Emerson Rosemount 3051SF Series, Rosemount 3051SFA, Rosemount 3051S Series, Rosemount 3051SFP, Rosemount 3051SFC Quick Start Manual

Quick Start Guide

00825-0100-4801, Rev NB

December 2018

Rosemount™ 3051S Series Pressure

Transmitter and Rosemount 3051SF

Series Flowmeter

with HART® Protocol

Safety messages

NOTICE

This guide provides basic guidelines for Rosemount™ 3051S Series Pressure Transmitters. It also

provides the basic electronic guidelines for the Rosemount 3051SFA Reference Manual, Rosemount

3051SFC Reference Manual, and Rosemount 3051SFP Reference Manual. It does not provide

instructions for diagnostics, maintenance, service, or troubleshooting. Refer to the Rosemount 3051S

HART Reference Manual for more instruction. This document is also available electronically on

Emerson.com/Rosemount.

WARNING

Explosions could result in death or serious injury.

Installation of device in an explosive environment must be in accordance with appropriate local,

national, and international standards, codes, and practices.

Review the Rosemount 3051S/3051SFx/3051S-ERS Product Certifications section of this guide for any

restrictions associated with a safe installation.

• Before connecting a handheld communicator in an explosive atmosphere, make sure the

instruments in the loop are installed in accordance with intrinsically safe or non-incendive field

wiring practices.

• In an explosion-proof/flameproof installation, do not remove the transmitter covers when power

is applied to the unit.

• Use appropriately rated Ex adaptors, blanking elements, or glands during installation.

• Keep process insulation at least 1 inch (25 mm) from transmitter connection.

Process leaks could result in death or serious injury.

• Install and tighten process connectors before applying pressure.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads can cause

electrical shock.

Conduit/cable entries

• Unless marked, the conduit/cable entries in the transmitter housing use a ½–14 NPT thread form.

Entries marked “M20” are M20 × 1.5 thread form. On devices with multiple conduit entries, all

entries will have the same thread form. Only use plugs, adapters, glands, or conduit with a

compatible thread form when closing these entries.

• When installing in a hazardous location, use only appropriately listed or Ex certified plugs, glands,

or adapters in cable/conduit entries.

