Supervisory Controller

Installation and Operation Manual

Site Supervisor Version 2.13

026-1800 Rev 18

Emerson Digital Solutions

Commercial and Residential Solutions

1065 Big Shanty Road NW, Suite 100

Kennesaw, GA 30144 USA

770-425-2724 • 1-800-829-2724

climate.emerson.com

Email:

ColdChain.TechnicalServices@Emerson.com

Solutions.CustomerService@Emerson.com

SUPERVISOR FIRMWARE VERSION

2.13F01

For more information on 2.13 features, see the Release Notes P/N 026-4064:

https://climate.emerson.com/documents/site-supervisor-release-notes-2-13f01-en-us-

1644516.pdf

FOR COMPLETE PRODUCT PART NUMBERS AND ORDERING,

CONTACT EMERSON SALES OR CUSTOMER SERVICE.

WARNING! The enclosure should

never be opened. Warranty void if

seal is tampered with or removed.

FCC COMPLIANCE NOTICE

This device complies with Part 15 of the FCC Rules Class A. Operation is subject to

the following two conditions: (1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

CE COMPLIANCE NOTICE

Class A Product Information for Supervisory Controllers:

The Emerson Supervisory Controllers are Class A products. In a domestic

environment this product may cause radio interference in which case the user may be

required to take adequate measures.

ULE211299

ELECTROSTATIC DISCHARGE CAUTION

This integrated circuit can be damaged by ESD. Failure to observe proper handling and

installation procedures can cause damage. ESD damage can range from subtle

performance degradation to complete device failure. Precision integrated circuits may

be more susceptible to damage because very small parametric changes may cause the

device to not meet its published specifications.

CONTENTS

1 BASIC SETUP INFORMATION ............................................................................................................................. 1-1

1.1 E

THERNET CONNECTION............................................................................................................................................ 1-1

1.2 D

IRECT CONNECT INSTRUCTIONS - CONNECT YOUR LAPTOP TO SUPERVISORY CONTROLLER’S ETHERNET PORT ETH1

7-1

1.3 L

OGGING INTO THE SUPERVISORY CONTROLLER ...................................................................................................... 1-2

1.4 S

ETUP WIZARD .......................................................................................................................................................... 1-3

1.4.1 Localization Screen ............................................................................................................................................ 1-3

1.4.2 System Values Screen ......................................................................................................................................... 1-4

1.4.3 Network Settings Screen ..................................................................................................................................... 1-4

1.5 S

ITE SUPERVISOR RS485 WIRING GUIDE EXAMPLES................................................................................................ 1-5

2 BASIC NAVIGATION............................................................................................................................................... 2-1

2.1 M

ENUS AND SUBMENUS ............................................................................................................................................ 2-1

2.2 O

VERVIEW.................................................................................................................................................................. 2-2

2.2.1 Conditional Visibility.......................................................................................................................................... 2-2

2.2.1.1 User View Details.................................................................................................................................................... 2-2

2.3 BASIC SCREEN ELEMENTS ......................................................................................................................................... 2-2

2.4 L

ANGUAGE SETTINGS ................................................................................................................................................ 2-2

2.5 L

OCATING AND WORKING WITH APPLICATIONS....................................................................................................... 2-3

2.6 A

PPLICATION TABS .................................................................................................................................................... 2-4

2.6.1 Performance Meter............................................................................................................................................. 2-4

2.6.2 Site Aggregation ................................................................................................................................................. 2-4

2.6.3 Control Inventory ............................................................................................................................................... 2-5

2.6.3.1 Adding Applications................................................................................................................................................ 2-5

2.7 ADFS ......................................................................................................................................................................... 2-6

2.8 C

REATING A BACKUP AND RESTORE ......................................................................................................................... 2-6

2.8.2 Restore................................................................................................................................................................ 2-7

2.9 U

SING THE HELP MENU ............................................................................................................................................. 2-7

2.10 I

CONS OR BUTTONS APPEARING ON THE HOME SCREEN ........................................................................................ 2-8

3 ALARM CONFIGURATION .................................................................................................................................... 3-1

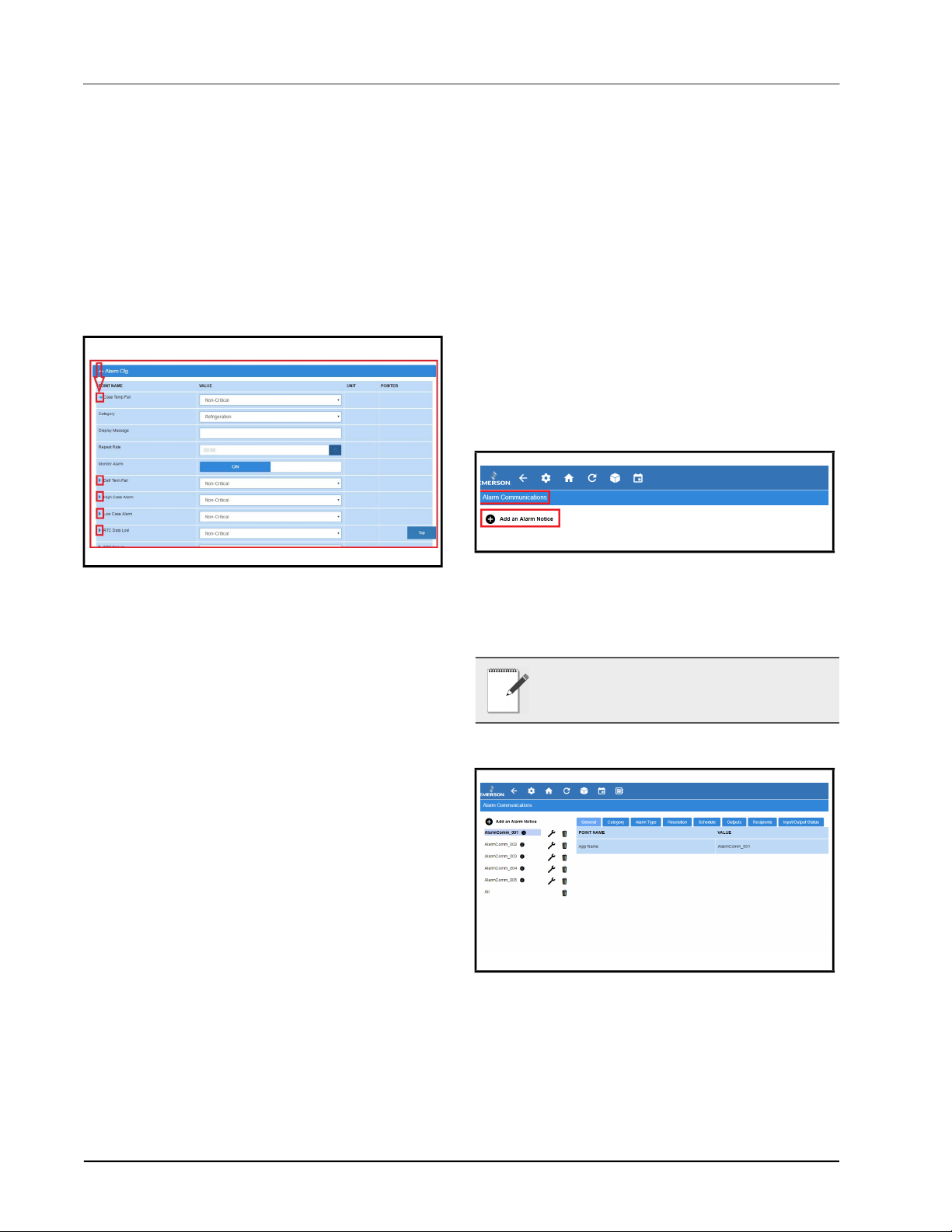

3.1 A

LARM CONFIGURATION .......................................................................................................................................... 3-2

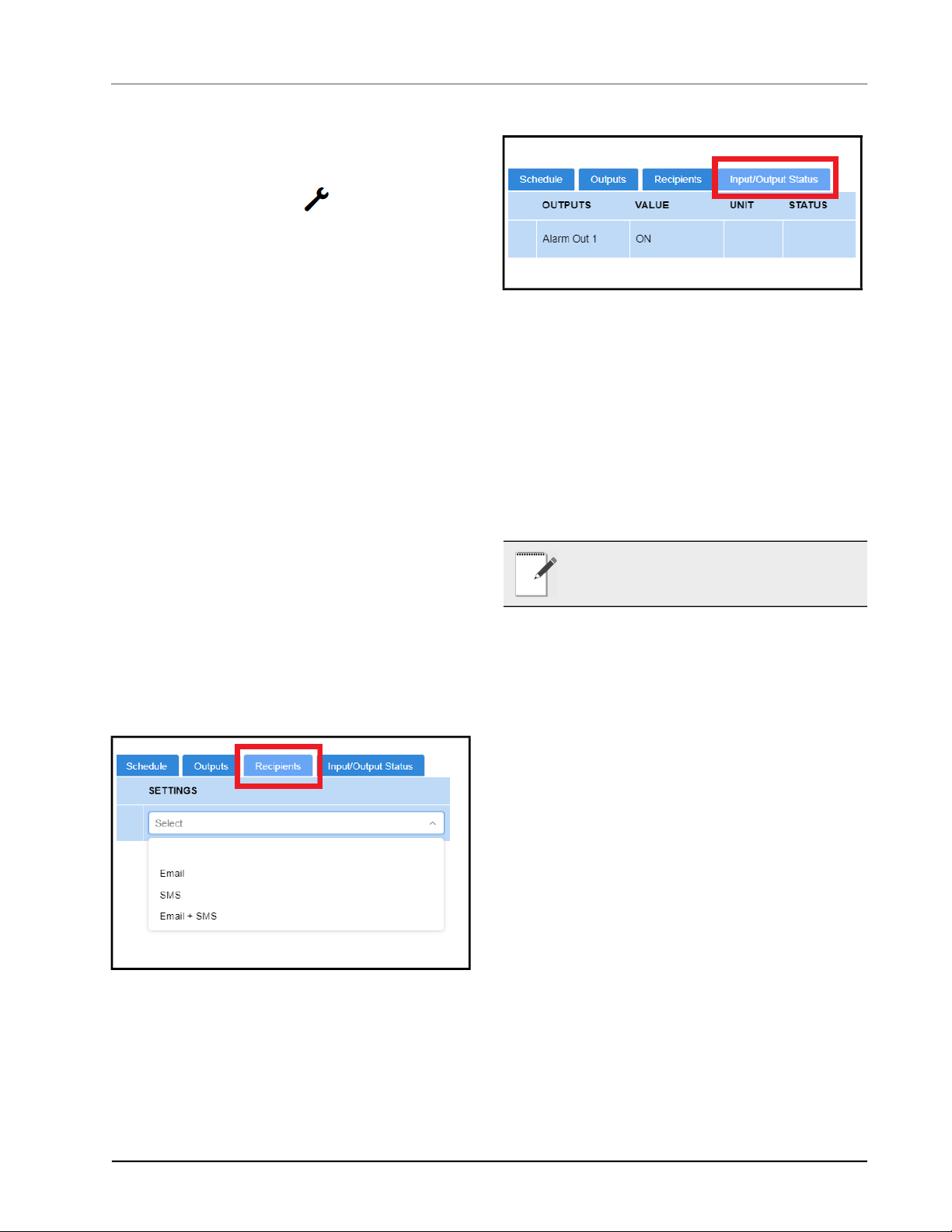

3.2 A

LARM COMMUNICATIONS SETTING ........................................................................................................................ 3-2

