Page 1

AC Power

For Business-Critical Continuity

™

Liebert®STS2 Static Transfer Switch2

The Cornerstone of High-Availability Power Systems

Page 2

The Power to Protect Your Critical Operations

For maximum availability applications, the Liebert Static

Transfer Switch2 (STS2) provides an automatic, seamless

transfer between your critical load and the outputs of two

independent UPS systems in a dual-bus power configuration.

If the primary UPS should fail, the switch will automatically

transfer the loads to the alternate UPS.

Liebert is the market leader in dual-bus power systems,

building the world’s most reliable UPS and Static Transfer

Switch products. Liebert STS2 further extends our

market leadership with design benefits unmatched by

competitive products.

Standard Features Of The

Liebert STS2 Provide Greater

Overall Protection

Reliability:

100% rated, fuseless design.

Hot-swappable circuit breakers.

sh memory enables firmware updates while

a

Fl

supporting critical load.

Rack-out control/power assembly on units up to

600A to allow maintenance, service or full

acement without disrupting the critical load.

l

p

e

r

Flexibility:

ernal CANBUS protocol: high-bandwidth

t

In

communication between system components via

ed-pair cables. Options can be added as

t

wis

t

simple network nodes.

Dual-lug installation bus with pem nuts for

single-hand installation and “hot” torque service.

Low Total Cost Of Ownership:

Conservative design margins and excellent

overload capacity.

UL listed.

Color Touch-Screen Interface

The color touch-screen LCD interface allows

uickly check the status of the unit and

o q

u t

o

y

identify problems. The controls of the Liebert

STS2 are intuitive and simple.

vided into three segments. In addition to a system

i

or is d

onit

CD m

olor L

The c

mimic diagram, there is a Status/Alarm panel and a section dedicated to

perator instructions and menus. The screen allows you to configure the unit,

o

ontrol of the preferred source, auto/manual retransfer selection,

g the c

in

d

lu

inc

alarm notification and other system setpoints. You benefit from improved

perator effectiveness, reduced training time, and less chance of operator error.

