Page 1

Quick Start Guide

00825-0100-5900, Rev AA

March 2020

Rosemount™ 5900S Radar Level Gauge

Parabolic antenna

Page 2

Quick Start Guide March 2020

Contents

About This Guide..........................................................................................................................3

General information..................................................................................................................... 7

Installation considerations........................................................................................................... 8

Mechanical installation...............................................................................................................14

Electrical installation.................................................................................................................. 29

Configuration.............................................................................................................................33

Product Certifications.................................................................................................................38

2 Rosemount 5900S Radar Level Gauge

Page 3

March 2020 Quick Start Guide

1 About This Guide

This Quick Start Guide provides basic guidelines for installation and

configuration of the Rosemount 5900S Radar Level Gauge with Parabolic

antenna.

NOTICE

Read this manual before working with the product. For personal and system

safety, and for optimum product performance, ensure you thoroughly

understand the contents before installing, using, or maintaining this

product.

For equipment service or support needs, contact your local Emerson

Automation Solutions/Rosemount Tank Gauging representative.

Spare Parts

Any substitution of non-recognized spare parts may jeopardize safety.

Repair, e.g. substitution of components etc, may also jeopardize safety and

is under no circumstances allowed.

Rosemount Tank Radar AB will not take any responsibility for faults,

accidents, etc caused by non-recognized spare parts or any repair which is

not made by Rosemount Tank Radar AB.

Specific ETSI Requirements (Europe)

The Rosemount 5900S is required to be installed at a permanent fixed

position at a closed (not open) metallic tank or reinforced concrete tank, or

similar enclosure structure made of comparable attenuating material.

Flanges and attachments of the Rosemount 5900S equipment shall provide

the necessary microwave sealing by design.

Manholes or connection flanges at the tank shall be closed to ensure a lowlevel leakage of the signal into the air outside the tank.

Installation and maintenance of the Rosemount 5900S equipment shall be

performed by professionally trained individuals only.

Specific FCC Requirements (USA)

Rosemount 5900S generates and uses radio frequency energy. If it is not

installed and used properly, that is, in strict accordance with the

manufacturer´s instructions, it may violate FCC regulations on radio

frequency emission.

Rosemount TankRadar 5900S has been FCC certified under test conditions

which assume a metallic tank.

Quick Start Guide 3

Page 4

Quick Start Guide March 2020

Specific IC Requirements (Canada)

Radio approvals for this device apply for installation in complete enclosed

container to prevent unwanted RF emission. In open air application site

license is required. Installation shall be done by trained installers, in

compliance with the manufacturer's instructions.

The use of this device is on a "no-interference, no-protection" basis. That is,

the user shall accept operations of high-powered radar in the same

frequency band which may interfere with or damage this device. Devices

found to interfere with primary licensing operations will be required to be

removed at the user's expense.

Low Emission of Microwave Radiation

The microwave radiation emitted by a Rosemount 5900S radar level gauge is

very low compared to limits given by the Rec. 1999/519/EC (much less than

0.1 mW). No additional safety measures are needed.

CAUTION

The products described in this document are NOT designed for nuclearqualified applications. Using non-nuclear qualified products in applications

that require nuclear-qualified hardware or products may cause inaccurate

readings. For information on Rosemount nuclear-qualified products, contact

your local Emerson Sales Representative.

NOTICE

The device is designed for installation in complete enclosed container to

prevent unwanted RF emission. Installation must be in accordance with local

regulations and may require local radio approvals.

Installation in open air applications may be subject for site license approval.

Installation shall be done by trained installers, in compliance with the

manufacturer's instructions.

4 Rosemount 5900S Radar Level Gauge

Page 5

March 2020 Quick Start Guide

WARNING

Failure to follow safe installation and servicing guidelines could result in

death or serious injury.

• Ensure only qualified personnel perform the installation.

• Use the equipment only as specified in this manual. Failure to do so may

impair the protection provided by the equipment.

• Do not perform any service other than those contained in this manual

unless you are qualified.

• To prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing.

• Substitution of components may impair Intrinsic Safety.

Explosions could result in death or serious injury.

• Verify that the operating atmosphere of the transmitter is consistent

with the appropriate hazardous locations certifications.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure that the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• Do not remove the gauge cover in explosive atmospheres when the

circuit is alive.

High voltage that may be present on leads could cause electrical shock.

• Avoid contact with the leads and terminals.

• Ensure the main power to the transmitter is off and the lines to any other

external power source are disconnected or not powered while wiring the

gauge.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

Quick Start Guide 5

Page 6

Quick Start Guide March 2020

WARNING

WARNING - Substitution of components may impair Intrinsic Safety.

AVERTISSEMENT - La substitution de composants peut compromettre la

sécurité intrinsèque.

WARNING - To prevent ignition of flammable or combustible atmospheres,

disconnect power before servicing.

AVERTISSEMENT - Ne pas ouvrir en cas de presence d'atmosphere explosive.

6 Rosemount 5900S Radar Level Gauge

Page 7

March 2020 Quick Start Guide

2 General information

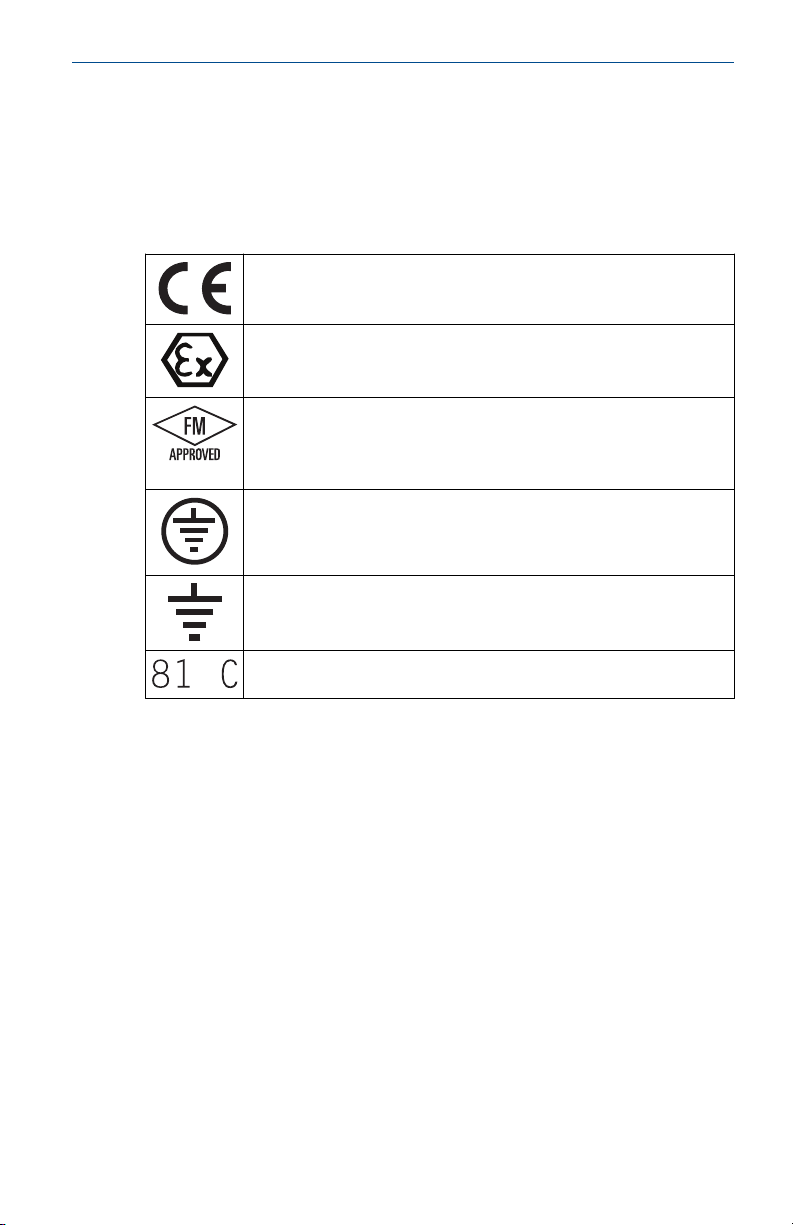

2.1 Symbols

Table 2-1: Symbols

The CE marking symbolizes the conformity of the product with the

applicable European Community Directives.

The EU-Type Examination Certificate is a statement of a Notified

Certification Body declaring that this product meets the Essential

Health and Safety Requirements of the ATEX directive

The FM APPROVED Mark indicates that the equipment is approved by

FM Approvals according to applicable Approval Standards and is

applicable for installation in hazardous locations

Protective Earth

Ground

External cabling must be approved for use in min. 81°C

2.2 Service support

For service support contact the nearest Emerson Automation Solutions /

Rosemount Tank Gauging representative. Contact information can be found

on the web site www.Emerson.com.