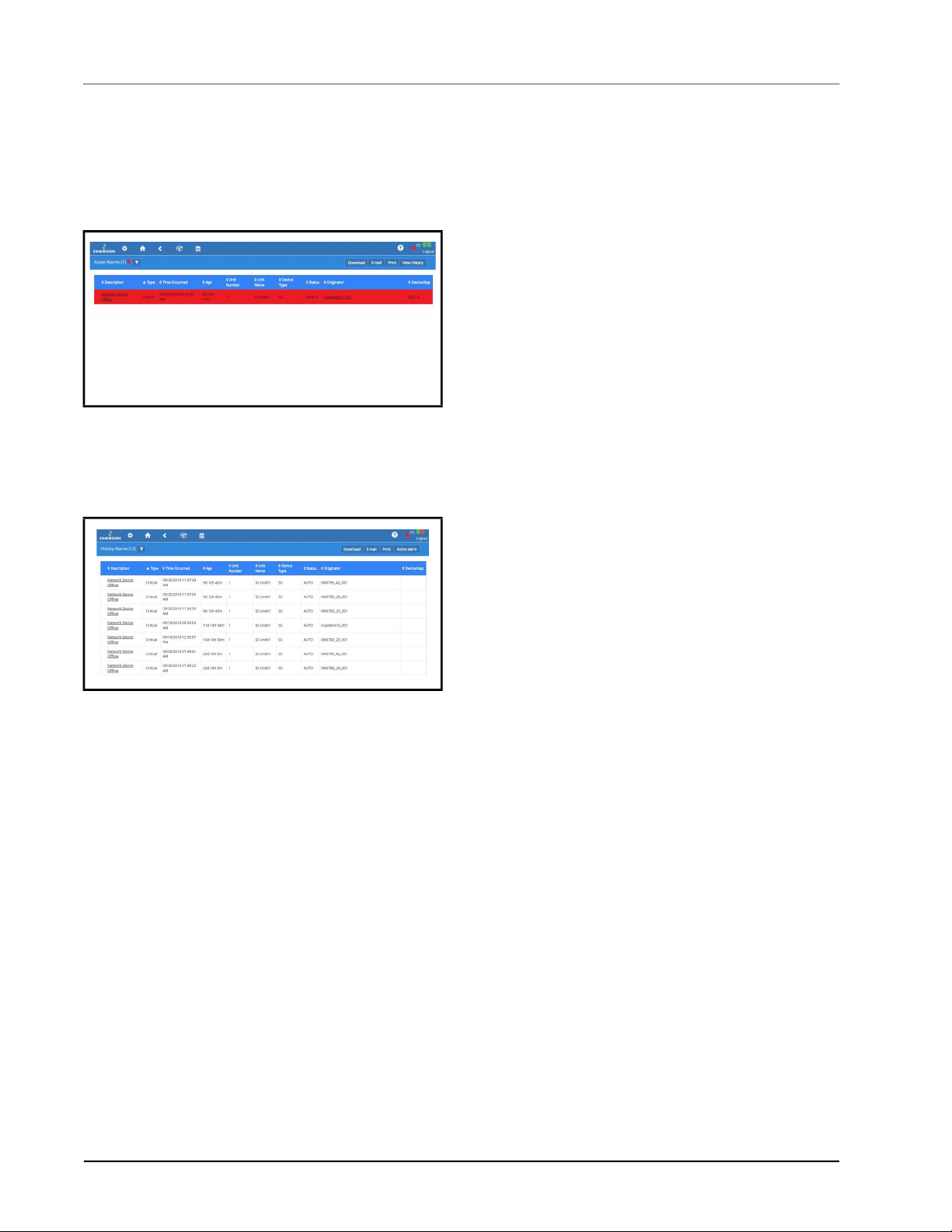

3.3 A

LARM LOG AND VIEW HISTORY.............................................................................................................................. 3-4

3.4 TEMPERATURE DIFFERENTIAL ALARMS ................................................................................................................... 3-5

3.5 L

IGHTING CYCLE ALARMS ....................................................................................................................................... 3-7

3.6 SMART ALARMING ..................................................................................................................................................... 3-7

3.6.1 Accessing Smart Alarms ..................................................................................................................................... 3-7

3.7 P

EER ALARMING ........................................................................................................................................................ 3-9

3.8 G

ENERIC ALARMS...................................................................................................................................................... 3-9

3.9 A

LARM TYPES............................................................................................................................................................ 3-9

4 HARDWARE OVERVIEW ...................................................................................................................................... 4-1

4.1 O

RDERING INFORMATION........................................................................................................................................... 4-1

4.2 T

ECHNICAL SPECIFICATIONS...................................................................................................................................... 4-1

4.3 H

OUSING DIMENSIONS AND MOUNTING.................................................................................................................... 4-2

4.4 W

IRING DIAGRAMS .................................................................................................................................................... 4-3

4.5 D

EVICE WIRING ......................................................................................................................................................... 4-5

4.6 S

ITE SUPERVISOR POWER, SERIAL, AND IO POSITIONS............................................................................................. 4-5

4.6.1 Termination Jumpers.......................................................................................................................................... 4-5

4.6.2 Using a DC Volt Meter to Check Termination and Bias.................................................................................... 4-6

4.6.3 Removing The SD Card ...................................................................................................................................... 4-6

Supervisory Controller 2.13 Installation and Operation Manual Table of Contents • v

4.6.4 LEDs ................................................................................................................................................................... 4-6

4.6.5 Dip Switch Termination and Biasing.................................................................................................................. 4-7

4.7 W

IRING TERMINAL DETAIL ....................................................................................................................................... 4-8

4.8 D

IGITAL INPUTS ........................................................................................................................................................ 4-8

4.9 R

ELAY OUTPUTS ....................................................................................................................................................... 4-8

4.10 A

4.11 S

4.12 F

NALOG INPUTS ...................................................................................................................................................... 4-9

ERIAL CONNECTIONS ........................................................................................................................................... 4-10

IRMWARE UPGRADE ............................................................................................................................................. 4-10

4.12.1 Firmware Update - Remote Access ................................................................................................................ 4-11

4.12.2 Firmware Update - USB Drive....................................................................................................................... 4-11

4.13 U

PLOADING SETPOINT FILES TO SUPERVISORY CONTROLLER .............................................................................. 4-13

5 RS485 I/O NETWORK BOARDS AND PERIPHERALS ..................................................................................... 5-1

5.1 T

HE I/O NETWORK..................................................................................................................................................... 5-1

5.2 I/O B

OARD NAMES AND TERMINOLOGY.................................................................................................................... 5-1

5.2.1 MultiFlex Boards................................................................................................................................................ 5-1

5.2.1.1 MultiFlex 16 Input Board........................................................................................................................................ 5-1

5.2.1.2 MultiFlex Combination Input/Output Boards.........................................................................................................

5-2

5.2.2 MultiFlex CUB Support...................................................................................................................................... 5-3

5.2.3 MultiFlex RTU Support ...................................................................................................................................... 5-3

5.2.3.1 I/O Network and MultiFlex RTU Setup on Serial Port........................................................................................... 5-3

5.2.3.2 Creating an Instance of RTU Application...............................................................................................................

5.2.3.3 Deleting/Checking Status of RTU Board................................................................................................................

5.2.3.4 Zone Management...................................................................................................................................................

5.2.3.5 Scheduling...............................................................................................................................................................

5.2.3.6 Alarming..................................................................................................................................................................

5.2.3.7 Real Time Clock Updates .......................................................................................................................................

5.2.3.8 Hand-Held Terminal Support..................................................................................................................................

5-4

5-4

5-4

5-4

5-4

5-4

5-4

5.2.4 MultiFlex RCB Support ...................................................................................................................................... 5-4

5.2.4.1 I/O Network and MultiFlex RCB Setup on Serial Port........................................................................................... 5-4

5.2.4.2 Creating an Instance of RCB Application...............................................................................................................

5.2.4.3 Deleting/Checking Status of RCB Board................................................................................................................

5.2.4.4 Zone Management...................................................................................................................................................

5.2.4.5 Scheduling...............................................................................................................................................................

5.2.4.6 Alarming..................................................................................................................................................................

5.2.4.7 Real Time Clock Updates .......................................................................................................................................

5.2.4.8 Hand-Held Terminal Support..................................................................................................................................

5-5

5-5

5-5

5-6

5-6

5-6

5-6

5.2.5 MultiFlex RTU.................................................................................................................................................... 5-6

5.2.6 MultiFlex Rooftop Control Board (RCB) ........................................................................................................... 5-6

5.2.7 The MultiFlex ESR Board................................................................................................................................... 5-7

5.2.8 Hand-held Terminal (P/N 814-3110) ................................................................................................................. 5-7

5.2.9 The 8RO and 8ROSMT Relay Boards ................................................................................................................ 5-8

5.2.10 4AO Analog Output Board ............................................................................................................................... 5-9

5.2.11 8DO Digital Output Board ............................................................................................................................... 5-9

5.

2.12 XM Series of Case Controllers ......................................................................................................................... 5-9

5.2.12.1 XM670K v3.4 ....................................................................................................................................................... 5-9

5.2.12.2 XM679K v3.4 and v4.2.........................................................................................................................................

5.2.12.3 XM678D v2.5 and v2.8.......................................................................................................................................

5-9

5-10

5.2.13 XEV22 v1.1 and v1.5 ...................................................................................................................................... 5-10

5.2.14 Wireless I/O .................................................................................................................................................... 5-10

5.2.15 Supervisor Displays........................................................................................................................................ 5-11

5.2.16 Emerson Programmable Touchscreen Thermostat ........................................................................................ 5-11

5.2.17 Control Techniques Drive (VSD) ................................................................................................................... 5-12

5.2.18 DAC ................................................................................................................................................................ 5-12

5.2.19 Copeland Discus with

vi • Table of Contents 026-1800 Rev 18

CoreSense Diagnostics (ISD)...................................................................................................................................... 5-13

5.2.20 Copeland Discus with

CoreSense Protection................................................................................................................................................. 5-13

5.2.21 Copeland Scroll – K5

Refrigeration Compressor........................................................................................................................................... 5-13

6 WIRING EXAMPLES ........................................................................................................................................... 6-1

7 SITE SUPERVISOR DISPLAYS ............................................................................................................................ 7-1

7.1 10.1-I

NCH TOUCHSCREEN DISPLAY .......................................................................................................................... 7-1

7.1.1 Display Connections .......................................................................................................................................... 7-1

7.1.2 Specifications ..................................................................................................................................................... 7-2

7.1.3 Mounting Dimensions ........................................................................................................................................ 7-2

7.1.4 Direct Connect to Site Supervisor...................................................................................................................... 7-3

7.2 15.6-I

NCH TOUCHSCREEN DISPLAY .......................................................................................................................... 7-4

7.2.1 Display Connections .......................................................................................................................................... 7-4

7.2.2 Specifications ..................................................................................................................................................... 7-4

7.2.3 Mounting Dimensions ........................................................................................................................................ 7-5

7.2.4 Direct Connect to Site Supervisor...................................................................................................................... 7-5

7.3 21.5-I

NCH TOUCHSCREEN DISPLAY .......................................................................................................................... 7-6

7.3.1 Display Connections .......................................................................................................................................... 7-6

7.3.2 Specifications ..................................................................................................................................................... 7-7

7.3.3 Mounting Dimensions ........................................................................................................................................ 7-7

7.3.4 Direct Connect to Site Supervisor...................................................................................................................... 7-8

7.4 S

ITE SUPERVISOR TOUCHSCREEN DISPLAY VERSION COMPATIBILITY..................................................................... 7-9

8 SOFTWARE OVERVIEW ...................................................................................................................................... 8-1

8.1 E

MERSON SUPERVISORY CONTROL APPLICATION AND SYSTEM CAPACITY MATRIX............................................... 8-1

8.2 E

MERSON SITE AGGREGATOR FEATURES ................................................................................................................. 8-6

