Page 1

Quick Start Guide

00825-0100-4832, Rev CA

Rosemount™ 3095FC MultiVariable™

Mass Flow Transmitter

with Modbus® Protocol

June 2016

Page 2

Quick Start Guide

June 2016

NOTICE

This guide provides basic guidelines for the Rosemount 3095FC with Modbus Protocol. It does not provide

instructions for configuration, diagnostics, maintenance, service, or troubleshooting. Refer to the

Rosemount 3095FC MultiVariable Mass Flow Transmitter Reference Manual

manuals are also available electronically on EmersonProcess.com/Rosemount

for more instruction. The

.

WARNING

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local,

national, and international standards, codes, and practices.

Before connecting communications in an explosive atmosphere, make sure the instruments in the loop

are installed in accordance with intrinsically safe or non-incendive field wiring practices.

In an Explosion-Proof/Flame-Proof installation, do not remove the transmitter covers when power is

applied to the unit.

Process leaks may cause harm or result in death.

To avoid process leaks, only use the o-ring designed to seal with the corresponding flange adapter.

Electrical shock can result in death or serious injury.

Avoid contact with the leads and the terminals. High voltage that may be present on leads can cause

electrical shock.

Contents

Mount the transmitter . . . . . . . . . . . . . . . . . . . . 3

Connect wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Set jumpers and apply power . . . . . . . . . . . . . . 8

Establish communication . . . . . . . . . . . . . . . . . . 9

2

Verify configuration . . . . . . . . . . . . . . . . . . . . . . 9

Trim the transmitter . . . . . . . . . . . . . . . . . . . . . . 9

Product Certifications . . . . . . . . . . . . . . . . . . . . 11

Page 3

June 2016

Quick Start Guide

1.0 Mount the transmitter

1.1 Installing the Rosemount 3095FC on a pipestand

The following steps must be taken to install the Rosemount 3095FC on a 2-in.

pipestand:

1. Install the pipestand using the pipestand documentation.

2. Remove the orifice/meter run from service.

3. Install the Rosemount 3095FC on a pipestand using clamps or mounting

brackets.

4. Connect the impulse lines.

1.2 Installing the Rosemount 3095FC on an orifice plate (direct

mount)

The following steps must be taken to install the Rosemount 3095FC on an orifice

plate:

1. Remove the orifice/meter run from service.

2. Install the Rosemount 3095FC on the meter run using a manifold and

hardware to secure the Rosemount 3095FC to the orifice flanges.

Figure 1. Gas Flow Application

3

Page 4

Quick Start Guide

A

4 × 1.75-in.

(44 mm)

D

4 × 1.75-in.

(44 mm)

4 × 2.25-in.

(57 mm)

C

4 × 1.75-in.

(44 mm)

4 × 1.50-in.

(38 mm)

B

4 × 2.88-in.

(73 mm)

