Page 1

MAS2600

Tank Contents Transmitter

Installation & User Manual

Ed 19UK

June 2013

Page 2

Installation & User Manual

Ed 19UK June 2013

Table of contents

Description and Operation ............................................................................................. 3

MAS2600 Tank Contents Tra nsmit ter ..............................................................................................3

Application .........................................................................................................................................3

Intrinsically Safe in Hazardous Areas ...............................................................................................3

Type Approvals .................................................................................................................................3

Technical Specifications ................................................................................................ 4

MAS2600 Ordering Information ................................................................................. 5

Type ...................................................................................................................................................6

Measuring Ranges .............................................................................................................................6

Selecting the Measuring Range .....................................................................................................7

Selecting the Transducer Type ......................................................................................................7

Absolute Transducers ....................................................................................................................8

Basic Rules ....................................................................................................................................8

Forepeak Tank ...............................................................................................................................8

Draft ...............................................................................................................................................9

Temperature Sensor ...........................................................................................................................9

Cable ..................................................................................................................................................9

Brackets for Interna l Mounting - drawing no. G022 P010 ......................................................... 10

Pole Mounting - drawing no. G022P 011 ................................................................................... 10

1” Pipe End Mounting - drawing no. G022P015 ....................................................................... 11

Flange Mounting - drawing no. G022P013 ................................................................................ 11

Flexible rubber tube mounting 80 .............................................................................................. 12

Flexible PTFE tube mounting .................................................................................................... 12

DN25 flange with 1” ball va lve – drawing no. G022 P019 ........................................................ 13

Amplifier Box ................................................................................................................................. 14

Deck Box 165B9035 .................................................................................................... 15

Handling ....................................................................................................................... 16

Installation .................................................................................................................... 17

Intrinsically Safe Installation ....................................................................................... 19

Testing and Recalibrating ............................................................................................ 22

Testing ............................................................................................................................................. 22

Recalibrating Gauge Tra nsmitter u si ng Te st Cup ty pe G022 S100 ................................................ 22

Recalibrating Gauge Transmitter using Vacuum (for gauge transmitters only) ............................ 23

Recalibrating the Absolu t e Tra nsm itter us ing Te st Cup type G022S100 ...................................... 24

Maintenance and Trouble Shooting ............................................................................. 26

Maintenance .................................................................................................................................... 26

Trouble Shooting ............................................................................................................................ 26

MAS2600 Test sheet ...................................................................................................................... 27

Page 2 of 28

Page 3

Installation & User Manual

CERTIFICATE REF.:

4-20 mA

Li nt = 20 uH

x

MARINE AUTOMAT ION DENMARK

S/N:

Umax = 33 V

T

Ci nt = 1 0 nF

C

i

EE

X

a

90-C.95948

T5

amb.: -40 to +85 °C

I 45 mA

K=

<

2600

TWO WI RE T RANSMITTER

2600 SERIES

S/N 46374

1.5 bar g

PDCR-941-1

MAS 2600

DMS

Amplifier box

June 2013 Ed 19UK

Description and Operation

MAS2600 Tank Contents Transmitter

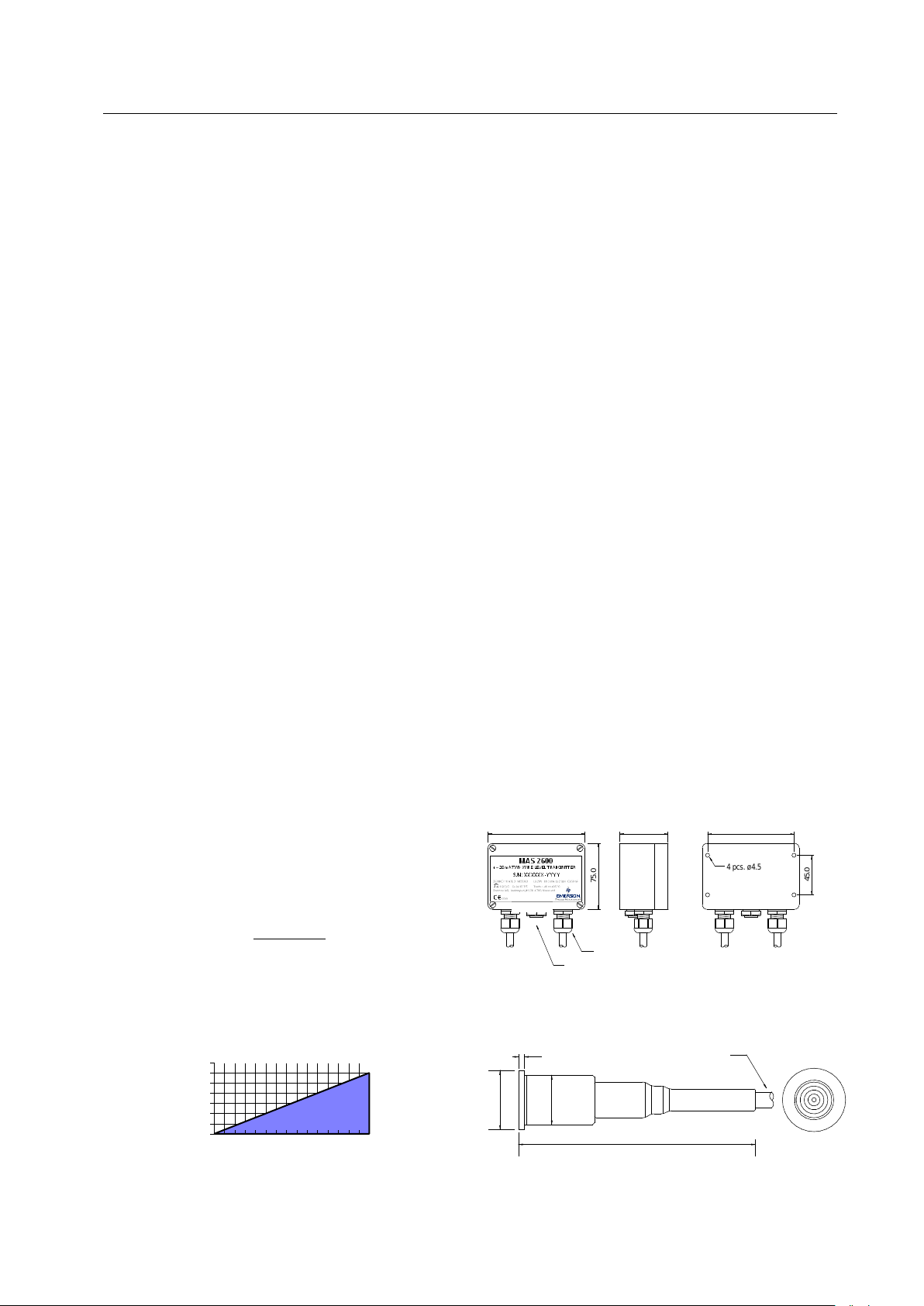

The MAS2600 is a 2-wire 4-20 mA level

transmitter consisting of a transducer and an

amplifier interconnected by a 6-core vented

cable.

Transducer:

The transducer is a pressure sensitive silicon

micro strain gauge sensor mounted in a glass

to metal seal. The sensor is protected by an

isolation diaphragm, electron beam welded

to the transducer housing, with an oil filling

between the sensor and the diaphragm.

Pressure changes on the front of the

diaphragm will bring a resistance change in

the Wheatstone bridge of the transducer.

This change in the Wheatstone bridge will

be transmitted to the amplifier as a change in

the electrical signal.

The transducer is fully welded, housed in

titanium with a titanium diaphragm.

All transducer types are submersible (IP68).

The transducer is available in three versions:

• Gauge version.

• Absolute version.

• High temperature gauge vers io n.

As optional the transducer is available with a

built-in Pt100 temperature sensor.

Amplifier:

The amplifier is available in the following

options:

• Programmable version: Calibration is

made by dip switches and potentiometers.