8.3 E

MERSON SYSTEM SUPERVISOR FEATURES .............................................................................................................. 8-7

8.4 E

MERSON SUPERVISORY CONTROL MODEL SELECTION GUIDE ............................................................................... 8-8

8.5 E

MERSON SUPERVISORY CONTROL TO E2 CROSS-REFERENCE GUIDE ................................................................... 8-10

8.6 E

MERSON SUPERVISORY CONTROL NEW FEATURES .............................................................................................. 8-11

8.7 S

UCTION GROUPS .................................................................................................................................................... 8-12

8.7.1 Introduction...................................................................................................................................................... 8-12

8.7.2 The (Standard) Suction Group Application ..................................................................................................... 8-12

8.7.2.1 Overview of PID Control Strategy ........................................................................................................................ 8-12

8.7.2.2 Variable-Speed Compressors................................................................................................................................. 8-12

8.7.2.3 Floating Setpoint Control....................................................................................................................................... 8-12

8.7.3 The Enhanced Suction Group Application....................................................................................................... 8-12

8.7.3.1 Learning Mode....................................................................................................................................................... 8-13

8.7.3.2 Circuit Load Analysis ............................................................................................................................................ 8-13

8.7.3.3 The Control/Cycles Parameter............................................................................................................................... 8-13

8.7.3.4 Variable-Speed, Digital Scroll, and Digital Discus Compressor Support ............................................................. 8-13

8.7.3.5 Floating Suction Control........................................................................................................................................ 8-13

8.7.4 Hardware Overview......................................................................................................................................... 8-13

8.8 A

NALOG SENSOR CONTROL .................................................................................................................................... 8-14

8.8.1 Control Strategy............................................................................................................................................... 8-14

8.8.2 Control Alarming ............................................................................................................................................. 8-15

8.8.3 Alarm Output When On/Off Parameters.......................................................................................................... 8-15

8.8.4 Control Bypass................................................................................................................................................. 8-15

8.9 D

IGITAL SENSOR CONTROL..................................................................................................................................... 8-15

8.9.1 Control Strategy............................................................................................................................................... 8-16

8.9.2 Command Alarming ......................................................................................................................................... 8-16

8.9.3 Alarm Output When On/Off Parameters.......................................................................................................... 8-16

Supervisory Controller 2.13 Installation and Operation Manual Table of Contents • vii

8.9.4 Control Bypass ................................................................................................................................................. 8-16

8.10 L

IGHTING CONTROL .............................................................................................................................................. 8-17

8.10.1 Lighting Control Logic................................................................................................................................... 8-17

8.10.2 Light Level Sensor Verification...................................................................................................................... 8-17

8.10.3 Solar Calculation ........................................................................................................................................... 8-17

8.10.4 Digital Lighting Output.................................................................................................................................. 8-18

8.10.5 Light Proofing ................................................................................................................................................ 8-18

8.10.6 Minimum On/Off Times.................................................................................................................................. 8-18

8.10.7 Dimming Control (Analog Output) ................................................................................................................ 8-18

8.10.8 External Schedule........................................................................................................................................... 8-19

8.10.9 Lighting Bypass Inputs................................................................................................................................... 8-19

8.10.10 Demand Shed Behavior................................................................................................................................ 8-20

8.11 G

LOBAL DATA....................................................................................................................................................... 8-20

8.11.1 Location From................................................................................................................................................ 8-20

8.11.2 Sundown ......................................................................................................................................................... 8-20

8.12 HVAC C

ONTROL ................................................................................................................................................... 8-20

8.12.1 Active Setpoint Determination ....................................................................................................................... 8-20

8.12.2 Setpoint Reset ................................................................................................................................................. 8-21

8.12.3 Demand Shed.................................................................................................................................................. 8-21

8.12.4 Heating and Cooling Control......................................................................................................................... 8-21

8.12.5 Control Logic ................................................................................................................................................. 8-21

8.12.6 Heat/Cool Lockout Based on Outside Air Temperature ................................................................................ 8-22

8.12.7 System Shutdown............................................................................................................................................ 8-22

8.12.8 Fan Control.................................................................................................................................................... 8-22

8.12.9 Fan Mode ....................................................................................................................................................... 8-22

8.12.10 Plenum Warmup/Purge................................................................................................................................ 8-22

8.12.11 Fan Proof Failure ........................................................................................................................................ 8-22

8.12.12 System Shutdown.......................................................................................................................................... 8-22

8.12.13 Economization (Damper) Control................................................................................................................ 8-23

8.12.14 Determine the Analog Damper Position ...................................................................................................... 8-23

8.12.15 Determine the Digital Damper Position ...................................................................................................... 8-24

8.12.16 Heat Pump Control ...................................................................................................................................... 8-24

8.12.17 Reversing Valve............................................................................................................................................ 8-24

8.12.18 Compressor Output ...................................................................................................................................... 8-24

8.12.19 Curtailment................................................................................................................................................... 8-24

8.13 T

IME SCHEDULE APPLICATION.............................................................................................................................. 8-24

8.13.1 Time Schedule Method ................................................................................................................................... 8-24

8.13.2 Standard Schedule.......................................................................................................................................... 8-25

8.13.3 Event Names................................................................................................................................................... 8-25

8.13.4 Maintenance Schedule.................................................................................................................................... 8-25

8.13.5 Maintenance Overrides.................................................................................................................................. 8-25

8.13.6 Output Calculation......................................................................................................................................... 8-27

8.13.7 Scheduling Logic............................................................................................................................................ 8-27

8.13.8 Control Override............................................................................................................................................ 8-28

8.13.9 Control Bypass ............................................................................................................................................... 8-28

8.13.10 Control Override.......................................................................................................................................... 8-28

8.13.11 Special Conditions........................................................................................................................................ 8-28

8.13.12 Priority of Services....................................................................................................................................... 8-28

8.13.13 Control Alarming ......................................................................................................................................... 8-29

8.13.14 Schedule Category........................................................................................................................................ 8-29

8.14 D

EMAND CONTROL................................................................................................................................................ 8-29

8.14.1 KWH Calculation ........................................................................................................................................... 8-29

8.14.2 Demand Calculation ...................................................................................................................................... 8-29

8.14.3 Shed Outputs .................................................................................................................................................. 8-29

viii • Table of Contents 026-1800 Rev 18

8.14.4 Application Alarms ........................................................................................................................................ 8-30

8.14.5 KW Load Specification................................................................................................................................... 8-30

8.14.6 Performance Requirements............................................................................................................................ 8-30

8.15 U

TILITY MONITORING ........................................................................................................................................... 8-31

8.15.1 Utility Usage Calculation .............................................................................................................................. 8-31

8.15.1.1 Utility Type.......................................................................................................................................................... 8-31

8.15.1.2 Analog Input ........................................................................................................................................................ 8-31

8.15.1.3 Digital Pulse Input ............................................................................................................................................... 8-31

8.15.1.4 Current/Voltage Inputs - Single/Three Phase ...................................................................................................... 8-31

8.15.2 Consumption Totalizing ................................................................................................................................. 8-31

8.15.2.1 Totalizer Output................................................................................................................................................... 8-31

8.15.2.2 Fixed Period Totalizers........................................................................................................................................ 8-31

8.15.3 Demand Trip .................................................................................................................................................. 8-31

8.15.3.1 Shed Output ......................................................................................................................................................... 8-31

8.15.3.2 Average Rate of Consumption Output................................................................................................................. 8-32

8.15.3.3 Demand Alarm..................................................................................................................................................... 8-32

8.15.3.4 Time In Shed Output............................................................................................................................................ 8-32

8.15.4 Application Specific Logs............................................................................................................................... 8-32

8.15.5 Units of Measurement .................................................................................................................................... 8-32

8.16 P

OWER MONITORING............................................................................................................................................. 8-32

8.16.1 Overview ........................................................................................................................................................ 8-32

8.16.2 Logging .......................................................................................................................................................... 8-33

8.16.2.1 Power Monitoring Input....................................................................................................................................... 8-33

8.17 ONBOARD I/O ....................................................................................................................................................... 8-34

8.17.1 Licensing ........................................................................................................................................................ 8-34

8.17.2 Adding and Deleting Onboard I/O Application............................................................................................. 8-34

8.17.3 Status and Detail Screen ................................................................................................................................ 8-35

8.17.4 Alarming......................................................................................................................................................... 8-36

8.18 XR75CX 5.6.......................................................................................................................................................... 8-36

8.19 XR35CX 5.6

AND 2.6............................................................................................................................................ 8-36

8.19.1 Overview ........................................................................................................................................................ 8-37

8.19.2 Command-Alarm Matrix ............................................................................................................................... 8-37

8.20 XC645CX 2.5........................................................................................................................................................ 8-39

8.20.1 Application Advisories ................................................................................................................................... 8-40

8.20.2 Command-Alarm Matrix ............................................................................................................................... 8-40

8.21 XR75CX C

ASE DISPLAY....................................................................................................................................... 8-42

8.21.1 Overview ........................................................................................................................................................ 8-42

8.21.2 Application Advisories ................................................................................................................................... 8-42

8.21.3 Inputs.............................................................................................................................................................. 8-43

8.22 XR75CX 2.6.......................................................................................................................................................... 8-44

8.22.1 Application Advisories .................................................................................................................................. 8-44

8.22.2 Command ....................................................................................................................................................... 8-45

8.23 E

MERSON T-STAT.................................................................................................................................................. 8-45

8.23.1 General Control ............................................................................................................................................. 8-45

8.23.2 Alarms ............................................................................................................................................................ 8-45

8.23.3 Device Commissioning................................................................................................................................... 8-45

8.24 T

8.25 E

8.26 D

8.27 F

8.28 RLDS (R

OUCH T-STAT ...................................................................................................................................................... 8-46

NERGY METER..................................................................................................................................................... 8-46

ATA LOGGING AND GRAPH................................................................................................................................. 8-46

LEXIBLE COMBINER............................................................................................................................................. 8-46

EFRIGERANT LEAK DETECTOR SYSTEM)................................................................................................ 8-47

8.28.1 Communication .............................................................................................................................................. 8-47

8.28.2 Supported Gases ............................................................................................................................................ 8-47

8.29 ECB VAV ............................................................................................................................................................. 8-48

8.30 MRLDS (M

ODULAR REFRIGERANT LEAK DETECTOR SENSORS)......................................................................... 8-48

Supervisory Controller 2.13 Installation and Operation Manual Table of Contents • ix

8.31 CONTROL LINK ANTI-CONDENSATE CONTROLLER (CL ACC)............................................................................. 8-49

8.31.1 Alarm Handling Logic.................................................................................................................................... 8-49

8.31.2 Alarms Configuration..................................................................................................................................... 8-49

8.32 HVAC Z

ONE.......................................................................................................................................................... 8-49

8.32.1 How It Works.................................................................................................................................................. 8-49

8.32.2 Compatible Applications to be Connected to HVAC Zones........................................................................... 8-49

8.32.3 Temperature Control...................................................................................................................................... 8-50

8.32.4 HVAC Zone Temperature............................................................................................................................... 8-50

8.32.5 Economizer Control ....................................................................................................................................... 8-50

8.32.6 Economization Enable.................................................................................................................................... 8-50

8.32.7 The Effect of Enabling Economization........................................................................................................... 8-51

8.32.8 Dehumidification Control .............................................................................................................................. 8-51

8.32.9 HVAC Zone Humidity Input ........................................................................................................................... 8-51

8.32.10 Enabling Dehumidification Effect................................................................................................................ 8-51

8.32.10.1 MultiFlex RTUs and RCBs................................................................................................................................ 8-51

8.32.11 Optimum Start/Stop (OSS) ........................................................................................................................... 8-51

8.32.12 Intelligent Pre-Starts and Pre-Stops ............................................................................................................ 8-52

