Page 1

Quick Start Guide

00825-0100-4021, Rev PB

Rosemount™ 3144P Temperature

Transmitter

with HART® Protocol and Rosemount

X-well™ Technology

March 2021

Page 2

Quick Start Guide March 2021

Contents

About this guide...........................................................................................................................3

System readiness......................................................................................................................... 5

Verify configuration..................................................................................................................... 6

Set the switches......................................................................................................................... 10

Mount the transmitter................................................................................................................11

Wire and apply power................................................................................................................ 13

Perform a loop test.....................................................................................................................18

Safety Instrumented Systems (SIS)............................................................................................. 19

Product certifications................................................................................................................. 20

2 Rosemount 3144P

Page 3

March 2021 Quick Start Guide

1 About this guide

This guide provides basic guidelines for installing the Rosemount 3144P

Transmitter. It does not provide instructions for detailed configuration,

diagnostics, maintenance, service, troubleshooting, Explosion-proof,

Flameproof, or intrinsically safe (I.S.) installations. Refer to the Rosemount

3144P Transmitter Reference Manual for more instructions. The manual and

this guide are also available electronically on Emerson.com/Rosemount.

WARNING

Explosions

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance

with appropriate local, national, and international standards, codes, and

practices.

Review the Product Certifications section of this document for any

restrictions associated with a safe installation.

Process leaks

Process leaks may cause harm or result in death.

Install and tighten thermowells and sensors before applying pressure.

Do not remove the thermowell while in operation.

Conduit/cable entries

The conduit/cable entries in the transmitter housing use a ½–14 NPT

thread form.

When installing in a hazardous location, use only appropriately listed or

Ex certified plugs, glands, or adapters in cable/conduit entries.

Electrical shock

Electrical shock can result in death or serious injury.

Avoid contact with the leads and terminals. High voltage that may be

present on leads could cause electrical shock.

Quick Start Guide 3

Page 4

Quick Start Guide March 2021

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

4 Rosemount 3144P

Page 5

March 2021 Quick Start Guide

2 System readiness

2.1 Confirm HART revision capability

If using HART based control or asset management systems, confirm the

HART capability of those systems prior to transmitter installation. Not all

systems are capable of communicating with HART Revision 7 Protocol. You

can configure the transmitter for either HART Revision 5 or 7.

For instructions on how to change the HART revision of your transmitter,

refer to Switch HART revision mode.

Quick Start Guide 5

Page 6

Quick Start Guide March 2021

3 Verify configuration

The Rosemount 3144P Transmitter communicates using a Field

Communicator (communication requires a loop resistance between 250 and

1100 ohms) or AMS Device Manager.

Do not operate when power is below 12 Vdc at the transmitter terminal.

Refer to the Rosemount 3144P Transmitter Reference Manual and Field

Communicator Reference Manual.

3.1 Update the Field Communicator software

To fully communicate with the Rosemount 3144P Transmitter, you need the

latest Field Communicator Field Device Revision Dev v5 or v7, DD v1 or

greater. Transmitters equipped with Rosemount X-well Technology require

DD revision 3144P Dev. 7 Rev. 1 or greater to view this functionality.

The Device Descriptors are available with new communicators at

Emerson.com/Rosemount, or you can download them into existing

communicators at any Emerson Service Center.

The device descriptors are as follows:

• Device in HART 5 mode: Device v5 DDv1

• Device in HART 7 mode: Device v7 DDv1

Complete the following steps to determine if you need to upgrade your

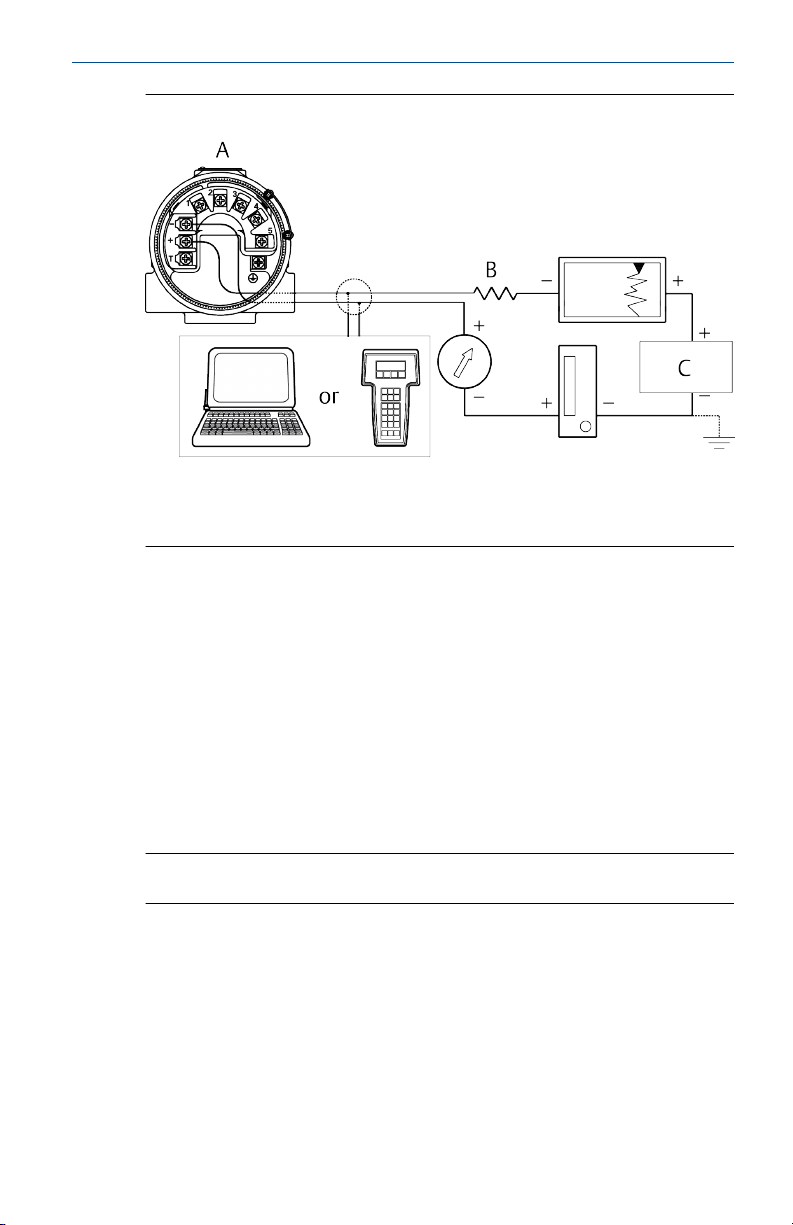

device. Refer to Figure 3-1.