2.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration

and disposed of in accordance with local and national legislation/

regulations.

Quick Start Guide 7

Page 8

Quick Start Guide March 2020

3 Installation considerations

3.1 General considerations

When finding an appropriate location on the tank for a Rosemount 5900S

Radar Level Gauge, the conditions of the tank must be carefully considered.

The gauge should be installed so that the influence of disturbing objects is

kept to a minimum, preferably outside the radar signal beam.

Ensure that the Rosemount 5900S is installed such that it is not exposed to

higher pressure and temperature than specified.

It is the responsibility of the user to ensure that the device meets the specific

inside tank installation requirements such as:

• chemical compatibility of wetted materials

• design/operation pressure and temperature

For a complete specification of the 5900S device to be installed, you can

identify the model code on the attached antenna label and match with

ordering information data.

Ensure that environmental conditions are within specified limits.

Do not install the Rosemount 5900S in non-intended applications, for

example environments where it may be exposed to extremely intense

magnetic fields or extreme weather conditions.

Antennas with plastic surfaces and painted surface, may under certain

extreme conditions generate an ignition-capable level of electrostatic

charge. When installing in hazardous areas ensure using tools, cleaning

material etc. which can not generate electrostatic charge.

See the Rosemount 5900S Reference Manual for more information.

8 Rosemount 5900S Radar Level Gauge

Page 9

March 2020 Quick Start Guide

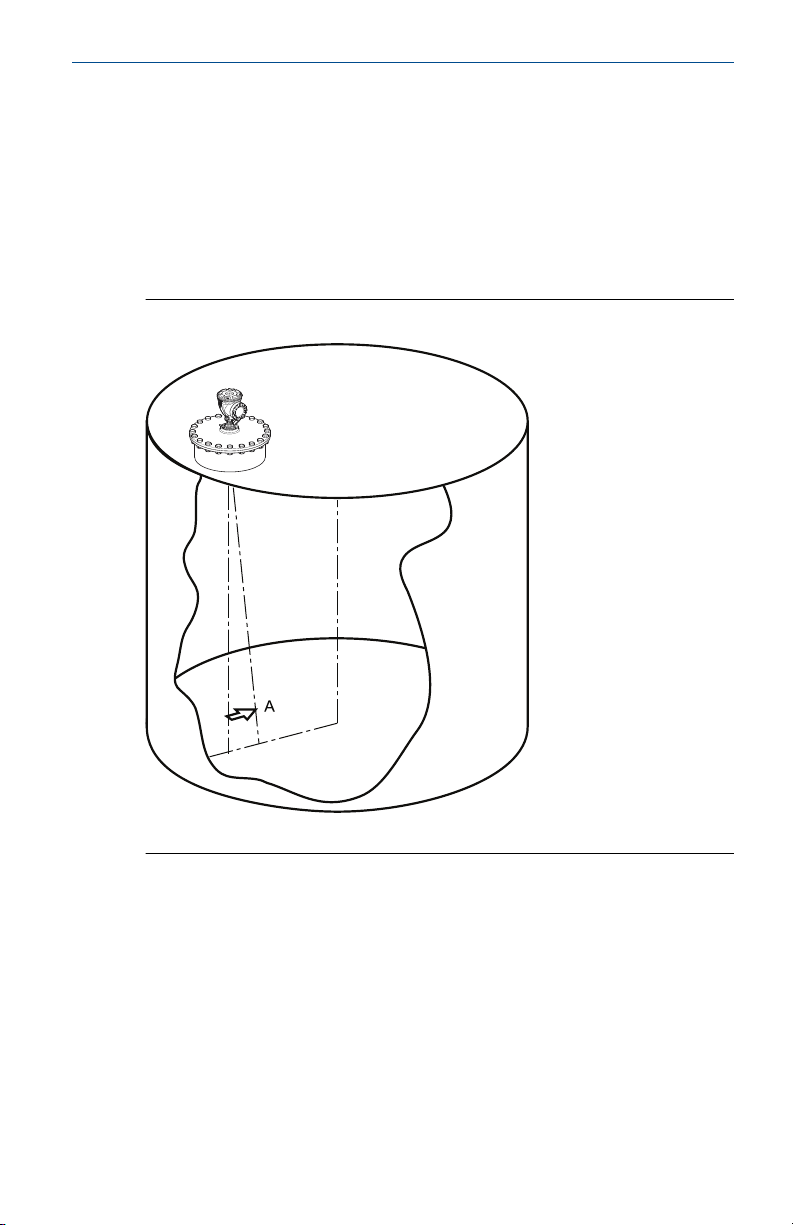

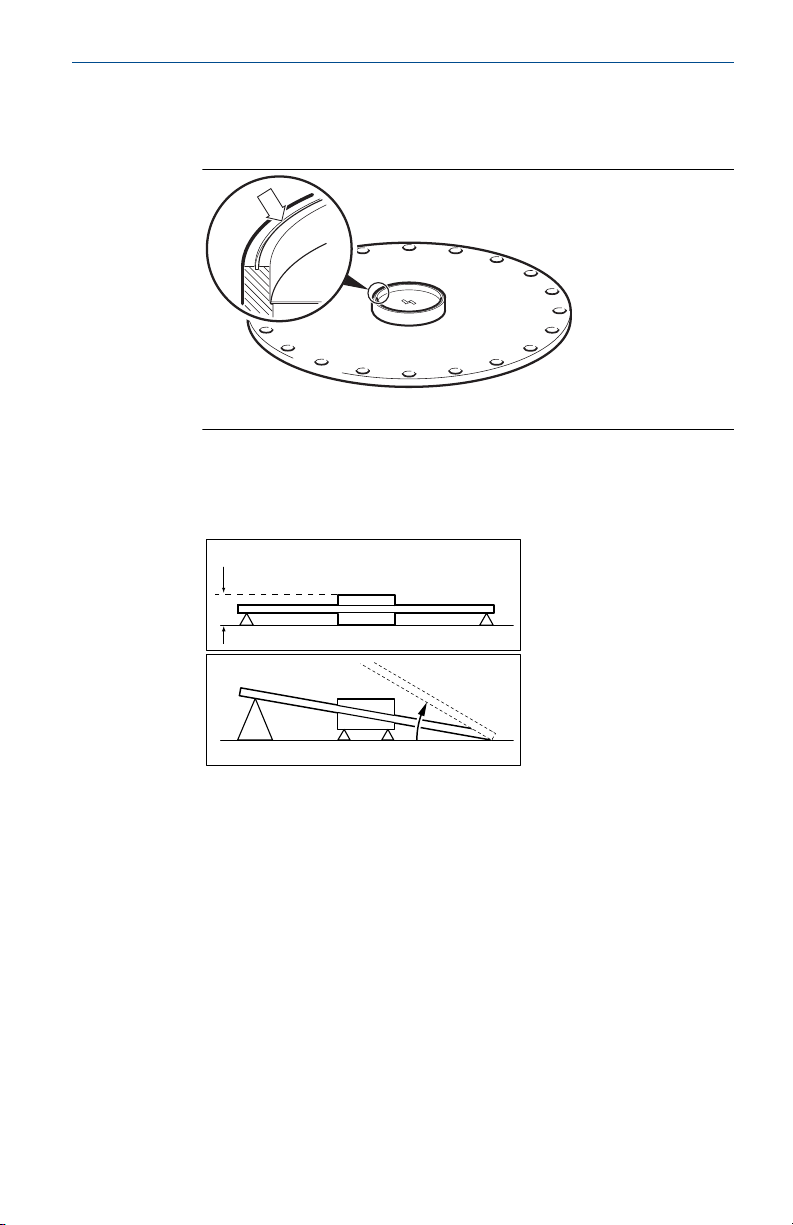

3.2 Parabolic antenna requirements

3.2.1 Inclination

The inclination of the Rosemount 5900S with Parabolic Antenna should not

exceed 1.5 ° towards the center of the tank. For products with high

condensation such as bitumen/asphalt applications, the radar beam should

be directed vertically without any inclination.

