, and regular reviews identify

opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier

of an article to inform the recipient if it contains more than a specified proportion of any substance which is considered by the European

Chemicals Agency (ECHA) to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for

compulsory authorisation.

For current information on how this requirement applies in relation to specific Emerson Industrial Automation’s products, please

approach your usual contact in the first instance. Emerson Industrial Automation’s position statement can be viewed at:

www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/reachregulation/Pages/reachregulation.aspx.

Copyright © May 2016 Emerson Industrial Automation.

The information contained in this guide is for guidance only and does not form part of any contract. The accuracy cannot be guaranteed

as Emerson have an ongoing process of development and reserve the right to change the specification of their products without notice.

Control Techniques Limited. Registered Office: The Gro, Newtown, Powys SY16 3BE. Registered in England and Wales. Company

Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France. Share Capital: 65

800 512 €, RCS Angoulême 338 567 258.

Issue Number: 5

Drive Firmware: 01.13.02.00

Page 3

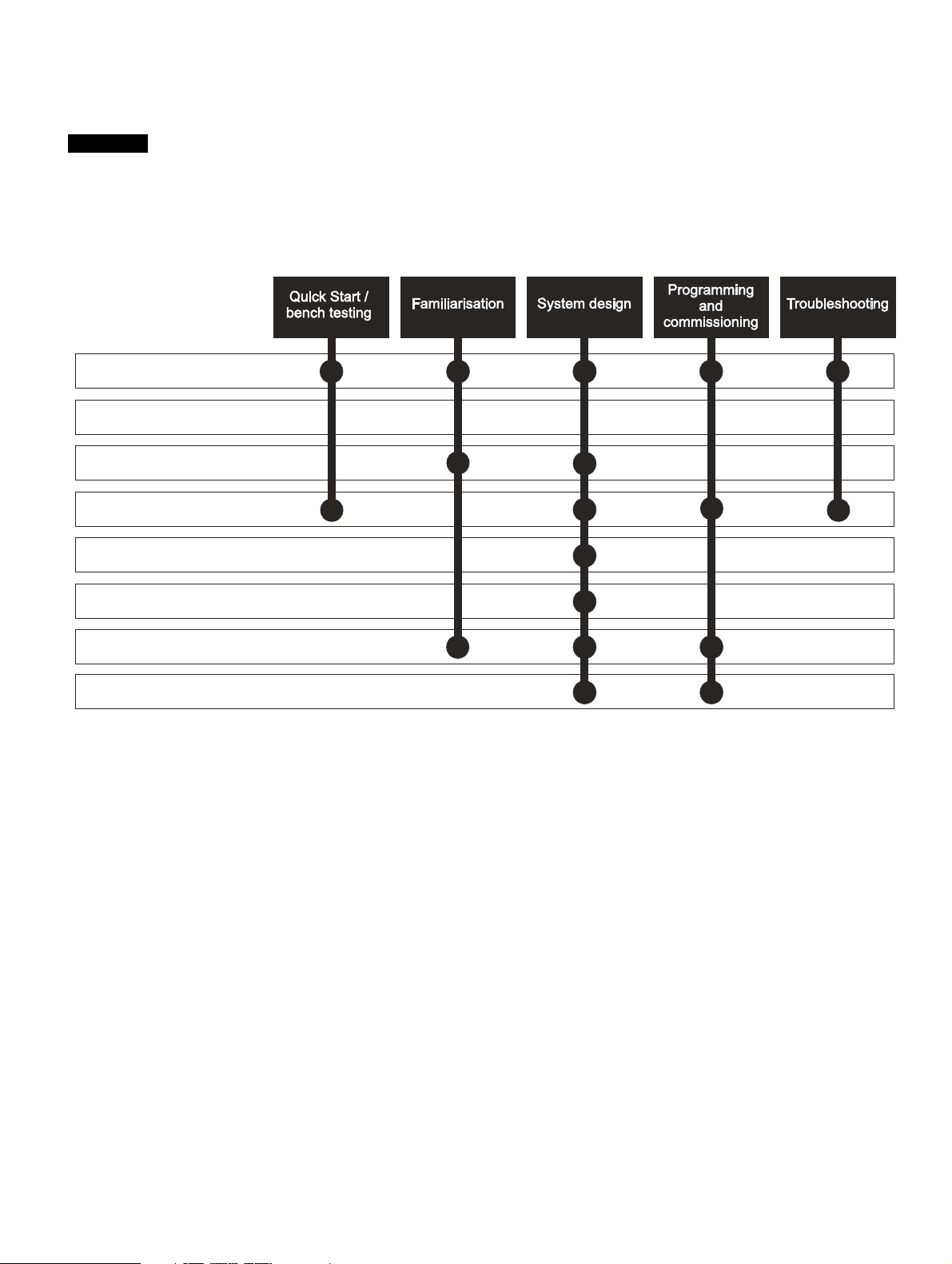

How to use this guide

NOTE

1 Safety information

2 Introduction

3 Product information

4 System configuration

5 Mechanical Installation

6 Electrical installation

7 Technical data

8 UL information

This installation guide provides complete information for installing and operating the drive from start to finish.

The information is in logical order, taking the reader from receiving the drive through to fine tuning the performance.

There are specific safety warnings throughout this guide, located in the relevant sections. In addition, Chapter 1 Safety

information contains general safety information. It is essential that the warnings are observed and the information

considered when working with or designing a system using the drive.

This map of the installation guide helps to find the right sections for the task you wish to complete, but for specific

information, refer to Contents on page 4:

Page 4

Contents

EU Declaration of Conformity ................. 5

EU Declaration of Conformity

(including 2006 Machinery Directive) ..... 6

1 Safety information .................................8

1.1 Warnings, Cautions and Notes .............................8

1.2 Electrical safety - general warning ........................8

1.3 System design and safety of personnel ................8

1.4 Environmental limits ..............................................8

1.5 Access ...................................................................8

1.6 Fire protection .......................................................8

1.7 Compliance with regulations .................................8

1.8 Motor .....................................................................8

1.9 Mechanical brake control ......................................8

1.10 Adjusting parameters ............................................8

1.11 Electrical installation ..............................................9

2 Introduction ..........................................10

2.1 Rectifier ..............................................................10

2.2 Size 9A drives .....................................................11

2.3 Size 9E, 10E and 11E drives ..............................12

2.4 Size 9D, 10D and 11D inverters ..........................13

2.5 Size 9T, 10T and 11T drives ...............................13

2.6 Input line reactor .................................................14

2.7 Output sharing choke ..........................................14

2.8 Model number .....................................................15

3 Product information ............................16

3.1 Ratings ................................................................16

3.2 Operating modes .................................................19

3.3 Nameplate description ........................................22

3.4 Supplied items .....................................................25

4 System configuration ..........................27

5 Mechanical Installation .......................39

5.1 Safety information ...............................................39

5.2 Planning the installation ......................................39

5.3 Terminal cover removal .......................................40

5.4 Mounting of the control master/follower/

standard pod .......................................................44

5.5 Dimensions and mounting methods ....................47

5.6 Enclosure ............................................................61

5.7 Heatsink fan operation ........................................67

5.8 Enclosing drive for high environmental

protection ............................................................68

5.9 External EMC filter ..............................................70

5.10 Line reactor mounting dimensions ......................74

5.11 Electrical terminals ..............................................77

5.12 Routine maintenance ..........................................79

6 Electrical Installation .......................... 85

6.1 Power connections ............................................. 86

6.2 AC supply requirements ..................................... 92

6.3 Output sharing choke specification .................... 95

6.4 Supplying the Unidrive M/Unidrive HS size

9A, 9D, 10D and 11D drives with

DC / DC bus paralleling ...................................... 96

6.5 Heatsink fan supply ............................................ 96

6.6 24 Vdc supply ..................................................... 96

6.7 Low voltage operation ........................................ 98

6.8 Status LED ......................................................... 98

6.9 Ratings ............................................................... 99

6.10 Output circuit and motor protection .................. 103

6.11 Braking ............................................................. 105

6.12 Ground leakage ................................................ 107

6.13 EMC (Electromagnetic compatibility) ............... 108

6.14 Communication connections ............................ 116

6.15 Control connections ......................................... 117

6.16 M70X/HS7X Position feedback connections .... 124

6.17 Safe Torque Off (STO) ..................................... 131

7 Technical data ................................... 133

7.1 Drive technical data .......................................... 133

7.2 Optional external EMC filters ........................... 151

8 UL Information .................................. 153

8.1 UL file reference ............................................... 153

8.2 Option modules, kits and accessories .............. 153

8.3 Enclosure ratings ............................................. 153

8.4 Mounting .......................................................... 153

8.5 Environment ..................................................... 153

8.6 Electrical Installation ........................................ 153

8.7 Motor overload protection and thermal memory

retention ........................................................... 154

8.8 Electrical supply ............................................... 154

8.9 External Class 2 supply .................................... 154

8.10 Requirement for Transient Surge Suppression 154

8.11 Group Installation and Modular Drive Systems 154

Index .................................................. 155

4 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 5

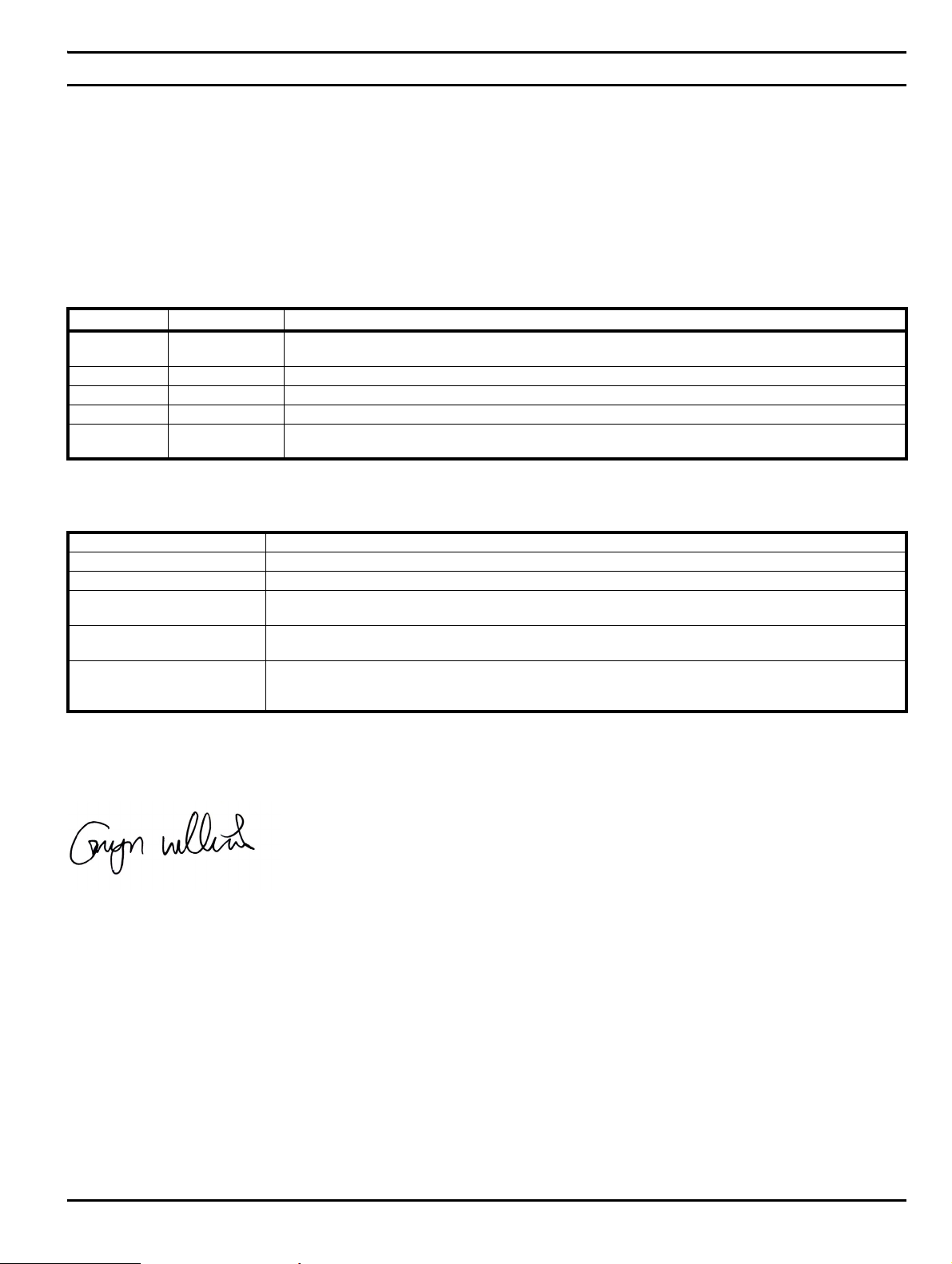

EU Declaration of Conformity

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

Model number Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the following European harmonized

standards:

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

EN 61000-6-4: 2007+ A1:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input power ≥1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage Directive (2014/35/EU) and the

Electromagnetic Compatibility Directive (2014/30/EU).

M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, F300, H300, E200,E300, HS30, HS70,

HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke),

T = 12P Rectifier + Inverter (external choke)

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission standard for industrial

environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current emissions (equipment input current

≤16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes, voltage fluctuations and flicker in

public, low voltage supply systems, for equipment with rated current ≤16 A per phase and not subject to

conditional connection

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

G Williams

Vice President, Technology

Date: 17th March 2016

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Un idrive M / Uni drive H S Modu lar In stall a tion G uide 5

Issue Number: 5

Page 6

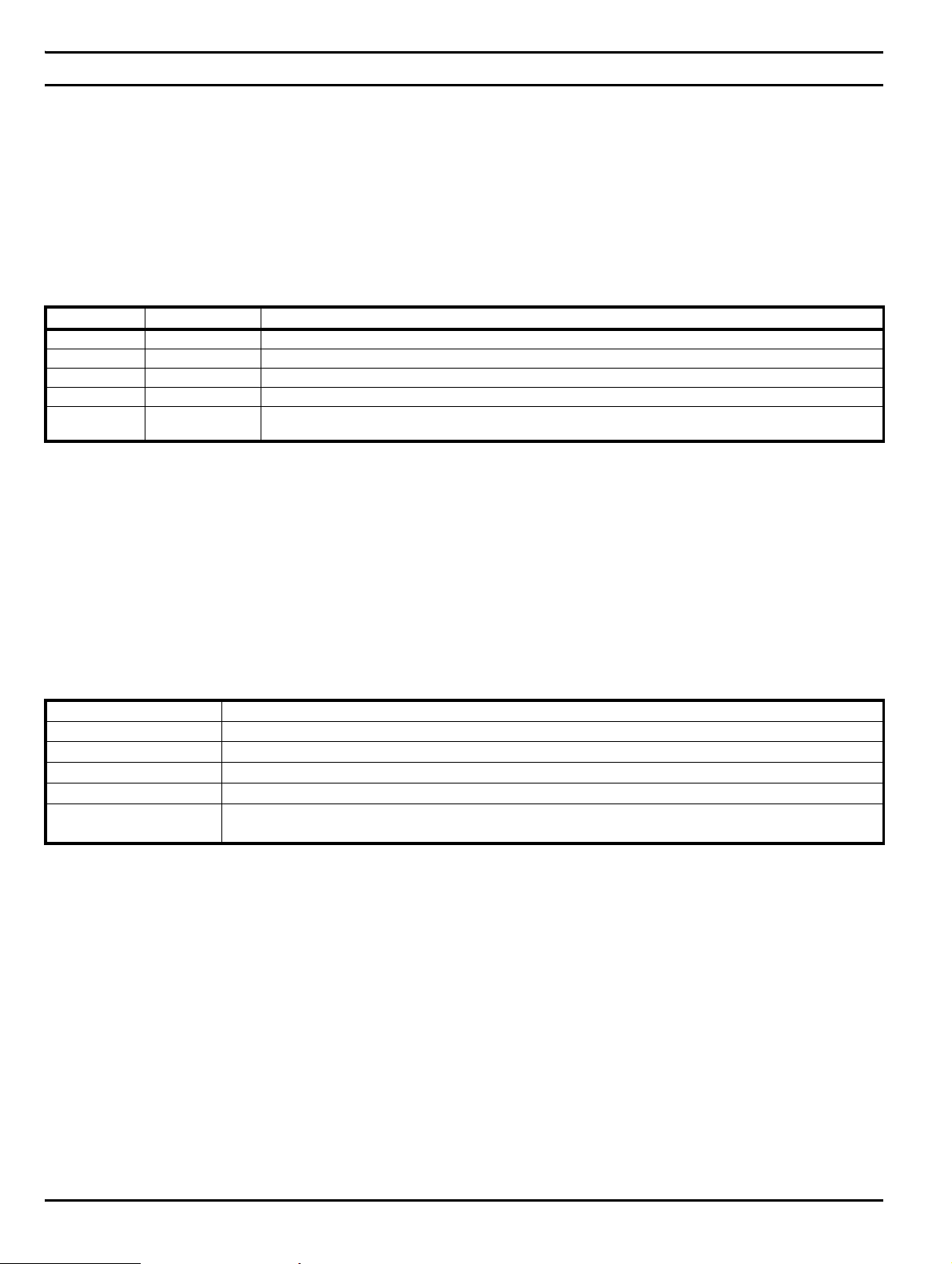

EU Declaration of Conformity (including 2006 Machinery Directive)

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in conformity with the relevant Union

harmonization legislation. The declaration applies to the variable speed drive products shown below:

Model No. Interpretation Nomenclature aaaa - bbc ddddde

aaaa Basic series M300, M400, M600, M700, M701, M702, F300, H300, E200, E300, HS30, HS70, HS71, HS72, M000, RECT

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe Torque Off function may be used

for a safety function of a machine. None of the other functions of the drive may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive 2006/42/EC and the Electromagnetic Compatibility Directive (2014/30/EU).