o

2

Page 3

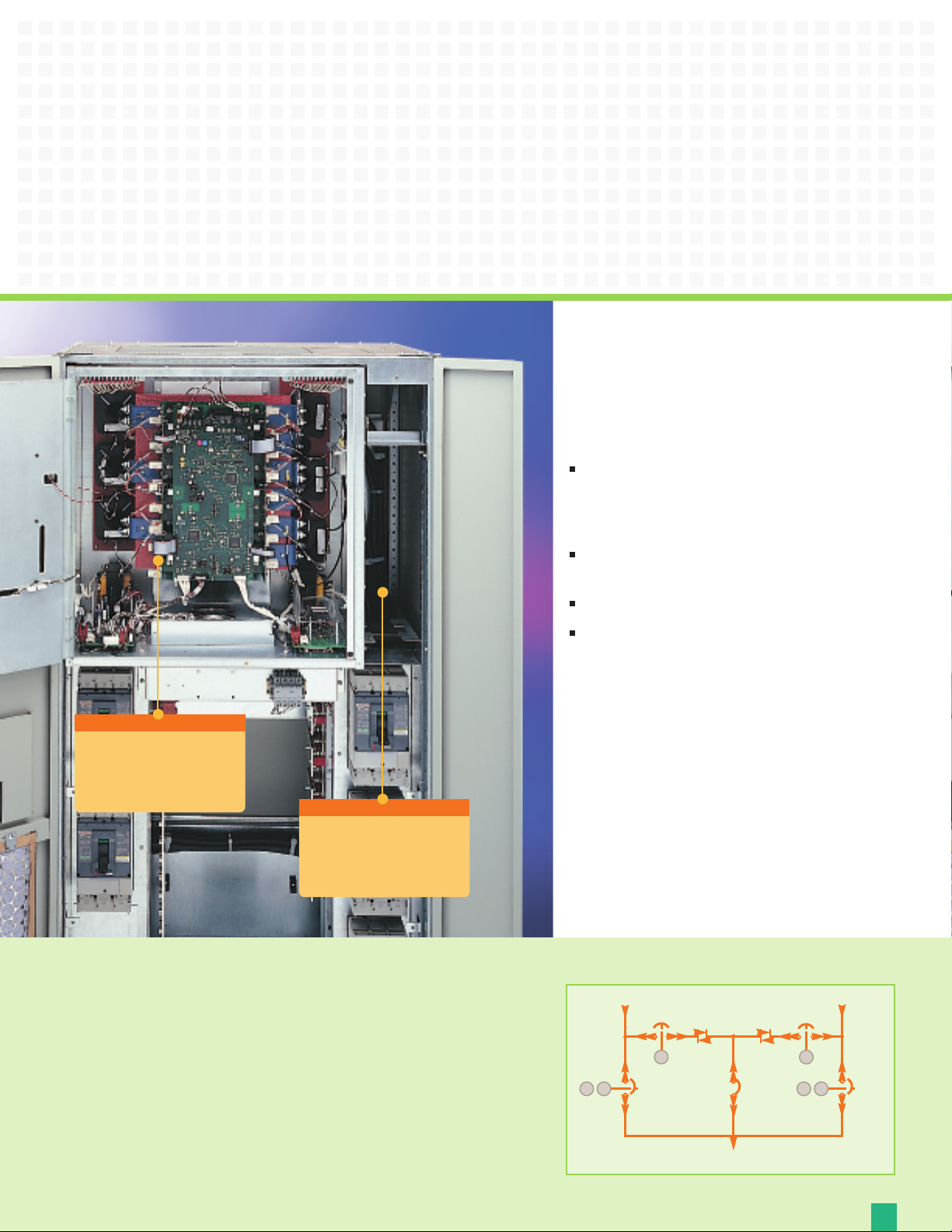

For units up to 600 amps,

the entire power and

ontrol module can be

c

removed as an assembly.

True Front-Access Design

All mechanical and electronic components of the Liebert

STS2 are accessible from the front of the unit for

installation and service—no side or rear access required.

This gives you several immediate benefits:

Greater freedom in system design. The Liebert STS2

can be placed adjacent to or in back of other

equipment. It can also be placed against a wall or

partition.

Simplified installation, with ample space for cable

connections through top and bottom access plates.

Less floor space required for maintenance access.

Designed for maintainability, with all key components

visible and accessible from the front of the unit,

without shutting down the connected load.

True Internal Redundancy

The Liebert STS2 has tripleredundant logic. Each DSP

controller is capable of working

independently, and each helps

monitor the other two. If one

malfunctions, the other two lock it

out. Each controller has power

feeds from both power supplies.

A separate compartment

for option modules

provides safe and

c

onvenient field access.

plies feature true

p

r su

e

w

o po

w

The t

dual-bus power distribution. Both

e dual inputs, one from each AC

v

a

h

e. All power connections

urc

o

t s

u

p

in

have diode protection, so that internal

ternal faults cannot propagate.

x

or e

, fault-resilient

ged

g

The r

sult is a r

e

u

package that is optimized for real-

ld applications.