6 Rosemount 3144P

Page 7

March 2021 Quick Start Guide

Figure 3-1: Connecting a Communicator to a Bench Loop

A. Power/signal terminals

B. 250 Ω ≤ RL ≤ 1100 Ω

C. Power supply

Procedure

1. Connect the sensor.

See the wiring diagram located on the inside of the housing cover.

2. Connect the bench power supply to the power terminals ("+" or "-").

3. Connect a Field Communicator to the loop across a loop resistor or at

the power/signal terminals on the transmitter.

The following message will appear if the communicator has a previous

version of the device descriptors (DDs):

NOTICE: Upgrade the communicator software to access new XMTR functions.

Continue with old description?

Note

If this notice does not appear, the latest DD is installed.

If the latest version is not available, the communicator will communicate

properly, but when the transmitter is configured some new capabilities may

not be visible.

To prevent this from happening, upgrade to the latest DD or answer NO to

the question and default to the generic transmitter functionality.

Quick Start Guide 7

Page 8

Quick Start Guide March 2021

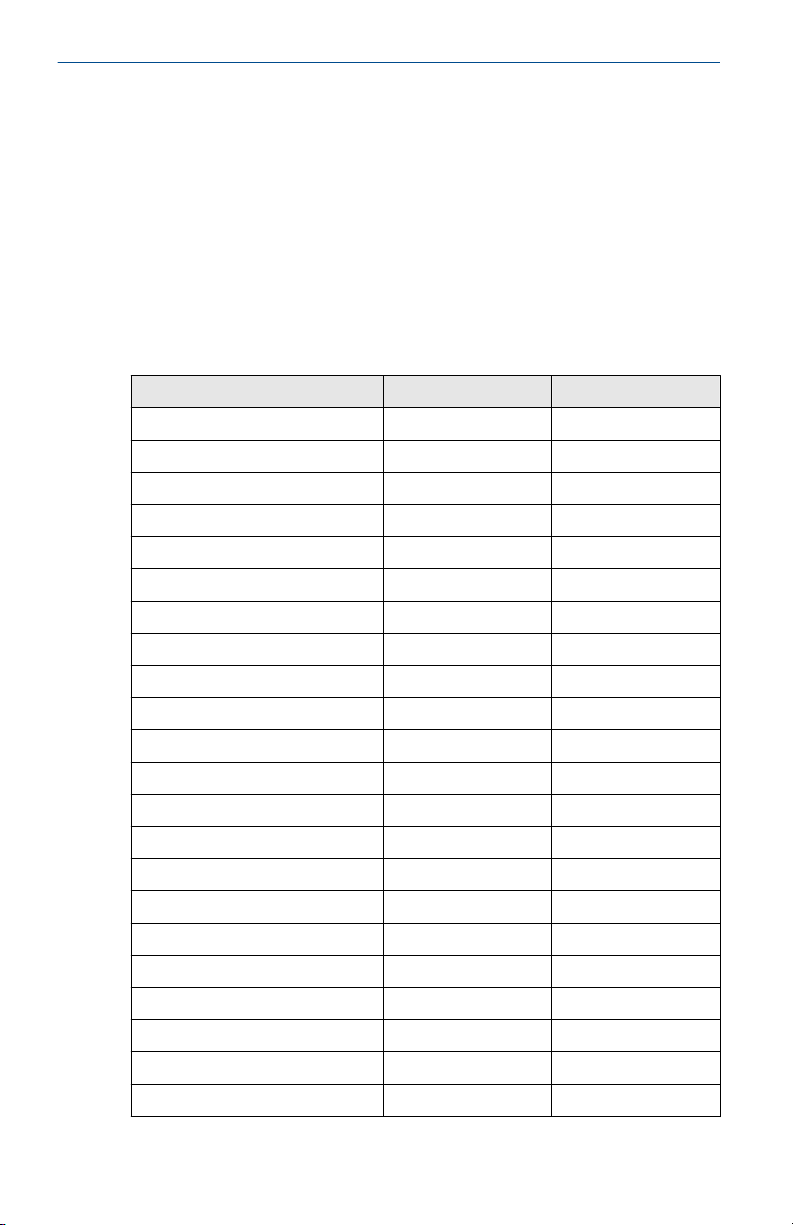

3.2 Switch HART revision mode

If the HART Protocol configuration tool is not capable of communicating

with HART Revision 7, the transmitter will load a generic menu with limited

capability. The following procedure will switch the HART Revision mode

from the generic menu.

Procedure

Select Manual Setup → Device Information → Identification → Message.

a) To change to HART Revision 5, enter HART5 in the Message field.

b) To change to HART Revision 7, enter HART7 in the Message field.

