Emerson Sempell S Series, Sempell SO, Sempell SB, Sempell SC, Sempell SOH Operating Instructions Manual

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

Before installation these instructions must be fully read and understood

ATTENTION

This operating instruction does not specify the

extent of delivery. It is valid for several sizes,

designs, accessories and additional devices.

It contents generally exceeds the contractual

determined extent of delivery.

1 DANGER AND WARNING INDICATIONS

The construction of the Sempell safety valves

of the series S corresponds to the standard

technology and the valid safety regulations.

Nevertheless, improper use or improper

installation can cause risks for the personnel

or can lead to restrictions in regard of the

operational safety. Therefore, the Sempell

GmbH recommends the operator of the safety

valves to take appropriate measures and make

sure that the present operating instructions

are read and understood by the assigned

personnel.

Type

Series S, types SO, SC, SB, SOH full-lift

safetyvalves

Orifice letter D - Z

Design

• Spring-loaded

• With DIN and ANSI connections

• According to API Standard 526

• According to AD A2, TRD 421

For the application of a pneumatic drive A160

see corresponding operating instruction

VCIOM-02239.

Observe design data on the nameplate!

APPLICATION LIMITS

It is only allowed to use the valves according to the

details of this operating instruction and according

to the parameters and application cases agreed

in the delivery contract (see nameplate). The

application of the valve has to take place adequate

to the medium tolerances of the used materials.

WARNINGS FOR THE OPERATING AND

MAINTENANCE PERSONNEL

Before commissioning and maintenance works

familiarise yourself with the legal accident

prevention regulations, the local safety

instructions and this operating instruction and

observe them.

Use the safety valve and its individual parts and

accessories only for the purpose intended byus.

Emerson.com/FinalControl © 2017 Emerson. All rights reserved.

MA.280.01.1215 E

VCIOM-02373-EN 16/07

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

Please observe the following points besides

the notes given in the text

• Danger of burning at safety valves and with

their connected lines while operating under

increased temperature.

• Disassembly of the safety valve only in case of

pressureless plant or after cooling down.

• Protection against risks caused by

evaporation also in case of pressureless

system; for information please contact the

safety inspector concerned.

• After assembly check all sealing points in

regard of tightness.

• In case of adjustment make changes at

pressure screw and adjusting ring only with

sunstantially reduced pressure to avoid

unintended response.

• Carry ear protection during adjustment,

ifnecessary.

• Danger of burning by discharge of small

amounts of possibly hot medium in case

of safety valves with open spring bonnet

(typeSO).

• Danger of injury while discharging in case of

disconnected discharge line.

• Extreme vibrations can lead to inadmissible

increase of operating pressure with the

possibly destruction of the safety valve or to

the destruction of the balanced bellows with

unintentional escape of medium.

• In case the valve is provided with a steam

jacket or a steam flushing device, the

corresponding design must be considered

while connecting.

Plant downtimes

NOTICE

For longer system downtimes, a downtime

preservation must be carried out.

If systems are set out of operation for a shorter

or longer time, procedures (VGB - R 116)

depending on downtime duration and frequency

should be applied to preserve the system.

Limitation of liability

All specifications and notices in this instruction

manual were drawn up with consideration of

the applicable standards and regulations, the

status of technology and our longstanding

findings and experiences.

The manufacturer does not assume liability for

damages in the following cases:

• Non-adherence to this instruction manual

• Usage deviating from the intended use

• Employment of untrained personnel

• Independent reconstruction

• Technical modifications

• Usage of unauthorized spare parts

• Use of unauthorized operating media

• Improper maintenance and setting of

thevalve

• Temporary or permanent connection of

devices not authorized by us

The actual scope of delivery may deviate from

the explanations and figures described here

regarding special versions, the utilization

of additional order options or due to newest

technical modifications.

The obligations, General Business Terms and

Conditions and the delivery conditions of the

manufacturer agreed upon in the delivery

contract are applicable, along with the legal

regulations valid at the time of contract

conclusion.

2 DESCRIPTION

Spring-loaded safety valves are direct acting

safety valves with which pressure vessels

are protected against inadmissible excess

pressure.

