Page 1

Quick Start Guide

00825-0200-4840, Rev BC

August 2019

Rosemount™ 3107 Level and 3108 Flow

Transmitters

Ultrasonic

Page 2

Quick Start Guide August 2019

Contents

About this guide...........................................................................................................................3

Overview of Rosemount 3107 and 3108.......................................................................................5

Considerations before you install................................................................................................. 8

Installation................................................................................................................................. 10

Connecting the transmitter........................................................................................................15

Configuration.............................................................................................................................17

Product Certifications.................................................................................................................31

2 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 3

August 2019 Quick Start Guide

1 About this guide

This installation guide provides basic guidelines for the Rosemount 3107

Level Transmitter and Rosemount 3108 Flow Transmitter. It does not

provide instructions for detailed configuration, diagnostics, maintenance,

service, troubleshooting, or installations. Refer to the Rosemount 3107 and

3108 Reference Manual for more instructions. Manuals are available

electronically on Emerson.com/Rosemount.

WARNING

Failure to follow these installation guidelines could result in death or

serious injury.

• The Rosemount 3107 and Rosemount 3108 are ultrasonic transmitters.

They must be installed, connected, commissioned, operated, and

maintained by suitably qualified personnel only, observing any national

and local requirements that may apply.

• Use the equipment only as specified. Failure to do so may impair the

protection provided by the equipment.

Explosions could result in death or serious injury.

• Installation of the transmitters in a hazardous environment must be in

accordance with the appropriate local, national, and international

standards, codes, and practices. Please review the Product Certifications

section for any restrictions associated with a safe installation.

• Before connecting a handheld communicator in an explosive

atmosphere, ensure the instruments are installed in accordance with

intrinsically safe or non-incendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent

with the appropriate hazardous locations certifications.

External surface may be hot. Care must be taken to avoid possible burns.

Process leaks could result in death or serious injury.

• Install and tighten process connectors before applying pressure.

• Do not attempt to loosen or remove process connectors while the

transmitter is in service.

Electrical shock could cause death or serious injury.

• Ensure that the transmitter is not powered when making connections.

• If the liquid level switch is installed in a high voltage environment and a

fault condition or installation error occurs, high voltage may be present

on leads and terminals.

Quick Start Guide 3

Page 4

Quick Start Guide August 2019

WARNING

Physical access

Unauthorized personnel may potentially cause significant damage to and/or

misconfiguration of end users’ equipment. This could be intentional or

unintentional and needs to be protected against.

Physical security is an important part of any security program and

fundamental to protecting your system. Restrict physical access by

unauthorized personnel to protect end users’ assets. This is true for all

systems used within the facility.

4 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 5

August 2019 Quick Start Guide

2 Overview of Rosemount 3107 and 3108

The Rosemount 3107 and 3108 are sealed 4–20 mA loop-powered liquid

level transmitters, specifically designed for use in waste water and effluent

treatment plant on aqueous applications.

These rugged UPVC transmitters are certified Intrinsically Safe for use in

Zone 0 areas, and factory fitted with up to 165 ft. (50 m) of two-core cable

for simple low cost installation in sumps, wet-wells and over open channel

flow structures.

The transmitter may be mounted in a hazardous area if powered from a

protected power supply. They can be connected directly to a plant control

system, or used with a Rosemount 3490 Series Control Unit for

programmable control functionality.

Theory of operation

Each transmitter is designed to be mounted above a liquid, and uses

ultrasonic pulses to continuously measure the distance to the liquid surface.

The microprocessor-controlled electronics calculates distance to the liquid

level from the time delay between the transmitting and receiving of signals.

When programmed with the bottom reference of the application – usually

the bottom of a tank – the transmitter will calculate the liquid depth (level),

and output the level (Figure 2-1) as a 4–20 mA signal and a digital HART

signal.

The Rosemount 3107 and 3108 can also calculate contents (volume) or

open channel flow, and then output the result as a 4–20 mA signal and a

digital HART signal.

Programming is achieved by remote communication using HART.