8.32.13 Setpoint Reset ............................................................................................................................................... 8-52

8.33 AHU ...................................................................................................................................................................... 8-53

8.34 A

8.35 A

8.36 C

NALOG AND DIGITAL COMBINER ........................................................................................................................ 8-53

NTI-SWEAT CONTROL ......................................................................................................................................... 8-54

ONDENSER CONTROL........................................................................................................................................... 8-54

8.36.1.1 Air Cooled Strategy ............................................................................................................................................. 8-54

8.36.1.2 Temperature Differential

Strategy ................................................................................................................................................................................ 8-54

8.36.2 Evaporative Condensers ................................................................................................................................ 8-55

8.36.3 Fan Control.................................................................................................................................................... 8-55

8.36.4 Condenser Split Mode .................................................................................................................................... 8-55

8.36.5 Fast Recovery................................................................................................................................................. 8-55

8.36.6 Hardware Overview ....................................................................................................................................... 8-55

8.37 S

8.38 C

TANDARD CIRCUITS ............................................................................................................................................. 8-56

ASE CONTROL CIRCUITS ..................................................................................................................................... 8-57

8.38.1 Overview......................................................................................................................................................... 8-57

8.38.2 Case Circuit Control Software Overview....................................................................................................... 8-57

8.38.2.1 Valve Control....................................................................................................................................................... 8-57

8.38.3 Refrigeration Control..................................................................................................................................... 8-58

8.38.3.1 EEVs (Liquid Pulse and Liquid Stepper)............................................................................................................. 8-58

8.38.3.2 EEPRs (Suction Stepper) ..................................................................................................................................... 8-58

8.38.4 Defrost Control ............................................................................................................................................. 8-59

8.38.4.1 Defrost States....................................................................................................................................................... 8-59

8.38.4.2 Defrost Types....................................................................................................................................................... 8-59

8.38.4.3 Defrost Termination............................................................................................................................................. 8-59

8.38.4.4 Demand Defrost................................................................................................................................................... 8-60

8.38.4.5 Emergency Defrost .............................................................................................................................................. 8-60

8.38.4.6 Defrost Schedule Summaries............................................................................................................................... 8-60

8.39 IRRIGATION CONTROL ........................................................................................................................................... 8-60

8.40 TD C

ONTROL ......................................................................................................................................................... 8-61

8.40.1 Overview......................................................................................................................................................... 8-61

8.40.2 Temperature Differential (TD) Strategy ........................................................................................................ 8-61

8.40.3 TD Control Fail-Safes.................................................................................................................................... 8-61

8.40.4 Configuration ................................................................................................................................................. 8-61

8.

40.5 Setpoints ......................................................................................................................................................... 8-62

8.40.6 Inputs.............................................................................................................................................................. 8-62

8.40.7 Alarms ............................................................................................................................................................ 8-62

8.41 L

OOP/SEQUENCE CONTROL ................................................................................................................................... 8-62

x • Table of Contents 026-1800 Rev 18

8.42 MODULAR CHILLER CONTROL .............................................................................................................................. 8-63

8.42.1 Learning Mode............................................................................................................................................... 8-63

8.42.2 The Control/Cycles Parameter ...................................................................................................................... 8-64

8.42.3 Compressor Control....................................................................................................................................... 8-64

8.42.3.1 Digital Scroll Compressor.................................................................................................................................... 8-64

8.42.3.2 Variable Frequency Drive Compressor ............................................................................................................... 8-65

8.42.3.3 Unequal Capacity Compressors........................................................................................................................... 8-65

8.42.4 Bypass Valve Control..................................................................................................................................... 8-65

8.43 XM C

IRCUIT CONTROL ......................................................................................................................................... 8-65

8.43.1 Associations ................................................................................................................................................... 8-65

8.43.1.1 Case Circuit Association Support ........................................................................................................................ 8-65

8.43.1.2 Dual Association Not Supported ......................................................................................................................... 8-66

8.43.1.3 Synchronized Parameters..................................................................................................................................... 8-66

8.43.1.4 Visibility of Associated Parameters..................................................................................................................... 8-66

8.43.2 Suction Group Interaction ............................................................................................................................. 8-66

8.43.2.1 Standard Suction .................................................................................................................................................. 8-66

8.43.2.2 Enhanced Suction................................................................................................................................................. 8-66

8.43.3 Supervisory Control Functions ...................................................................................................................... 8-66

8.43.3.1 Dewpoint Value ................................................................................................................................................... 8-66

8.43.3.2 Lighting Control................................................................................................................................................... 8-66

8.43.3.3 Active Setpoint Output ........................................................................................................................................ 8-66

8.43.3.4 Defrost Scheduling............................................................................................................................................... 8-67

8.43.3.5 Case States ........................................................................................................................................................... 8-67

8.43.3.6 Case Type............................................................................................................................................................. 8-67

8.43.4 Application Advisory...................................................................................................................................... 8-67

8.43.4.1 Synchronized Alarm Parameters.......................................................................................................................... 8-67

8.43.5 Application Commands .................................................................................................................................. 8-68

8.43.5.1 Start Defrost......................................................................................................................................................... 8-68

8.43.5.2 Stop Defrost ......................................................................................................................................................... 8-68

8.43.6 Product Probe Support .................................................................................................................................. 8-68

8.44 XR75CX C

8.45 B

OILER................................................................................................................................................................... 8-68

8.46 XJ C

8.47 CAN B

ASE DISPLAY....................................................................................................................................... 8-68

ONDENSING UNIT........................................................................................................................................... 8-68

US - IPX (EXPANSION MODULE) ............................................................................................................... 8-69

8.47.1 IPX 6 Relay .................................................................................................................................................... 8-71

8.47.2 IPX 15 Relay .................................................................................................................................................. 8-71

8.47.3 IPX 25 Relay .................................................................................................................................................. 8-71

8.48 S

UPPORTED REFRIGERANTS................................................................................................................................... 8-72

9 FLOOR PLANS ......................................................................................................................................................... 9-1

APPENDIX A: ALARM ADVISORIES.................................................................................................................... A-1

APPENDIX B: TROUBLESHOOTING.................................................................................................................... B-1

APPENDIX C: SETTING UP EMAIL AND TEXT ALERTS IN YOUR SUPERVISORY CONTROLLER . C-1

APPENDIX D: UTILITY MONITORING .............................................................................................................. D-1

APPENDIX E: PEER TO PEER NETWORK SETUP FOR MIXED SITES (2 SUPERVISORS AND 1 E2) .. E-1

Supervisory Controller 2.13 Installation and Operation Manual Table of Contents • xi

1 Basic Setup Information

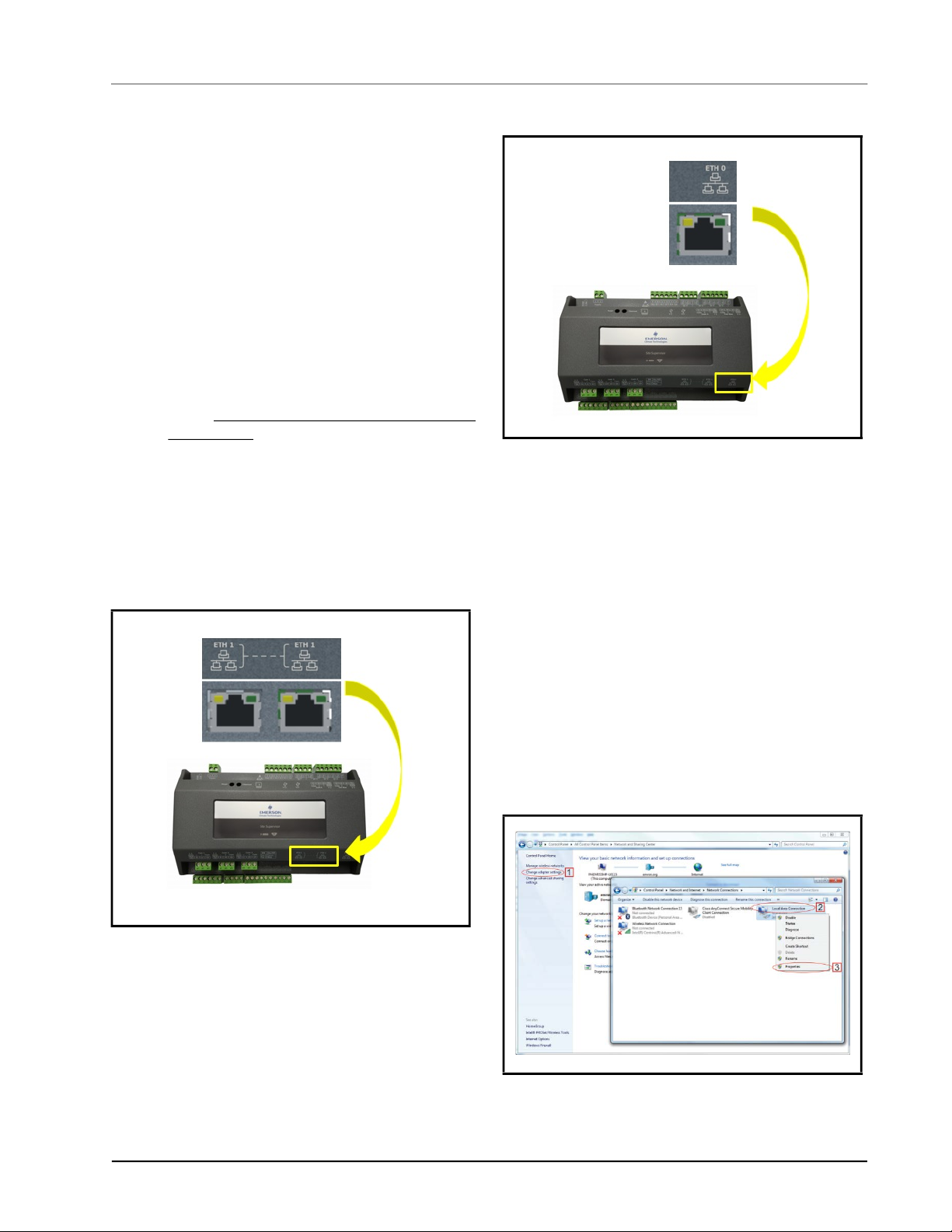

1.1 Ethernet Connection

1. ETH1 is designed to be used for directly

connecting to laptop, PC, or optional touchscreen

with a CAT5 network cable.

2. The default IP for ETH1 is 192.168.1.250.

3. The optional touchscreen default IP is

192.168.1.200 and will connect automatically to

the Supervisory Controller when plugged into

ETH1. It is recommended that you do not change

these defaults.

4. ETH0 should be reserved for the secure network

connections: store or corporate networks. Ask

your network administrator for the correct

network IP address for ETH0.

5. ETH0 and ETH1 are physically separated for

added security. Directly connecting to ETH1 will

not access the secure network connection on

ETH0.