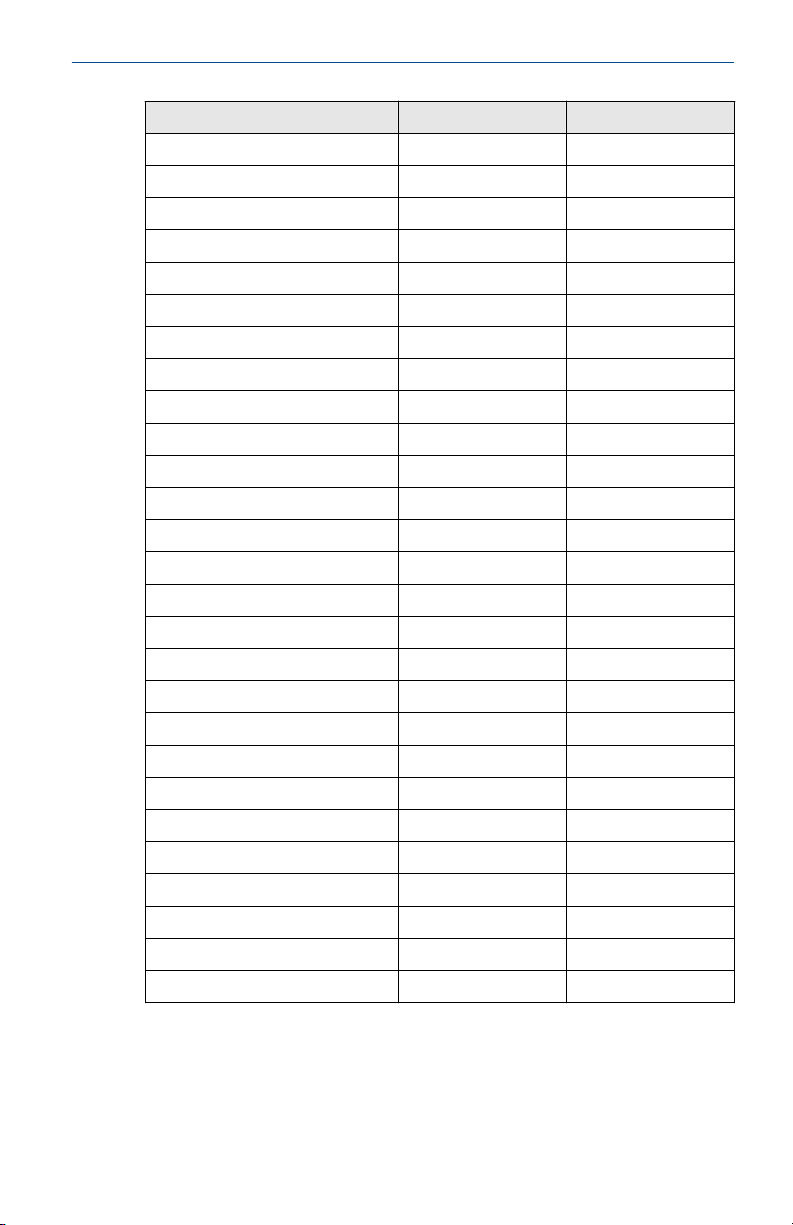

Function HART 5 Fast Keys HART 7 Fast Keys

2-wire offset sensor 1 2, 2, 1, 5 2, 2, 1, 6

2-wire offset sensor 2 2, 2, 2, 5 2, 2, 2, 6

Alarm values 2, 2, 5, 6 2, 2, 5, 6

Analog calibration 3, 4, 5 3, 4, 5

Analog output 2, 2, 5 2, 2, 5

Average temperature setup 2, 2, 3, 3 2, 2, 3, 3

Burst mode N/A 2, 2, 8, 4

Comm status N/A 1, 2

Configure additional messages N/A 2, 2, 8, 7

Configure Hot Backup

Date 2, 2, 7, 1, 2 2, 2, 7, 1, 3

Descriptor 2, 2, 7, 1, 3 2, 2, 7, 1, 4

Device information 2, 2, 7, 1 2, 2, 7, 1

Differential temperature setup 2, 2, 3, 1 2, 2, 3, 1

Filter 50/60 Hz 2, 2, 7, 5, 1 2, 2, 7, 5, 1

Find device N/A 3, 4, 6, 2

First good temperature setup 2, 2, 3, 2 2, 2, 3, 2

Hardware revision 1, 8, 2, 3 1, 11, 2, 3

HART lock N/A 2, 2, 9, 2

Intermittent sensor detect 2, 2, 7, 5, 2 2, 2, 7, 5, 2

Lock status N/A 1, 11, 3, 7

Long tag N/A 2, 2, 7, 2

™

2, 2, 4, 1, 3 2, 2, 4, 1, 3

8 Rosemount 3144P

Page 9

March 2021 Quick Start Guide

Function HART 5 Fast Keys HART 7 Fast Keys

Loop test 3, 5, 1 3, 5, 1

LRV (lower range value) 2, 2, 5, 5, 3 2, 2, 5, 5, 3

Message 2, 2, 7, 1, 4 2, 2, 7, 1, 5

Open sensor holdoff 2, 2, 7, 4 2, 2, 7, 4

Percent range 2, 2, 5, 4 2, 2, 5, 4

Sensor 1 configuration 2, 2, 1 2, 2, 1

Sensor 1 serial number 2, 2, 1, 7 2, 2, 1, 8

Sensor 1 setup 2, 2, 1 2, 2, 2

Sensor 1 status N/A 2, 2, 1, 2

Sensor 1 type 2, 2, 1, 2 2, 2, 1, 3

Sensor 1 unit 2, 2, 1, 4 2, 2, 1, 5

Sensor 2 configuration 2, 2, 2 2, 2, 2

Sensor 2 serial number 2, 2, 2, 7 2, 2, 2, 8

Sensor 2 setup 2, 2, 2 2, 2, 2

Sensor 2 status N/A 2, 2, 2, 2

Sensor 2 type 2, 2, 2, 2 2, 2, 2, 3

Sensor 2 unit 2, 2, 2, 4 2, 2, 2, 5

Sensor drift alert 2, 2, 4, 2 2, 2, 4, 2

Simulate device variables N/A 3, 5, 2

Software revision 1, 8, 2, 4 1, 11, 2, 4

Tag 2, 2, 7, 1, 1 2, 2, 7, 1, 1

Terminal temperature units 2, 2, 7, 3 2, 2, 7, 3

URV (upper range value) 2, 2, 7, 3 2, 2, 7, 3

Variable mapping 2, 2, 8, 5 2, 2, 8, 5

Thermocouple diagnostic 2, 1, 7, 1 2, 1, 7, 2

Min/max tracking 2, 1, 7, 2 2, 1, 7, 2

Rosemount X-well configuration N/A 2, 2, 1, 11

Quick Start Guide 9

Page 10

Quick Start Guide March 2021

4 Set the switches

The Rosemount 3144P Transmitter comes with hardware switches to

configure alarms and lock the device. Use the following procedures to set

the switches.