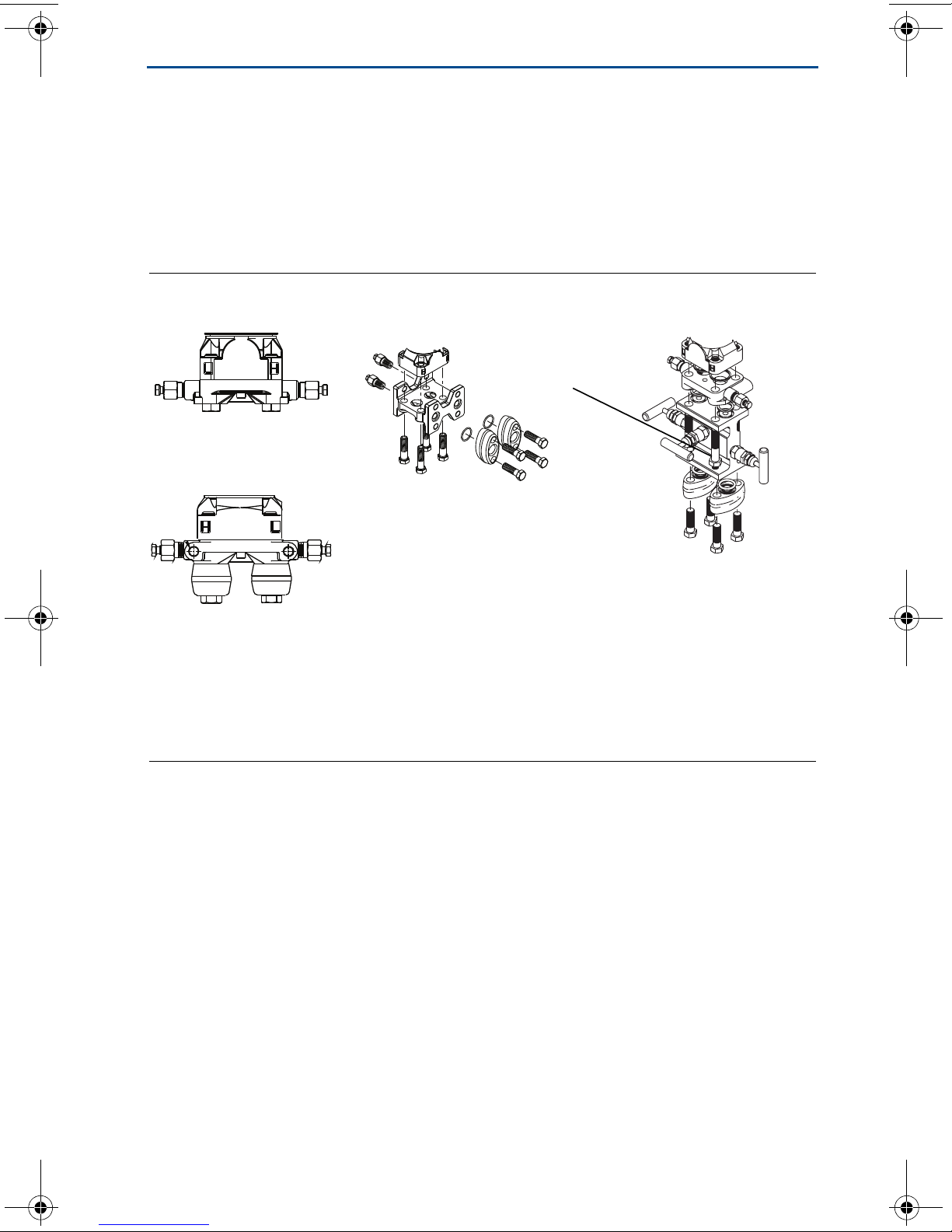

1.3 Bolting considerations

If the transmitter installation requires assembly of the process flanges, manifolds,

or flange adapters, follow these assembly guidelines to ensure a tight seal for

optimal performance characteristics of the transmitters. Use only bolts supplied

with the transmitter or sold by Emerson as spare parts. Figure 2 illustrates

common transmitter assemblies with the bolt length required for proper

transmitter assembly.

Figure 2. Common Transmitter Assemblies

June 2016

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional manifold and flange adapters

Bolts are typically carbon steel or stainless steel. Confirm the material by viewing

the markings on the head of the bolt and referencing Tabl e 1 . If bolt material is

not shown in Tabl e 1 , contact the local Emerson Process Management

representative for more information.

Use the following bolt installation procedure:

1. Carbon steel bolts do not require lubrication and the stainless steel bolts are

coated with a lubricant to ease installation. However, no additional lubricant

should be applied when installing either type of bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern. See

Table 1 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing pattern. See

Table 1 for final torque value.

5. Verify that the flange bolts are protruding through the isolator plate before

applying pressure.