A cylindrical compression spring creates the

closing force on the valve disc against the

opening pressure of the medium below the

valve disc. Under normal operating conditions

the valve seat is kept tight.

By changing the spring compression the

set pressure can be changed. When the set

pressure is surpassed, the pressure of the

medium prevails and the safety valve opens.

In case of full-lift characteristic the safety valve

opens abruptly over the full lift and discharges

the whole mass flow which is necessary to

prevent further increase of the pressure.

The safety valve closes again after a defined

pressure reduction.

Please observe the planning manual for the

precise design of the safety valves.

For the application of this operating instruction

please take the exact type name (e.g. SC, SB)

from the nameplate of your valve.

Use within areas exposed to danger of

explosion:

The safety valves underwent a hazard analysis

according to code 94/9/EC with the following

result:

• The safety valves do not have a potential

ignition source. ATEX 94/9/EC is not

applicable to these valves.

• The valves safety may be used in the EX area

• Electrical / pneumatically accessories have to

undergo a separate assessment of conformity

according to ATEX.

• The surface temperature does not depend

from the valve itself but from the operational

conditions. Observe while installing.

2

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

3 OPERATION

3.1 Warning indications for the operation

Observe safety regulations!

ATTENTION

Unstable behaviour of safety valves such as

chattering or vibrating can destroy the valve seat,

the safety valve or the line and thus causing the

failure of the safety function or the shutdown of

the plant.

Therefore, observe regulations and empirical

notes regarding design and dimensioning, fitting

and installation.

• Design and dimensioning: do not use larger

safety valves than necessary! In case of back

pressure use safety valves with bellows.

• Fitting and installation: design supply line

as short as possible. Use as few bends as

possible.

• Keep supply line free from vibrations. Absorb

or avoid pressure surges and waves, e. g.

caused by pumps or other valves.

• Drain the discharge line and the valve body at

their lowest point. Condensate can impair the

function of the safety valve.

• Protect lines and valve against freezing.

3.2 Storage rules

To preclude damages during loading and

unloading move the valves cautiously.

At delivery the outsides of all ferritic parts of

the safety valve are supplied with a coat of paint

except the welding edges and gasket surfaces.

The insides are protected by a watery corrosion

preservative that has a long-term effect

because of the film formative active agents.

All connection inlets are closed by

corresponding caps.

In this state the safety valve can be stored in

closed, dust-free and dry rooms lying on a

pallet without difficulties. Time of storage about

six months.

Storage of more than six months asks for a

disassembly and a visual check of the inner

parts of the safety valves. A weather-protected

outside storage is not allowed.

For spare parts out of elastic material

(O-rings, scraper rings, rod and piston

gaskets) additionally apply:

Moisture

To prevent the formation of condensate, avoid

moist storerooms. A relative humidity of

below65% is at best.

Lighting

The products of elastic materials are to protect

from direct sun light and from strong artificial

light with a high ultraviolet part. Therefore

supply the windows of the storerooms with a

red or orange (in no case blue) paint.

Ozone

Protect products of elastic materials from

ozone (formation of cracks and embrittlement).

The storeroom may not contain ozone

generating systems (fluorescing sources

of light, mercury vapour lamps, electric

motors,etc.).

Oxygen

Protect products out of elastic materials from

draught by storage in airtight boxes. Oxygen

causes cracking and embrittlement.

If these requirements are guaranteed for

products out of elastic materials the storage

time is about 5 years.

For spare parts out of steel

Store the parts in closed, dust-free and dry

rooms so that damages do not occur.

Especially the following protection measures

have to take place:

Disc (3): wax coat of the gasket, net coat

Disc holder (7): protection by net coat

3.3 Transport instructions

The welding ends or flanges are protected by

plastic caps.

The coating is a primer which is designed to

provide protection against corrosion during

transport and storage. Do not damage the layer

of coating.

Transport is only permitted on original

manufacturer’s transport items (e.g. pallets).

WARNING

Material damage due to improper transport!

If not transported properly, transport items can

fall or crash. This can result in significant material

and personal damage.

Temperature

The temperature of the storage shall be

between 0°C and 25°C since otherwise a

hardening of the material and so a shortening

of durability will follow. Shield heating elements

and lines in heated storeroom so that no direct

heat irradiation arises. The distance between

the heat source and the stocks has to be 1 m

at least.