WARNING

Enclosure

Enclosure covers must be fully engaged to meet explosion-proof

requirements.

4.1 Set the switches with an LCD display

Procedure

1. Set the loop to manual (if applicable) and disconnect the power.

2. Remove the electronics housing cover.

3. Unscrew the LCD display screws and gently slide the meter straight

off.

4. Set the alarm and security switches to the desired position.

5. Gently slide the LCD display back into place.

6. Replace and tighten the LCD display screws to secure the LCD

display.

7. Reattach housing cover.

8. Apply power and set the loop to automatic control.

4.2

10 Rosemount 3144P

Set the switches without an LCD display

Procedure

1. Set the loop to manual (if applicable) and disconnect the power.

2. Remove the electronics housing cover.

3. Set the alarm and security switches to the desired position.

4. Reattach housing cover.

5. Apply power and set the loop to automatic control.

Page 11

March 2021 Quick Start Guide

5 Mount the transmitter

Mount the transmitter at a high point in the conduit run to prevent moisture

from draining into the transmitter housing.

5.1 Typical North American installation

Procedure

1. Mount the thermowell to the process container wall.

2. Install and tighten thermowells.

3. Perform a leak check.

4. Attach any necessary unions, couplings, and extension fittings. Seal

the fitting threads with an approved thread sealant, such as silicone

or PTFE tape (if required).

5. Screw the sensor into the thermowell or directly into the process

(depending on installation requirements).

6. Verify all sealing requirements.

7. Attach the transmitter to the thermowell/sensor assembly. Seal all

threads with an approved thread sealant, such as silicone or PTFE

tape (if required).

8. Install field wiring conduit into the open transmitter conduit entry

(for remote mounting) and feed wires into the transmitter housing.

9. Pull the field wiring leads into the terminal side of the housing.

10. Attach the sensor leads to the transmitter sensor terminals.

The wiring diagram is located inside the housing cover.

11. Attach and tighten both transmitter covers.

5.2

Quick Start Guide 11

Typical European installation

Procedure

1. Mount the thermowell to the process container wall.

2. Install and tighten thermowells.

3. Perform a leak check.

4. Attach a connection head to the thermowell.

5. Insert sensor into the thermowell and wire the sensor to the

connection head.

The wiring diagram is located inside the connection head.

6. Mount the transmitter to a 2-in. (50 mm) pipe or a panel using one of

the optional mounting brackets.

Page 12

Quick Start Guide March 2021

7. Attach cable glands to the shielded cable running from the

connection head to the transmitter conduit entry.

8. Run the shielded cable from the opposite conduit entry on the

transmitter back to the control room.

9. Insert shielded cable leads through the cable entries into the

connection head/transmitter. Connect and tighten cable glands.

10. Connect the shielded cable leads to the connection head terminals

(located inside the connection head) and to the sensor wiring

terminals (located inside the transmitter housing).

12 Rosemount 3144P

Page 13

March 2021 Quick Start Guide

6 Wire and apply power

6.1 Wire the transmitter

Wiring diagrams are located inside the terminal block cover.

See Table 6-1.

Table 6-1: Single Sensor

2-wire RTD and

ohms

(1) Emerson provides 4-wire sensors for all single-element RTDs. You can use these RTDs in 3-

wire configurations by leaving the unneeded leads disconnected and insulated with

electrical tape.

(2) Transmitter must be configured for a 3-wire RTD in order to recognize an RTD with a

compensation loop.

3-wire RTD and

(1)

ohms

4-wire RTD and

ohms

T/Cs and

millivolts

RTD with

compensation

(2)

loop

Table 6-2: Dual Sensor

Emerson provides 4-wire sensors for all single-element RTDs. To use these RTDs in three-wire

configurations, leave the unneeded leads disconnected and insulated with electrical tape This

table refers to wiring dual sensors for ΔT and Hot Backup™.

With two

RTDs

With two

thermocouples

With RTDs/

thermocouples

With RTDs/

thermocouples

With two RTDs

with

compensation

loop

Quick Start Guide 13

Page 14

Quick Start Guide March 2021

6.2 Power the transmitter

An external power supply is required to operate the transmitter.

A. Sensor terminals (1–5)

B. Power terminals

C. Ground

Procedure

1. Remove the terminal block cover.

2. Connect the positive power lead to the "+" terminal.

3. Connect the negative power lead to the "-" terminal.

4. Tighten the terminal screws.

5. Reattach and tighten the cover.

WARNING

Enclosure

Enclosure covers must be fully engaged to meet explosion-proof

requirements.

6. Apply power.

14 Rosemount 3144P

Page 15

March 2021 Quick Start Guide

6.3 Ground the transmitter

6.3.1 Ungrounded thermocouple, mV, and RTD/ohm inputs

Each process installation has different requirements for grounding. Use the

grounding options recommended by the facility for the specific sensor type

or begin with grounding option 1 (the most common).

Ground the transmitter: option 1

Emerson recommends this option for ungrounded transmitter housing.

Procedure

1. Connect signal wiring shield to the sensor wiring shield.

2. Ensure the two shields are tied together and electrically isolated from

the transmitter housing.

3. Ground shield at the power supply end only.

4. Ensure that the sensor shield is electrically isolated from the

surrounding grounded fixtures.

A. Remote sensor housing

B. Sensor

C. Transmitter

D. Shield ground points

Ground the transmitter: option 2

Emerson recommends this method for grounded transmitter housing.

Procedure

1. Connect sensor wiring shield to the transmitter housing.

Do this only if the housing is grounded.

2. Ensure that the sensor is electrically isolated from surrounding

fixtures that may be grounded.

3. Ground signal wiring shield at the power supply end.

Quick Start Guide 15

Page 16

Quick Start Guide March 2021

A. Remote sensor housing

B. Transmitter

C. Sensor

D. Shield ground parts

Ground the transmitter: option 3

Procedure

1. Ground sensor wiring shield at the sensor, if possible.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing and other grounded fixtures.

