Emerson Unidrive M600, Unidrive M700, Unidrive M800, Unidrive M702, Unidrive M70 Installation Manual

...Page 1

Power Installation Guide

Unidrive M

Frame 5 to 6

Part Number: 0478-0255-03

Issue: 3

Page 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC.

General Information

This guide covers the basic information that is required to set-up and run the drive, in applications where a

drive malfunction does not result in a mechanical hazard. When the drive is used in a safety related

application, i.e. where a malfunction might result in a hazard, it is essential to refer to the full user guide. The

Drive User Guide is available for download from www.controltechniques.com/userguides.

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or

incorrect installation or adjustment of the optional operating parameters of the equipment or from

mismatching the variable speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment

to a policy of continuous development and improvement, the manufacturer reserves the right to change the

specification of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means,

electrical or mechanical including photocopying, recording or by an information storage or retrieval system,

without permission in writing from the publisher.

Drive firmware version

This product is supplied with the latest firmware version. If this drive is to be connected to an existing system

or machine, all drive firmware versions should be verified to confirm the same functionality as drives of the

same model already present. This may also apply to drives returned from a Control Techniques Service

Centre or Repair Centre. If there is any doubt please contact the supplier of the product.

The firmware version of the drive can be checked by looking at Pr 11.029

Environmental statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations

and of its products throughout their life cycle. To this end, we operate an Environmental Management System

(EMS) which is certified to the International Standard ISO 14001. Further information on the EMS, our

Environmental Policy and other relevant information is available on request, or can be found at

www.greendrives.com.

The electronic variable-speed drives manufactured by Control Techniques have the potential to save energy

and (through increased machine/process efficiency) reduce raw material consumption and scrap throughout

their long working lifetime. In typical applications, these positive environmental effects far outweigh the

negative impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but

should instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the products

easy to dismantle into their major component parts for efficient recycling. Many parts snap together and can

be separated without the use of tools, while other parts are secured with conventional fasteners. Virtually all

parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while

smaller products come in strong cardboard cartons which themselves have a high recycled fibre content. If

not re-used, these containers can be recycled. Polythene, used on the protective film and bags for wrapping

product, can be recycled in the same way. Control Techniques' packaging strategy prefers easily-recyclable

materials of low environmental impact, and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best

practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals

(REACH) requires the supplier of an article to inform the recipient if it contains more than a specified

proportion of any substance which is considered by the European Chemicals Agency (ECHA) to be a

Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory

authorisation.

For current information on how this requirement applies in relation to specific Control Techniques products,

please approach your usual contact in the first instance. Control Techniques position statement can be

viewed at:

http://www.controltechniques.com/REACH

Copyright © February 2015 Control Techniques Ltd

Issue Number: 3

Drive Firmware: 01.07.01.00 onwards

Page 3

Contents

1 Safety information .......................................................................................8

1.1 Warnings, Cautions and Notes ................................................................................ 8

1.2 Electrical safety - general warning ........................................................................... 8

1.3 System design and safety of personnel ................................................................... 8

1.4 Environmental limits ................................................................................................ 9

1.5 Access ..................................................................................................................... 9

1.6 Fire protection .......................................................................................................... 9

1.7 Compliance with regulations ....................................................................................9

1.8 Motor .......................................................................................................................9

1.9 Mechanical brake control ......................................................................................... 9

1.10 Adjusting parameters ............................................................................................. 10

1.11 Electrical installation .............................................................................................. 10

2 Product information ..................................................................................11

2.1 Model number ........................................................................................................ 11

2.2 Nameplate description ........................................................................................... 11

2.3 Ratings .................................................................................................................. 12

2.4 Drive features ........................................................................................................ 14

3 Mechanical installation .............................................................................15

3.1 Safety information .................................................................................................. 15

3.2 Fire protection ........................................................................................................ 15

3.3 Mounting methods .................................................................................................15

3.4 Drive dimensions ................................................................................................... 16

3.5 Surface mounting .................................................................................................. 18

3.6 Through-panel mounting ....................................................................................... 18

3.7 Installation of high IP insert for size 5 .................................................................... 19

3.8 Terminal size and torque settings ..........................................................................20

3.9 Enclosure ............................................................................................................... 23

3.10 EMC filters ............................................................................................................. 24

4 Electrical installation ................................................................................. 27

4.1 Supply types .......................................................................................................... 28

4.2 Supply requirements .............................................................................................. 28

4.3 Motor requirements ............................................................................................... 28

4.4 Ratings .................................................................................................................. 29

4.5 Power connections ................................................................................................30

4.6 Ground connections ..............................................................................................32

4.7 Braking resistor values .......................................................................................... 32

5 Technical data ............................................................................................ 33

5.1 Drive technical data ............................................................................................... 33

6 UL listing information ...............................................................................42

6.1 General ..................................................................................................................42

6.2 Overload, overcurrent and overspeed protection .................................................. 42

6.3 Short-circuit protection for branch circuits ............................................................. 43

6.4 Control circuit protection ........................................................................................ 43

6.5 Wiring terminal markings ....................................................................................... 44

6.6 Environment .......................................................................................................... 44

6.7 Mounting ................................................................................................................ 44

6.8 Listed accessories ................................................................................................. 45

Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 4

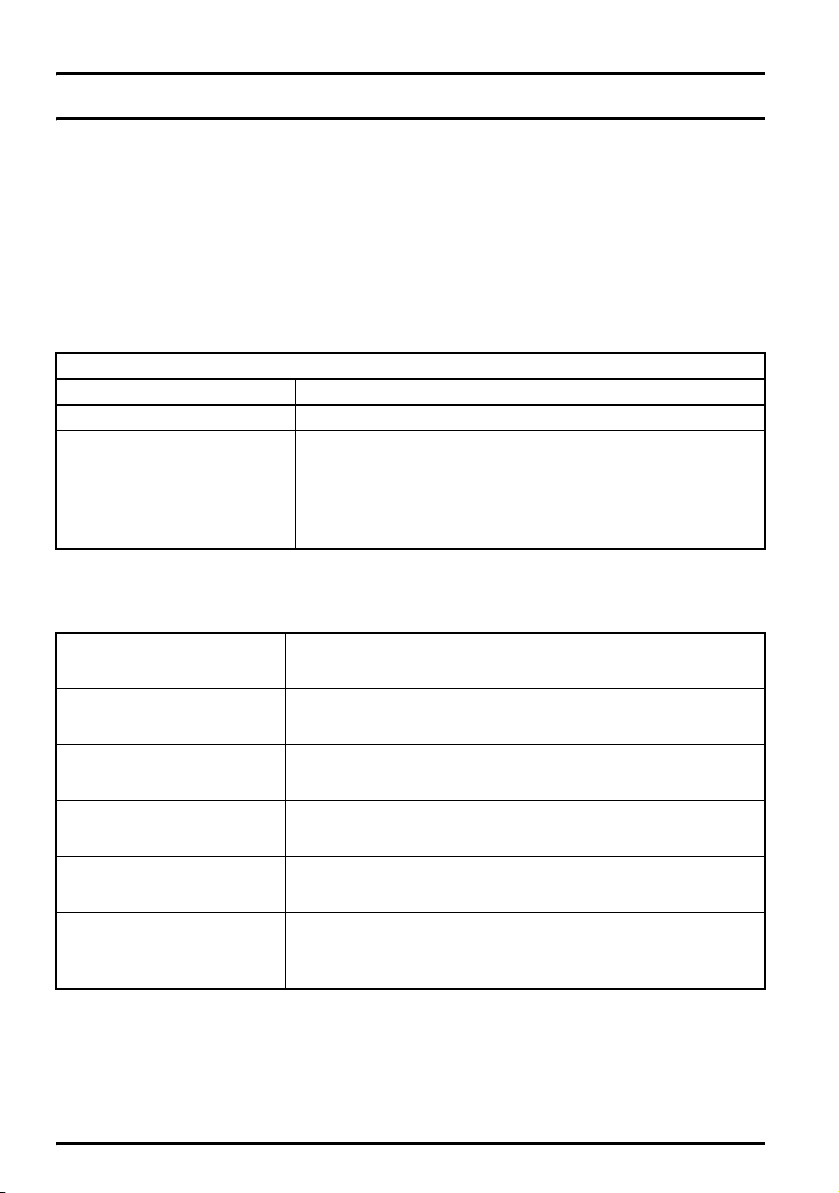

Declaration of Conformity

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration applies to Unidrive M/HS variable speed drive products, comprising models

numbers as shown below:

Xaaa-bbbbbbbbb Valid characters:

X M or HS*

aaa 600, 700, 701, 702, 800, 810, 70, 71, 72

05200250A, 05400270A, 05400300A, 05500030A, 05500040A,

05500069A

bbbbbbbbb

* HS = High Speed.

The AC variable speed drive products listed above have been designed and manufactured in

accordance with the following European harmonized standards:

EN 61800-5-1:2007

EN 61800-3:2004

06200330A, 06200440A, 06400350A, 06400420A, 06400470A,

06500100A, 06500150A, 06500190A, 06500230A, 06500290A,

06500350A

Adjustable speed electrical power drive systems - safety

requirements - electrical, thermal and energy

Adjustable speed electrical power drive systems. EMC product

standard including specific test methods

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

EN 61000-6-2:2005

EN 61000-6-4:2007

EN 61000-3-2:2006

EN 61000-3-3:2008

EN 61000-3-2:2006 Applicable where input current <16 A. No limits apply for professional equipment

where input power >1 kW.