or

w

One-Line Diagram

e 1

urc

So

CB1

K1

K2 K3 K1

CB4

CB3

System Output

CB2

K2

K3

Source 2

CB5

3

Page 4

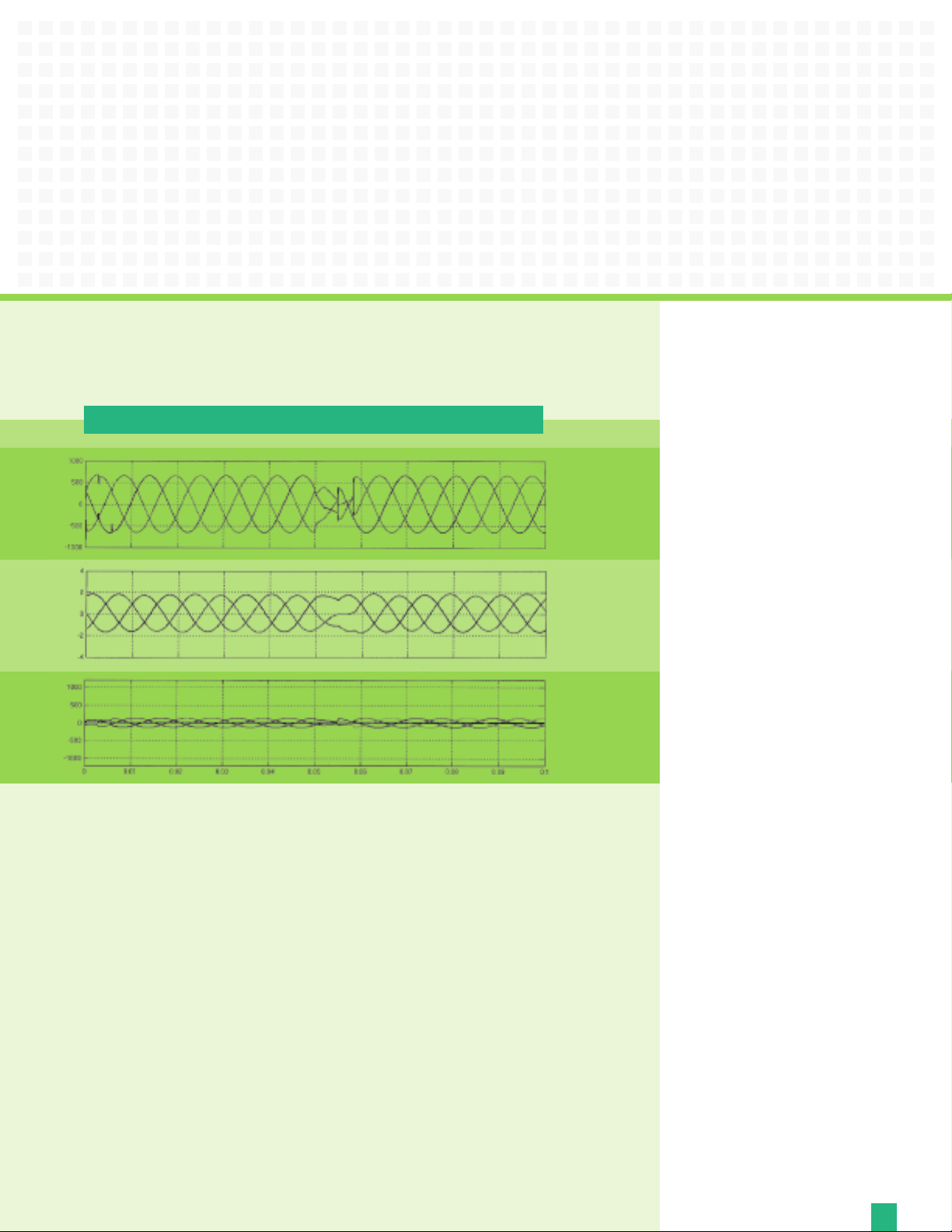

Figures 1 and 2

show results for the

standard STS2 vs.

the optimized STS2

for the same

condition

(alternate source

lags 120 degrees)

respectively. The

optimized transfer

control algorithm

minimizes the

transformer

saturation current

resulting from an

out of phase

transfer.

Optimized Transfer Option Enhances

Cost-Efficient System Operation

Liebert offers a patented optimized transfer option for the Liebert STS2 that greatly

improves operation when used in primary side switching applications.

Figure 1 Standard STS2 transfer

load voltages

transformer fluxes

primary currents

ee also

S

e Paper “STS2

Whit

ptimized Transfer

O

une 4, 2004)

(J

.liebert.com.

www

4

” a

The Liebert STS2 can be used in two different types of high-availability dual bus

configurations—as primary or secondary side switches. For primary side switching,

imary or input of a downstream transformer. On

r

o the p

ed t

t

the unit is c

secondary side switching the Liebert STS2 is connected to the secondary or output of

two transformers.

