Page 1

Quick Start Guide

00825-0300-2654, Rev FA

February 2020

Rosemount™ Volume 1 Sensor Assembly

Page 2

Quick Start Guide February 2020

Contents

About this guide...........................................................................................................................3

Wiring diagrams...........................................................................................................................4

Rosemount Series 58C sheath cutting ......................................................................................... 5

Drawings......................................................................................................................................6

Product certifications................................................................................................................. 10

2 Emerson.com/Rosemount

Page 3

February 2020 Quick Start Guide

1 About this guide

This guide provides basic guidelines for Rosemount 0068, 0078, and 0183

Sensor models. It does not provide instructions for configuration,

diagnostics, maintenance, service, troubleshooting, explosion-proof,

flameproof, or intrinsically safe (I.S.) installations. If the Rosemount Volume

1 Sensor was ordered assembled to a temperature transmitter, see the

appropriate transmitter Quick Start Guide for information on configuration

and hazardous locations certifications.

NOTICE

Complications can arise when sensors and the transmitters to which they are

assembled have compatible but unique approvals. Be aware of the following

situation:

• If an I.S. approved 1067 sensor is ordered with a housing and

transmitter, the transmitter enclosed in that housing may have a

different I.S. approval rating. Refer to the transmitter IS certificate if

applicable.

• If a sensor and transmitter have different certifications, or if either has

more certifications than the other, installation must comply with the

most restrictive requirements of either component. This is especially

(but not exclusively) relevant when combination approvals are ordered

on either the sensor or transmitter. Review certifications on both the

sensor and transmitter for installation requirements and ensure

installation of the sensor/transmitter assembly complies with a single

certification that is shared by both of these components and that meets

the requirements of the application.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 3