• Differential version: For measuring of

both pressure and vacuum measuring.

The amplifier is housed in a sea water

resistant polyester casing (IP56).

Application

The MAS2600 has been developed for level

measuring in ballast, oil, service and fresh

water tanks as well as tanks containing

media which are not hostile to titanium.

Intrinsically Safe in Hazardous Areas

The MAS2600 is DEMKO approved for use

with standard transmitter zener barriers or

Ex isolation amplifiers and is Ex ia IIC T4

compliant in accordance with IEC 600790:2007 and IEC 60079-11:2006.

Type Approvals

DNV, GL, LRS, MRS, BV, RINA, KRS,

ABS.

CE marked in accordance with EU directive.

Transducer

Page 3 of 28

Page 4

Installation & User Manual

17

20

23

26

29

32

mA25

17V-U

Loop

MARINE AUTOMATION DENMARK

Cint = 10 nF

2600 SERIES

4-20 mA

CERTIFICATE REF.:

Lint = 20 uH

x

EE

X

i

a

C

amb.: -40 to +85 °C

I 45 mA

S/N:

Umax = 33 V

T5

90-C.95948

2600

T

K=

<

TWO WIRE TRANSMITTER

55.0

110.0

75.0

45.0

98.0

PG11

cable gland

1/8" NPT

vent fitting

4 pcs. ø4.5

Use 4x20mm bolts and nuts

for suspension on a 4mm

thick surface

120.0

3.0

30.0

25.0

6-core vented cable, ø8.0

Front view

Ed 19UK June 2013

Technical Specifications

Transducer Ranges:

Gauge: 0-3.5 / 0-7 / 0-16 / 0-35 m H2O.

Absolute: 0-20.394 / 0-35.690 m H2O.

Programmable Measuring Ranges:

Each transducer range is programmable in 8

steps.

Accuracy:

± 0.25% F.S. at 20°C.

Stability:

Max. ± 0.1% / Year.

TEB (Total Error Band):

± 2.0% F.S. at -20 to +80°C.

EMC immunity influence < ±0.5%FS

Overload Capability:

Min. 4 x transducer range with no changes in

calibration.

6 x transducer range burst pressure.

Built-in Temperature Sensor Pt100:

Optional.

Power Supply:

Output Current:

4-20 mA DC, loop powered 2-wire system.

Current Limiting:

Max: 25 mA

Sensor Materials:

Housing: Titanium Grade 2

Diaphragm: Titanium Grade 4

Operating Temperature Ranges:

Transducer: -20 to +125°C

Standard cable: -20 to + 80°C

High temperature cable: -20 to +125°C

Amplifier: -40 to + 85°C

Protection Class:

Transducer: IP 68

Amplifier: IP 56

Intrinsic Safety:

Ex ia IIC T4 compliant.

Max. 75 m cable between transducer and

transmitter amplifier.

Transmitter dimensions

Amplifier box:

The Power Supply can vary from 17-33

VDC. Permissible load resistance is shown

graphically below. Calculation formula:

R

loop max.

Page 4 of 28

(Kohm) =

Max. load resistance

at various power supply

700

600

500

400

300

200

100

0

Load resistance (ohm)

Power supply (V)

Transducer:

Page 5

Installation & User Manual

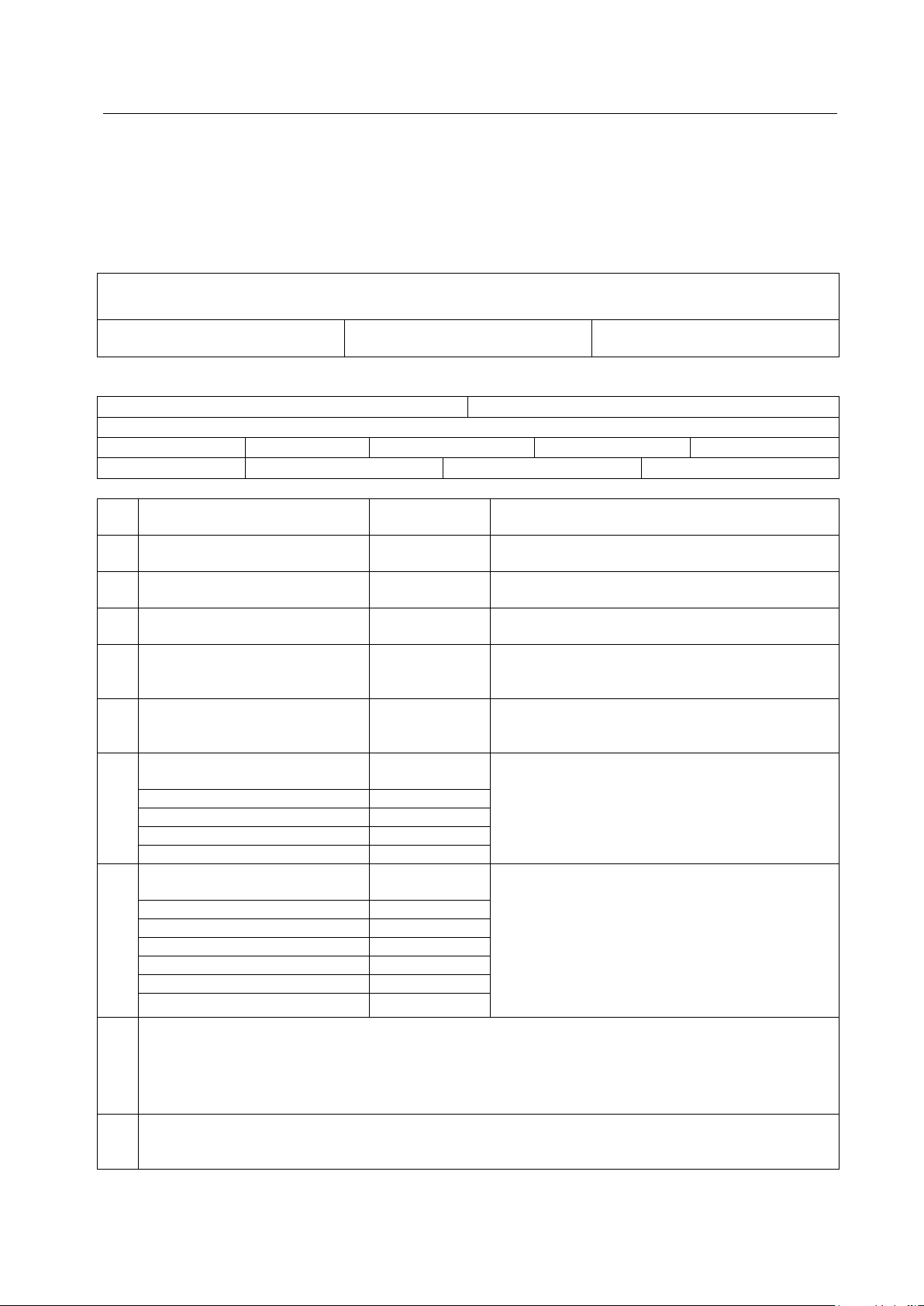

Type

H high temperature gauge transducer

Transducer Ranges

Temperature Sensor

1 Built-in Pt100 (Not available for IS installations )

Cable Max. 300 meters – max 75 meters for IS installations

Mounting

A-M replacement

Amplifier Box

8 standard box with PG 11 / PG 16 – filling hole

Amplifier PCB

M differential output range gauge

X X X - XX - X / X

X

June 2013 Ed 19UK

MAS2600 Ordering Information

A absolute transducer

G gauge transducer

1 3,5 mH2O gauge or high temp.

2 7,0 mH

3 16,0 mH

4 35,0 mH

7 0,8 – 2,0 bar absolute

0 without

O gauge or high temp.

2

O gauge or high temp.

2

O gauge or 0,8 – 3,5 bar absolute

2

XX XLPE standard cable length in meters (up to 80°C).