Figure 1-2 - Supervisory Controller ETH0 Port

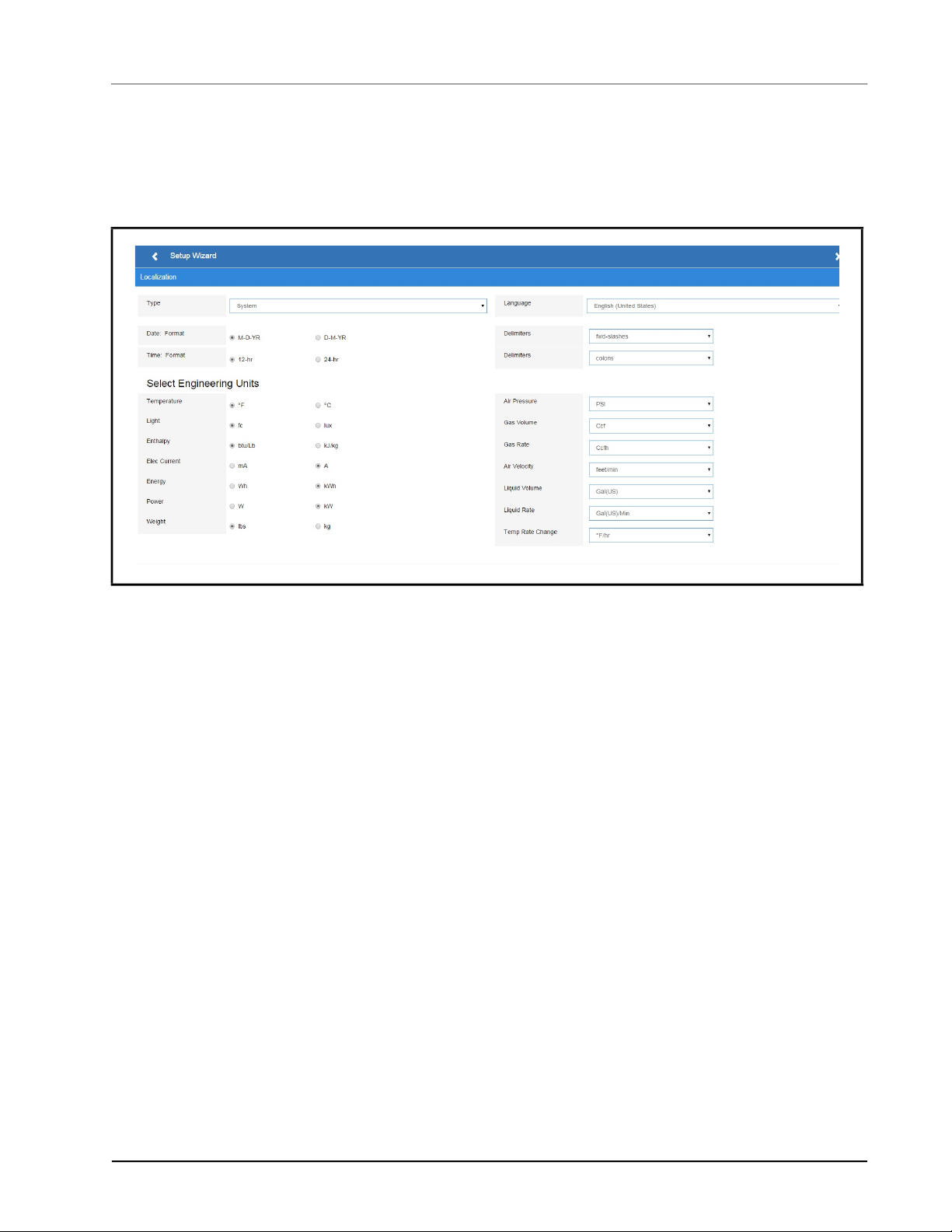

1.2 Direct Connect

Instructions - Connect

your laptop to

Supervisory

Figure 1-1

Controller’s Ethernet

Port ETH1

1. Under Control Panel - Network and Sharing

Center, select Change adapter settings.

2. Select the Local Area Connection port being

used.

3. Select Properties.

- Supervisory Controller ETH1 Ports

Figure 1-3 - Change Adapter Settings

Ethernet Connection Basic Setup Information • 1-1

4. Highlight the section Internet Protocol Version

4 (TCP/IPv4) and click Properties:

1.3 Logging Into the Supervisory Controller

1. Launch a preferred Web browser: IE 9 and above,

Firefox 13 and above, Chrome (all versions), and

Safari (all versions) are the supported browsers.

2. Enter the IP Address of the device.

3. Enter the Username/Password (default user/pass)

and click Login. Update the password to the

minimum complexity requirements and click

Save. Note that after the first login using the

default user/pass, the password must be updated.

NOTE: When directly connecting your laptop

or PC to ETH1, enter the default IP into the

browser address bar: ETH1 Default IP

Address is 192.168.1.250.

Figure 1-4

- Highlight Internet Protocol Version 4 (TCP/IPv4)

5. Click Use the following IP address: and enter

the IP address 192.168.1.251 and the Subnet

mask 255.255.255.0 of the PC being used on the

Local Area Network or direct connection and

click OK:

Figure 1-6

To ensure the highest level of protection and security,

Emerson requires users to create passwords for logging

into Supervisor controllers that meet certain criteria and

National Institute of Standards and Technology (NIST)

recommendations.

• Passwords must contain 8 to 24 characters.

• Passwords cannot be composed of all the same

• Passwords cannot contain a commonly-used phrase.

- Login Screen at Controller Startup

characters (for example, “aaaaaaaa” or

“&&&&&&&&”).

Figure 1-5 - IP Address and Subnet Mask

1-2 • Supervisory Controller 2.13 Installation and Operation Manual 026-1800 Rev 18

1.4 Setup Wizard

If your unit has been received directly from the Emerson factory, the Setup Wizard will open and take you through the

following setup screens:

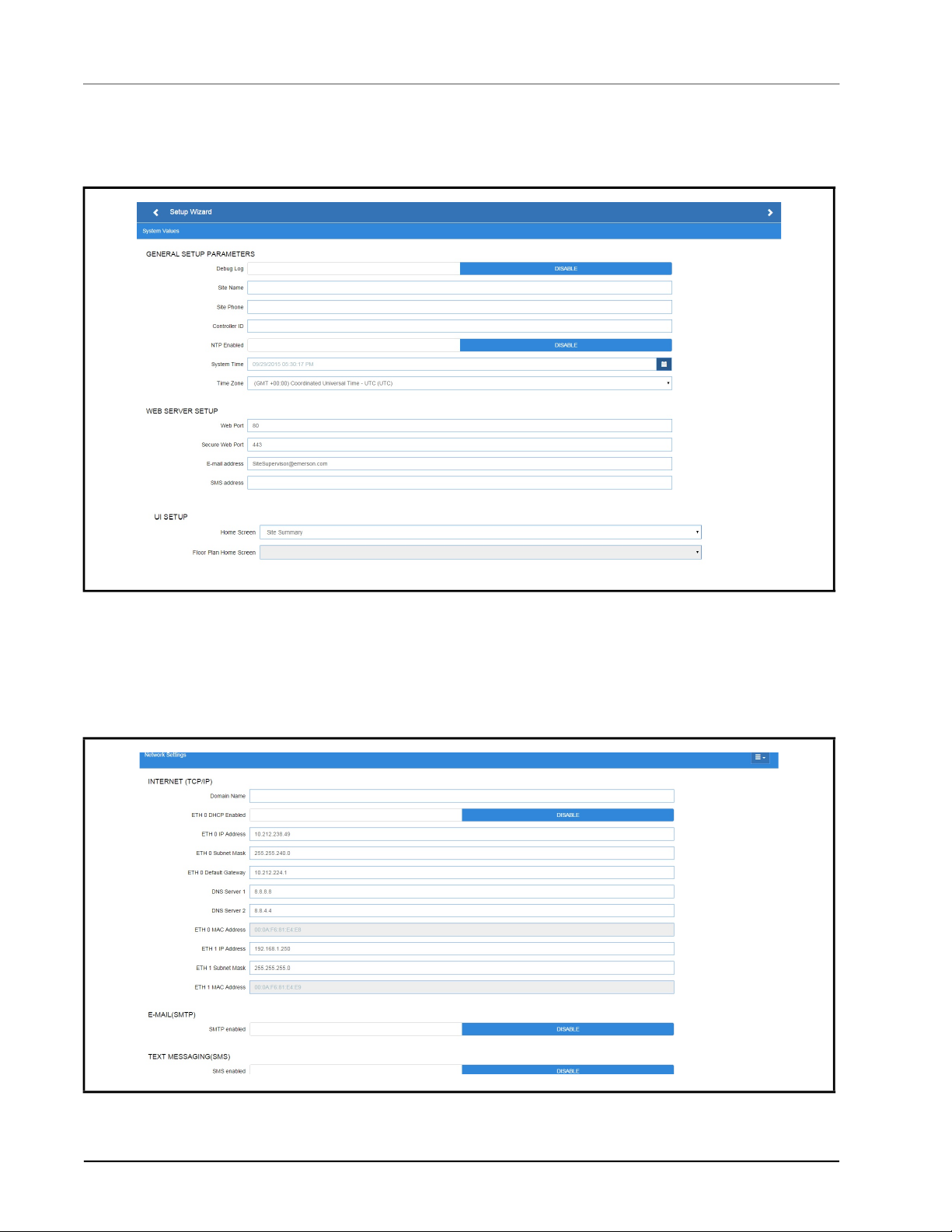

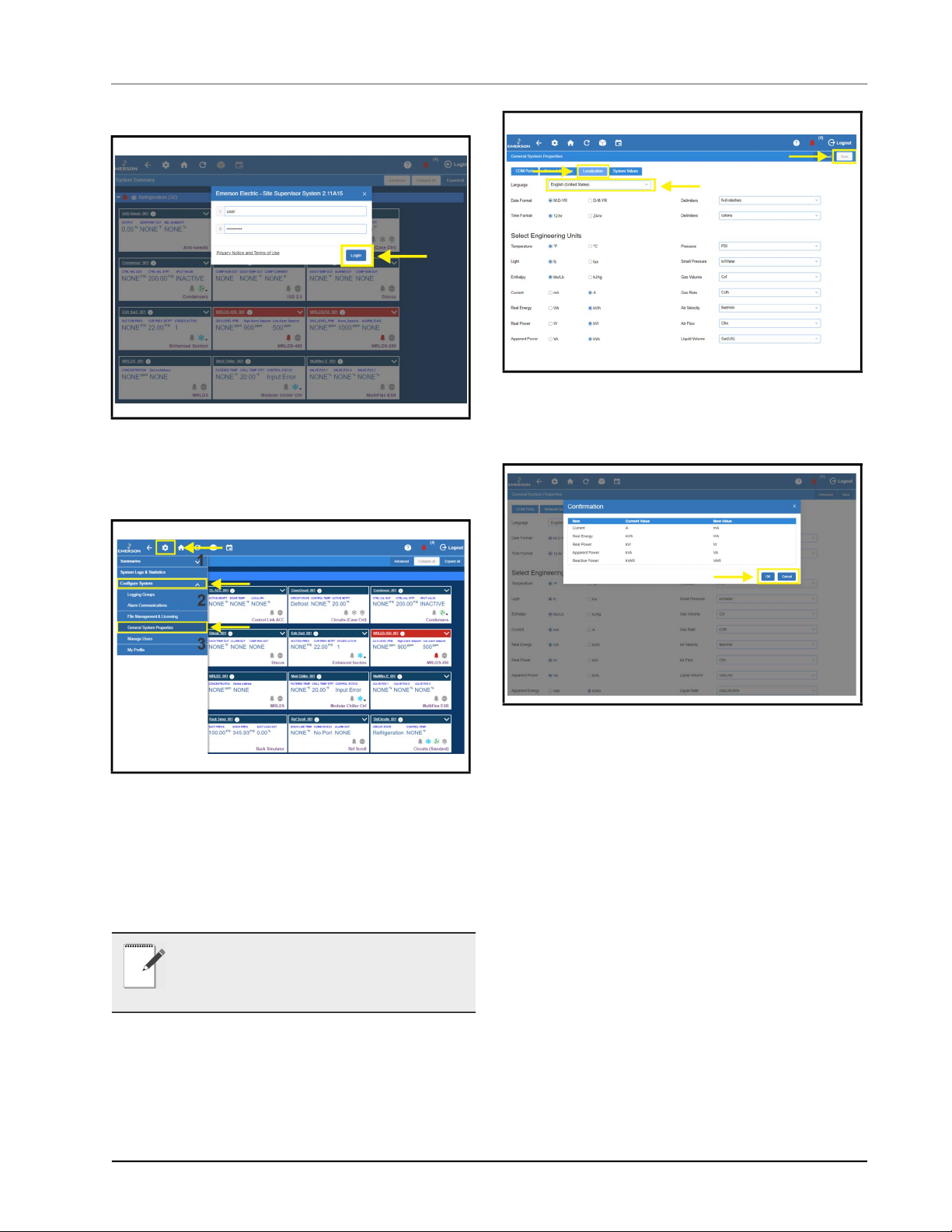

1.4.1 Localization Screen

Figure 1-7

Set the Supervisory Controller’s localization data such as language, date and time formats, and engineering units from the

Localization screen.