3. Ground signal wiring shield at the power supply end.

A. Sensor

B. Transmitter

C. Shield ground points

16 Rosemount 3144P

Page 17

March 2021 Quick Start Guide

6.3.2 Ground thermocouple inputs

Procedure

1. Ground sensor wiring shield at the sensor.

2. Ensure the sensor wiring and signal wiring shields are electrically

isolated from the transmitter housing and other grounded fixtures.

3. Ground signal wiring shield at the power supply end.

A. Sensor wires

B. Transmitter

C. Shield ground point

D. 4–20 mA loop

Quick Start Guide 17

Page 18

Quick Start Guide March 2021

7 Perform a loop test

The loop test verifies transmitter output, loop integrity, and operation of any

recorders or similar devices installed in the loop.

The following procedures are for the device dashboard - device revisions 5

and 7, DD v1.

7.1 Initiate a loop test

Procedure

1. Connect an external ampere meter in series with the transmitter loop

(so the power to the transmitter goes through the meter at some

point in the loop).

2. From the Home screen, select 3 Service Tools → 5 Simulate → 1

Perform Loop Test

The communicator displays the loop test menu.

3. Select a discrete milliampere level for the transmitter to output.

a) At Choose Analog Output, select 1 4 mA or 2 20 mA. If you

want to enter a different value, select 4 Other to manually

input a value between 4 and 20 milliamperes.

b) Select Enter to show the fixed output.

c) Select OK.

4. In the test loop, check that the transmitter's actual mA output and

the HART mA reading are the same value.

If the readings do not match, either the transmitter requires an

output trim or the current meter is malfunctioning.

After completing the test, the display returns to the loop test screen

where you can choose another output value.

5. To end the loop test, select 5 End and Enter.

7.2

18 Rosemount 3144P

Initiate simulation alarm

Procedure

1. From the Home screen, select 3 Service Tools → 5 Simulate → 1

Perform Loop Test → 3 Simulate Alarm.

The transmitter will output the alarm current level based on the

configured alarm parameter and switch settings.

2. Select 5 End to return the transmitter to normal conditions.

Page 19

March 2021 Quick Start Guide

8 Safety Instrumented Systems (SIS)

For safety certified installations, refer to the Rosemount 3144P Reference

Manual. The manual is available electronically on Emerson.com/Rosemount.

You can also contact an Emerson representative for the manual.

Quick Start Guide 19

Page 20

Quick Start Guide March 2021

9 Product certifications

Rev 2.8

9.1 European Directive information

A copy of the EU Declaration of Conformity can be found at the end of this

guide The most recent revision of the EU Declaration of Conformity can be

found at Emerson.com/Rosemount.

9.2 Ordinary location certification

As standard, the device has been examined and tested to determine that the

design meets the basic electrical, mechanical, and fire protection

requirements by a nationally recognized test laboratory (NRTL) as accredited

by the Federal Occupational Safety and Health Administration (OSHA).

9.3 North America

9.3.1 E5 FM Explosionproof, Dust-Ignitionproof, and Nonincendive

Certificate

Standards

Markings

FM16US0202X

FM Class 3600: 2011, FM Class 3611: 2004, FM Class 3615:

2006, FM Class 3810: 2005, ANSI/NEMA 250: 1991, ANSI/ISA

60079-0: 2009, ANSI/ISA 60079-11: 2009

XP CL I, DIV 1, GP A, B, C, D; T5(-50 °C ≤ Ta ≤ +85 °C);

DIP CL II/III, DIV 1, GP E, F, G; T5(-50 °C ≤ Ta ≤ +75 °C); T6(-50

°C ≤ Ta ≤ +60 °C); when installed per Rosemount drawing

03144-0320;

NI CL I, DIV 2, GP A, B, C, D; T5(-60 °C ≤ Ta ≤ +75 °C); T6(-60 °C

≤ Ta ≤+60 °C); when installed per Rosemount drawing

03144-0321, 03144-5075.

9.3.2 I5 FM Intrinsic Safety and Nonincendive

Certificate

Standards

Markings

FM16US0202X

FM Class 3600: 2011, FM Class 3610: 2010, FM Class 3611:

2004, FM Class 3810: 2005, ANSI/NEMA 250: 1991, ANSI/ISA

60079-0: 2009, ANSI/ISA 60079-11: 2009

IS CL I/II/III, DIV 1, GP A, B, C, D, E, F, G; T4(-60 °C ≤ Ta ≤ +60

°C);

IS [Entity] CL I, Zone 0, AEx ia IIC T4(-60 °C ≤ Ta ≤ +60 °C);

NI CL I, DIV 2, GP A, B, C, D; T5(-60 °C ≤ Ta ≤ +75 °C); T6(-60 °C

≤ Ta ≤ +60 °C); when installed per Rosemount drawing

03144-0321, 03144-5075.

20 Rosemount 3144P

Page 21

March 2021 Quick Start Guide

9.3.3 I6 CSA Intrinisic Safety and Division 2

Certificate

Standards

Markings

1242650

CAN/CSA C22.2 No. 0-M91 (R2001), CAN/CSA-C22.2 No. 94M91, CSA Std C22.2 No. 142-M1987, CAN/CSA-C22.2 No.

157-92, CSA Std C22.2 No. 213-M1987

Intrinsically Safe for Class I Groups A, B, C, D; Class II, Groups E,

F, G; Class III;

[HART only zone markings]: Intrinsically Safe for Class I Zone 0

Group IIC; T4(-50 °C ≤ Ta ≤ +60 °C); Type 4X;

Suitable for Class I, Div. 2, Groups A, B, C, D;

[HART only zone markings]: Suitable for Class I Zone 2 Group

IIC; T6(-60 °C ≤ Ta ≤ +60 °C); T5(-60 °C ≤ Ta ≤ +85 °C); when

installed per Rosemount drawing 03144-5076.

9.3.4 K6 CSA Explosionproof, Intrinsic Safety, and Division 2

Certificate

Standards

Markings

1242650

CAN/CSA C22.2 No. 0-M91 (R2001), CSA Std C22.2 No.