These products comply with the requirements of the Restriction of Hazardous Substances (RoHS)

Directive 2011/65/EU, the Low Voltage Directive 2006/95/EC and the Electromagnetic Compatibility

Directive 2004/108/EC.

Electromagnetic compatibility (EMC). Generic standards.

Immunity standard for industrial environments

Electromagnetic compatibility (EMC). Generic standards.

Emission standard for industrial environments

Electromagnetic compatibility (EMC), Limits, Limits for harmonic

current emissions (equipment input current <16 A per phase)

Electromagnetic compatibility (EMC), Limits, Limitation of

voltage fluctuations and flicker in low-voltage supply systems for

equipment with rated current <16 A

4 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 5

These electronic drive products are intended to be used with appropriate motors, controllers,

T. Alexander

Control Techniques Vice President, Technology

Newtown

Date: 9th December 2014

electrical protection components and other equipment to form complete end products or

systems. Compliance with safety and EMC regulations depends upon installing and

configuring drives correctly, including using the specified input filters. The drives must be

installed only by professional assemblers who are familiar with requirements for safety and

EMC. The assembler is responsible for ensuring that the end product or system complies

with all the relevant laws in the country where it is to be used. Refer to the Drive User Guide.

An EMC Data Sheet is also available giving detailed EMC information.

Unidrive M Frame 5 to 6 Power Installation Guide 5

Issue Number: 3

Page 6

De cl ar at io n o f C on fo rm ity

NOTE

(including 2006 Machinery Directive)

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration applies to the Unidrive M/HS variable speed drive product range, comprising model

numbers composed as shown below:

Maaa-bbbbbbbbb Valid characters:

X M or HS*

aaa 600, 700, 701, 702, 800, 810, 70, 71, 72

05200250A, 05400270A, 05400300A, 05500030A, 05500040A, 05500069A

bbbbbbbbb

* HS = High Speed

This declaration relates to these products when used as a safety component of a machine.

Only the SAFE TORQUE OFF function may be used for a safety function of a machine. None

of the other functions of the drive may be used to carry out a safety function.

These products fulfil all the relevant provisions of Directives 2006/42/EC (The Machinery Directive)

and 2004/108/EC (The EMC Directive).

EC type-examination has been carried out by the following notified body:

TÜV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 K

Notified Body identification number: 0035

EC type-examination certificate number: 01/205/5270/12

Öln

06200330A, 06200440A, 06400350A, 06400420A, 06400470A, 06500100A,

06500150A, 06500190A, 06500230A, 06500290A, 06500350A

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

For more information regarding SAFE TORQUE OFF, refer to section 3.4 in the Drive User

Guide.

6 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 7

The harmonized standards used are shown below:

T. Alexander

VP Technology

Date: 10th December 2014

Place: Newtown, Powys. UK

EN 61800-5-1:2007

EN 61800-3:2004

EN 61000-6-2:2005

EN 61000-6-4:2007

EN 61000-3-2:2006

EN 61000-3-3:2008

Person authorised to compile the technical file:

C Hargis

Chief Engineer

Newtown, Powys. UK

IMPORTANT NOTICE

These drive products are intended to be used with appropriate motors, sensors, electrical

protection components and other equipment to form complete systems. It is the

responsibility of the installer to ensure that the design of the complete machine, including its

safety-related control system, is carried out in accordance with the requirements of the

Machinery Directive and any other relevant legislation. The use of a safety-related drive in

itself does not ensure the safety of the machine.

Compliance with safety and EMC regulations depends upon installing and configuring

inverters correctly. The inverters must be installed only by professional assemblers who are

familiar with requirements for safety and EMC. The assembler is responsible for ensuring that

the end product or system complies with all the relevant laws in the country where it is to be

used. Refer to the Drive User Guide.

Adjustable speed electrical power drive systems - safety

requirements - electrical, thermal and energy

Adjustable speed electrical power drive systems. EMC product

standard including specific test methods

Electromagnetic compatibility (EMC). Generic standards.

Immunity standard for industrial environments

Electromagnetic compatibility (EMC). Generic standards.

Emission standard for industrial environments

Electromagnetic compatibility (EMC), Limits, Limits for harmonic

current emissions (equipment input current <16 A per phase)

Electromagnetic compatibility (EMC), Limits, Limitation of

voltage fluctuations and flicker in low-voltage supply systems for

equipment with rated current <16 A

Unidrive M Frame 5 to 6 Power Installation Guide 7

Issue Number: 3

Page 8

1 Safety information

WARNING

CAUT ION

NOTE

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could

be lethal. Extreme care is necessary at all times when working with or adjacent to the

drive. Specific warnings are given at the relevant places in this guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete

equipment or a system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy,

and is used to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid

hazards either in normal operation or in the event of equipment malfunction. System

design, installation, commissioning/start-up and maintenance must be carried out by

personnel who have the necessary training and experience. They must read this safety

information and this User Guide carefully.

The STOP and SAFE TORQUE OFF functions of the drive do not isolate dangerous

voltages from the output of the drive or from any external option unit. The supply must be

disconnected by an approved electrical isolation device before gaining access to the

electrical connections.

With the sole exception of the SAFE TORQUE OFF function, none of the drive

functions must be used to ensure safety of personnel, i.e. they must not be used

for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a

hazard, either through their intended behavior or through incorrect operation due to a

fault. In any application where a malfunction of the drive or its control system could lead to

or allow damage, loss or injury, a risk analysis must be carried out, and where necessary,

further measures taken to reduce the risk - for example, an over-speed protection device

in case of failure of the speed control, or a fail-safe mechanical brake in case of loss of

motor braking.

The SAFE TORQUE OFF function may be used in a safety-related application. The

system designer is responsible for ensuring that the complete system is safe and

designed correctly according to the relevant safety standards.

8 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 9

1.4 Environmental limits

Instructions in this guide regarding transport, storage, installation and use of the drive

must be complied with, including the specified environmental limits. Drives must not be

subjected to excessive physical force.

1.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which

apply at the place of use must be complied with.

Safety information

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must

be provided. For further information, refer to the Drive User Guide.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national

wiring regulations, accident prevention regulations and electromagnetic compatibility

(EMC) regulations. Particular attention must be given to the cross-sectional areas of

conductors, the selection of fuses or other protection, and protective ground (earth)

connections.

This guide contains instruction for achieving compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used must comply with

the following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations.

Ensure the motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is

intended to use the capability of the drive to run a motor at speeds above its designed

maximum, it is strongly recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less

effective. The motor should be installed with a protection thermistor. If necessary, an

electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection of the motor. The

default values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 motor rated current. This

affects the thermal protection of the motor.

Product information Mechanical installation Electrical installation Technical data UL listing information

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated operation of an

external brake with the drive. While both hardware and software are designed to high

standards of quality and robustness, they are not intended for use as safety functions, i.e.

where a fault or failure would result in a risk of injury. In any application where the

incorrect operation of the brake release mechanism could result in injury, independent

protection devices of proven integrity must also be incorporated.

Unidrive M Frame 5 to 6 Power Installation Guide 9

Issue Number: 3

Page 10

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be

altered without careful consideration of the impact on the controlled system. Measures

must be taken to prevent unwanted changes due to error or tampering.

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric shock and may

be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be

touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the

AC supply has been disconnected. If the drive has been energized, the AC supply must

be isolated at least ten minutes before work may continue.

10 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 11

2 Product information

Identification Label

Electrical Specifications

Derivative

Unidrive M400

Unidrive M600

Unidrive M700

Unidrive M701

Unidrive M702

Product Line

Frame Size:

Voltage Rating:

Current Rating:

Heavy Duty current rating x 10

Power Format:

Reserved

0

Optional Build

Customer Code

01

A B 1 00

Customer Code:

00 = 50 Hz

01 = 60 Hz

Reserved:

Conformal Coating:

0 = Standard

IP / NEMA Rating:

1 = IP20 / NEMA 1

Brake Transistor:

B = Brake

Cooling:

A=Air

Documentation

1

Documentation:

0 - Supplied separately

1 - English

2-200V(200-240

-400V(380-480

-575V(500-575

-690V(500-690

± 10 %)

4 ±

±

±

10 %)

510%)

610%)

Power

Format

M600 - 03 4 00078 A

A - AC inAC out (with internal choke)

D - DC in AC out (Inverter)

C - AC in DC out (Rectifier)

E - AC in AC out (without internal choke)