Language: The default for the language selection is American English (United States). The system stores a setting for the

preferred system language (internal language code). The default language is used when no user is currently logged into the

Supervisor or when the currently active preferred language does not have a translation for a given label, prompt, or

display text.

Date: The Date format can be set to either Day, Month, and full Year (D-M-YR) or Month-Day and full Year (M-D-YR)

format. The day, month, and year values are separated by either a forward slash or a dash line depending on user selection.

The Date Format can be changed based on user preference and saved to user profiles. On initial Supervisor startup, the

Date format defaults to the format of the language selected. For example, en-US will default to D-M-YR and all others

will default to M-D-YR.

Time: The Time format can be set to either a 12-hour (12-hr) format or 24-hour (24-hr) format. The hour, minute, and

second values are separated by either a colon or a period depending on user selection.The Time format can be changed

based on user preference and saved to user profiles. On initial Supervisor startup, the Time format defaults to the format of

the language selected. Date and Time delimiters default to forward slashes and colons.

Engineering Units: The default engineering units are based on the assigned units for the chosen preferred language.

Users can choose or change their preferred set of engineering units and save them to their user profiles. The default

engineering units are based on the International System of Units (SI System) format.

Set the system language type in the Language drop-down menu. Click the right arrow > to save and proceed to the

System Values screen.

- Localization Screen

Setup Wizard Basic Setup Information • 1-3

1.4.2 System Values Screen

From the System Values screen, name the unit by entering it in the Site Name field. The Confirmation window will slide

open. Click OK. Then click the right arrow > to proceed to the Network Settings Screen.

Figure 1-8

- System Values Screen

1.4.3 Network Settings Screen

Configure the settings on the Internet TCP/IP screen such as host name, text, and email settings. If you have Internet

access, enter the IP Subnet Mask and Default Gateway settings (see your IT Administrator). If connecting directly to a

laptop, use the Default IP and leave the DHCP set to Disable. For text messaging, enable the SMS setting and use the

SMTP address (see your IT Administrator).Click the arrow > to save and finish the Setup Wizard.

Figure 1-9 - Network Settings Screen

1-4 • Supervisory Controller 2.13 Installation and Operation Manual 026-1800 Rev 18

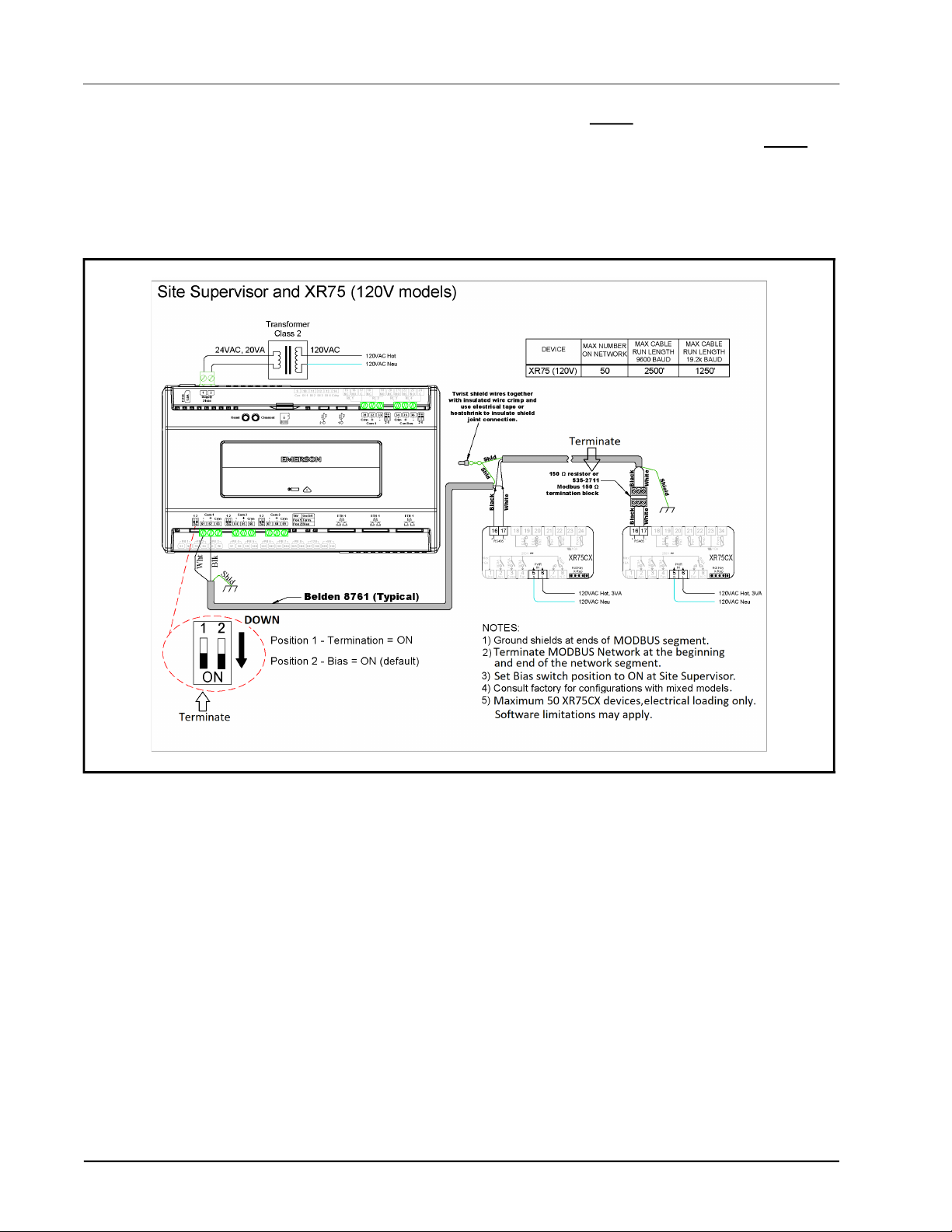

1.5 Site Supervisor RS485 Wiring Guide Examples

• Site Supervisor IONet connections must be wired reverse polarity.

• For Site Supervisor Serial IONet connections, connect the white wire to the negative terminal and the black wire to

the positive terminal.

• For 8RO and MultiFlex RS485 IONet connections, connect the white wire to the positive terminal and the black

wire to the negative terminal.

• Connect the shield wire to earth/chassis at the Site Supervisor end of the IONet network segment. DO NOT

connect the shield wire to any connector on the Site Supervisor.

• For daisy-chain configurations, terminate devices at the beginning and the end of the network segment. All other

devices in the network segment are not terminated (termination jumpers in the not-terminated position).

Figure 1-10

Site Supervisor RS485 Wiring Guide Examples Basic Setup Information • 1-5

- Site Supervisor and MultiFlex Wiring Layout

• Site Supervisor and XR75CX share the same MODBUS network polarity. Do not reverse polarity.

• Connect the shield wire to earth/chassis at the Site Supervisor end of the MODBUS network segment. Do not

con-

nect the shield wire to any connector on the Site Supervisor or XR75CX.

• For daisy-chain configurations, terminate devices at the beginning and the end of the network segment. Set the dip

switch position 1 and 2 to the ON position on Site Supervisor. For XR75CX end of network, terminate with a 150ohm resistor or 535-2711 termination block. All other devices in the network segment are not terminated

Figure 1-11

1-6 • Supervisory Controller 2.13 Installation and Operation Manual 026-1800 Rev 18