Contents

Mount the transmitter................................... 5

Consider housing rotation............................11

Set switches and jumpers.............................12

Connect wiring and power up...................... 14

Verify configuration..................................... 22

Trim the transmitter.................................... 26

Safety instrumented systems installation.....28

Rosemount 3051S/3051SFx/3051S-ERS

Product Certifications.................................. 29

Quick Start Guide December 2018

2 Rosemount 3051S

Rosemount 3051S Declaration of Conformity

.................................................................... 45

China RoHS.................................................. 49

December 2018 Quick Start Guide

Quick Start Guide 3

Quick Start Guide December 2018

4 Rosemount 3051S

1 Mount the transmitter

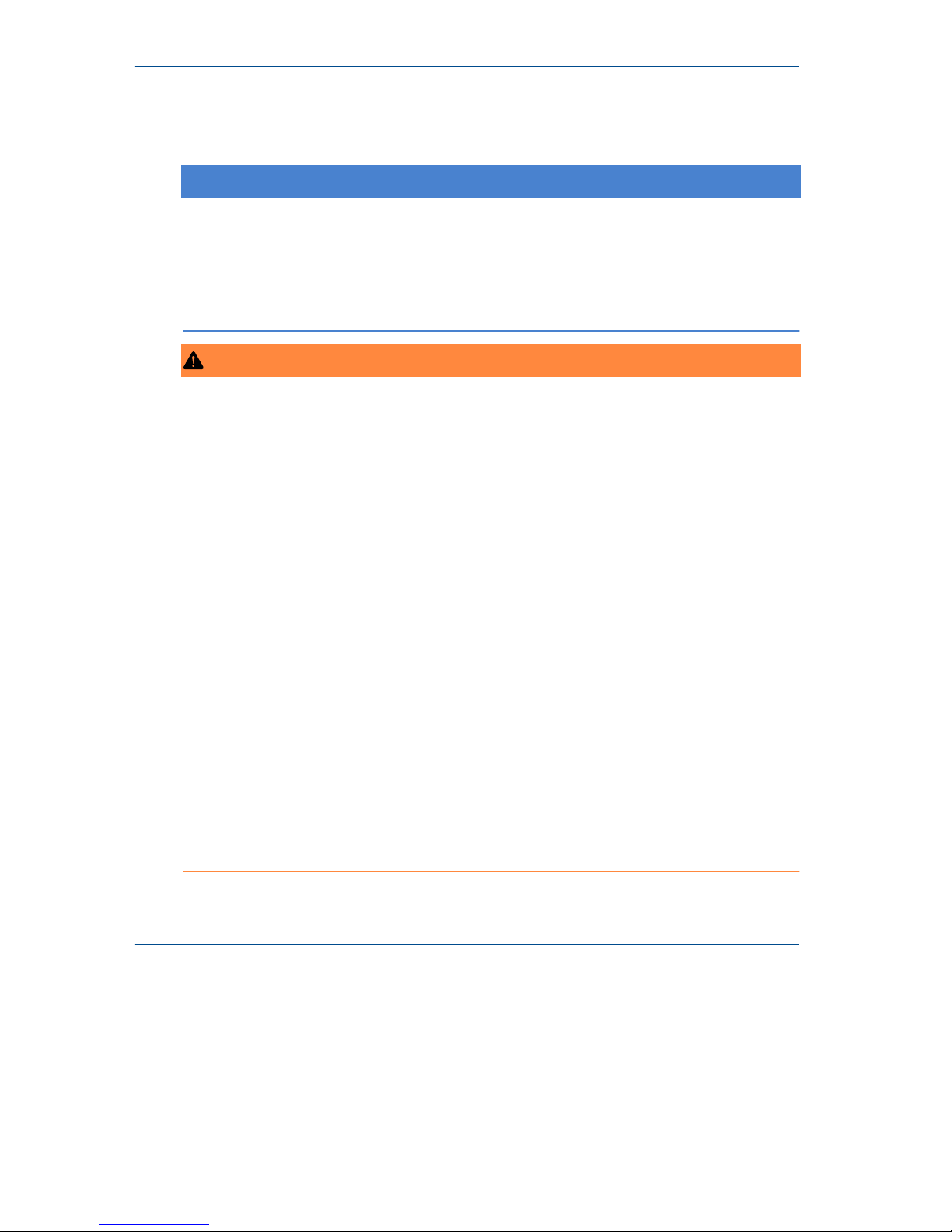

1.1 Liquid flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the drain/vent valves are oriented

upward.