3

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

• Proceed with caution and observe the

information on the packaging when unloading

the transport items on delivery and when

transporting internally.

• Protect the valve against bumps and blows

during transport.

• Use the attachment points provided.

• Only remove packaging just before assembly.

To preclude damages during transport move

valves by hand or with suitable lifting gears.

It is not permitted in any case to lift or transport

the valve by means of the lifting lever.

Actuator elements are not suitable as

attachment points. If the use of a lifting device

is necessary, it is preferable to wind a round

sling around the valve body and upper part in

order to transport the valve in a vertical position

to its destination.

3.4 Installation instructions

NOTE

Clean lines before installing safety valves as otherwise

the valve seats can be damaged by foreign particles

when discharging!

• Remove plastic caps protection just before

installation.

• Check plant identification and details on the

nameplate.

• Vertical installation position, inlet from

below. Prevent bracing of the valve body by

connected line.

3.5 Connection of lines

3.5.1 Inlet line

If possible arrange safety valve directly at the

nozzle of the tank to be protected. Otherwise

lay inlet line between tapping point and safety

valve as short and as low in resistance as

possible.

In no case the inlet line diameter shall be

smaller than the inlet nominal size of the

safetyvalve.

The pressure loss in the inlet line must not

exceed 3% of the set pressure at the highest

possible discharge quantity.

Check inlet line in regard of pressure vibrations

according to FBR 153 as far as possible.

ATTENTION

A pressure loss higher than the closing pressure

difference may lead to an unstable, uncontrollable

behaviour of the safety valve; chattering or

vibrating may destroy the valve seat, the safety

valve or the line and thus lead to the failure of the

safety function or to the shutdown of the plant!

In order to facilitate the drainage of

condensate, the inlet line must be mounted to

the valve with at least a 15-degree ascending

slope position.

ATTENTION

Condensate at the inlet of the safety valve

changes the functional behaviour and may lead

to an inadmissible pressure increase. Danger of

explosion!