Refer to

User Guide

Model

Frame

size

Voltage

Heavy Duty

current rating

Drive format

M600-032 00050 A

Approvals

Input voltage

Output

voltage

Heavy Duty /

Normal Duty

power rating

Customer and

date code

Serial

number

Input

frequency

No.of phases &

Typical input current for

Normal Duty rating

Heavy Duty /

Normal Duty rating

output current

Key to approvals

CE approval Europe

C Tick approval Australia

UL / cUL approval USA & Canada

RoHS compliant Europe

R

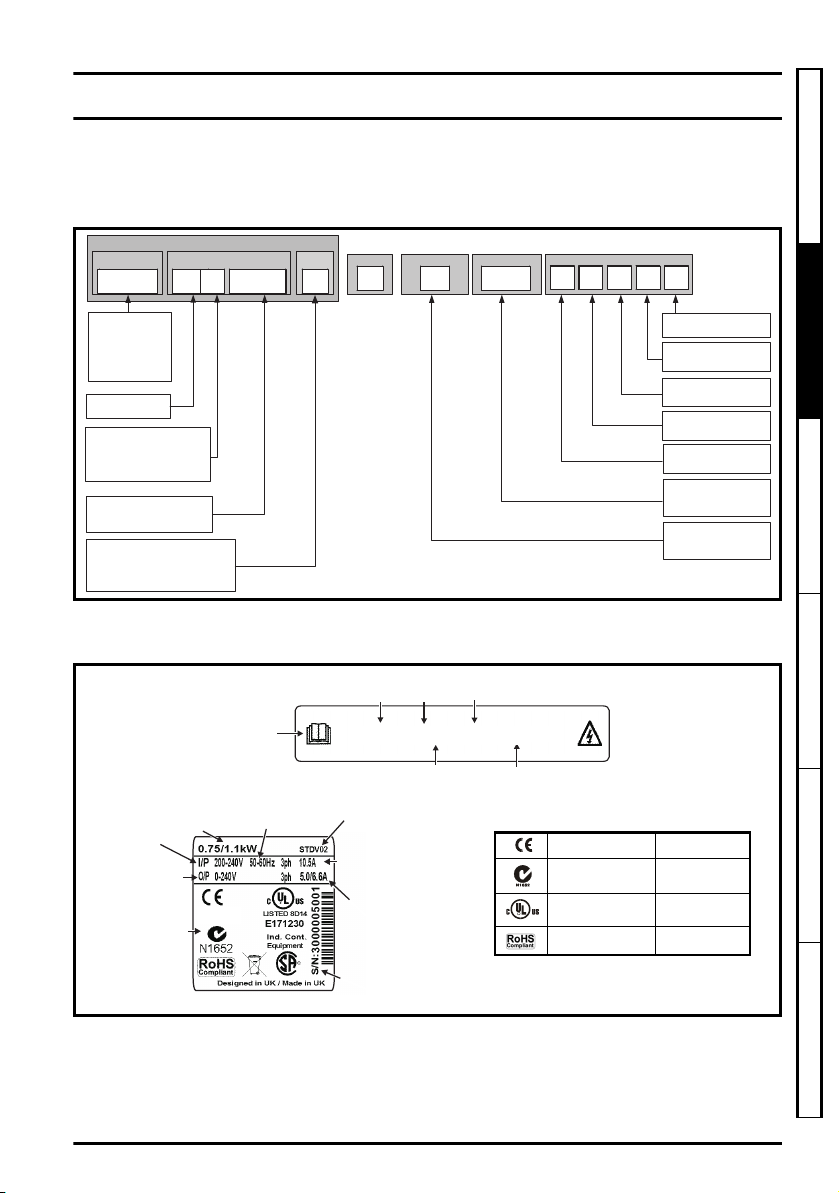

2.1 Model number

The way in which the model numbers for the Unidrive M product range is formed is

illustrated below:

Figure 2-1 Model number

2.2 Nameplate description

Figure 2-2 Typical drive rating labels

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 11

Refer to Figure 2-1 Model number on page 11 for further information relating to the labels.

Issue Number: 3

Page 12

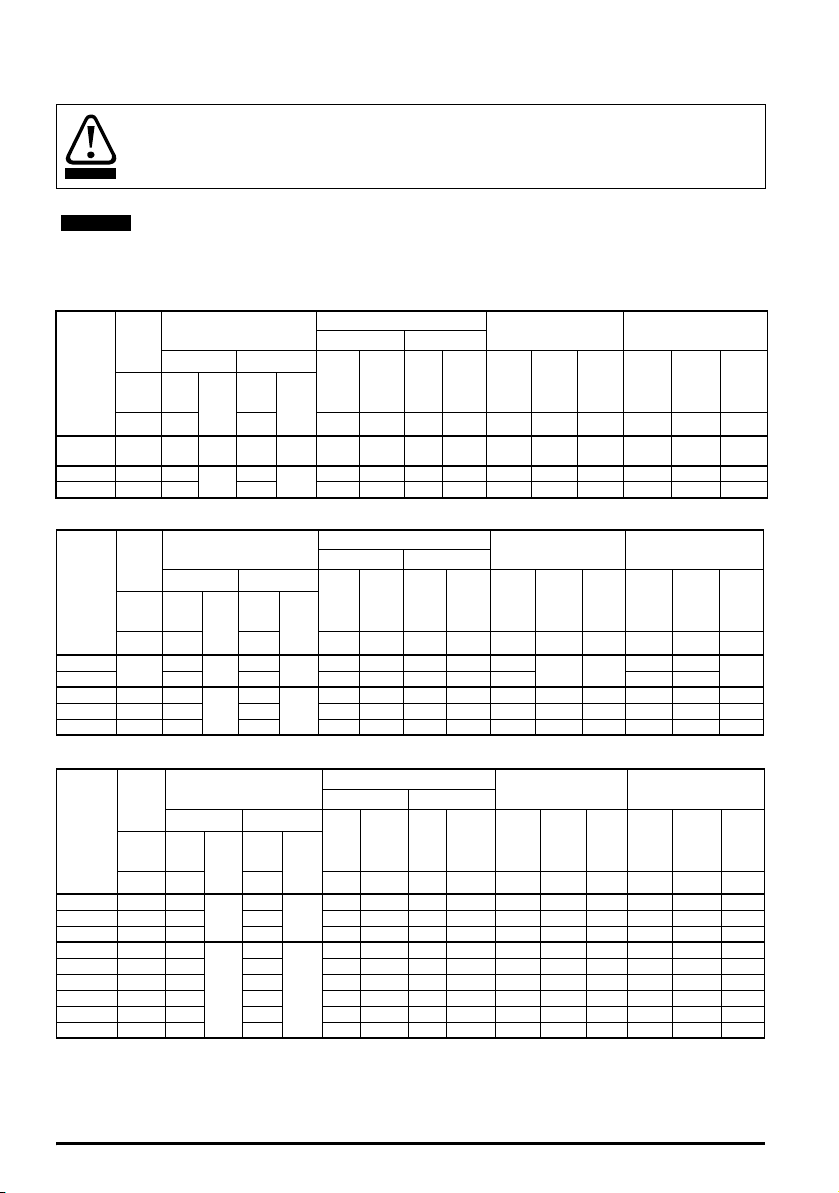

2.3 Ratings

WARNING

NOTE

Fuses

The AC supply to the drive must be installed with suitable protection against overload and

short-circuits. The following section shows recommended fuse ratings. Failure to observe

this requirement will cause risk of fire.

Nominal cables sizes below are based on the cable installation method B2 (ref: IEC603645-52:2001) unless otherwise specified, and are provided as a guide only. Ensure cables

used suit local wiring regulations.

Table 2-1 200 V drive ratings, cable sizes and fuse ratings

Max.

cont.

input

current

Model

05200250 31 40 gG 40

06200330 48.8 63

06200440 56.6 63 70 25 25 3 3 58 15 20 44 11 15

3ph Nom

AA A

Fuse

IEC UL

Nom

Class

60

gG

Class

CC,

J or T*

CC,

J or T*

Nominal cable size

European USA

Input Output Input Output

2

mm2mm

10 10 8 8 30 7.5 10 25 5.5 7.5

16 16 4 4 50 11 15 33 7.5 10

AWG AWG A kW hp A k W hp

Normal Duty Heavy Duty

Max.

Nom

Motor

cont.

output

current

power

@

230 V

power

@

230 V

Max.

cont.

output

current

Nom

power

@

230 V

Table 2-2 400 V drive ratings, cable sizes and fuse ratings

Max.

cont.

input

current

Model

3ph Nom

05400270

05400300 40 35 6 6 8 8 31 30 15

06400350 36 63

06400420 46 63 50 16 16 4 4 48 22 30 42 18.5 30

06400470 60 63 70 25 25 3 3 63 30 40 47 22 30

AA A

29

Fuse

IEC UL

Class

40

gG

gR

Nom

35

40

Class

CC,

J or T*

HSJ or

DFJ

Nominal cable size

European USA

Input Output Input Output

2

mm2mm

668 830

10 10 6 6 38 18.5 25 35 15 25

AWG AWG A kW hp A k W h p

Normal Duty Heavy Duty

Max.

Nom

Motor

cont.

output

current

power

@

400 V

15 20

power

@

460 V

Max.

cont.

output

current

27 11

Nom

power

@

400 V

Motor

power

460 V

Table 2-3 575 V drive ratings, cable sizes and fuse ratings

Max.

cont.

input

current

Model

05500030 4.3 10

05500040 5.7 10 10 1 1 14 14 6.1 4 5 4 2.2 3

05500069 9.3 20 20 1.5 1.5 14 14 10 5.5 7.5 6.9 4 5

06500100 13.2 20

06500150 18.7 32 25 4 4 10 10 17 11 15 15 7.5 10

06500190 24.3 40 30 6 6 10 10 22 15 20 19 11 15

06500230 29.4 50 35 10 10 8 8 27 18.5 25 23 15 20

06500290 37.1 50 40 10 10 6 6 34 22 30 29 18.5 25

06500350 46.9 63 50 16 16 6 6 43 30 40 35 22 30

3ph Nom

AA A

Fuse

IEC UL

Nom

Class

10

gG

20

gG

Class

CC,

J or

CC,

J or

Nominal cable size

European USA

Input Output Input Output

2

mm2mm

0.75 0.75 16 16 3.9 2.2 3 3 1.5 2

T*

2.5 2.5 14 14 12 7.5 10 10 5.5 7.5

T*

AWG AWG A kW hp A kW hp

Normal Duty Heavy Duty

Max.

