Page 1

Ultrasplice 40

Metal Welding

40 kHz Portable

Ultrasonic Wire Splicer

The Branson Ultrasplice-40 joins wires

quickly and reliably while providing

maximum maneuverability. It splices

up to 4 #16 AWG or a total of 6mm sq

wires in-line, or in a pig tail configuration.

Splicing ultrasonically results in a superior

electrical connection over crimping,

soldering, or resistance welding, and

offers savings in power consumption,

elimination of consumables, and longer

tool life.

EASY TO USE

The Ultrasplice 40's convenient design

enables the operator to feed wires easily

into the splicing nest. A gathering

mechanism positions wires accurately

and catches frayed wires to ensure a

high quality weld. Typically, a weld is

completed in less than one half second.

Since ultrasonics does not generate

appreciable heat, wires can be handled

immediately after splicing.

The Ultrasplice 40 can be readily used for

wire tipping (the solidification of the ends

of strands of wires to keep them from

splaying). This process is especially useful

to prevent unravelling when wires must

be plugged into a connector. The wire

is placed into the large nest area and the

Ultrasplice 40 is activated to collect the

strands and weld them into a precise

configuration.

The Ultrasplice 40 is easily mounted into

an automated wire preparation machine

for total automation of the tipping

process. Production rates in the automated mode can be as high as 60 parts

per minute. The rugged construction

of this system and long tool life makes

the Ultrasplice 40 the perfect method for

wire tipping.

ECONOMICAL

Tool life usually exceeds 100,000 welds.

Electrical power consumption with

ultrasonics averages only 1/30 of the

amount used by resistance welding, and

ultrasonic welding eliminates the need

for costly clips, solder, and flux.

Page 2

Metal Welding

TECHNICAL SUPPORT

Every Branson product is backed by

our technical staff, who provide our

customers with training in operation

and maintenance.

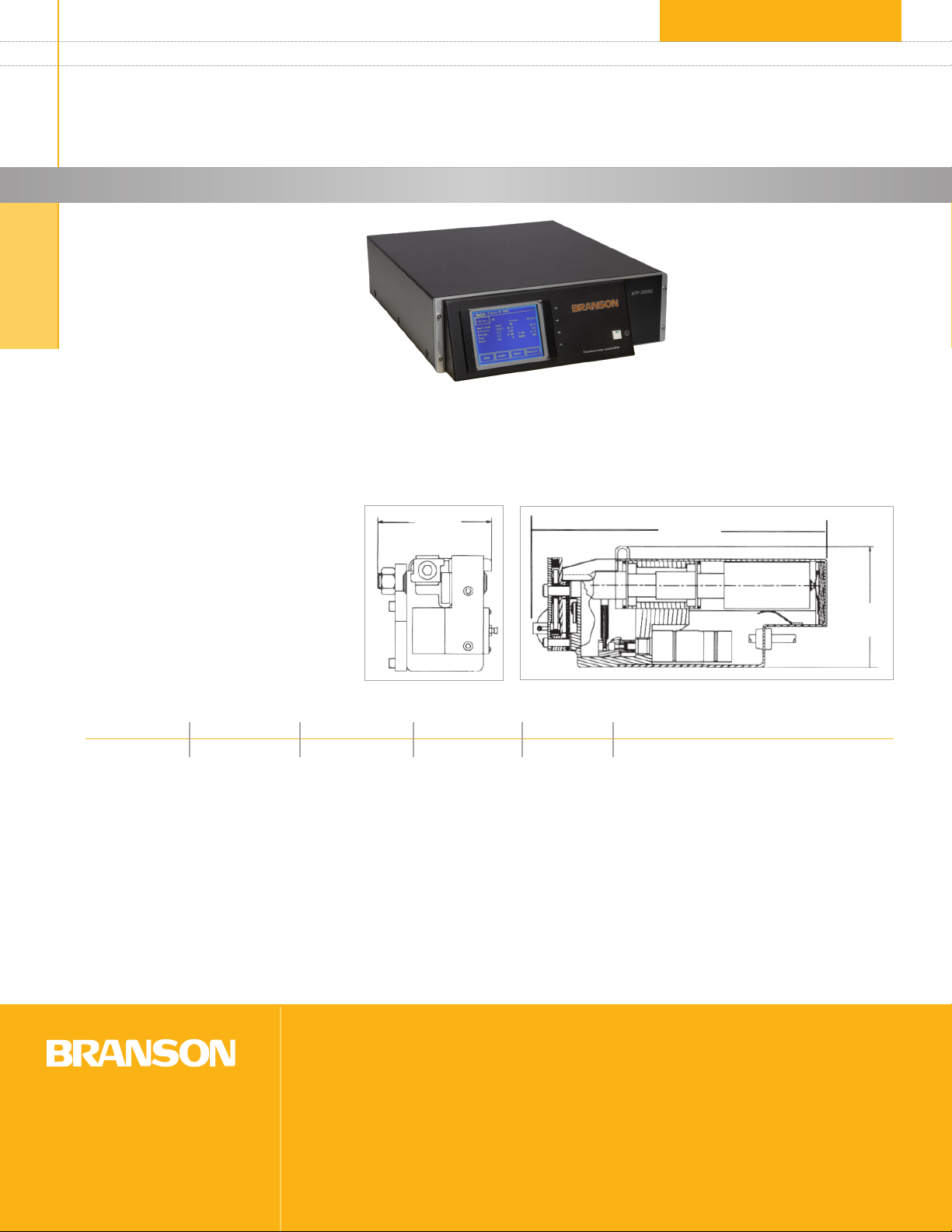

ADVANCED PROCESS CONTROL WITH

THE TOUCH SCREEN CONTROLLER

The Branson Touch Screen

controller monitors and displays all

ultrasonic metal weld parameters to

maintain the highest standards in

weld quality. It features an advanced

microprocessor

the weld cycle through a power

feedback signal. The power in watts

applied to the weld is integrated over

the weld time to determine the total

energy applied. This automatically

adjusts the weld cycle to produce

perfect quality welds, regardless of

part variations.

control that monitors

Control limits on the Touch Screen

controller can be pre-set for weld time

and power. If any weld falls outside the

preset limits, a signal alerts the operator

3.665

(93 mm)

Ultrasplice 40

Touch Screen Controller

to isolate the suspect assembly. A

printer port and RS232 communication

port are standard to support SPC and

ISO 9000 requirements.

10.1

(257 mm)

5.0

(125 mm)

Weight Height Width Length Requirements

Ultrasplice 40 2.3 kg

Electrical requirements are 110 Volts or 200-245 Volts AC, fused at 5 amp 50/60 Hz.

Branson Ultrasonics Corporation

41 Eagle Road, Danbury, CT 06813-1961

(203) 796-0400 • Fax: (203) 796-9838

www.bransonultrasonics.com

e-mail: info@bransonultrasonics.com

125 mm 93 mm 257 mm Pneumatically actuated- 80 psig clean, dry air.

Ultrasplice 40 © Branson Ultrasonics Corporation 2011

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Revised and printed in the U.S.A. 10/2011

Loading...

Loading...