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier + Inverter (external choke), T = 12P

Rectifier + Inverter (external choke)

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

EC type-examination certificate numbers:

01/205/5270.01/14 dated 2014-11-11

01/205/5387.01/15 dated 2015-01-29

01/205/5383.02/15 dated 2015-04-21

Notified body identification number: 0035

The harmonized standards used are shown below:

EN 61800-5-1:2007 Adjustable speed electrical power drive systems - Part 5-1: Safety requirements - Electrical, thermal and energy

EN 61800-5-2:2007 Adjustable speed electrical power drive systems - Part 5-2: Safety requirements - Functional

EN ISO 13849-1:2008 Safety of Machinery, Safety-related parts of control systems, General principles for design

EN ISO 13849-2:2008 Safety of machinery, Safety-related parts of control systems. Validation

EN 61800-3: 2004+A1:2012 Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific test methods

EN 62061:2005

Person authorised to complete the technical file:

P Knight

Conformity Engineer

Newtown, Powys, UK

Safety of machinery, Functional safety of safety related electrical, electronic and programmable electronic control

systems

6 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 7

G. Williams

Vice President, Technology

Date: 17th March 2016

Place: Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection components and other

equipment to form complete end products or systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety and EMC. Refer to the Product

Documentation. An EMC data sheet is available giving detailed information. The assembler is responsible for ensuring that the end product

or system complies with all the relevant laws in the country where it is to be used.

Unidrive M / Unidrive HS Modular Installation Guide 7

Issue Number: 5

Page 8

Safety

WARNING

CAUTION

NOTE

information

Introduction Product information

System

configuration

1 Safety information

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive.

Specific warnings are given at the relevant places in this Installation

Guide.

1.3 System design and safety of

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly, the drive may

present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

design to avoid hazards either in normal operation or in the event of

equipment malfunction. System design, installation, commissioning/

start-up and maintenance must be carried out by personnel who have

the necessary training and experience. They must read this safety

information and this Installation Guide carefully.

The STOP and Safe Torque Off functions of the drive do not isolate

dangerous voltages from the output of the drive or from any external

option unit. The supply must be disconnected by an approved electrical

isolation device before gaining access to the electrical connections.

With the sole exception of the Safe Torque Off function, none of the

drive functions should be used to ensure safety of personnel, i.e.

they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which

might result in a hazard, either through their intended behavior or

through incorrect operation due to a fault. In any application where a

malfunction of the drive or its control system could lead to or allow

damage, loss or injury, a risk analysis must be carried out, and where

necessary, further measures taken to reduce the risk - for example, an

over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

The Safe Torque Off function may be used in a safety-related

application. The system designer is responsible for ensuring that the

complete system is safe and designed correctly according to the

relevant safety standards.

personnel

Mechanical

Installation

Electrical

Installation

Technical data UL Information

1.5 Access

Drive access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire

enclosure must be provided. For further information, refer to section

5.2.5 Fire protection on page 39.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

This Installation Guide contains instruction for achieving compliance with

specific EMC standards.

Within the European Union, all machinery in which this product is used

must comply with the following directives:

Safety of Machinery 2006/42/EC

Electromagnetic Compatibility (EMC) Directive 2014/30/EU

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations. Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed

operation. If it is intended to use the capability of the drive to run a motor

at speeds above its designed maximum, it is strongly recommended that

the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective. The motor should be installed with a protection

thermistor. If necessary, an electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 motor rated

current. This affects the thermal protection of the motor.

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated

operation of an external brake with the drive. While both hardware and

software are designed to high standards of quality and robustness, they

are not intended for use as safety functions, i.e. where a fault or failure

would result in a risk of injury. In any application where the incorrect

operation of the brake release mechanism could result in injury,

independent protection devices of proven integrity must also be

incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive.

They must not be altered without careful consideration of the impact on

the controlled system. Measures must be taken to prevent unwanted

changes due to error or tampering.

1.4 Environmental limits

Instructions in this Installation Guide regarding transport, storage,

installation and use of the drive must be complied with, including the

specified environmental limits. Drives must not be subjected to

excessive physical force.

8 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 9

Safety

information

Introduction Product information

System

configuration

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric

shock and may be lethal:

AC supply cables and connections

Output cables and connections

Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and

must not be touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated at least ten minutes before

work may continue.

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Unidrive M / Unidrive HS Modular Installation Guide 9

Issue Number: 5

Page 10

Safety information Introduction Product information

CAUTION

L3

+DC

-DC

L2

L1

+DC

-DC

L1

L1

L2

L2

L3

L3

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

2 Introduction

The Unidrive M / Unidrive HS modular drive offers the possibility of implementing many custom power systems with a wide range of power modules.

The power range is 110 kW to 2.8 MW and the modular design of input and output stages enables a wide range of very compact and efficient systems

to be realized. These include:

• Parallel output stages for higher power motors:

Size 9 and 10:

Up to a maximum of 20 modules

(1 master module with up to 19 follower modules, OR

1 remote mounted control master pod controlling up to 20 followers. This allows the user to place all control circuitry in one low voltage

cabinet)

Size 11:

Up to a maximum of 10 modules

(1 master module with up to 9 follower modules OR 1 remote mounted control master pod controlling up to 10 followers).

• Common DC bus multi-drive systems for:

Connection to larger existing power supplies

Energy sharing between motoring and regenerating drives

• Active front end drive systems for:

Minimizing supply current harmonics

Four quadrant motor control

• Multiple controlled rectifier bridges for:

Minimizing supply current harmonics by drawing 6, 12 or 18 pulse supply load currents.

2.1 Rectifier

A separate input line reactor (INLXXX) of at least the value shown in Table 6-2 Model and line reactor part numbers on page 93 must be

used with the rectifiers. Failure to provide sufficient reactance could damage or reduce the service life of the rectifier or inverter.

The Unidrive M / Unidrive HS rectifier is a half controlled SCR/thyristor bridge and is used as a front end to the size 9, size 10 or size 11 inverter

module. The rectifier cannot be used as a stand alone rectifier for several smaller drives.

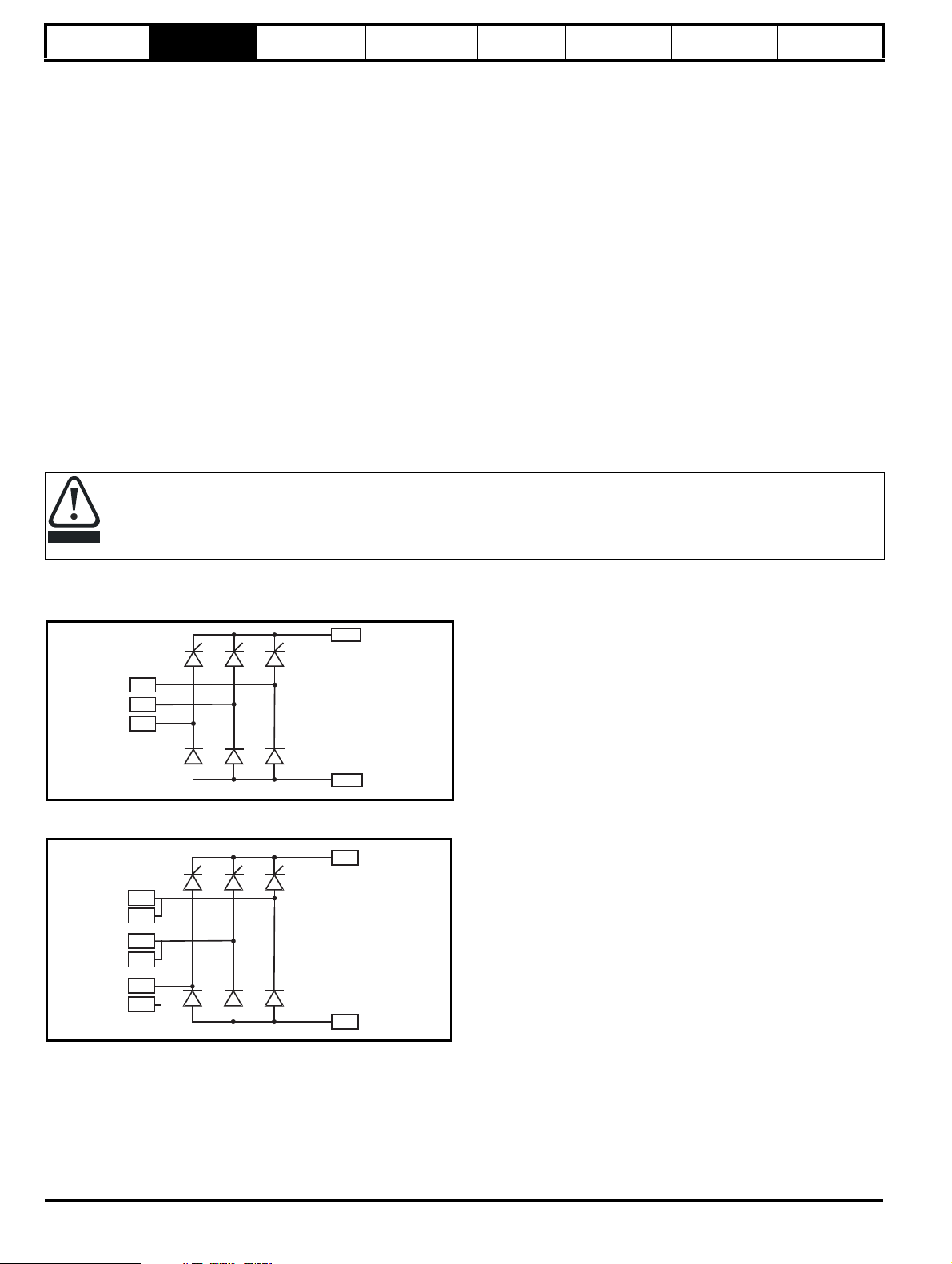

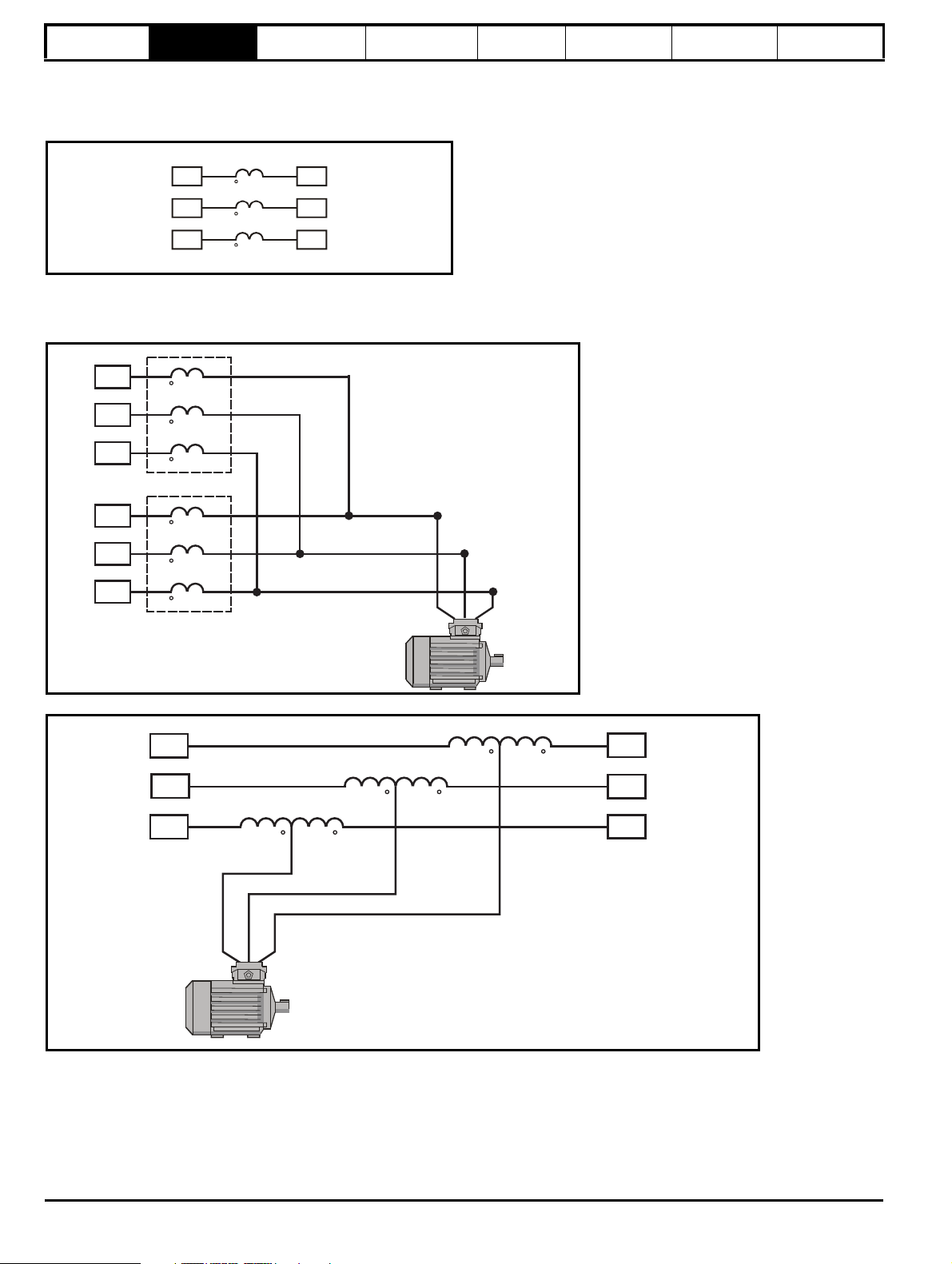

Figure 2-1 Frame 10 single half controlled SCR/thyristor

Figure 2-2 Frame 11 single half controlled SCR/thyristor

10 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 11

Safety information Introduction Product information

+DC

-DC

+DC

-DC

L1

L2

L3

L1

L2

L3

L1

L2

L3

BR

U

V

W

+DC

-DC

Optional

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Figure 2-3 Frame 11 twin half controlled SCR/thyristor