Page 4

A

A

B

B

B

B

A

C

C

D

Quick Start Guide February 2020

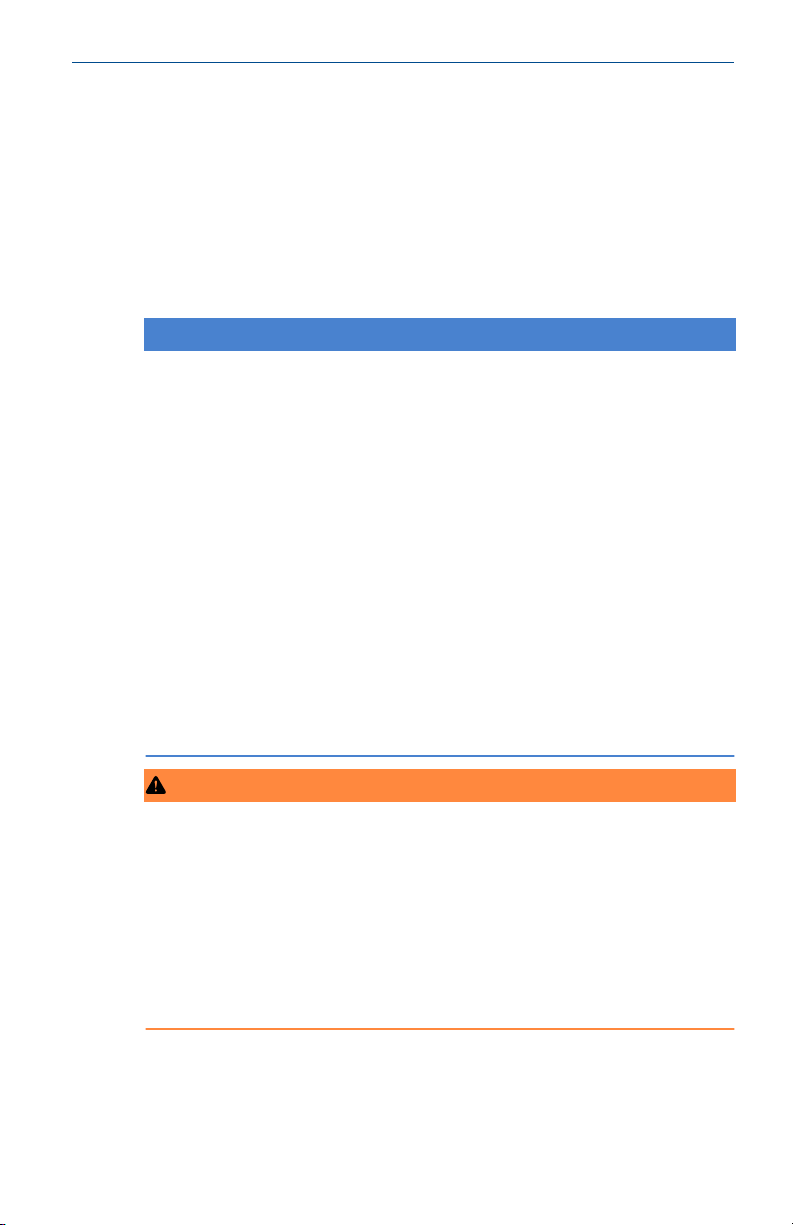

2 Wiring diagrams

Figure 2-1: Rosemount Series 68, 68Q, 78, and 58C RTD Wire Colors

Single Element Dual Element

(1) Dual element sensors are only available on Rosemount Series 68Q and 78

Sensors.

A. Red

B. White

C. Green

D. Black

(1)

Note

For three-wire systems, use one white and two red leads. Do not connect the

white leads. Insulate or terminate the unused white lead in a manner that

prevents shorting to the ground. For two-wire systems, connect both sets of

leads.

4 Emerson.com/Rosemount

Page 5

February 2020 Quick Start Guide

3 Rosemount Series 58C sheath cutting

Procedure

1. Determine the length to which the sheath will be cut. The finished

length needs to include an additional 1.5-in. (3.8 cm) for

compression fittings or 2.5-in. (6.5 cm) for spring-loaded fittings (see

Figure 4-1).

2. Remove and save the heat shrink tubing from the rear of the sensor.

3. Place the sensor in a vise, taking care not to overtighten, and position

the tubing cutter on the sheath.

4. Score the sheath to a depth of approximately 1/64-in. (0.4 cm) To

prevent damage to the lead wire insulation, do not cut completely

through the sheath.

5. Firmly grasp the end of the sheath with your hand or a pair of pliers.

Using a sharp snapping motion, break off and remove the excess

sheath material. Take care not to strip or damage the lead wire

insulation while removing the excess sheath material.

Note

If you are unable to easily break off excess sheath material, deepen

the score and repeat Step 5.

