Page 1

Bulletin 71.4:SR8

Type SR8 Sanitary Backpressure Regulator

May 2010

Sanitary Design Standards

Wide Control Range

Superior Flow Performance and Accuracy

Diaphragm Cycle Life

Highly Stable Large Turndown Ratio

Easy Maintenance Tight Shutoff

Covered Adjusting Screw

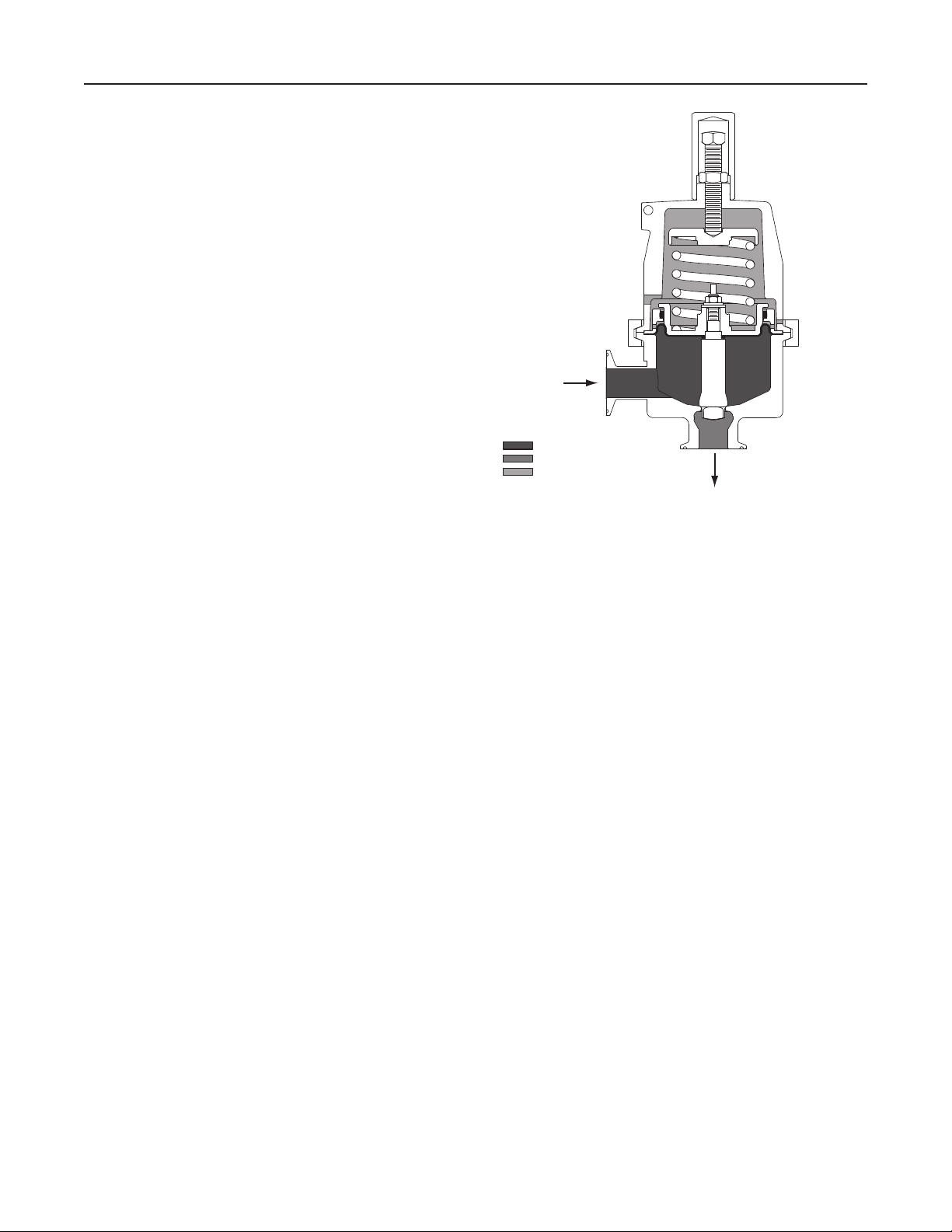

W8967

Figure 1. Type SR8 Sanitary Backpressure Regulator

Optional T-Handle Available

Nonporous Polished Body and Internals

www.sherregulators.com

Self-Draining

Remote Setpoint Capability

Optional Diaphragm Support

D103106X012

Page 2

Bulletin 71.4:SR8

Features

• Nonporous Polished Body and Internals for

High Purity Processing—Body, plug, and

diaphragm plate (when applicable) are machined

from 316L Stainless steel. All internal wetted

surfaces are mechanically polished and

electropolished to 20 µin (0,5 µm) Ra.

• Wide Control Range—Typical setpoints range

from 2 to 125 psig (0,14 to 8,6 bar) to cover a wide

range of applications.

• Self-Draining—Fluids will drain toward the outlet of

the body when the regulator is installed with the

spring case in the upright vertical position.

• Tight Shutoff—Soft seat is available to ensure

better shutoff.

• Superior Flow Performance and Accuracy—The

Type SR8 is designed to deliver high ows with

minimal buildup to maintain an even pressure over

the full range of ow.

• Sanitary Design Standards—Designed to meet

3A®, ASME BPE, and European Hygienic

Equipment Design Group criteria.

• Highly Stable—The upper guide ring provides for

stable control over entire operating range.

• Easy Maintenance—The design incorporates

a metal-to-metal stop to protect diaphragms

from damage due to over compression at outer

circumference. Tri-Clamp® allows easy access to

internal parts.

• Large Turndown Ratio—No need for reduced C

trims at low ows.

• Optional Diaphragm Support—A diaphragm

support is added to the regulator for installations

that will be exposed to vacuum conditions.

• Covered Adjusting Screw—Electropolished

stainless steel adjusting screw cover improves the

aesthetics and cleanability of the regulator.

• Diaphragm Cycle Life—Metal 316L Stainless

steel diaphragm is designed to maximize service life.

• Optional T-Handle Available—T-Handle option

available to accommodate frequent adjustments.

• Remote Setpoint Capability—An optional spring

case conguration permits pressure loading.

Loading pressure varied from a remote location

adjusts the setpoint in direct proportion.

v

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type SR8 Operational Schematic

Introduction

The Type SR8 backpressure regulator is a compact,

large capacity, direct-operated backpressure

regulator. It is designed for use in applications where

a sanitary design is essential, such as pharmaceutical,

biotechnology, or food and beverage industries. The

unit is available in NPS 1/2 through 3 (DN 15 through

80) sizes with end connections that will match up to

Tri-Clamp® sanitary ttings. The Type SR8 is suitable

for use in steam, liquid, or gas service.

Principle of Operation

The Type SR8 is a direct-operated regulator. Pressure

in the controlled system (regulator inlet pressure)

registers beneath the diaphragm of the regulator and

opposes the force provided by the predetermined

spring compression. When regulator spring force

exceeds diaphragm force exerted by the inlet

pressure, the spring will keep the valve plug closed

to prevent ow to the downstream system. As inlet

pressure increases above setpoint, this increase

registers on the diaphragm and the valve plug opens

to allow ow to the downstream system.

Tri-Clamp® is a mark owned by Tri-Clover, Incorporated.

3-A® is a mark owned by 3-A Sanitary Standards, Incorporated.

2

Page 3

Specications

Bulletin 71.4:SR8

Body Size, Inlet and Outlet Connection

NPS 1/2, 3/4, 1, 1-1/2, 2 and 3 (DN 15, 20, 25,

40, 50 and 80)

Service Media

All Sizes: Steam, Gas, and Liquid

End Connection

Tri-Clamp® Sanitary connections

Body Pressure/Temperature Ratings

MAXIMUM

TEMPERATURE,

°F (°C)

150 (65) 210 (14,5) 210 (14,5)

275 (135) 180 (12,4) 180 (12,4)

400 (204) 160 (11,0) 160 (11,0)

MAXIMUM INLET

PRESSURE,

PSIG (bar)

Maximum Operating Pressures

BODY SIZE,

NPS (DN)

1/2 through

1-1/2

(DN 15

through 40)

2 and 3

(DN 50

and 80)

MAXIMUM

TEMP, °F (°C)

150 (65) 210 (14,5) 210 (14,5)

275 (135) 180 (12,4) 180 (12,4)

400 (204) 160 (11,0) 160 (11,0)

150 (65) 150 (10,3) 150 (10,3)

275 (135) 125 (8,6) 125 (8,6)

400 (204) 110 (7,6) 110 (7,6)

(5)

(1)

MAXIMUM OUTLET

PRESSURE,

(1)(3)

MAX INLET

PRESSURE,

PSIG (bar)

Set Pressure Ranges

See Table 1

Maximum Differential Pressures

(1)

See Table 1

Temperature Capabilities

(1)

See Table 2

Flow Coefcients

See Table 4

Construction Materials

See Table 3

Pressure Registration

Internal

PSIG (bar)

MAX OUTLET

PRESSURE,

PSIG (bar)

Pressure Loaded Spring Case Option

Maximum Loading Pressure

NPS 1/2 through 1-1/2 (DN 15 to 40) body:

125 psig (8,6 bar)

NPS 2 and 3 (DN 50 and 80) body:

60 psig (4,1 bar)

1/4 NPT Tapped Vent Connection

Vacuum Protection Option

Maximum Vacuum Pressure

14 psig (1,0 bar) (vacuum)

Certications Available Upon Request

3A® certicate (Ethylenepropylene (EPDM) and

316L Stainless steel diaphragms only)

FDA approved elastomers/plastics

Material and Functional Test Certicates

USP Class VI approved elastomers/plastics

Spring Case Construction

Drilled untapped vent holes (standard)

1/4 NPT for Pressure Load Connection (optional)

Pressure Setting Adjustment

Adjusting screw with Electropolished

Cover (standard)

T-Handle adjusting screw (optional)

Shutoff Classication per ANSI/FCI 70-3-2003

Metal Seat: ANSI Class III

Polytetrauoroethylene (PTFE) Soft Seat:

ANSI Class VI

Polyetheretherketone (PEEK) Soft Seat:

ANSI Class VI (150-400°F)

(4)

Approximate Weight

NPS 1/2 and 3/4 (DN 15 and 20):

9 pounds (4 kg)

NPS 1 and 1-1/2 (DN 25 and 40):

18 pounds (8 kg)

NPS 2 and 3 (DN 50 and 80):

60 pounds (27 kg)

Options

Vacuum protection

Pressure Loaded spring case

T-handle adjusting screw

(2)

1. The pressure/temperature limits in this bulletin and any applicable standard or code limitation should not be exceeded.

2. Contact your Local Sales Ofce for details on available constructions.

3. Maximum pressure to prevent damage to internal parts and leakage to atmosphere.

4. Polyetheretherketone (PEEK) Seat meets ANSI Class IV or better below 150°F (66°C).

5. End connection clamps and gaskets to be supplied by the user.

Tri-Clamp® is a mark owned by Tri-Clover, Incorporated.

3-A® is a mark owned by 3-A Sanitary Standards, Incorporated.