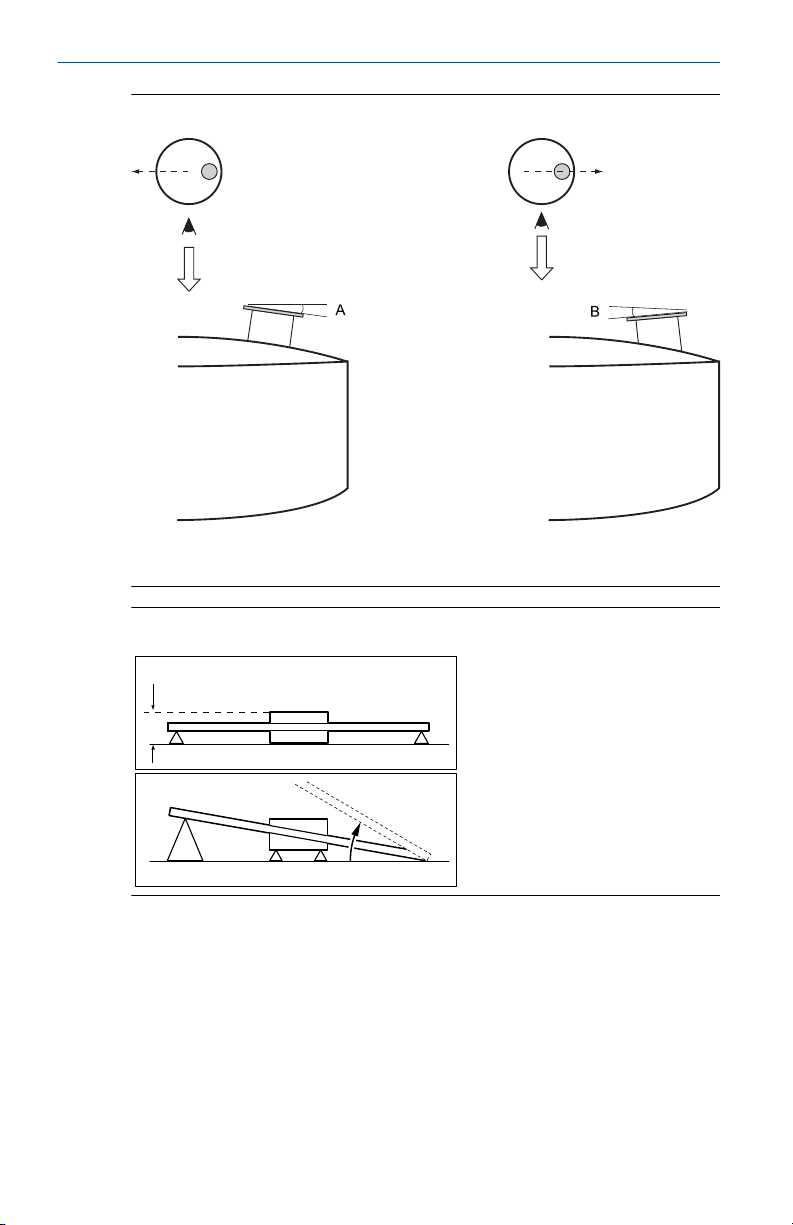

Figure 3-1: Maximum Inclination with Parabolic Antenna

A. Maximum inclination 1.5°

3.2.2 Flange requirements

The tank flange has to meet the following inclination requirements (see

Figure 3-2) in order to allow proper adjustment of the antenna:

• maximum 4.5° away from the tank wall

• maximum of 2° towards the tank wall

• in case the nozzle inclination exceeds the recommended values, you may

use the welded flange ball which can be mounted at a maximum angle of

17°

Quick Start Guide 9

Page 10

60 mm (2.4 in.)

< 17°

Quick Start Guide March 2020

Figure 3-2: Maximum Inclination of Tank Flange

A. 4.5° max

B. 2.0° max

Figure 3-3: Maximum Inclination with Welded Flange

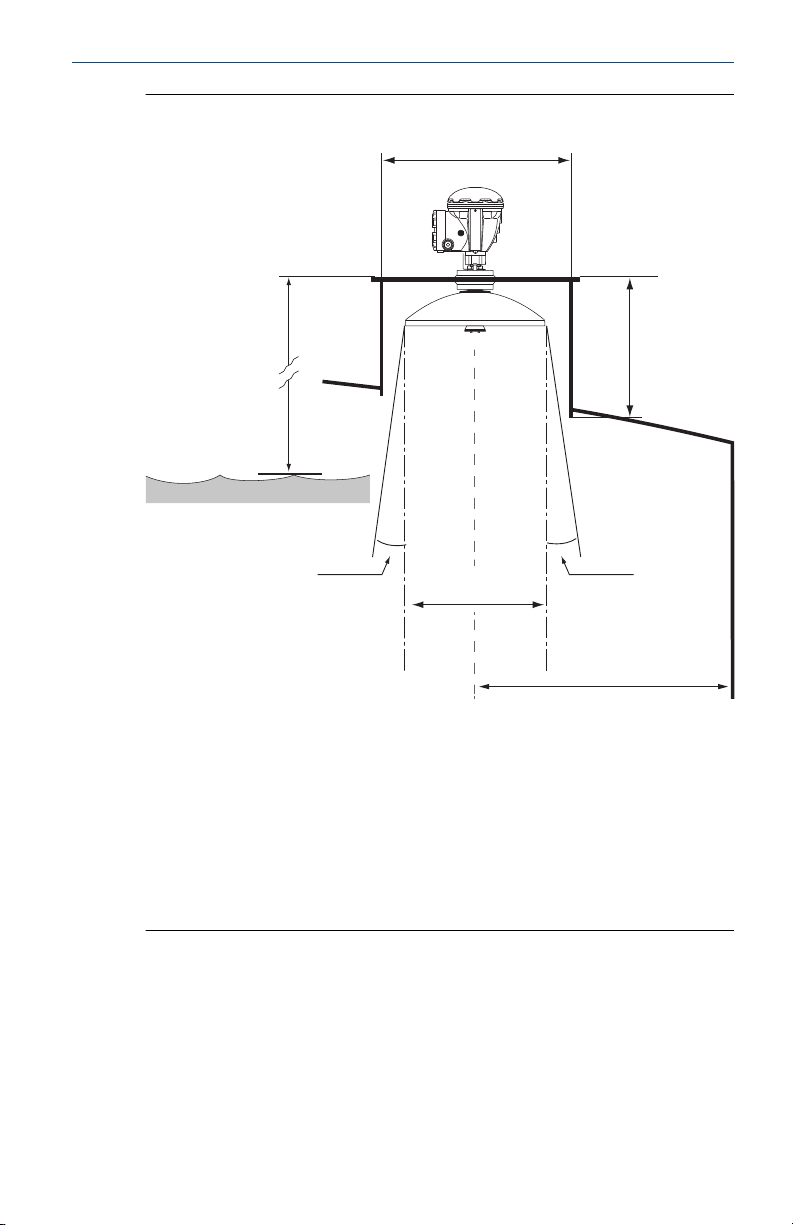

3.2.3 Nozzle and free space requirements

When installing the Rosemount 5900S with parabolic antenna on a Ø 20"

nozzle, consider the following recommendations.

10 Rosemount 5900S Radar Level Gauge

Obstacles (construction bars, pipes larger than Ø 2", etc.) within the 10° wide

radar beam are generally not accepted, as these may result in disturbing

echoes. However, in most cases a smooth tank wall or small objects will not

have any significant influence.

Page 11

C

E

B

F

F

G

A

D

D

March 2020 Quick Start Guide

Figure 3-4: Nozzle and Free Space Requirements for Parabolic Antenna

A. Minimum 800 mm (31 in.) for highest accuracy. Minimum 500 mm (20

in.) with reduced accuracy.

B. Recommended height: 400 mm (16 in.). Maximum height: 600 mm (24

in.).

C. Minimum nozzle diameter: 500 mm (20 inch.)

E. Ø 440 mm (17.3 in.)

Vertical plumb line

D.

F. 5° minimum

G. > 800 mm (31.5 in.)

Quick Start Guide 11

Page 12

$

Quick Start Guide March 2020

3.3 Electrical requirements

3.3.1 Cable/conduit entries

The electronics housing has two entries for ½ - 14 NPT. Optional M20×1.5,

minifast and eurofast adapters are also available. The connections must be

made in accordance with local or plant electrical codes.

Make sure that unused ports are properly sealed to prevent moisture or

other contamination from entering the terminal block compartment of the

electronics housing.

Note

Use the enclosed metal plugs to seal unused ports. The plastic plugs

mounted at delivery are not sufficient as seal!

Note

Thread sealing (PTFE) tape or paste on male threads of conduit is required to

provide a water/dust tight conduit seal and to meet the required degree of

ingress protection as well as to enable future removal of the plug/gland.

NPT is a standard for tapered threads. Engage the gland with 5 to 6 threads.

Note that there will be a number of threads left outside the housing as

illustrated below.

Figure 3-5: Cable Entry with NPT Threaded Gland

A. The NPT threaded gland leaves a number of threads outside the housing

Ensure that glands for the cable entries meet requirements for IP class 66

and 67.

3.3.2 Grounding

The housing should always be grounded in accordance with national and

local electrical codes. Failure to do so may impair the protection provided by

the equipment. The most effective grounding method is direct connection

to earth ground with minimal impedance.