®

Quick Start Guide 5

Page 6

Quick Start Guide August 2019

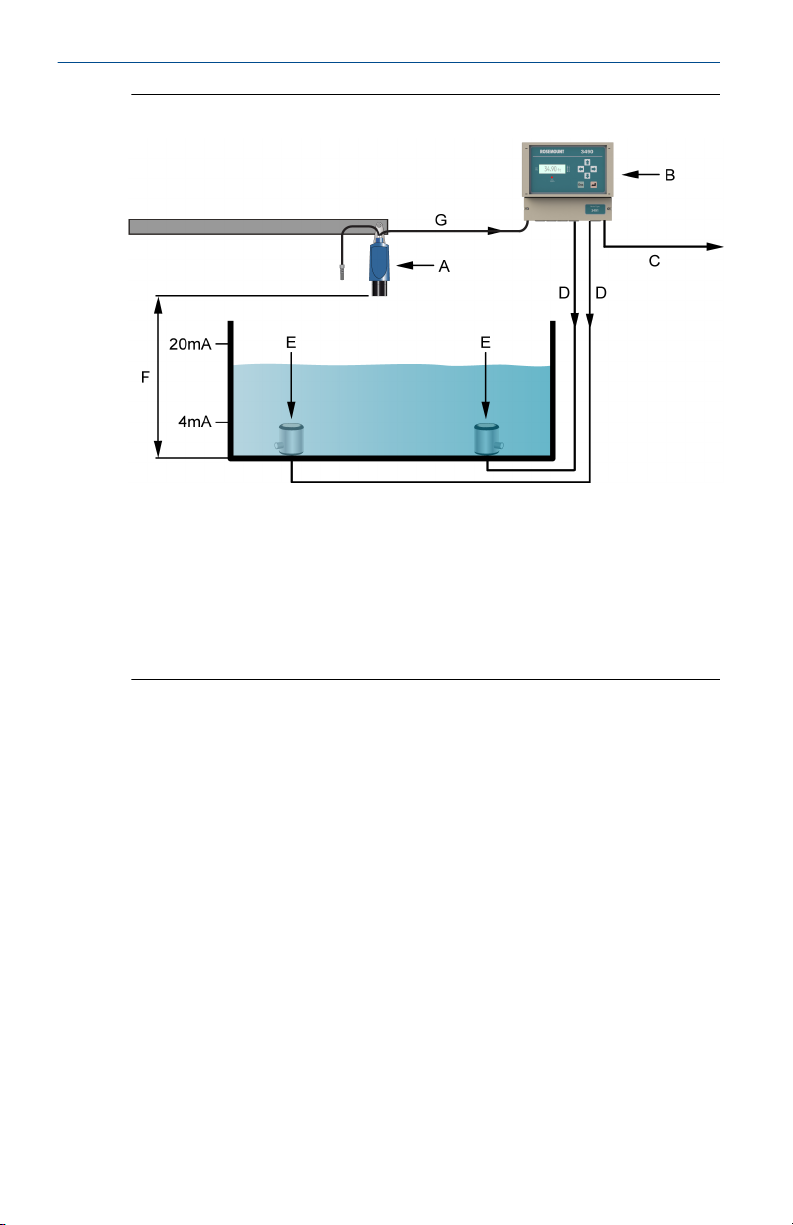

Figure 2-1: Typical Application

A. Rosemount 3108 Flow Transmitter

B. Rosemount 3490 Series Control Unit

C. 4–20 mA signal output

D. Relay

E. Pump

F. Transmitter Bottom Reference

G. 4–20 mA and HART signal input

Components of the transmitter

The transmitter has a housing containing advanced electronics to generate

ultrasonic pulses, process the resultant signals, and provide a 4–20 mA and

HART output.

There is a factory-fitted cable for the signal output and connecting an

external power supply. The Rosemount 3108 has a factory-fitted remote

temperature sensor.

6 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 7

E

A

D

D

C

B

August 2019 Quick Start Guide

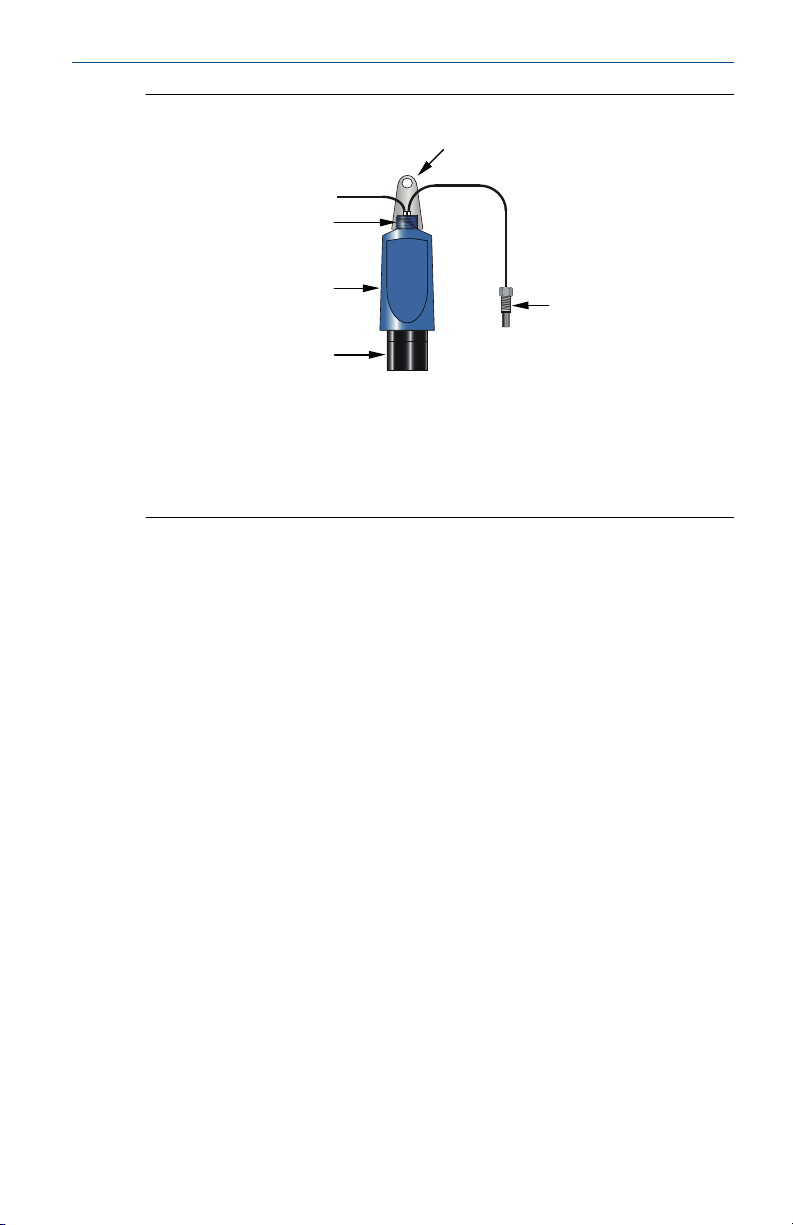

Figure 2-2: Transmitter Components

A. Mounting bracket

B. Two-core cable

C. 1-in. mounting thread

D. UPVC wetted parts

E. Remote temperature sensor (Rosemount 3108 only)

Quick Start Guide 7

Page 8

Quick Start Guide August 2019

3 Considerations before you install

Install the transmitter where it is protected from ultraviolet radiation to

prevent long-term degradation of the plastics used in its construction (e.g.

shrouded from direct sunlight).

Note

See also Product Certifications for special conditions for safe use.

General

• Installation must be carried out by suitably trained personnel in

accordance with the applicable code of practice.

• If the equipment is likely to come into contact with aggressive

substances, it is the responsibility of the user to take suitable precautions

that prevent it from being adversely affected, thus ensuring that the type

of protection is not compromised.

• Aggressive substances are acidic liquids or gases that may attack metals

or solvents that may affect polymeric materials.

• Suitable precautions are regular checks as part of routine inspections, or

establishing, from the material's data sheet, that it is resistant to specific

chemicals.

• The equipment should only be cleaned with a damp cloth; do not use

solvents.

• The transmitter is double insulated, and therefore protective earthing is

not required. However, the cable screen should be connected (see Figure

5-1).

• Note that if the equipment is used in a manner not specified by the

manufacturer, the protection afforded by the equipment may be

impaired.

• This transmitter is classified Type A in accordance with the European

EMC directive 2004/108/EC. To ensure electro-magnetic compatibility,

in any member state, it should not be installed in a residential area.

Note

It is not advisable to mount the transmitter in close proximity to a source of

electrical noise such as a variable-speed drive, or other high-powered

electrical device.