XX FEP high temperature cable length in meters (up to 125°C) (Not IS inst).

0 without fittings

1 brackets for internal mounting

2 pole mounting

3 1" pipe end mounting

4 flange mounting DN 25

5 flange mounting DN 40

6 flange mounting DN 50

9 flexible rubber tube mounting – 80 ºC (add length in meters)

P flexible PTFE tube mounting – 125 ºC (add length in meters) (Not IS inst)

V DN25 flange / 1” ball valve

0 not supplied

1 standard box with PG 11 / PG 11

2 standard box with PG 11 / PG 13,5

3 standard box with PG 11 / PG 16

5 standard box with PG 13,5 / PG 13,5

6 standard box with PG 11 / PG 11 – filling hole

7 standard box with PG 11 / PG 13,5 – filling hole

0 not supplied

without terminals for temperature sensors:

P programmable output range gauge

D differential output range gauge

with terminals for temperature sensors:

S programmable output range gauge

Page 5 of 28

Page 6

Installation & User Manual

Range No.

Ed 19UK June 2013

Type MAS2600-XXX-XX-X/XX

A: Absolute Transducer. The absolute transducer has no breather pipe, because it refers to

absolute vacuum. An atmospheric pressure sensor is used to compensate for the atmospheric

pressure. The absolute transducer is especially suitable for open deck applications, where the

amplifier box may be exposed to flooding.

G: Gauge Transducer. The gauge transducer is fitted with a breather pipe at the back of the

diaphragm to compensate for the atmospheric pressure. The breather pipe is connected to a

vent plug in the amplifier box. The gauge transducer is suitable for most applications.

H: High Temperature Transducer. The high temperature transducer is available in gauge version

only. The transducer is mounted with a special high temperature cable and designed for

heated tanks e.g. HFO tanks, and other applications with high tank media temperatures. The

transducer can be flange mounted or internally mounted.

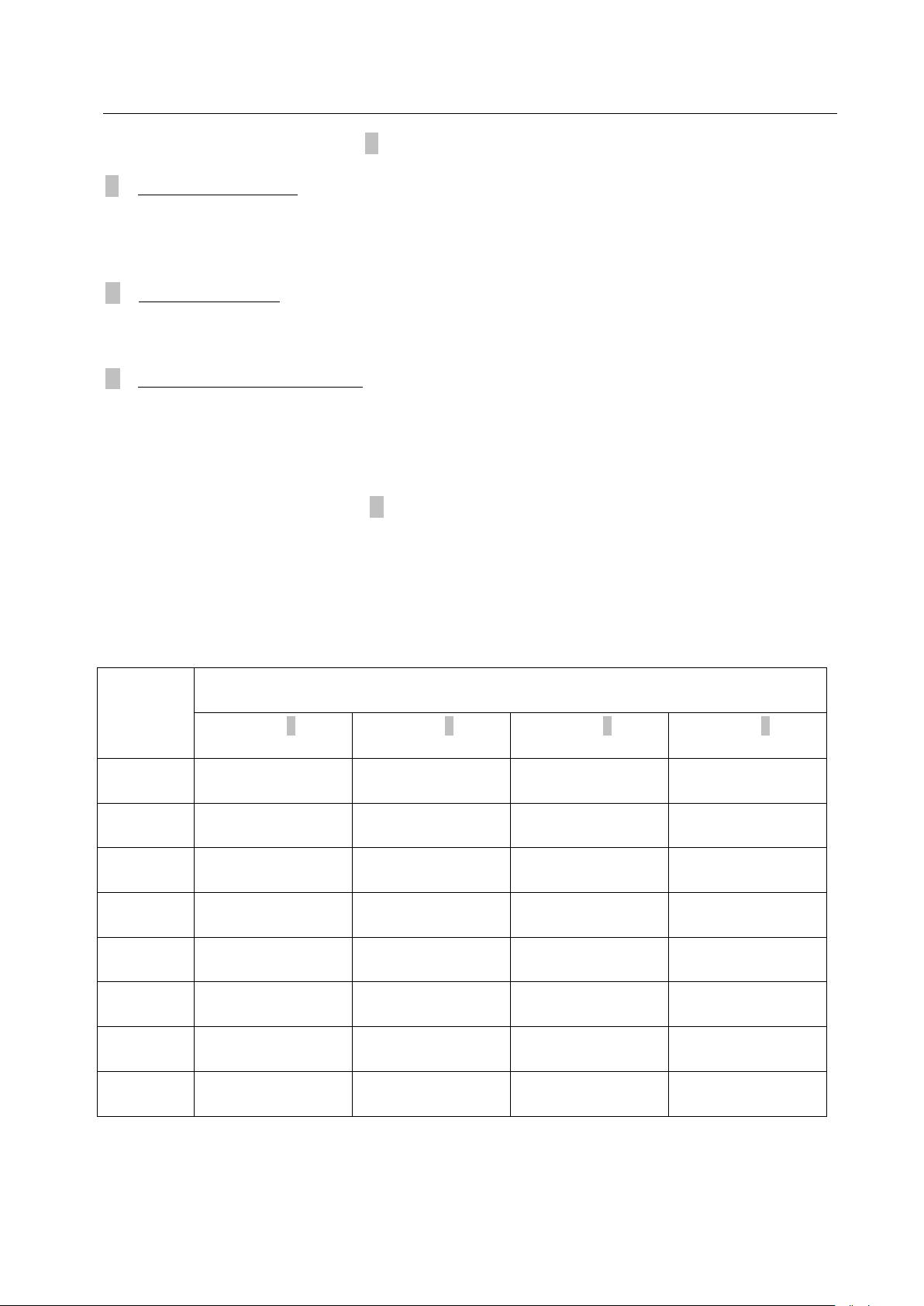

Measuring Ranges MAS2600-XXX-XX-X/XX

Gauge Transmitter:

The MAS2600 Gauge Transmitter is supplied in 4 ranges. In the programmable amplifier the

measuring range is divided into 8 sub-ranges and operated by means of the range select switch.

The transmitter output signal can be adjusted to 20 mA within the following sub-ranges.

Transducer type

Type 1:

0 – 3.5 mH2O

1 0.20 – 0.37 mH2O 0.20 – 0.30 mH2O 0.50 – 0.75 mH2O 1.00 – 1.90 mH2O

2 0.37 – 0.54 mH2O 0.30 – 0.50 mH2O 0.75 – 1.00 mH2O 1.90 – 2.80 mH2O

3 0.54 – 0.73 mH2O 0.50 – 0.70 mH2O 1.00 – 1.50 mH2O 2.80 – 3.90 mH2O

4 0.73 – 1.10 mH2O 0.70 – 1.10 mH2O 1.50 – 2.50 mH2O 3.90 – 5.80 mH2O

5 1.10 – 1.92 mH2O 1.10 – 1.80 mH2O 2.50 – 4.00mH2O 5.80 – 9.90 mH2O

6 1.92 – 3.10 mH2O 1.80 – 3.00 mH2O 4.00 – 6.00 mH2O 9.90 – 15.30 mH2O

7 3.10 – 3.50 mH2O 3.00 – 4.80 mH2O 6.00 – 10.00 mH2O 15.30 – 25.10 mH2O

8

NOT

APPLICABLE

Type 2:

0 – 7.0 mH2O

4.80 – 7.10 mH2O 10.00 – 16.00 mH2O 25.10 – 35.60 mH2O

Type 3:

0 – 16.0 mH2O

Type 4:

0 – 35.0 mH2O

Page 6 of 28

Page 7

Installation & User Manual

MAS 2600 A m plifier box

Flange mounted

G022P013

Sensor pos. above

lowest point

Tankheight

Vent pipe height

TWO WIRE TRANSMITTER

2600 SERIES

90-C.95948

T5

Cint = 10 nF

C

CERTIFICATE REF.:

4-20 mA

Lint = 20 uH

x

i

EE

X

a

MARINE AUTOMATION DENMARK

S/N:

Umax = 33 V

T

amb.: -40 to +85 °C

I 45 mA

K=

<

2600

June 2013 Ed 19UK

Absolute Transmitter:

The MAS2600 Absolute Transmitter is available in two ranges.