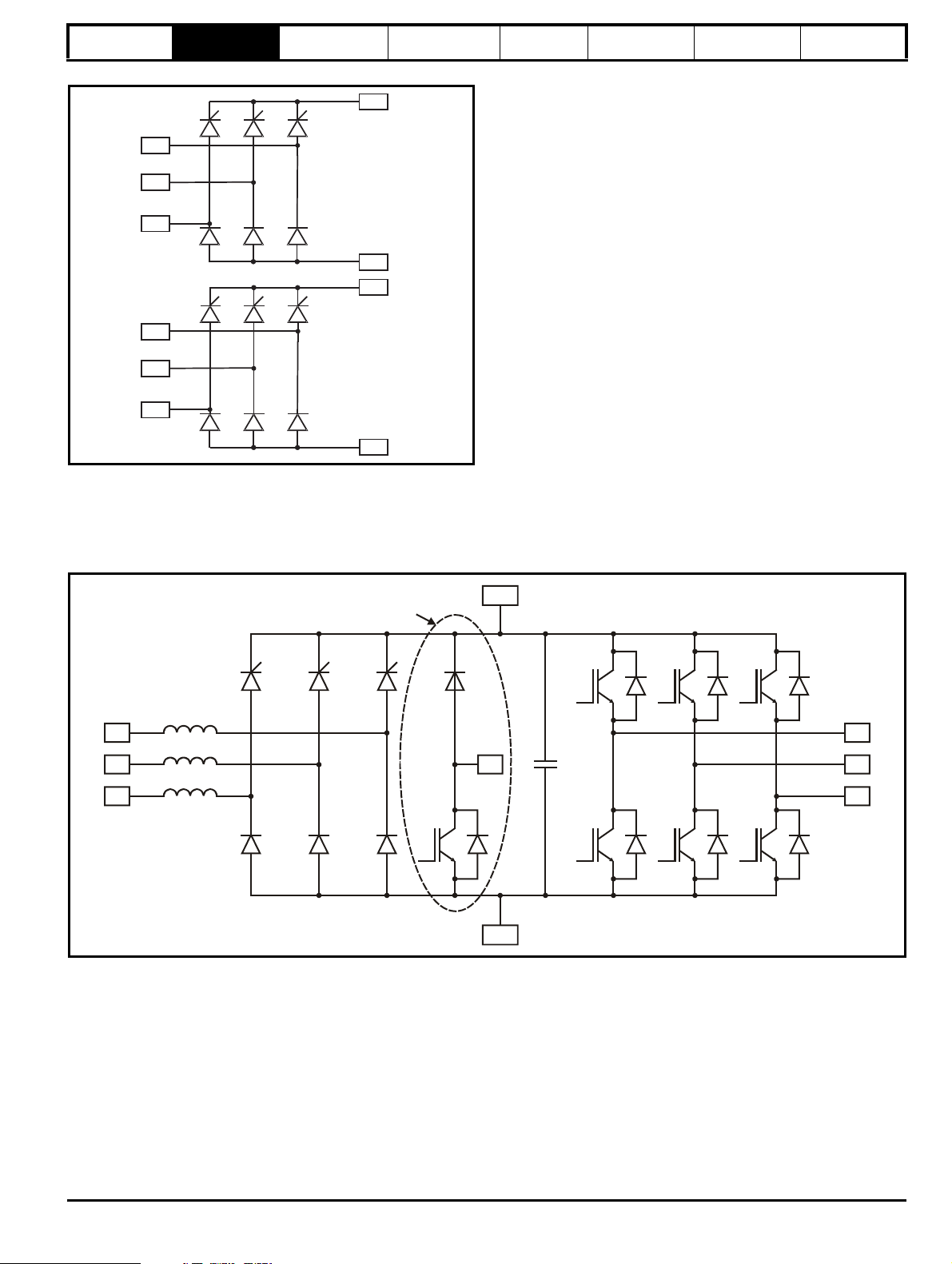

2.2 Size 9A drives

The size 9A is a complete drive with internal rectifier and AC input line chokes (AC in to AC out). It can provide a maximum continuous output current

of 266 A (400 V drive). DC connections are available for use in regen and bus-parallel applications. The size 9A is available with or without a braking

IGBT installed.

Figure 2-4 Size 9A inverter schematic

Unidrive M / Unidrive HS Modular Installation Guide 11

Issue Number: 5

Page 12

Safety information Introduction Product information

L1

L2

L3

BR

U

V

W

+DC

Optional

L1

L2

L3

BR

U

V

W

+DC

Optional

L1

L2

L3

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

2.3 Size 9E, 10E and 11E drives

The size 9E,10E and 11E are complete drives with internal rectifier (AC in to AC out). External AC line chokes are required.

Figure 2-5 Size 9E and 10E inverter schematic

Figure 2-6 Size 11E inverter schematic

12 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 13

Safety information Introduction Product information

BR

U

V

W

-DC

+DC

Optional

+DC

-DC

NOTE

U

V

W

BR

+DC

Optional

L1

L2

L3

L1

L2

L3

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

2.4 Size 9D, 10D and 11D inverters

Size 9D, 10D and 11D are inverter stage only (DC in to AC out). If a rectifier is required, then an AC input line reactor must also be installed. DC

connections can be used for regen and bus-parallel applications. Size 9D, 10D and 11D are available with or without a braking IGBT installed.

Figure 2-7 Size 9D, 10D and 11D inverter schematic

The above diagram shows size 11D which has double DC terminals, size 9D and 10D have single DC terminals.

2.5 Size 9T, 10T and 11T drives

Size 9T, 10T and 11T are complete drives with internal 12 pulse rectifier (AC in to AC out). External AC line chokes are required unless the required

reactance is incorporated into a 12 pulse transformer.

Figure 2-8 Size 9T, 10T and 11T inverter schematic

Unidrive M / Unidrive HS Modular Installation Guide 13

Issue Number: 5

Page 14

Safety information Introduction Product information

L1

L2

L3

L1A

L2A

L3A

U1

V1

W1

U2

V2

W2

UVW

UVW

U1 U2

V1 V2

W1 W2

Drive 1

Drive 2

U1

V1

W1

U2

V2

W2

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

2.6 Input line reactor

The INL line reactor must be used in conjunction with the Unidrive M / Unidrive HS rectifiers. See section 6.2.2 Input line reactor specifications on

page 93 for further information.

Figure 2-9 Single input line reactor (INLX0X)/force cooled (INLX0XW)

2.7 Output sharing choke

The OTL output sharing choke must be used on the output of Unidrive M / Unidrive HS when more than one module is paralleled together.

Figure 2-10 Single output sharing choke (OTLX0X) - two chokes shown

Figure 2-11 Dual output sharing choke (OTLX1X)

For a physical representation of the input line reactors and output sharing chokes, see section 2.6 and section 2.7 Output sharing choke on page 14.

14 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 15

Safety information Introduction Product information

RECT

10 6 02480

A

Model

Frame size

Voltage 2=200 V

4=400 V

6=690 V

Current rating

Rectifier format

Identification Label

Unidrive Range:

M600- EIA 485

M700- Ethernet

M701- EIA 485

M702- Ethernet, 2 x STO

HS70- Ethernet, High speed

HS71- EIA 485, High speed

HS72- Ethernet, 2 x STO, High speed

Range &

Derivative

Power

Format

Mxxx-

09

4

02240

Configuration

1

Electrical Specifications Drive Format

Frame & Volts

Frames

Power

Description

Power Format

Control

Unassigned

Range ID

Frame

size

Current rating:

Heavy duty

rating x 10

Voltage

rating:

2=200 V

4=400 V

5=575 V

6=690 V

Current

A

0

09 to 11

AC to AC

DC to AC

Single drives

Mxxx-

Modular drives

M000-

(Unassigned

power stage

with no control

fitted)

E

1

U

Standard

M000-FOLLOWER011100A0100

Mxxx-MASTER00011100A0100

Mxxx- STANDARD011100A0100

Control Module Range for Unassigned Modular Drives

MMaster

D

FFollower

A

AC to AC integrated

Rectifier, Inverter.

Internal line choke

AC to AC integrated

Rectifier, Inverter.

External line choke

DC to AC Inverter

T

12P Rectifier plus

Inverter

Reserved

Optional Build

Customer Code

01

A B

1

00

Customer Code

:

00 =

50

Hz

01 =60Hz

Reserved:

Conformal Coating:

0=Standard

IP /NEMARating:

1 =IP20 / NEMA 1

Brake Transistor:

B = Brake

Cooling

:

A=

Air

Documentation

1

Documentation:

0 - Supplied separately

1 - English

2 - French

3 - Italian

4 - German

5 - Spanish

N = No Brake

INL:

Current rating step

OTL: Output sharing choke

INL

4 0 1

Input line reactor

0: Single

1: Dual

Voltage rating

4: 380V to 480V

6: 500V to 690V

System

configuration

Mechanical

Installation

2.8 Model number

The model numbers for the Unidrive M / Unidrive HS range are formed as illustrated below.

Figure 2-12 Rectifier model number

Figure 2-13 Drive model number

Electrical

Installation

Technical data UL Information

Figure 2-14 Input line reactor / output sharing choke

Unidrive M / Unidrive HS Modular Installation Guide 15

Issue Number: 5

Page 16

Safety information Introduction

Available output

current

Overload limit -

Heavy Duty

Maximum

continuous

current (above

50% base

speed) -

Normal Duty

Maximum

continuous

current -

Heavy Duty

Motor rated

current set

in the drive

Heavy Duty

- with high

overload capability

Normal Duty

Overload limit -

Normal Duty

NOTE

NOTE

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%15%

Pr = 0

Pr = 1

04.025

04.025

Motor total

current (Pr 04.001)

as a percentage

of motor rated

current

Motor speed as a

percentage of base speed

100%

Max. permissible

continuous

current

100%

I t protection operates in this region

2

70%

50%

Pr = 0

Pr = 1

04.025

04.025

Product

information

System

configuration

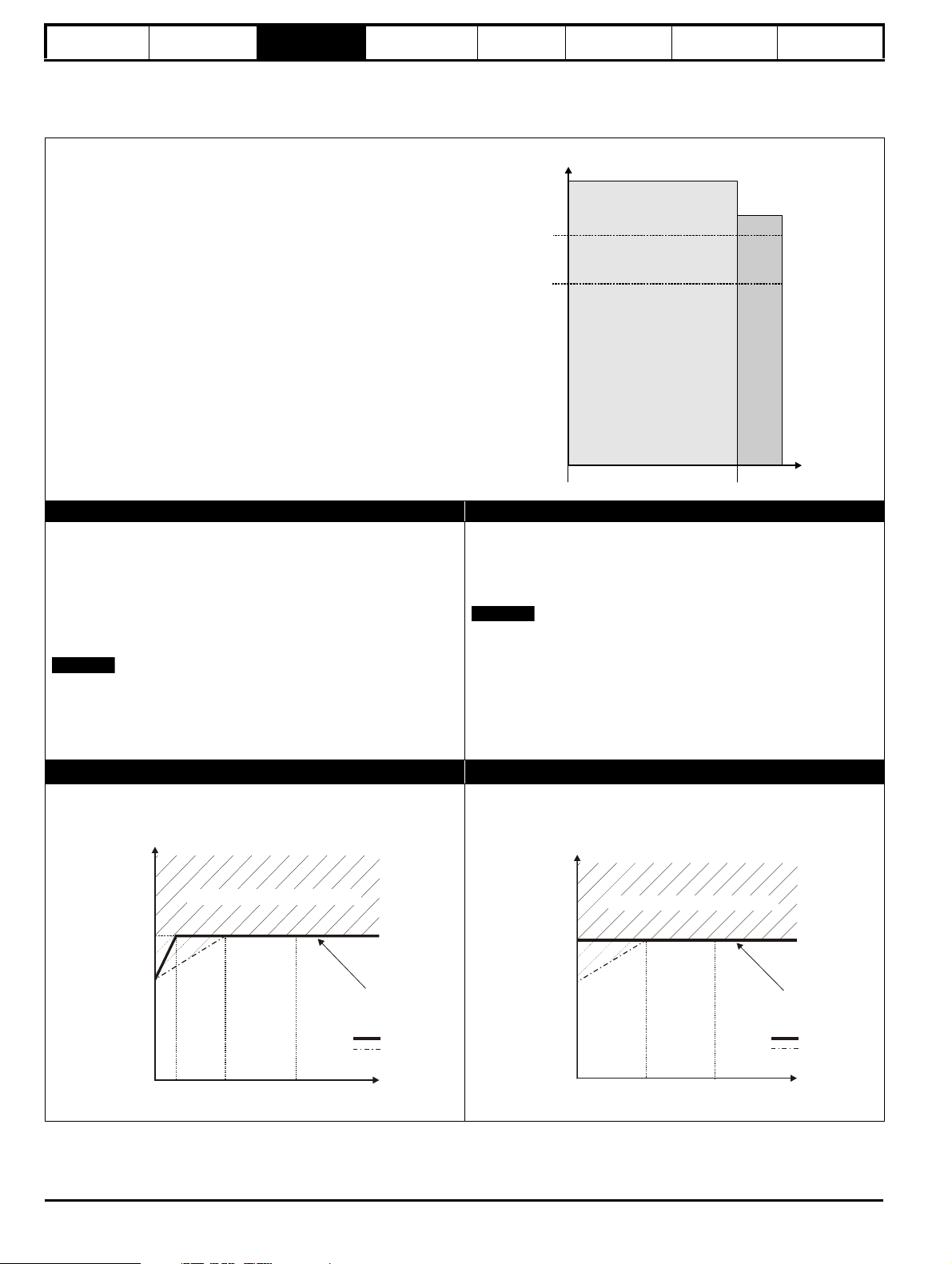

3 Product information

3.1 Ratings

The drive is dual rated.

The setting of the motor rated current determines which rating applies Heavy Duty or Normal Duty.

The two ratings are compatible with motors designed to IEC60034.

The graph aside illustrates the difference between Normal Duty and

Heavy Duty with respect to continuous current rating and short term

overload limits.

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Normal Duty Heavy Duty (default)

For applications which use Self ventilated (TENV/TEFC) induction

motors and require a low overload capability, and full torque at low

speeds is not required (e.g. fans, pumps).

Self ventilated (TENV/TEFC) induction motors require increased

protection against overload due to the reduced cooling effect of the fan

at low speed. To provide the correct level of protection the I

operates at a level which is speed dependent. This is illustrated in the

graph below.

The speed at which the low speed protection takes effect can be

changed by the setting of Low Speed Thermal Protection Mode

(04.025). The protection starts when the motor speed is below 15 % of

base speed when Pr 04.025 = 0 (default) and below 50 % when

Pr 04.025 = 1.

Operation of motor I2t protection

Motor I2t protection is fixed as shown below and is compatible with:

• Self ventilated (TENV/TEFC) induction motors

2

t software

For constant torque applications or applications which require a high

overload capability, or full torque is required at low speeds (e.g. winders,

hoists).

The thermal protection is set to protect force ventilated induction motors

and permanent magnet servo motors by default.

N

If the application uses a self ventilated (TENV/TEFC) induction motor

and increased thermal protection is required for speeds below 50 %

base speed, then this can be enabled by setting Low Speed Thermal

Protection Mode (04.025) = 1.