A

A. Direction of flow

1.2 Gas flow applications

Procedure

1. Place taps in the top or side of the line.

2. Mount beside or above the taps.

A

A. Direction of flow

December 2018 Quick Start Guide

Quick Start Guide 5

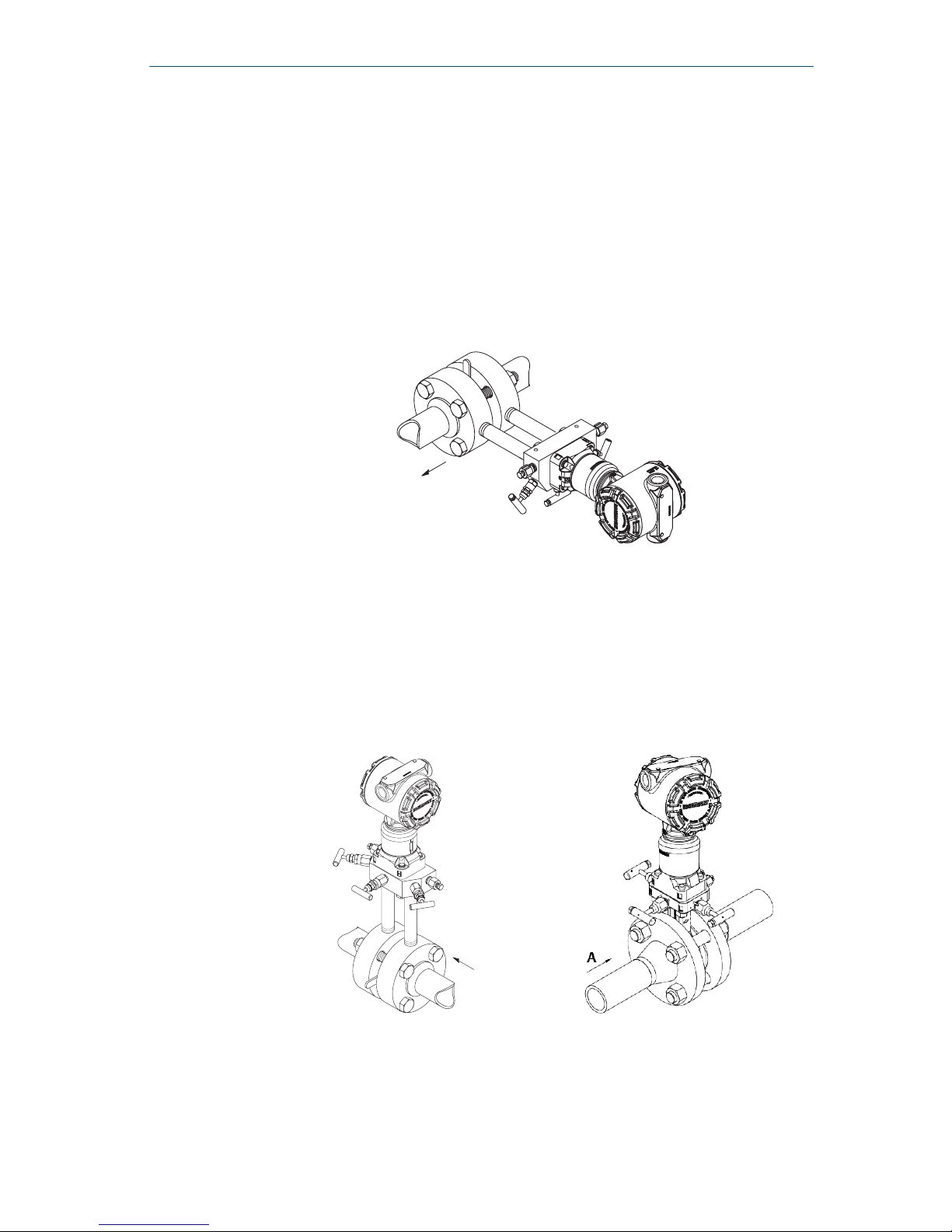

1.3 Steam flow applications

Procedure

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

A

A. Direction of flow

1.4 Using a mounting bracket

If the transmitter requires the use of a mounting bracket, use the images

below for instructions on how to properly mount the transmitter using the

Emerson™ provided mounting brackets. Use only bolts provided with the

transmitter or sold as Emerson spare parts.