6. Replace the heat shrink tubing.

Quick Start Guide 5

Page 6

A

B

C

D

E

F

+ A

- B

+ C

- B

+ D

- B

+ E

- B

Quick Start Guide February 2020

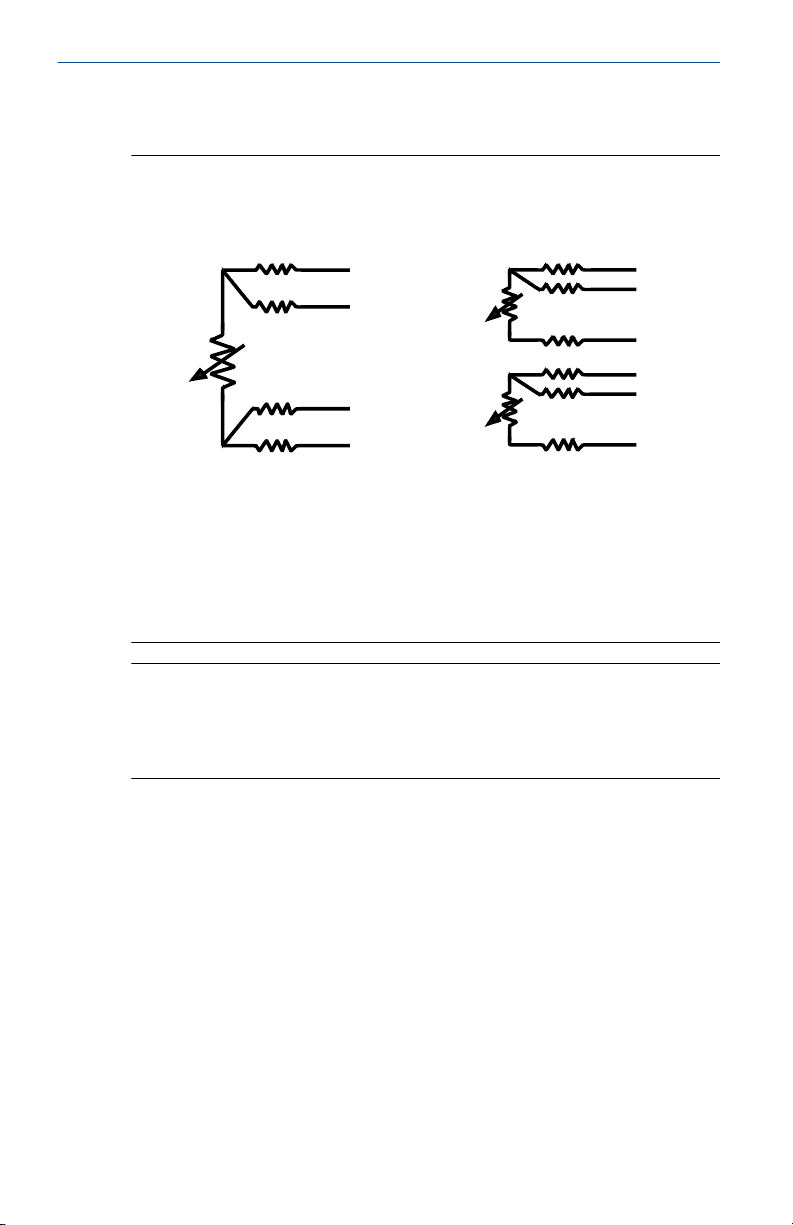

4 Drawings

Figure 4-1: Rosemount Series 58C Sensor

A. Four lead wires 6-in. (152 mm) long.

B. X length ±0.25 (±6)

C. 0.25 ±0.002 (6.35 ±0.13) diameter

D. Heat shrink tubing

E. Do not cut or bend sheath within 2-in (51 mm)

F. 0.6-in. (15 mm) max. sensing element

Figure 4-2: Rosemount Series 183 Thermocouple Wire Colors

Type J Type E

Type K Type T

A. White

B. Red

C. Purple

6 Emerson.com/Rosemount

D. Yellow

E. Blue

Page 7

February 2020 Quick Start Guide

Table 4-1: Rosemount Series 183 Thermocouple Characteristics

Thermocouple

types

J Iron/

K Chromel®/

E Chromel/

T Copper/

Thermocouple

wire alloys

constantan

®

Alumel

constantan

constantan

Temperature range Limits of error

°C °F

0 to 760 32 to

1400

0 to 1150 32 to

2102

0 to 871 32 to

1600

–180 to 0 –292 to32±1.0 °C (1.8 °F) or

0 to 371 32 to 700 ±0.5 °C (1.0 °F) or

(interchangeability)

±1.1 °C (2.0 °F) or

±0.4% of measured

temperature,

whichever is greater

±1.1 °C (2.0 °F) or

±0.4% of measured

temperature,

whichever is greater

±1.0 °C (1.8 °F) or

±0.4% of measured

temperature,

whichever is greater

±1.5% of measured

temperature,

whichever is greater

±0.4% of measured

temperature,

whichever is greater

Note

To distinguish the two sensors in dual Rosemount 183 Sensors, there is an

outer insulation wrapped around each pair of sensor wires.