There are three grounding screw connections provided. Two are located

inside the terminal compartment of the housing and the third is located on

12 Rosemount 5900S Radar Level Gauge

Page 13

March 2020 Quick Start Guide

the housing. The internal ground screws are identified by a ground symbol:

.

Note

Grounding the transmitter via threaded conduit connection may not provide

sufficient ground.

Grounding - FOUNDATION™ Fieldbus

Signal wiring of the fieldbus segment can not be grounded. Grounding out

one of the signal wires may shut down the entire fieldbus segment.

Shield wire ground

To protect the fieldbus segment from noise, grounding techniques for shield

wire usually require a single grounding point for shield wire to avoid creating

a ground loop. The ground point shall be located at the power supply.

The devices designed for “daisy-chain” connection offer an isolated shield

loop-through terminal in order to enable a continuous shield throughout the

Tankbus network.

In order to avoid unintentional grounding points, the cable shield inside the

terminal compartment must be isolated.

3.3.3 Hazardous areas

When the Rosemount 5900S level gauge is installed in hazardous areas, local

regulations and specifications in applicable certificates must be observed.

Certificates for Rosemount Tank Gauging products, such as the Rosemount

5900, are available on Emerson.com/Rosemount Tank Gauging.

3.3.4 Power requirements

The Rosemount 5900S is powered over the intrinsically safe Tankbus by the

Rosemount 2410 Tank Hub. The 2410 feeds the intrinsically safe fieldbus

segment by acting as a FISCO power supply on the Tankbus.

When installed in a FOUNDATION Fieldbus system without a Rosemount 2410

Tank Hub, the Rosemount 5900S is powered by the FF segment.

Quick Start Guide 13

Page 14

Quick Start Guide March 2020

4 Mechanical installation

4.1 Parabolic antenna

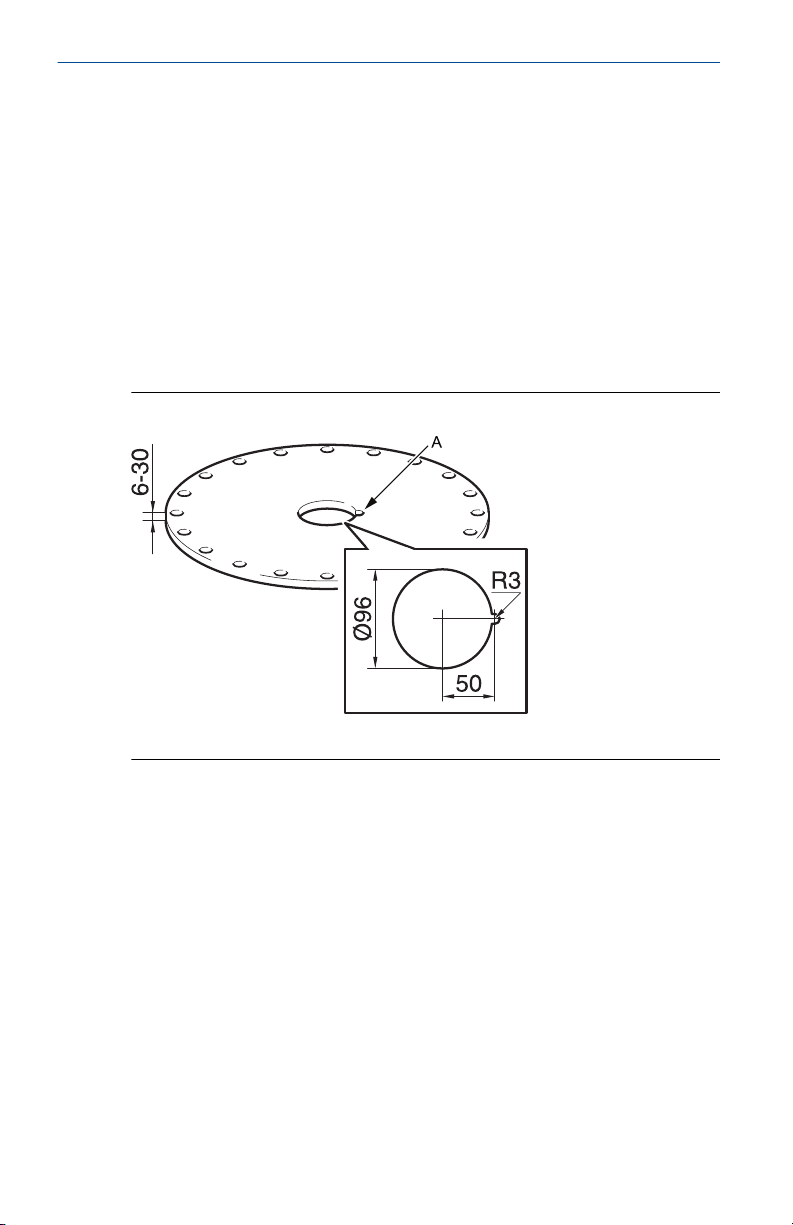

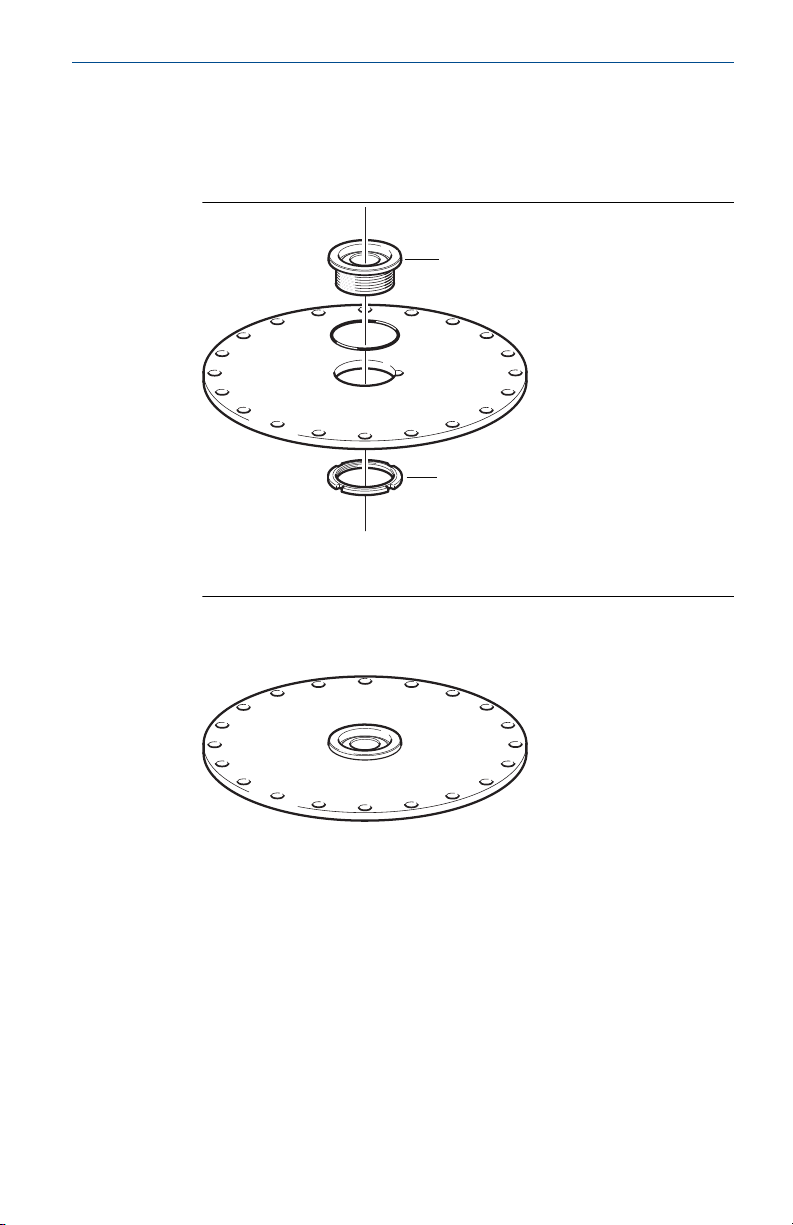

4.1.1 Mounting the clamped Flange Ball

Follow this instruction when installing the clamped Flange Ball on a flange.

Prerequisites

1.

Use a flange of thickness 6 - 30 mm.

Make sure that the diameter of the hole is 96 mm. Make a small

2.

recess at one side of the flange hole.

Figure 4-1: Flange Requirements

A. Recess

14 Rosemount 5900S Radar Level Gauge

Page 15

$

%

March 2020 Quick Start Guide

Procedure

1. Put the O-ring on the flange and insert the Flange Ball into the hole.

Make sure that the guide pin on the side of the Flange Ball fits into

the recess on the flange.

