Page 1

Quick Start Guide

SK- 07787 , Rev B

Rosemount™ 370XA Gas Chromatograph

Helium to Hydrogen Gas Conversion Kit

March 2020

Page 2

Safety and information notices

DANGER

WILL CAUSE DEATH

Failure to follow this warning will result in death or serious injury to personnel.

WARNING

DANGER TO PERSONNEL

Failure to follow this warning may result in serious injury to personnel.

WARNING

SAFETY COMPLIANCE

Repairs or alterations are not permitted on any flame-proof paths, features, or joints.

Failure to follow this warning may compromise the product’s safety protection method and void the product certification.

NOTICE

Important messages will appear in this format.

2

Page 3

Quick Start Guide Contents

SK- 07787 March 2020

Contents

Chapter 1 Safety requirements...................................................................................................5

1.1 Rosemount 370XA Hydrogen Conversion Kit Gas Chromatograph safety warnings..................... 5

Chapter 2 Installation.................................................................................................................7

2.1 Installing the Rosemount 370XA helium to hydrogen gas conversion kit..................................... 7

2.2 Installing the carrier shut-off valve............................................................................................... 9

2.3 Purging the carrier gas lines....................................................................................................... 12

2.4 Changing the thermistors.......................................................................................................... 13

2.5 Adjusting the carrier pressure.................................................................................................... 20

2.6 Configure the valve timing.........................................................................................................24

Chapter 3 Ordering information...............................................................................................27

3.1 Parts list.....................................................................................................................................27

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 3

Page 4

Contents Quick Start Guide

March 2020 SK- 07787

4 Emerson.com/Rosemount

Page 5

Quick Start Guide Safety requirements

SK- 07787 March 2020

1 Safety requirements

1.1 Rosemount 370XA Hydrogen Conversion Kit Gas Chromatograph safety warnings

Observe these safety messages for the Rosemount 370XA Hydrogen Conversion Kit Gas

Chromatograph.

WARNING

EXPLOSION HAZARD

Failure to de-energize the analyzer may cause serious injury or death to personnel.

Do not open when energized or when an explosive atmosphere may be present.

Keep cover tight while circuits are live.

WARNING

EXPLOSION/FIRE HAZARD

Failure to observe this warning may cause serious injury or death to personnel.

Do not open when an explosive atmosphere may be present.

Do not open while energized.

Use supply cables or wires suitable for at least 176 °F (80 °C).

WARNING

BURN HAZARD

Internal components may be hot. Failure to allow the GC to cool down may result in injury

to personnel.

Allow the GC to cool down before disassembling any components.

Always wear proper personal protective equipment (PPE) when disassembling the

analyzer.

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or unintentional and

needs to be protected against.

Physical security is an important part of any security program and fundamental to

protecting your system. Restrict physical access by unauthorized personnel to protect end

users’ assets. This is true for all systems used within the facility.