Motor I2t protection defaults to be compatible with:

• Forced ventilation induction motors

• Permanent magnet servo motors

16 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 17

Safety information Introduction

Product

information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

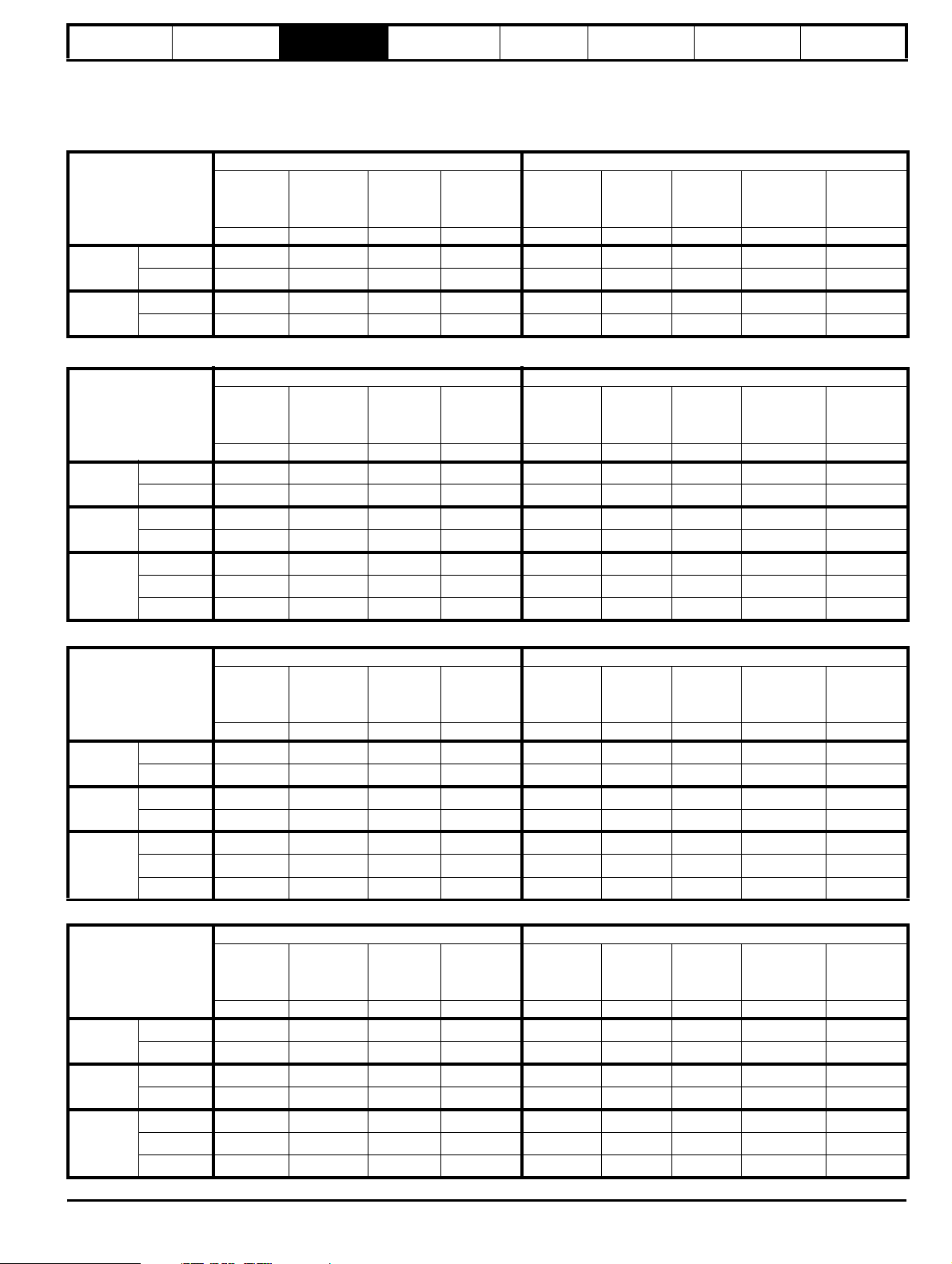

The continuous current ratings given are for maximum 40 °C (104 °F), 1000 m altitude and 2 kHz switching frequency. Derating is required for higher

switching frequencies, ambient temperature >40 °C (104 °F), high altitude and parallel applications. For further information, refer to section

7.1.1 Power and current ratings (Derating for switching frequency and temperature) on page 133, 5 % derating should be applied when paralleling

two or more inverters.

Table 3-1 Size 9 and 10 200 V drive ratings (200 V to 240 V ±10 %)

Normal Duty Heavy Duty

9A / 9E / 9D

10D / 10E

Maximum

Model

09201760 216 55 75 238 176 264 308 45 60

09202190 266 75 100 293 219 328 383 55 75

10202830 325 90 125 357 283 424 495 75 100

10203000 360 110 150 396 300 450 525 90 125

continuous

output

current

AkWhpA A AAkW hp

Nominal

power at

230 V

Motor

power at

230 V

Peak

current

Maximum

continuous

output

current

Open loop

peak

current

RFC peak

current

Nominal

power at

230 V

Motor

power at

230 V

Table 3-2 Size 9, 10 and 11 400 V drive ratings (380 V to 480 V ±10 %)

Normal Duty Heavy Duty

9A / 9E / 9D

/ 9T

10D / 10E /

10T

11D / 11E /

11T

Maximum

Model

09402000 221 110 150 243 200 300

09402240 266 132 200 293 224 336

10402700 320 160 250 352 270 405

10403200 361 200 300 397 320 480

11403770 437 225 350 481 377 565

11404170 487 250 400 536 417 625

11404640 507 280 450 558 464 696

continuous

output

current

AkWhpA A AAkW hp

Nominal

power at

400 V

Motor

power at

460 V

Peak

current

Maximum

continuous

output

current

Open loop

peak

current

RFC peak

current

350

392

472

560

660

730

812

Nominal

power at

400 V

90 150

110 150

132 200

160 250

185 300

200 350

250 400

Motor

power at

460 V

Table 3-3 Size 9, 10 and 11 575 V drive ratings (500 V to 575 V ±10 %)

Normal Duty Heavy Duty

9A / 9E / 9D

/ 9T

10D / 10E /

10T

11D / 11E /

11T

Model

09501040

09501310

10501520

10501900

11502000

11502540

11502850

Maximum

continuous

output

current

AkWhpA A AAkW hp

125 110 125 137 104 156 182 75 100

150 110 150 165 131 196 229 90 125

200 130 200 220 152 228 266 11 0 150

200 150 200 220 190 285 332 132 200

248 185 250 273 200 300 350 150 200

288 225 300 317 254 381 444 185 250

315 250 350 346 285 427 499 225 300

Nominal

power at

575 V

Motor

power at

575 V

Peak

current

Table 3-4 Size 9, 10 and 11 690 V drive ratings (500 V to 690 V ±10 %)

Normal Duty Heavy Duty

9A / 9E / 9D

/ 9T

10D / 10E /

10T

11D / 11E /

11T

Model

09601040

09601310

10601500

10601780

11602100

11602380

11602630

Maximum

continuous

output

current

AkWhpA A AAkW hp

125 110 150 137 104 156 182 90 125

155 132 175 170 131 196 229 11 0 150

172 160 200 189 150 225 262 132 175

197 185 250 217 178 267 311 160 200

225 200 250 247 210 315 367 185 250

275 250 300 302 238 357 416 200 250

305 280 400 335 263 394 460 250 300

Nominal

power at

690 V

Motor

power at

690 V

Peak

current

Maximum

continuous

output

current

Maximum

continuous

output

current

Open loop

peak

current

Open loop

peak

current

RFC peak

current

RFC peak

current

Nominal

power at

575 V

Nominal

power at

690 V

Motor

power at

575 V

Motor

power at

690 V

Unidrive M / Unidrive HS Modular Installation Guide 17

Issue Number: 5

Page 18

Safety information Introduction

NOTE

Product

information

Table 3-5 Rectifier ratings at 40° C (104° F)

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Model

10204100 200

10404520 400

10502430 575

10602480 690

11406840 400

11503840 575

11604060 690

1142X400* 400

1162X380* 690

Vol ta ge r a tin g

VA A A

Typical input

current

333 361 494

370 396 523

202 218 313

202 225 313

557 594 752

313 338 473

331 362 465

2 x 326 2 x 358 2 x 397

2 x 308 2 x 339 2 x 375

Maximum continuous

input current

Maximum overload

input current

Typical continuous

DC output current

AA

409 413

452 455

243 246

247 251

684 689

384 387

406 411

2 x 395 2 x 400

2 x 375 2 x 380

Maximum DC output

current

* Twin rectifier

3.1.1 Typical short term overload limits

The maximum percentage overload limit changes depending on the selected motor. Variations in motor rated current, motor power factor and motor

leakage inductance all result in changes in the maximum possible overload. The exact value for a specific motor can be calculated using the

equations detailed in Menu 4 in the Parameter Reference Guide.

Typical values are shown in the table below for RFC (RFC-A or RFC-S) and open loop (OL) modes:

Table 3-6 Typical overload limits

Operating mode RFC from cold RFC from 100 %

Normal Duty overload with motor rated current = drive rated

current

Heavy Duty overload with motor rated current = drive rated

current (size 9, 10 and 11)

Open loop from

cold

110 % for 165 s 110 % for 9 s 110 % for 165 s 110 % for 9 s

175 % for 42 s 175 % for 5 s 150 % for 60 s 150 % for 7 s

Open loop from

100 %

Generally the drive rated current is higher than the matching motor rated current allowing a higher level of overload than the default setting.

The time allowed in the overload region is proportionally reduced at very low output frequency on some drive ratings.

The maximum overload level which can be attained is independent of the speed.

18 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 19

Safety information Introduction

Product

information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

3.2 Operating modes

The drive is designed to operate in any of the following modes:

1. Open loop mode

Open loop vector mode

Fixed V/F mode (V/Hz)

Quadratic V/F mode (V/Hz)

2. RFC - A mode

With position feedback sensor

Without position feedback sensor (Sensorless)

3. RFC - S mode

With position feedback sensor

Without position feedback sensor (Sensorless)

4. Regen mode

3.2.1 Open loop mode

The drive applies power to the motor at frequencies varied by the user. The motor speed is a result of the output frequency of the drive and slip due

to the mechanical load. The drive can improve the speed control of the motor by applying slip compensation. The performance at low speed depends

on whether V/F mode or open loop vector mode is selected.

Open loop vector mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where the drive uses motor parameters to apply the

correct voltage to keep the flux constant under varying load conditions.

Typically 100 % torque is available down to 1 Hz for a 50 Hz motor.

Fixed V/F mode

The voltage applied to the motor is directly proportional to the frequency except at low speed where a voltage boost is provided which is set by the

user. This mode can be used for multi-motor applications.

Typically 100 % torque is available down to 4 Hz for a 50 Hz motor.

Quadratic V/F mode

The voltage applied to the motor is directly proportional to the square of the frequency except at low speed where a voltage boost is provided which is

set by the user. This mode can be used for running fan or pump applications with quadratic load characteristics or for multi-motor applications. This

mode is not suitable for applications requiring a high starting torque.

3.2.2 RFC-A mode

Rotor Flux Control for Asynchronous (induction) motors (RFC-A) encompasses closed loop vector control with a position feedback device

With position feedback

For use with induction motors with a feedback device installed. The drive directly controls the speed of the motor using the feedback device to ensure

the rotor speed exactly as demanded. Motor flux is accurately controlled at all times to provide full torque all the way down to zero speed.

Without position feedback (Sensorless)

Sensorless mode provides closed loop control without the need for position feedback by using current, voltages and key motor parameters to

estimate the motor speed. It can eliminate instability traditionally associated with open loop control such as operating large motors with light loads at

low frequencies.

3.2.3 RFC-S mode

Rotor Flux Control for Synchronous (permanent magnet brushless) motors (RFC-S) provides closed loop control with position feedback device.

With position feedback

For use with permanent magnet brushless motors with a feedback device installed.

The drive directly controls the speed of the motor using the feedback device to ensure the rotor speed is exactly as demanded. Flux control is not

required because the motor is self excited by the permanent magnets which form part of the rotor.

Absolute position information is required from the feedback device to ensure the output voltage is accurately matched to the back EMF of the motor.

Full torque is available all the way down to zero speed.

3.2.4 Regen mode

For use as a regenerative front end for four quadrant operation.

Regen operation allows bi-directional power flow to and from the AC supply. This provides far greater efficiency levels in applications which would

otherwise dissipate large amounts of energy in the form of heat in a braking resistor.

The harmonic content of the input current is negligible due to the sinusoidal nature of the waveform when compared to a conventional bridge rectifier

or SCR/thyristor front end.