3

Page 4

Bulletin 71.4:SR8

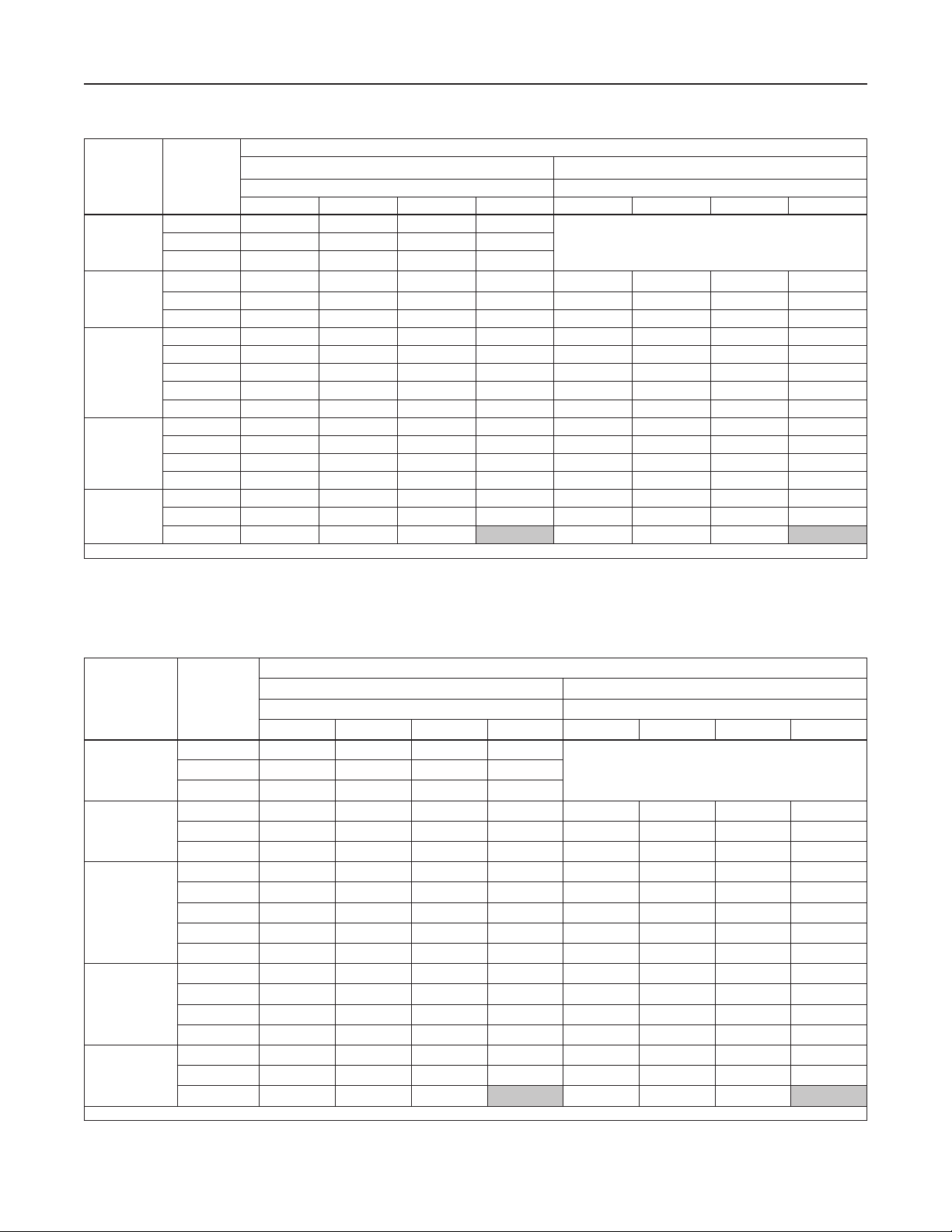

Table 1. Set Pressure Ranges, Control Spring Data, and Maximum Differential Pressures

BODY SIZE,

NPS (DN)

1/2 and 3/4

(15 and 20)

1 and 1-1/2 (25 and 40)

full port

1-1/2 x 1 (40 x 25)

2 and 3

(50 and 80)

1. The 2 to 8 psig (0,14 to 0,55 bar) spring is not available with the metal diaphragm.

Table 2. Temperature Capabilities

SEAT TYPE DIAPHRAGM MATERIAL O-RING MATERIAL TEMPERATURE RANGE, °F (°C)

Metal (316L)

(PTFE/316L)

(Polyetheretherketone (PEEK)/316L)

1. O-ring material is PTFE for the NPS 1/2 and 3/4 (DN 15 and 20) sizes. Temperature range is the same.

SET PRESSURE RANGES,

2 to 8 (0,14 to 0,55)

5 to 25 (0,34 to 1,7) 40 (2,7) Silver GE06781X012 0.177 (4,50) 2.75 (69,9)

10 to 50 (0,69 to 3,4) 100 (6,9) Green GE06782X012 0.192 (4,88) 2.75 (69,9)

35 to 100 (2,4 to 6,9) 140 (9,6) Red GE06783X012 0.225 (5,72) 2.75 (69,9)

75 to 125 (5,2 to 8,6) 160 (11,0)

2 to 8 (0,2 to 0,5)

5 to 25 (0,4 to 1,7) 40 (2,7) Silver GE02764X012 0.282 (7,16) 3.25 (82,6)

15 to 70 (1,0 to 4,8) 100 (6,9) Green GE02765X012 0.331 (8,41) 3.25 (82,6)

25 to 90 (1,7 to 6,2) 125 (8,6) Red GE02766X012 0.362 (9,19) 3.25 (82,6)

35 to 100 (2,4 to 6,9) 140 (9,6)

75 to 125 (5,2 to 8,6) 160 (11,0)

10 to 25 (0,7 to 1,7) 50 (3,4) Silver GE14003X012 0.562 (14,3) 6.00 (152)

15 to 50 (1,0 to 3,4) 75 (5,2) Green GE14004X012 0.625 (15,9) 6.00 (152)

25 to 60 (1,7 to 4,1) 75 (5,2) Red GE14005X012 0.625 (15,9) 6.00 (152)

Soft

Soft

PSIG (bar)

MAXIMUM DIFFERENTIAL

PRESSURE, PSID (bar d)

(1)

(1)

Ethylenepropylene (EPDM) Ethylenepropylene (EPDM) - 20 to 275 ( -28 to 135)

316L Stainless Steel PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM) PTFE/Fluorocarbon (FKM) 20 to 400 ( -6 to 204)

Ethylenepropylene (EPDM) Ethylenepropylene (EPDM) - 20 to 150 ( -28 to 65)

316L Stainless Steel PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM) PTFE/Fluorocarbon (FKM) 20 to 150 ( -6 to 65)

Ethylenepropylene (EPDM) Ethylenepropylene (EPDM) -20 to 275 (-28 to 135)

316L Stainless Steel PTFE/Fluorocarbon (FKM)

PTFE/Fluorocarbon (FKM) PTFE/Fluorocarbon (FKM) 20 to 400 ( -6 to 204)

15 (1,0) Blue GE06780X012 0.138 (3,51) 2.75 (69,9)

15 (1,0) Blue GE02763X012 0.225 (5,72) 3.25 (82,6)

COLOR

CODE

Red/

Yellow

Green/

Yellow

Red/

Yellow

PART NUMBER

GE06783X012/

GE06784X012

GE02765X012/

GE06090X012

GE02766X012/

GE06090X012

WIRE DIAMETER,

(1)

(1)

(1)

INCH (mm)

0.225 (5,72)/

0.148 (3,76)

0.331 (8,41)

0.250 (6,35)

0.362 (9,19)/

0.250 (6,35)

20 to 400 ( -6 to 204)

20 to 150 ( -6 to 65)

20 to 400 ( -6 to 204)

FREE LENGTH,

INCH (mm)

2.75 (69,9)/

2.75 (69,9)

3.25 (82,6)

3.25 (82,6)

3.25 (82,6)/

3.25 (82,6)

Table 3. Construction Materials

PART MATERIAL

Body 316L Stainless steel, 20 µin (0,5 µm) Ra with Electropolish

Spring Case 316 Stainless steel with Electropolish

Plug and Diaphragm Plate 316L Stainless steel, 20 µin (0,5 µm) Ra with Electropolish

Soft Seat Virgin PTFE or Polyetheretherketone (PEEK)

Diaphragm Ethylenepropylene (EPDM)(FDA), Virgin PTFE coated Fluorocarbon (FKM), or 316L Stainless steel

Control Springs Inconel® or 302 Stainless steel

Guide Ring and Upper and lower spring seats 300 Series Stainless steel

Adjusting Screw and locknut 300 Series Stainless steel

Closing Cap 300 Series Stainless steel with Electropolish or Plastic

T-handle and Locking Lever 300 Series Stainless steel

O-rings Ethylenepropylene (EPDM) (FDA), Virgin PTFE encapsulated Fluorocarbon (FKM), or Virgin PTFE

Piston Ring Expanded PTFE with 302 Stainless steel

Gaskets (Stainelss steel diaphragm only) Virgin PTFE

Bolted Clamp 304 Stainless steel with Brass or Stainless steel Nuts

Bead Chain and Ring Grip 300 Series Stainless steel

Inconel® is a mark owned by Special Metals Corporation.

4

Page 5

Table 4. Flow Coefcients

Bulletin 71.4:SR8

SIZE, NPS (DN)

1/2 (15) 27 1.4 1.3 19.1 0.54 0.73 0.23 0.40

3/4 (20) 70 3.1 3.5 22.8 0.61 0.78 0.33 0.41

1 (25) 202 7.2 10.1 28.1 0.63 0.79 0.50 0.42

1-1/2 x 1 (40 x 25) 216 7.6 10.8 28.4 0.60 0.77 0.51 0.42

1-1/2 (40) full port 309 10.9 15.5 28.4 0.68 0.82 0.51 0.40

2 (50) 962 34.4 48 28.0 0.60 0.78 0.49 0.32

3 (80) 1114 40.3 56 27.6 0.44 0.67 0.48 0.36

WIDE OPEN COEFFECIENTS

C

g

C

v

C

C

s

1

K

m

F

L

X

T

Capacity Data

The capacity information on the following pages is

based on four buildup factors, 10, 20, 30, and 40

percent. Buildup is the increase above setpoint required

to open and is usually stated in percentage of setpoint

value. Flow at setpoint (set ow) is approximately

10% of maximum ow. Greater capacities are

obtained with higher buildups over the relief pressure

setting, as shown in the capacity tables. To evaluate

the performance of a regulator, compare the stated

capacities at equivalent operating pressures and buildup

factors. Comparing the wide open Cv does not consider

the overall accuracy.

Buildup is derived by applying the applicable percentage

buildup to the setpoint. Buildup of 10 percent on a

20 psig (1,4 bar) setpoint would be 2 psig (0,14 bar) for a

total pressure of 22 psig (1,5 bar). Capacity information

assumes full drop. For instances where full drop is not

applicable, it is easiest to use the Fisher® Sizing program

and the Cv values listed in Table 5.

For the most accurate control, use the lowest range

spring that can be adjusted to the desired setpoint

(see Table 1 for part numbers of appropriate springs

for each body size). If closer control is necessary,

a regulator of larger capacity should be selected, so

that the necessary ow can be obtained with a smaller

offset factor.

It may be necessary to interpolate the capacity table

data to determine capacity for settings not given. To

maintain accuracy, it is important when interpolating to

stay within a spring range if possible.

An alternative method for interpolating capacities is

to use the Cv as shown in Table 5 in the Fisher Sizing

Program. When using this method remember that

P1 pressure is the sum of the setpoint and applicable

buildup. Do not use the wide open coefcients shown

in Table 4 for interpolating capacities.

Contact your nearest local Sales Ofce if you should

have any questions about selecting the proper regulator.

Regulating capacities in Table 6 are shown in SCFH

(60°F and 14.7 psia) of air at 60°F and normal cubic

meters per hour at 0°C and 1.01325 bar. For gases of

other specic gravities, divide by the square root of the

appropriate specic gravity.

Capacities in Table 7 are in pounds per hour and

kilograms per hour of saturated steam.

All water capacities in Tables 8 are shown in gallons

per minute and liters per minute. The Km values

listed in Table 4 can be used to predict choked ow

on liquid service.

Installation

The Type SR8 regulator may be installed in any

position, as long as ow will be in the same direction as

that indicated by the body arrow. However, to ensure

self-draining (from inlet to outlet) the regulator should

be installed with the spring case in the upright vertical

position. The regulator should be installed so that the

spring case vent is protected from anything that might

interfere with it.

Emerson Process Management Regulator Technologies,

Inc. provides an instruction manual with every regulator

shipped. Refer to this for complete installation,

operation and maintenance instructions. Included is a

complete listing of individual parts and recommended

spare parts.