25-1966, CSA Std C22.2 No. 30-M1986; CAN/CSA-C22.2 No.

94-M91, CSA Std C22.2 No. 142-M1987, CAN/CSA-C22.2 No.

157-92, CSA Std C22.2 No. 213-M1987

Explosionproof for Class I, Groups A, B, C, D; Class II, Groups E,

F, G; Class III;

[HART only zone markings]: Suitable for Class I Zone 1 Group

IIC; Intrinsically Safe for Class I Groups A, B, C, D; Class II,

Groups E, F, G; Class III;

[HART only zone markings]: Suitable for Class I Zone 0 Group

IIC; T4(-50 °C ≤ Ta ≤ +60 °C); Type 4X; Suitable for Class I, Div.

2, Groups A, B, C, D;

[HART only zone markings]: Suitable for Class I Zone 2 Group

IIC; T6(-60 °C ≤Ta ≤ +60 °C); T5(-60 °C ≤ Ta ≤ +85 °C); when

installed per Rosemount drawing 03144-5076.

9.4 Europe

9.4.1 E1 ATEX Flameproof

Certificate

Standards

Quick Start Guide 21

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-1: 2014, EN

60529:1991 +A1:2000+A2:2013

Page 22

Quick Start Guide March 2021

Markings

II 2 G Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…

T1(-50 °C ≤ Ta ≤ +60 °C);

See Process temperature limits for process temperatures.

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than

four joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

9.4.2 I1 ATEX Intrinsic Safety

Certificate

Standards

Markings

BAS01ATEX1431X [HART]; Baseefa03ATEX0708X [Fieldbus]

EN IEC 60079-0: 2018; EN 60079-11:2012

HART: II 1 G Ex ia IIC T5/T6 Ga; T6(-60 °C ≤ Ta ≤ +50 °C),

T5(-60 °C ≤ Ta ≤ +75 °C)

Fieldbus: II 1 G Ex ia IIC T4 Ga; T4(-60 °C ≤ Ta ≤ +60 °C)

See Table 9-5 for entity parameters.

Special Conditions for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

not capable of passing the 500 V insulation test. This must be taken

into account during installation.

2. The enclosure may be made from aluminum alloy with a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion when located in Zone 0.

22 Rosemount 3144P

Page 23

March 2021 Quick Start Guide

9.4.3 N1 ATEX Type n

Certificate

Standards

Markings

Special Condition for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

BAS01ATEX3432X [HART]; Baseefa03ATEX0709X [Fieldbus]

EN IEC 60079-0:2018, EN 60079-15:2010

HART: II 3 G Ex nA IIC T5/T6 Gc; T6(-40 °C ≤ Ta ≤ +50 °C),

T5(-40 °C ≤ Ta ≤ +75 °C);

Fieldbus: II 3 G Ex nA IIC T5 Gc; T5(-40 °C ≤ Ta ≤ +75 °C);

not capable of passing the 500 V electrical strength test as defined in

clause 6.5.1 of EN 60079-15: 2010. This must be taken into account

during installation.

9.4.4 ND ATEX Dust

Certificate

Standards

Markings

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

FM12ATEX0065X

EN 60079-0: 2012+A11:2013, EN 60079-31:2014, EN

60529:1991 +A1:2000+A2:2013

See Process temperature limits for process temperature.

II 2 D Ex tb IIIC T130°C Db, (-40 °C ≤ Ta ≤ +70 °C); IP66

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than

four joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

Quick Start Guide 23

Page 24

Quick Start Guide March 2021

9.5 International

9.5.1 E7 IECEx Flameproof

Certificate

Standards

Markings

Specific Conditions of Use (X):

1. See certificate for ambient temperature range.

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

6. Care shall be taken by the end user to ensure that the external

7. Non-standard paint options may cause risk of electrostatic discharge.

IECEx FMG 12.0022X

IEC 60079-0:2011, IEC 60079-1:2014-06

Ex db IIC T6…T1 Gb, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C ≤

Ta ≤ +60 °C)

See Process temperature limits for process temperatures.

a source of ignition in Group III environments.

four joules.

to temperature probes with Enclosure option "N".

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

Additionally available with option K7

IECEx Dust

Certificate

Standards

Markings

Specific conditions of use (X):

1. See certificate for ambient temperature range.

24 Rosemount 3144P

IECEx FMG 12.0022X

IEC 60079-0:2011 and IEC 60079-31:2013

Ex tb IIIC T130 °C Db, (-40 °C ≤ Ta ≤ +70 °C); IP66

See Process temperature limits for process temperatures.

Page 25

March 2021 Quick Start Guide

2. The non-metallic label may store an electrostatic charge and become

a source of ignition in Group III environments.

3. Guard the LCD display cover against impact energies greater than

four joules.

4. Flameproof joints are not intended for repair.

5. A suitable certified Ex d or Ex tb enclosure is required to be connected

to temperature probes with Enclosure option "N".

6. Care shall be taken by the end user to ensure that the external

surface temperature on the equipment and the neck of DIN Style

Sensor probe does not exceed 266 °F (130 °C).

7. Non-standard paint options may cause risk of electrostatic discharge.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

9.5.2 I7 IECEx Intrinsic Safety

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

2. The enclosure may be made from aluminum alloy with a protective

IECEx BAS 07.0002X [HART]; IECEx BAS 07.0004X [Fieldbus]

IEC 60079-0: 2017; IEC 60079-11: 2011

HART: Ex ia IIC T5/T6 Ga; T6(-60 °C ≤ Ta ≤ +50 °C), T5(-60 °C ≤

Ta ≤ +75 °C);

Fieldbus: Ex ia IIC T4 Ga; T4(-60 °C ≤ Ta ≤ +60 °C)

See Table 9-5 for entity parameters.

not capable of passing the 500 V electrical strength test as defined in

Clause 6.3.13 of IEC 60079-11: 2011. This must be taken into

account during installation.

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion when located in Zone 0.