Unidrive M / Unidrive HS Modular Installation Guide 19

Issue Number: 5

Page 20

Safety information Introduction

15

19

15

13

14

19

15

19

13

19

16

14 15

18

17

9A

9E

10E

2

13

14

14

15

18

17

2

2

9D

10D

14

15

16

2

14

15

17

18

2

19

14

19

13

9T

10T

14

15

1717

1718

Size 10

Rectifier

13

14

2

14 15

16

3

Master Pod

Output to follower

1

2

3

4

5

6

7

8

9

10

11

12

Follower Pod

Input from Master /

Output to follower

Cover

Base

1

4

3

Standard Pod

1

2

3

4

5

6

7

8

9

10

11

12

Single drive systems Parallel systems

Product

information

System

configuration

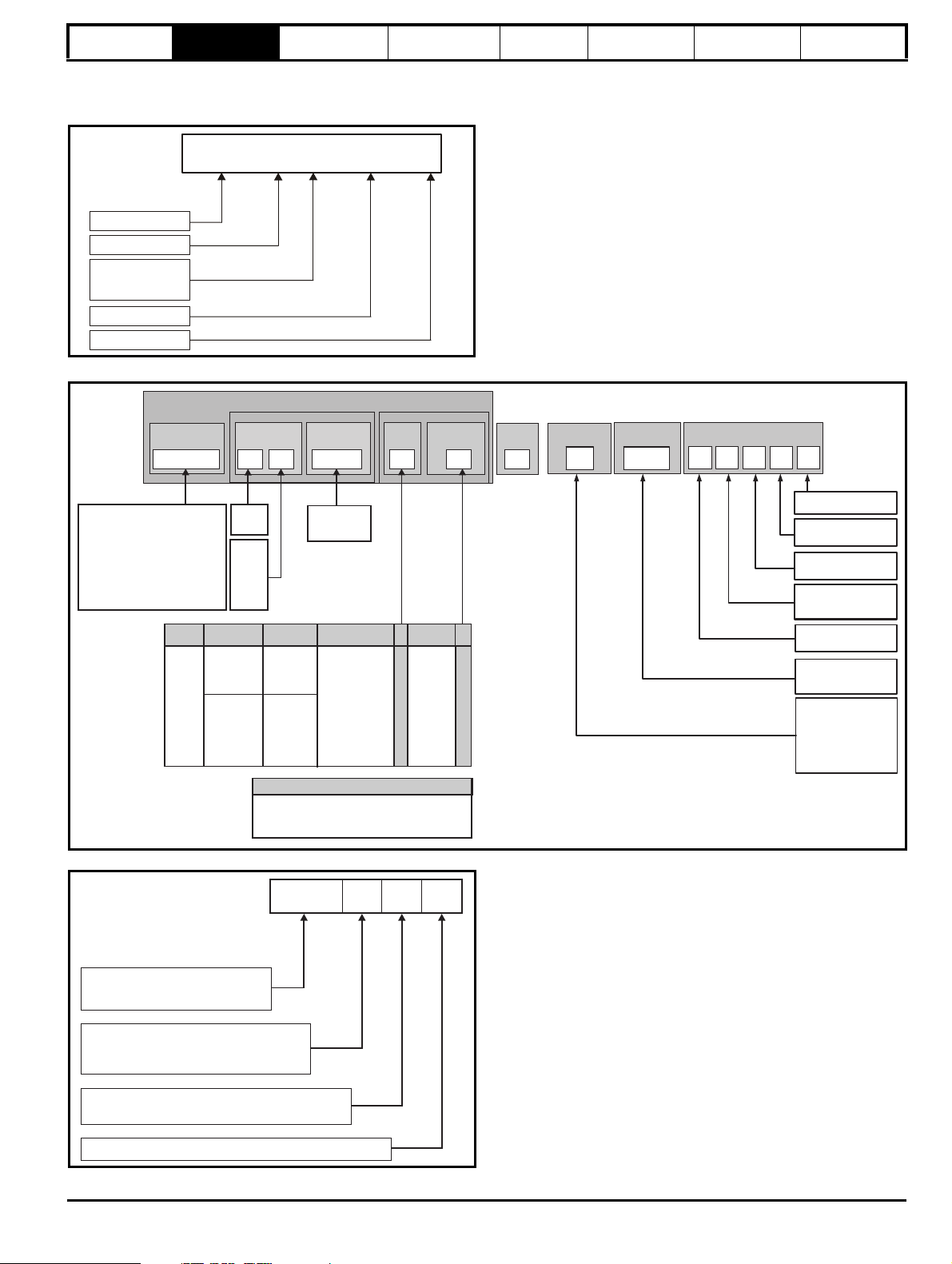

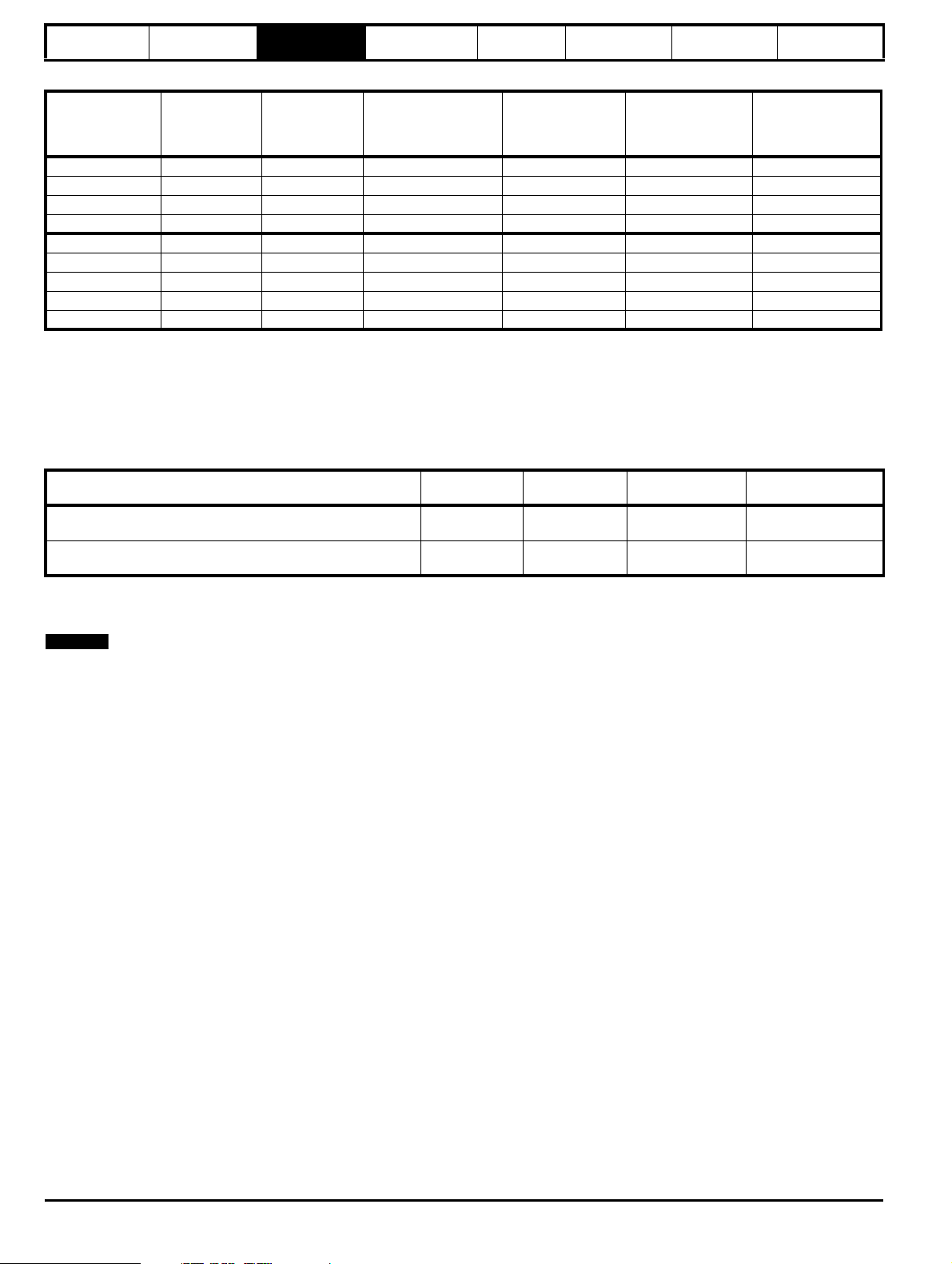

Figure 3-1 Features of the Unidrive M / Unidrive HS size 9 and 10

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Key

1. Rating label 6. Option module slot 3 11. NV media card slot 16. DC bus -

2. Identification label 7. Relay connections 12. Keypad connection 17. Motor connections

3. Status LED 8. Position feedback connections 13. AC supply connections 18. Braking terminal

4. Option module slot 1 9. Control connections 14. Ground connections

5. Option module slot 2 10. Communications port 15. DC bus +

20 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 21

Safety information Introduction

14

17

14

15

18

13

2

11E 11 T

14

15

16

15

18

14

11D

2

Master Pod

Output to follower

1

2

3

4

5

6

7

8

9

10

11

12

Follower Pod

Input from Master /

Output to follower

Cover

Base

1

4

3

Standard Pod

1

2

3

4

5

6

7

8

9

10

11

12

Single drive systems Parallel systems

15

16

14

Size 11

Rectifier

15

16

14

15

16

14

3

2

14

13

Figure 3-2 Features of the Unidrive M / Unidrive HS size 11

Product

information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Key

1. Rating label 6. Option module slot 3 11. NV media card slot 16. DC bus -

2. Identification label 7. Relay connections 12. Keypad connection 17. Motor connections

3. Status LED 8. Position feedback connections 13. AC supply connections 18. Braking terminal

4. Option module slot 1 9. Control connections 14. Ground connections

5. Option module slot 2 10. Communications port 15. DC bus +

Unidrive M / Unidrive HS Modular Installation Guide 21

Issue Number: 5

Page 22

Safety information Introduction

Model

Approvals

Inputphases & input current

Outputphases&Heavy

Duty/Normal Dutyrating

Serial number

Input voltage

Output voltage

Customer anddatecode

M000-094 02240 EUO

110/132kW STDN39

Input frequencyInput frequency

M000-094 02240 EU0

Model

Frame

Voltage

Heavy Duty

current rating

Power

format

No control podfitted

Fan power

supplyfitted

Refer to

User Guide

Normal/Heavy

Duty power rating

Approvals

Inputphases & input current

Outputphases&Heavy

Duty/Normal Dutyrating

Serial number

Input voltage

Output voltage

Customer anddatecode

110/132kW STDN39

Large Label

CE approval Europe

RCM regulatory

compliance mark

Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Functional safety

USA &

Canada

Eurasian conformity Eurasia

R

Key to approvals

NOTE

Product

information

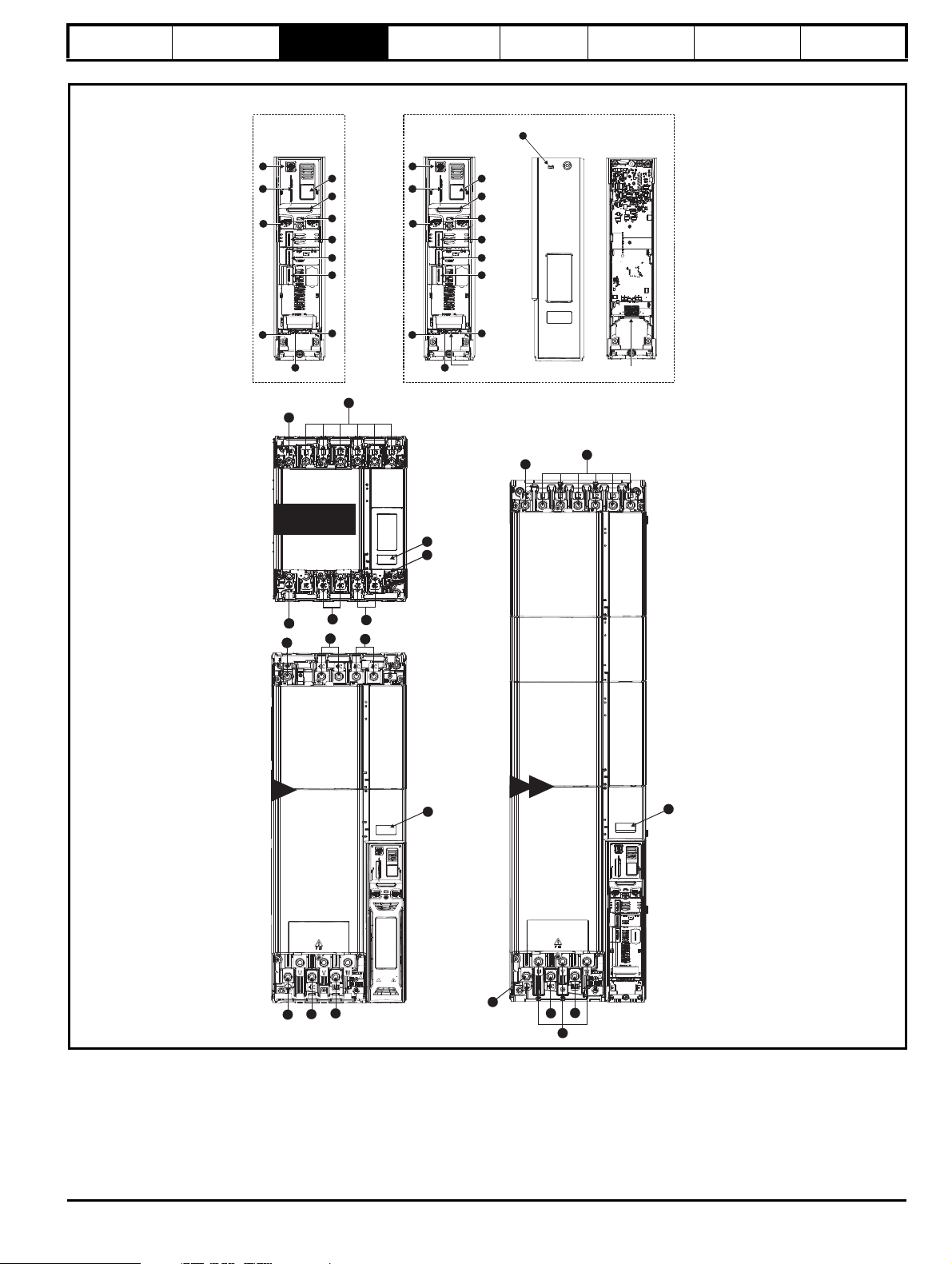

3.3 Nameplate description

Figure 3-3 illustrates typical nameplate and rating labels.

Figure 3-3 Typical drive rating labels

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Refer to Figure 2-13 Drive model number on page 15 for further information relating to the labels.

Date code format

The date code is split into two sections: a letter followed by a number. The letter indicates the year, and the number indicates the week number (within

the year) in which the drive was built. The letters go in alphabetical order, starting with A in 1991 (B in 1992, C in 1993 etc).

Example:

A date code of W28 would correspond to week 28 of year 2013.

22 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 23

Safety information Introduction

Approvals

Input voltage

Output

voltage

Customer and

datecode

Serial

number

Input

frequency

No.of phases &

Typical input current for

Normal Dutyrating

Output current

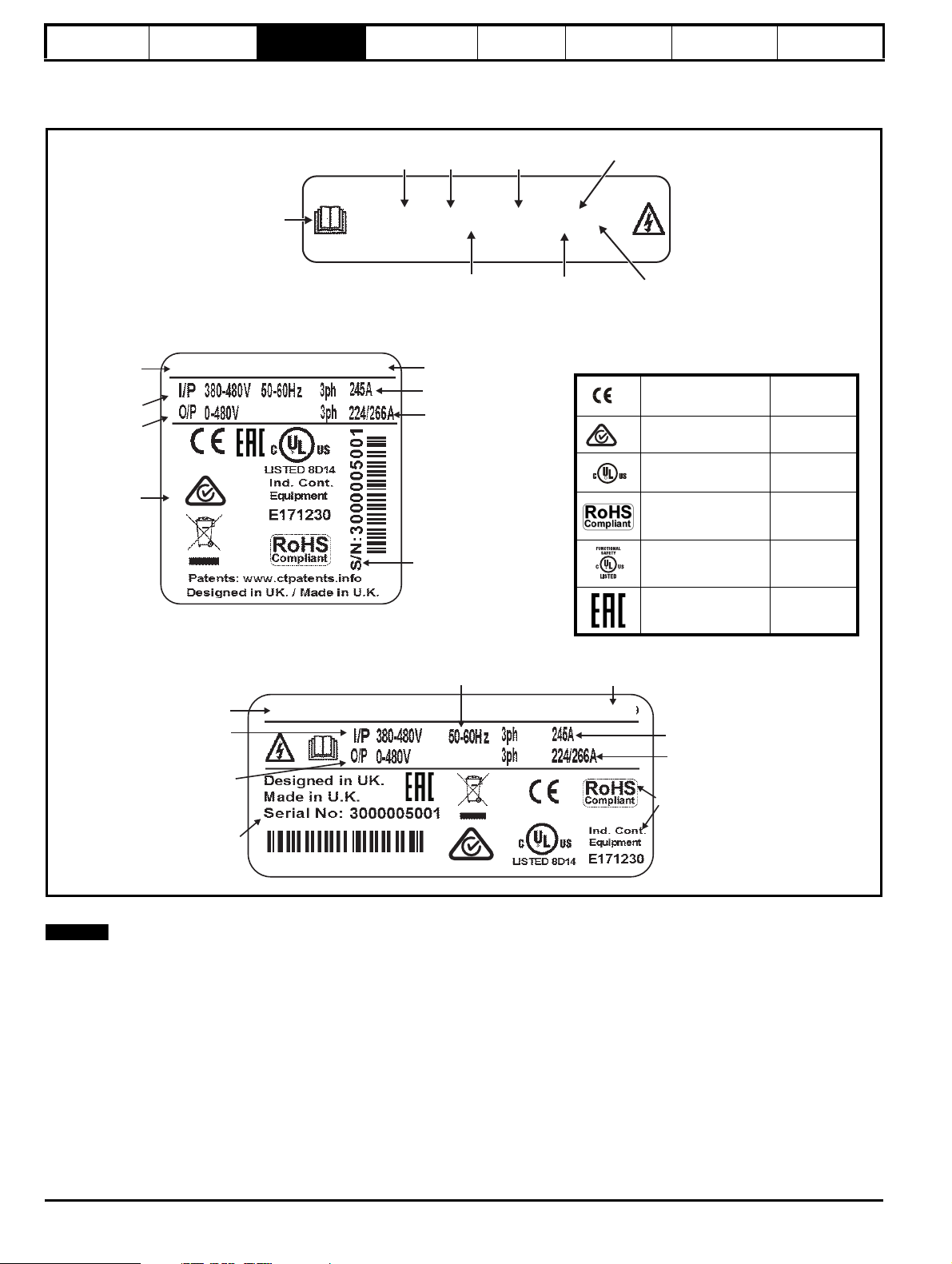

RECT-106 02480A STDN39

I/P 500-690V 50-60Hz 3ph 202A

O/P 640-1067V247A

Designed in UK

Made in U.K.