Environmental

The Rosemount 3107 and 3108 ultrasonic transmitters are Intrinsically Safe

(IS) approved for hazardous area installations.

8 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 9

OKOK OK

August 2019 Quick Start Guide

• The Rosemount 3107 is designed for open or closed tank installation. It is

weatherproof and protected against the ingress of dust

• The Rosemount 3108 is designed for open channel flow measurement. It

is weatherproof and protected against the ingress of dust

• Avoid installing the Rosemount 3107 and 3108 transmitters near heat

sources

Figure 3-1: Environmental Considerations

Quick Start Guide 9

Page 10

Quick Start Guide August 2019

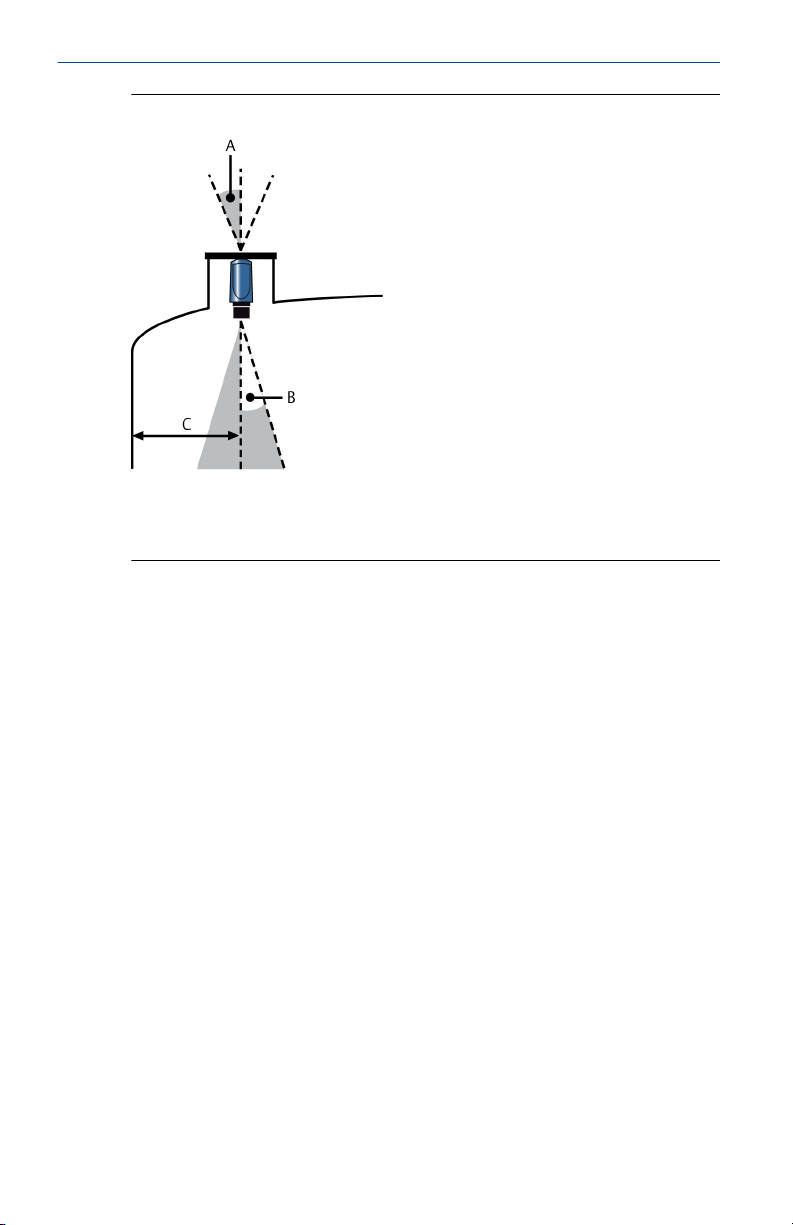

4 Installation

• Mount the transmitter above the liquid using the 1-in. threaded

connection provided, but no closer than 13.8 in. (0,35 m) to the surface.

The transmitter does not detect any liquid surface closer than 12 in. (0,3

m) to the transmitter face.

• The transmitter should be mounted vertically to ensure a good echo

from the liquid surface. The beam half angle of the transmitter is 6

degrees (Figure 4-2).

• Obstructions in the tank, or well, may generate echoes which can be

confused with the real liquid surface echo. Obstructions within the beam

angle generate strong false echoes. Wherever possible, the transmitter

should be positioned to avoid false echoes.

• To avoid detecting unwanted objects in the tank or well, it is advisable to

maintain a distance of at least 1.3-in (33.02 mm). from the center line of

the transmitter for every foot (11 cm per meter) range to the

obstruction. (See Figure 4-2).

• No false echoes are generated if the transmitter is located near the side

of the tank or well and the wall is smooth and free of protrusions.

However, there will still be a reduction in the echo size. It is

recommended that the transmitter be mounted no closer than 12 in.

(0,3 m) to the wall to avoid a large reduction in the echo size.

• If the transmitter is mounted in an enclosed tank with a domed top,

avoid mounting the transmitter in the center of the tank roof because

this could act as a parabolic reflector and create unwanted echoes.

• Avoid applications where heavy condensation could form on the

transmitter face.

• If the transmitter is mounted in a stand-off or nozzle, the transmitter

face should protrude at least 0.2 in. (5 mm) into the tank.

• If the transmitter is used in environments where direct sunlight can

cause high surface temperatures on exposed instruments, a sun-shade is

recommended.