One of the main advantages of using primary side switching is lower cost.

The

to 480V vs. 208V, and lower installation and wiring cost thanks to use of smaller three

wir

The one dr

saturation current each time switching occurs. The downstream transformer can

cause large peak saturation current during automatic transfers. The transformer

saturation is caused by DC-flux built-up during transfer, especially when the sources

are not in phase.

t

onnec

se savings are the result of only one power distribution unit, a lower current due

le.

b

e ca

figuration is the creation of transformer inrush

on

f this c

ck o

wba

a

Page 5

Figure 2 Optimized STS transfer

The patented Liebert static switch optimized transfer control algorithm

eliminates the downstream transformer inrush saturation.

The Liebert algorithm is designed to optimize transfer timing such that the volt-seconds applied to the

wnstream transformer primary is balanced, thus minimizing peak saturation current. This balance is

o

d

eved by directly computing the volt-second applied to the transformer during transfer events and

hi

c

a

determining the optimum time to turn on the alternate source SCRs in order to balance the volt-

fied tolerance.

i

d within s

on

ec

s

This results in a volt-second balancing algorithm that is independent of voltage wave shape,

voltage failure decay rate, etc., making it superior to other algorithms based on voltage

phase angle difference only.

pec

Liebert’s transfer control does

more than balance the flux.

Due to our unique approach to the

optimized transfer algorithm, transfer

time should not be the only performance

measure for this new optimized switch.

Liebert’s method, whenever possible,

also seeks to minimize voltage

disturbances while maintaining

transformer flux balance. It takes both

voltage disturbance and volt-second

balance into consideration.

Liebert has a unique flux balance

algorithm that doesn’t just “sit and

wait” for the balance point to occur.

Rather, we will “pulse fire” the SCRs

as soon as possible in order to

minimize the load discontinuity and

e the voltage disruption.

c

n

e

h

So how safe is this new

optimized Liebert STS2 for your

critical loads?

timized Liebert STS2 safely meets

p

The o

tandard (prior to 1996)

cal lo

e

x.

EMA s

ds. Li

a

le its al

hi

, w

s

r

ebert’s optimized

orithm control

g

th the CB

bo

and the latest ITIC standard (1996) for

iti

cr

STS2 eliminates the risk of transformer

saturation problems during automatic

ansf

tr

ensures minimum voltage disturbance

during transfers while still balancing

the flu

5

Page 6

Liebert STS2 Communication

and Product Options

Liebert STS2 has a wide choice of monitoring and

communications options to keep you connected to your

critical power protection system.

S-232 Terminal Port

R

is primarily used as an alternate user interface to

configure, control, and diagnose the system.

Input Contact Isolator (ICI) Board — Customizable

input relays allow alarms from other devices to be

displayed on Liebert STS2 display. Provides an interface

for up to eight user inputs. External messages and alarms

can be routed to the unit, via the ICI.

Programmable Relay Board (PRB) — Programmable

output relays for custom customer alarms and

connections. Up to two PRBs can be installed in the

Liebert STS2 to route system events to external devices.

Comms Board — Includes a terminal block to provide a

DTE connection to an external modem. This board also

provides a direct connection to a Liebert SiteScan

system, via an RS-422. SiteLink-12 or SiteLink-4 is

required for SiteScan to communicate with the

Liebert STS2.

Liebert IntelliSlot™485 Web Card ADPT

ystems to be viewed from the network using a web browser.

ws s

Allo

rs SNMP, Telnet and web management.

e

v

li

e

D

urity using HTTPS message encryption.

ec

s s

de

vi

o

Pr

Supports 10 and 100 MBit Ethernet for legacy and modern networks.