Serial No: 3000005001

Input current

Output current

Model

Input

frequency

Customer and

datecode

Approvals

Serial

number

Output

voltage

Input

voltage

Refer to

User Guide

Model

Frame

size

Voltage

Current rating

Rectifier format

RECT-106 02480A

Key to approvals

CE approval Europe

RCM regulatory

compliance mark

Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Functional safety

USA &

Canada

Eurasia conformity Eurasia

R

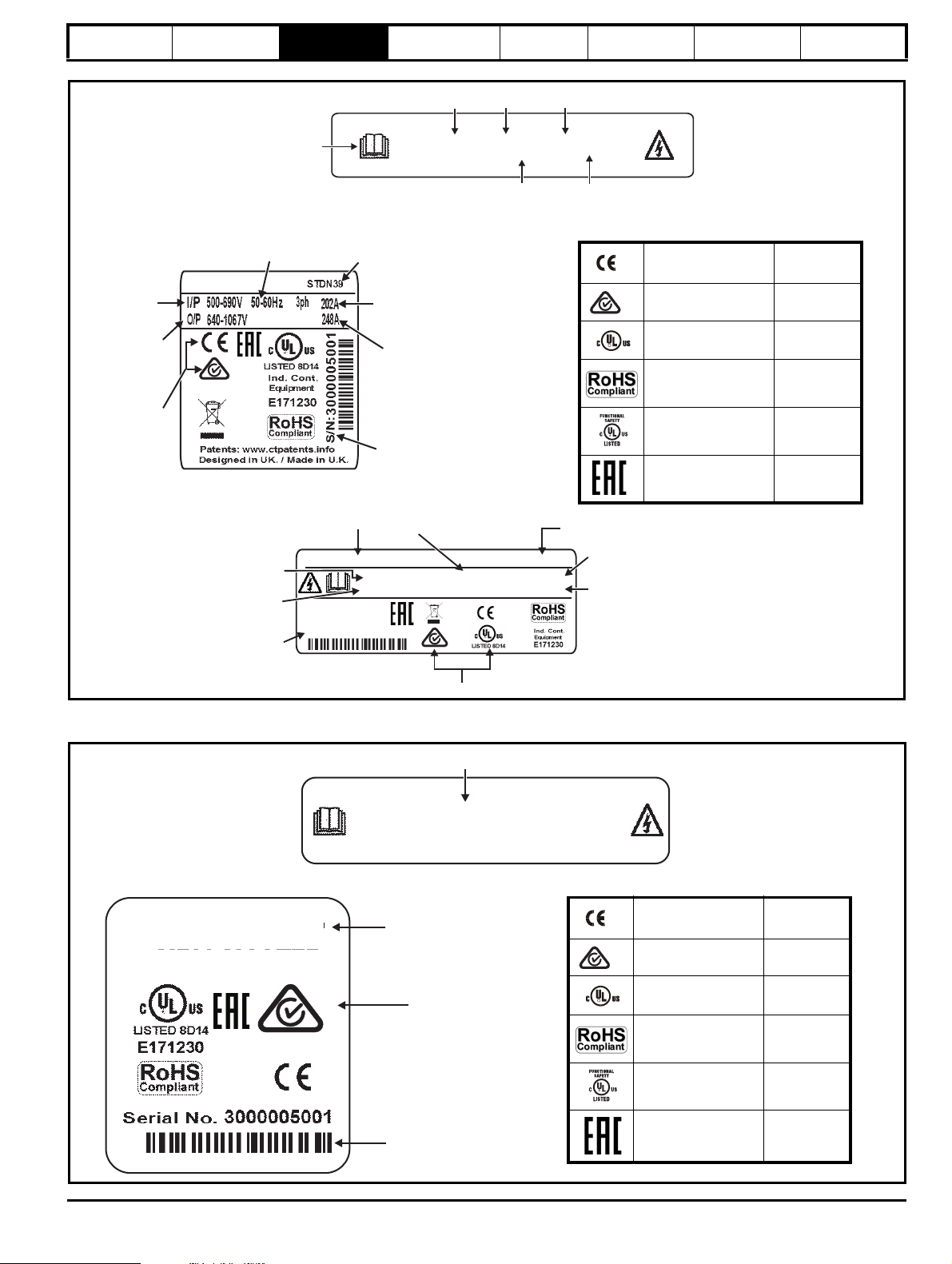

M700-MASTER

STDN39 Customer anddatecode

Approvals

Serial numbers

M700-MASTER

Model

Key to approvals

CE approval Europe

RCM regulatory

compliance mark

Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Functional safety

USA &

Canada

Eurasian conformity Eurasia

R

information

Figure 3-4 Typical rectifier rating labels

Product

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Refer to Figure 2-12 Rectifier model number on page 15 for further information relating to the labels.

Figure 3-5 Typical master pod rating labels

Unidrive M / Unidrive HS Modular Installation Guide 23

Issue Number: 5

Page 24

Safety information Introduction

Model

Serial number

Customer anddatecode

M000-FOLLOWER

STDN39

Approvals

Key to approvals

CE approval Europe

RCM regulatory

compliance mark

Australia

UL / cUL approval

USA &

Canada

RoHS compliant Europe

Functional safety

USA &

Canada

Eurasian conformity Eurasia

R

Size 9 and 10 single input line

reactor (INLX0X)

Size 9 and 10 dual output

sharing chokes (OTLX1X) for

parallel module drives

Size 9 and 10 single output

sharing choke (OTLX0X) for

parallel module drives

Size 11 single output sharing

choke (OTLX0X) for parallel

module drives.

EMC filter

Size 11 single input line

reactor (INLX0X)

Finger-guard

grommet double entry

kit 3470-0107 x 8

Size 11D Lifting tool

7778-0031

Size 9E/D/T, 10E/D/T and

size 10 Rectifier Lifting tool

7778-0016

Size 11E/T and size 11

single/twin Rectifier Lifting tool

7778-0030

*

Size 9A Lifting tool

7778-0045

CAUTION

Product

information

System

configuration

Figure 3-6 Typical follower pod rating label

Figure 3-7 Options available for Unidrive M/HS modular drives

Mechanical

Installation

Electrical

Installation

Technical data UL Information

* Limit drive output current to rating of dual output sharing choke.

A separate input line reactor of at least the value shown in Table 6-2 on page 93 must be used with all modular drives other than size 9A

(which has an internal line reactor). Failure to provide sufficient reactance could damage or reduce the service life of the rectifier or inverter.

24 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 25

Safety information Introduction

6612

NOTE

Product

information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

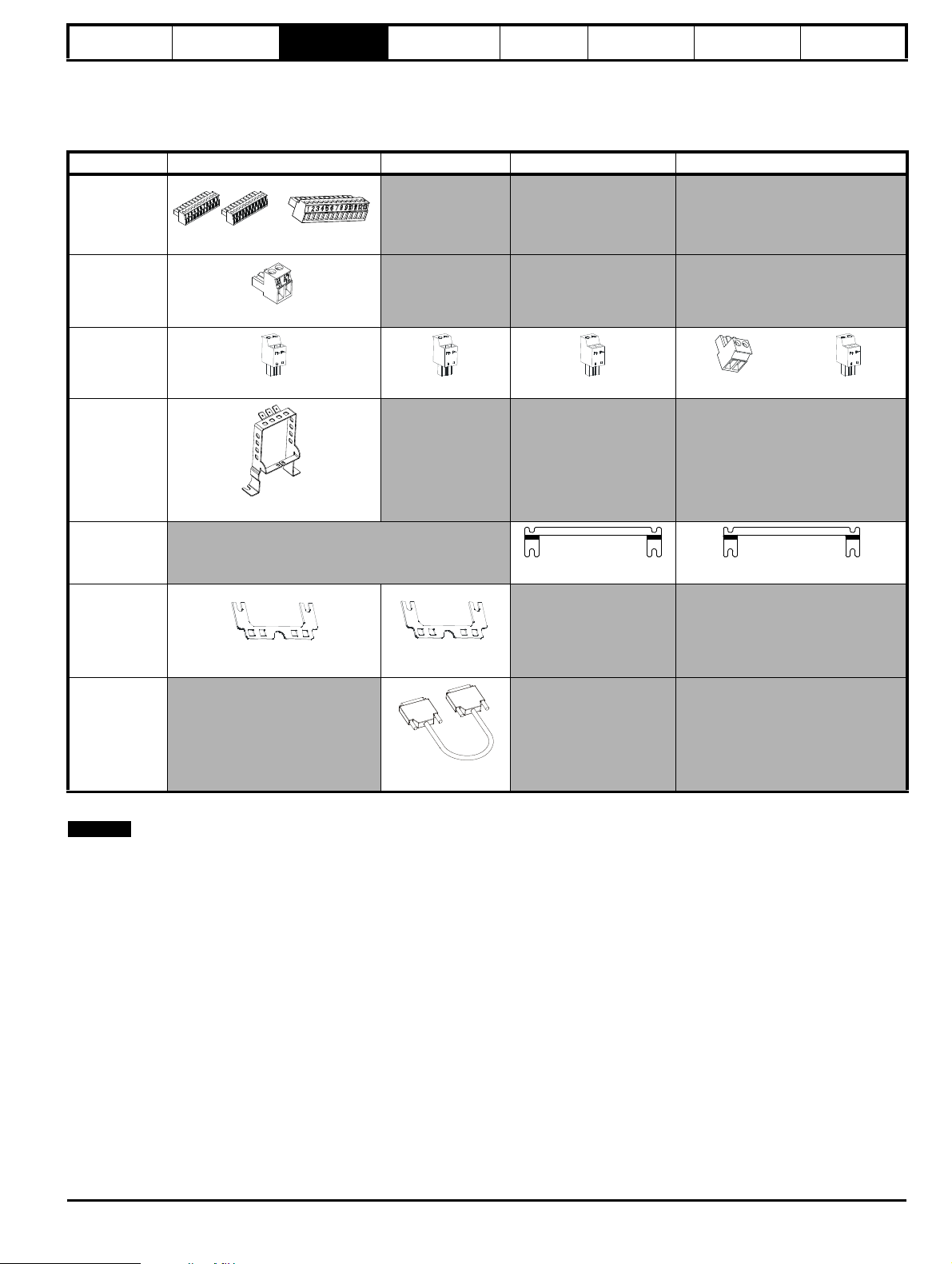

3.4 Supplied items

The drive/rectifier/pod is supplied with a safety information booklet, the Certificate of Quality and an accessory kit box including the items shown in

Table 3-7 (frame 9 and 10), and Table 3-8 (frame 11).

Table 3-7 Parts supplied with the size 9A/E/T, 10E/D

Description Standard / Master Pod Follower Pod Size 10 rectifier Size 9 and 10 inverter

Control

connections

x 1 x 1 x 1

Relay

connector

x 1

24 V power

supply

x 1 x 1 x 1 x1 x1

Grounding

bracket

Surface

mounting

bracket

Paralleling

cable

management

bracket

Paralleling

cable (2m)*

* A two meter paralleling cable is supplied with each follower pod, 1m, 2m and 5m cables are also available separately. Please see

section 4.1.2 Paralleling cable on page 38 for further details.

x 1

x 2 x 2

x 1 x 1

x 1

Unidrive M / Unidrive HS Modular Installation Guide 25

Issue Number: 5

Page 26

Safety information Introduction

6612

6612

NOTE

Product

information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

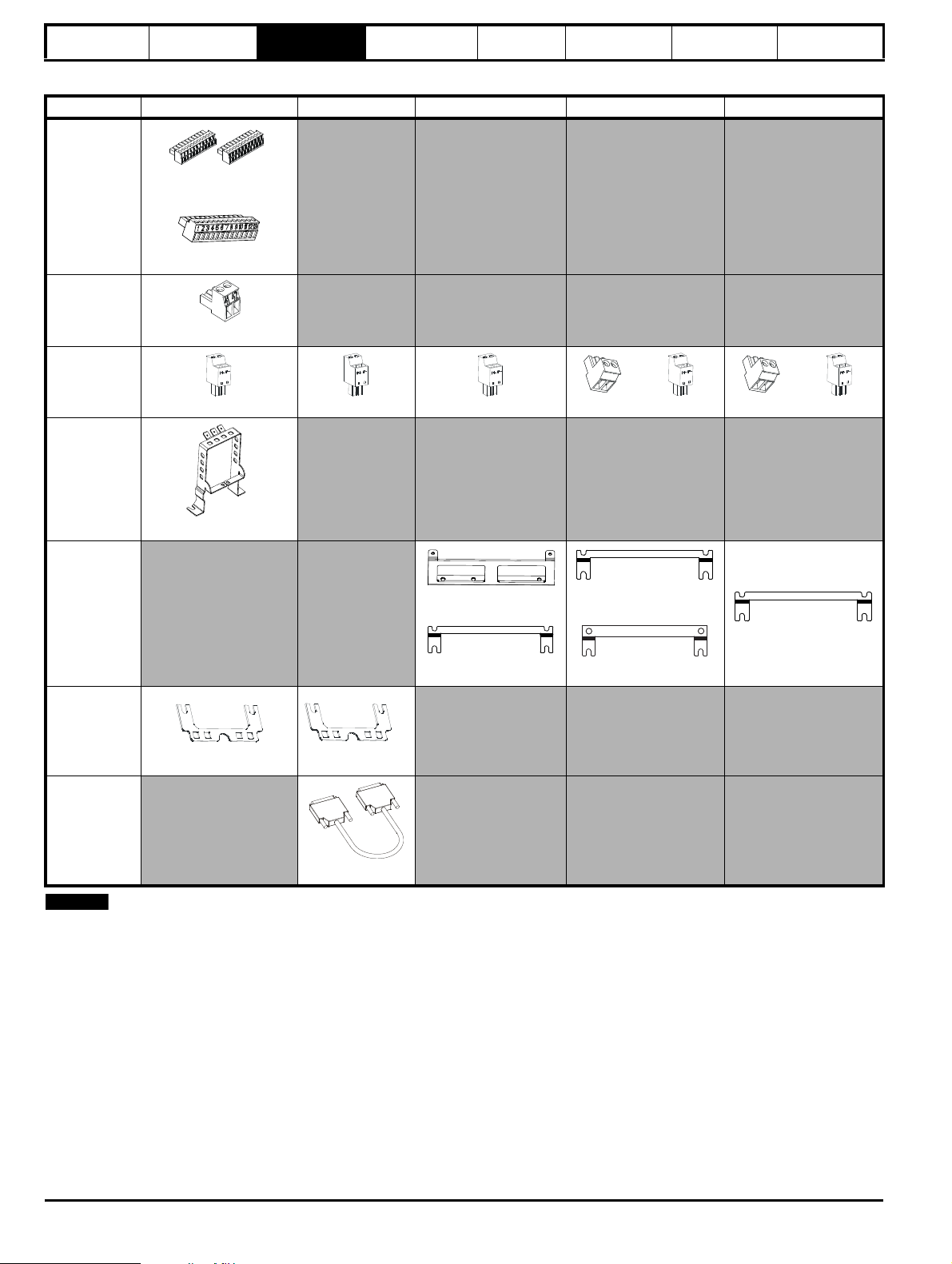

Table 3-8 Parts supplied with the size 11E/ D/T

Description Standard / Master Pod Follower Pod Size 11 rectifier Size 11E Size 11D

Control

connections

Relay

connector

24 V power

supply

Grounding

bracket

Surface

mounting

bracket

x 1 x 1

x 1

x 1

x 2 x 1 x 1 x1 x1 x1 x1

x 1

x 1

x 2

Paralleling

cable

management

bracket

Paralleling

cable (2m)

* A two meter paralleling cable is supplied with each follower pod, 1m, 2m and 5m cables are also available separately. Please see

section 4.1.2 Paralleling cable on page 38 for further details.