- Site Supervisor and XR75CX Wiring Layout

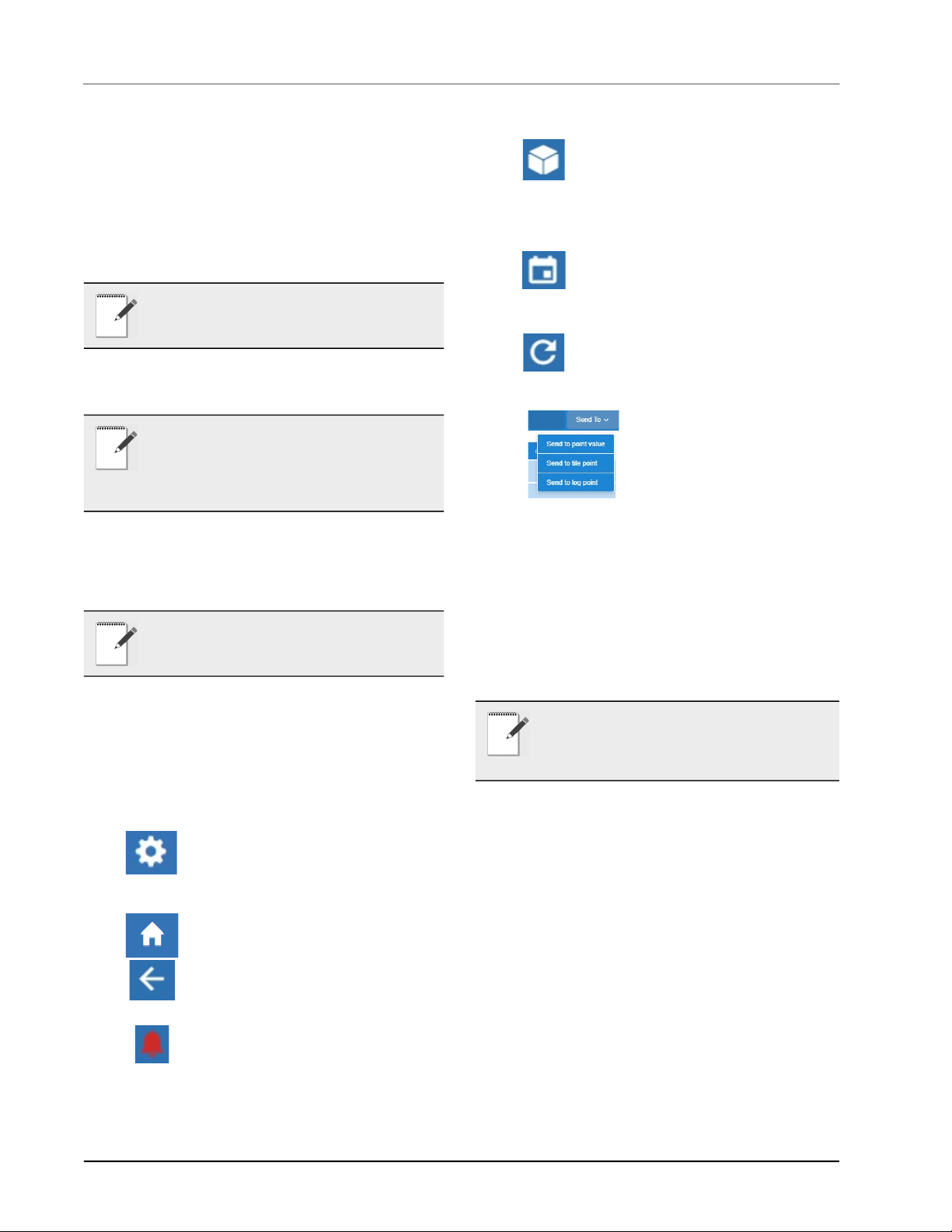

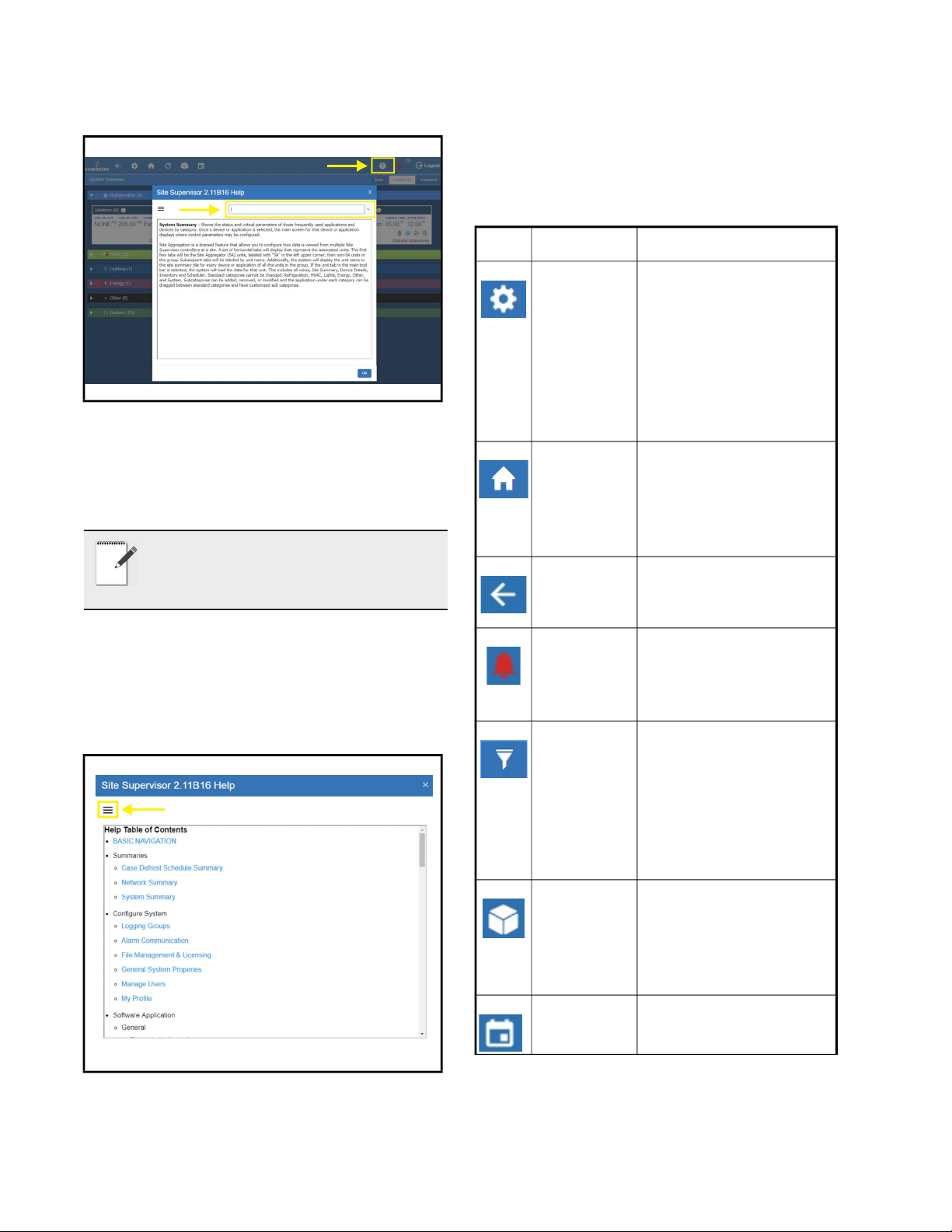

2 Basic Navigation

Log into Site Supervisor by clicking the Login icon in the

upper right part of the screen. For the Main Menu, click

the gear icon and the panel will slide open. Click the gear

icon again or to the right of the panel to close.

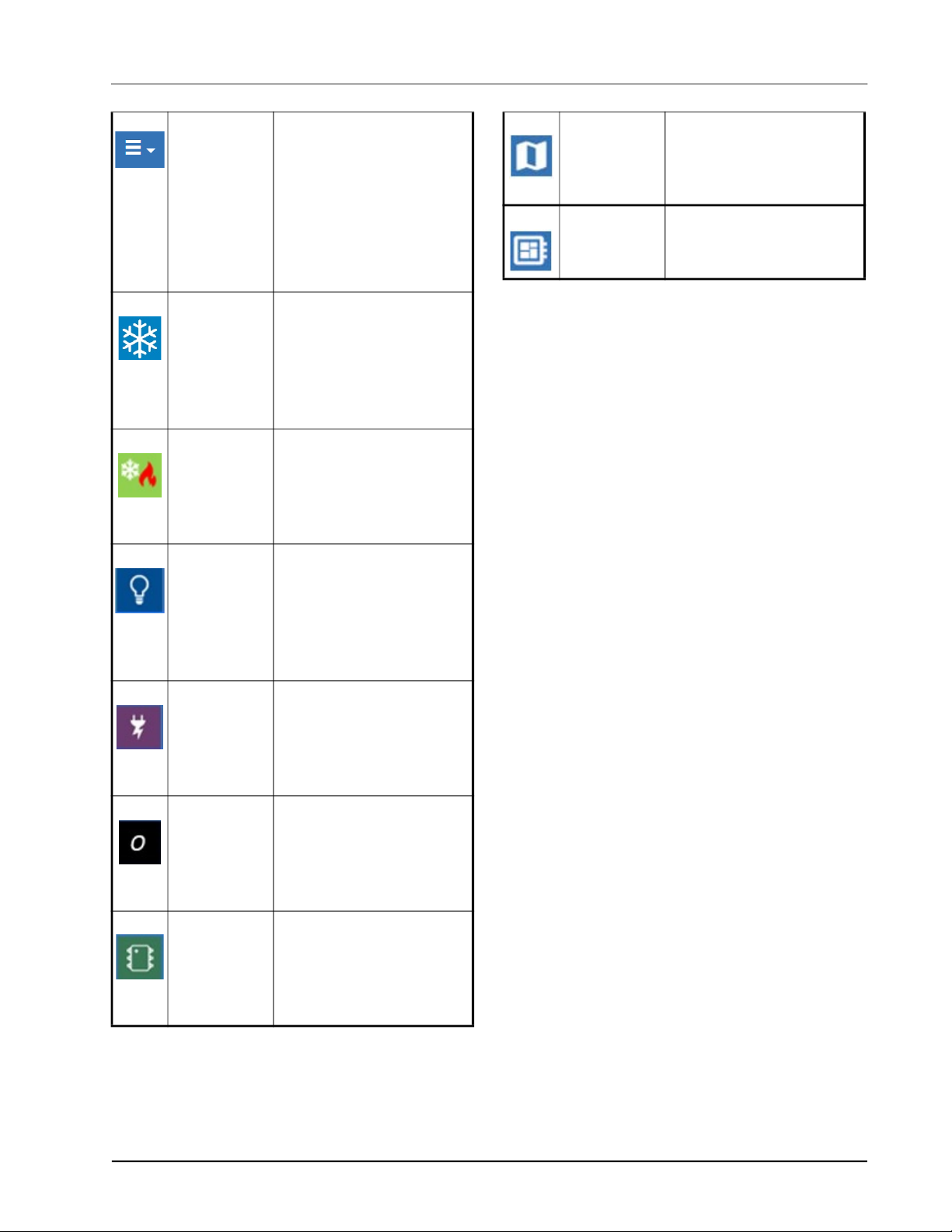

Six icons at the first row along the top of the screen are the

Back Arrow, Main Menu, Home, Refresh, Control

Inventory, and Schedule and Events. Refer to (Table 2-1)

for icon descriptions.

2.1 Menus and Submenus

1. Login - Logs you into the Supervisory controller.

Click and enter your username and password.

Once logged in, clicking Logout will log you

back out of the system. (You will automatically

be logged out of the system after a specified

period of idle time.)

Enter your Username/Password (default user/pass) and

click Login. Then update your password to the minimum

complexity requirements and click Save.

2. Home - Returns you to the set Home screen.

Click the Home icon to return to the Home screen

from anywhere in the system.

3. Summaries - Three submenus will display: Case

Defrost Schedule Summary, Network Summary,

and System Summary. Click each selection or

drop-down arrow (caret) to expand. Note that if

Peer Network is set up, the area controllers will

display under the Summaries menu under Area

Controllers.

• Case Defrost Schedule Summary- Takes you to

the Case Defrost Schedule Summary page where

edits to case defrost schedules can be managed.

• Network Summary - The network summary shows

the status of all network devices associated with

this Site Supervisor.

• Online - The device is online and communicating

normally

• Offline - The device is not communicating

(dropped off the network, has not been

commissioned, is not functional, or is not

powered up)

• Unknown - Unable to communicate with the

device

• This Supvr - Represents the current Supervisory

controller you are using; therefore, only one entry

in the list can show this status

• System Summary - Returns you to the home

screen

4. System Logs & Statistics - Contains controller

system information for technical personnel-level

users. Setpoint files can now be printed. Select

Setpoint Report. This report can be downloaded,

saved, or printed. Select Service Log for Clean

Out and Reset buttons. Clean Out will return the

controller to factory defaults. The controller will

reboot after a clean out with all programmed

applications, logs, and other data erased.

CAUTION: A clean out will erase all

programmed parameters from memory. The

Reset button only restarts and reboots the

controller.

5. Configure System- Contains navigation to

Logging Groups, Alarm Communications, File

Management & Licensing, General System

Properties, Manage Users (performs account

creation and role assignment for system users,

view, edit, and remove users) and My Profile

(allows you to create or edit your personal profile

page, create keyboard shortcuts, set localization

and engineering unit settings and more). Click

the drop-down arrow (caret) to expand.

• Logging Groups - Allows you to view log

parameters, add new logging groups, edit

parameters of existing logging groups, and delete

logging groups.

• Alarm Communications - View, edit, or delete

alarm notices from this page. Enable All to view all

notices in the system.