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 5

Page 6

Safety requirements Quick Start Guide

March 2020 SK- 07787

6 Emerson.com/Rosemount

Page 7

Quick Start Guide Installation

SK- 07787 March 2020

2 Installation

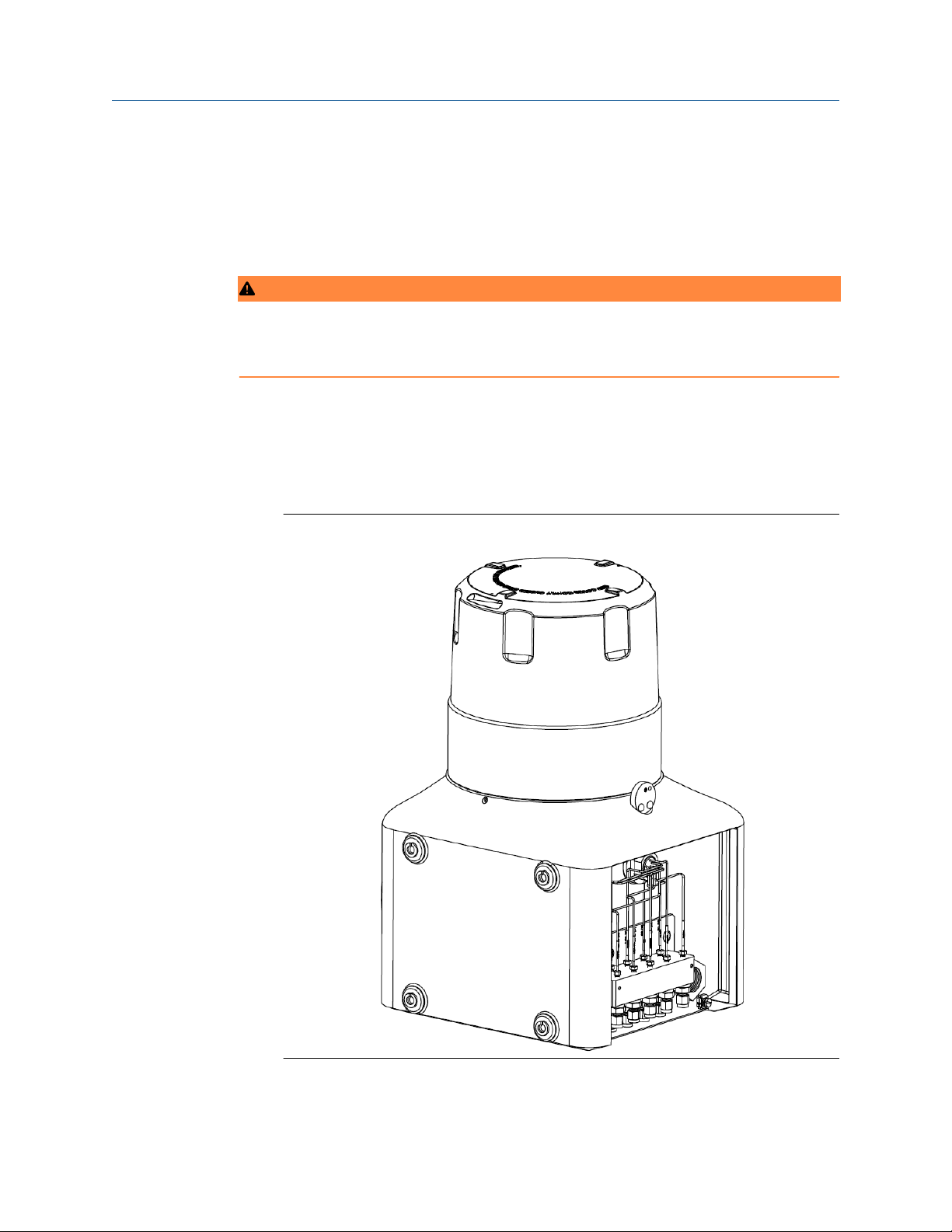

2.1 Installing the Rosemount 370XA helium to hydrogen gas conversion kit

These are the instructions to install the hardware for the helium to hydrogen gas

conversion kit for the Rosemount 370XA Hydrogen Conversion Kit Gas Chromatograph.

The installation kit (7A00003) contains the hardware necessary to convert helium to

hydrogen gas for the GC.

WARNING

Explosion Hazard

Before converting carrier gas to hydrogen, review local hazardous area requirements to

ensure compliance.

The procedure to convert the Rosemount 370XA Gas Chromatograph from helium to

hydrogen gas includes:

• Changing the thermistors (2-6-5000-084)

• Adding a carrier shut-off valve (2-4-4000-197)

• Purging the carrier gas

• Adjusting the carrier pressure (MON2000 2-3-9000-522)

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 7

Page 8

Installation Quick Start Guide

March 2020 SK- 07787

The contents of the kit are listed in Helium Conversion Kit P/N 7A00003, Parts list and are

illustrated in the Table 2-1.

Table 2-1: Hydrogen Conversion Kit Main Components

Carrier shut-off valve Thermistors

P/N 2-4-4000-197

7A0003G02 - Field retrofit kit

P/N 2-5-1611-007

8 Emerson.com/Rosemount

Page 9

Quick Start Guide Installation

SK- 07787 March 2020

2.2 Installing the carrier shut-off valve

This procedure describes installing the carrier shut-off valve and tubing for hydrogen

applications.

Refer to the Parts List and the following steps to perform this task.

WARNING

Explosion Hazard

Do not use hydrogen for valve actuation.

Procedure

1. Shut off the carrier and actuation gas supply.

2. Wait until the carrier gas pressure gauge reads zero psi.

3. Disconnect the carrier gas tubing from the tee fitting that is connected to the

carrier gas supply.

Figure 2-1: Current Carrier Gas Line Configuration Using Helium

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 9

Page 10

Installation Quick Start Guide

March 2020 SK- 07787

Note

The tee fitting positioning may vary, but is often found at the inlet of the carrier gas

regulator. A reducer is provided in the kit to make a connection directly from the

carrier gas cylinder to take the tubing size down from ¼-in. to ⅛-in.