Provides compatibility with

vent data loss and ensure data availability.

e

r

o p

t

t SiteScan WEB

ts

por

p

Su

trending for proactive analysis and maintenance to ensure facility uptime.

Interfaces to

quick corrective action.

t In

r

be

e

Li

TCP/IP-based Ethernet network to allow the device to communicate with

network management systems (NMS) via SNMP. Events can be

ansmitted to the NMS to provide remote status monitoring,

tr

plus fault and alarm detection. The card includes an RJ-45 port for

r

an Ethe

e the s

t

a

egr

t

in

System (BMS) or out-of-band monitoring, using Modbus.

r

be

e

i

L

Liebert Nform alarm notification software, to facilitate

telliSlot 485 Web Card ADPT provides connectivity to any

net connection, via Category 5 cable. The card can also

tem with an existing Building Management

s

y

Liebert MultiLink shutdown software,

prise monitoring software, to provide

r

e

t

n

e

tandard on all units, this port

— S

®

Web

Options and Accessories

Seismic Anchors

f seismic activity, anchors are available for securing the unit to

o

a concrete floor to meet seismic Zone 4 requirements.

Seismic Floor Stand — Designed to level the unit and provide

bottom cabling access without relying upon a raised floor for

support. Available in 18, 24, 30, 36 inch heights.

Distribution Cabinet (Up to 600A) — An output distribution

cabinet mounts on the side of the STS2. It is a full height

section with hinged doors to allow for easy access. The cabinet

contains one vertically mounted I-line panelboard for load

distribution. The panelboard is totally enclosed with an accent

cover that provides access without exposing other portions of

the unit. The panelboard provides space for 100A through 250A

three-pole branch circuit breakers. It also includes a separate

isolated neutral bus bar and safety-ground bus bar for the

neutral and safety-ground connections.

Redundant Output Breaker — An output plug-in, nonautomatic circuit breaker provides redundancy in the output

power path. The breaker is connected in parallel with the

output plug-in non-automatic circuit breaker.

Input Junction Boxes and Cable (Up to 600A) — The input

junction box option is available to simplify input connections to

the STS2. Two input junction boxes and the associated flexible

10-foot long input cables are provided with this option.

vailable with bottom cable entrance only, typically when the

A

unit is located on a raised floor.

te Source Selection

o

m

e

R

Se

lection board may be installed in your STS2. This option

allows you choose the preferred input source from a remote

location. Terminal connections enable you to remotely select a

ed source in the same process as the local source

r

r

e

f

e

r

p

ansfer selection.

tr

Key Lockout Switch — The key lockout switch activates a

software lockout of the touch-screen display to prevent manual

transfers and configuration changes. When locked out, the

touch-screen becomes a read only display. A key is needed to

rform manual transfers or change settings.

pe

— To ensure stability for the unit in the event

al Remote Source

on

ti

p

— An o

6

Page 7

Critical Space Support from Emerson Network Power Service

rvice Capability

e

al S

t

o

T

Emerson Network Power Service provides a Basic, Essential and

Preferred level of maintenance and service that allows you to

select the complement of critical power system services that

uirements. These programs include

eq

ur r

o

t fits y

s

be

guaranteed four-hour response time, emergency service and

preventive maintenance.

With more than 300 Liebert-employed Customer Engineers and

a network of over 900 factory authorized service personnel, our

bilities, geographical coverage and ability to

a

p

cal ca

hni

ec

t

respond are second to none. These factory-trained service

professionals have direct access to the most comprehensive

actory authorized parts network in the industry. We also

f

provide them with immediate online access to detailed

hematics and your equipment’s complete service record

c

s

from the time it was started up.

e Monitoring — Always There, Always Alert

t

o

m

e

R

The key to providing proper service for your critical power systems is being aware of

that equipment’s operating status at any given time. For customers who need to have

these vital protection systems continuously monitored, but don’t want to do it

s, Emerson Network Power Service offers Remote Monitoring Service. This

e

v

l

e

ms

the

seamless, rapid-response system is designed to maximize the capabilities of your

Liebert equipment by maximizing the effectiveness of its monitoring capabilities.