F

d

5

Page 6

Bulletin 71.4:SR8

Table 5. Cv Coefcients

CV AT % BUILD-UP

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14) 0.45 0.55 0.65 0.75

5 (0,34) 0.45 0.67 0.84 0.99

8 (0,55) 0.50 0.80 1.03 1.22

5 (0,34) 0.35 0.49 0.62 0.80 0.32 0.36 0.40 0.47

15 (1,0) 0.59 0.94 1.13 1.26 0.40 0.55 0.67 0.81

25 (1,7) 0.71 1.15 1.36 1.40 0.44 0.64 0.78 0.96

10 (0,69) 0.40 0.65 0.87 1.10 0.35 0.42 0.50 0.57

15 (1,0) 0.54 0.87 1.04 1.21 0.38 0.49 0.62 0.74

30 (2,1) 0.76 1.22 1.30 1.37 0.43 0.59 0.82 0.98

45 (3,1) 0.86 1.39 1.40 1.40 0.45 0.64 0.91 1.09

50 (3,4) 0.89 1.40 1.40 1.40 0.45 0.66 0.93 1.12

35 (2,4) 0.60 0.95 1.24 1.40 0.42 0.60 0.75 0.94

50 (3,4) 0.69 1.10 1.35 1.40 0.46 0.69 0.89 1.11

75 (5,2) 0.77 1.23 1.40 1.40 0.50 0.77 1.02 1.27

100 (6,9) 0.82 1.30 1.40 1.40 0.53 0.82 1.09 1.36

75 (5,2) 1.16 1.40 1.40 1.40 1.12 1.40 1.40 1.40

100 (6,9) 1.13 1.40 1.40 1.40 1.10 1.40 1.40 1.40

125 (8,6) 1.23 1.36 1.39 1.02 1.40 1.40

Elastomer Diaphragm Metal Diaphragm

NPS 1/2 (DN 15) NPS 1/2 (DN 15)

Not Available

Table 5. Cv Coefcients (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14) 0.58 0.67 0.90 1.07

8 (0,55) 1.04 1.94 2.96 3.10

5 (0,34) 0.60 0.87 1.16 1.44 0.51 0.56 0.64 0.75

15 (1,0) 1.04 2.10 2.69 2.82 0.56 0.70 0.86 1.03

25 (1,7) 1.26 2.67 3.10 3.10 0.59 0.76 0.95 1.15

10 (0,69)

15 (1,0) 0.80 1.35 1.70 2.11 0.51 0.65 0.78 0.93

30 (2,1) 1.09 2.02 2.34 2.72 0.59 0.80 1.02 1.23

45 (3,1) 1.23 2.34 2.64 3.00 0.62 0.87 1.13 1.37

50 (3,4) 1.26 2.41 2.70 3.06 0.63 0.88 1.16 1.40

35 (2,4) 0.91 1.83 2.71 3.10 0.56 0.73 0.89 1.06

50 (3,4) 1.34 2.36 3.00 3.10 0.62 0.83 1.09 1.35

75 (5,2) 1.72 2.83 3.10 3.10 0.67 0.93 1.27 1.59

100 (6,9) 1.94 3.10 3.10 3.10 0.70 0.98 1.36 1.73

75 (5,2) 1.66 2.80 3.04 3.10 1.01 1.58 1.92 2.10

100 (6,9) 1.96 3.10 3.10 3.10 1.01 1.33 1.85 2.21

125 (8,6) 2.21 3.10 3.10 1.01 1.47 1.96

0.62 0.92 1.28 1.70 0.47 0.55 0.62 0.73

Elastomer Diaphragm Metal Diaphragm

NPS 3/4 (DN 20) NPS 3/4 (DN 20)

CV AT % BUILD-UP

Not Available5 (0,34) 0.82 1.38 2.08 2.27

6

Page 7

Table 5. Cv Coefcients (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 1.79 2.48 3.02 4.13

8 (0,55) 2.18 3.70 5.29 6.57

5 (0,34) 1.37 1.79 2.28 2.91 1.03 1.25 1.53 1.76

15 (1,0) 1.70 3.03 4.49 5.46 1.11 1.52 2.12 2.74

25 (1,7) 2.13 4.01 6.00 7.20 1.19 1.69 2.43 3.21

15 (1,0) 1.19 2.19 3.34 4.26 1.04 1.32 1.68 2.11

30 (2,1) 2.06 4.07 5.20 5.99 1.60 2.35 3.25 4.12

45 (3,1) 2.48 4.96 6.06 6.78 1.87 2.84 3.98 5.03

50 (3,4) 2.58 5.16 6.25 6.96 1.93 2.95 4.14 5.23

60 (4,1) 2.73 5.47 6.56 7.20 2.03 3.12 4.40 5.55

70 (4,8) 2.84 5.71 6.79 7.20 2.10 3.25 4.59 5.79

35 (2,4) 1.08 1.70 2.44 3.31 1.01 1.39 1.90 2.47

50 (3,4) 1.76 3.24 4.58 5.27 1.39 2.20 3.10 3.98

75 (5,2) 2.38 4.61 6.48 7.00 1.73 2.93 4.16 5.32

90 (6,2) 2.60 5.12 7.18 7.20 1.85 3.20 4.55 5.80

35 (2,4) 1.55 2.46 3.57 4.66 1.11 1.52 2.02 2.58

50 (3,4) 1.98 3.45 5.02 5.87 1.41 2.19 3.05 3.86

75 (5,2) 2.38 4.33 6.31 6.95 1.68 2.79 3.96 4.98

100 (6,9) 2.60 4.82 7.02 7.20 1.83 3.12 4.46 5.60

75 (5,2) 5.21 7.07 7.20 7.20 3.45 4.94 5.81 5.66

100 (6,9) 5.88 7.20 7.20 7.20 3.30 4.93 5.28 6.00

125 (8,6) 5.84 7.20 7.20 3.51 5.17 5.79

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 1 (DN 25) NPS 1 (DN 25)

CV AT % BUILD-UP

Bulletin 71.4:SR8

Not Available5 (0,34) 1.82 3.14 4.37 5.75

Table 5. Cv Coefcients (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 1.97 2.72 3.31 4.54

8 (0,55) 2.38 4.05 5.78 7.16

5 (0,34) 1.50 1.96 2.49 3.18 1.12 1.37 1.67 1.92

15 (1,0) 1.85 3.30 4.89 5.95 1.21 1.65 2.31 2.99

25 (1,7) 2.32 4.37 6.54 7.60 1.30 1.84 2.65 3.50

15 (1,0) 1.29 2.39 3.64 4.64 1.13 1.44 1.83 2.30

30 (2,1) 2.24 4.43 5.66 6.52 1.74 2.56 3.54 4.48

45 (3,1) 2.70 5.40 6.60 7.38 2.04 3.09 4.33 5.48

50 (3,4) 2.80 5.62 6.81 7.58 2.10 3.21 4.51 5.70

60 (4,1) 2.97 5.96 7.14 7.60 2.21 3.40 4.79 6.05

70 (4,8) 3.10 6.22 7.39 7.60 2.29 3.55 5.00 6.31

35 (2,4) 1.17 1.86 2.65 3.61 1.10 1.51 2.07 2.69

50 (3,4) 1.91 3.52 4.98 5.74 1.51 2.40 3.37 4.34

75 (5,2) 2.59 5.03 7.06 7.60 1.88 3.19 4.53 5.80

90 (6,2) 2.84 5.57 7.60 7.60 2.02 3.48 4.95 6.32

35 (2,4) 1.69 2.68 3.89 5.08 1.21 1.65 2.20 2.81

50 (3,4) 2.16 3.75 5.47 6.40 1.53 2.38 3.32 4.20

75 (5,2) 2.59 4.71 6.87 7.57 1.83 3.04 4.31 5.43

100 (6,9) 2.83 5.25 7.60 7.60 1.99 3.40 4.86 6.10

75 (5,2) 5.49 6.87 7.45 7.60 3.38 5.05 6.01 6.05

100 (6,9) 5.44 7.52 7.60 7.60 3.58 5.25 5.87 6.92

125 (8,6) 6.42 7.60 7.60 3.64 4.91 6.63

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) Reduced Port NPS 1-1/2 (DN 40) Reduced Port

CV AT % BUILD-UP

Not Available5 (0,34) 2.00 3.44 4.78 6.29

7

Page 8

Bulletin 71.4:SR8

Table 5. Cv Coefcients (continued)

SPRING RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 1.95 2.54 2.81 3.31

8 (0,55) 1.47 3.05 6.32 8.91

5 (0,34) 1.37 1.64 2.54 2.94 1.37 1.51 1.81 2.06

15 (1,0) 1.87 4.12 7.34 8.17 1.31 1.68 2.40 3.08

25 (1,7) 2.16 5.32 9.55 10.50 1.35 1.81 2.71 3.57

15 (1,0) 1.87 2.94 4.14 5.83 1.37 1.62 2.16 2.79

30 (2,1) 4.83 7.28 7.83 8.70 1.66 2.59 3.66 4.76

45 (3,1) 6.25 9.33 9.54 10.01 1.81 3.05 4.36 5.66

50 (3,4) 6.57 9.79 9.92 10.30 1.84 3.16 4.52 5.86

60 (4,1) 7.09 10.52 10.52 10.76 1.89 3.32 4.77 6.18

70 (4,8) 7.48 10.90 10.90 10.90 1.93 3.44 4.95 6.42

35 (2,4) 1.85 3.13 4.40 5.66 1.07 1.41 1.75 2.25

50 (3,4) 3.61 6.48 7.44 8.17 1.46 2.29 3.11 4.05

75 (5,2) 5.20 9.49 10.15 10.39 1.82 3.08 4.31 5.65

90 (6,2) 5.79 10.59 10.90 10.90 1.96 3.37 4.75 6.22

35 (2,4) 2.93 3.99 5.59 8.06 1.47 2.00 2.59 3.28

50 (3,4) 4.13 6.41 7.91 9.36 1.64 2.47 3.57 4.75

75 (5,2) 5.22 8.60 9.97 10.51 1.80 2.90 4.45 6.04

100 (6,9) 5.83 9.80 10.90 10.90 1.88 3.13 4.93 6.75

75 (5,2) 5.85 9.55 10.56 10.51 3.62 5.21 6.22 6.38

100 (6,9) 6.05 10.50 10.74 10.41 3.89 5.08 6.70 7.87

125 (8,6) 7.46 10.68 10.81 3.96 5.52 7.34

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) NPS 1-1/2 (DN 40)

CV AT % BUILD-UP

Not Available5 (0,34) 1.55 2.73 4.87 6.66

Table 5. Cv Coefcients (continued)

SPRING RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 9.54 12.90 20.16 25.94 6.97 9.73 12.00 14.51

15 (1,0) 13.77 25.30 30.19 30.19 9.10 11.66 14.20 17.37

25 (1,7) 19.87 30.19 30.19 30.19 9.39 12.66 16.48 19.66

15 (1,0) 12.16 17.45 24.11 28.98 6.97 9.67 11.54 12.29

25 (1,7) 14.20 24.03 29.03 30.08 8.32 11.20 14.90 17.73

50 (3,4) 22.24 28.76 29.98 29.90 9.57 15.28 20.12 23.86

25 (1,7) 12.93 21.88 30.01 30.19 8.26 11.29 15.06 18.15

50 (3,4) 18.16 29.95 30.19 30.19 9.12 14.28 19.11 22.97

60 (4,1) 22.06 30.19 30.19 10.75 17.53 22.96

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 2 (DN 50) NPS 2 (DN 50)

Table 5. Cv Coefcients (continued)

SPRING

RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 12.81 17.24 24.09 28.28 8.76 14.51 19.01 22.35

15 (1,0) 13.42 21.30 28.37 35.03 11.58 17.34 21.63 25.08

25 (1,7) 17.78 28.44 37.90 39.21 13.03 19.27 23.95 28.24

15 (1,0) 10.11 15.34 22.43 28.58 11.25 16.30 20.36 23.58

25 (1,7) 12.15 23.16 33.49 39.21 10.85 18.05 22.17 26.93

50 (3,4) 12.51 26.03 38.44 39.08 14.70 23.64 28.97 33.40

25 (1,7) 11.29 20.42 28.43 35.61 10.73 17.26 22.36 26.33

50 (3,4) 13.31 25.82 37.56 39.11 13.57 21.54 27.47 31.76

60 (4,1) 24.47 34.81 39.21 15.57 23.99 30.03

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 3 (DN 80) NPS 3 (DN 80)

CV AT % BUILD-UP

CV AT % BUILD-UP

8

Page 9

Table 6. Air Capacities

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 140 (3,8) 180 (4,8) 220 (5,9) 260 (7,0

8 (0,55) 270 (7,2) 450 (12) 600 (16) 730 (20)

5 (0,34) 160 (4,3) 230 (6,2) 300 (8,0) 400 (11) 120 (3,2) 140 (3,8) 160 (4,3) 190 (5,1)

15 (1,0) 430 (12) 720 (19) 900 (24) 1050 (28) 240 (6,4) 340 (9,1) 430 (12) 550 (15)

25 (1,7)

10 (0,7) 240 (6,4) 400 (11) 560 (15) 730 (20) 170 (4,6) 210 (5,6) 260 (7,0) 310 (8,3)

15 (1,0) 390 (10) 660 (18) 830 (22) 1000 (27) 220 (5,9) 300 (8,0) 400 (11) 500 (13)

30 (2,1) 850 (23) 1450 (39) 1630 (44) 1820 (49) 390 (10) 570 (15) 830 (22) 1060 (28)

45 (3,1) 1300 (35) 2240 (60) 2430 (65) 2630 (70) 550 (15) 840 (23) 1260 (34) 1610 (43)

50 (3,4) 1450 (39) 2500 (67) 2700 (72) 2900 (78) 600 (16) 930 (25) 1400 (38) 1800 (48)

35 (2,4) 750 (20) 1260 (34) 1750 (47) 2150 (58) 420 (11) 640 (17) 860 (23) 1130 (30)

50 (3,4) 1130 (30) 1920 (51) 2520 (68) 2970 (80) 610 (16) 980 (26) 1350 (36) 1790 (48)

75 (5,2) 1770 (47) 3010 (81) 3810 (102) 4330 (116) 930 (25) 1540 (41) 2180 (58) 2900 (78)