9.5.3 N7 IECEx Type n

Certificate

Standards

Markings

IECEx BAS 07.0003X [HART]; IECEx BAS 07.0005X [Fieldbus]

IEC 60079-0:2017, IEC 60079-15:2010

HART: Ex nA IIC T5/T6 Gc; T6(-40 °C ≤ Ta ≤ +50 °C), T5(-40 °C ≤

Ta ≤ +75 °C);

Fieldbus: Ex nA IIC T5 Gc; T5(-40 °C ≤ Ta ≤ +75 °C);

Quick Start Guide 25

Page 26

Quick Start Guide March 2021

Special Condition for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

not capable of passing the 500 V electrical strength test as defined in

clause 6.5.1 of EN 60079-15: 2010. This must be taken into account

during installation.

9.6 Brazil

9.6.1 E2 INMETRO Flameproof and Dust

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. See product description for ambient temperature limits and process

2. The non-metallic label may store an electrostatic charge and become

3. Guard the LCD display cover against impact energies greater than

4. Consult the manufacturer if dimensional information on the

UL-BR 13.0535X

ABNT NBR IEC 60079-0:2013; ABNT NBR IEC 60079-1:2016;

ABNT NBR IEC 60079-31:2014

Ex db IIC T6...T1 Gb; T6(-50 °C ≤ Ta ≤ +40 °C); T5...T1(-50 °C ≤

Ta ≤ +60 °C)

Ex tb IIIC T130 °C Db; IP66; (-40 °C ≤ Ta ≤ +70 °C)

temperature limits.

a source of ignition in Group III environments.

four joules.

flameproof joints is necessary.

9.6.2 I2 INMETRO Intrinsic Safety [HART]

Certificate

Standards

Markings

UL-BR 15.0088X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

Ex ia IIC T6 Ga (-60 °C < Ta < 50 °C), Ex ia IIC T5 Ga (-60 °C < Ta <

75 °C)

See Table 9-5 for entity parameters.

Special Conditions for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

not capable of withstanding the 500 V electrical strength test as

defined in ABNT NBR IEC60079-11. This must be taken into account

during installation.

2. The enclosure may be made from aluminum alloy with a protective

polyurethane paint finish; however, care should be taken to protect it

26 Rosemount 3144P

Page 27

March 2021 Quick Start Guide

from impact and abrasion when located in areas that require EPL Ga

(Zone 0).

INMETRO Intrinsic Safety [Fieldbus/FISCO]

Certificate

Standards

Markings

Special Conditions for Safe Use (X):

1. When fitted with the transient terminal options, the equipment is

2. The enclosure may be made from aluminum alloy with a protective

UL-BR 15.0030X

ABNT NBR IEC 60079-0:2013, ABNT NBR IEC 60079-11:2013

Ex ia IIC T4 Ga (-60 °C < Ta < +60 °C)

See Table 9-5 at the end of the Product Certifications section

for Entity Parameters

not capable of withstanding the 500 V electrical strength test as

defined in ABNT NBR IEC60079-11. This must be taken into account

during installation.

polyurethane paint finish; however, care should be taken to protect it

from impact and abrasion when located in areas that require EPL Ga

(Zone 0).

9.7 China

9.7.1 E3 China Flameproof

Certificate

Standards

Markings

9.7.2 I3 China Intrinsic Safety

GYJ16.1339X

GB3836.1-2010, GB3836.2-2010

Ex d IIC T6…T1 Gb

Certificate

Standards

Markings

GYJ16.1338X

GB3836.1-2010, GB3836.4-2010, GB3836.20-2010

Ex ia IIC T4/T5/T6 Ga

9.7.3 N3 China Type n

Certificate

Standards

Markings

Quick Start Guide 27

GYJ20.1086X [Fieldbus]; GYJ20.1091X [HART]

GB3836.1-2010, GB3836.8-2014

Ex nA IIC T5 Gc [Fieldbus]; Ex nA IIC T5/T6 Gc [HART]

Page 28

Quick Start Guide March 2021

Output T code Ambient temperature

Fieldbus T5 -40 °C ≤ Ta ≤ +75 °C

HART T6 -40 °C ≤ Ta ≤ +50 °C

T5 -40 °C ≤ Ta ≤ +75 °C

9.8 EAC - Belarus, Kazakhstan, Russia

9.8.1 EM Technical Regulation Customs Union (EAC) Flameproof

Standards

Markings

Special Condition for Safe Use (X):

1. Non-standard paint options may cause risk of electrostatic discharge.

GOST 31610.0-2014, GOST IEC 60079-1-2013

1Ex db IIC T6…T1 Gb X, T6(-50 °C ≤ Ta ≤ +40 °C), T5…T1(-50 °C

≤ Ta ≤ +60 °C)

See Process temperature limits for process temperatures.

Avoid installations that cause electrostatic build-up on painted

surfaces and only clean the painted surfaces with a damp cloth. If

paint is ordered through a special option code, contact the

manufacturer for more information.

9.8.2 IM Technical Regulation Customs Union (EAC) Intrinsic Safety

Standards

Markings

Special Conditions for Safe Use (X):

1. When fitted with the transient terminal options, the apparatus is not

GOST 31610.0-2014, GOST IEC 60079-11-2014

[HART]: 0Ex ia IIC T5, T6 Ga X, T6(-60 °C ≤ Ta ≤ +50 °C),

T5(-60 °C ≤ Ta ≤ +75 °C);

[Fieldbus/PROFIBUS]: 0Ex ia IIC T4 Ga X, T4(-60 °C ≤ Ta ≤ +60 °C

See Table 9-5 for entity parameters.

capable of withstanding the 500 V electrical strength test as defined

in Clause 6.3.13 of GOST 31610.11-2014. This must be taken into

account during installation.

2. The enclosure may be made from aluminum alloy with a protective

polyurethane paint finish; however, care should be taken to protect it

from impact or abrasion when located in Zone 0.