1.5

Bolting considerations

About this task

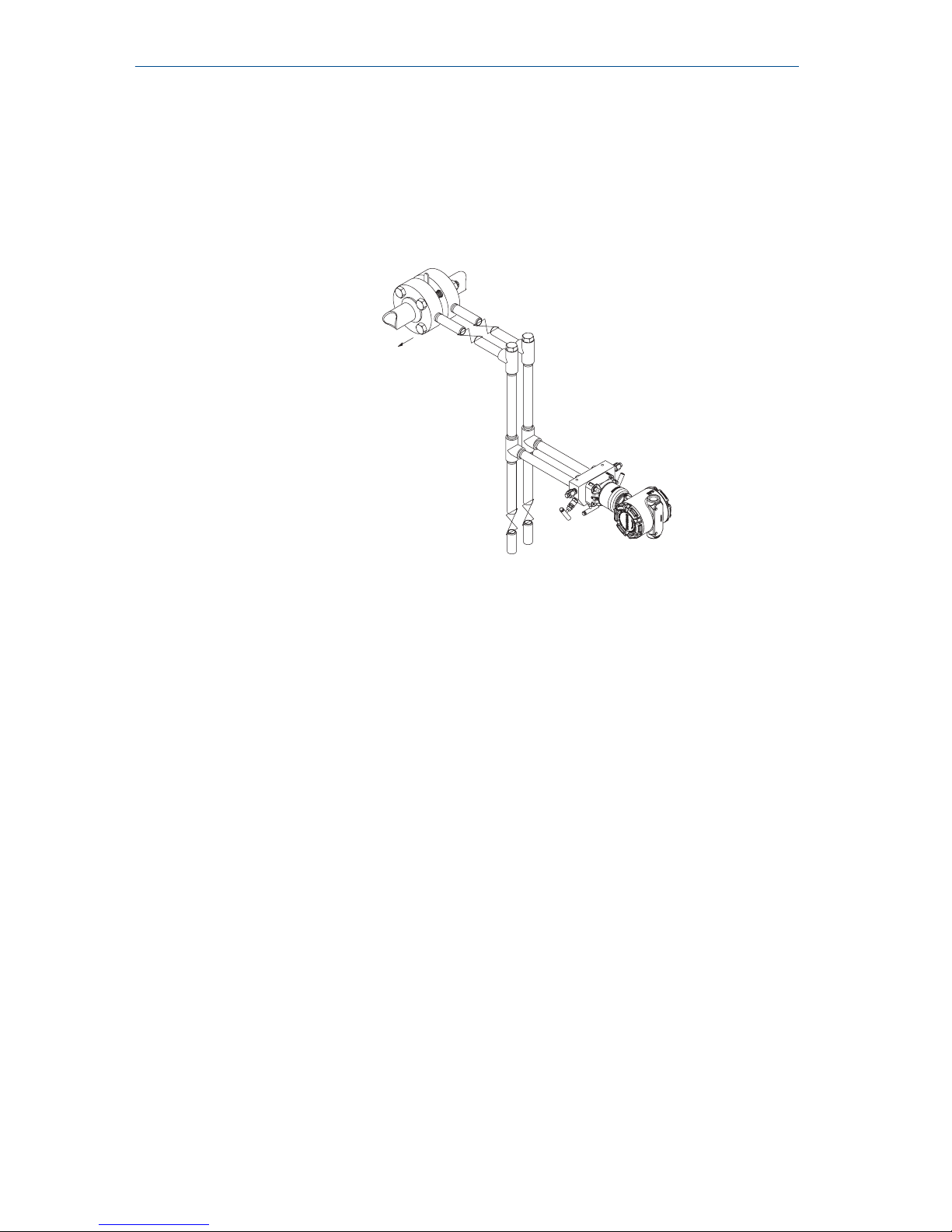

If the transmitter installation requires assembly of a process flange, manifold,

or flange adapters, follow these assembly guidelines to ensure a tight seal for

optimal performance characteristics of the transmitter. Only use bolts

supplied with the transmitter or sold by Emerson™ as spare parts. Figure 1-1

illustrates common transmitter assemblies with the bolt length required for

proper transmitter assembly.

Quick Start Guide December 2018

6 Rosemount 3051S

Figure 1-1: Common Transmitter Assemblies

A

4 × 1.75-in.

(44 mm)

D

4 × 1.75-in.

(44 mm)

4 × 2.25-in.

(57 mm)

C

4 × 1.75-in.

(44 mm)

4

× 1.50-in.

(38 mm)

B

4 × 2.88-in.

(73 mm)

A. Transmitter with coplanar flange

B. Transmitter with coplanar flange and optional flange adapters

C. Transmitter with traditional flange and optional flange adapters

D. Transmitter with coplanar flange and optional Rosemount Conventional

Manifold and flange adapters

Note

For all other manifolds, contact Customer Central technical support.

Bolts are typically carbon steel or stainless steel. Confirm the material by

viewing the markings on the head of the bolt and referencing Table 1-1 . If

bolt material is not shown in Table 1-1, contact the local Emerson

representative for more information.

Use the following bolt installation procedure:

Procedure

1. Carbon steel bolts do not require lubrication and the stainless steel

bolts are coated with a lubricant to ease installation. However, no

additional lubricant should be applied when installing either type of

bolt.

2. Finger-tighten the bolts.

3. Torque the bolts to the initial torque value using a crossing pattern.

See Table 1-1 for initial torque value.