100 (6,9) 2400 (64) 4100 (110) 5100 (137) 5700 (153) 1250 (34) 2100 (56) 3000 (80) 4000 (107)

75 (5,2) 2650 (71) 3590 (96) 3960 (106) 4100 (110) 2060 (55) 3160 (85) 3650 (98) 4100 (110)

100 (6,9) 3310 (89) 4550 (122) 4910 (132) 5580 (150) 2610 (70) 4190 (112) 4360 (117) 4950 (133)

125 (8,6) 4390 (118) 5250 (141) 5770 (155) 2970 (80) 4870 (131) 5310 (142)

10% 20% 30% 40% 10% 20% 30% 40%

700 (19) 1200 (32) 1500 (40) 1700 (46) 350 (9,4) 540 (14) 700 (19) 900 (24)

Elastomer Diaphragm Metal Diaphragm

NPS 1/2 (DN 15) NPS 1/2 (DN 15)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Bulletin 71.4:SR8

Not Available5 (0,34) 210 (5,6) 320 (8,6) 410 (11) 500 (13)

Table 6. Air Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14) 180 (4,8) 220 (5,9) 300 (8,0) 370 (9,9)

8 (0,55) 550 (15) 1060 (28) 1670 (45) 1840 (49)

5 (0,34) 270 (7,2) 400 (11) 550 (15) 700 (19) 230 (6,2) 260 (7,0) 310 (8,3) 370 (9,9)

15 (1,0) 740 (20) 1550 (42) 2080 (56) 2280 (61) 400 (11) 520 (14) 660 (18) 830 (22)

25 (1,7) 1200 (32) 2700 (72) 3600 (96) 3850 (103) 560 (15) 770 (21) 1020 (27) 1300 (35)

10 (0,69) 360 (9,6) 550 (15) 800 (21) 1100 (29) 270 (7,2) 330 (8,8) 390 (10) 480 (13)

15 (1,0) 570 (15) 990 (27) 1310 (35) 1700 (46) 360 (9,6) 480 (13) 600 (16) 750 (20)

30 (2,1) 1180 (32) 2330 (62) 2850 (76) 3500 (94) 640 (17) 920 (25) 1240 (33) 1590 (43)

45 (3,1) 1800 (48) 3660 (98) 4390 (118) 5300 (142) 910 (24) 1350 (36) 1890 (51) 2420 (65)

50 (3,4) 2000 (54) 4100 (110) 4900 (131) 5900 (158) 1000 (27) 1500 (40) 2100 (56) 2700 (72)

35 (2,4) 1100 (29) 2350 (63) 3700 (99) 4800 (129) 680 (18) 940 (25) 1220 (33) 1540 (41)

50 (3,4) 2120 (57) 4000 (107) 5430 (146) 6480 (174) 980 (26) 1420 (38) 1980 (53) 2590 (69)

75 (5,2) 3810 (102) 6750 (181) 8320 (223) 9290 (249) 1490 (40) 2210 (59) 3240 (87) 4350 (117)

100 (6,9) 5500 (147) 9500 (255) 11200 (300) 12100 (324) 2000 (54) 3000 (80) 4500 (121) 6100 (163)

75 (5,2) 3660 (98) 6670 (179) 7760 (208) 8680 (233) 2240 (60) 3760 (101) 4910 (132) 5710 (153)

100 (6,9) 5570 (149) 9520 (255) 10540 (282) 11300 (303) 2860 (77) 4080 (109) 6100 (163) 7800 (209)

125 (8,6) 7650 (205) 11690 (313) 12680 (340) 3510 (94) 5510 (148) 7940 (213)

Elastomer Diaphragm Metal Diaphragm

NPS 3/4 (DN 20) NPS 3/4 (DN 20)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Not Available5 (0,34) 370 (9,9) 640 (17) 990 (27) 1110 (30)

9

Page 10

Bulletin 71.4:SR8

Table 6. Air Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 590 (16) 850 (23) 1070 (29) 1520 (41)

5 (0,34) 930 (25) 1660 (44) 2400 (64) 3270 (88)

8 (0,55) 1380 (37) 2450 (66) 3640 (98) 4680 (125)

5 (0,34) 700 (19) 950 (25) 1250 (34) 1650 (44) 520 (14) 660 (18) 840 (23) 1000 (27)

15 (1,0) 1480 (40) 2750 (74) 4270 (114) 5430 (146) 960 (26) 1380 (37) 2020 (54) 2730 (73)

25 (1,7) 2500 (67) 5000 (134) 7900 (212) 10000 (268) 1400 (38) 2100 (56) 3200 (86) 4450 (119)

15 (1,0)

30 (2,1) 2740 (73) 5760 (154) 7790 (209) 9490 (254) 2130 (57) 3330 (89) 4870 (131) 6520 (175)

45 (3,1) 4450 (119) 9520 (255) 12410 (333) 14740 (395) 3350 (90) 5450 (146) 8150 (218) 10940 (293)

50 (3,4) 5020 (135) 10780 (289) 13950 (374) 16490 (442) 3760 (101) 6160 (165) 9240 (248) 12410 (333)

60 (4,1) 6160 (165) 13290 (356) 17020 (456) 20000 (536) 4580 (123) 7580 (203) 11420 (306) 15350 (411)

70 (4,8) 7300 (196) 15800 (423) 20100 (539) 23500 (630) 5400 (145) 9000 (241) 13600 (364) 18300 (490)

35 (2,4) 1600 (43) 2700 (72) 4100 (110) 5900 (158) 1500 (40) 2200 (59) 3200 (86) 4400 (118)

50 (3,4) 3430 (92) 6760 (181) 10210 (274) 12500 (335) 2700 (72) 4600 (123) 6910 (185) 9450 (253)

75 (5,2) 6470 (173) 13540 (363) 20390 (546) 23500 (630) 4700 (126) 8600 (230) 13090 (351) 17850 (478)

90 (6,2)

35 (2,4) 2300 (62) 3900 (105) 6000 (161) 8300 (222) 1650 (44) 2400 (64) 3400 (91) 4600 (123)

50 (3,4) 3870 (104) 7200 (193) 11190 (300) 13930 (373) 2750 (74) 4570 (122) 6790 (182) 9150 (245)

75 (5,2) 6480 (174) 12700 (340) 19850 (532) 23320 (625) 4570 (122) 8180 (219) 12450 (334) 16720 (448)

100 (6,9) 9100 (244) 18200 (488) 28500 (764) 32700 (876) 6400 (172) 11800 (316) 18100 (485) 24300 (651)

75 (5,2) 14200 (381) 20740 (556) 23630 (633) 26090 (699) 9400 (252) 14480 (388) 18280 (490) 18990 (509)

100 (6,9) 20550 (551) 28460 (763) 32210 (863) 34940 (936) 11530 (309) 18640 (500) 21420 (574) 26050 (698)

125 (8,6) 24920 (668) 35760 (958) 40760 (1092) 15000 (402) 23880 (640) 28790 (772)

10% 20% 30% 40% 10% 20% 30% 40%

1030 (28) 1990 (53) 3180 (85) 4230 (113) 900 (24) 1200 (32) 1600 (43) 2100 (56)

8300 (222) 17600 (472) 26500 (710) 30100 (807) 5900 (158) 11000 (295) 16800 (450) 22900 (614)

Elastomer Diaphragm Metal Diaphragm

NPS 1 (DN 25) NPS 1 (DN 25)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Not Available

Table 6. Air Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 650 (17) 930 (25) 1180 (32) 1670 (45)

8 (0,55) 1520 (41) 2700 (72) 4000 (107) 5150 (138)

5 (0,34) 760 (20) 1040 (28) 1380 (37) 1820 (49) 570 (15) 730 (20) 920 (25) 1100 (29)

15 (1,0) 1620 (43) 3030 (81) 4700 (126) 5970 (160) 1060 (28) 1520 (41) 2220 (59) 3000 (80)

25 (1,7) 2750 (74) 5500 (147) 8690 (233) 11000 (295) 1540 (41) 2310 (62) 3520 (94) 4900 (131)

15 (1,0) 1130 (30) 2190 (59) 3500 (94) 4650 (125) 990 (27) 1320 (35) 1760 (47) 2310 (62)

30 (2,1) 3010 (81) 6330 (170) 8570 (230) 10430 (280) 2340 (63) 3660 (98) 5360 (144) 7170 (192)

45 (3,1) 4900 (131) 10480 (281) 13650 (366) 16220 (435) 3690 (99) 6000 (161) 8960 (240) 12030 (322)

50 (3,4) 5520 (148) 11860 (318) 15340 (411) 18140 (486) 4140 (111) 6780 (182) 10160 (272) 13650 (366)

60 (4,1) 6780 (182) 14620 (392) 18730 (502) 22000 (590) 5040 (135) 8340 (224) 12560 (337) 16890 (453)

70 (4,8) 8030 (215) 17380 (466) 22110 (593) 25850 (693) 5940 (159) 9900 (265) 14960 (401) 20130 (539)

35 (2,4) 1760 (47) 2970 (80) 4510 (121) 6490 (174) 1650 (44) 2420 (65) 3520 (94) 4840 (130)

50 (3,4) 3770 (101) 7440 (199) 11230 (301) 13750 (369) 2970 (80) 5060 (136) 7600 (204) 10390 (278)

75 (5,2) 7120 (191) 14890 (399) 22430 (601) 25850 (693) 5170 (139) 9460 (254) 14400 (386) 19640 (526)

90 (6,2) 9130 (245) 19360 (519) 29150 (781) 33110 (887) 6490 (174) 12100 (324) 18480 (495) 25190 (675)

35 (2,4) 2530 (68) 4290 (115) 6600 (177) 9130 (245) 1820 (49) 2640 (71) 3740 (100) 5060 (136)

50 (3,4) 4260 (114) 7920 (212) 12310 (330) 15320 (411) 3020 (81) 5030 (135) 7470 (200) 10060 (270)

75 (5,2) 7130 (191) 13970 (374) 21830 (585) 25650 (687) 5030 (135) 9000 (241) 13690 (367) 18400 (493)

100 (6,9) 10010 (268) 20020 (537) 31350 (840) 35970 (934) 7040 (189) 12980 (348) 19910 (534) 26730 (716)

75 (5,2) 15080 (404) 20360 (546) 23670 (634) 26040 (698) 9290 (249) 14970 (401) 19070 (511) 20510 (550)

100 (6,9) 19200 (515) 28690 (769) 31780 (852) 34820 (933) 12660 (339) 20040 (537) 24040 (644) 30340 (813)

125 (8,6) 27700 (742) 36570 (980) 40860 (1095) 15690 (420) 22930 (615) 33290 (892)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) Reduced Port NPS 1-1/2 (DN 40) Reduced Port

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Not Available5 (0,34) 1020 (27) 1830 (49) 2640 (71) 3600 (96)

10

Page 11

Table 6. Air Capacities (continued)

SPRING RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14)

8 (0,55) 940 (25) 2030 (54) 4380 (117) 6400 (172)

5 (0,34) 700 (19) 870 (23) 1400 (38) 1680 (45) 700 (19) 800 (21) 1000 (27) 1180 (32)

15 (1,0) 1640 (44) 3790 (102) 7050 (189) 8190 (219) 1150 (31) 1540 (41) 2300 (62) 3090 (83)

25 (1,7) 2570 (69) 6700 (180) 12700 (340) 14700 (394) 1600 (43) 2280 (61) 3600 (96) 5000 (134)

15 (1,0) 1640 (44) 2700 (72) 3980 (107) 5850 (157) 1200 (32) 1490 (40) 2070 (55) 2800 (75)

30 (2,1) 6480 (174) 10400 (279) 11850 (318) 13910 (373) 2240 (60) 3710 (99) 5550 (149) 7620 (204)

45 (3,1) 11330 (304) 18100 (485) 19720 (528) 21980 (589) 3270 (88) 5920 (159) 9020 (242) 12440 (333)

50 (3,4) 12940 (347) 20660 (554) 22350 (599) 24670 (661) 3620 (97) 6660 (178) 10180 (273) 14040 (376)

60 (4,1) 16170 (433) 25800 (691) 27590 (739) 30040 (805) 4310 (116) 8140 (218) 12500 (335) 17260 (463)

70 (4,8) 19400 (520) 30930 (829) 32840 (880) 35420 (949) 5000 (134) 9620 (258) 14820 (397) 20470 (549)

35 (2,4) 2770 (74) 5000 (134) 7480 (200) 10170 (273) 1600 (43) 2250 (60) 2970 (80) 4050 (109)

50 (3,4) 7100 (190) 13670 (366) 16760 (449) 19560 (524) 2880 (77) 4830 (129) 7000 (188) 9710 (260)

75 (5,2) 14310 (384) 28130 (754) 32240 (864) 35210 (944) 5020 (135) 9120 (244) 13700 (367) 19140 (513)