4

Page 5

June 2016

B7M

316

316

316

SW

316

STM

316

R

B8M

Table 1. Torque Values for the Flange and Flange Adapter Bolts

Quick Start Guide

Bolt material Head Markings

Carbon Steel (CS)

Stainless Steel (SST) 150 in-lb 300 in-lb

Initial

Tor q ue

300 in-lb 650 in-lb

Final Torque

1.4 O-rings with flange adapters

WARNING

Failure to install proper flange adapter O-rings may cause process leaks, which can result in death or

serious injury. The two flange adapters are distinguished by unique O-ring grooves. Only use the O-ring

that is designed for its specific flange adapter, as shown below:

Rosemount 3051S/3051/2051/3095

A

B

C

D

Rosemount 1151

A

B

C

D

A. Flange adapter

B. O-ring

C. PFTE

D. Elastomer

Whenever the flanges or adapters are removed, visually inspect the o-rings. Replace them if there are any

signs of damage, such as nicks or cuts. If you replace the o-rings, re-torque the flange bolts and alignment

screws after installation to compensate for seating of the PTFE o-ring.

5

Page 6

Quick Start Guide

2.0 Connect wiring

Use the following steps to wire the transmitter:

1. Remove the electronics housing cover on the side marked FIELD TERMINALS.

2. Wire the RTD.

Temperature is input through the Resistance Temperature Detector (RTD)

probe and circuitry. The Rosemount 3095FC provides terminations for a 2- or

3-wire 100-ohm platinum RTD with a IEC 751 curve. The RTD has an alpha (α)

equal to 0.00385.

The RTD mounts directly to the piping using a thermowell. RTD wires should

be protected by a metal sheath or by a conduit connected to a conduit wiring

fitting on the enclosure. The RTD wires connect to the three screw terminals

designated “RTD” on the Termination Board.

Wiring between the RTD and Rosemount 3095FC should be shielded wire,

with the shield grounded only at one end to prevent ground loops. Ground

loops cause RTD input signal errors.

Table 2 displays the RTD terminal connections for the various RTD probes.

June 2016

Table 2. RTD Signal Routing

Ter mi nal Designation 3-wire RTD 2-wire RTD

RTD + Signal positive input RTD + RTD +

RTD + Signal positive input RTD + Jumper to RTD +

RTD RET Return reference RTD RET RTD RET

3. Wire the power supply.

The terminals are labeled CHG+ for positive power connection and CHG- for

negative power connection on a label on the termination board. These

connections provide the input voltage and power for the battery charging

circuit. The maximum voltage that can be applied to the CHG+/CHGterminals is 28 Volts dc.

Pin Signal Description

1 CHG+ Battery 8.0 to 28 V Power

2 CHG- Battery Common

4. Communications wiring

The Local Operator Interface (LOI) port provides direct communications

between the Rosemount 3095FC and the serial port of an operator interface

device, such as an IBM compatible PC using an EIA-232 (RS-232) link. The

interface allows access to the Rosemount 3095FC (using Rosemount User

Interface Software) for configuration and transfer of stored data.

6

Page 7

June 2016

1

6

7

892

3

4

5

To screw

terminals

Connection at PC COM port

White TX

Red TX

Black TX

Connection at LOI port

White TX

Red TX

Black TX

Using the prefabricated operator interface cable, physically connect the

Rosemount 3095FC to the PC running the Rosemount User Interface

Software. One end of the cable (a 9-pin, D-shell, female connector) plugs into

a serial communications port on the PC. The other end of the cable plugs into

the Rosemount 3095FC.

Figure 3. Operator Interface Wiring

Quick Start Guide

Table 3. Local Operator Interface Port Wiring

1. Do not use the LOI to power external devices.

Signal Label

Common COM

LOI Power

(1)

TX + V

Common COM

Ready to Send RTS

Receive RX

Tra ns mi t TX

7

Page 8

Quick Start Guide

A

B

C

D

E

F

G.

H

Figure 4. Rosemount 3095FC Terminal Block and Wiring Diagram

2 OR 3 WIRE RTD

June 2016

OPERATOR

INTERFACE

CABLE

A. LOI

B. RET

C. RTD

D. CHG

LOI

RET

RTD

+

+

+

CHG

POWER

SUPPLY

PC

E. 2 or 3 wire RTD

F. Power supply

G. PC

H. Operator interface cable

3.0 Set jumpers and apply power

To prevent unnecessary battery drainage, the Rosemount 3095FC is delivered

with the reset jumper in the OFF position. To apply power to the Rosemount

3095FC:

1. Complete the necessary wiring.

2. Unscrew the front end cap cover (LCD display end).

3. Place the power jumper in the ON position. The jumper is located on the LCD

display (if installed) or at J1 on the Battery Charger Board.