4. Mount the carrier shut-off valve to the bracket on the back frame rail.

Figure 2-2: Carrier Gas, Actuation Gas Line, and Shut-off Valve Connections

A. Bracket

B. Carrier shut-off valve

C. Actuation gas connection

D. Tee fitting and actuation gas line, stainless steel, ⅛-in. tubing

5. Connect a ⅛-in. tubing from the tee to the input port of the shut-off valve.

10 Emerson.com/Rosemount

Page 11

Quick Start Guide Installation

SK- 07787 March 2020

6. Use a ⅛-in. national pipe thread (NPT) to ⅛-in. Swagelok tee fitting to connect the

carrier gas line located at the top port of the shut-off valve.

Figure 2-3: Carrier and Actuation Gas Tubing Connections

A. Carrier gas tubing input to shut-off valve

B. Actuation gas tubing input to carrier shut-off valve

7. Connect a piece of ⅛-in. tubing from the actuation port of the shut-off valve to the

⅛-in. bulkhead fitting.

8. Connect the actuation line (N2) to the ⅛-in. input port.

9. Ensure that all tube fittings are properly connected. Then label the new actuation

gas inlet and reconnect gases to their appropriate entries.

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 11

Page 12

Installation

March 2020 SK- 07787

Quick Start Guide

2.3 Purging the carrier gas lines

Use this procedure to purge the gas chromatograph's gas lines.

Refer to Figure 2-4.

Procedure

1. Close all valves and tighten all fittings.

2. Run tubing to the GC, but do not connect.

3. Back off pressure regulator (turn counterclockwise) fully.

Refer to Figure 2-4 to complete Step 4 through Step 12.

Figure 2-4: Carrier Gas Valve Configuration

4. Open cylinder valve for Carrier Cylinder 1.

The pressure indicator will read the cylinder pressure.

5. Open the shut-off valve attached to the carrier regulator.

6. Regulate pressure out of the cylinder to 20 psig; then close the cylinder valve.

7. Open V-1 (bleed valve) and let the carrier gas bleed to atmosphere until both

gauges read 0 psig and then close V-1.

8. Repeat Step 4 and Step 5 twice to purge the line to V-2.

9. Purge the line to V-3 by repeating Step 2 through Step 6, but this time, use bleed

valve V-4 and Carrier Cylinder 2.

12 Emerson.com/Rosemount

Page 13

Quick Start Guide Installation

SK- 07787 March 2020

10. With valves 1-4 closed, open both cylinder valves and regulate both carriers to

approximately 10 psig.

11. Open V-2 and V-3 simultaneously; then turn both cylinder valves off and let the

carrier gases bleed through the line to the GC until all gauges read 0 psig.

12. Repeat Step 8 and Step 9 twice to purge the line to the GC.

13. Leak check all the fittings carefully.

14. Let the GC run overnight before calibrating.

2.4 Changing the thermistors

Use this procedure to remove the helium thermistors and install the hydrogen compatible

thermistors.

WARNING

EXPLOSION HAZARD

Failure to observe this warning may cause death or serious injury to personnel.

Hydrogen is potentially explosive. Use extreme caution when using hydrogen as the

gas chromatograph's carrier gas.

To prevent ignition of hazardous atmospheres, disconnect from supply circuit before

opening the enclosure. Keep tightly closed when circuits are alive. For division

installations using a conduit, a sealing device must be connected within 18 in. (460

mm).

2.4.1 Removing the thermistors

Use this procedure to remove the helium thermistors.

Procedure

1. Turn off power to the gas chromatograph.

2. Remove the dome cover (P/N 7P00057H01).

3. Remove the upper enclosure insulation cover (P/N 7A00058G01).

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 13

Page 14

Installation Quick Start Guide

March 2020 SK- 07787

4. Lift the analytical heater assembly (P/N 7A00005G01) and allow it to hang by the

heater strap.

Figure 2-5: Removing the Dome Cover, Insulation Cover, and Heater Assembly

A. Dome cover

B. Insulation cover

C. Analytical module heater assembly

14 Emerson.com/Rosemount

Page 15

Quick Start Guide Installation

SK- 07787 March 2020

5. Remove the O-Ring from the valve mounting plate groove.

Figure 2-6: Mounting Plate Slot

A. O-Ring

B. Valve mounting plate slot

See Figure 2-7 and Figure 2-8 for Step 5 through Step 12.