Nom

Motor

cont.

output

current

power

@

575 V

power

@

575 V

Max.

cont.

output

current

Nom

power

@

575 V

power

* These fuses are fast acting.

Motor

power

@

230 V

@

20

Motor

@

575 V

12 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 13

Table 2-4 Protective ground cable ratings

NOTE

Input phase conductor size Minimum ground conductor size

≤ 10 mm

> 10 mm

> 16 mm

> 35 mm

2

2

and ≤ 16 mm

2

and ≤ 35 mm

2

Either 10 mm2 or two conductors of the same cross-sectional area as the input

phase conductor

2

The same cross-sectional area as the input phase conductor

2

2

16 mm

Half of the cross-sectional area of the input phase conductor

Typical short term overload limits

The maximum percentage overload limit changes depending on the selected motor. Variations in

motor rated current, motor power factor and motor leakage inductance all result in changes in the

maximum possible overload. Typical values are shown in the table below:

Table 2-5 Typical overload limits

Operating mode RFC from cold RFC from 100 %

Normal Duty overload with motor rated

current = drive rated current

Heavy Duty overload with motor rated

current = drive rated current (size 8 and

below)

Heavy Duty overload with motor rated

current = drive rated current (size 9E and

10)

Open loop

from cold

110 % for 165 s 110 % for 9 s 110 % for 165 s 110 % for 9 s

200 % for 28 s 200 % for 3 s 150 % for 60 s 150 % for 7 s

175 % for 42 s 175 % for 5 s 150 % for 60 s 150 % for 7 s

Open loop

from 100 %

Generally the drive rated current is higher than the matching motor rated current allowing a higher

level of overload than the default setting.

The time allowed in the overload region is proportionally reduced at very low output frequency on

some drive ratings.

The maximum overload level which can be attained is independent of the speed.

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Output current

The continuous output current ratings given on the rating label are for maximum 40 °C (104 °F),

1000 m altitude and 3.0 kHz switching frequency. Derating is required for higher switching

frequencies, ambient temperatures >40 °C (104 °F) and higher altitude. For derating information,

refer to the Drive User Guide.

Input current

The input current is affected by the supply voltage and impedance. The input current given on the

rating label is the typical input current and is stated for a balanced supply.

Unidrive M Frame 5 to 6 Power Installation Guide 13

Issue Number: 3

Page 14

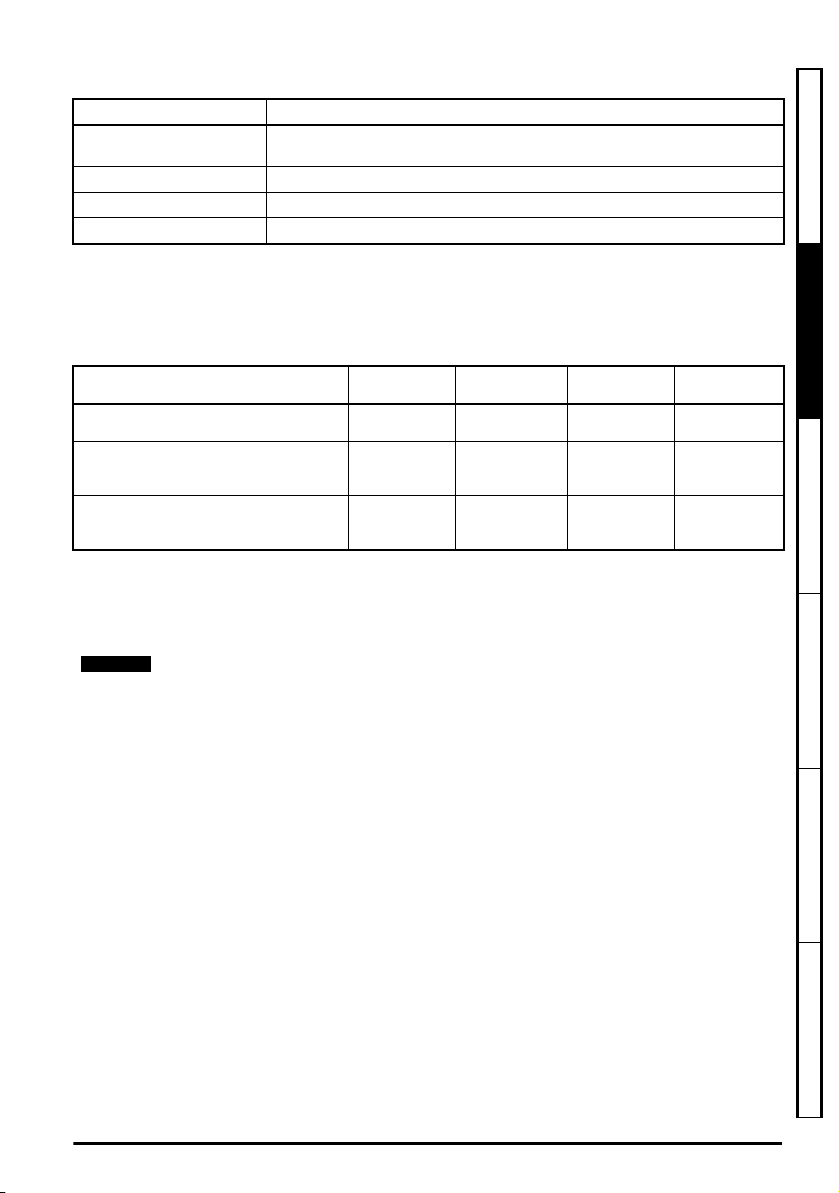

2.4 Drive features

15

14

15

12

12

15

15

14

18

17

16

15

14

12

17 16

18

1

2

3

4

5

6

7

8

9

10

11

13

13

Figure 2-3 Features of the drive (size 3 to 5)

Key

1. Keypad connection 6. Option module slot 2 11. NV media card slot 16. Motor connections

2. Rating label 7. Option module slot 3 12. Braking terminal 17. AC supply connections

3. Identification label 8. Relay connections 13. Internal EMC filter 18. Ground connections

4. Status LED 9. Control connections 14. DC bus +

5. Option module slot 1 10. Communications port 15. DC bus -

14 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 15

3 Mechanical installation

WARNING

WARNING

WARNING

WARNING

WARNING

3.1 Safety information

Follow the instructions

The mechanical and electrical installation instructions must be adhered to. Any questions

or doubt should be referred to the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and any external option unit, and

the way in which they are operated and maintained, comply with the requirements of the

Health and Safety at Work Act in the United Kingdom or applicable legislation and

regulations and codes of practice in the country in which the equipment is used.

Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the

AC supply has been disconnected. If the drive has been energized, the AC supply must

be isolated at least ten minutes before work may continue.

Normally, the capacitors are discharged by an internal resistor. Under certain, unusual

fault conditions, it is possible that the capacitors may fail to discharge, or be prevented

from being discharged by a voltage applied to the output terminals. If the drive has failed

in a manner that causes the display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Control Techniques or their authorized

distributor.

Competence of the installer

The drive must be installed by professional assemblers who are familiar with the

requirements for safety and EMC. The assembler is responsible for ensuring that the end

product or system complies with all the relevant laws in the country where it is to be used.

Enclosure

The drive is intended to be mounted in an enclosure which prevents access except by

trained and authorized personnel, and which prevents the ingress of contamination. It is

designed for use in an environment classified as pollution degree 2 in accordance with IEC

60664-1. This means that only dry, non-conducting contamination is acceptable.

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

3.2 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must

be provided.

For installation in the USA, a NEMA 12 enclosure is suitable.

For installation outside the USA, refer to the Drive User Guide.

3.3 Mounting methods

Drive sizes 5 to 6 can be either surface or through-panel mounted using the appropriate

brackets.

If the drive has been used at high load levels for a period of time, the heatsink can reach

temperatures in excess of 70 °C (158 °F). Human contact with the heatsink should be

prevented.