A. Flange Ball

B. Nut

2. Tighten the nut so that the Flange Ball fits tightly to the flange

(torque 50 Nm).

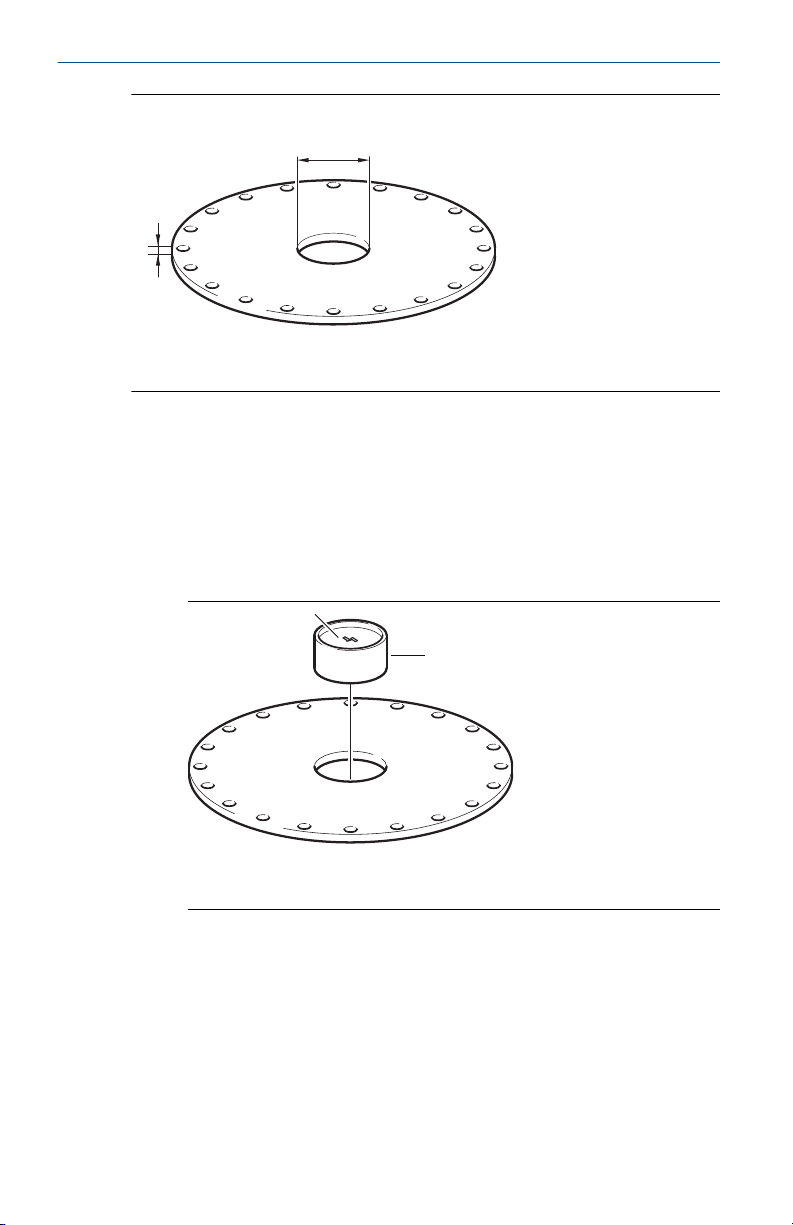

4.1.2 Mounting the welded Flange Ball

Follow this instruction when installing the welded Flange Ball on a flange.

Prerequisites

For horizontal mounting according to requirements in chapter Parabolic

antenna requirements, make sure that the diameter of the hole is 116 ± 2

mm.

Quick Start Guide 15

Page 16

$

%

%

$

Quick Start Guide March 2020

Figure 4-2: Flange Requirements

A. 116±2 mm

B. 6-38 mm

In case the flange requirements in chapter Parabolic antenna requirements

are not met, the hole needs to be machined to an oval shape prepared for

inclined welding of the Flange Ball.

Procedure

1.

Let the protection plates remain on the Flange Ball until welding is

finished. These plates protect the surface of the Flange Ball from

welding sparks.

A. Protection plate

B. Flange Ball

16 Rosemount 5900S Radar Level Gauge

Page 17

$

60 mm (2.4 in.)

< 17°

March 2020 Quick Start Guide

2. Make sure that the Flange Ball is mounted in such a way that the

grove is directed upwards when the flange is mounted on the tank

nozzle.

A. Groove

3. If the tank flange is inclined, make sure that the Flange Ball is welded

so that the Flange Ball is horizontal when it is mounted on the tank.

The tank flange inclination should not exceed 17 degrees.

Quick Start Guide 17

Page 18

$

$

Quick Start Guide March 2020

4. Remove the protection plates when the Flange Ball is welded to the

flange.

A. Protection plate

4.1.3 Mounting the parabolic antenna

This section describes how to install the Rosemount 5900S with Parabolic

antenna.

Follow this instruction to install the Parabolic antenna and transmitter head

assembly on a tank.

Prerequisites

• See Parabolic antenna requirements for considerations before installing

the gauge on the tank.

• Check that all parts and tools are available before carrying them up to

the tank top.

18 Rosemount 5900S Radar Level Gauge

Page 19

$

%

&

March 2020 Quick Start Guide

Procedure

1. Fit the Parabolic Reflector onto the Antenna Feeder and tighten the

five M5 screws.

A. M5x5

B. Parabolic Reflector

C. Antenna Feeder

2. Check that all parts are properly mounted.

Quick Start Guide 19

Page 20

&

$

%

'

Quick Start Guide March 2020

3. Put the two O-rings in the grooves on the upper surface of the Flange

Ball.

A. 2 O-rings

B. Grooves

C. Flange Ball

D.

Flange

20 Rosemount 5900S Radar Level Gauge

Page 21

$

%

&

'

(

*

+

)

March 2020 Quick Start Guide

4. Turn the flange around and insert the Antenna Waveguide into the

flange hole.

A. Nut

B. Tab Washer

C. Antenna label plate

Finger Nut

D.

E. Washer Ball

F. Stop Washer

G. Flange

H. Antenna Waveguide

5. Mount the washers and nuts.

Note that the purpose of the Stop Washer is to prevent the antenna

from falling down into the tank. Therefore it fits tightly to the

Antenna Waveguide.

Quick Start Guide 21

Page 22

$

%

C

B

A

D

Quick Start Guide March 2020

6. Tighten the finger nut and the upper nut by hand.

A. Finger Nut

B. Upper Nut

7. Place the antenna and flange assembly on the tank nozzle and

tighten the flange screws.

A. Antenna Waveguide

B. Flange

C. Antenna

D.

Nozzle

22 Rosemount 5900S Radar Level Gauge

Page 23

&

%

$

March 2020 Quick Start Guide

8. Put the level gauge on the Antenna Waveguide. Ensure that the

guide pin inside the transmitter head fits into the groove on the

Antenna Waveguide.

A. Nut

B. Antenna Waveguide

C. Finger Nut

9. Tighten the nut that connects the transmitter head to the antenna.

10.

Loosen the finger nut slightly.

Quick Start Guide 23

Page 24

$

&

%

r

r

Quick Start Guide March 2020

11. Align the level gauge by using the cross hairs on top of the

transmitter head.

In case the weather protection hood is attached, the gauge can be

aligned by using a line of sight along the screws on top of the head.

A. Tank

B. Tank center

C. Line of sight

12. Ensure that the gauge is directed at an angle of 45° to the line of sight

from the center of the tank to the wall.

24 Rosemount 5900S Radar Level Gauge

Page 25

March 2020 Quick Start Guide

13. Use the marks on the Washer Ball to adjust the gauge so the antenna

is inclined roughly 1.5° towards the center of the tank.

Note

For products with high condensation, such as bitumen, the gauge

should be mounted with 0° inclination in order to achieve maximum

signal strength.

A. Marks

B. Plumb line

C. Tank center

D. Incline antenna 1.5° towards tank center

14. Tighten the finger nut.

Quick Start Guide 25

Page 26

Quick Start Guide March 2020

15. You may use a level (optional) to verify correct inclination of 1.5°

towards the tank center. Ensure that the level is put on a flat and

steady surface on top of the transmitter head. If needed, loosen the

finger nut and adjust the gauge.

Note

Make sure the air bubble touches, but doesn't overlap the 1.5° mark.

A. Finger Nut

16. Tighten the finger nut firmly.

26 Rosemount 5900S Radar Level Gauge

Page 27

March 2020 Quick Start Guide

17. In case the Weather Protection Hood was removed, put it back on

top of the transmitter head and tighten the screw.

A. Weather Protection Hood

B. Finger Nut

Quick Start Guide 27

Page 28

Quick Start Guide March 2020

18. Tighten the upper nut to lock the finger nut (you may temporarily

remove the transmitter head to make room for tools if needed), and

secure by folding the tab washer over the nut.