4.1

10 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

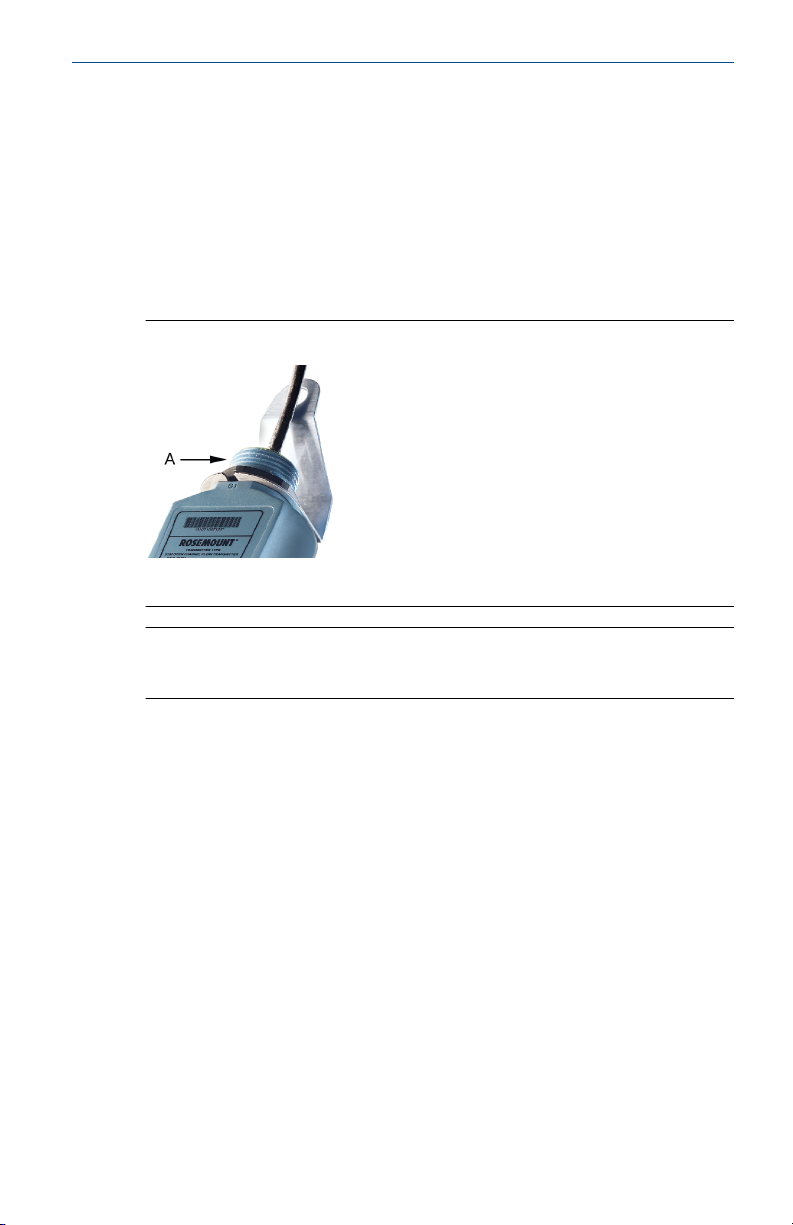

Mounting the transmitter above the liquid surface

A one-inch threaded process connection is provided to mount the

transmitter (Figure 4-1). The thread form is either BSPP (G1) or NPT, and is

marked below the mounting thread.

Mounting bracket

The transmitter is supplied with a purpose made 316 Stainless Steel

mounting bracket (Figure 4-1), which should be used to mount the

Page 11

August 2019 Quick Start Guide

transmitter over the liquid surface. The bracket is designed to fit over the

threaded neck of the transmitter and is retained by a locknut.

Use a chain or wire through the hole provided in the bracket, which is shaped

to ensure that the transmitter will hang perpendicular to the water surface.

Never suspend the transmitter by the cable. Check that the material of the

chain or wire is corrosion resistant to the liquids and any vapors present.

The bracket may be bolted to a suitable crossmember above the liquid

surface. Ensure the transmitter is perpendicular to the surface to maximize

the return echo size.

Figure 4-1: Mounting Thread and Supplied Bracket

A. 1-in. threaded process connection

Note

To help with alignment, the echo size (signal strength) can be indicated on

the Rosemount 3490 Series Control Unit or a Field Communicator.

Flange mounting

The instrument (accessory) flanges supplied by Emerson are manufactured

from PVC and are a full face design. Care must be taken when installing to a

raised face mating flange on the tank or vessel to prevent distortion of the

PVC flange by overtightening the bolts. See Product Data Sheet for a list of

all accessories and their part numbers.

Quick Start Guide 11

Page 12

Quick Start Guide August 2019

Figure 4-2: Recommended Mounting Position

A. Transmitter is mounted vertically (maximum deviation of 3°).

B. 6° beam half angle.

C. 1.3 in./ft. (11 cm/m). Minimum of 12 in. (0.3 m).

Mounting from a conduit

The transmitters can be mounted from a conduit using the optional adaptor

accessory. See Product Data Sheet for a list of all accessories and their part

numbers.

4.2

12 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Open channel flow installations

Mount an ultrasonic transmitter over an area of clear liquid. Avoid mounting

the transmitter directly over any inlet stream. Never suspend the transmitter

by the cable.

The positioning is critical, and should be the correct distance upstream from

the flow structure as stated in the relevant standard for your country. For

example, in the ISO standards, the distance should be four to five times the

maximum height of the water (Hmax) for a thin plate weir, or three to four

times Hmax for a flume. For optimum accuracy, position the transmitter’s

front face at a height equal to the sum of the maximum flow depth plus the

transmitter deadband of 12.2 in. (300 mm) plus an extra 2 in. (50 mm).

It is important that the bottom reference of the transmitter should be

related to the datum of the primary measuring device (Figure 4-4).

When setting the bottom reference on a ‘V’- notch weir, it is important the

true invert is used (Figure 4-5) and not the meniscus level.

Page 13

$

&

%

$

%

'

&

August 2019 Quick Start Guide

Figure 4-3: Choosing the Height Position Above a Flow

A. Transmitter front face

B. Hmax

C. Transmitter bottom reference = Hmax + 12.2 in. (300 mm) + 2 in. (50

mm)

Figure 4-4: Bottom Reference of a Flume or Weir

A. Transmitter bottom reference

B. Primary element (e.g. flume, weir) invert

C. Approach channel

D. Flow

Note

The transmitter should be free from a situation where it is likely to "drown"

(refer to the relevant standard for further information)

Quick Start Guide 13

Page 14

$

%

Quick Start Guide August 2019

Figure 4-5: Bottom Reference of a ‘V’ Notch Weir

A. Transmitter bottom reference (i.e. true invert)

B. Meniscus level

The Rosemount 3108 transmitter has a factory fitted remote temperature

sensor. The temperature sensor is enclosed in a M8 × 1.5 threaded stainless

steel body, and can be installed in a suitable plastic conduit box and clamped

in place using a suitable compression-type cable gland.

4.3 Open weir chamber

Mount the remote temperature sensor so that it is representative of the

mean air temperature in the chamber and is in a shaded area away from

direct sunlight and solar radiation.