90 (6,2) 18640 (500) 36800 (986) 41520 (1113) 44600 (1195) 6300 (169) 11700 (314) 17730 (475) 24800 (665)

35 (2,4) 4390 (118) 6380 (171) 9500 (255) 14500 (389) 2200 (59) 3200 (86) 4400 (118) 5900 (158)

50 (3,4) 8130 (218) 13540 (363) 17810 (477) 22420 (601) 3230 (87) 5220 (140) 8050 (216) 11370 (305)

75 (5,2) 14370 (385) 25470 (683) 31660 (848) 35610 (954) 4940 (132) 8580 (230) 14140 (379) 20480 (549)

100 (6,9) 20600 (552) 37400 (1002) 45510 (1220) 48810 (1308) 6650 (178) 11940 (320) 20230 (542) 29600 (793)

75 (5,2) 16090 (431) 28300 (758) 33550 (899) 35600 (954) 9940 (266) 15430 (414) 19740 (529) 21630 (580)

100 (6,9) 21360 (572) 40070 (1074) 44020 (1180) 45650 (1223) 13730 (368) 19400 (520) 27470 (736) 34480 (924)

125 (8,6) 32190 (863) 49830 (1335) 54270 (1454) 17060 (457) 25780 (691) 36860 (988)

10% 20% 30% 40% 10% 20% 30% 40%

640 (17) 870 (23) 1000 (27) 1220 (33)

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) NPS 1-1/2 (DN 40)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Bulletin 71.4:SR8

Not Available5 (0,34) 790 (21) 1450 (39) 2690 (72) 3810 (102)

Table 6. Air Capacities (continued)

SPRING RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 6370 (171) 8950 (240) 14520 (389) 19370 (519) 4700 (126) 6830 (183) 8740 (234) 10960 (294)

15 (1,0) 11190 (300) 21560 (578) 29180 (782) 30980 (830) 7480 (200) 10050 (269) 12810 (343) 16360 (438)

25 (1,7) 21920 (587) 38350 (1028) 41540 (1113) 43490 (1166) 10470 (281) 14970 (401) 20580 (552) 25870 (693)

15 (1,0) 9880 (265) 14880 (399) 21500 (576) 26990 (723) 5730 (154) 8340 (224) 10410 (279) 11570 (310)

25 (1,7) 15660 (420) 28080 (753) 35840 (961) 39130 (1049) 9290 (249) 13240 (355) 18600 (498) 23320 (625)

50 (3,4) 40670 (1090) 56380 (1511) 62730 (1681) 66500 (1782) 17700 (474) 30300 (812) 42580 (1141) 53670 (1438)

25 (1,7) 14260 (382) 25580 (686) 37060 (993) 41230 (1105) 9210 (247) 13350 (358) 18800 (504) 23880 (640)

50 (3,4) 33210 (890) 58720 (1574) 64870 (1739) 68920 (1847) 16860 (452) 28320 (759) 40440 (1084) 51660 (1384)

60 (4,1) 56330 (1509) 83590 (2240) 89580 (2401) 27760 (744) 48800 (1308) 68490 (1836)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 2 (DN 50) NPS 2 (DN 50)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

Table 6. Air Capacities (continued)

SPRING

RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 9050 (243) 12710 (341) 18470 (495) 22500 (603) 6080 (163) 10500 (281) 14290 (383) 17430 (467)

15 (1,0) 11620 (311) 19350 (519) 26980 (723) 34790 (932) 9830 (263) 15440 (414) 20150 (540) 24400 (654)

25 (1,7) 20900 (560) 35440 (950) 49900 (1337) 55940 (1499) 15010 (402) 23530 (631) 30890 (828) 38370 (1028)

15 (1,0) 8760 (235) 13940 (374) 21320 (571) 28380 (761) 9550 (256) 14510 (389) 18960 (508) 22940 (615)

25 (1,7) 14280 (383) 28860 (773) 44090 (1182) 56210 (1506) 12500 (335) 22040 (591) 28600 (766) 36590 (981)

50 (3,4) 24390 (654) 54400 (1458) 85750 (2298) 92660 (2483) 28080 (753) 48410 (1297) 63320 (1697) 77610 (2080)

25 (1,7) 13280 (356) 25440 (682) 37430 (1003) 49380 (1323) 12360 (331) 21070 (565) 28840 (773) 35770 (959)

50 (3,4) 25950 (695) 53950 (1446) 83780 (2245) 92740 (2485) 25930 (695) 44100 (1182) 60040 (1609) 73790 (1978)

60 (4,1) 66630 (1786)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 3 (DN 80) NPS 3 (DN 80)

102120 (2737) 123800 (3318)

CAPACITIES IN SCFH (Nm3/h) OF AIR AT % BUILD-UP

41530 (1113) 68970 (1848) 92510 (2479)

11

Page 12

Bulletin 71.4:SR8

Table 7. Steam Capacities

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 6.4 (2,9) 8.3 (3,8) 10 (4,5) 12 (5,4)

5 (0,34) 9.2 (4,2) 14 (6,4) 18 (8,2) 22 (10)

8 (0,55) 12 (5,4) 20 (9,1) 27 (12) 32 (15)

5 (0,34) 7.2 (3,3) 10 (4,5) 13 (5,9) 18 (8,2) 5.3 (2,4) 6.2 (2,8) 7.1 (3,2) 8.4 (3,8)

15 (1,0)

25 (1,7) 31 (14) 53 (24) 66 (30) 72 (33) 15 (6,8) 24 (11) 31 (14) 40 (18)

10 (0,69) 11 (5,0) 18 (8,2) 25 (11) 32 (15) 7.5 (3,4) 9.3 (4,2) 12 (5,4) 14 (6,4)

15 (1,0) 17 (7,7) 29 (13) 37 (17) 44 (20) 10 (4,5) 13 (5,9) 18 (8,2) 22 (10)

30 (2,1) 37 (17) 64 (29) 72 (33) 80 (36) 17 (7,7) 25 (11) 37 (17) 47 (21)

45 (3,1) 57 (26) 99 (45) 110 (50) 110 (50) 24 (11) 37 (17) 56 (25) 71 (32)

50 (3,4) 64 (29) 110 (50) 120 (54) 120 (54) 27 (12) 41 (19) 62 (28) 80 (36)

35 (2,4) 33 (15) 56 (25) 77 (35) 92 (42) 19 (8,6) 28 (13) 38 (17) 50 (23)

50 (3,4) 50 (23) 85 (39) 110 (50) 120 (54) 27 (12) 43 (20) 60 (27) 79 (36)

75 (5,2) 78 (35) 130 (59) 160 (73) 170 (77) 41 (19) 68 (31) 96 (44) 130 (59)

100 (6,9) 110 (50) 180 (82) 210 (95) 220 (100) 55 (25) 93 (42) 130 (59) 180 (82)

75 (5,2) 120 (54) 150 (68) 160 (73) 170 (77) 91 (41) 120 (54) 130 (59) 140 (64)

100 (6,9) 150 (68) 200 (91) 210 (95) 220 (100) 120 (54) 160 (73) 170 (77) 180 (82)

125 (8,6) 190 (86) 230 (104) 260 (118) 130 (59) 190 (86) 210 (95)

10% 20% 30% 40% 10% 20% 30% 40%

19 (8,6) 32 (15) 40 (18) 46 (21) 10 (4,5) 15 (6,8) 19 (8,6) 24 (11)

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 1/2 (DN 15) NPS 1/2 (DN 15)

Not Available

Table 7. Steam Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14) 8.3 (3,8) 9.9 (4,5) 14 (6,4) 17 (7,7)

5 (0,34) 16 (7,3) 28 (13) 44 (20) 49 (22)

8 (0,55) 24 (11) 47 (21) 74 (34) 80 (36)

5 (0,34) 12 (5,4) 18 (8,2) 24 (11) 31 (14) 10 (4,5) 12 (5,4) 14 (6,4) 16 (7,3)

15 (1,0) 33 (15) 69 (31) 92 (42) 100 (45) 17 (7,7) 23 (10) 29 (13) 37 (17)

25 (1,7) 53 (24) 120 (54) 150 (68) 150 (68) 25 (11) 34 (15) 45 (20) 58 (26)

10 (0,7) 16 (7,3) 24 (11) 35 (16) 49 (22) 12 (5,4) 15 (6,8) 17 (7,7) 21 (9,5)

15 (1,0) 25 (11) 44 (20) 58 (26) 75 (34) 16 (7,3) 21 (9,5) 27 (12) 33 (15)

30 (2,1) 52 (24) 100 (45) 130 (59) 150 (68) 28 (13) 40 (18) 55 (25) 70 (32)

45 (3,1) 79 (36) 160 (73) 190 (86) 230 (104) 40 (18) 60 (27) 83 (38) 110 (50)

50 (3,4) 89 (40) 180 (82) 220 (100) 260 (118) 44 (20) 66 (30) 93 (42) 120 (54)

35 (2,4) 49 (22) 100 (45) 160 (73) 200 (91) 30 (14) 42 (19) 54 (25) 68 (31)

50 (3,4) 94 (43) 180 (82) 240 (109) 260 (118) 44 (20) 63 (29) 87 (39) 110 (50)

75 (5,2) 170 (77) 300 (136) 350 (159) 370 (168) 66 (30) 98 (44) 140 (64) 190 (86)

100 (6,9) 240 (109) 420 (191) 450 (204) 480 (218) 89 (40) 130 (59) 200 (91) 270 (123)

75 (5,2) 160 (73) 300 (136) 340 (154) 370 (168) 99 (45) 170 (77) 220 (100) 250 (114)

100 (6,9) 250 (114) 420 (191) 450 (204) 480 (218) 130 (59) 180 (82) 270 (123) 350 (159)

125 (8,6) 340 (154) 520 (236) 550 (250) 160 (73) 240 (109) 350 (159)

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 3/4 (DN 20) NPS 3/4 (DN 20)

Not Available

12

Page 13

Table 7. Steam Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14)

5 (0,34) 42 (19) 75 (34) 110 (50) 150 (68)

8 (0,55) 62 (28) 110 (50) 160 (73) 210 (95)

5 (0,34) 32 (15) 43 (20) 57 (26) 75 (34) 24 (11) 30 (14) 38 (17) 45 (20)

15 (1,0) 65 (30) 120 (54) 190 (86) 240 (109) 42 (19) 61 (28) 89 (40) 120 (54)

25 (1,7) 110 (50) 220 (100) 350 (159) 440 (200) 62 (28) 93 (42) 140 (64) 200 (91)

15 (1,0) 46 (21) 88 (40) 140 (64) 190 (86) 40 (18) 53 (24) 71 (32) 93 (42)

30 (2,1) 120 (54) 250 (114) 340 (154) 420 (191) 94 (43) 150 (68) 220 (100) 290 (132)

45 (3,1) 200 (91) 420 (191) 550 (250) 650 (295) 150 (68) 240 (109) 360 (163) 480 (218)

50 (3,4) 220 (100) 480 (218) 620 (281) 730 (331) 170 (77) 270 (123) 410 (186) 550 (250)

60 (4,1) 270 (123) 590 (268) 750 (341) 880 (400) 200 (91) 340 (154) 510 (232) 680 (309)

70 (4,8) 320 (145) 700 (318) 890 (404) 1010 (459) 240 (109) 400 (182) 600 (272) 810 (368)

35 (2,4) 71 (32) 120 (54) 180 (82) 260 (118) 66 (30) 97 (44) 140 (64) 190 (86)

50 (3,4) 150 (68) 300 (136) 450 (204) 550 (250) 120 (54) 200 (91) 310 (141) 420 (191)

75 (5,2) 290 (132) 600 (272) 900 (409) 1040 (472) 210 (95) 380 (173) 580 (263) 790 (359)

90 (6,2) 370 (168) 780 (354) 1170 (531) 1260 (572) 260 (118) 490 (222) 740 (336) 1010 (459)

35 (2,4) 100 (45) 170 (77) 270 (123) 370 (168) 73 (33) 110 (50) 150 (68) 200 (91)

50 (3,4) 170 (77) 320 (145) 500 (227) 620 (281) 120 (54) 200 (91) 300 (136) 400 (182)

75 (5,2) 290 (132) 560 (254) 880 (400) 1030 (468) 200 (91) 360 (163) 550 (250) 740 (336)

100 (6,9) 400 (182) 810 (368) 1260 (572) 1380 (627) 280 (127) 520 (236) 800 (363) 1080 (490)

75 (5,2) 630 (286) 920 (418) 1000 (454) 1070 (486) 420 (191) 640 (291) 810 (368) 840 (381)

100 (6,9) 910 (413) 1200 (545) 1290 (586) 1380 (627) 510 (232) 830 (377) 950 (431) 1150 (522)