x 1 x 1

x 1

x 1

x 1

x 2

26 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 27

Input connections

Mains

Supply

L1 L2

Optional

EMC filter

Fuses

L3

L1 L2 L3

PE

Supply

ground

+DC -DC

U V W

Motor

Optional ground

connection

+DC BR

Thermal

overload

protection

device

Output connections

Internal EMC

filter

9A

Input connections

Mains

Supply

L1 L2

Line reactor

Optional

EMC filter

Fuses

L3

L1 L2

L3

PE

Supply

ground

9E

10E

UVW

Motor

Optional ground

connection

Output connections

+DC

BR

Thermal

overload

protection

device

Safety information Introduction Product information

System

configuration

Mechanical

Installation

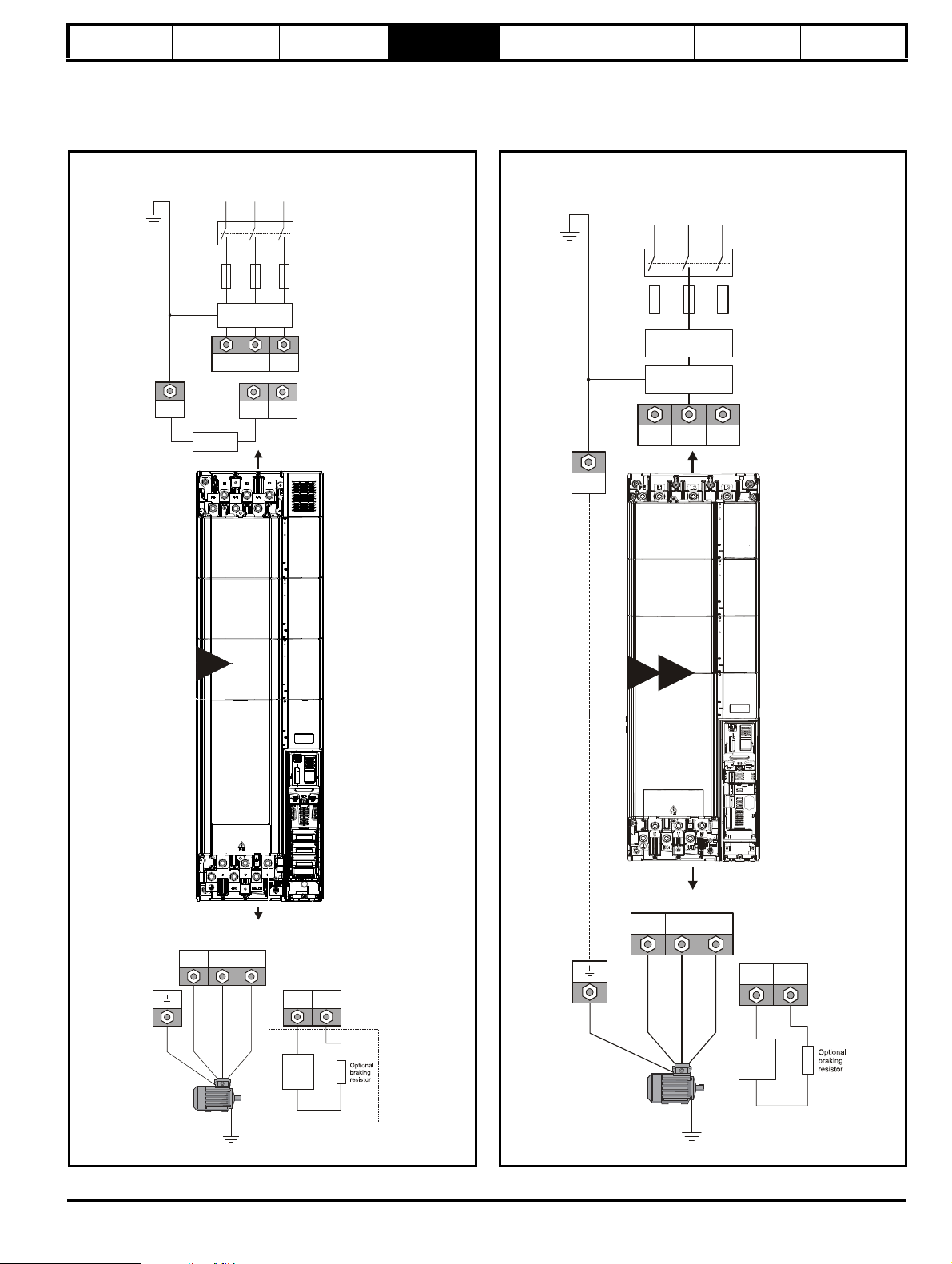

4 System configuration

This chapter describes the various Unidrive M / Unidrive HS size 9, 10 and 11 system configurations.

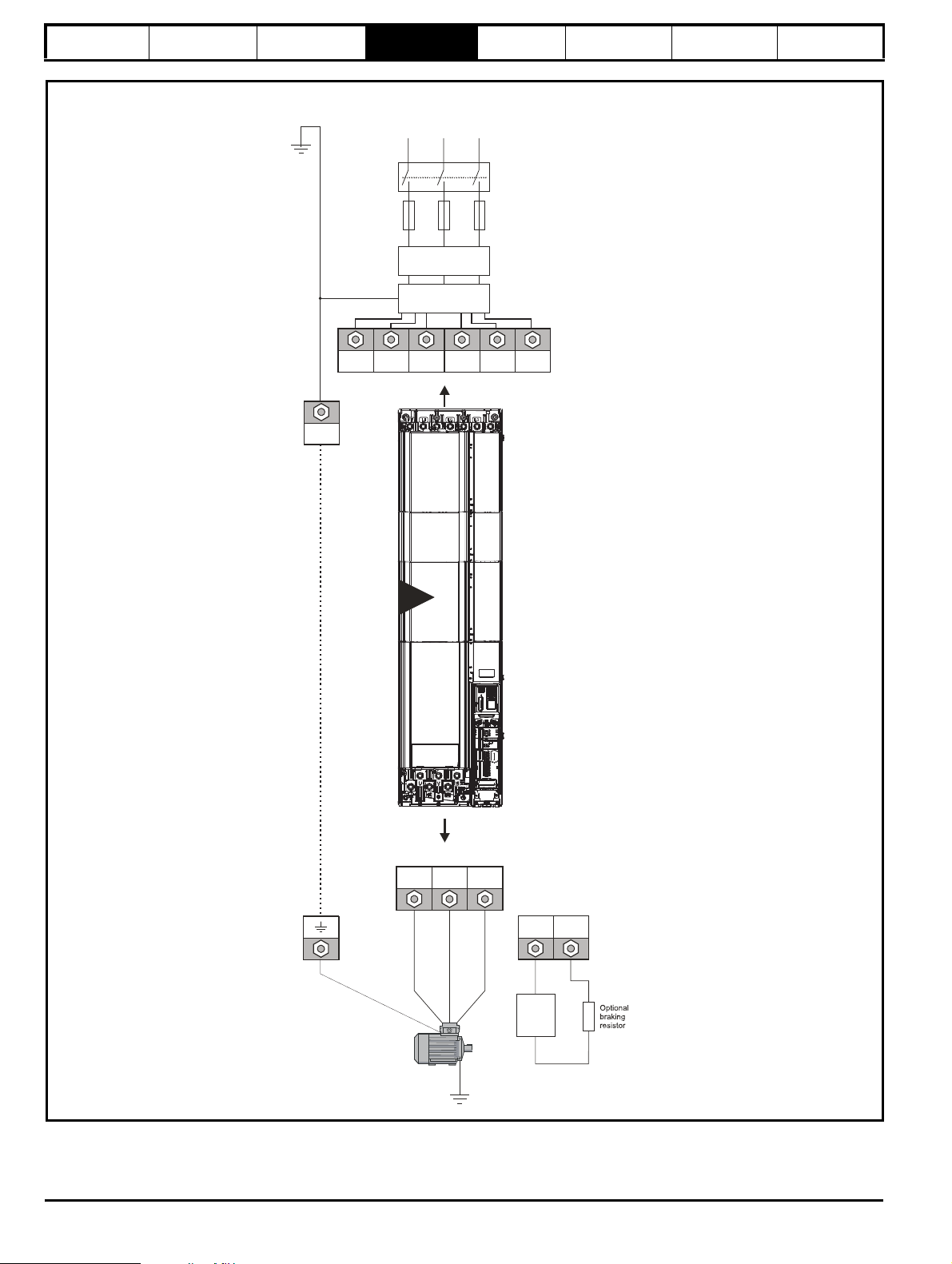

Figure 4-1 Layout for a Unidrive M / Unidrive HS size 9A module

operating on a 3-phase AC supply

Figure 4-2 Layout for a Unidrive M / Unidrive HS size 9E or 10E

module operating on a 3-phase AC supply

Electrical

Installation

Technical data UL Information

Unidrive M / Unidrive HS Modular Installation Guide 27

Issue Number: 5

Page 28

Safety information Introduction Product information

Supply connections

Mains

Supply

L1 L2

Linereactor

Optional

EMC filter

Fuses

L3

Supply

ground

U V W

Motor

Optional ground

connection

+DC BR

Thermal

overload

protection

device

Motor connections

PE

14

11E

L1 L1 L2

L2

L3

L3

*

System

configuration

Mechanical

Installation

Electrical

Installation

Figure 4-3 Layout for a Unidrive M / Unidrive HS size 11E module operating on a 3-phase AC supply

Technical data UL Information

* Connect to either terminal.

28 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 29

PE

Input connections

Mains

Supply

L1 L2

Line reactor

Optional EMC filter

Fuses

L3

Supply

ground

U V W

Motor

Optional ground

connection

Output connections

L1 L2 L3

+DC BR

Thermal

overload

protection

device

+DC

-DC

24 V

0 V

Comms

9D 10D

10

PE

Input connections

Mains

Supply

L1 L2

Line reactor

Optional EMC filter

Fuses

L3

Supply

ground

U V W

Motor

Optional ground

connection

Output connections

+DC BR

Thermal

overload

protection

device

24 V

0 V

Comms

11D

11

L1 L1 L2 L2 L3 L3

*

Safety information Introduction Product information

System

configuration

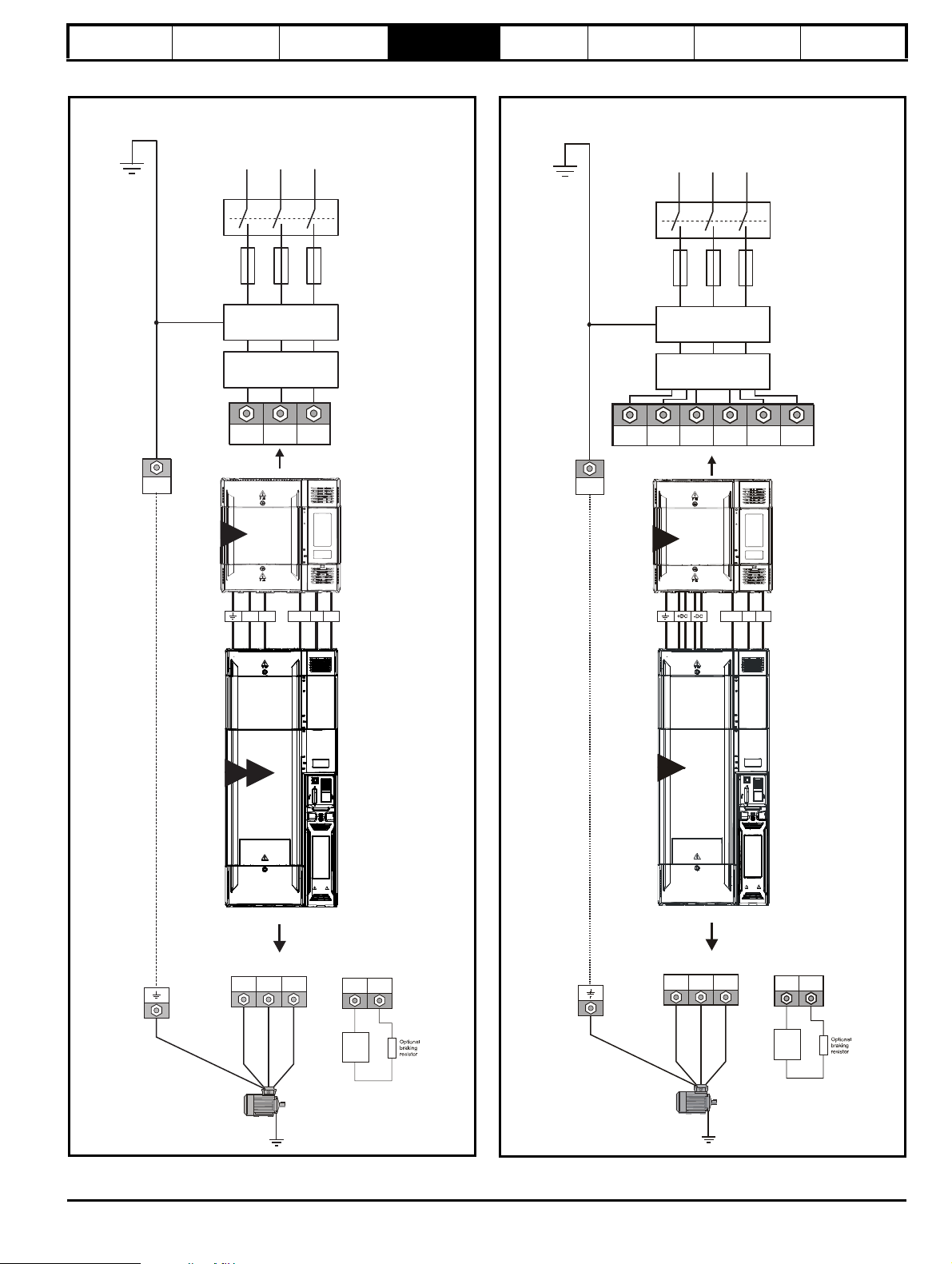

Figure 4-4 Layout for a Unidrive M / Unidrive HS size 9D and 10D

module operating on a 3-phase supply

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Figure 4-5 Layout for a Unidrive M / Unidrive HS size 11D

operating on a 3-phase supply

* Connect to either terminal.

Unidrive M / Unidrive HS Modular Installation Guide 29

Issue Number: 5

Page 30

Safety information Introduction Product information

Input connections

Mains

Supply

Mains

Supply

L1 L2

Line reactor*

Optional

EMC filter

Fuses

L3

L1 L2 L3

PE

Supply

ground

U V W

Motor

Optional ground

connection

Output connections

+DC BR

Thermal

overload

protection

device

L1 L2

Line reactor*

Optional

EMC filter

Fuses

L3

L1 L2 L3

11T

Rear row

of terminals

Front row

of terminals

System

configuration

Mechanical

Installation

Electrical

Installation

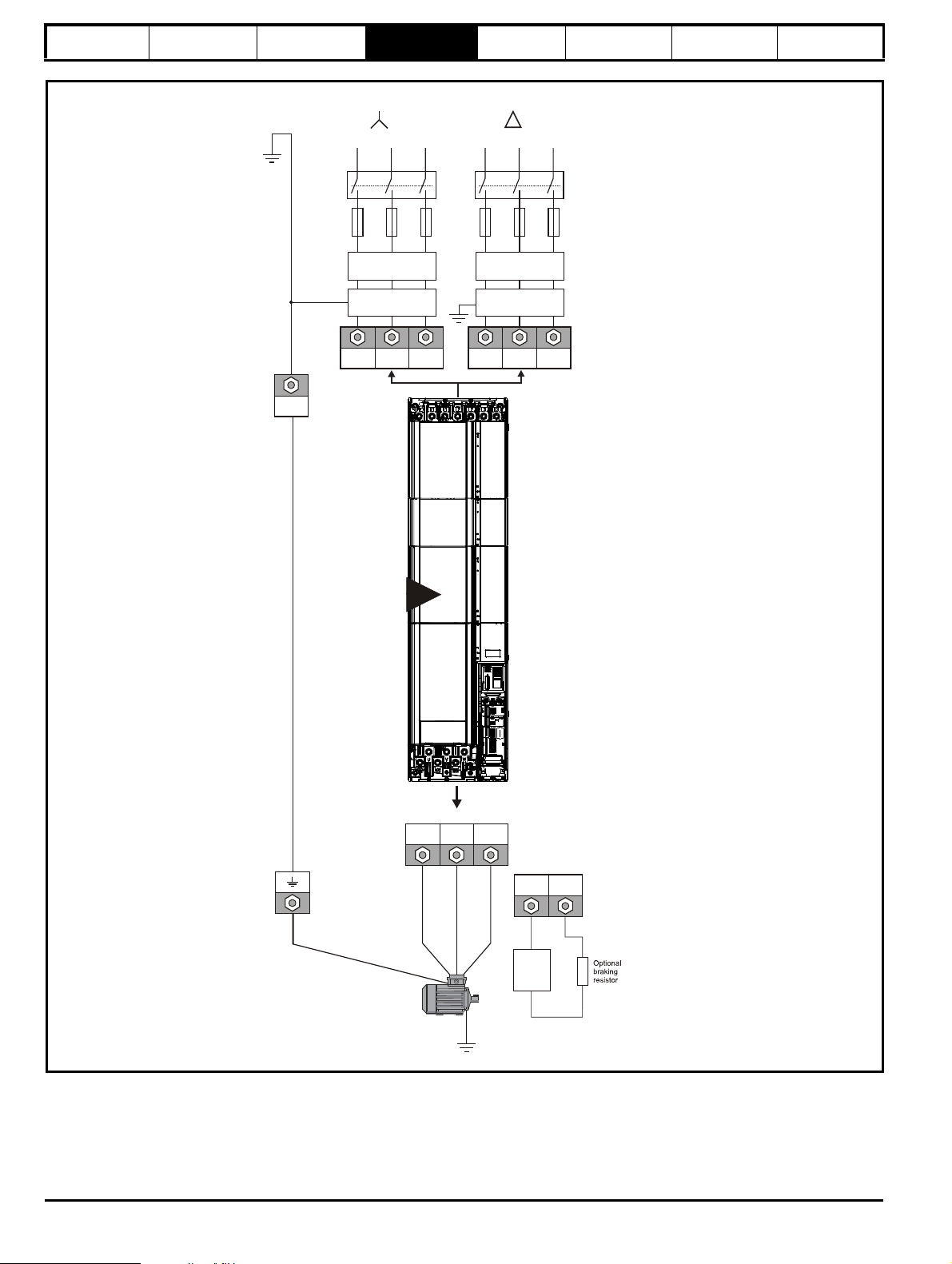

Figure 4-6 Layout for a Unidrive M / Unidrive HS size 11T supplied from a 12 pulse phase shifted AC supply

Technical data UL Information

* INL chokes may be omitted if:

1. The transformer is dedicated to the drive i.e. not shared with other equipment.

2. The transformer has reactances from primary to secondary and between secondaries of at least 4 % based on the drive rating. This represents a

fully wound transformer with loosely coupled secondaries whose rating (kVA) does not match the drive rating.