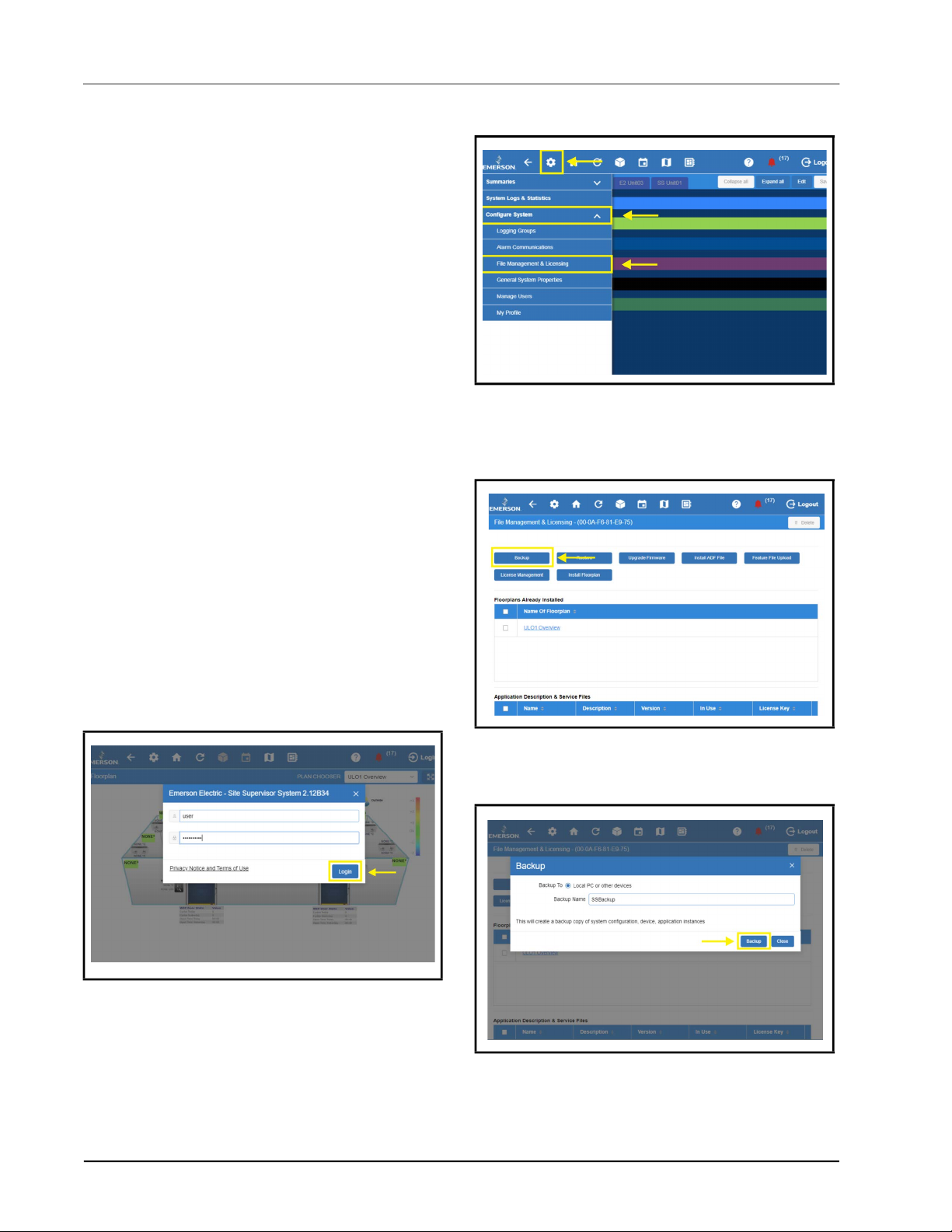

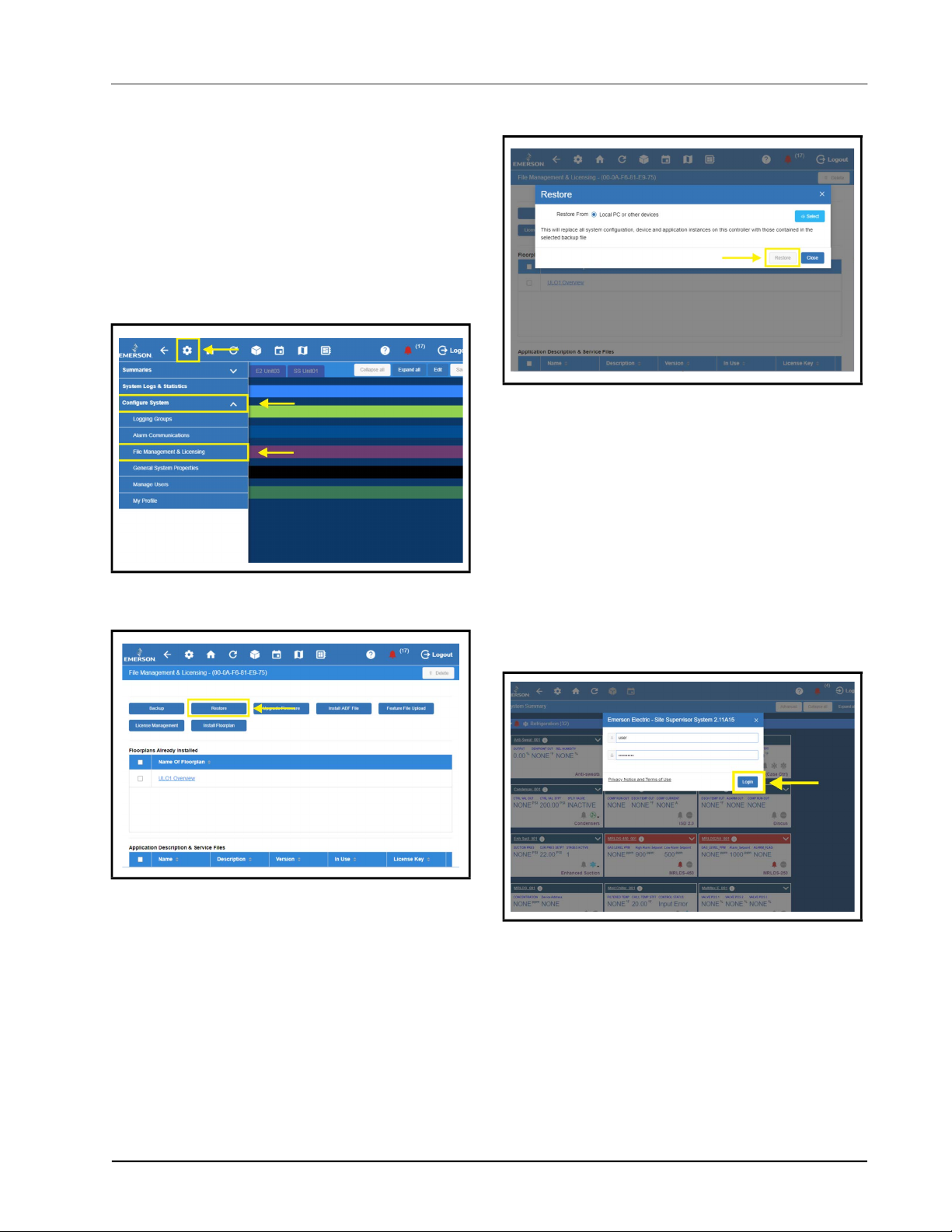

• File Management & Licensing - File Management

opens the File Management screen where you can

install and delete application description (ADF)

files, backup and restore system configuration,

install and delete floorplans, add/delete a license,

view application licenses in the system, add a

Feature Set, and upgrade firmware.

• General System Properties - Contains a

drop-down menu that includes these submenus:

COM Ports (COM Ports and baud rate settings),

Network Settings (Internet, subnet mask, DNS,

MAC Address, Email (SMTP), Text messaging

(SMS) and more), Localization (language and

engineering unit settings), and System Values

(general setup parameters, Web server and UI

setup).

Menus and Submenus Basic Navigation • 2-1

2.2 Overview

2.2.1 Conditional Visibility

Conditional Visibility allows points to be viewed that are

applicable to the defined view level (Basic or Advanced equivalent to “Full Options” in previous generation

controllers) for certain (not all) applications.

NOTE: The mobile Supervisory Controller

view does not support conditional visibility.

2.2.1.1 User View Details

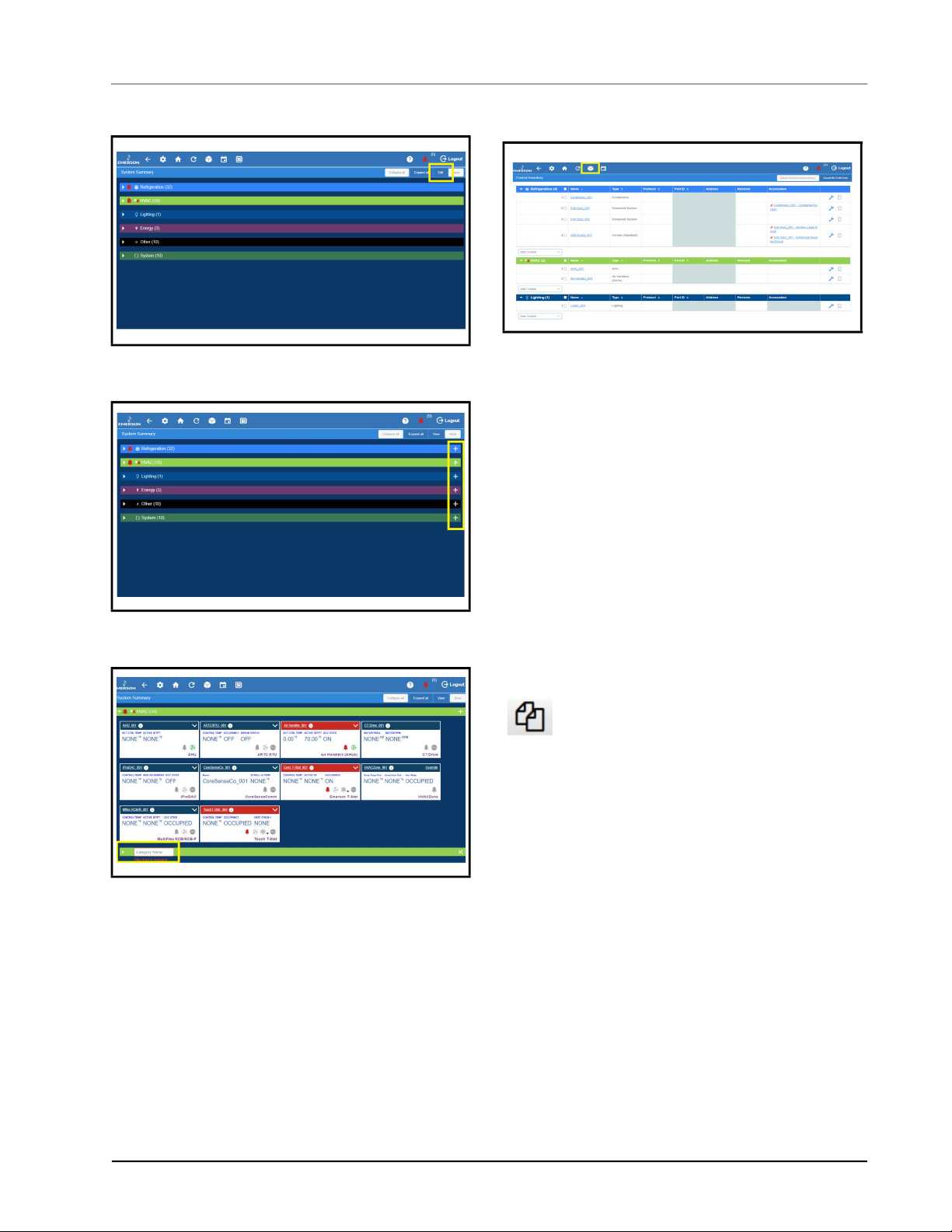

mark.

• Control Inventory (box) - Select this

box to access the Control Inventory

screen where applications can managed.

• Time Schedules (calendar) - Select to

access the Schedules and Events screen

where Schedules, Events, Inputs/Outputs,

Alarms, and System information is located.

• Refresh - Select to return to the Home

screen and log out.

NOTE: When you navigate to a specified

screen, you will see the points equal to or less

than your View Level available on the

Supervisory Controller’s rule. The basic user

level does not see the Advanced view level point.

Some screen information and contents are editable, which

when clicked can either display additional or related

information or move to another screen.

NOTE: The screen will only display applicable

points according to your view level and the

Supervisory Controller’s rules.

2.3 Basic Screen Elements

• Main display - This is the main section of the

screen, which contains and displays the content of

the chosen selection such as reports, device

information, configuration settings, and more.

• Main Menu (gear) - When clicked, the

Main Menu panel will slide open

containing the menus and submenus of

the controller.

• Home button - Returns you to the

default Home screen of the controller.

• Back button - This button will return

you to the previous screen. The Back

button is indicated by a left arrow icon.

• Active Alarms (red circle with excla-

mation mark) - When this icon is clicked,

the screen will display the

current active alarms. The number of alarms is

displayed in parentheses next to the exclamation

• Send To- Changes to multiple

applications at the same time

using the Send To button.