4.4

14 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Enclosed or partially-covered flume chamber

Mount the remote temperature sensor in the approach channel, in a shaded

area away from direct sunlight and solar radiation. The temperature sensor

should be positioned in the weir chamber or flume approach channel so the

average air temperature can be accurately measured. The temperature

sensor must be protected at all times from direct sunlight and any radiated

heat.

In extreme high temperatures, for the best accuracy and stability of level

measurement reading, the transmitter should be shrouded to prevent the

incidence of direct sunlight and solar radiation. If the flow structure permits,

mount the transmitter within the flow channel or chamber.

Note

For some installations, the use of a calibration device is mandatory. Emerson

offers the Rosemount Head Verification Device (HVD) for this purpose. See

theQuick Installation Guide for more information.

Page 15

August 2019 Quick Start Guide

5 Connecting the transmitter

Note

To comply with the Canadian Standards Association (CSA) requirements, the

transmitters must be powered from a Rosemount 3490 Series Control Unit,

or a class 2 or separate extra-low voltage (SELV) source. Other devices may

reset if connecting the transmitter to a multi-drop system while the loop is

powered. De-energize loop to avoid devices being reset.

The Rosemount 3107 and 3108 are two-wire, loop-powered transmitters

accepting external power supplies as follows:

• 12 to 40 Vdc in a non-hazardous area

• 12 to 30 Vdc in a hazardous area

Each transmitter is supplied with a factory-fitted PVC sheathed, two-core,

shielded cable for communications and external power supply connections.

There are no cable conduit entries or covers to remove. The cable may be

cut to length on site or may be extended using a junction box and suitable

extension cable.

5.1 Installation in a non-hazardous area

Procedure

1. Make sure that the power supply is disconnected.

2. Connect the cable wires (Figure 5-1), taking note of the required

voltage of 12 to 40 Vdc for non-hazardous applications.

5.2

Quick Start Guide 15

Installation in a hazardous area

When the transmitters are used with a Rosemount 3490 Series Control Unit,

no additional safety barriers are required. If powering the transmitter from

any other source, ensure a suitable Intrinsically Safe barrier is fitted in the

non-hazardous (safe) area.

To connect the transmitter:

Procedure

1. Make sure that the power supply is disconnected.

2. Connect the cable wires (Figure 5-1), taking note of the restricted

voltage of 12 to 30 Vdc for hazardous applications.

Page 16

%

$

&

'

Quick Start Guide August 2019

Figure 5-1: Wiring

A. Remote temperature sensor (Rosemount 3108 only)

B. Black: 0 Vdc

C. Red: 12 to 40 Vdc (non-hazardous area), 12 to 30 Vdc from

protective barrier (hazardous area)

D. Non-hazardous area: connect cable screen to standard ground

(Earth) or hazardous area: connect cable screen to I.S. ground

(Earth)

16 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 17

August 2019 Quick Start Guide

6 Configuration

The transmitter can be configured and verified using a Field Communicator

or a Rosemount 3490 Series Control Unit.

The parameters in this section are sufficient for a basic level, contents

(volume), or open channel flow application. For a more advanced

application, refer to the Rosemount 3107 Level and 3108 Flow Transmitters

Reference Manual.

6.1 Transmitter base units

When the transmitter is shipped from the factory, the default factory setting

for Base Units is “metric” or “imperial ft” depending on the model order

code.

Note

Keep a record of your programmed settings. Changing the base units will

reset parameters to their default factory settings in the appropriate units.

6.1.1 Selecting Base Units (Field Communicator or AMS)

To change the transmitter base units:

Procedure

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance.

3. Select 3: Utilities.

4. Select 3: Set Base Units.

5. Select new base units.

Note

When on-screen messages appear, take action if needed and press

“OK”.

Quick Start Guide 17

Page 18

Base Units

Esc=Quit =Edit

metric

Quick Start Guide August 2019

6.1.2 View or change the transmitter base units (Rosemount 3490 Series Control Unit)

To view or change the transmitter base units:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, and then select Base Units.

4. Select new base units.

Note

To get the same base units on the control unit, switch the power off

and then on again. The control unit prompts for the transmitter’s

Bottom Reference value in the new base units.

6.2 Transmitter bottom reference

This is the transmitter’s Bottom Reference setting. It is the distance measured

vertically along the ultrasonic beam path from the User Preferred Sensor

Reference Point (UPSRP) to the Zero Level of a tank or an open channel

(Figure 6-4).

The zero level establishes where the transmitter starts to measure the

process value. It is not necessary to have the 4 mA output start at the zero

level, and the 4 mA starting pointing can be any liquid height above or below

this zero level.

Note

This parameter is important for calibrating and configuring the transmitter.

6.2.1 Viewing of changing P010 (Field Communicator or AMS)

To view or change the bottom reference:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 1: Basic Setup.

4. Select 2: Bottom Reference P010.

5. Input the new bottom reference, and press “ENTER” to save it.

18 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 19

Bottom Reference P010

40.000 ft

40.000 ft

ESCDEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

-

+

/

.

0

7

4

1

8

5

2

9

6

3

iko

l

FN

Bottom Ref. P010

40.000ft

Esc=Quit =Edit

August 2019 Quick Start Guide

6. Press “SEND” to update the transmitter.

6.2.2 Viewing of changing P010 (Rosemount 3490 Series Control Unit)

To view or change the bottom reference:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY, and then select Bottom Ref.

4. Follow the on-screen instructions to input and save the new setting.

6.3 Transmitter primary variable units (P012)

6.3.1 Field Communicator or AMS

Quick Start Guide 19

This selects alternative display units for the HART Primary Variable (PV),

which is reported to a HART Master Device e.g. a Rosemount 3490 Series

Control Unit.

Note

Selecting alternative display units does not automatically re-scale the PV

value. Use the parameter Transmitter Scale Factor (Transmitter scale

factor/K-factor (P013)) to manually re-scale the value (or base units) into

appropriate units.

To view or change the PV Units:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Profiling.

4. Select 1: Primary Variable Units P012.

Page 20

Primary Variable Units P012

ft

Cum

Cum/h

Cum/s

ft

gal/min

Impgal

Impgal/d

ft

ENTER

ESC

Quick Start Guide August 2019

5. Select new units, and then press “Enter” to save the selection.

6. Press “SEND” to update the transmitter.

Note

If the HART PV has no units, select and confirm the “None”,

“Unknown”, or “Not Used” option as appropriate for the HART

Master Device (host).