30 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 31

L3

L2

L1

Fuses Fuses

Master Follower

OTLXXX

sharing

chokes

UVW UVW

Paralleling cable

OTLXXX

sharing

chokes

9A

9A

Safety information Introduction Product information

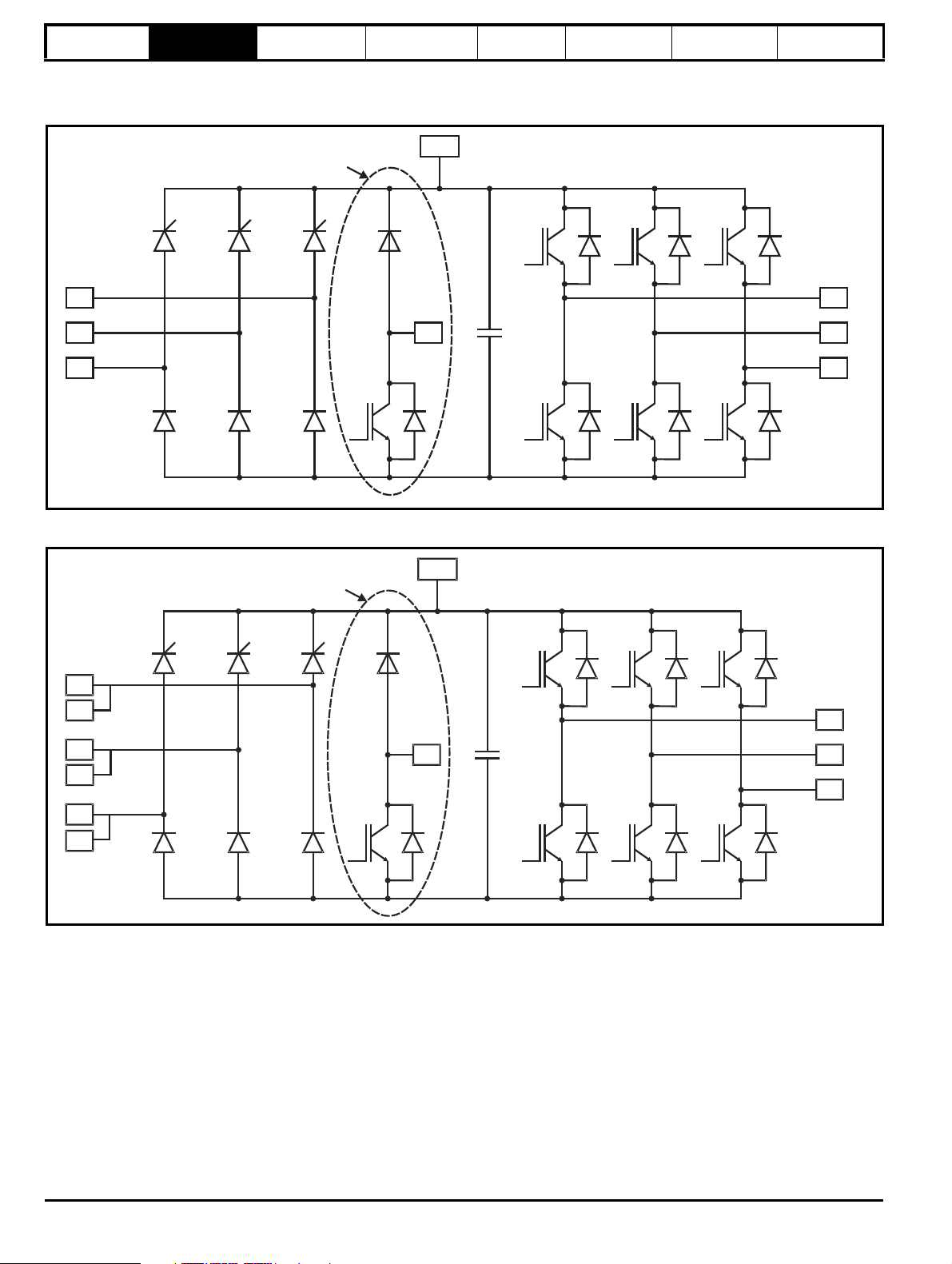

Figure 4-7 Layout for two Unidrive M / Unidrive HS size 9A modules operating on a 6 pulse 3-phase AC supply

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Unidrive M / Unidrive HS Modular Installation Guide 31

Issue Number: 5

Page 32

Safety information Introduction Product information

L3

L2

L1

Fuses

Fuses

Master Follower

OTLXXX

sharing

chokes

UVW UVW

Paralleling cable

OTLXXX

sharing

chokes

INLXXX

Line reactor

INLXXX

Line reactor

9E

11E

10E

9E

11E

10E

10E

Figure 4-8 Layout for two Unidrive M / Unidrive HS size 9E, 10E or 11E modules operating on a 6 pulse 3-phase AC supply

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

32 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 33

L3

L2

L1

MasterMaster FollowerFollower

INLXXX

Line reactor

INLXXX

Line reactor

CommsComms

24 V24 V

0 V0 V

FusesFuses

OTLXXX

sharing

chokes

U V W U V W

OTLXXX

sharing

Parallelling cable

chokes

9D9D

11

+DC

-DC

+DC

-DC

10D10D 11D 9D9D 10D10D 11D

111010 11 11 111010 11

Safety information Introduction Product information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Figure 4-9 Layout for two or more Unidrive M / Unidrive HS size 9D, 10D or 11D with single size 10 or 11 rectifiers operating on a 6 pulse

3-phase AC supply

Unidrive M / Unidrive HS Modular Installation Guide 33

Issue Number: 5

Page 34

Safety information Introduction Product information

MasterMaster FollowerFollower

INLXXX

Line reactor*

INLXXX

Line reactor*

FusesFuses

OTLXXX

sharing

chokes

U V W U V W

OTLXXX

sharing

Parallelling cable

chokes

L3

L2

L1

L3

L2

L1

11D 11D

11

11

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Figure 4-10 Layout for two Unidrive M / Unidrive HS size 11D with single size 11 rectifiers operating on a 12 pulse phase shifted AC supply

* INL chokes may be omitted if:

1. The transformer is dedicated to the drive i.e. not shared with other equipment.

2. The transformer has reactances from primary to secondary and between secondaries of at least 4% based on the drive rating. This represents a

fully-wound transformer with loosely-coupled secondaries whose rating (kVA) does not much exceed the drive rating.

34 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 35

2 x INLXXX

Line reactor

Comms

24 V

0 V

Fuses

Fuses

OTLXXX

sharing

chokes

U V W

OTLXXX

sharing

Parallelling cable

chokes

9D9D 10D10D

9D9D 10D10D

L3

L2

L1

L3

L2

L1

+DC

-DC

11

Safety information Introduction Product information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

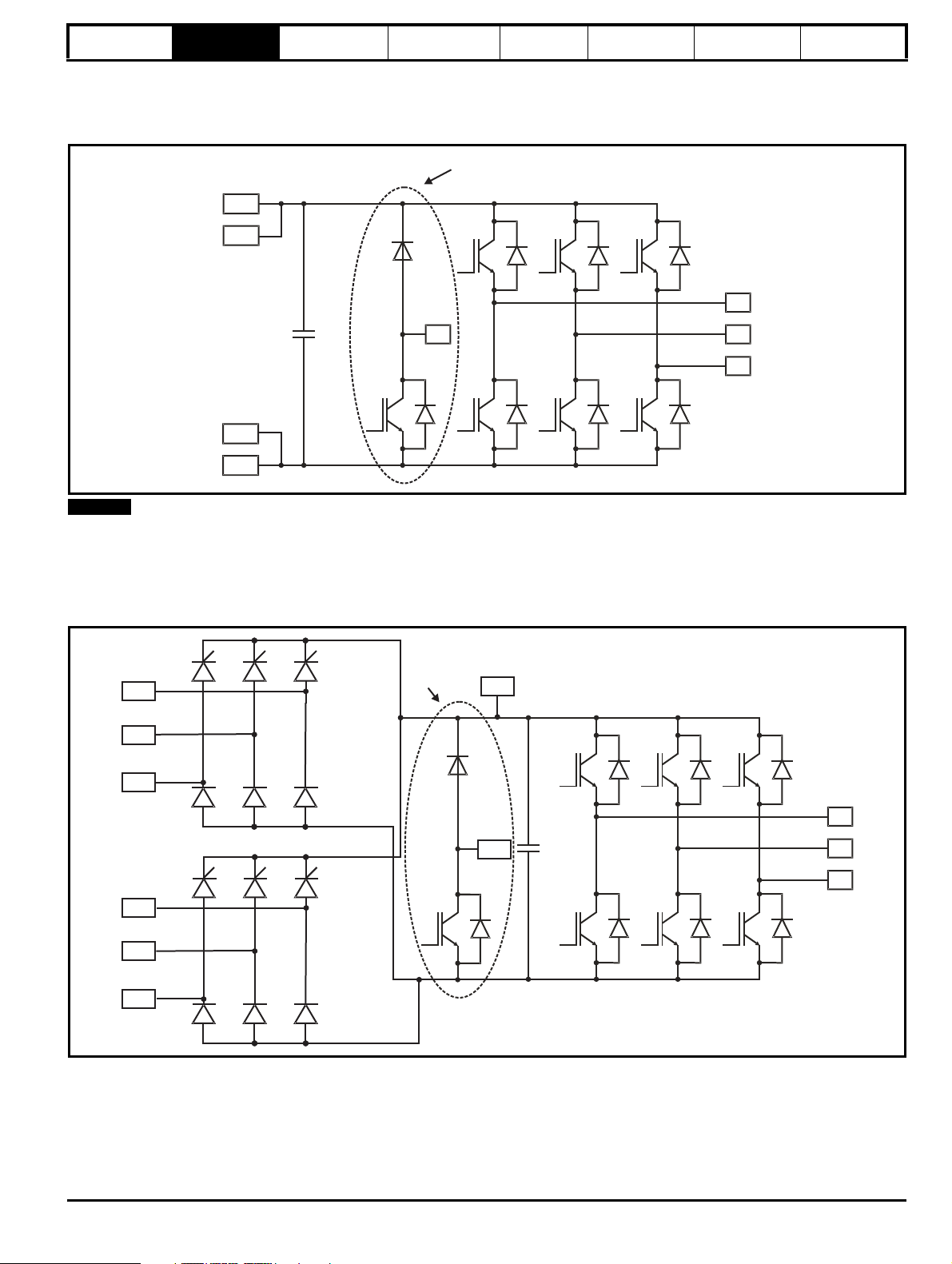

Figure 4-11 Layout for two Unidrive M / Unidrive HS size 9D/10D with twin size 11 rectifier on a 6 pulse 3-phase supply

Unidrive M / Unidrive HS Modular Installation Guide 35

Issue Number: 5

Page 36

Safety information Introduction Product information

2 x INLXXX

Line reactor*

Fuses

Fuses

L3

L2

L1

L3

L2

L1

OTLXXX

sharing

chokes

U V W

OTLXXX

sharing

Parallelling cable

chokes

9D9D 10D10D

9D9D 10D10D

11

+DC

-DC

U V W

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

Figure 4-12 Layout for two Unidrive M / Unidrive HS size 9D/10D with twin size 11 rectifier operating on a 12 pulse phase shifted AC supply

* INL chokes may be omitted if:

1. The transformer is dedicated to the drive i.e. not shared with other equipment.

2. The transformer has reactances from primary to secondary and between secondaries of at least 4% based on the drive rating. This represents a

fully-wound transformer with loosely-coupled secondaries whose rating (kVA) does not much exceed the drive rating.

36 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 37

Safety information Introduction Product information

(2)

(2)

(2)

AC fuses not adequate

DC fuses are required

AC fuses are adequate

(3)

(3)

(3) (3)

(2)

(3)

(2)

(3)

NOTE

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

4.1.1 DC fusing

The Unidrive M/HS modular system has undergone safety testing and proving when using the specified AC input fuses, including the case where the

size 11 twin rectifier is used to supply two D type modules. A fault in any module is cleared by the AC input fuses.

If more rectifiers or inverters are connected to the DC bus then the prospective fault current and the energy delivered before a fault is cleared are

increased because of the multiple sources and the increased stored energy in the inverter capacitors. It then becomes necessary to provide fuses in

the DC bus. This is illustrated in Figure 4-13.

Figure 4-13 Fault current contributions

As shown in Figure 4-14 when DC fuses are required they must be placed in the rectifier output circuits as well as the inverter inputs, since they are

also exposed to the total fault-current infeed. For the size 11 twin rectifier, only one fuse pair is needed for the complete module.

The only exception to this rule is where the rectifier input fuses are reduced in rating so that the total i2t let-through for all of the phases is no greater

than that for the standard recommended fuses for the 6-pulse arrangement. This will be the case for some of the lower-power multi-pulse

arrangements. This needs to be verified on a case-by-case basis.

All DC fuses are in pairs, i.e. one in each pole, to provide protection against earth faults.

Figure 4-14 12-pulse system using twin rectifiers and 6-phase AC distribution with odd number of inverter modules

Please see Table 6-15 DC fuse and cable ratings for Unidrive M / HS size 9, 10 and 11 inverters on page 102 for DC fuse ratings.

Unidrive M / Unidrive HS Modular Installation Guide 37

Issue Number: 5

Page 38

Safety information Introduction Product information

System

configuration

Mechanical

Installation

Electrical

Installation

Technical data UL Information

4.1.2 Paralleling cable

Part numbers

A single two meter paralleling cable is supplied with each follower pod. 1 m, 2 m and 5 m cables are also available separately (see Table 4-1 for part

numbers)

Table 4-1 Paralleling cable part numbers

Description Part number

1 m paralleling cable 3471-9842

2 m paralleling cable 3471-0013

5 m paralleling cable 3471-6850

Maximum lengths

Individual links between modules should be nominally 2 m in length however a maximum of two 5 m lengths can be used in a parallel system. The

maximum combined paralleling cable length can not exceed 40 m.

38 Unidrive M / Unidrive HS Modular Installation Guide

Issue Number: 5

Page 39

Safety information Introduction Product information

WARNING

WARNING

WARNING

WARNING

NOTE

Drive

5

o

5

o

Notless

tha n 2X

Ba ffle plate s (m ay be

aboveor below bottom

ofenclosure)

X

Bottom of fire

enclosure

Not less

than 2

times ‘X’

Baffle plates (may be above or

below bottom of enclosure)

Bottom of fire enclosure

X

System

configuration

5 Mechanical Installation