125 (8,6) 1100 (499) 1470 (667) 1580 (717) 660 (300) 1060 (481) 1270 (577)

27 (12) 39 (18) 49 (22) 70 (32)

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 1 (DN 25) NPS 1 (DN 25)

Bulletin 71.4:SR8

Not Available

Table 7. Steam Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 30 (14) 43 (20) 54 (24) 77 (35)

8 (0,55) 68 (31) 120 (54) 180 (82) 230 (104)

5 (0,34) 35 (16) 47 (21) 62 (28) 82 (37) 26 (12) 33 (15) 42 (19) 50 (23)

15 (1,0) 72 (33) 130 (59) 210 (95) 260 (118) 47 (21) 67 (30) 98 (44) 130 (59)

25 (1,7) 120 (54) 240 (109) 380 (173) 470 (213) 68 (31) 100 (45) 160 (73) 220 (100)

15 (1,0) 50 (23) 97 (44) 150 (68) 210 (95) 44 (20) 58 (26) 78 (35) 100 (45)

30 (2,1) 130 (59) 280 (127) 380 (173) 460 (209) 100 (45) 160 (73) 240 (109) 320 (145)

45 (3,1) 220 (100) 460 (209) 600 (272) 720 (327) 160 (73) 270 (123) 400 (182) 530 (241)

50 (3,4) 240 (109) 520 (236) 680 (309) 800 (363) 180 (82) 300 (136) 450 (204) 600 (272)

60 (4,1) 300 (136) 650 (295) 830 (377) 940 (427) 220 (100) 370 (168) 560 (254) 750 (341)

70 (4,8) 360 (163) 770 (350) 980 (445) 1070 (486) 260 (118) 440 (200) 660 (300) 890 (404)

35 (2,4) 78 (35) 130 (59) 200 (91) 290 (132) 73 (33) 110 (50) 160 (73) 210 (95)

50 (3,4) 170 (77) 330 (150) 500 (227) 610 (277) 130 (59) 220 (100) 340 (154) 460 (209)

75 (5,2) 320 (145) 660 (300) 990 (449) 1140 (518) 230 (104) 420 (191) 640 (291) 870 (395)

90 (6,2) 400 (182) 860 (390) 1250 (568) 1340 (608) 290 (132) 540 (245) 820 (372) 1110 (504)

35 (2,4) 110 (50) 190 (86) 290 (132) 400 (182) 80 (36) 120 (54) 170 (77) 220 (100)

50 (3,4) 190 (86) 350 (159) 540 (245) 680 (309) 130 (59) 220 (100) 330 (150) 450 (204)

75 (5,2) 320 (145) 620 (281) 970 (440) 1140 (518) 220 (100) 400 (182) 610 (277) 810 (368)

100 (6,9) 440 (200) 890 (404) 1380 (627) 1470 (667) 310 (141) 570 (259) 880 (400) 1180 (536)

75 (5,2) 670 (304) 900 (409) 1050 (477) 1140 (518) 410 (186) 660 (300) 840 (381) 910 (413)

100 (6,9) 850 (386) 1270 (577) 1380 (627) 1470 (667) 560 (254) 890 (404) 1060 (481) 1340 (608)

125 (8,6) 1230 (558) 1570 (713) 1690 (767) 690 (313) 1010 (459) 1470 (667)

10% 20% 30% 40% 10% 20% 30% 40%

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) Reduced Port NPS 1-1/2 (DN 40) Reduced Port

Not Available5 (0,34) 46 (21) 83 (38) 120 (54) 160 (73)

13

Page 14

Bulletin 71.4:SR8

Table 7. Steam Capacities (continued)

SPRING RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14)

8 (0,55) 42 (19) 91 (41) 200 (91) 290 (132)

5 (0,34) 32 (15) 40 (18) 64 (29) 76 (35) 32 (15) 36 (16) 45 (20) 53 (24)

15 (1,0) 72 (33) 170 (77) 310 (141) 360 (163) 51 (23) 68 (31) 102 (46) 140 (64)

25 (1,7) 110 (50) 300 (136) 560 (254) 650 (295) 71 (32) 100 (45) 160 (73) 220 (100)

15 (1,0) 73 (33) 120 (54) 180 (82) 260 (118) 53 (24) 66 (30) 92 (42) 120 (54)

30 (2,1) 290 (132) 460 (209) 520 (236) 620 (281) 100 (45) 160 (73) 250 (114) 340 (154)

45 (3,1) 500 (227) 800 (363) 870 (395) 970 (440) 140 (64) 260 (118) 400 (182) 550 (250)

50 (3,4) 570 (259) 910 (413) 990 (449) 1090 (495) 160 (73) 290 (132) 450 (204) 620 (281)

60 (4,1) 720 (327) 1140 (518) 1220 (554) 1330 (604) 190 (86) 360 (163) 550 (250) 760 (345)

70 (4,8) 860 (390) 1350 (613) 1440 (654) 1540 (699) 220 (100) 430 (195) 660 (300) 910 (413)

35 (2,4) 123 (56) 220 (100) 330 (150) 450 (204) 71 (32) 100 (45) 130 (59) 180 (82)

50 (3,4) 310 (141) 610 (277) 740 (336) 870 (395) 130 (59) 210 (95) 310 (141) 430 (195)

75 (5,2) 630 (286) 1240 (563) 1430 (649) 1560 (708) 220 (100) 400 (182) 610 (277) 850 (386)

90 (6,2) 820 (372) 1630 (740) 1800 (817) 1920 (872) 280 (127) 520 (236) 780 (354) 1100 (499)

35 (2,4) 190 (86) 280 (127) 420 (191) 640 (291) 97 (44) 140 (64) 190 (86) 260 (118)

50 (3,4) 360 (163) 600 (272) 790 (359) 990 (449) 140 (64) 230 (104) 360 (163) 500 (227)

75 (5,2) 640 (291) 1130 (513) 1400 (636) 1580 (717) 220 (100) 380 (173) 630 (286) 910 (413)

100 (6,9) 910 (413) 1660 (754) 1980 (899) 2110 (958) 290 (132) 530 (241) 900 (409) 1310 (595)

75 (5,2) 710 (322) 1250 (568) 1480 (672) 1580 (717) 440 (200) 680 (309) 870 (395) 960 (436)

100 (6,9) 950 (431) 1770 (804) 1950 (885) 2020 (917) 610 (277) 860 (390) 1220 (554) 1530 (695)

125 (8,6) 1420 (645) 2210 (1003) 2400 (1090) 760 (345) 1140 (518) 1630 (740)

10% 20% 30% 40% 10% 20% 30% 40%

30 (14) 40 (18) 46 (21) 56 (25)

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) NPS 1-1/2 (DN 40)

Not Available5 (0,34) 36 (16) 66 (30) 120 (54) 170 (77)

Table 7. Steam Capacities (continued)

SPRING RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 280 (127) 400 (182) 640 (291) 860 (390) 210 (95) 300 (136) 390 (177) 490 (222)

15 (1,0) 500 (227) 950 (431) 1190 (540) 1240 (563) 330 (150) 440 (200) 570 (259) 720 (327)

25 (1,7) 970 (440) 1560 (708) 1650 (749) 1740 (790) 460 (209) 660 (300) 910 (413) 1140 (518)

15 (1,0) 440 (200) 660 (300) 950 (431) 1190 (540) 250 (114) 370 (168) 460 (209) 510 (232)

25 (1,7) 690 (313) 1240 (563) 1590 (722) 1730 (785) 410 (186) 590 (268) 820 (372) 1030 (468)

50 (3,4) 1800 (817) 2500 (1135) 2780 (1262) 2940 (1335) 780 (354) 1340 (608) 1880 (854) 2380 (1081)

25 (1,7) 630 (286) 1130 (513) 1640 (745) 1740 (790) 410 (186) 590 (268) 830 (377) 1060 (481)

50 (3,4) 1470 (667) 2600 (1180) 2800 (1271) 2970 (1348) 750 (341) 1250 (568) 1790 (813) 2290 (1040)

60 (4,1) 2490 (1130) 3680 (1671) 3940 (1789) 1230 (558) 2160 (981) 3030 (1376)

10% 20% 30% 40% 10% 20% 30% 40%

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 2 (DN 50) NPS 2 (DN 50)

Table 7. Steam Capacities (continued)

SPRING

RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 400 (182) 560 (254) 820 (372) 1000 (454) 270 (123) 470 (213) 630 (286) 770 (350)

15 (1,0) 510 (232) 860 (390) 1190 (540) 1540 (699) 440 (200) 680 (309) 890 (404) 1080 (490)

25 (1,7) 930 (422) 1570 (713) 2210 (1003) 2410 (1094) 660 (300) 1040 (472) 1370 (622) 1700 (772)

15 (1,0) 390 (177) 620 (281) 940 (427) 1260 (572) 420 (191) 640 (291) 840 (381) 1020 (463)

25 (1,7) 630 (286) 1280 (581) 1950 (885) 2410 (1094) 550 (250) 980 (445) 1270 (577) 1620 (735)

50 (3,4) 1080 (490) 2410 (1094) 3800 (1725) 4100 (1861) 1240 (563) 2140 (972) 2800 (1271) 3430 (1557)

25 (1,7) 590 (268) 1130 (513) 1660 (754) 2190 (994) 550 (250) 930 (422) 1280 (581) 1580 (717)

50 (3,4) 1150 (522) 2390 (1085) 3710 (1684) 4100 (1861) 1150 (522) 1950 (885) 2660 (1208) 3270 (1485)

60 (4,1) 2950 (1339) 4520 (2052) 5460 (2479) 1840 (835) 3050 (1385) 4090 (1857)

10% 20% 30% 40% 10% 20% 30% 40%

CAPACITIES IN POUNDS PER HOUR (kg/h) SATURATED STEAM AT % BUILD-UP

Elastomer Diaphragm Metal Diaphragm

NPS 3 (DN 80) NPS 3 (DN 80)

14

Page 15

Table 8. Liquid Capacities

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 0.7 (2,6) 0.9 (3,4) 1.1 (4,2) 1.2 (4,5)

5 (0,34) 1.1 (4,2) 1.6 (6,1) 2.1 (7,9) 2.6 (9,8)

8 (0,55) 1.5 (5,7) 2.5 (9,5) 3.3 (12) 4.1 (16)

5 (0,34) 0.8 (3,0) 1.2 (4,5) 1.6 (6,1) 2.1 (7,9) 0.7 (2,6) 0.9 (3,4) 1.0 (3,8) 1.2 (4,5)

15 (1,0)

25 (1,7) 3.3 (12) 5.6 (21) 6.8 (26) 7.2 (27) 2.1 (7,9) 3.1 (12) 3.9 (15) 4.9 (19)

10 (0,69) 1.3 (4,9) 2.2 (8,3) 3.1 (12) 4.1 (16) 1.2 (4,5) 1.4 (5,3) 1.8 (6,8) 2.1 (7,9)

15 (1,0) 2.2 (8,3) 3.6 (14) 4.4 (17) 5.2 (20) 1.5 (5,7) 2.0 (7,6) 2.6 (9,8) 3.2 (12)

30 (2,1) 3.8 (14) 6.3 (24) 6.9 (26) 7.5 (28) 2.1 (7,9) 3.1 (12) 4.3 (16) 5.4 (20)

45 (3,1) 5.0 (19) 8.4 (32) 8.7 (33) 9.0 (34) 2.6 (10) 3.9 (15) 5.6 (21) 7.0 (26)

50 (3,4) 5.4 (20) 8.8 (33) 9.1 (34) 9.4 (36) 2.8 (11) 4.1 (16) 6.0 (23) 7.5 (28)

35 (2,4) 3.2 (12) 5.2 (20) 7.0 (26) 8.1 (31) 2.2 (8,3) 3.3 (12) 4.2 (16) 5.4 (20)

50 (3,4) 4.2 (16) 6.9 (26) 8.8 (33) 9.4 (36) 2.8 (11) 4.3 (16) 5.8 (22) 7.5 (28)

75 (5,2) 5.6 (21) 9.1 (34) 11 (42) 11 (42) 3.6 (14) 5.8 (22) 7.9 (30) 10 (38)

100 (6,9) 6.7 (25) 11 (42) 12 (45) 13 (49) 4.3 (16) 6.9 (26) 9.5 (36) 12 (45)

75 (5,2) 8.3 (31) 10 (38) 11 (42) 11 (42) 8.0 (30) 10 (38) 11 (42) 11 (42)

100 (6,9) 9.2 (35) 12 (45) 12 (45) 13 (49) 8.9 (34) 12 (45) 12 (45) 13 (49)

125 (8,6) 11 (42) 13 (49) 13 (49) 9.2 (35) 13 (49) 14 (53)