Unidrive M Frame 5 to 6 Power Installation Guide 15

Issue Number: 3

Page 16

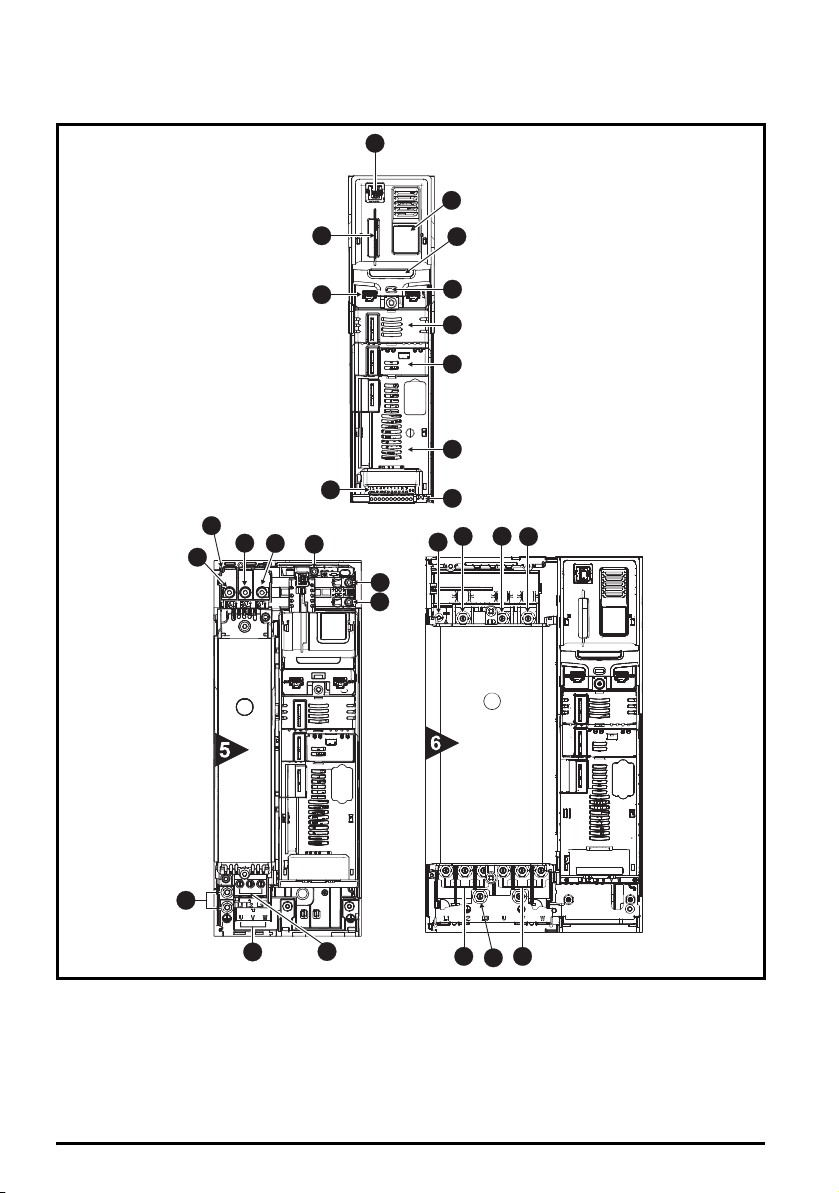

3.4 Drive dimensions

H

W

D

Figure 3-1 Drive dimensions (size 5 illustrated)

Size

5

6 210 8.27 227 8.94

HWD

mm in mm in mm in

365 14.37

143 5.63 202 7.95

16 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 17

3.4.1 Items supplied with the drive

51 52

The drive is supplied with a copy of the Power Installation Guide and a copy of the Getting Started

Guide, a safety information booklet, the Certificate of Quality and an accessory kit box including the

items shown in Table 3-1.

Table 3-1 Parts supplied with the drive

Description Size 5 Size 6

Control connectors (1 to 11 and 21 to 31)

x 1* x 1*

Control connectors (1 to 13)

x 1**

Relay connector

x 1

24 V power supply connector

x 1

Grounding bracket

Safety information Product information

Mechanical installation

x 1

Surface mounting brackets

x 2 x 2

Grounding clamp

x 1 x 1

Terminal nuts

M8 x 12 M10 x 12

Supply and motor connector

x 1 x 1

Finger guard grommets

x 3 x 2

* Available with Unidrive M700 / M701 / M600 only.

** Available with Unidrive M702 only.

Unidrive M Frame 5 to 6 Power Installation Guide 17

Issue Number: 3

Electrical installation Technical data UL listing information

Page 18

3.5 Surface mounting

9mm

(0.35 in)

8mm

(0.32 in)

375 mm (14.76 in)

6.5 mm

(0.26 in)

5

106 mm (4.17 in)

Æ

378 mm

(14.88 in)

196 mm

(7.72 in)

6.0 mm

(0.24 in)

Æ

7.0 mm

(0.27 in)

7.0 mm

(0.28 in)

6

5

6

Figure 3-2 Surface mounting dimensions (size 5 to 6)

3.6 Through-panel mounting

Figure 3-3 Through-panel mounting dimensions (size 5 to 6)

18 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 19

3.7 Installation of high IP insert for size 5

1

2

3

The standard drive is rated to IP20 pollution degree 2 (dry, non-conductive contamination only)

(NEMA 1). However, it is possible to configure the drive to achieve IP65 rating (sizes 5 to 6) (NEMA

12) at the rear of the heatsink for through-panel mounting (some current derating is required).

On drive size 5, in order to achieve the high IP rating at the rear of the heatsink it is necessary to seal

a heatsink vent by installing the high IP insert as shown in Figure 3-4.

Figure 3-4 Installation of high IP insert for size 5

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

1. To install the high IP insert, firstly place a flat head screwdriver into the slot highlighted (1).

2. Pull the hinged baffle up to expose the ventilation holes, install the high IP inserts into the

ventilation holes in the heatsink (2).

3. Ensure the high IP inserts are securely installed by firmly pressing them into place (3).

4. Close the hinged baffle as shown (1).

To remove the high IP insert, reverse the above instructions.

The guidelines in Table 3-2 should be followed.

Unidrive M Frame 5 to 6 Power Installation Guide 19

Issue Number: 3

Page 20

Table 3-2 Environment considerations

NOTE

Environment High IP insert Comments

Clean Not installed

Dry, dusty (non-conductive) Installed

Regular cleaning recommendedDry, dusty (conductive) Installed

IP65 compliance Installed

A current derating must be applied to the drive if the high IP insert is installed. Derating information is

provided in the Drive User Guide. Failure to do so may result in nuisance tripping.

3.8 Terminal size and torque settings

Table 3-3 Drive control and relay terminal data

Model Connection type Torque setting

All Plug-in terminal block 0.5 N m (0.4 lb ft)

Table 3-4 Drive power terminal data

Model size

5

6

3.8.1 Internal braking resistor

Size 5 has been designed with an optional space-saving heatsink mounted resistor. The resistor can

be installed within the heatsink fins of the drive. When the heatsink resistor is used, an external

thermal protection device is not required as the resistor is designed such that it will fail safely under

any fault conditions. The in-built software overload protection is set-up at default to protect the

resistor. The resistor is rated to IP54 (NEMA 12).

AC terminals DC and braking Ground terminal

Recommended

Plug-in terminal block

1.8 N m (1.3 lb ft)

1.5 N m (1.1 lb ft) 1.5 N m (1.1 lb ft) 2.0 N m (1.47 Ib ft)

T20 Torx (M4) /

M4 Nut (7 mm AF)

M6 Nut (10 mm AF)

6.0 N m (4.42 Ib ft)

M5 Nut (8 mm AF)

20 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 21

Figure 3-5 Brake resistor installation on size 5

1. Remove the terminal covers.

2. Remove the brake resistor bung from the hole in the chassis, the closed end of the bung will

need to be pierced so that the cable has access to be routed through.

3. Feed brake resistor bung onto outer insulation of brake resistor cable. The wider end of the bung

should be inserted first. The Narrow end should align with end of insulation.

4. Install the braking resistor to the heatsink using the captive screws. The screws should be tighten to a

maximum torque of 2 N m (1.5 lb ft).

5. Route the cables through the provided hole at the rear of the heatsink as shown in Figure 3-5

and take the cable out from the front side of the drive. Ensure the cables are routed between the

fins of the heatsink, and the cables are not trapped between the heatsink fins and the resistor.

6. Crimp the cable ends and make appropriate connections. The brake terminals must be tightened

to a maximum torque of 2 N m (1.5 Ib ft).

7. Replace the terminal covers on the drive, tighten to a maximum torque of 1 N m (0.7 lb ft).

3.8.2 External brake resistor

External brake resistors are available from Control Techniques for drive sizes 5 to 6. They can be

mounted in the enclosure as per mounting recommendation in Figure 3-9 Enclosure layout on

page 23 using mounting brackets part number 6541-0187-00. Figure 3-6 below shows the brake

resistor mounted on the mounting bracket. Two M4 screws and nuts (2) can be used to fix the brake

resistor to the mounting bracket. One M4 nut with washer (1) is provided to use for the ground

connection. The brake resistor is equipped with a thermal switch, the thermal switch should be

integrated in the control circuit by the user.

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 21

Issue Number: 3

Page 22

Figure 3-6 Brake resistor with the mounting bracket

1

2

118 mm (4.65 in)

15.5 mm

(0.61 in)

Æ 4.5 mm (0.18 in)

x 2 holes

1.5 mm

(0.06 in)

30.5 mm

(1.20 in)

80 mm (3.15 in)

130 mm (5.12 in)

Æ 4.5x6mm(0.18 in)

x 2 holes

R = 1.5 mm

(0.06)

1. Ground connection (1 x M4 nut and washer).

2. Attaching the brake resistor to the mounting bracket (using 2 x M4 screws and nuts).

Figure 3-7 Mounting bracket dimensions

Issue Number: 3

22 Unidrive M Frame 5 to 6 Power Installation Guide

Page 23

Figure 3-8 Brake resistor dimensions

60 mm (2.36 in)

68 mm (2.68 in)

118 mm (4.65 in)

130 mm (5.12 in)

Æ 4.5 mm (0.18 in)

x 4 holes

15 mm

(0.59 in)

³100 mm

(4 in)

Enclosure

AC supply

contactor and

fuses or MCB

Locate as

required

Locate as

required

External

controller

Signal cables

Plan for all signal cables

to be routed at least

300 mm (12 in) from the

drive and any power cable

Ensure minimum clearances

are maintained for the drive

and external EMC filter. Forced

or convection air-flow must not

be restricted by any object or

cabling

³100mm

(4in)

Optional braking resistor and overload

Locate optional braking

resistor external to

cubicle (preferably near to or

on top of the cubicle).