Quick Start Guide 7

Page 8

A

B

D

C

E

F

I

G

H

K

J

L

M

O

N

P

Q

R

S

T

Quick Start Guide February 2020

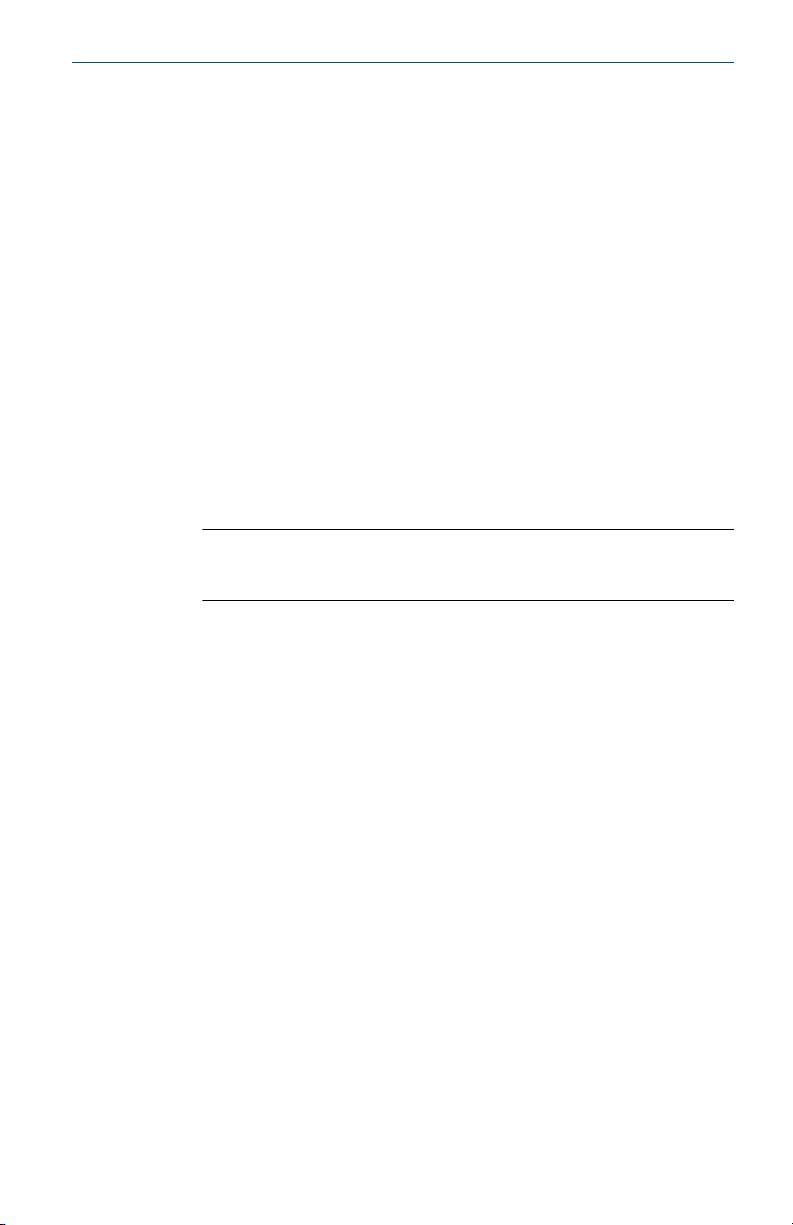

Figure 4-3: Sensor Assembly

A

Open identification tag

B

Standard adapter sensor assembly

C

Sensor immersion length “X”

D

0.5-in. (13 mm) nominal

engagement

E

F

G

H

I

J

8 Emerson.com/Rosemount

Coupling nipple

Extension length

Overall thermowell length

Lead wire extensions and seals

0.5-in. (13 mm) nominal

engagement

Extensions

K

Union nipple

L

Flat or extended cover aluminum

connection heads

M

Threaded thermowell

N

Thermowells

O

T + 1.75-in. (44.5 mm)

P

Socket weld thermowell

Q

Polypropylene connection head

R

Thermowell immersion length

S

Flanged thermowell

T

Rosemount aluminum connection

head

Page 9

February 2020 Quick Start Guide

Note

Sensor assemblies can be provided without an enclosure or with an

enclosure such as the connection heads shown above or assembled to a

Rosemount transmitter.