6.3.2 Viewing or changing P012 (Rosemount 3490 Series Control Unit)

To view or change the existing setting:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select UNITS, and then select PV Units.

4. Follow the on-screen instructions to select and confirm the new

setting. If the HART PV has no units, select and confirm the “None”

option.

5. Select Quit to exit to the previous menu.

6.4

Transmitter tank shape/non-linear profile (P011)

This selects the shape of a tank or an open channel, and establishes the

linear or non-linear relationship between the live liquid level (height) and the

process value (PV) derived from that level. The transmitter is preprogrammed with popular profiles that are mathematical formulas to

convert a linear level reading to a flow or volumetric process value (PV). The

Current Output is then driven by the flow or volumetric PV.

Note

Select “Linear” if the process value (PV) is a level measurement.

20 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 21

Tank Shape P011

Linear

Esc=Quit =Edit

August 2019 Quick Start Guide

6.4.1 Changing P011 (Field Communicator or AMS)

To change the tank shape / non linear profile:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Profiling.

4. Select 2: Set Non-Linear Profile.

5. Select a new profile, and then press “Enter” to save the selection.

6. Press “SEND” to update the transmitter.

The selected profile can be viewed at Fast Key sequence 2, 2, 3, 3.

Note

When on-screen messages appear, take action if needed and press

“OK”.

6.4.2 Viewing or changing P011 (Rosemount 3490 Series Control Unit)

Quick Start Guide 21

To change the tank shape/non linear profile:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY, and then select Tank Shape.

4. Follow the on-screen instructions to select and save the new setting.

Page 22

$

%

&

'

(

Quick Start Guide August 2019

6.5 Transmitter scale factor/K-factor (P013)

Level measurement

When the process value (PV) is a level measurement in meters, feet, or

inches, this parameter converts the level measurement into alternative units

before being output. Enter a value of 1.0 if alternative units are not required.

Volume measurement

When the PV is a volume measurement from a standard non-linear-shaped

tank (e.g. cylinder or sphere), use this parameter to enter the volume of the

ideal shaped tank (Figure 6-1).

When the PV is a volume measurement from a regular-shaped tank (e.g.

square or rectangular), use this parameter to enter the volume change per

unit of the base unit.

When the PV is a volume measurement from an irregular-shaped tank, use

this parameter to enter the maximum volume relating to the Profile Height

(Profile height/Power factor (P014)). See also Procedure for P011=“Special

Plot” for defining the irregular-shaped tank.

Figure 6-1: Volume from a Cylinder/Sphere

P013 = Full Volume of Ideal Cylindrical or Spherical Tank of Constant

Diameter P014

A. Rosemount 3107 or 3108

B. Rosemount 3490 Series Control Unit

C. 4–20mA/HART

D. Bottom reference (P010)

E. Profile height (P014)

Open channel measurement

When the PV is the flow rate in a standard open channel, use this parameter

to enter the scale factor ("k" term) in a flow rate calculation. See Transmitter

tank shape/non-linear profile (P011) for selecting a flow profile.

22 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 23

Scale Factor P013

1

1

ESCDEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

-

+

/

.

0

7

4

1

8

5

2

9

6

3

iko

l

FN

PV Scale Factr P013

1.000

Esc=Quit =Edit

August 2019 Quick Start Guide

When the PV is the flow rate in an irregular-shaped open channel, use this

parameter to enter the maximum flow rate. See also Procedure for

P011=“Special Plot” for defining the irregular-shaped channel.

6.5.1 Viewing or changing P013 (Field Communicator or AMS)

To view or change the scale factor/k-factor:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Profiling.

4. Select 4: Scale Factor P013 or 4: k-factor P013, depending on the

Non-Linear Profile selected.

5. Input the factor, and press “ENTER” to save it.

6.5.2 Viewing or changing P013 (Rosemount 3490 Series Control Unit)

Quick Start Guide 23

6. Press “SEND” to update the transmitter.

To view or change the scale factor/k-factor:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY, and then select PV Scale Factor.

4. Follow the on-screen instructions to edit and save the new setting.

Note

Some flow profiles automatically populate this parameter, and do

not allow editing.

Page 24

Non-Linear Profile Height P014

1 ft

1

ESCDEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

-

+

/

.

0

7

4

1

8

5

2

9

6

3

iko

l

FN

Quick Start Guide August 2019

6.6 Profile height/Power factor (P014)

Level measurement

This is not used for level measurements. It does not appear on the Field

Communicator unless required for volume or flow measurements.

Volume measurement

When the process value (PV) is a volume measurement from a standard nonlinear-shaped tank (e.g. an ideal horizontal cylinder or a sphere), use this

parameter to enter the diameter (see Figure 6-1).

When the PV is a volume measurement from a regular-shaped tank (e.g.

square or rectangular), this parameter is not used.

When the PV is a volume measurement from an irregular-shaped tank, use

this parameter to enter the maximum height. See also Procedure for

P011=“Special Plot” for defining the irregular-shaped tank.

Open channel measurement

When the PV is a flow rate in a standard open channel, this parameter is used

as the power factor ("pwr" term) in a flow rate calculation. See Transmitter

tank shape/non-linear profile (P011) for selecting a flow profile.

When the PV is the flow rate in an irregular-shaped open channel, use this

parameter to enter the maximum height. See also Procedure for

P011=“Special Plot” for defining the irregular-shaped channel.

6.6.1 Viewing or changing P014 (Field Communicator or AMS)

To view or change the diameter, maximum height, or power factor:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Profiling.

4. Select 5: Non-Linear Profile Height P014 or 5:Power Factor P014,

depending on the Non-Linear Profile selected.

5. Input a new value, and press “ENTER” to save it.

24 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 25

Profile Height P014

1.0000ft

Esc=Quit =Edit

August 2019 Quick Start Guide

6. Press “SEND” to update the transmitter.

6.6.2 Viewing or changing P014 (Rosemount 3490 Series Control Unit)

To view or change the diameter, maximum height, or power factor:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY.

4. Select Profile Height.

5. Follow the on-screen instructions to edit and save the new setting.

(Press the Enter (

line”).

6. Select “Quit” to exit to the previous menu.

Note

Some flow profiles automatically populate this parameter, and do

not allow editing.