Locate the overload protection

device as required

The external EMC filter can be

bookcase mounted (next to the

drive) or footprint mounted (with

the drive mounted onto the filter).

Note

For EMC compliance:

1) When using an external EMC

filter, one filter is required for

each drive

2) Power cabling must be at

least 100 mm (4 in) from the

drive in all directions

A

³30mm (1.18 in)

A

A

3.9 Enclosure

Enclosure Layout

Please observe the clearances in the diagram below taking into account any appropriate notes for

other devices / auxiliary equipment when planning the installation.

Figure 3-9 Enclosure layout

Safety information Product information

Mechanical installation

Unidrive M Frame 5 to 6 Power Installation Guide 23

Issue Number: 3

Electrical installation Technical data UL listing information

Page 24

3.10 EMC filters

1

2

3

1

3.10.1 Internal filter

It is recommended that the internal EMC filter be kept in place unless there is a specific reason for

removing it. If the drive is part of a regen system or it is connected to an IT supply then the internal

EMC filter must be removed. The internal EMC filter reduces radio-frequency emission into the line

power supply. Where the motor cable is short, it permits the requirements of EN 61800-3:2004 to be

met for the second environment - for further information see the Drive User Guide. For longer motor

cables the filter continues to provide a useful reduction in emission level, and when used with any

length of shielded motor cable up to the limit for the drive, it is unlikely that nearby industrial

equipment will be disturbed. It is recommended that the filter be used in all applications unless the

instructions given above require it to be removed or the ground leakage current of the drive is

unacceptable.

Figure 3-10 Removal of the size 5 internal EMC filter

Remove the three M5 terminal nuts (1). Lift away the cover (2) to expose the M4 Torx internal EMC

filter removal screw. Finally remove the M4 Torx internal EMC filter removal screw (3) to electrically

disconnect the internal EMC filter.

Figure 3-11 Removal of the size 6 internal EMC filter

To electrically disconnect the Internal EMC filter, remove the screw (1) as highlighted above.

24 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 25

3.10.2 External EMC filter

The external EMC filters for sizes 5 to 6 can be footprint or bookcase mounted as shown below in

Figure 3-12 and Figure 3-13.

Figure 3-12 Footprint mounting the EMC filter

Figure 3-13 Bookcase mounting the EMC filter

3.10.3 Optional external EMC filters

Table 3-5 EMC filter cross reference

Model CT part number

200 V

05200250 4200-0312

06200330 to 06200440 4200-2300

400 V

05400270 to 05400300 4200-0402

06400350 to 06400470 4200-4800

575 V

05500030 to 05500069 4200-0122

06500100 to 06500350 4200-3690

3.10.4 EMC filter ratings

Table 3-6 Optional external EMC filter details

Maximum

continuous

current

CT part

number

4200-0312 31 28.5 250 300

4200-2300 55 51 250 300 41 35 4.2 69

4200-0402 40 36.8 528 600 47 40 18.7 197

4200-4800 63 58 528 600 54 46 11.2 183

4200-0122 12 11 760 600

4200-3690 42 39 760 600 45 39 12 234

(104 °F)

@ 50 °C

(122 °F)

AAVV WW mA mAMΩ

Voltage

rating

IEC UL

IP

rating

20

Power dissipation

at rated current

@ 40 °C

(104 °F)

@ 50 °C

(122 °F)

20 17 2.0 80

Ground leakage

Balanced

supply

phase-to-

phase and

phase-to-

ground

Worst

case@ 40 °C

Discharge

resistors

1.68

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 25

Issue Number: 3

Page 26

Figure 3-14 External EMC filter (size 5 to 6)

Y

ED

Z

L

1

'

L

2

'

L

3

'

X

X

Y

V

Y

A

B

H

CW

Z

Z

CS

Line

Load

PE

L1 L2 L3

L1 L2 L3

V: Ground stud

X: Threaded holes for footprint

mounting of the drive

Z: Bookcase mounting slot diameter. CS: Cable size

Table 3-7 Size 5 external EMC filter dimensions

CT part

number

4200-0312

4200-0402

4200-0122

ABCDEHWV/XY/ZCS

395 mm

(15.55 in)

425 mm

(16.73 in)

106 mm

(4.17 in)

60 mm

(2.36 in)

Table 3-8 Size 6 external EMC filter dimensions

CT part

number

4200-2300

4200-4800

4200-3690

3.10.5 EMC filter torque settings

Table 3-9 Optional external EMC Filter terminal data

4200-0122

4200-0312

4200-0402

4200-2300

4200-4800

4200-3690

ABCDEHWV/XY/ZCS

CT part

number

392 mm

(15.43 in)

420 mm

(16.54 in)

Max cable

16 mm

16 mm

16 mm

16 mm

16 mm

16 mm

size

2

(6 AWG)

2

(6 AWG)

2

(6 AWG)

2

(6 AWG)

2

(6 AWG)

2

(6 AWG)

180 mm

(7.09 in)

Power

connections

60 mm

(2.36 in)

Max torque Ground stud size Max torque

2.3 N m (1.7 lb ft) M6 5.0 N m (3.7 lb ft)

1.8 N m (1.4 lb ft) M6 5.0 N m (3.7 lb ft)

1.8 N m (1.4 lb ft) M6 5.0 N m (3.7 lb ft)

2.3 N m (1.70 Ib ft) M6 5.0 N m (3.7 lb ft)

2.3 N m (1.70 Ib ft) M6 5.0 N m (3.7 lb ft)

2.3 N m (1.70 Ib ft) M6 5.0 N m (3.7 lb ft)

33 mm

(1.30 in)

33 mm

(1.30 in)

437 mm

(17.2 in)

434 mm

(17.09

in)

Y: Footprint mounting hole diameter

143 mm

(5.63 in)

210 mm

(8.27 in)

6.5 mm

M6

(0.26 in)

6.5 mm

M6

(0.26 in)

Ground

connections

10 mm

(8 AWG)

2.5 mm

(14 AWG)

16 mm

(6 AWG)

2

2

2

26 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 27

4 Electrical installation

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

Electric shock risk

The voltages present in the following locations can cause severe electric shock and may be

lethal:

AC supply cables and connections

DC and brake cables, and connections

Output cables and connections

Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

Isolation device

The AC and / or DC power supply must be disconnected from the drive using an approved

isolation device before any cover is removed from the drive or before any servicing work

is performed.

STOP function

The STOP function does not remove dangerous voltages from the drive, the motor or any

external option units.

SAFE TORQUE OFF function

The SAFE TORQUE OFF function does not remove dangerous voltages from the drive,

the motor or any external option units.

Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the

AC and / or DC power supply has been disconnected. If the drive has been energized,

the AC and / or DC power supply must be isolated at least ten minutes before work may

continue. Normally, the capacitors are discharged by an internal resistor. Under certain,

unusual fault conditions, it is possible that the capacitors may fail to discharge, or be

prevented from being discharged by a voltage applied to the output terminals. If the drive

has failed in a manner that causes the display to go blank immediately, it is possible the

capacitors will not be discharged. In this case, consult Control Techniques or their

authorized distributor.

Safety information Product information Mechanical installation

Electrical installation

Technical data UL listing information

Equipment supplied by plug and socket

Special attention must be given if the drive is installed in equipment which is connected to

the AC supply by a plug and socket. The AC supply terminals of the drive are connected

to the internal capacitors through rectifier diodes which are not intended to give safety

isolation. If the plug terminals can be touched when the plug is disconnected from the

socket, a means of automatically isolating the plug from the drive must be used (e.g. a

latching relay).

Permanent magnet motors

Permanent magnet motors generate electrical power if they are rotated, even when the

supply to the drive is disconnected. If that happens then the drive will become energized

through its motor terminals. If the motor load is capable of rotating the motor when the

supply is disconnected, then the motor must be isolated from the drive before gaining

access to any live parts.

Unidrive M Frame 5 to 6 Power Installation Guide 27

Issue Number: 3

Page 28

4.1 Supply types

NOTE

All drives are suitable for use on any supply type i.e TN-S, TN-C-S, TT and IT.

Supplies with voltage up to 600 V may have grounding at any potential, i.e. neutral, centre

or corner (“grounded delta”)

Supplies with voltage above 600 V may not have corner grounding

Drives are suitable for use on supplies of installation category III and lower, according to

IEC 60664-1. This means they may be connected permanently to the supply at its origin in

a building, but for outdoor installation additional over-voltage suppression (transient

voltage surge suppression) must be provided to reduce category IV to category III.

If the drive is to be used on an IT (ungrounded) supply, refer to the Drive User Guide for

more information.

4.2 Supply requirements

AC supply voltage:

200 V drive: 200 V to 240 V ±10 %

400 V drive: 380 V to 480 V ±10 %

575 V drive: 500 V to 575 V ±10 %

Number of phases: 3

Maximum supply imbalance: 2 % negative phase sequence (equivalent to 3 % voltage

imbalance between phases).

Frequency range: 45 to 66 Hz

For UL compliance only, the maximum supply symmetrical fault current must be limited to

100 kA

Table 4-1 Supply fault current used to calculate maximum input currents

Model Symmetrical fault level (kA)

All 100

4.3 Motor requirements

No. of phases: 3

Maximum voltage:

200 V drive: 240 V

400 V drive: 480 V

575 V drive: 575 V

28 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 29

4.4 Ratings

NOTE

WARNING

See section 2.3 Ratings on page 12.