A. Upper Nut

19. Wire the gauge and configure by using the RosemountTankMaster

WinSetup software (see the Rosemount Tank Gauging System

Configuration Manual).

28 Rosemount 5900S Radar Level Gauge

Page 29

March 2020 Quick Start Guide

5 Electrical installation

5.1 Wiring

To connect the Rosemount 5900S level gauge:

Procedure

Ensure that the power supply is switched off.

1.

2. Remove the cover on the terminal compartment.

3. Run the wires through the appropriate cable gland/conduits. Install

cables with a drip loop in such a way that the lower part of the loop is

under the cable/conduit entry.

4.

Connect wires as described in Terminal blocks.

5. Ensure that the positive lead is connected to the terminal marked FB

+ and the negative lead to the terminal marked FB-.

6. Use metal plugs to seal unused ports.

The cover on the terminal compartment should be tightened to

7.

mechanical stop (metal to metal). Make sure the cover is fully

engaged to meet explosion-proof requirements and to prevent water

from entering the terminal compartment.

8. Tighten the cable gland/conduit. Note that adapters are required for

M20 glands.

Note

Ensure that O-rings and seats are in good condition prior to

mounting the cover in order to maintain the specified level of ingress

protection. The same requirements apply for cable inlets and outlets

(or plugs). Cables must be properly attached to the cable glands.

Quick Start Guide 29

Page 30

AA

B

D

E

C

F

Quick Start Guide March 2020

Figure 5-1: Terminal Compartment

A. Cable glands

B. Internal Ground screws

C. Terminals for signal and power supply

Locking screw (Unscrew to lock)

D.

E. External Ground screw

F. Cover

30 Rosemount 5900S Radar Level Gauge

Page 31

B

A A

C

+

-

+

-

C

March 2020 Quick Start Guide

5.2 Terminal blocks

Figure 5-2: Rosemount 5900S Terminal Compartment

A. Test terminals

B. Ground terminals, internal

C. Field bus

Table 5-1: Terminal Block Connections for the Rosemount 5900S

Connection Description

X1: Tankbus in Intrinsically safe Tankbus input, power and communication

X2: Terminate on The integrated line terminator is connected over the Tankbus

X3: Shield loop

through

X4: Tankbus out Tankbus output connected to X1 for optional daisy-chain

Test terminals Test terminals for temporary connection of a Field

(spur in FOUNDATION Fieldbus system)

when a jumper is placed in the terminal block

Cable shield daisy-chain connector (not grounded)

connection to other devices

Communicator

Quick Start Guide 31

Page 32

A

FB +

FB -

B

C

Quick Start Guide March 2020

5.2.1 Terminal block two-in-one single bus

Figure 5-3: Terminal Compartment 2-in-1 Version

A. Test terminals

B. Ground terminals, internal

C. Jumpers between X3 and X4

FB. Field Bus

Table 5-2: Rosemount 5900S Two-in-One with Single Tankbus

Connection Two-in-One / Single tankbus

X1: Primary

Tankbus in

X2: Primary

Terminate on

X3: Primary

Tankbus out

X4: Secondary

Tankbus in

Test terminals Test terminals for temporary connection of a field

Intrinsically safe Tankbus input, power and communication

Termination for primary tankbus. The integrated line

terminator is connected over the Tankbus when a jumper is

placed in the terminal block.

Jumpers between X3 and X4

communicator

32 Rosemount 5900S Radar Level Gauge

Page 33

March 2020 Quick Start Guide

6 Configuration

6.1 Tank geometry parabolic antenna

The following parameters are used for tank geometry configuration of a

Rosemount 5900S Radar Level Gauge with parabolic antenna:

Figure 6-1: Tank Geometry Parameters for the Rosemount 5900S

A. Tank Reference Point

B. Tank Ullage

C. Minimum Level Offset (C); distance from Zero Level to tank bottom

Ullage

D.

E. Product level

F. Zero Level (Dipping Datum Point)

G. Gauge Reference Distance (G); distance from Tank Reference Point to the

Gauge Reference Point

H. Gauge Reference Point

I. Hold Off Distance; defines how close to the Gauge Reference Point levels

can be measured

J. Measuring range

K. Tank Reference Height (R); distance from Tank Reference Point to Zero

level

Quick Start Guide 33

Page 34

1. Communication

2. Preferences

3. Rosemount 2460 System Hub

4. Rosemount 2410 Tank Hub

6. Tanks

7. Calibration

5. Rosemount 5900 and other field

devices

Rosemount 2460

Rosemount TankMaster

Rosemount 2410

Rosemount 2230

Rosemount 2240S

Rosemount 5900S

Quick Start Guide March 2020

6.2 Configuration using WinSetup

A Rosemount 5900S is typically installed by using the installation wizard in

TankMaster WinSetup configuration software. It is recommended that the

Rosemount 2460 System Hub and Rosemount 2410 Tank Hub are installed

and configured prior to field devices such as level gauges, temperature, and

pressure transmitters as illustrated in Figure 6-2.

It is important that the tank database of the Rosemount 2410 Tank Hub has

all the information that is stored in the Rosemount 2460 System Hub’s

database. This ensures that new devices are mapped to the correct tanks,

and that all tank variables are properly updated and distributed.

See the System Configuration Manual (Document no. 00809-0300-5100) for

more information.

Figure 6-2: Installation Procedure

34 Rosemount 5900S Radar Level Gauge

Page 35

March 2020 Quick Start Guide

Configuration in TankMaster WinSetup

A field device such as the Rosemount 5900S level gauge is typically installed

as part of the Rosemount 2410 Tank Hub installation procedure in

TankMaster.

Once the gauge is installed, click the Properties option to configure the

device.

Figure 6-3: TankMaster WinSetup Workspace with Installed Devices

Quick Start Guide 35

Page 36

A

B

D

E

F

G

H

C

Quick Start Guide March 2020

The Properties window includes tabs for basic and advanced configuration.

Figure 6-4: Properties Window

A. Tabs for basic and advanced configuration

B. Tank hub that the radar level gauge is connected to

C. Position in the tank hub's database

Communication channel

D.

E. Modbus address

F. Unit Id

G. Application and boot firmware versions

H. Red icon means that the device is not configured

See the System Configuration Manual (Document no. 00809-0300-5100) for

more information.

36 Rosemount 5900S Radar Level Gauge

Page 37

March 2020 Quick Start Guide

Basic configuration

The Properties window has a number of tabs that lets you configure the

device for optimum performance. The Communication, Antenna, and

Geometry tabs cover basic configuration of the Rosemount 5900S.

Figure 6-5: Antenna Configuration

Figure 6-6: Tank Geometry Configuration

Quick Start Guide 37

Page 38

Quick Start Guide March 2020

A Product Certifications

Rev 7.15

A.1 European directive information

The most recent revision of the EU Declaration of Conformity can be found

at Emerson.com/Rosemount.

A.2 Ordinary Location Certification

As standard, the transmitter has been examined and tested to determine

that the design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

Complies with FM 3810:2005 and CSA: C22.2 No. 1010.1.

A.3 Telecommunication compliance

A.3.1 FCC

This device complies with Part 15C of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Certificate: K8C5900

A.3.2 IC

This device complies with RSS210-7.

Certificate: 2827A-5900

A.3.3 Radio Equipment Directive (RED)

This device complies with ETSI EN 302 372 and EN 62479. EU directive

2014/53/EU. The device shall be installed according to requrements ETSI EN

302372.

A.4 CE-mark

The product complies with applicable EU directives (EMC, ATEX, LVD, and

RED). Based on the low emitted effects from the gauges (below 0.1 mW)

compared to limits given by the Rec. 1999/519/EC, no additional measures

are needed.

38 Rosemount 5900S Radar Level Gauge

Page 39

March 2020 Quick Start Guide

A.5 Installing Equipment in North America

The US National Electrical Code® (NEC) and the Canadian Electrical Code

(CEC) permit the use of Division marked equipment in Zones and Zone

marked equipment in Divisions.

The markings must be suitable for the area classification, gas, and

temperature class. This information is clearly defined in the respective

codes.

A.6 North America

A.6.1 I5 USA Intrinsic Safety

Certificate

Standards

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Specific Conditions for Safe Use (X):

1. The enclosure contains aluminum and is considered to present a

potential risk of ignition by impact or friction. When installed as EPL

Ga, care must be taken during installation and use to prevent impact

or friction.