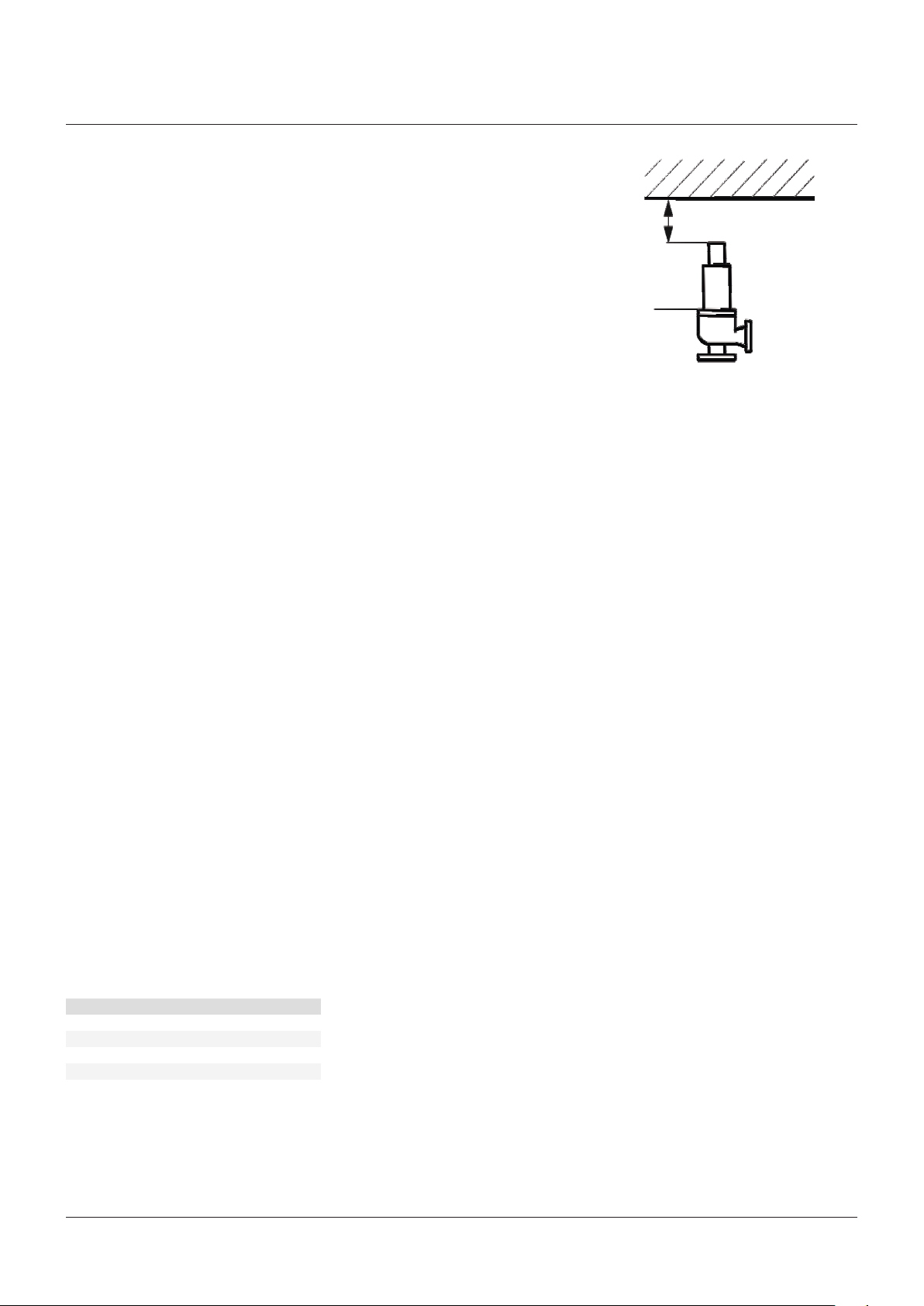

X

Y

PLEASE NOTE

Stresses at the valve body may lead to leaking at

the valve seat!

The installation point must be easily accessible

so that necessary maintenance works can be

carried out. The free space above the valve

should at least correspond to the dimensionX

(see table). In case of major valves (over 4”)

additional space should be provided for lifting

gears, at least 500 mm.

In case of hot medium, e. g. steam, insulate

supply line and valve body. The spring bonnet

must remain free. Without insulation the

produced condensate may cause malfunction.

Orifice letter Overhead dimension X (mm)

D - J 300

K - R 700

T 900

T1 1000

U - Z 1200

Y = Upper edge insulation

In case of liquids with temperatures higher than

the ambient temperature, the inlet line must

be assembled with slope to the safety valve, or

designed as a siphon-type bend in front of the

safety valve. Thereby, a heat transmission to

the safety valve is avoided which could impair

the tightness at the valve seat.

4

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

ADMISSIBLE BACK PRESSURES

Valve type Medium Maximum back pressure

SO.. Gases/vapours Superimposed back pressure constant 0% p

Superimposed back pressure variable 0% p

Built-up back pressure 15% p

SC.. Gases/vapours Superimposed back pressure constant 50% p

Superimposed back pressure variable 0% p

Built-up back pressure 15% p

Liquid Superimposed back pressure constant 80% p

Superimposed back pressure variable 0% p

Built-up back pressure 15% p

SB.. Gases/vapours Superimposed back pressure constant 50% p

Superimposed back pressure variable 50% p

Built-up back pressure 50% p

Liquid Superimposed back pressure constant 50% p

Superimposed back pressure variable 50% p

Built-up back pressure 50% p

3.5.2 Exhaust line

In no case the exhaust line diameter must be

smaller than the outlet nominal size of the

safety valve.

For valves type SO and SC back pressures

up to 15% of the set pressure and for valves

with bellows of type SB and valves with

compensating piston (SN 144) back pressures

up to 50% are acceptable unless there are

other restrictions such as mechanical loading

capacity of the bellows or insufficient strength

of the body connection flange.

ATTENTION

Higher back pressures may lead to an unstable,

uncontrollable behaviour of the safety valve;

chattering or vibrating may destroy the valve seat,

the safety valve or the line and thus lead to failure

of the safety function or to shutdown of the plant!

ATTENTION

An icy, frozen or clogged exhaust line leads to the

failure of the safety function! Dangerof explosion

in case of excess-pressure!