Quick Start Guide 9

Page 10

Quick Start Guide February 2020

5 Product certifications

Rev 2.14

5.1 European Directive Information

A copy of the EC Declaration of Conformity can be found at the end of the

Quick Start Guide. The most recent revision of the EC Declaration of

Conformity can be found at Emerson.com/Rosemount.

5.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

5.3 North America

The US National Electrical Code (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions. The markings must be suitable for the area

classification, gas, and temperature class. This information is clearly defined

in the respective codes.

5.4 USA

E5 FM Explosion proof, Dust-Ignition proof

Certificate

Standards

Markings

FM17US0170X

FM Class 3600: 2011; FM Class 3611: 2004; FM Class 3615:

2006; FM Class 3810: 2005; ANSI/NEMA - 250: 1991

XP CL I, Div 1, GP B, C, D; DIP CL II/III, Div 1, GP E, F, G; T5(-50

°C ≤ Ta ≤ 85 °C); when installed per Rosemount drawing

00068-0013; Type 4X

5.5 Canada

E6 CSA Explosion proof and Dust-Ignition proof

Certificate

Standards

Markings

10 Emerson.com/Rosemount

1063635

CSA C22.2 No. 0-M91; CSA C22.2 No. 25-1966; CSA C22.2 No.

30-M1986; CSA C22.2 No. 94-M91; CSA C22.2 No. 142M1987; CSA C22.2 No. 213-M1987

XP CL I, Div 1, GP B, C, D; DIP CL II/III, Div 1, GP E, F, G; CL I, Div

2, GP A, B, C, D; (-50 °C ≤ Ta ≤ 85 °C); when installed per

Page 11

February 2020 Quick Start Guide

Rosemount drawing 00068-0033; Type 4X (Spring loaded

sensors must be installed in a thermowell to maintain Type 4X

and Cl. II/III rating)

5.6 Europe

E1 ATEX Flameproof

Certificate

Standards

Markings

Special Conditions for Safe Use(X)

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-Standard Paint options may cause risk from electrostatic

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-1: 2014, EN

60529:1991 +A1:2000 + A2:2013

II 2 G Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…

T1(-50 °C ≤ Ta ≤ +60 °C)

See Process Temperature Limits for process temperatures.

a source of ignition in Group III environments.

joules.

to temperature probes with Enclosure option “N”.

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

discharge. Avoid installations that cause electrostatic build-up on

painted surfaces, and only clean the painted surfaces with a damp

cloth. If paint is ordered through a special option code, contact the

manufacturer for more information.

5.7

Quick Start Guide 11

International

E7 IECEx Flameproof

Certificate

Standards

IECEx FMG 12.0022X

IEC 60079-0:2011, IEC 60079-1:2014-06

Page 12

Quick Start Guide February 2020

Markings

Special Conditions for Safe Use(X)

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than 4

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-Standard Paint options may cause risk from electrostatic

5.8 Brazil

E2 INMETRO Flameproof

Certificate

Standards

Markings

Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C ≤

Ta ≤ +60 °C)

a source of ignition in Group III environments.

joules.

to temperature probes with Enclosure option “N”.

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

discharge.

UL-BR 13.0535X

ABNT NBR IEC 60079-0:2013; ABNT NBR IEC 60079-1:2016;

ABNT NBR IEC 60079-31:2014

Ex db IIC T6…T1 Gb T6…T1(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50

°C ≤ Ta ≤ +60 °C)

Ex tb IIIC T130 °C Db (-40 °C ≤ Ta ≤ +70 °C)

Special Conditions for Safe Use(X)

1. See product description for ambient temperature limits and process

temperature limits.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than 4

joules.

4. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

12 Emerson.com/Rosemount

Page 13

February 2020 Quick Start Guide

5. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 130 °C.