4. Screw the front-end cap cover (LCD display end).

After the Rosemount 3095FC completes start-up diagnostics (RAM and other

internal checks), the optional LCD display shows the date and time to indicate

that the Rosemount 3095FC completed a valid reset sequence.

8

Page 9

June 2016

Quick Start Guide

4.0 Establish communication

1. Open the Rosemount 3095FC User Interface Software

2. Enter the factory-assigned User ID and Password:

User ID: LOI

Password: 1000

3. Select Direct Connect, located on the software toolbar.

5.0 Verify configuration

1. Select Device > Clock from the menu tab.

2. Verify the correct time and date for the transmitter’s memory logs, and click

OK to exit the screen.

3. Select Device > Information from the menu tab.

4. Verify the correct station name, address number, group number, and contract

hour. Select OK to exit the screen.

5. Select Meter > Set Up from the menu tab.

6. Verify values of pipe and orifice diameter by selecting the General tab.

7. Select Inputs from the top of the screen and verify the correct range and units

of measure for the analog inputs.

8. Select the Gas Quality tab from the top of the screen and verify the correct gas

composition for your process.

9. Select the Advanced tab from the top of the screen. Verify the correct values

for FPV method, units of measure, and all geographical parameters. Select OK

to exit the screen.

6.0 Trim the transmitter

Note

Transmitters are shipped from Emerson™ Process Management, Emerson fully calibrated

per request or by the factory default of full scale.

6.1 Zero trim

A zero trim is a single-point adjustment used for compensating mounting

position effects. When performing a zero trim, ensure the low side block valve is

closed, the equalize valve is open, the high side block valve is open, and all wet

legs are filled to the correct level.

To check or adjust for zero shift, leave the sensor by-pass valve open (to simulate

a no-flow condition), with either line pressure or a normal operating SP from the

calibrator applied to the sensor. This applies the same pressure to both sides of

the DP diaphragm to give a zero DP reading.

9

Page 10

Quick Start Guide

Perform the following steps:

1. Connect the Rosemount User Interface Software to the Rosemount 3095FC

and run the calibration procedure.

2. Select Meter>Calibration >Freeze.

3. Under the Diff Press input, click Zero Shift to open the Set Zero Shift window.

4. Verify Reading to determine if a Zero Sift correction is required.

5. If the reading is not zero, select Set Zero Shift to adjust the Zero and select

Done. If the reading is zero, select Done.

6. Select Done to close the calibration window and cancel the freeze values to

begin using live readings for the flow calculations.

7. Once the zero trim is complete, verify that the high side block valve is open,

close the equalize valve tightly, then open the low side block valve.

June 2016

10

Page 11

June 2016

Quick Start Guide

7.0 Product Certifications

7.1 Approved Manufacturing Locations

Rosemount Inc. — Chanhassen, Minnesota USA

7.2 European Directive Information

The EC declaration of conformity for all applicable European directives for this product can

be found on the Rosemount website at EmersonProcess.com/Rosemount

be obtained by contacting our local sales office.

ATEX Directive (94/9/EC)

Emerson Process Management complies with the ATEX Directive.

European Pressure Equipment Directive (PED) (97/23/EC)

Rosemount 3095F_2/3,4/D Flow Transmitters

— QS Certificate of Assessment - EC No. PED-H-100 Module H Conformity Assessment

All other 3095_ Transmitters/Level Controller

— Sound Engineering Practice

. A hard copy may

Transmitter Attachments: Process Flange - Manifold

— Sound Engineering Practice

Electro Magnetic Compatibility (EMC) (2004/108/EC)

Rosemount 3095F Flow Transmitters - EN 61326-1:1997 - A1, A2, and A3

Ordinary Location Certification for Factory Mutual

As standard, the Rosemount 3095FB Transmitter has been examined and tested to

determine that the design meets basic electrical, mechanical, and fire protection

requirements by FM, a nationally recognized testing laboratory (NRTL) as accredited by the

Federal Occupational Safety and Health Administration (OSHA).

