Page 1

Ultraseam 20

Metal Welding

ULTRASEAM® 20 Metal Seam

Welder

Continuous

Tube

Continuous

Seam Welding

The Ultraseam® 20 is the ultimate

metal seam welder – ideal for

continuous welding of aluminum

and copper foils at speeds up to 22

meters per minute. It uses ultrasonic

energy for low cost, clean, and

efficient operation. Tool life can

exceed one million meters of weld.

System Description: The complete

®

Ultraseam

two modules: the power control

system and the weld head. The

power control incorporates a

4,000 Watt, 20 kHz power supply

and a DC motor speed control.

Amplitude is electronically

adjustable to enable welding of

a range of material, thicknesses,

and operating speeds.

The weld head is extremely

rugged and features heavy

duty tapered roller bearings.

A DC motor provides variable

bi-directional speed control.

-20 as shown consists of

A pneumatic cylinder and

pressure regulator permit easy

adjustment of the weld force.

Equipment Features:

• True metallurgic bonds provide

excellent heat transfers.

• All mechanical process - no

electrical current passes through

the work-piece and no melting

occurs.

• Ideal for welding similar or

dissimilar electrical grade alloys

and nonferrous metals of varying

thicknesses.

• Lowest cost per weld compared to

fusion methods for metal joining.

• Superior tool life.

• Welding variables can be precisely

monitored and controlled

providing consistent results

and SPC capabilities.

• Energy efficient.

• Easy to set up and operate.

Page 2

Metal Welding

Ultraseam 20

Optional Equipment

• Rotating anvil assembly for

continuous welding.

• Machine base with drive

mechanism to shuttle the weld

head over a fixtured workpiece.

Process Description

Ultrasonic welding is a mechanical

process. No electrical current nor

thermal energy passes through the

workpiece and no melting occurs.

It is ideal for welding similar or

dissimilar alloys since resistance and

thermal conductivity are not factors.

Non-ferrous metals of different

thicknesses are effectively welded

by this system. The thermal and

electrical properties of the weld are

unrivaled by any other process.

machine’s housing Single point air

and electrical inputs provide simplified

installation and maintenance.

Specifications

Weld head weight: 34 kg (80 lbs.)

Weld head size: Width: 362 mm (14.25 in.), height: 203 mm

(8.0 in.), length: 578 mm (22.75 in.)

Voltage: 200-250 V AC, 50/60 Hz, 1Ø, 20 amps service

Cooling requirements: 80 liters/minute (2 cfm)

Air pressure: 5 Bar (60 psig)

Range of weldable materials: 2 layers of 0.2 mm (0.008 in.) up to

1.0 mm (0.039 in.) of annealed copper

or aluminum

Linear speed: Adjustable up to 15 meters per minute

(22 by special order)

Compared to fusion methods of

joining metals, ultrasonic metal

welding provides the lowest cost.

This is achieved through low power

(1/30th that of comparable resistance

welding) and superior tool life.

The Branson metal welding system

is energy efficient and easy to set

up and operate. It requires only

compressed air and a 200-250 V

AC, 20 Amp service.

All power, control, and electrical

equipment is located inside the

Branson Ultrasonics Corporation

41 Eagle Road, Danbury, CT 06813-1961

(203) 796-0400 • Fax: (203) 796-9838

www.bransonultrasonics.com

e-mail: info@bransonultrasonics.com

Solar Panels

Battery Anode/

Cathode

Tabbing

Ultraseam® 20 © Branson Ultrasonics Corporation 2011

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Revised and printed in the U.S.A. 9/2011

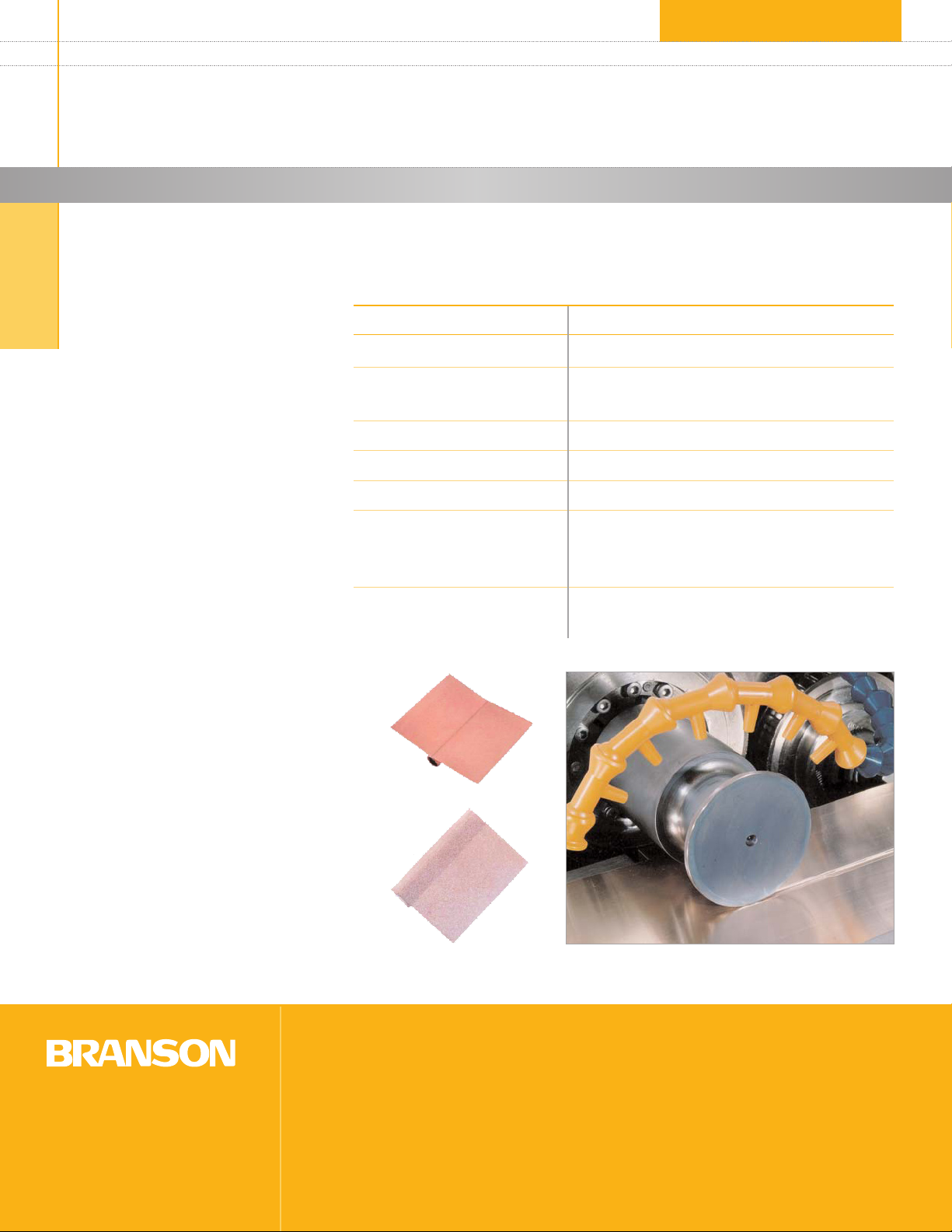

This close-up emphasizes the cleanliness, uniformity, and

consistency of the ultrasonic weld.

Loading...

Loading...