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 15

Page 16

Installation Quick Start Guide

March 2020 SK- 07787

6. Remove the columns.

Figure 2-7: Removing the Columns and Disconnecting the Thermistor Wires

A. Columns

B. Thermistor wiring sensor harness screws

7. Remove the heat pipes spring block.

8. Remove the two heat pipe springs.

9. Remove the two heat pipe bracket screws from the TCD block.

10. Use a standard flathead or a Phillips screwdriver and loosen the four thermistor

wiring screws in the sensor harness.

11. Remove the two ⅜-in. thermistor nuts.

16 Emerson.com/Rosemount

Page 17

Quick Start Guide Installation

SK- 07787 March 2020

12. Remove the thermistors and the PTFE seals (P/N 2-6-5000-084) from the detector

block.

Figure 2-8: Thermistor disassembly

A. Heat pipe bracket

B. Heat pipe spring block

C. Heat pipe springs

D. Thermistors

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 17

Page 18

Installation

March 2020 SK- 07787

Quick Start Guide

2.4.2 Installing the hydrogen thermistors

Use this procedure to install the hydrogen thermistors.

Figure 2-9: Thermistor disassembly

A. Heat pipe bracket

B. Heat pipe spring block

C. Heat pipe springs

D. Thermistors

Procedure

1. Replace the thermistor seals and the thermistors (P/N 2-5-1611-007) that shipped

with the retrofit kit.

2. Thread the thermistors through the two ⅜-in. thermistor nuts and tighten the nuts.

Using the proper wrench, apply 20 ft.-lb. of torque.

3. Attach the thermistors into the sensor harness connector and tighten the four

screws.

4. Reinstall the two heat pipe bracket screws into the TCD block.

5. Reinstall the two heat pipe springs.

6. Reinstall the heat pipes spring block.

7. Reinstall the columns.

18 Emerson.com/Rosemount

Page 19

Quick Start Guide Installation

SK- 07787 March 2020

8. Make sure all of the wires are not pinched and are in the mounting plate slot. See

Figure 2-10.

9. Install the O-Ring (P/N 7C00030-366) over the columns and wires and fit into the

valve mounting plate groove.

Figure 2-10: Mounting Plate Slot

A. O-Ring

B. Valve mounting plate slot

10. Reinstall the heater insulation cover.

11. Reinstall the dome cover and ensure it is tightly sealed.

12. Turn on the gas chromatograph power.

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 19

Page 20

Installation Quick Start Guide

March 2020 SK- 07787

2.5 Adjusting the carrier pressure

This section describes the manual carrier pressure adjustment after performing the helium

to hydrogen gas conversion.

Procedure

1. Adjust the carrier pressure to approximately half of what it was with the helium.

2. Make a single run with calibration gas and see how close the chromatogram is when

compared to the chromatogram with helium. If it is too fast, reduce the carrier

pressure. If it is too slow, increase the carrier pressure.

3. Continue to make single runs and adjust the carrier pressure until it looks close to

what it was with the helium carrier.

4. If necessary, make any required valve timing changes to bring the GC back to full

function.

Use the following guide to help in valve adjustments. The guide is specific to C6+

BTU analysis, backflush to measure, dual column arrangement, but can be used for

any valve timing adjustments required using the appropriate valve and component.

20 Emerson.com/Rosemount

Page 21

Quick Start Guide Installation

SK- 07787 March 2020

Figure 2-11: Backflush Valve Timing

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 21

Page 22

Installation Quick Start Guide

March 2020 SK- 07787

Table 2-2: Example Backflush Valve Timing

PA Old

RT BF TIME PA n-Pentane % Change

219 20 76822312

219 21 82954542 7.982355439

219 22 85914053 3.567629847

219 24 88965346 3.551564492

219 25 92305383 3.754312381

219 26 93208291 0.978174805

219 27 94027248 0.878631065

219 28 93370502 0.698463492

219 29 94646236 1.36631374

22 Emerson.com/Rosemount

Page 23

Quick Start Guide Installation

SK- 07787 March 2020

Figure 2-12: Dual Column Valve Timing

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 23

Page 24

Installation Quick Start Guide

March 2020 SK- 07787

Table 2-3: Example Dual Column Valve Timing

BF TIME PA C3 PA C2 % Change

38 7.62+E08 5.60E+08 N/A

39 8.399+08 6.32E+08 12.85714

40 8.129+E08 6.70E+08 6.012658

41 N/A 6.87E+08 2.537313

42 N/A 6.95E+08 1.164483

43 N/A 6.98E+08 0.431655

44 N/A 7.01E+08 0.429799

5. Input the proper retention times into the Component Data Table.

6. Run forced calibration.

Postrequisites

After performing the manual carrier pressure adjustment, run MON2020 to Configure the

valve timing.