9.8.3 KM Technical Regulation Customs Union (EAC) Flameproof, Intrinsic Safety, and Dust

Standards

28 Rosemount 3144P

GOST 31610.0-2014, GOST IEC 60079-1-2013, GOST IEC

60079-11-2014, GOST IEC 60079-31-2013

Page 29

March 2021 Quick Start Guide

Markings

Special Condition for Safe Use (X):

1. See certificate for special conditions.

Ex tb IIIC T130 °C Db X (-40 °C ≤ Ta ≤ +70 °C), IP 66 in addition

to markings listed for EM and IM above.

9.9 Japan

9.9.1 E4 Japan Flameproof

Certificate

Markings

Special Conditions for Safe Use:

1. Flameproof joints are not intended for repair.

2. Models with LCD display cover shall have the display cover protected

3. For Models 65 and 185, the user shall ensure the external surface

4. Non-standard paint options may cause risk from electrostatic

5. The wiring used shall be suitable for temperature over 80 °C.

CML 17JPN1316X

Ex d IIC T6…T1 Gb; T6 (-50 °C ≤ Ta ≤ +40 °C); T5...T1 (-50 °C ≤

Ta ≤ +60 °C)

from impact energies greater than 4 Joules.

temperature of the equipment and the neck of the DIN Style probe

does not exceed 130 °C.

discharge.

9.10

Korea

9.10.1 EP Korea Flameproof

Certificate

Markings

Special Condition for Safe Use (X):

1. See certificate for special conditions.

10-KB4BO-0011X

Ex d IIC T6/T5; T6(-40 °C ≤ T

+80 °C)

≤ +70 °C), T5(-40 °C ≤ T

amb

amb

≤

9.10.2 IP Korea Intrinsic Safety

Certificate

Markings

Quick Start Guide 29

09-KB4BO-0028X

Ex ia IIC T6/T5; T6(-60 °C ≤ T

+75 °C)

≤ +50 °C), T5(-60 °C ≤ T

amb

amb

≤

Page 30

Quick Start Guide March 2021

Special Condition for Safe Use (X):

1. See certificate for special conditions.

9.11 Combinations

K1

K2

K5

KB

KP

9.12 Tables

Process temperature limits

Table 9-1: Sensor Only (No Transmitter Installed)

Extension length Process temperature [˚C]

Any extension

length

Table 9-2: Transmitter

Extension length Process temperature [˚C]

No extension 55 70 100 170 280 440 100

3-in. extension 55 70 110 190 300 450 110

6-in. extension 60 70 120 200 300 450 110

9-in. extension 65 75 130 200 300 450 120

Combination of E1, I1, N1, and ND

Combination of E2 and I2

Combination of E5 and I5

Combination of K5, I6, and K6

Combination of EP and IP

Gas Dust

T6 T5 T4 T3 T2 T1 T130 °C

85 100 135 200 300 450 130

Gas Dust

T6 T5 T4 T3 T2 T1 T130 °C

Adhering to the process temperature limitations of Table 9-3 will ensure that

the service temperature limitations of the LCD display cover are not

exceeded. Process temperatures may exceed the limits defined in Table 9-3

if the temperature of the LCD display cover is verified to not exceed the

service temperatures in Table 9-4 and the process temperatures do not

exceed the values specified in Table 9-2.

30 Rosemount 3144P

Page 31

March 2021 Quick Start Guide

Table 9-3: Transmitter with LCD Display Cover

Extension length Process temperature [˚C]

Gas Dust

T6 T5 T4...T1 T130 °C

No extension 55 70 95 95

3-in. extension 55 70 100 100

6-in. extension 60 70 100 100

9-in. extension 65 75 110 110

Table 9-4: Transmitter with LCD Display Cover

Extension length Service temperature [˚C]

Gas Dust

T6 T5 T4...T1 T130 °C

Any extension length 65 75 95 95

Entity parameters

Table 9-5: Entity Parameters

Parameters HART Fieldbus/

PROFIBUS

Voltage Ui (V) 30 30 17.5

Current Ii (mA) 300 300 380

Power Pi (W) 1 1.3 5.32

Capacitance Ci (nF) 5 2.1 2.1

Inductance Li (mH) 0 0 0

FISCO

9.13 Additional certifications

SBS American Bureau of Shipping (ABS) Type Approval

Certificate

Intended use

SBV Bureau Veritas (BV) Type Approval

Certificate

Quick Start Guide 31

16-HS1488352-PDA

Measurement of temperature for marine and offshore

applications

23154

Page 32

Quick Start Guide March 2021

Requirements

Application

Bureau Veritas Rules for the Classification of Steel Ships

Class notations: AUT-UMS, AUT-CCS, AUT-PORT and AUTIMS; Temperature transmitter type 3144P cannot be

installed on diesel engines.

SDN Det Norske Veritas (DNV) Type Approval

Certificate

Intended use

TAA00001JK

Det Norske Veritas’ Rules for Classification of Ships, High

Speed & Light Craft and Det Norske Veritas’ Offshore

Standards

Application

Table 9-6: Location Classes

Temperature D

Humidity B

Vibration A

EMC A

Enclosure D

SLL Lloyds Register (LR) type approval

Certificate

Application

11/60002

Environmental categories ENV1, ENV2, ENV3, and ENV5

32 Rosemount 3144P

Page 33

March 2021 Quick Start Guide

9.14 Installation drawings for intrinsic safety

Quick Start Guide 33

Page 34

Quick Start Guide March 2021

34 Rosemount 3144P

Page 35

March 2021 Quick Start Guide

Quick Start Guide 35

Page 36

Quick Start Guide March 2021

9.15 Declaration of conformity

36 Rosemount 3144P

Page 37

March 2021 Quick Start Guide

Quick Start Guide 37

Page 38

Quick Start Guide March 2021

38 Rosemount 3144P

Page 39

March 2021 Quick Start Guide

9.16 China RoHS

Quick Start Guide 39

Page 40

*00825-0100-4021*

00825-0100-4021, Rev. PB

Quick Start Guide

March 2021

©

2021 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo

is a trademark and service mark of

Emerson Electric Co. Rosemount is a mark

of one of the Emerson family of

companies. All other marks are the

property of their respective owners.

Loading...

Loading...