At the deepest point the exhaust line must be

equipped with a drain large enough to enable

the discharge of minor leaks, e. g. in case of

untight valve seat. Particularly in the open air

exhaust line, valve body and drain must be

protected against icing and freezing, e.g. by

(electrical) trace heating; merely insulating is

not sufficient!

CAUTION

In case of several safety valves with one common

exhaust line, take special safety precautions for

disassembling of only one safety valve to exclude

danger in case of unintended discharge of other

safety valves!

Recommendation! Sound isolate exhaust line

and/or provide the same with silencer; in doing

so, regard allowable back pressure!

3.6 Pressure test of installation

The response of the safety valve must be

prevented.

Either flange off the safety valve and close

the supply line with a blind flange or block

the valve. In case of welded-in safety valve a

pressure test insert can be used.

ATTENTION

In case of a blocked safety valve the test pressure

can amount up to 1.5 × of the set pressure without

consultation with Sempell.

5

35

U - Z

21.1

20

U - Z

21.1

20

SEMPELL SERIES S, TYPES SO, SC, SB, SOH FULL-LIFT SAFETY VALVES

OPERATING INSTRUCTIONS

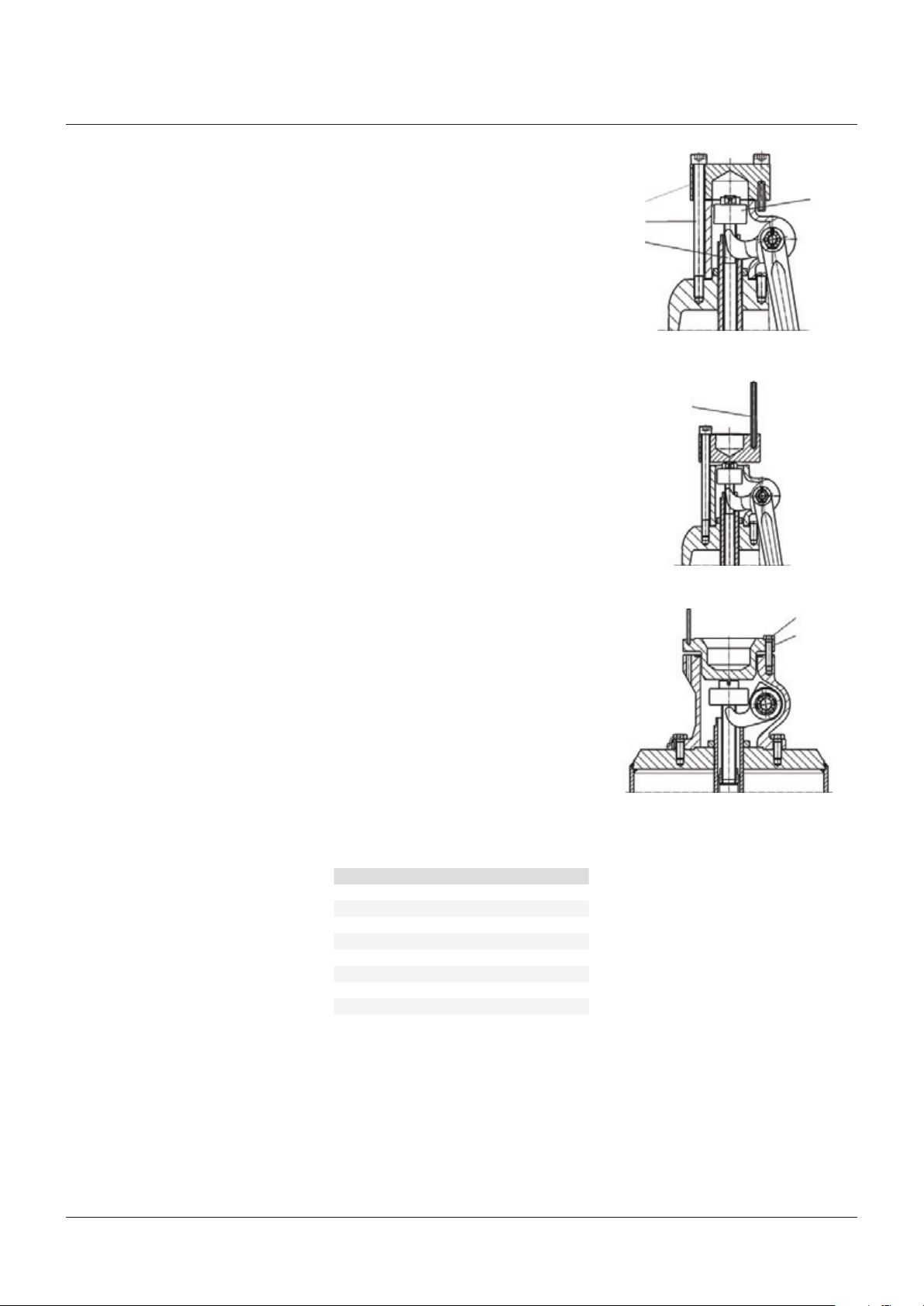

For orifice D to T1 loosen the 4 cap bolts

(21) and for orifice U to Z the four hexagonal

screws (21.1). Remove the cap top (20) and put

it reversed on place again. Now it rests on the

spindle end (11) and will be retightened again.

Now the valve is blocked. The signal pin (35)

or the blocking screw fixed in the cap top (20)

points upward and so shows the blocked state.

ATTENTION

After the pressure test restore and control the

ready-to-operate state.

3.7 Commissioning

The blocking screw must be removed for all

valves delivered in the blocked position.

The safety valve is ready for operation.

Theset pressure is adjusted and lead sealed

to prevent unauthorized adjustment. Higher

medium temperatures can lower the response

point by about 1% per 100 °C and require a

readjustment under operating conditions.

Please take standard values from the table in

section 3.9, “Adjustment of the set pressure”.

3.8 Operational test, discharge test

The function and reliability of the safety

valves, type S, have been proved by a type test

conducted by the US National Board of Boiler

and Pressure Vessels Inspectors as well as