Important

Only make adjustments to the values at the direction of an Emerson Customer Care

technician.

2.6 Configure the valve timing

Use this feature to set and adjust the valve timing.

Note

Auto valve timing is only available with the Rosemount™ 370XA Gas Chromatograph.

The function of valve timing is to switch the analytical flow path after the peak of a lighter

component has left a column, but before the next component comes out. The first image

below shows the valve timing occurring in-between the C6+ and n-Pentane peaks

correctly on a standard 4-minute C6+ application. The second image shows what happens

when the valve timing is too early and cuts off some of the first peak. The third image

shows what happens when the valve timing is too late and cuts of some of the second

peak. In the last two examples, not all of the component will reach the detector at the

expected time, and therefore will not be measured correctly.

Table 2-4: The effect of valve timing on component leaks.

Correct timing Early valve timing error Late valve timing error

24 Emerson.com/Rosemount

Page 25

Quick Start Guide Installation

SK- 07787 March 2020

Historically, a technician monitors the peak areas of the two affected peaks while making

changes to the valve timing, and determine the correct timing using personal judgment.

The intention of the auto valve timing (AVT) process is to automatically make the

adjustments and monitor the peak areas to determine the correct valve timing

automatically, reducing the load on the technician to just selecting when to initiate the

AVT process.

The AVT is a process that runs on the calibration gas stream. The process consists of the

following activities:

• Correctly identify all the component peaks.

• Adjust the timed events based on peak retention times.

• Automatically adjust the valve time.

• Run a calibration cycle after the adjustments have been made.

• Check the range and order of response factors.

Procedure

1. Select Control → Auto Valve Timing to open the Start Auto Valve Timing dialog.

2. If you are installing a new module, select the Factory Defaults checkbox;

otherwise, select the Use Current checkbox.

3. Click OK.

The AVT process will run. When it completes, it will generate and display an Auto

Valve Timing report.

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 25

Page 26

Installation Quick Start Guide

March 2020 SK- 07787

Figure 2-13: Auto Valve Timing sample report

26 Emerson.com/Rosemount

Page 27

Quick Start Guide Ordering information

SK- 07787 March 2020

3 Ordering information

3.1 Parts list

Part number Description Required Units

2-6-5000-084 Seal, thermistor PTFE 2 EA

2-5-1611-007 Thermistor matched

pair 9K double dipped

(GOWMAC

instruments only)

2-6-5000-487 Tubing, 1/8 in.

ODX .085 ID

9C00012-008 SHCS, M4X0.7X8MM,

18-8 SST

7C00129-001 Fitting, Tee, 1/8" Tube,

Swagelok SS-200-3

2-4-5000-395

2-4-9500-012 Connector, male 1/8 T

7P00214H01 Bracket, hydrogen

2-4-4000-197 Valve, carrier shut-off 1 EA

7A00003G02 Kit, hydrogen shut-off

(1) The reducer is provided if a ¼-in. direct connection from the carrier gas cylinder to the ⅛-in. tee

fitting is configured.

(1)

Reducer 1/4 T X 1/8 SS 1 EA

X 1/8 NPT SS,

SS-200-1-2

shut-off valve, 370XA

valve, 370XA, field

retrofit

1 EA

4 FT

4 EA

1 EA

1 EA

1 EA

1 EA

Rosemount 370XA Gas Chromatograph Helium to Hydrogen Gas Conversion Kit 27

Page 28

SK- 07787

Rev. B

2020

AMERICAS

Emerson Automation Solutions

10241 West Little York, Suite 200

Houston, TX 77040 USA

Toll Free 866 422 3683

+1 713 396 8880 (North America)

+1 713 396 8759 (Latin America)

+1 713 466 8175

gc.csc@emerson.com

EUROPE

Emerson

Neuhofstrasse 19a PO Box 1046

CH-6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

gc.csc@emerson.com

Linkedin.com/company/Emerson-Automation-Solutions

twitter.com/rosemount_news

Facebook.com/Rosemount

youtube.com/RosemountMeasurement

MIDDLE EAST AND AFRICA

Emerson

Emerson FZE

Jebel Ali Free Zone

Dubai, United Arab Emirates, P.O. Box 17033

+971 4 811 8100

+971 4 886 5465

gc.csc@emerson.com

©

2020 Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. Rosemount is a

mark of one of the Emerson family of companies. All other marks are the property of their

respective owners.

ASIA-PACIFIC

Emerson

1 Pandan Crescent

Singapore 128461

Republic of Singapore

+65 6 777 8211

+65 6 777 0947

gc.csc@emerson.com

Loading...

Loading...