The output signals are calibrated as follows:

Transducer type 4 : 0.8 - 3.5 bar abs

Transducer type 7 : 0.8 - 2.0 bar abs

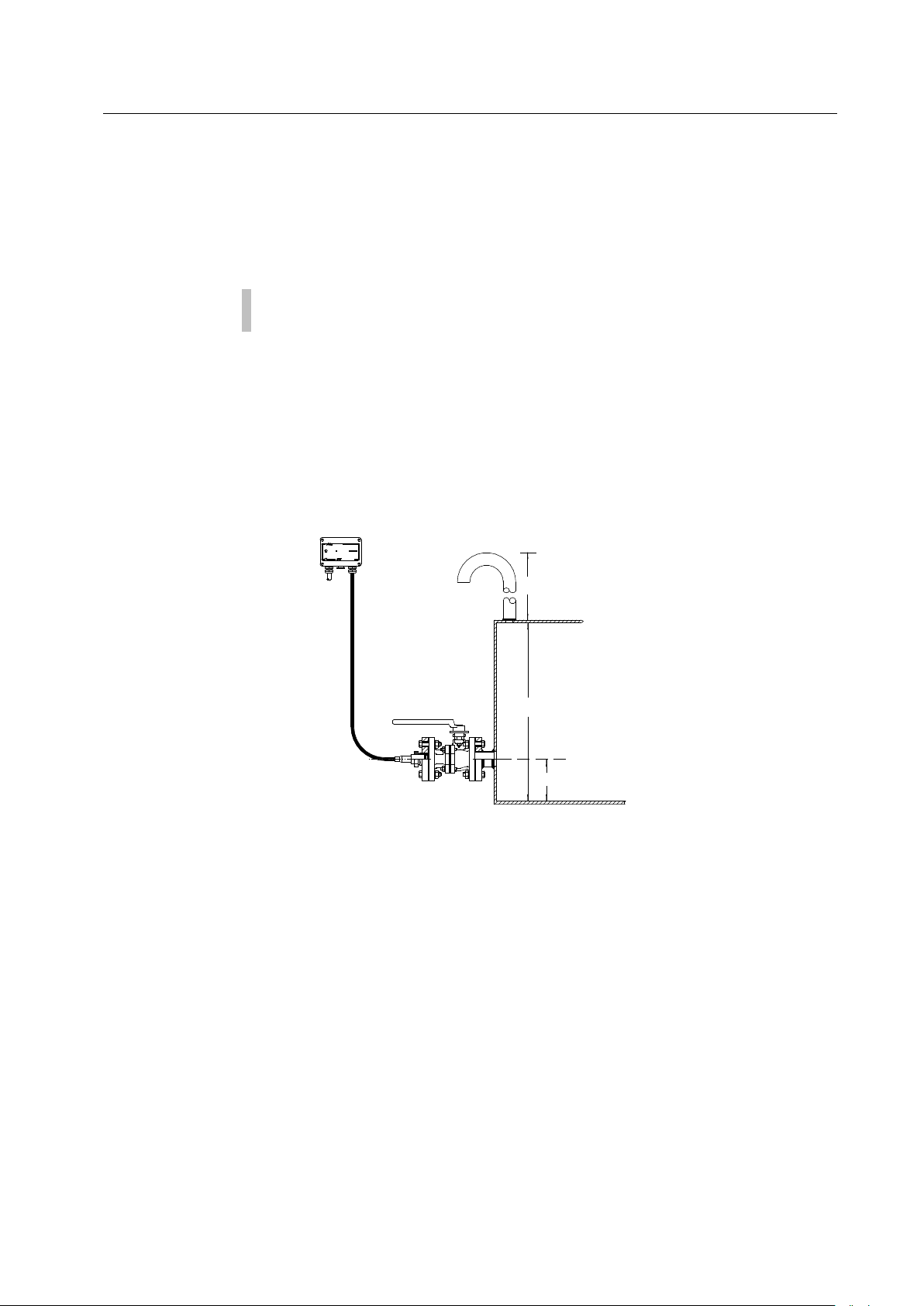

Selecting the Measuring Range:

When selecting the measuring range it is important to consider the tank height, vent pipe height,

the tank type and the specific gravity (SG) of the tank contents.

The transducer measures the height of the fluid (water gauge) from the transducer diaphragm to

the surface of the fluid, including the fluid in the vent pipe.

To ensure measuring accuracy a transducer type within the range no. 4, 5, 6, 7 and 8 is

recommended.

Guidelines for selection of transducer measuring ranges are set out in the following.

Selecting the Transducer Type:

Gauge and High Temperature Gauge Transducers:

The Gauge Transmitter is normally used on dry and pressure neutral locations.

The Gauge Transmitter is available in 4 ranges:

0-3.5 mH2O.

0-7.0 mH2O.

0-16.0 mH2O.

0-35.0 mH2O.

Page 7 of 28

Page 8

Installation & User Manual

tank height + vent pipe height

2

6+14

2

Ed 19UK June 2013

Absolute Transducers

The Absolute Transmitter is typically used if the amplifier is exposed to water, e.g. on open deck.

The Absolute Transmitter is available in 2 ranges: 0-20 and 0-35 mH2O. In practice this means 10

mH2O less than the nominal range because of the atmospheric pressure which must be taken into

consideration when choosing the transducer.

A transducer with an effective range larger than the tank height should be selected.

:

Basic Rules:

1. The selected measuring range must be larger than the tank height.

2. The selected measuring range must be larger than

EXAMPLE: Tank height = 6 m

Vent pipe height = 14 m

1. The selected measuring range must be larger than 6 m due to the height of the tank.

2. The selected measuring range must be larger than

= 10 m due to the total height of the

tank and the vent pipe combined.

Select a transducer with a measuring range of 16 mH2O as this is the next measuring range larger

than 10 m.

Turn the range select switch on the amplifier to range No. 7.

Normally the selection of transducer, range select and calibration are done by DAMCOS.

Special consideration applies to e.g. forepeak tanks and draft measuring when selecting the

measuring range of the transducer.

Forepeak Tank:

Transducer measuring range > tank height: Select the next measuring range.

EXAMPLE: Tank height 12 m.

Based on the tank height a transducer with a measuring range of 16 mH2O should be selected.

However, due to the dynamic conditions in the forepeak tank, a transducer with a measuring

range of 35 mH2O, i.e. the next in line, should be selected.

Turn amplifier range select switch to range No. 6.

Page 8 of 28

Page 9

Installation & User Manual

TWO WIRE TRANSMITTER

2600 SERIES

90-C.95948

T5

Cint = 10 nF

C

CERTIFICATE REF.:

4-20 mA

Lint = 20 uH

x

i

EE

X

a

MARINE AUTOMATION DENMARK

S/N:

Umax = 33 V

T

amb.: -40 to +85 °C

I 45 mA

K=

<

2600

MAS2600 amplifier box

Sensor pos. above

Ships hull

Min. draft

June 2013 Ed 19UK

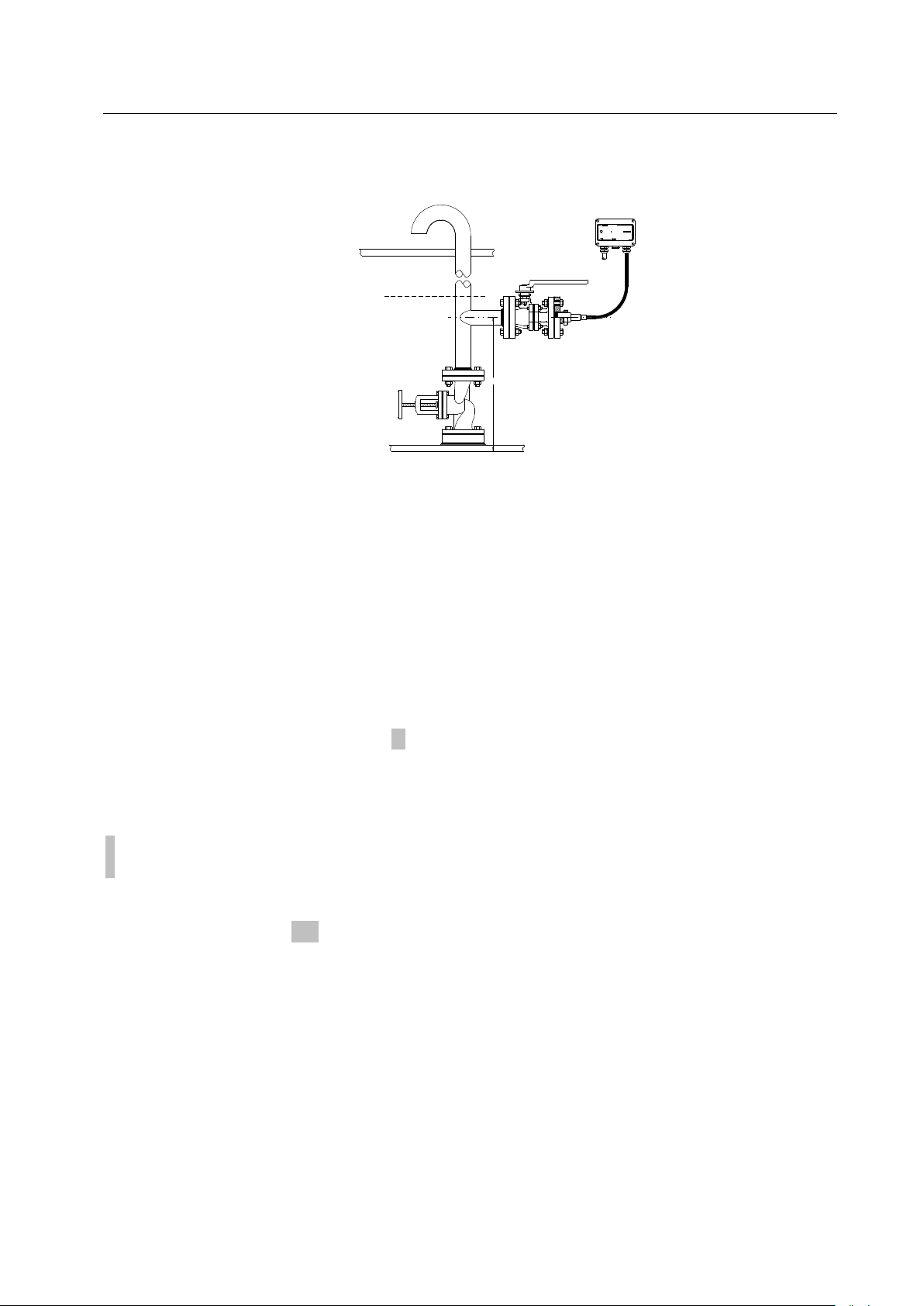

Draft

Transducer measuring range > max. draft minus sensor position.

This rule applies provided the transducer is mounted in accordance with the installation drawing

for draft transmitters (vent pipe min. 1"). The sensor may be mounted direct on the sea valve with

an air release valve if the ship is sailing in calm waters.

If the transducer is installed in tanks which may have excessive dynamic stresses such as e.g.

high pump pressure, long bottomed tanks with a risk of slashing etc., contact Emerson Process

Management Marine Solutions, Damcos.

Temperature Sensor MAS2600-XXX-XX-X/XX

The transducer can be supplied with a built-in Pt100 temperature sensor. The temperature sensor

will only give a proper reading, if the transducer is an internally mounted type.

0: Without temperature sensor.

1: With temperature sensor

Cable MAS2600-XXX-XX-X/XX

Two types of transducer cable is available. The standard cable for applications with temperatures

never exceeding 80°C, and high temperature cable for applications with temperatures up to

125°C. The transducer cable is delivered in whole meters.

For further information require data sheet.

To make the MAS2600 transmitter easy to install, and for later service purposes, the transducer

cable should be as short as possible, though considering the position of the transducer and

amplifier box.

Max. cable length: 300 m.

When installing in hazardous areas max. cable length: 75 m.

:

Weather deck

Class approved

Sea valve

Vent pipe min. 1”

Ships hull

Page 9 of 28

Page 10

Installation & User Manual

Bulkhead

Tank bottom

TWO WIRE TRANSMITTER

2600 SERIES

90-C.95948

T5

Cint = 10 nF

C

CERTIFICATE REF.:

4-20 mA

Lint = 20 uH

x

i

EE

X

a

MARINE AUTOMATION DENMARK

S/N:

Umax = 33 V

T

amb.: -40 to +85 °C

I 45 mA

K

=

<

2600

Tank top

125.0

160.0

38.0

55.0

40.0

45.0

TWO WIRE TRANSMI TTER

2600 SERIES

90-C.95948

T5

Cint = 10 nF

C

CERTIFICATE REF.:

4-20 mA

Lint = 20 uH

x

i

EE

X

a

MARINE AUTOMATION DENMARK

S/N:

Umax = 33 V

T

amb.: -40 to +85 °C

I 45 mA

K=

<

2600

Bulkhead

Tank top

Tank bottom

34.0

26.0

40.0

24.0

41.0

26.0

1" Thread

Ed 19UK June 2013

Brackets for Internal Mounting - drawing no. G022P010:

The brackets are U-shaped and manufactured of 2 mm SS 316L plated steel. Diameter of

mounting holes: 11.5 mm.

The transducer is secured by means of a spring fitted into two holes in the “U” shape, and can be

mounted/dismounted without the use of tools.

When installing in hazardous areas the cable must be protected by a steel pipe welded to the tank.

Pole Mounting - drawing no. G022P011:

The weldable collar and the nut are manufactured of SS 316L steel. The gaskets are made of

nitrile rubber.

Note: Max torque 20 Nm (slightly tighten by the hand + 1/8-1/4 turn). Remember the gasket.

Page 10 of 28

Page 11

Installation & User Manual

19,5

D

k

d

b

25,0

55,0

80,0

34.0

26,0

24.0

41,0

26,0

DN

Flange

Bolts

D

Mm

B

mm

K

Mm

No. of

bolts

thread

dia.

d

mm

25

115

16

85 4 M12

14

40

150

16

110

4

M16

18

50

165

18

125

4

M16

18

June 2013 Ed 19UK

1” Pipe End Mounting - drawing no. G022P015

Tank t op

Bulkhead

Tank bot tom

The thread collar and the nut are manufactured of SS 316L steel. The gaskets are made of nitrile

rubber.

Note: Max torque 20 Nm (slightly tighten by the hand + 1/8-1/4 turn). Remember the gasket.

2600 SERIES

TWO WIRE TRANS MITTER

4-20 mA

2600

x

a

i

X

T5

C

EE

S/N:

amb.: -40 to +85 °C

90-C.95948

CERTIFICATE REF.:

T

<

Cint = 10 nF

Lint = 20 uH

Umax = 33 V

I 45 mA

K=

MARINE AUTOMATION DENMARK

:

Flange Mounting - drawing no. G022P013:

Tank t op

Bulkhead

Tank bot tom

The standard transducer is supplied with DN25, DN40 or DN50 PN16 DIN2527 flange

manufactured in AISI 316L steel.

2600 SERIES

4-20 mA

TWO WIRE TRANSMITTER

2600

x

a

i

X

S/N:

C

T5

EE

amb.: -40 to +85 °C

T

CERTIFICATE REF.:

90-C.95948

<

I 45 mA

Umax = 33 V

Lint = 20 uH

Cint = 10 nF

K=

MARINE AUTOMATION DENMARK

Note: Max torque 20 Nm (slightly tighten by the hand + 1/8-1/4 turn). Remember the gasket.