Maximum continuous input current

The values of maximum continuous input current are given to aid the selection of cables

and fuses. These values are stated for the worst case condition with the unusual

combination of stiff supply with high imbalance. The value stated for the maximum

continuous input current would only be seen in one of the input phases. The current in the

other two phases would be significantly lower.

The values of maximum input current are stated for a supply with a 2 % negative phasesequence imbalance and rated at the maximum supply fault current given in section

2.3 Ratings on page 12.

The nominal cable sizes given in section 2.3 Ratings on page 12 are only a guide. Refer

to local wiring regulations for the correct size of cables. In some cases a larger cable is

required to avoid excessive voltage drop.

The nominal output cable sizes in section 2.3 Ratings on page 12 assume that the motor

maximum current matches that of the drive. Where a motor of reduced rating is used the

cable rating may be chosen to match that of the motor. To ensure that the motor and cable

are protected against over-load, the drive must be programmed with the correct motor

rated current.

Fuses

The AC supply to the drive must be installed with suitable protection against overload and

short-circuits. Nominal fuse ratings are shown in section 2.3 Ratings on page 12. Failure

to observe this requirement will cause risk of fire.

A fuse or other protection must be included in all live connections to the AC supply.

Fuse types

The fuse voltage rating must be suitable for the drive supply voltage.

Safety information Product information Mechanical installation

Electrical installation

Technical data UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 29

Issue Number: 3

Page 30

4.5 Power connections

Optional

braking

resistor

Thermal

overload

protection

device

BR

+DC

-DC

DC / Brake connections

BR

Optional

braking

resistor

Thermal

overload

protection

device

DC -

DC +

L1 L2

L2L1 L3 U V W

Optional EMC

filter

Optional

line reactor

Fuses

L3

Mains

Supply

Motor

Optional ground

connection

Supply

Ground

PE

AC Connections Motor Connections

1

2

Figure 4-1 Size 5 power and ground connections

The upper terminal block (1) is used for AC supply connection.

The lower terminal block (2) is used for Motor connection.

Issue Number: 3

30 Unidrive M Frame 5 to 6 Power Installation Guide

Page 31

Figure 4-2 Size 6 power and ground connections

L1 L2

L2L1 L3 U V W

Optional EMC

filter

Optional

line reactor

Fuses

L3

Mains

Supply

Motor

Optional ground

connection

Supply

Ground

PE

AC Connections

BR

Optional

braking

resistor

Thermal

overload

protection

device

DC - DC +

DC Connections

(DC and braking)

Motor Connections

6

Ground connection

studs

Safety information Product information Mechanical installation

Electrical installation

Technical data UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 31

Issue Number: 3

Page 32

4.6 Ground connections

WARNING

NOTE

WARNING

Electrochemical corrosion of grounding terminals

Ensure that grounding terminals are protected against corrosion i.e. as could be caused

by condensation.

The drive must be connected to the system ground of the AC supply. The ground wiring

must conform to local regulations and codes of practice.

For further information on ground cable sizes, refer to Table 2-4 Protective ground cable

ratings on page 13.

On size 5, the supply and motor ground connections are made using the M5 studs

located near the plug-in power connector. Refer to Figure 4-1.

On a size 6, the supply and motor ground connections are made using the M6 studs

located above the supply and motor terminals. Refer to Figure 4-2.

The ground loop impedance must conform to the requirements of local safety regulations.

The drive must be grounded by a connection capable of carrying the prospective fault

current until the protective device (fuse, etc.) disconnects the AC supply.

The ground connections must be inspected and tested at appropriate intervals.

4.7 Braking resistor values

Table 4-2 Minimum resistance values and peak power rating for the braking resistor at 40 °C (104 °F)

Model

200 V

05200250 16.5 10.3 8.6

06200330

06200440 16.4

400 V

05400270 31.5 21.5 16.2

05400300 18 37.5 19.6

06400350

06400420 25

06400470 32.7

575 V

05500030

05500040 4.6

05500069 6.5

06500100

06500150 12.3

06500190 16.3

06500230 19.9

06500290 24.2

06500350 31.7

* Resistor tolerance: ±10 %

Minimum resistance * Instantaneous power rating

Ω kW kW

8.6 19.7

17 39.8

80 12.1

13 74

Continuous power

rating

12.6

21.6

2.6

8.7

32 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 33

5 Technical data

5.1 Drive technical data

5.1.1 Power and current ratings (Derating for switching frequency and

temperature)

For a full explanation of ‘Normal Duty’ and ‘Heavy Duty’ refer to section 2 Product

information on page 11.

Table 5-1 Maximum permissible continuous output current @ 40 °C (104 °F) ambient

Normal Duty Heavy Duty

Safety information Product information Mechanical installation Electrical installation

Model

200 V

05200250 7.5 10 30 27.6 23.7 5.5 7.5 25 24.8 21.5 18.8

06200330 11 15 50 42.3 24.5 7.5 10 33.0 32 27

06200440 15 20 58 53 42.3 32.5 11 15 44.0 40 33 27.3

400 V

05400270 15 20 30 25.8 22.2 17.1 13.5 11 20 27 25.4 23.7 20.3 17.6 13.8 11.1

05400300 15 20 31 30.7 26.4 18.3 14.1 15 20 30 27.9 24 21 14.9 12.2

06400350 18.5 25 38 31 24.3 15 25 35 30 23 18.5

06400420 22 30 48 41 31 24.5 18.5 30 42 35 30 23 18.5

06400470 30 40 63 57 48 41 31 24.5 22 30 47 46 42 35 30 23 18.5

575 V

05500030 2.2 3.0 3.9 1.5 2.0 3.0

05500040 4.0 5.0 6.1 2.2 3.0 4.0

05500069 5.5 7.5 10 4.0 5.0 6.9

06500100 7.5 10 12 5.5 7.5 10

06500150 11 15 17 14.8 7.5 10 15 11.6

06500190 15 20 22 20.5 15 11 15 19 15.4 11.6

06500230 18.5 25 27 26.2 20 16 15 20 23 20 15.4 12.8

06500290 22 30 34 31 26.2 20 16.8 18.5 25 29 23.8 20 15.4 12.8

06500350 30 40 43 39.6 31 26.2 20 16.8 22 30 35 34 29.8 23.8 20 15.4 13

Nominal

kW hp

Maximum permissible continuous output

rating

current (A) for the following switching

2

kHz3kHz4kHz6kHz8kHz12kHz16kHz

frequencies

Nominal

rating

kW hp

Maximum permissible continuous output

current (A) for the following switching

2

kHz3kHz4kHz6kHz8kHz12kHz16kHz

frequencies

Technical data

UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 33

Issue Number: 3

Page 34

Table 5-2 Maximum permissible continuous output current @ 50 °C (122 °F)

Normal Duty Heavy Duty

Maximum permissible continuous output current (A)

Model

200 V

05200250 30 29.7 25.2 21.6 25 23 19.8 17.3

06200330 50 49 38 30 33 29 24.6

06200440 58 56 49 38 30.2 44 41 36 29 24.6

400 V

05400270 25.5 23.6 20.4 15.6 12.3 24 23.5 21.6 18.6 16.2 12.7 10

05400300 25.5 23.6 15.9 12.3 24 21.9 19.2 13.8 10.5

06400350 38 37 28 21.4 35 32 27 21 16.5

06400420 48 43 36.5 27.4 21.4 42 38 32 27 21 16.5

06400470 63 58 52 43 37 28 21.4 47 42 38 32 27 21 16.5

for the following switching frequencies

2

kHz3kHz4kHz6kHz8kHz12kHz16kHz2kHz3kHz4kHz6kHz8kHz12kHz16kHz

Maximum permissible continuous output current (A)

for the following switching frequencies

34 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 35

5.1.2 Power dissipation

Table 5-3 Losses @ 40° C (104° F) ambient

Normal Duty Heavy Duty

Model

200 V

05200250 7.5 10 291 302 324 344 356 342 5.5 7.5 245 254 272 288 284 282

06200330 11 15 394 413 452 490 480 7.5 10 277 290 316 342 382

06200440 15 20 463 484 528 522 481 11 15 366 382 417 410 388

400 V

05400270 15 20 324 353 356 355 359 362 11 20 276 282 285 290 301 310

05400300 15 20 332 367 434 441 417 424 15 20 322 333 352 374 372 439

06400350 18.5 25 417 456 532 613 652 645 15 25 389 424 498 496 502 513

06400420 22 30 515 561 657 651 646 650 18.5 30 455 497 487 486 495 513

06400470 30 40 656 659 650 646 643 22 30 500 496 487 486 495

575 V

05500030 2.2 3 92 102 121 142 1.5 2 82 91 108 126

05500040 4 5 135 150 180 209 2.2 3 94 104 124 145

05500069 5.5 7.5 194 215 260 302 4 5 153 170 204 236

06500100 7.5 10 215 239 287 334 5.5 7.5 187 208 249 291

06500150 11 15 284 315 376 438 7.5 10 265 294 351 410

06500190 15 20 362 399 484 569 11 15 317 350 418 496

06500230 18.5 25 448 505 596 682 15 20 382 421 508 523

06500290 22 30 623 712 810 822 18.5 25 533 610 628 635

06500350 30 40 798 836 813 823 22 30 546 624 622 627

Nominal

rating

kW hp

Drive losses (W) taking into account any

current derating for the given conditions

2

kHz3 kHz 4 kHz 6 kHz 8 kHz

12

kHz

16

kHz

Nominal

rating

kW hp

Drive losses (W) taking into account any

current derating for the given conditions

2

Khz3 kHz 4 kHz 6 kHz 8 kHz

12

kHz

16

kHz

Safety information Product information Mechanical installation Electrical installation