) key if prompted to change the mode to “off-

6.7

6.7.1 Viewing or changing P030-P039 (Field Communicator or AMS)

Quick Start Guide 25

Profile points 1 to 10 (P030 to P039)

These parameters are used to define an irregular-shaped profile for

calculating the process value (PV) from a live level reading. See Figure 6-2

and Figure 6-3 for an example of how these parameters are used.

To view or change the profile point:

Procedure

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 3: Profiling.

4. Select 6: Plot Non-Linear Profile Points.

5. Select a profile point e.g. 1: Profile Point1 P030.

6. Input a new value, and then select “ENTER” to save it.

Page 26

Profile Point1 P030

10.000%

10.000%

ESCDEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

-

+

/

.

0

7

4

1

7

4

1

7

4

1

iko

l

FN

Profile Pt. 1

10.000%

Esc=Quit =Edit

Quick Start Guide August 2019

7. Press “SEND” to update the transmitter.

Note

The profile point parameters are only accessible on a Field

Communicator if they are required for a selected profile. The points

can be changed only if the “Special Plotted” profile has been

selected.

6.7.2 Viewing or changing P030-P039 (Rosemount 3490 Series Control Unit)

To view or change a profile point:

Procedure

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY, and then NLP CURVE.

4. Select a profile point e.g. “Profile Pt. 1”.

5. Follow the on-screen instructions to edit and save the new setting.

(Press the Enter ( ) key if prompted to change the mode to “offline”).

6. Select “Quit” to exit to the previous menu.

6.7.3 Procedure for P011=“Special Plot”

Procedure

1. Draw the graph of process value (PV) versus liquid height, and note

the maximum points (Figure 6-3).

2. Enter the maximum volume or flow into Transmitter scale factor/K-

26 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

factor (P013).

Page 27

$

'

(

%

)

*

&

August 2019 Quick Start Guide

3. Enter the maximum liquid height into Profile height/Power factor

(P014).

4. Use parameters Profile points 1 to 10 (P030 to P039) to enter the Yaxis percentages that relate to the X-axis fixed percentages and

produce the curve.

Example

In the example, 60 percent of the maximum height (on the X-axis) relates to

a percentage of the maximum PV on the Y-axis. The related percentage on

the Y-axis, say 55 percent, is entered into parameter Profile Point 6 (P035).

The transmitter interpolates linearly between the plotted points to give an

accurate curve fit, which will determine the output process value (PV) from

the live level (height) measurement.

Figure 6-2: Volume or Flow from 2-stage Weir

A. Rosemount 3107 or 3108

B. 4–20 mA/HART

C. Rosemount 3490 Series control unit

D. Rectangular weir

E. V-notch weir

F. Profile height (P014)

G. Bottom reference (P010)

Quick Start Guide 27

Page 28

Y

X

0,0

10%

P030

P031

P032

P033

P034

P035

P036

P037

P038

P039

20%

30% 40%

50%

B

DDD

C

A

60% 70% 80% 90% 100%

Quick Start Guide August 2019

Figure 6-3: Graph of PV versus Height

A. (Entered percentages relating output PV to maximum PV)

B. (Fixed percentages relating height to maximum height)

C. P013 = Maximum volume or flow; P039 = Maximum process value (PV)

28 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

D. Maximum height (P014)

Page 29

$

%

&

'

( *

+

,

-

/

0

1

2

3

5

4

.

)

August 2019 Quick Start Guide

6.8 Tank geometry

Figure 6-4: Tank Geometry

A. Upper blanking (P023) J. Tank Reference Point (TRP)

Quick Start Guide 29

B. 20 mA point K. Zero level

C. 4 mA point L. Bottom reference (P010)

D. Level offset (P069) M. User Preferred SRP (UPSRP)

E. Level SV (D901) N. Distance offset (P060)

F. Distance (D910) O. Sensor Reference Point (SRP)

G. Liquid Level P. 4–20 mA/HART

H. Distance TV (D902) Q. Rosemount 3107 or 3108

I. Lower blanking (P063) R. Rosemount 3490 Series control

unit

Page 30

Quick Start Guide August 2019

6.9 Rosemount 3107 and 3108 parameters on the Rosemount 3490

The process value (e.g. liquid level) is indicated in the HART Primary Variable

(D900), which drives the 4–20 mA output signal.

Parameter Fast key 3490 Series menu navigation

Lower blanking (P063) 2, 2, 5, 6 SETUP,[Tag], ENGINEERING, Lower

Upper blanking (P023) 2, 2, 5, 5 SETUP,[Tag], ENGINEERING, Upper

Distance offset (P060) 2, 2, 2, 2 SETUP,[Tag], DUTY, Distance offset

Level offset (P069) 2, 2, 2, 4 SETUP,[Tag], DUTY, Level offset

20mA point

4mA point

Primary variable

(D900)

Level SV (D901) 1, 2, 2 MONITOR,[Tag], READINGS,

Distance TV (D902) 3, 2, 1, 3 MONITOR,[Tag], READINGS,

Distance (D910) 3, 1, 2, 1, 1 MONITOR,[Tag], DIAGNOSTICS,

(1)

(1)

2, 2, 1, 3 SETUP, [Tag], OUTPUT, CURRENT,

2, 2, 1, 4 SETUP, [Tag], OUTPUT, CURRENT,

1, 2, 1 MONITOR,[Tag], READINGS,

blanking

blanking

Upper range val.

Lower range val.

VARIABLES, Primary variable

VARIABLES, Level SV

VARIABLES, Distance TV

Distance

(1) Configure this parameter if not communicating HART variables (PV, SV, TV, and

FV) to a host.

30 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 31

August 2019 Quick Start Guide

7 Product Certifications

7.1 Approved manufacturing locations

Rosemount Inc. – Chanhassen, Minnesota, USA

Rosemount Measurement Limited – Slough, Berkshire, United Kingdom

Emerson Asia Pacific Private Limited – Singapore

7.2 European Union directive information

The EU Declaration of Conformity begins on page 35, and the most recent

revision can be found at Emerson.com/Rosemount.

ATEX directive (94/9/EC)

Emerson complies with the ATEX directive.

Pressure Equipment Directive (PED) (97/23/EC)

The Rosemount 3107 and 3108 are outside the scope of PED directive.