FM 17US0030X

FM Class 3600:2018, FM Class 3610:2018, FM Class

3810:2005, ANSI/ISA 61010-1:2004, ANSI/NEMA

250:2003, ANSI/IEC 60529:2004, ANSI/UL

60079-0:2013 Ed 6, ANSI/UL 60079-11:2014 Ed 6.3,

ANSI/UL 60079-26:2017 Ed 3

IS/I,II,III/1/ABCDEFG/T4

DIP/II,III/1/EFG/T5

CL 1 ZN 0 AEx ia IIC T4 Ga

CL 1 ZN 0/1 AEx ib IIC T4 Ga/Gb

Ta = -50°C to 80°C - 9240040-917;

Type 4X; IP66; IP67

Ii (lmax) Pi Ci Li

(Vmax)

2. Non-metallic surfaces and the surface of the painted housing may,

under certain extreme conditions, generate an ignition-capable level

of electrostatic. Appropriate measures must be taken to prevent

electrostatic discharge.

3. Using the box provided on the nameplate, the User shall

permanently mark the type of protection chosen for the specific

Quick Start Guide 39

Page 40

Quick Start Guide March 2020

installation. Once the type of protection has been marked it shall not

be changed.

4.

When installed as Ex ib Ga/Gb, the partition wall materials separating

EPL Ga from EPL Gb are constructed of different materials depending

on the antenna option. Please refer to Control Drawing

D9240040-917 for the material type of each antenna. The material

shall not be subject to environmental conditions which might

adversely affect the partition wall.

Maximum Process Temperatures are as follows:

5.

When option n=Tank

Seal

PV or QV Viton -15°C to +180°C

PK, FK, HK or QK Kalrez -20°C to +230°C

PE or QE EPDM -40°C to +110°C

PB or QB BUNA-N -35°C to +90°C

PM, FF, HH or QM FVMQ -60°C to +155°C

PF or QF FEP -60°C to +180°C

A.6.2 I6 Canada Intrinsic Safety

Certificate

Standards

Markings

FM17CA0016X

CSA-C22.2 No. 25-2017

CSA-C22.2 No. 94-M91:1991 (R2011)

CSA-C22.2 No. 1010-1:2004 (R2009)

CSA-C22.2 No. 60529:2016

CSA-C22.2 No. 60079-0:2015

CSA-C22.2 No. 60079-11:2014

CSA-C22.2 No. 60079-26:2016

IS/I,II,III/1/ABCDEFG/T4

Ex ia IIC T4 Ga

Ex ib IIC T4 Ga/Gb

DIP/II,III/1/EFG/T5

Ta = -50°C to 80°C

9240040-917

Type 4X; IP66; IP67

O-ring Type Min/Max Process

Temperature Range

40 Rosemount 5900S Radar Level Gauge

Page 41

March 2020 Quick Start Guide

Ui

(Vmax)

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Ii (lmax) Pi Ci Li

Specific Conditions for Safe Use (X):

1. The enclosure contains aluminum and is considered to present a

potential risk of ignition by impact or friction. When installed as EPL

Ga, care must be taken during installation and use to prevent impact

or friction.

2. Non-metallic surfaces and the surface of the painted housing may,

under certain extreme conditions, generate an ignition-capable level

of electrostatic. Appropriate measures must be taken to prevent

electrostatic discharge.

3. Using the box provided on the nameplate, the User shall

permanently mark the type of protection chosen for the specific

installation. Once the type of protection has been marked it shall not

be changed.

4. When installed as Ex ib Ga/Gb, the partition wall materials separating

EPL Ga from EPL Gb are constructed of different materials depending

on the antenna option. Please refer to Control Drawing

D9240040-917 for the material type of each antenna. The material

shall not be subject to environmental conditions which might

adversely affect the partition wall.

5. Maximum Process Temperatures are as follows:

When option n=Tank

Seal

PV or QV Viton -15°C to +180°C

PK, FK, HK or QK Kalrez -20°C to +230°C

PE or QE EPDM -40°C to +110°C

PB or QB BUNA-N -35°C to +90°C

PM, FF, HH or QM FVMQ -60°C to +155°C

PF or QF FEP -60°C to +180°C

O-ring Type Min/Max Process

Temperature Range

A.7 Europe

A.7.1 I1 ATEX Intrinsic Safety

Certificate

Quick Start Guide 41

FM09ATEX0057X

Page 42

Quick Start Guide March 2020

Standards

EN IEC 60079-0:2018, EN 60079-11:2012, EN

60079-26:2015, EN 60529:1991+A1(2000)+A2(2013)

Markings

II 1 G Ex ia IIC T4 Ga

II 1/2 G Ex ib IIC T4 Ga/Gb

Ta = -50°C to 80°C; IP66, IP67

Ui

(Vmax)

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Ii (lmax) Pi Ci Li

Specific Conditions for Safe Use (X):

1. The enclosure contains aluminum and is considered to present a

potential risk of ignition by impact or friction. When installed as EPL

Ga, care must be taken during installation and use to prevent impact

or friction.

2. Non-metallic surfaces and the surface of the painted housing may,

under certain extreme conditions, generate an ignition-capable level

of electrostatic. Appropriate measures must be taken to prevent

electrostatic discharge.

3.

Using the box provided on the nameplate, the User shall

permanently mark the type of protection chosen for the specific

installation. Once the type of protection has been marked it shall not

be changed.

4. When installed as Ex ib Ga/Gb, the partition wall materials separating

EPL Ga from EPL Gb are constructed of different materials depending

on the antenna option. Please refer to Control Drawing

D9240040-917 for the material type of each antenna. The material

shall not be subject to environmental conditions which might

adversely affect the partition wall.

5. Maximum Process Temperatures are as follows:

When option n=Tank

Seal

PV or QV Viton -15°C to +180°C

PK, FK, HK or QK Kalrez -20°C to +230°C

PE or QE EPDM -40°C to +110°C

PB or QB BUNA-N -35°C to +90°C

42 Rosemount 5900S Radar Level Gauge

O-ring Type Min/Max Process

Temperature Range

Page 43

March 2020 Quick Start Guide

When option n=Tank

Seal

PM, FF, HH or QM FVMQ -60°C to +155°C

PF or QF FEP -60°C to +180°C

A.8 International

A.8.1 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Specific Conditions for Safe Use (X):

1. The enclosure contains aluminum and is considered to present a

potential risk of ignition by impact or friction. When installed as EPL

Ga, care must be taken during installation and use to prevent impact

or friction.

IECEx FMG 09.0009X

IEC 60079-0:2017, IEC 60079-11:2011, IEC

60079-26:2014

Ex ia IIC T4 Ga

Ex ib IIC T4 Ga/Gb

Ta = -50°C to +80°C; IP66, IP67

(Vmax)

O-ring Type Min/Max Process

Temperature Range

Ii (lmax) Pi Ci Li

2. Non-metallic surfaces and the surface of the painted housing may,

under certain extreme conditions, generate an ignition-capable level

of electrostatic. Appropriate measures must be taken to prevent

electrostatic discharge.

3. Using the box provided on the nameplate, the User shall

permanently mark the type of protection chosen for the specific

installation. Once the type of protection has been marked it shall not

be changed.

4. When installed as Ex ib Ga/Gb, the partition wall materials separating

EPL Ga from EPL Gb are constructed of different materials depending

on the antenna option. Please refer to Control Drawing

D9240040-917 for the material type of each antenna. The material

shall not be subject to environmental conditions which might

adversely affect the partition wall.

Quick Start Guide 43

Page 44

Quick Start Guide March 2020

5. Maximum Process Temperatures are as follows:

When option n=Tank

Seal

PV or QV Viton -15°C to +180°C

PK, FK, HK or QK Kalrez -20°C to +230°C

PE or QE EPDM -40°C to +110°C

PB or QB BUNA-N -35°C to +90°C

PM, FF, HH or QM FVMQ -60°C to +155°C

PF or QF FEP -60°C to +180°C

A.9 Brazil

A.9.1 I2 INMETRO Intrinsic Safety

Certificate

Standards

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

UL-BR 17.0982X

ABNT NBR IEC 60079-0:2013, 60079-11:2013,

60079-26:2016

Ex ia IIC T4 Ga/Gb

Tamb: -50 °C to + 80 °C

IP66/IP67

(Vmax)

O-ring Type Min/Max Process

Temperature Range

Ii (lmax) Pi Ci Li

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

A.10 China

A.10.1

44 Rosemount 5900S Radar Level Gauge

I3 China Intrinsic Safety

Certificate

Standards

Markings

GYJ16.1251X

GB 3836.1 - 2010, GB 3836.4 - 2010, GB 3836.20 - 2010

Ex ia IIC T4 Ga

Page 45

March 2020 Quick Start Guide

Ui

(Vmax)

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Ii (lmax) Pi Ci Li

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

A.11 Technical Regulations Customs Union (EAC)