Technical data

Unidrive M Frame 5 to 6 Power Installation Guide 35

Issue Number: 3

UL listing information

Page 36

Table 5-4 Losses @ 40°C (104° F) ambient with high IP insert installed

Normal Duty Heavy Duty

Model

200 V

05200250 244 249 262 274 298 328 245 251 264 278 301 306

400 V

05400270 170 173 182 194 223 268 172 177 184 194 225 265

05400300 218 240 284 329 432 564 218 240 284 325 425 560

575 V

05500030

05500040

05500069

Drive losses (W) taking into consideration any current

derating for the given conditions

2

kHz3 kHz 4 kHz 6 kHz 8 kHz

12

kHz

kHz 2 kHz3 kHz 4 kHz 6 kHz 8 kHz

Drive losses (W) taking into consideration any

current derating for the given conditions

16

12

kHz

16

kHz

36 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 37

Table 5-5 Losses @ 50° C (122° F) ambient

Normal Duty Heavy Duty

Model

200 V

05200250 292 306 331 357 357 357 247 258 279 278 283 288

06200330 394 413 452 481 434 277 290 316 342 346

06200440 463 484 509 483 437 366 382 389 369 342

400 V

05400270 288 323 368 384 417 267 274 290 305 340 373

05400300 280 316 366 452 453 511 264 297 383 420 463 523

06400350 417 456 536 607 609 597 389 424 459 452 468 472

06400420 515 561 597 595 601 614 455 449 450 445 468 491

06400470 613 600 593 601 613 455 449 450 446 464

575 V

05500030 92 102 121 142 82 91 108 126

05500040 135 150 180 209 94 104 124 145

05500069 194 215 260 302 153 170 204 236

06500100 215 239 287 334 187 208 249 291

06500150 284 315 376 443 265 294 351 410

06500190 362 399 482 575 317 350 421 504

06500230 445 490 592 614 382 422 477 504

06500290 623 712 739 751 533 574 580 555

06500350 774 758 734 757 572 572 572 607

Drive losses (W) taking into account any current

derating for the given conditions

2

kHz3 kHz 4 kHz 6 kHz 8 kHz

12

kHz

Drive losses (W) taking into account any current

derating for the given conditions

16

kHz 2 kHz3 kHz 4 kHz 6 kHz 8 kHz

12

kHz

Table 5-6 Power losses from the front of the drive when through-panel mounted

Frame size Power loss

5 ≤ 100 W

6 ≤ 100 W

5.1.3 Temperature, humidity and cooling method

Ambient temperature operating range:

- 20 °C to 50 °C (- 4 °F to 122 °F).

Output current derating must be applied at ambient temperatures >40 °C (104 °F).

Cooling method: Forced convection

Maximum humidity: 95 % non-condensing at 40 °C (104 °F)

16

kHz

Safety information Product information Mechanical installation Electrical installation

Technical data

UL listing information

Unidrive M Frame 5 to 6 Power Installation Guide 37

Issue Number: 3

Page 38

5.1.4 Storage

-40 °C (-40 °F) to +55 °C (122 °F) for long term storage, or to +70 °C (158 °F) for short

term storage.

Storage time is 2 years.

Electrolytic capacitors in any electronic product have a storage period after which they

require reforming or replacing.

The DC bus capacitors have a storage period of 10 years.

The low voltage capacitors on the control supplies typically have a storage period of 2

years and are thus the limiting factor.

Low voltage capacitors cannot be reformed due to their location in the circuit and thus

may require replacing if the drive is stored for a period of 2 years or greater without power

being applied.

It is therefore recommended that drives are powered up for a minimum of 1 hour after

every 2 years of storage. This process allows the drive to be stored for a further 2 years.

5.1.5 Altitude

Altitude range: 0 to 3,000 m (9,900 ft), subject to the following conditions:

1,000 m to 3,000 m (3,300 ft to 9,900 ft) above sea level: de-rate the maximum output

current from the specified figure by 1% per 100 m (330 ft) above 1,000 m (3,300 ft)

For example at 3,000 m (9,900 ft) the output current of the drive would have to be derated by 20 %.

5.1.6 IP / UL Rating

The drive is rated to IP20 pollution degree 2 (dry, non-conductive contamination only)

(NEMA 1). However, it is possible to configure the drive to achieve IP65 rating (NEMA 12)

at the rear of the heatsink for through-panel mounting (some current derating is required).

In order to achieve the high IP rating at the rear of the heatsink with drive size 5 it is

necessary to seal a heatsink vent by installing the high IP insert.

The IP rating of a product is a measure of protection against ingress and contact to

foreign bodies and water. It is stated as IP XX, where the two digits (XX) indicate the

degree of protection provided as shown in Table 5-7

38 Unidrive M Frame 5 to 6 Power Installation Guide

Issue Number: 3

Page 39

Table 5-7 IP Rating degrees of protection

NOTE

First digit Second digit

Protection against contact and ingress of

Protection against ingress of water

foreign bodies

0 No protection 0 No protection

Protection against large foreign bodies φ >

1

50 mm (large area contact with the hand)

Protection against medium size foreign

2

bodies φ > 12 mm (finger)

Protection against small foreign bodies φ >

3

2.5 mm (tools, wires)

Protection against granular foreign bodies

4

φ > 1mm (tools, wires)

Protection against dust deposit, complete

5

protection against accidental contact.

Protection against dust ingress, complete

6

protection against accidental contact.

Protection against vertically falling drops of

1

water

Protection against spraywater (up to 15 °

2

from the vertical)

Protection against spraywater (up to 60 °

3

from the vertical)

Protection against splashwater (from all

4

directions)

Protection against heavy splash water (from

5

all directions, at high pressure)

Protection against deckwater (e.g. in heavy

6

seas)

7 - 7 Protection against immersion

8 - 8 Protection against submersion

Table 5-8 UL enclosure ratings

UL rating Description

Type 1

Enclosures are intended for indoor use, primarily to provide a degree

of protection against limited amounts of falling dirt.

Enclosures are intended for indoor use, primarily to provide a degree

Type 12

of protection against dust, falling dirt and dripping non-corrosive

liquids.

Safety information Product information Mechanical installation Electrical installation

5.1.7 Corrosive gasses

Concentrations of corrosive gases must not exceed the levels given in:

• Table A2 of EN 50178:1998

• Class 3C2 of IEC 60721-3-3

This corresponds to the levels typical of urban areas with industrial activities and/or heavy

traffic, but not in the immediate neighborhood of industrial sources with chemical

emissions.

5.1.8 RoHS compliance

The drive meets EU directive 2002-95-EC for RoHS compliance.

Vibration

Maximum recommended continuous vibration level 0.14 g r.m.s. broad-band 5 to 200 Hz.

This is the limit for broad-band (random) vibration. Narrow-band vibration at this level

which coincides with a structural resonance could result in premature failure.

Bump Test

Unidrive M Frame 5 to 6 Power Installation Guide 39

Issue Number: 3

Testing in each of three mutually perpendicular axes in turn.

Referenced standard:IEC 60068-2-29: Test Eb:

Severity: 18 g, 6 ms, half sine

No. of Bumps: 600 (100 in each direction of each axis)

Technical data

UL listing information

Page 40

Random Vibration Test

Testing in each of three mutually perpendicular axes in turn.

Referenced standard:IEC 60068-2-64: Test Fh:

Severity: 1.0 m²/s³ (0.01 g²/Hz) ASD from 5 to 20 Hz

-3 dB/octave from 20 to 200 Hz

Duration: 30 minutes in each of 3 mutually perpendicular axes.

Sinusoidal Vibration Test

Testing in each of three mutually perpendicular axes in turn.

Referenced standard: IEC 60068-2-6: Test Fc:

Frequency range: 5 to 500 Hz

Severity: 3.5 mm peak displacement from 5 to 9 Hz

10 m/s² peak acceleration from 9 to 200 Hz

15 m/s² peak acceleration from 200 to 500 Hz

Sweep rate: 1 octave/minute

Duration: 15 minutes in each of 3 mutually perpendicular axes.

EN 61800-5-1:2007, Section 5.2.6.4. referring to IEC 60068-2-6

Frequency range: 10 to 150 Hz

Amplitude: 10 to 57 Hz at 0.075 mm pk

57 to 150 Hz at 1g p

Sweep rate: 1 octave/minute

Duration: 10 sweep cycles per axis in each of 3 mutually perpendicular axes

5.1.9 Starts per hour

By electronic control: unlimited

By interrupting the AC supply: ≤20 (equally spaced)

5.1.10 Acoustic noise

The heatsink fan generates the majority of the sound pressure level at 1 m produced by the

drive. The heatsink fan is a variable speed fan. The drive controls the speed at which the

fan runs based on the temperature of the heatsink and the drive's thermal model system.

Table 5-9 gives the sound pressure level at 1 m produced by the drive for the heatsink fan

running at the maximum and minimum speeds.

Table 5-9 Acoustic noise data

Size

5

64840

Max speed

dBA

Min speed

dBA

5.1.11 Weights