Page 11 of 28

Page 12

Bulkhead

Tank bot tom

Tank t op

TWO WIRE TRANSMI TTER

2600 SERIES

90-C.95948

T5

Cint = 10 nF

C

CERTIFICATE REF.:

4-20 mA

Lint = 20 uH

x

i

EE

X

a

MARINE AUTOMATION DENMARK

S/N:

Umax = 33 V

T

amb.: -40 to +85 ° C

I 45 mA

K

=

<

2600

H

Installation & User Manual

Ed 19UK June 2013

Flexible rubber tube mounting 80 ºC - drawing no. G022P001:

A top flange made of SS 316L connected to rubber tube by a tightening clip using a special tool.

The opposite hose end covers the transducer body and is fixed by a tightening clip.

NB: When ordering this mounting type always specify length for the measurement of H

cf. above drawing.

Flexible PTFE tube mounting 125ºC - drawing no. G022P021:

Tank t op

H

A top flange made of SS 316L connected to a Stainless Steel braided PTFE tube by fittings fixed

to the tube by using special tools. A fitting in the opposite tube end is fixed to the transducer by

Tank bot tom

means of nut and ferrules. Min. hose bending radius 130 mm.

NB: This mounting type cannot be used in hazardous area.

When ordering this mounting type always specify length for the measurement of H

cf. above drawing.

Note: This mounting type can only be assembled by Emerson Process Management Marine

Solutions, Damcos because it requires special tools. The customer can exchange the MAS2600

transmitter by ordering a G022B085 and a G022B082 together with the new MAS2600

transducer. It must clearly be specified that it is a replacement for an MAS2600 HXX-XX-P/XX.

4-20 mA

CERTIFICATE REF.:

Lint = 20 uH

x

EE

2600 SERIES

TWO WIRE TRANSMITTER

a

i

X

T5

C

90-C.95948

Cint = 10 nF

2600

S/N:

amb.: -40 to +85 °C

T

<

Umax = 33 V

I 45 mA

=K

MARINE AUTOMATION DENMARK

Bulkhead

Page 12 of 28

Page 13

Installation & User Manual

June 2013 Ed 19UK

DN25 flange with 1” ball valve – drawing no. G022P019:

Tank t op

Bulkhead

Tank bot tom

Flange, valve and nut are manufactured of SS 316L steel. The gaskets are made of nitrile rubber.

Note: Max torque 20 Nm (slightly tighten by the hand + 1/8-1/4 turn). Remember the gasket.

4-20 mA

CERTIFICATE REF.:

Lint = 20 uH

x

a

i

X

EE

2600 SERIES

TWO WIRE TRANSMITTER

C

T5TS/N:

90-C.95948

Umax = 33 VCint = 10 nF

MARINE AUTOMATION DENMARK

2600

amb.: -40 to +85 °C

<

I 45 mA

=K

Page 13 of 28

Page 14

Installation & User Manual

MARINE AUT OMATION DENMARK

Cint = 10 nF

2600 SERIES

4-20 mA

CERTIFICATE REF.:

Lint = 20 uH

x

EE

X

i

a

C

amb.: -40 to +85 °C

I 45 mA

S/N:

Umax = 33 V

T5

90-C.95948

2600

T

K=

<

TWO WIRE TRANSMITTER

55.0

110.0

75.0

45.0

98.0

PG11

cable gland

1/8" NPT

vent fitting

4 pcs. ø4.5

Use 4x20mm bolts and nuts

for suspension on a 4m m

thick surface

Ed 19UK June 2013

Amplifier Box MAS2600-XXX-XX-X/XX

The MAS2600 amplifier box is manufactured in polyester, which has the strength and stability of

aluminium, insulation and resistance properties of plastics. Colour code RAL 7000.

The amplifier box is protected to the level of IP 56 and must be mounted outside the tank, e.g. in

the engine room or other dry areas.

The amplifier box is available with a PG9 hole for silicone gel filling to protect the amplifier

from moisture.

When the amplifier box is mounted on open deck with the risk of being drenched it is

recommended to mount the amplifier box inside the deck box 165B9035. To further reduce the

exposure of water place the amplifier box to the centre of the vessel.

0: Without amplifier box.

1: Standard box with PG 11/PG 11 cable glands. For cable diameter 5 -10 mm.

2: Standard box with PG 11/PG 13.5 cable glands. For cable diameter 6-12 mm.

3: Standard box with PG 11/PG 16 cable glands. For cable diameter 10-14 mm.

5: Standard box with PG 13.5/PG 13.5 cable glands. For cable diameter 6-12 mm.

6: Standard box with PG 11/PG 11 cable glands and filling hole. For cable diameter 5 -10 mm.

7: Standard box with PG 11/PG 13.5 cable glands and filling hole. For cable diameter 6-12 mm.

8: Standard box with PG 11/PG 16 cable glands and filling hole. For cable diameter 10-14 mm.

Page 14 of 28

Page 15

Installation & User Manual

Programmable Range (Type P and S)

June 2013 Ed 19UK

Amplifier PCB MAS2600-XXX-XX-X/XX

The PCB is available in different types for the different transducers, with or without terminals for

Pt100 temperature sensor.

0: Without amplifier PCB.

P or S: Programmable output range. The amplifier can be calibrated to 4-20 mA output in

whatever range wanted within the transducer range. Calibration is made by means of dip

switches and potentiometers.

D or M: Differential output range. The output can be adjusted to 12 mA output with no pressure

applied. With pressure or vacuum, the output goes against 20 mA and 4 mA

respectively. Full-scale and zero point calibration by means of software, e.g. tank

monitoring software.

• The types S and M are with terminals for temperature sensors.

• The types P and D are without terminals for temperature sensors.

Deck Box 165B9035

Page 15 of 28

Page 16

Installation & User Manual

Ed 19UK June 2013

Handling

The MAS2600 transducer is a highly sensitive electronic piece of equipment and proper handling

is most important.

To avoid damaging the transducers:

• NEVER lift by the cable if transducer is mounted with fittings.

• NEVER remove the protection cap in front of the diaphragm before installation.

• NEVER knock the transducer.

• NEVER apply pressure to the diaphragm in any way whatsoever, whether using fingers, tools

or sharp objects.

• NEVER use sharp objects when cleaning the diaphragm.

• NEVER submerge the cable so that the breather tube is under water.

• NEVER bend the cable in a radius of less than 90 mm.

Page 16 of 28

Page 17

Installation & User Manual

June 2013 Ed 19UK

Installation

Prior to installation please check that:

• the serial numbers on the transducer, amplifier and lid of amplifier box agree. The serial

numbers are to be found on the inside of the lid of the amplifier box on the bottom line amplifier S/N and transducer S/N on the range label.

• the transducer is fitted in the correct tank.

• the transducer is correctly connected to the amplifier.

NOTE: The white and brown wires in the transducer cable are only used when a Pt100 sensor

is built into the transducer.

• all cable glands are properly secured to the amplifier box. Use torque of 6 Nm.

• the amplifier box is mounted in such a way that the breather tube cannot be flooded.

• the cable is fastened with cable clips with a distance of max. 50 cm.

• the cable isolation is not damaged (cracks, weld spatter, burns etc.).

• shut-off valves can be either ball valves or other valves not generating over pressure exceeding

4 x the transducer range between valve seat and transducer when the valve is closed.

As for flange mounted applications it is recommended that a ball valve is fitted in the front of the

transducer to facilitate testing and calibrating of the transmitter.

Using a shielded cable to the 4-20 mA signal, the shield should not be connected in the amplifier

box but the earth terminal of the instrument. Using a shielded cable ensures maximum protection

against electric noise.