10% 20% 30% 40% 10% 20% 30% 40%

2.4 (9,1) 3.9 (15) 4.8 (18) 5.5 (21) 1.6 (6,1) 2.3 (8,7) 2.8 (11) 3.5 (13)

Elastomer Diaphragm Metal Diaphragm

NPS 1/2 (DN 15) NPS 1/2 (DN 15)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Bulletin 71.4:SR8

Not Available

Table 8. Liquid Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

10 to 50

(0,69 to 3,4)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10% 20% 30% 40% 10% 20% 30% 40%

2 (0,14) 0.9 (3,4) 1.0 (3,8) 1.4 (5,3) 1.8 (6,8)

8 (0,55) 3.1 (12) 6.0 (23) 9.5 (36) 10 (38)

5 (0,34) 1.4 (5,3) 2.1 (7,9) 3.0 (11) 3.8 (14) 1.2 (4,5) 1.4 (5,3) 1.6 (6,1) 2.0 (7,6)

15 (1,0) 4.2 (16) 8.9 (34) 12 (45) 13 (49) 2.3 (8,7) 3.0 (11) 3.8 (14) 4.7 (18)

25 (1,7) 6.3 (24) 14 (53) 16 (61) 17 (64) 2.9 (11) 3.9 (15) 5.1 (19) 6.3 (24)

10 (0,69) 2.1 (7,9) 3.2 (12) 4.6 (17) 6.4 (24) 1.5 (5,7) 1.9 (7,2) 2.2 (8,3) 2.7 (10)

15 (1,0) 3.3 (12) 5.7 (22) 7.5 (28) 9.7 (37) 2.1 (7,9) 2.7 (10) 3.4 (13) 4.3 (16)

30 (2,1) 5.8 (22) 11 (42) 13 (49) 16 (61) 3.1 (12) 4.4 (17) 5.8 (22) 7.2 (27)

45 (3,1) 7.7 (29) 15 (57) 18 (68) 21 (79) 3.9 (15) 5.6 (21) 7.5 (28) 9.4 (36)

50 (3,4) 8.2 (31) 16 (61) 19 (72) 22 (83) 4.1 (16) 5.9 (22) 8.0 (30) 10 (38)

35 (2,4) 5.2 (20) 11 (42) 16 (61) 19 (72) 3.2 (12) 4.3 (16) 5.4 (20) 6.6 (25)

50 (3,4) 8.7 (33) 16 (61) 21 (79) 22 (83) 4.0 (15) 5.6 (21) 7.6 (29) 9.6 (36)

75 (5,2) 13 (49) 23 (87) 26 (98) 26 (98) 5.2 (20) 7.4 (28) 10 (38) 14 (53)

100 (6,9) 17 (64) 28 (106) 29 (110) 30 (114) 6.1 (23) 8.8 (33) 13 (49) 17 (64)

75 (5,2) 13 (49) 22 (83) 25 (95) 26 (98) 7.8 (30) 13 (49) 16 (61) 18 (68)

100 (6,9) 17 (64) 28 (106) 29 (110) 30 (114) 8.7 (33) 12 (45) 17 (64) 21 (79)

125 (8,6) 21 (79) 31 (117) 32 (121) 9.7 (37) 15 (57) 20 (76)

Elastomer Diaphragm Metal Diaphragm

NPS 3/4 (DN 20) NPS 3/4 (DN 20)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Not Available5 (0,34) 1.9 (7,2) 3.4 (13) 5.3 (20) 6.0 (23)

15

Page 16

Bulletin 71.4:SR8

Table 8. Liquid Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 2.7 (10) 3.8 (14) 4.9 (19) 6.9 (26)

8 (0,55) 6.5 (25) 11 (42) 17 (64) 22 (83)

5 (0,34) 3.2 (12) 4.4 (17) 5.8 (22) 7.7 (29) 2.4 (9,1) 3.1 (12) 3.9 (15) 4.7 (18)

15 (1,0) 6.9 (26) 13 (49) 20 (76) 25 (95) 4.5 (17) 6.4 (24) 9.4 (36) 13 (49)

25 (1,7) 11 (42) 21 (79) 32 (121) 40 (151) 6.1 (23) 8.8 (33) 13 (49) 18 (68)

15 (1,0) 4.8 (18) 9.3 (35) 15 (57) 20 (76) 4.2 (16) 5.6 (21) 7.4 (28) 9.7 (37)

30 (2,1) 11 (42) 23 (87) 30 (114) 35 (132) 8.7 (33) 13 (49) 19 (72) 24 (91)

45 (3,1) 16 (61) 32 (121) 41 (155) 47 (178) 12 (45) 19 (72) 27 (102) 35 (132)

50 (3,4) 17 (64) 35 (132) 44 (167) 50 (189) 13 (49) 20 (76) 29 (110) 38 (144)

60 (4,1)

70 (4,8) 21 (79) 45 (170) 55 (208) 60 (227) 16 (61) 25 (95) 37 (140) 48 (182)

35 (2,4) 6.2 (23) 10 (38) 15 (57) 21 (79) 5.8 (22) 8.2 (31) 12 (45) 16 (61)

50 (3,4) 12 (45) 22 (83) 32 (121) 38 (144) 9.1 (34) 15 (57) 22 (83) 29 (110)

75 (5,2) 18 (68) 37 (140) 54 (204) 60 (227) 13 (49) 24 (91) 35 (132) 46 (174)

90 (6,2) 22 (83) 45 (170) 65 (246) 67 (254) 16 (61) 28 (106) 41 (155) 54 (204)

35 (2,4) 8.9 (34) 15 (57) 22 (83) 29 (110) 6.4 (24) 9.0 (34) 12 (45) 16 (61)

50 (3,4) 13 (49) 23 (87) 35 (132) 43 (163) 9.2 (35) 15 (57) 21 (79) 28 (106)

75 (5,2) 18 (68) 35 (132) 53 (201) 60 (227) 13 (49) 22 (83) 33 (125) 43 (163)

100 (6,9) 23 (87) 44 (167) 67 (254) 71 (269) 16 (61) 29 (110) 42 (159) 55 (208)

75 (5,2)

100 (6,9) 52 (197) 66 (250) 68 (257) 71 (269) 29 (110) 45 (170) 50 (189) 59 (223)

125 (8,6) 57 (216) 73 (276) 76 (288) 34 (129) 52 (197) 61 (231)

10% 20% 30% 40% 10% 20% 30% 40%

19 (72) 40 (151) 50 (189) 56 (212) 14 (53) 23 (87) 33 (125) 43 (163)

40 (151) 57 (216) 60 (227) 62 (235) 27 (102) 40 (151) 49 (185) 49 (185)

Elastomer Diaphragm Metal Diaphragm

NPS 1 (DN 25) NPS 1 (DN 25)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Not Available5 (0,34) 4.3 (16) 7.7 (29) 11 (42) 15 (57)

Table 8. Liquid Capacities (continued)

SPRING

RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14)

5 (0,34)

8 (0,55)

5 (0,34) 3.5 (13) 4.8 (18) 6.4 (24) 8.4 (32) 2.6 (9,8) 3.3 (12) 4.3 (16) 5.1 (19)

15 (1,0) 7.5 (28) 14 (53) 22 (83) 27 (102) 4.9 (19) 7.0 (26) 10 (38) 14 (53)

25 (1,7) 11 (42) 22 (83) 34 (129) 41 (155) 6.4 (24) 9.4 (36) 14 (53) 19 (72)

15 (1,0) 5.3 (20) 10 (38) 16 (61) 21 (79) 4.6 (17) 6.1 (23) 8.1 (31) 11 (42)

30 (2,1) 12 (45) 24 (91) 32 (121) 38 (144) 9.2 (35) 14 (53) 20 (76) 26 (98)

45 (3,1) 17 (64) 34 (129) 43 (163) 50 (189) 12 (45) 20 (76) 28 (106) 37 (140)

50 (3,4) 18 (68) 37 (140) 47 (178) 53 (201) 13 (49) 21 (79) 31 (117) 40 (151)

60 (4,1) 20 (76) 43 (163) 53 (201) 58 (220) 15 (57) 24 (91) 35 (132) 46 (174)

70 (4,8) 23 (87) 47 (178) 58 (220) 62 (235) 17 (64) 27 (102) 39 (148) 51 (193)

35 (2,4) 6.5 (25) 11 (42) 16 (61) 22 (83) 6.1 (23) 8.7 (33) 12 (45) 16 (61)

50 (3,4) 12 (45) 23 (87) 34 (129) 41 (155) 9.7 (37) 16 (61) 23 (87) 31 (117)

75 (5,2) 20 (76) 39 (148) 57 (216) 64 (242) 14 (53) 25 (95) 37 (140) 49 (185)

90 (6,2) 23 (87) 47 (178) 67 (254) 69 (261) 17 (64) 30 (114) 44 (167) 58 (220)

35 (2,4) 9.4 (36) 15 (57) 23 (87) 31 (117) 6.8 (26) 9.5 (36) 13 (49) 17 (64)

50 (3,4) 14 (53) 25 (95) 37 (140) 45 (170) 9.8 (37) 16 (61) 23 (87) 30 (114)

75 (5,2) 20 (76) 37 (140) 56 (212) 64 (242) 14 (53) 24 (91) 35 (132) 46 (174)

100 (6,9) 24 (91) 47 (178) 70 (265) 73 (276) 17 (64) 30 (114) 45 (170) 58 (220)

75 (5,2) 42 (159) 54 (204) 61 (231) 64 (242) 26 (98) 40 (151) 49 (185) 51 (193)

100 (6,9) 47 (178) 67 (254) 70 (265) 73 (276) 31 (117) 47 (178) 54 (204) 66 (250)

125 (8,6) 61 (231) 75 (284) 78 (295) 34 (129) 48 (182) 68 (257)

10% 20% 30% 40% 10% 20% 30% 40%

2.9 (11) 4.2 (16) 5.3 (20) 7.6 (29)

4.7 (18) 8.4 (32) 12 (45) 17 (64)

7.1 (27) 13 (49) 19 (72) 24 (91)

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) Reduced Port NPS 1-1/2 (DN 40) Reduced Port

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Not Available

16

Page 17

Table 8. Liquid Capacities (continued)

SPRING RANGE,

PSIG (bar)

2 to 8

(0,14 to 0,55)

5 to 25

(0,34 to 1,7)

15 to 70

(1,0 to 4,8)

25 to 90

(1,7 to 6,2)

35 to 100

(2,4 to 6,9)

75 to 125

(5,2 to 8,6)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

2 (0,14) 2.9 (11) 3.9 (15) 4.5 (17) 5.5 (21)

8 (0,55) 4.4 (17) 9.4 (36) 20 (76) 30 (114)

5 (0,34) 3.2 (12) 4.0 (15) 6.5 (25) 7.8 (30) 3.2 (12) 3.7 (14) 4.6 (17) 5.5 (21)

15 (1,0) 7.6 (29) 18 (68) 32 (121) 37 (140) 5.3 (20) 7.1 (27) 11 (42) 14 (53)

25 (1,7) 11 (42) 29 (110) 53 (201) 60 (227) 7.1 (27) 9.9 (37) 15 (57) 21 (79)

15 (1,0) 7.6 (29) 12 (45) 18 (68) 27 (102) 5.6 (21) 6.9 (26) 9.5 (36) 13 (49)

30 (2,1) 27 (102) 42 (159) 47 (178) 53 (201) 9.4 (36) 15 (57) 22 (83) 29 (110)

45 (3,1) 41 (155) 63 (238) 67 (254) 72 (273) 12 (45) 21 (79) 30 (114) 41 (155)

50 (3,4) 45 (170) 69 (261) 72 (273) 77 (291) 13 (49) 22 (83) 33 (125) 44 (167)

60 (4,1) 52 (197) 80 (303) 83 (314) 87 (329) 14 (53) 25 (95) 38 (144) 50 (189)

70 (4,8) 59 (223) 89 (337) 92 (348) 95 (360) 15 (57) 28 (106) 42 (159) 56 (212)

35 (2,4) 11 (42) 19 (72) 28 (106) 37 (140) 6.3 (24) 8.6 (33) 11 (42) 15 (57)

50 (3,4) 25 (95) 46 (174) 54 (204) 61 (231) 10 (38) 16 (61) 23 (87) 30 (114)

75 (5,2) 42 (159) 79 (299) 88 (333) 93 (352) 15 (57) 26 (98) 37 (140) 51 (193)

90 (6,2) 50 (189) 96 (363) 100 (379) 110 (416) 17 (64) 31 (117) 45 (170) 60 (227)

35 (2,4) 17 (64) 24 (91) 35 (132) 53 (201) 8.7 (33) 12 (45) 16 (61) 21 (79)

50 (3,4) 28 (106) 45 (170) 58 (220) 70 (265) 11 (42) 17 (64) 26 (98) 36 (136)