Electro Magnetic Compatibility (EMC) (2004/108/EC)

EN 61326-1:2006

7.3 MCERTS certification

MCERTS certification (Rosemount 3108 only)

Sira certificate number: MC080131

7.4

Hazardous locations certificates

Note

Refer to the housing label to identify the approvals for your transmitter.

7.4.1 American and Canadian certifications I5 Factory Mutual (FM) Approval Intrinsically Safe

Markings:

Temperature

Codes:

Entity

Parameters:

Quick Start Guide 31

Intrinsically Safe for Class I, Division 1, Groups A, B, C,

and D Zone Marking: Class I, Zone 0, AEx ia llC

Intrinsically Safe when installed in accordance with

Rosemount drawing 71097/1300

IP66, IP68

T6 (Ta = 55 °C)

T4 (Ta = 60 °C)

VMax = 30 V, IMax = 120 mA, Pi = 0.82 W

Li = 27 µH, Ci = 5 nF

Page 32

Quick Start Guide August 2019

Special Condition for Safe Use (X):

1. To protect against UV exposure when installed outdoors, the

transmitter shall be installed in accordance with the section

Environmental.

I6 Canadian Standards Association (CSA)

Certificate Number:

Markings:

Temperature Codes:

Entity parameters:

Special Condition for Safe Use (X):

1. Risk of electrostatic charge build up on plastic surfaces. Clean only

with a damp cloth.

02 CSA 1352094 X

Ex ia IIC

Intrinsically Safe when installed with certified

barrier meeting transmitter

T4 at Ta = –40 to 60 °C

T6 at Ta = –40 to 55 °C

Ui=30V, Ii=120mA, Pi=0.82W, Ci=5nF, Li=27uH

7.4.2 European certifications I1 ATEX Intrinsic Safety

Certificate number:

Markings:

Sira 09ATEX2299X

II 1G, Ex ia IIC Ga

T6 (Ta = –40 to 55 °C), T4 (Ta = –40 to 60 °C)

Ui = 30V, li = 120mA, Pi = 0.82W, Li = 27µH, Ci = 5nF

IP66, IP68

7.4.3 Rest of the world certifications I7 IECEx Intrinsic Safety

Certificate No.:

Markings:

Special Conditions for Safe Use (X):

Model numbers covered: 3107*****I1****, 3108*****I1****,

3107*****I7****, and 3108*****I7****

('*' indicates options in construction, function and materials).

32 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

IECEx SIR 09.0124X

Ex ia IIC Ga

T6 (Ta = –40 to 55 °C), T4 (Ta = –40 to 60 °C)

Ui = 30V, li = 120mA, Pi = 0.82W, Li = 27µH, Ci = 5nF

IP66, IP68

Page 33

August 2019 Quick Start Guide

The following instructions apply to equipment covered by certificate

number Sira 09ATEX2299X:

1. The equipment may be used with flammable gases and vapors with

apparatus groups IIA, IIB, and IIC, and with temperature classes T1,

T2, T3, T4, T5, and T6.

2. Installation of this equipment shall be carried out by suitably trained

personnel, in accordance with the applicable code of practice.

3. The equipment is not intended to be repaired by the user and is to be

replaced by an equivalent certified unit. Repairs should only be

carried out by the manufacturer or approved repairer.

4. If the equipment is likely to come into contact with aggressive

substances, it is the responsibility of the user to take suitable

precautions that prevent it from being adversely affected, thus

ensuring that the type of protection is not compromised.

Aggressive Substances e.g. acidic liquids or gases that may attack

metals or solvents that may affect polymeric materials.

Suitable Precautions e.g. regular checks as part of routine inspections

or establishing from the material's data sheet that it is resistant to

specific chemicals.

5. The apparatus electronics is only certified for use in ambient

temperatures in the range of –40 to 60 °C for T4 or –40 to 55 °C for

T6. It should not be used outside this range.

6. It is the responsibility of the user to ensure the voltage and current

limits for this equipment are not exceeded.

7. Technical Data:

a. Materials of construction:

UPVC moulded body and front face. PVC sheathed 2 core

shielded cable. Glass filled nylon lock nut. 316SS hanging

bracket. Epoxy adhesive sealant.

b. Coding:

ATEX: II 1 G, Ex ia IIC Ga, T6 (Ta = –40 to 55 °C), T4 (Ta = –40

to 60 °C)

IECEx: Ex ia IIC Ga, T6 (Ta = –40 to 55 °C), T4 (Ta = –40 to 60

°C)

Ui = 30V, li = 120mA, Pi = 0.82W, Li = 27µH, Ci = 5nF

8. Special conditions for safe use:

a. The equipment must not be installed directly in any process

where the enclosure might be charged by the rapid flow of

non-conductive media.

Quick Start Guide 33

Page 34

Quick Start Guide August 2019

b. The equipment must only be cleaned with a damp cloth.

c. Do not mount the 3107/3108 on a structure that is subject to

vibration, or in a position where damage may be caused by

impact or thermal stress.

d. The equipment is not intended to be used in areas exposed to

dust.

9. Manufacturer:

Rosemount Measurement Limited

158 Edinburgh Avenue, Slough, Berkshire, SL1 4UE, UK

34 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 35

August 2019 Quick Start Guide

7.5 EU Declaration of Conformity

Figure 7-1: EU Declaration of Conformity

Quick Start Guide 35

Page 36

Quick Start Guide August 2019

36 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 37

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 3107/8

List of Rosemount 3107/8 Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

XOOOO

O

༣փ㓴Ԧ

Housing

Assembly

OOOOO

O

Րᝏಘ㓴Ԧ

Sensor

Assembly

XOOOO

O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

August 2019 Quick Start Guide

7.6 China RoHS

Quick Start Guide 37

Page 38

Quick Start Guide August 2019

38 Rosemount Ultrasonic 3107 Level and 3108 Flow Transmitters

Page 39

August 2019 Quick Start Guide

Quick Start Guide 39

Page 40

*00825-0200-4840*

00825-0200-4840, Rev. BC

Quick Start Guide

August 2019

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RFQ.RMD-RCC@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 204 8889

RMT-NA.RCCRFQ@Emerson.com

Europe Regional Office

Emerson Automation Solutions Europe

GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Linkedin.com/company/Emerson-

Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/user/

RosemountMeasurement

©

2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are

available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric

Co. Rosemount is a mark of one of the Emerson

family of companies. All other marks are the

property of their respective owners.

Loading...

Loading...