Page 17 of 28

Page 18

Installation & User Manual

4-20 mA signal cable

1/8” NPT fitting

Shield bracket

Breather tube

Terminal block for Pt100

Breather hose

Transducer cable

Ed 19UK June 2013

If the amplifier box is installed in an area with over pressure or negative pressure in relation to

the atmospheric pressure in the tank, the breather tube must be directed to an area with

atmospheric pressure equalling the pressure inside the tank. This applies to gauge transmitters

only. For absolute transmitters this has no affect, due to the reference to absolute vacuum and not

atmospheric pressure. This is also the reason why no breather tube is necessary.

Be sure that the cable glands are tight. Use a torque of 6 Nm.

Do not fasten to tight

element

for breather tube

Page 18 of 28

Page 19

Installation & User Manual

June 2013 Ed 19UK

Intrinsically Safe Installation

The MAS2600 is designed for use in an approved intrinsically safe installation. The amplifier is

fitted with a label describing the IS category:

S/N: XXXXXX-YYYY

DEMKO 11 ATEX 146506X IECEx ULD 10.0013X

Ui: 29V Ii: 93 mA Li: 20µH Ci: 60 nF Pi: 0.68 W

II 2(1) G Ex ia IIC T4 Tamb.: -20 to +80 °C

Damcos A/S, Aaderupvej 41,DK-4700, Naestved

Where

S/N : serial number – production year.

: Ex identification according to guideline 94/9/EC (ATEX).

II : other aria than mines.

2(1) : sensor mounted in zone 0 and amplifier in zone 1

Ex ia : denotes the type of protection intrinsic safety , i.e. the system is incapable of causing

ignition in normal operation or with any combination of up to two faults applied. This

category will be adequate for use in zone 0, 1 and 2.

IIC : denotes the group of gases.

T4 : denotes the maximum surface temperature classification specified (T4: 135 °C).

Tamb : denotes the minimum and maximum ambient temperature for the amplifier box

permitted by the certificate.

DEMKO 11 ATEX 146506X:

The ATEX Certificate No 146506 is issued by DEMKO 201 with remarks.

Inmetro:

Inmetro Certificate No. UL BR 12.0116X issued by UL do Brazil

Relevant intrinsic safety certificates to be supplied with the system units.

The certification of electric apparatus as intrinsically safe requires the apparatus to be designed

and tested in accordance with approved drawings and the apparatus to be installed in accordance

with approved block schematic diagrams.

Page 19 of 28

Page 20

Installation & User Manual

Ed 19UK June 2013

Before installing intrinsically safe units within an approved installation, it is essential to ensure

that there are no deviations from the conditions of the order or the requirements of the approved

block schematic diagram and the following related instructions:

1. No circuits other than those shown on the drawing are permitted. There must be no

interconnection to any other circuits.

2. The intrinsically safe cabling must not be connected to non-intrinsically safe circuits, through

any plug, socket or other form of electric connector containing the cable.

3. Adequate precautions must be taken to prevent danger arising from the charging of the

intrinsically safe circuit by the contact leakage or inductance from any other circuit. To

prevent static electricity do not rub cables or amplifier housing with a dry piece of cloth.

4. The intrinsically safe circuit must be adequately insulated from earth in the hazardous area

and the insulation of all cabling must be at least 500 V r.m.s.

5. The safety barrier (zener barrier) must be placed in a safe area and be mounted within a

protective enclosure with a protection degree, at least equal to IP 20.

6. The cable between the safety barrier and the amplifier should be provided with a cable shield

which is connected to earth at the zener barrier. The impedance between the safety barrier

earth rail and a secure bond to the hull must not exceed 1 ohm.

7. Safe area apparatus must not be supplied from, nor contain, a source of potential with respect

to earth under normal or abnormal conditions exceeding 250V r.m.s. or 250 V DC.

8. The inductance/resistance ratio, total inductance and total capacitance, of the cable and the

amplifier must not exceed the values stated by the manufacturer of the approved safety

barriers.

9. Prevent impacts on the sensor housing to avoid sparks. Do not mount or dismount the sensor

when there is a hazardous condition in the tank. Be sure the tank is vented and gas free.

10. Be sure that the amplifier box is dry and clean before the lid is mounted. The four screws

in the lid should be tightened fully.

11. Be sure to order and use sensor cable with the right temperature specification. Check that

the ambient temperature for the entire cable run do not exceed the max limit for the cable.

12. MAS2600 contain no repairable parts. Repairing or fixing the circuit or replacing

components may impact the intrinsic safety.

13. The sensor cable shall remain in one piece from sensor to amplifier box.

Reference is made to manufacturer instructions of zener barriers and to the rules in force at the

time in question concerning intrinsically safe area installation.

Page 20 of 28

Page 21

Installation & User Manual

4-20 mA

Hazardous area

Safe area

Any 28V / 300R

Shunt zener diode safty

barrier or Ex repeater

certified to Ex Ia IIC.

Transducer

Amplifier box

MARINE AUTOMATI ON DENMARK

Cint = 10 nF

2600 SERIES

4-20 mA

CERTIFICATE REF.:

Lint = 20 uH

x

EE

X

i

a

C

amb.: -40 to +85 °C

I 45 mA

S/N:

Umax = 33 V

T5

90-C.95948

2600

T

K=

<

TWO WIRE TRANSMITTER

-

-

+

+

m3

Indication by simple gauge

or tankmonitoring computer

4-20 mA

24 VDC

June 2013 Ed 19UK

Any Shunt zener diode

barrier or Ex repeater with Uo

<= 28V DC and Io <= 93 mA

Page 21 of 28

Page 22

Installation & User Manual

Ed 19UK June 2013

Testing and Recalibrating

Please observe that testing and recalibration of sensors mounted in hazardous arias shall be

carried out of Ex qualified personnel.

Testing

Before dispatch, the MAS2600 transmitter is calibrated in accordance with the requirements

specified in the order.

The transducer and the amplifier are calibrated together and must, therefore, always be used

together.

A programmable measuring range transmitter will in conditions of no pressure (empty tank) give

an output signal of 4 mA, and in conditions of maximum pressure (full tank) an output signal of

20 mA.

The transmitter should be tested by applying to the transducer a known pressure from a calibrator

and reading the equivalent milliamp signal on a milliamp meter.

The above-mentioned applies to the gauges transmitter only. For absolute transmitters the output

signal will be higher than 4 mA, because it is calibrated for 4 mA at 0.8 bar abs. The output

signal will typically be 5-7.5 mA in atmospheric pressure, depending on the transducer range and

the actual atmospheric pressure. Maximum output signal 20 mA, will be at the transducers

absolute range.

Recalibrating Gauge Transmitter using Test Cup type G022S100

When recalibrating the MAS2600 Gauge Transmitter a pressure calibrator with a range of

-1 to 3.5 bar should be used. It should have an accuracy of 0.05% FS or better, as well as a 4½

digit milliamp meter.

1. Set the calibrator to pressure mode.

2. Connect the pressure calibrator to the transducer via MAS2600 Test Cup, type G022S100.

3. Check that the range select switch on the amplifier is correctly set.

4. In conditions of no pressure (atmospheric pressure) the output signal should be adjusted to

4.00 mA on the zero potentiometer.

5. Increase the pressure to maximum and adjust the output signal to 20.00 mA on the span

potentiometer.

6. Remove the pressure and check the zero point

7. Check the linearity at 0-25-50-75 and 100% of the measuring range.

8. If necessary, repeat the steps 4 to 7.

Page 22 of 28

Page 23

Installation & User Manual

( ) * .20 4 75

15

12

−

=

June 2013 Ed 19UK

Recalibrating Gauge Transmitter using Vacuum (for gauge transmitters only)

An internally mounted transducer can also be recalibrated by using vacuum.

1. Check that the tank is empty.

2. Check that the range select switch on the amplifier is correctly set.

3. Set the calibrator to vacuum mode.

4. Connect the hose from the calibrator to the breather tube from the transducer cable.

5. In conditions of no pressure the output signal should be adjusted to 4.00 mA on the zero

potentiometer.