by a component test according to VdTÜV 966.

Therefore, an operational test in the plant

need not be conducted and is restricted to

exceptions, normally at the time of revision of

steam boiler safety valves.

Before discharge test, apply ear plugs.

Slowly increase the operating pressure in the

plant until the safety valve is fully opened.

Lower the operating pressure until the safety

valve closes.

In case of several discharge tests with hot

steam allow intermediate cooling down of the

safety valve as, caused by the heating of the

spring, a slight decrease of the set pressure is

possible.

ATTENTION

In case of safety valves, type SO.. (with open valve

bonnet) some leaking medium may pass out

at the bonnet (12) when discharging. Danger of

scalding by steam!

3.9 Adjusting the set pressure

ATTENTION

A change of the lead sealed spring adjustment

must only take place in the presence of the

competent inspector.

The adjustment of the set pressure takes place

on the test stand. It shall be adjusted in the

plant only if there is no other possibility.

In any case the adjustment in the plant should

be applied with the pneumatic measuring

device A143 as by means of this device the set

pressure can be adjusted without increasing

the operating pressure (see Technische Schrift

KW 271: Sesi-Test, “Mobile Device A 143 for the

Test of Spring-loaded Safety Valves”.)

Apply ear plugs.

ATTENTION

Perform adjusting works only at lowered

pressure. At operating pressure, unscheduled

response of the safety valve can occur when the

adjusting screw (17). Small amounts of leakages

can escape at the spindle guide of the adjusting

screw (17).

Remove the lead seal; take off cap (19, 20, 21).

Loosen adjusting screw nut (18). For work at

the adjusting screw (17) secure spindle (11)

(or(7.2) (at orifice U-Z), SOH) against turning

for otherwise the valve seat (2.1) or the bellows

(8) can be damaged.

Tighten adjusting screw (17) (turn right) =

setpressure higher

Loosen adjusting screw (17) (turn left) =

setpressure lower.

Secure adjusting screw (17) with adjusting

screw nut (18). Mount cap (19 ... 21) and

leadseal.

Standard values for the change of the set

pressure in % for a quarter turn of the adjusting

screw (17):

Orifice letter Change

D/E 10

F 7

G-K 4

L-N 3

P-R 1.5

T 1

T1 1

U-Z 0.5

20

21

11

U - Z

22

35

21.1

20

6

Loading...

Loading...