7.3 Hazardous Locations Certifications

North American Certifications

Canadian Standards Association (CSA) - U.S. and Canada

M Explosion-Proof for Class I, Division 1, Groups C and D including optional solar panel:

mast option: Suitable for use in Class I, Division 2, Groups A, B, C, D, and T3. CSA

Enclosure Type 4.

European Certifications

H ATEX Flame4proof

Certificate: LCIE05ATEX6057X II 2 G

EEx d IIB T5

V

= 28V dc

max

IP66

1180

Special Conditions for Safe Use (x):

1. Operating ambient temperature: –40 °C to 75 °C.

2. The users have to make sure that the thermal fluid transfer doesn’t overheat the

equipment to a temperature corresponding to the spontaneous combustion

temperature of surrounding gas.

11

Page 12

Quick Start Guide

Figure 5. Rosemount 3095FC Declaration of Conformity

June 2016

12

Page 13

June 2016

Quick Start Guide

13

Page 14

Quick Start Guide

June 2016

14

Page 15

June 2016

Quick Start Guide

15

Page 16

Quick Start Guide

ᴹ

China RoHS

㇑᧗⢙䍘䎵䗷ᴰབྷ⎃ᓖ䲀٬Ⲵ䜘Ԧරࡇ㺘

Rosemount 3095FC

List of Rosemount 3095FC Parts with China RoHS Concentration above MCVs

䜘Ԧ〠

Part Name

ᴹᇣ⢙䍘䍘

/ Hazardous Substances

䫵

Lead

(Pb)

⊎

Mercury

(Hg)

䭹

Cadmium

(Cd)

ޝԧ䬜䬜

Hexavalent

Chromium

(Cr +6)

ཊⓤ㚄㚄㤟

Polybrominated

biphenyls

(PBB)

ཊⓤ㚄㚄㤟䟊

Polybrominated

diphenyl ethers

(PBDE)

⭥ᆀ㓴Ԧ

Electronics

Assembly

XO O O O O

༣փ㓴Ԧ

Housing

Assembly

XO O X O O

Րᝏಘ㓴Ԧ

Sensor

Assembly

XO O X O O

ᵜ㺘Ṭ㌫ᦞ

SJ/T11364

Ⲵ㿴ᇊ㘼ࡦ

This table is proposed in accordance with the provision of SJ/T11364.

O:

Ѫ䈕䜘ԦⲴᡰᴹ൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿൷վҾ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

Ѫ൘䈕䜘Ԧᡰ֯⭘Ⲵᡰᴹ൷䍘ᶀᯉ䟼ˈ㠣ቁᴹа㊫൷䍘ᶀᯉѝ䈕ᴹᇣ⢙䍘Ⲵ䟿儈Ҿ

GB/T 26572

ᡰ㿴ᇊⲴ䲀䟿㾱≲

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

June 2016

16

Page 17

June 2016

Quick Start Guide

17

Page 18

*00825-0100-4832*

Quick Start Guide

00825-0100-4832, Rev CA

June 2016

Global Headquarters

Emerson Process Management

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@EmersonProcess.com

North America Regional Office

Emerson Process Management

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Process Management

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@EmersonProcess.com Linkedin.com/company/Emerson-Process-Management

Europe Regional Office

Emerson Process Management Europe GmbH

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@EmersonProcess.com

Asia Pacific Regional Office

Emerson Process Management Asia Pacific Pte Ltd

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.EmersonProcess.com

Middle East and Africa Regional Office

Emerson Process Management

Emerson FZE P.O. Box 17033,

Jebel Ali Free Zone - South 2

Dubai, United Arab Emirates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/ user/RosemountMeasurement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found at

www.Emerson.com/en-us/pages/Terms-of-Use.aspx

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

MultiVariable, Rosemount, and Rosemount logotype are

trademarks of Emerson Process Management.

Modbus is a registered trademark of Gould Inc.

All other marks are the property of their respective owners.

© 2016 Emerson Process Management. All rights reserved.

Loading...

Loading...