6. Consult the manufacturer if dimensional information on the

flameproof joints is necessary.

5.9 EAC

EM Technical Regulations Customs Union (EAC) Flameproof

5.10

Markings

Special Condition for Safe Use (X)

1. See certificate.

IM Technical Regulations Customs Union (EAC) Flameproof

Markings:

Special Condition for Safe Use (X)

1. See certificate.

KM Technical Regulations Customs Union (EAC) Flameproof

Markings:

Special Condition for Safe Use (X)

1. See certificate.

1Ex db IIC T6…T1 Gb X; T6 (-55 to 40 °C); T5..T1 (-55 to 60 °C);

IP66, IP68

0Ex ia IIC T5/T6 Ga X; T5, Pi = 0.29 W, (-60 to +70 °C); T6, Pi =

0.29 W, (-60 to +60 °C); T6, Pi = 0.192 W, (-60 to +70 °C)

Ex tb IIIC T130 °C Db X (-60 to +70 °C); Markings for both EM

and IM above are included with this option.

Korea

EP Korea Explosionproof/Flameproof

Certificate

Markings

13-KB4BO-0560X

Ex d IIC T6…T1; T6(–50 °C ≤ Ta ≤ +40 °C), T5…T1(–50 °C ≤ Ta ≤

+60 °C)

Special Condition for Safe Use(X)

1. See certificate.

Quick Start Guide 13

Page 14

Quick Start Guide February 2020

5.11 Combinations

KF

KD

KM

Combination of E1 and E6

Combination of E5, E6, and 1

Combination of EM and IM

5.12 Process temperature limits

Table 5-1: Sensor Only (No Transmitter Installed)

Process temperature (°C)

Extension

length

T6 T5 T4 T3 T2 T1 T130 °C

Any

extension

length

Table 5-2: Transmitter

Extension

length

No

extention

3-in.

extension

6-in.

extension

9-in

extension

85 100 135 200 300 450 130

Process temperature (°C)

T6 T5 T4 T3 T2 T1 T130 °C

55 70 100 170 280 440 100

55 70 110 190 300 450 110

60 70 120 200 300 450 110

65 75 130 200 300 450 120

Gas Dust

Gas Dust

Adhering to the process temperature limitations of Table 5-3 will ensure that

the service temperature limitations of the LCD cover are not exceeded.

Process temperatures may exceed the limits defined in Table 5-3 if the

temperature of the LCD cover is verified to not exceed the service

temperatures in Table 5-4 and the process temperatures do not exceed the

values specified in Table 5-2.

14 Emerson.com/Rosemount

Page 15

February 2020 Quick Start Guide

Table 5-3: Transmitter with LCD Cover - Process Temperature (°C)

Extension length

T6 T5 T4...T1 T130 °C

No extension 55 70 95 95

3-in. extension 55 70 100 100

6-in. extension 60 70 100 100

9-in. extension 65 75 110 110

Gas Dust

Table 5-4: Transmitter with LCD Cover - Service Temperature (°C)

Extension length

T6 T5 T4...T1 T130 °C

No extension 65 75 95 95

Gas Dust

Quick Start Guide 15

Page 16

Quick Start Guide February 2020

5.13 Declaration of Conformity

Figure 5-1: Rosemount Series 68, 68Q, 78, and 58C Declaration of

Conformity

16 Emerson.com/Rosemount

Page 17

February 2020 Quick Start Guide

Quick Start Guide 17

Page 18

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 68/78/183

List of Rosemount 68/78/183 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

O O O O O

O

༣փ㓴Ԧ

Housing

Assembly

O O O O O

O

Րᝏಘ㓴Ԧ

Sensor

Assembly

O O O O O

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

Quick Start Guide February 2020

5.14 China RoHS

18 Emerson.com/Rosemount

Page 19

February 2020 Quick Start Guide

Quick Start Guide 19

Page 20

*00825-0300-2654*

00825-0300-2654, Rev. FA

Quick Start Guide

February 2020

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...