6. Increase the vacuum equal to the maximum height of the fluid (water gauge) and adjust the

output signal to 20.00 mA on the span potentiometer.

7. Remove the vacuum and check the zero point.

8. Check the linearity at 0-25-50-75 and 100% of the measuring range.

9. If necessary, repeat the steps 5 to 8.

NOTE: If the calibrated maximum water gauge is greater than the maximum water gauge

that can be generated by the vacuum calibrator, the proportional mA output signal

equal to the maximum vacuum signal should be calculated.

EXAMPLE: If the full-scale of the transmitter is 15 mH2O, and the maximum capacity of the

vacuum calibrator is 7.5 mH2O, the mA output signal at 7.5 mH2O is calculated as:

15 mH2O = 20 mA and 0 mH2O = 4 mA

7.5 mH2O = 4 +

mA

The span potentiometer is adjusted so that the output signal shows 12 mA at 7.5 mH2O.

Page 23 of 28

Page 24

Installation & User Manual

4

16 800

800

+

−

−

*( . )

.

Atm press

Trd range

Trd range Atm press. .−

4

16 800

800

+

− +

−

*( . )

.

Atm press P

Trd range

Ed 19UK June 2013

Recalibrating the Absolute Transm itt er us ing Tes t Cup t ype G02 2S1 00

When recalibrating the MAS2600 Absolute Transmitter a pressure calibrator with a range of

-1 to 3.5 bar should be used. It should have an accuracy of 0.05% FS or better, as well as a 4½

digit milliampmeter. If a calibrator without reference transmitter is used, the atmospheric pressure

must be known to calculate the correction.

Atmospheric pressure and Transducer range to be entered into the formulas as mbar.

1. The calibrator with the output selector switch set to pressure mode is connected to the

MAS2600 transmitter via a Test Cup, type G022S100.

2. Check the transducer range.

The transducer range is indicated on the lid inside the amplifier box.

3. Calculate output signal in conditions of no pressure (atmospheric pressure), using below

formula. The output signal should be adjusted to the calculated value on the zero

potentiometer.

mA @ Atmospheric pressure =

4. Calculate the pressure for maximum output signal, using the following formula.

mbarg @ 20 mA =

Increase the pressure to calculated pressure and adjust the output signal to 20.00 mA on the

span potentiometer.

5. Remove the pressure and check the zero point.

6. Check the linearity at 0-25-50-75 and 100% of the measuring range.

Output signal at different pressures P can be calculated, using the following formula.

mA @ P mbarg =

7. If necessary, repeat the steps 3 to 6.

Page 24 of 28

Page 25

Installation & User Manual

4

16 1005 800

3500 800

+

−

−

*( )

3500 1005−

4

16 1005 800 1750

3500 800

+

− +

−

*( )

June 2013 Ed 19UK

EXAMPLE: If the range of the transducer is 3.5 bar abs and the atmospheric pressure is

1005 mbar.

Calculated output at atmospheric pressure:

mA @ Atm.press =

= 5.215 mA

Calculated applied pressure for maximum output:

mbarg @ 20 mA =

= 2495 mbarg

Calculated pressure at 50% of the transducer range:

mA @ P mbarg =

= 15.585 mA

Page 25 of 28

Page 26

Installation & User Manual

Ed 19UK June 2013

Maintenance and Trouble Shooting

Maintenance

Damcos recommends that the following to be checked annually:

1. Visual inspection of the cable, transducer and amplifier.

2. Compare signal with e.g. hand sounding, and if necessary perform a zero and full-scale

calibration.

Trouble Shooting

If the MAS2600 transmitter is not functioning in accordance with Emerson Process Management

Marine Solutions, Damcos instructions, check that:

1. the 24 VDC power supply has been correctly connected, and is between 14-33 VDC.

2. the 4 - 20 mA output signal is functioning (compared with e.g. hand sounding).

3. the transducer cable has been correctly fitted and the shield connected to the shield terminal

in the amplifier box.

4. the diaphragm has not been damaged.

If this does not succeed, fill in the test sheet on page 27 and submit this to our Service department

fax no.: +45 5578 7272.

When contacting our Service department please specify the serial numbers of both transducer and

amplifier.

The test sheet will be examined to see whether it can be established that the transmitter is broken

or not.

When returning a defective MAS2600 transmitter for repairs, please ensure that:

• The transducer diaphragm is protected against blows of any kind.

• Both the transducer and the amplifier are returned.

• A detailed description of the fault is enclosed.

Page 26 of 28

Page 27

Installation & User Manual

Name:

Ship name:

Yard:

NB No:

Transducer serial no.:

Amplifier serial no.:

Tank name:

Liquid in tank

HFO:

DO:

Ballast:

Other:

The tank is

Full:

Empty:

Other:

1

Measure voltage between terminal

5 and 6

Voltage should be in the range 14 to 33 V DC.

Check power supply.

2

Measure ripple voltage between

Voltage must not exceed 2 V AC. Check power

3

Measure sensor excitation voltage

between terminal 7 and 10

4

Measure sensor excitation voltage

5

Measure current in supply lead to

Current should be in the range 4 to 20 mA and the

6

Measure current in supply lead to

Current should be in the range 4 to 20 mA and the

7

Measure sensor resistance with

sensor cable unconnected

If the resistance measured is less that 1 M Ohm the

Terminal 7 to cable shield

M Ohm

Terminal 8 to cable shield

M Ohm

Terminal 9 to cable shield

M Ohm

Terminal 10 to cable shield

M Ohm

8

Measure sensor bridge resistance

If the resistance measured is less than 1 K Ohm or

Terminal 7 to Terminal 8

K Ohm

Terminal 7 to Terminal 9

K Ohm

Terminal 7 to Terminal 10

K Ohm

Terminal 8 to Terminal 9

K Ohm

Terminal 8 to Terminal 10

K Ohm

Terminal 9 to Terminal 10

K Ohm

9

Visual inspection of the transmitter:

10

Comments:

June 2013 Ed 19UK

MAS2600 Test sheet

ATT.: Emerson Process Management

Marine Solutions

Damcos A/S, Service Department

FAX.: +45 5578 7272

MAS2600:

Measurements:

V DC

terminal 5 and 6

between terminal 8 and 9

terminal 5 mA DC

terminal 6 mA DC

with sensor cable unconnected

V AC

V DC Voltage should be in t he range 3.0 to 6.2 V DC

mV DC Voltage should be in the range -15 to 100 mV DC

supply.

same value as measured in po int 6. If not the

amplifier may be defect.

same value as measured in po int 5. If not the

amplifier may be defect.

sensor is defect.

greater that 50 K Ohm the sensor is defect.

Is the cable damaged?

Are there sharp bends on the cable?

Are there moisture/liquids in the breather tube?

Is the diaphragm damaged?

Page 27 of 28

Page 28

Installation & User Manual

Ed 19UK June 2013

Emerson Process Management

Damcos A/S

Aaderupvej 41

DK-4700 Naestved

T +45 5578 7200

F +45 5578 7272

www.EmersonProcesss.com/mtm

Emerson Process Management

Rosemount Tank Radar AB

Box 13045

SE-40251 Göteborg

T +46 31 337 00 00

F +46 31 25 30 22

www.EmersonProcesss.com/mtm

Page 28 of 28

©2013 Emerson Process Management. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Damcos and the

Damcos logotype are registered trademarks of Damcos A/S. Rosemount and the Rosemount

logotype are registered trademarks of Rosemount Inc. TankRadar, LevelDatic and MAS2600 are

trademarks of Rosemount Tank Radar AB. Damcos A/S and Rosemount Tank Radar AB are

members of the Emerson Process Management family of companies. All other marks are the

property of their respective owners.

The contents of this publication are presented for information purposes only, and while effort

has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use

or applicability. All sales are governed by our terms and conditions, which are available on

request. We reserve the right to modify or improve the designs or specifications of our products

at any time without notice.

Loading...

Loading...