A.11.1 IM EAC Intrinsic Safety

Certificate

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

RU C-SE.AA87.B.00346

Ga/Gb Ex ia IIC T4 X

Tamb: -50 °C to + 80 °C

IP66/IP67

Ii (lmax) Pi Ci Li

(Vmax)

A.12 Japan

A.12.1 I4 Japan Intrinsic Safety

Certificate

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

Quick Start Guide 45

CML 17JPN2301X

Ex ia IIC T4 Ga/Gb

-50 °C ≤ Ta ≤ +80 °C

Ii (lmax) Pi Ci Li

(Vmax)

Page 46

Quick Start Guide March 2020

A.13 Republic of Korea

A.13.1 IP Korea Intrinsic Safety

Certificate

Markings

Ui

Entity parameters 30 V 300 mA 1.3 W 1.1 nF 1.5 µH

FISCO parameters 17.5V 380 mA 5.32 W 1.1 nF 1.5 µH

Special Conditions for Safe Use (X):

1. See certificate for special conditions.

14-KB4BO-0573X

Ex ia IIC T4 Ga/Gb

(-50 °C ≤ Ta ≤ +80 °C)

Ii (lmax) Pi Ci Li

(Vmax)

A.14 Additional certifications

A.14.1 Functional Safety Certification (SIS)

3 Functional Safety

Certificate

Standards

S Functional Safety

Certificate

Standards

Certificate

Standards

ROS 1312032 C001

SIL 3 2-in-1 (1oo2) option (SIS-relays)

IEC 61508:2010 Parts 1-7

ROS 1312032 C004

SIL 2 1-in-1 (1oo1) option, with 4-20mA or K1/K2 relay

IEC 61508:2010 Parts 1-7

ROS 1312032 C005

SIL 2 2-in-1 (1oo1) option, with 4-20mA or K1/K2 relay

IEC 61508:2010 Parts 1-7

A.14.2 Germany WHG Certification (DIBt)

Certificate

Z-65.16-500

A.14.3 Belgium Overfill Certification (Vlarem)

Certificate

46 Rosemount 5900S Radar Level Gauge

99/H031/13072201

Page 47

March 2020 Quick Start Guide

A.14.4 India Intrinsic Safety

Certificate

Markings

P349859/1

Ex ia IIC Ga/Gb

A.15 Custody Transfer Certifications

Australia Custody Transfer

Certificate

Standards

Belgium Custody Transfer

BMS Certificate

Bulgaria Custody Transfer

Bulgaria Institute of Metrology

China Custody Transfer

CPA Pattern Approval

Certificate

Croatia Custody Transfer

Certificate

No 5/1/7

Regulation 60: National Measurement Regulations 1999

NR. P6.0.014.02-B-16

18.10.5106.1

2012-L134

558-02-01_01-15-2

Czech Republic Custody Transfer

Certificate

Estonia Custody Transfer

Certificate

France Custody Transfer

Certificate

Germany Custody Transfer

Certificate

Quick Start Guide 47

0111-CS-C022-10

TJA 6.13-3_15.09.11

No. LNE-24609

PTB-1.5-4058175

Page 48

Quick Start Guide March 2020

India Custody Transfer

Certificate

IND/13/12/191

Indonesia Custody Transfer

Certificate

DITJEN MIGAS CT approval 26.10.2010

Italy Custody Transfer

Certificate

183349 (Raptor system)

Kazakhstan Custody Transfer

GOST Pattern Approval:

Certificate

KZ.02.02.06177-2018 No.14983 (5900)

KZ.02.02.04018-2014 No.10790 (System)

Malaysia Custody Transfer

Certificate

ATS 09-11

Netherlands Custody Transfer

NMI Certificate

TC7982

Norway Custody Transfer

Certificate

No. N-11-7146

Poland Custody Transfer

Certificate

ZT-7 2013

Portugal Custody Transfer

Certificate

P12_101.12_31

Russia Custody Transfer

GOST Pattern Approval:

Certificate

SE.C.29.639.A No. 66902 (5900)

Serbia Custody Transfer

Certificate

48 Rosemount 5900S Radar Level Gauge

393-7_0-01-2088

Page 49

March 2020 Quick Start Guide

South Africa Custody Transfer

Certificate

Switzerland Custody Transfer

Certificate

OIML Custody Transfer

Certificate

SAEx S11-065

Zulassungszertifikat CH-L-11127-01

R85-2008-SE-11.01

A.16 Product Certifications Rosemount 2051

Extract from Rosemount 2051 Product Certifications Rev: 1.13

A.16.1 North America

IE USA FISCO

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

The Model 2051 transmitter housing contains aluminum and is

1.

considered a potential risk of ignition by impact or friction. Care must

be taken into account during installation and use to prevent impact

and friction.

FM16US0231X

FM Class 3600 – 2011, FM Class 3610 – 2010, FM Class

3611 – 2004, FM Class 3810 – 2005

IS CL I, DIV 1, GP A, B, C, D when connected per

Rosemount drawing 02051-1009 (-50°C ≤ Ta ≤ +60°C);

Type 4x

IF Canada Intrinsic Safety

Certificate

Standards

Markings

Quick Start Guide 49

2041384

CSA Std. C22.2 No. 142 - M1987, CSA Std. C22.2 No.

213 - M1987, CSA Std. C22.2 No. 157 - 92, ANSI/ISA

12.27.01 – 2003, CAN/CSA-E60079-0:07, CAN/CSAE60079-11:02

Intrinsically safe for Class I, Division 1, Groups A, B, C,

and D when connected in accordance with Rosemount

drawing 02051-1008. Ex ia IIC T3C. Single Seal.

Enclosure Type 4X

Page 50

Quick Start Guide March 2020

A.16.2 Europe

IA ATEX FISCO

A.16.3

Certificate

Standards

Markings

Ui Ii Pi Ci Li

FISCO

parameters

Baseefa08ATEX0129X

EN60079-0:2012+A11:2013, EN60079-11:2012

II 1 G Ex ia IIC T4 Ga (-60°C ≤ Ta ≤ +60°C)

17.5V 380 mA 5.32 W 0 µF 0 mH

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90V transient suppressor,

it is incapable of withstanding the 500V isolation from earth test and

this must be taken into account during installation.

2. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however care should be taken to protect it

from impact and abrasion when located in Zone 0.

International

IG IECEx FISCO

Certificate

Standards

Markings

IECExBAS08.0045X

IEC60079-0:2011, IEC60079-11:2011

Ex ia IIC T4 Ga (-60°C ≤ Ta ≤ +60°C)

Ui Ii Pi Ci Li

FISCO

parameters

17.5V 380 mA 5.32 W 0 nF 0 µH

Special Conditions for Safe Use (X):

1. If the equipment is fitted with an optional 90V transient suppressor,

it is incapable of withstanding the 500V isolation from earth test and

this must be taken into account during installation.

2. The enclosure may be made of aluminum alloy and given a protective

polyurethane paint finish; however care should be taken to protect it

from impact and abrasion when located in Zone 0.

3.

The equipment contains thin wall diaphragms. The installation,

maintenance and use shall take into account the environmental

conditions to which the diaphragms will be subjected. The

50 Rosemount 5900S Radar Level Gauge

Page 51

March 2020 Quick Start Guide

manufacturer’s instructions for installation and maintenance shall be

followed in detail to assure safety during its expected lifetime.

A.17 Declaration of conformity

Emerson.com/Rosemount

Figure A-1: Rosemount 5900S EU Declaration of Conformity (page 1)

Quick Start Guide 51

Page 52

Quick Start Guide March 2020

Figure A-2: Rosemount 5900S EU Declaration of Conformity (page 2)

52 Rosemount 5900S Radar Level Gauge

Page 53

March 2020 Quick Start Guide

Figure A-3: Rosemount 5900S EU Declaration of Conformity (page 3)

Quick Start Guide 53

Page 54

Quick Start Guide March 2020

A.18 China RoHS

Figure A-4: Rosemount 5900S China RoHS

54 Rosemount 5900S Radar Level Gauge

Page 55

March 2020 Quick Start Guide

Quick Start Guide 55

Page 56

Global Headquarters and Europe

Regional Office Tank Gauging

Emerson Automation Solutions

Box 150

(Visiting address: Layoutvägen 1)

SE-435 23 Mölnlycke

Sweden

+46 31 337 00 00

+46 31 25 30 22

Sales.RTG@Emerson.com

*00825-0100-5900*

Quick Start Guide

00825-0100-5900, Rev. AA

March 2020

North America Regional Office Tank

Gauging

Emerson Automation Solutions

6005 Rogerdale Road

Mail Stop NC 136

Houston, TX 77072, USA

+1 281 988 4000 or +1 800 722 2865

Sales.RTG.HOU@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RMTLAContactUS@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RTGMEA.Sales@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Specialist-OneLevel.RMT-

AP@Emerson.com

©

2020 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...