75 (5,2) 42 (159) 72 (273) 86 (326) 94 (356) 14 (53) 24 (91) 39 (148) 54 (204)

100 (6,9) 53 (201) 93 (352) 110 (416) 110 (416) 17 (64) 30 (114) 49 (185) 69 (261)

75 (5,2) 47 (178) 80 (303) 91 (344) 94 (356) 29 (110) 44 (167) 54 (204) 57 (216)

100 (6,9) 55 (208) 100 (379) 110 (416) 110 (416) 36 (136) 48 (182) 66 (250) 80 (303)

125 (8,6) 75 (284) 110 (416) 120 (454) 40 (151) 58 (220) 80 (303)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 1-1/2 (DN 40) NPS 1-1/2 (DN 40)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Bulletin 71.4:SR8

Not Available5 (0,34) 3.6 (14) 6.7 (25) 12 (45) 18 (68)

Table 8. Liquid Capacities (continued)

SPRING RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 32 (121) 45 (170) 72 (273) 95 (360) 23 (87) 33 (125) 42 (159) 52 (197)

15 (1,0) 53 (201) 99 (375) 120 (454) 120 (454) 34 (129) 44 (167) 55 (208) 69 (261)

25 (1,7) 88 (333) 140 (530) 140 (530) 150 (568) 41 (155) 56 (212) 75 (284) 92 (348)

15 (1,0) 46 (174) 68 (257) 96 (363) 120 (454) 26 (98) 37 (140) 45 (170) 49 (185)

25 (1,7) 63 (238) 110 (416) 140 (530) 150 (568) 36 (136) 50 (189) 68 (257) 83 (314)

50 (3,4) 130 (492) 170 (643) 180 (681) 190 (719) 53 (201) 88 (333) 120 (454) 150 (568)

25 (1,7) 58 (220) 100 (379) 140 (530) 150 (568) 36 (136) 50 (189) 69 (261) 85 (322)

50 (3,4) 100 (379) 180 (681) 190 (719) 190 (719) 51 (193) 82 (310) 110 (416) 140 (530)

60 (4,1) 150 (568) 210 (795) 220 (833) 71 (269) 120 (454) 160 (606)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 2 (DN 50) NPS 2 (DN 50)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

Table 8. Liquid Capacities (continued)

SPRING

RANGE,

PSIG (bar)

10 to 25

(0,69 to 1,7)

15 to 50

(1,0 to 3,4)

25 to 60

(1,7 to 4,1)

Shaded areas indicate conditions where maximum differential pressure for the spring range is exceeded.

SET

PRESSURE,

PSIG (bar)

10 (0,69) 42 (159) 60 (227) 85 (322) 100 (379) 28 (106) 48 (182) 64 (242) 77 (291)

15 (1,0) 50 (189) 82 (310) 110 (416) 140 (530) 42 (159) 64 (242) 81 (307) 97 (367)

25 (1,7) 78 (295) 130 (492) 180 (681) 190 (719) 55 (208) 83 (314) 110 (416) 130 (492)

15 (1,0) 38 (144) 59 (223) 88 (333) 120 (454) 40 (151) 60 (227) 77 (291) 91 (344)

25 (1,7) 53 (201) 100 (379) 160 (606) 190 (719) 45 (170) 78 (295) 98 (371) 120 (454)

50 (3,4) 70 (265) 150 (568) 230 (871) 240 (908) 79 (299) 130 (492) 170 (643) 200 (757)

25 (1,7) 49 (185) 90 (341) 130 (492) 170 (643) 45 (170) 74 (280) 99 (375) 120 (454)

50 (3,4) 75 (284) 150 (568) 230 (871) 240 (908) 73 (276) 120 (454) 160 (606) 190 (719)

60 (4,1) 160 (606) 240 (908) 280 (1060) 99 (375) 160 (606) 210 (795)

10% 20% 30% 40% 10% 20% 30% 40%

Elastomer Diaphragm Metal Diaphragm

NPS 3 (DN 80) NPS 3 (DN 80)

CAPACITIES IN GPM (l/min) WATER AT % BUILD-UP

17

Page 18

Bulletin 71.4:SR8

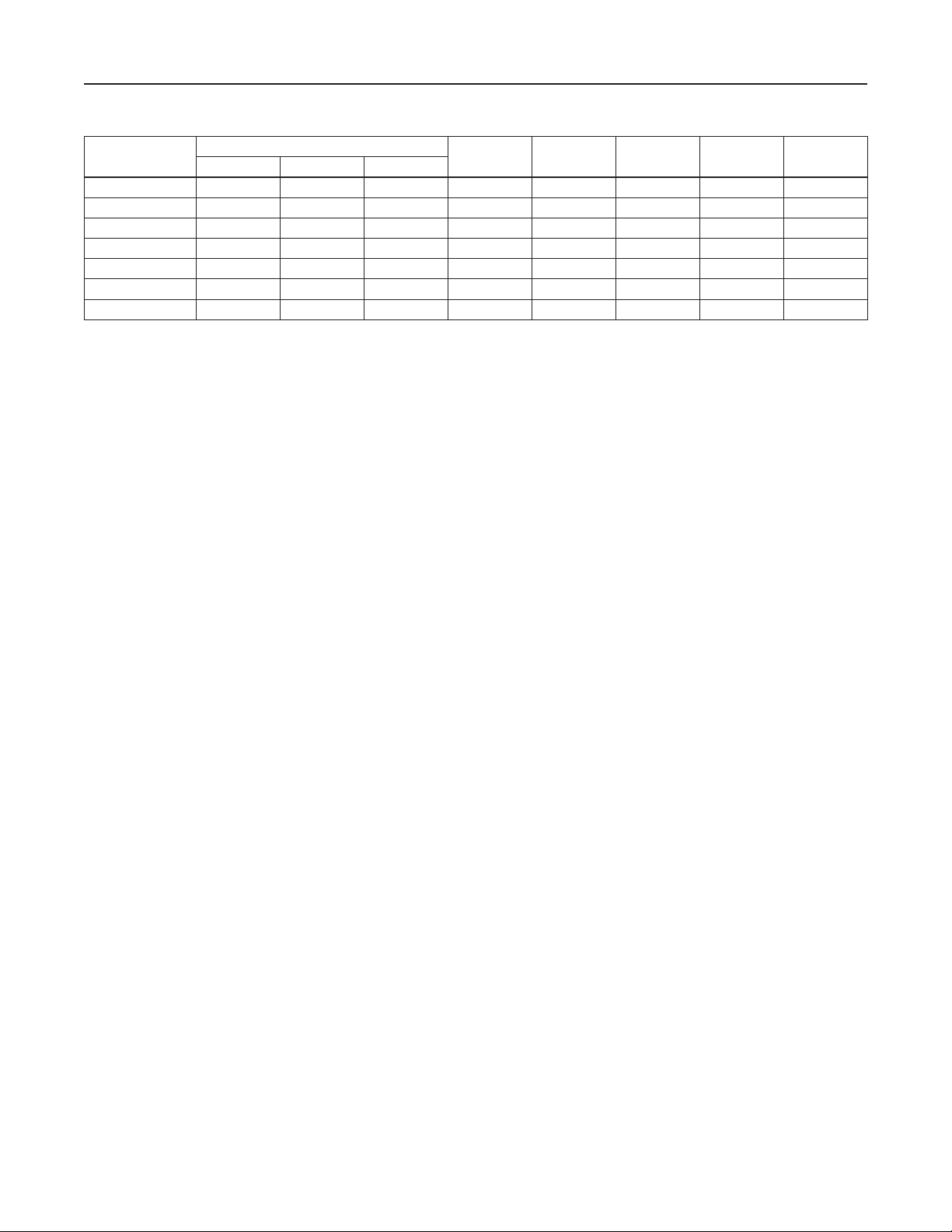

D (MAXIMUM)

G

A

OPTIONAL T-HANDLE

SIZE,

NPS (DN)

1/2 (15) 3.00 (76) 5.11 (130) 7.17 (182) 1.50 (38) 4.00 (102)

3/4 (20) 3.00 (76) 5.11 (130) 7.17 (182) 1.50 (38) 4.00 (102)

1 (25) 3.25 (83) 6.20 (158) 8.20 (208) 2.00 (51) 5.00 (127)

1-1/2 (40) 3.25 (83) 6.20 (158) 8.20 (208) 2.50 (64) 5.00 (127)

1-1/2 x 1 (40 x 25) 3.25 (83) 6.20 (158) 8.20 (208) 2.50 (64) 5.00 (127)

2 (50) 5.50 (140) 10.6 (269) 13.76 (350) 4.00 (102) 5.00 (127)

3 (80) 5.50 (140) 10.6 (269) 13.76 (350) 4.00 (102) 5.00 (127)

A C D G J

DIMENSIONS, INCHES (mm)

C

J

Figure 3. Dimensions

18

Page 19

Product Ordering Guide

Bulletin 71.4:SR8

Body Size (Select One)

¨ NPS 1/2 (DN 15)**

¨ NPS 3/4 (DN 20)**

¨ NPS 1 (DN 25)**

¨ NPS 1-1/2 x 1 (DN 40 x 25)**

¨ NPS 1-1/2 (DN 40) full port**

¨ NPS 2 (DN 50)**

¨ NPS 3 (DN 80)**

Internal Finish (Select One)

¨ 20 µin (0,5 µm) Ra**

¨ Other, please specify ______________________

Seat (Select One)

¨ Metal**

¨ Soft, Virgin PTFE**

¨ Soft Polyetheretherketone (PEEK)**

Diaphragm and O-ring Material (Select One)

¨ Ethylenepropylene (EPDM) (FDA)**

¨ PTFE coated Fluorocarbon (FKM)

(NPS 1/2 through 1-1/2 (DN 15 through 40) only)**

¨ 316L Stainless Steel with

PTFE/Fluorocarbon (FKM) O-ring**

Spring Range (Select One)

NPS 1/2 and 3/4 (DN 15 and 20)

¨ 2 to 8 psig (0,14 to 0,55 bar) (Not available with

metal diaphragm)**

¨ 5 to 25 psig (0,34 to 1,7 bar)**

¨ 10 to 50 psig (0,69 to 3,4 bar)**

¨ 35 to 100 psig (2,4 to 6,9 bar)**

¨ 75 to 125 psig (5,2 to 8,6 bar)**

NPS 1, 1-1/2, and 1-1/2 x 1 (DN 25, 40, and 40 x 25)

¨ 2 to 8 psig (0,14 to 0,55 bar) (Not available with

metal diaphragm)**

¨ 5 to 25 psig (0,34 to 1,7 bar)**

¨ 15 to 70 psig (1,0 to 4,8 bar)**

¨ 25 to 90 psig (1,7 to 6,2 bar)**

¨ 35 to 100 psig (2,4 to 6,9 bar)**

¨ 75 to 125 psig (5,2 to 8,6 bar)**

NPS 2 and 3 (DN 50 and 80)

¨ 10 to 25 psig (0,69 to 1,7 bar)**

¨ 15 to 50 psig (1,0 to 3,4 bar)**

¨ 25 to 60 psig (1,7 to 4,1 bar)**

Fisher Regulators Quick Order Guide

* * *

* *

Availability of the product being ordered is determined by the component with the

longest shipping time for the requested construction.

Standard – Readily Available for Shipment

Non-Standard – Allow Additional Time for Shipment

Special Order – Constructed from Non-Stocked Parts.

*

Consult your local Sales Ofce for Availability.

T-handle Adjusting Screw (Optional)

¨ Yes**

¨ No

Pressure Loaded Spring Case (Optional)

¨ Yes*

¨ No

Vacuum Protection (Optional – elastomer

diaphragm only)

¨ Yes*

¨ No

Certicates (Optional)

¨ 3A® (Ethylenepropylene (EPDM) and

316L Diaphragms only)**

¨ FDA Elastomers/Plastics**

¨ Materials**

¨ Functional Test**

¨ USP Class VI Elastomers/Plastics**

Parts Kit (Optional)

¨ Yes, please send a parts kit to match this order.**

¨ No

Specication Worksheet

Application:

Specic Use

Line Size

Fluid Type and Specic Gravity

Fluid Temperature

Upstream Regulator Specications:

Brand of Upstream Regulator?

Orice Size of the Upstream Regulator?

Wide-Open Coefcient of the Upstream Regulator?

Maximum Inlet Pressure (P

Downstream Pressure Setting(s)(P2)

Maximum Flow (Q

Relief Valve Specications:

Relief Valve Setpoint

Accuracy Requirements?

Need for Extremely Fast Response?

Other Requirements:

max

)

1max

)

19

Page 20

Bulletin 71.4:SR8

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.sherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 2006, 2010; All Rights Reserved

Loading...

Loading...