Continuous 24-hour remote monitoring of UPS/power conditioning equipment,

environmental products and other critical space support systems is available. No

re your facilities are located, we can provide continuous oversight of a

he

r w

e

tt

a

m

wide range of critical installations from our Customer Response Center.

When a problem is detected, the monitoring system immediately alerts the Customer

e Center where each alarm is evaluated and processed. The center offers

pons

s

e

R

instant phone assistance using a customer-defined response and call escalation plan.

ll coordinate all service vendors, track the response and solution time for

t wi

r

be

e

Li

service calls and provide comprehensive reports on alarms and corrective actions.

7

Page 8

Emerson Network Power.

The global leader in enabling Business-Critical Continuity

™

.

EmersonNetworkPower.com

AC Power

Connectivity

DC Power

Embedded Computing

Embedded Power

Monitoring

Outside Plant

Power Switching & Controls

Racks & Integrated Cabinets

Services

Precision Cooling

Surge Protection

Liebert Corporation

1050 Dearborn Drive

P.O. Box 29186

Columbus, Ohio 43229

800 877 9222 Phone (U.S. &

Canada Onl

y)

614 888 0246 Phone (Outside U.S.)

614 841 6022

FAX

Via

Leonardo Da Vinci 8

Zona Industriale Tognana

35028 Piove Di Sacco (PD)

Italy

39 049 9719 111 Phone

39 049 5841 257 FAX

Emerson Network Power Asia Pacific

7/F., Dah Sing Financial Centre

108 Gloucester Rd, Wanchai

Hong Kong

852 25722201 Phone

852 28029250 FAX

liebert.com

24 x 7 Tech Support

800 222 5877 Phone

614 841 6755 (outside U.S.)

Ensuring The High Availability Of

Mission-Critical Data And Applications.

Specifications

eat Uncrated Dimensions Uncrated Shipping Dimensions

H

p Output (WxDxH) Weight (WxDxH) Weight

Am

ating (KW) (inches) (mm) (lbs) (kg) (inches) (mm) (lbs) (kg)

R

100 0.8 30x32x77 762x813x1956 780 354 48x44x82 1016x1194x2082 880 399

1.37 30x32x77 762x813x1956 780 354 48x44x82 1016x1194x2082 880 399

250

400 2.04 38x32x77 965x813x1956 1200 544 48x44x82 1016x1194x2082 1300 590

600 3.08 38x32x77 965x813x1956 1200 544 48x44x82 1016x1194x2082 1300 590

800 4.03 84x32x77 2134x813x1956 2500 1134 92x53x82 2337x1346x2082 2600 1179

1000 5.09 84x32x77 2134x813x1956 2500 1134 92x53x82 2337x1346x2082 2600 1179

Note: 1Shipping dimensions and weight include the pallet and packing material. Actual weights will vary depending on installed options.

1

Shi

pping

1

Operating Specifications

Voltage: 208, 220, 240, 380, 400, 415, 480 or 600 VAC (field selectable), +/- 10%

Frequency: 50 or 60 Hz (field selectable), +/- 0.5 Hz

Overload Capability: 125% for 10 minutes,150% for 2 minutes

Operating Temperature: 0 to 40° C

le every precaution has been taken to ensure accuracy and

Whi

completeness in this literature, Liebert Corporation assumes no

responsibility, and disclaims all liability for damages resulting

rom use of this information or for any errors or omissions.

f

ation. All rights reserved throughout

por

or

t C

r

be

e

© 2006 Li

pecifications subject to change without notice.

. S

ld

or

the w

All names referred to are trademarks or registered trademarks

of their respective owners.

ebert and the Liebert logo are registered trademarks

® Li

of the Liebert Corporation.

SL-20600 (R03/08) Printed in USA

Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co. ©2006 Emerson Electric Co.

Loading...

Loading...