4. Torque the bolts to the final torque value using the same crossing

pattern. See Table 1-1 for final torque value.

December 2018 Quick Start Guide

Quick Start Guide 7

5. Verify the flange bolts are protruding through the sensor module

before applying pressure (see Figure 1-2).

Example

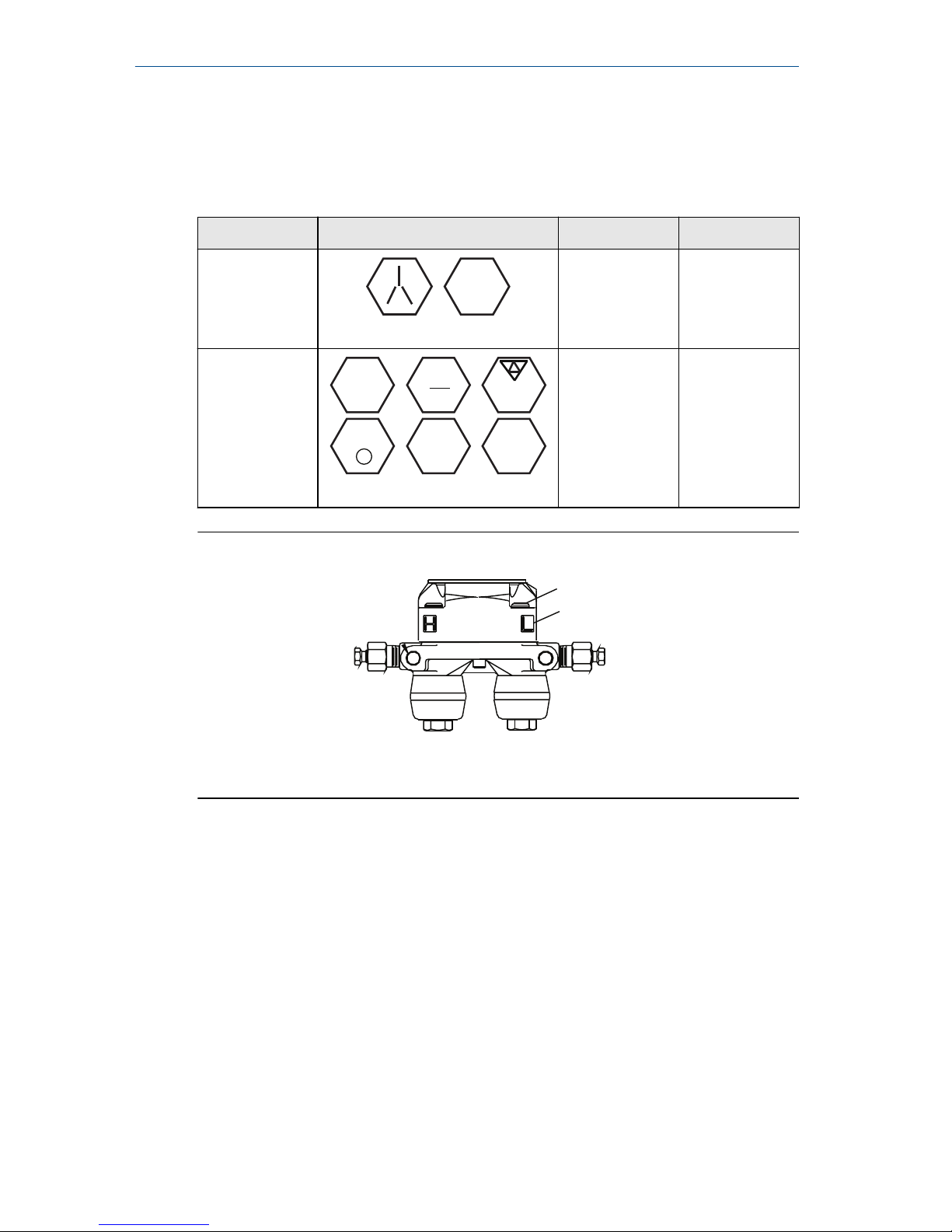

Table 1-1: Torque Values for the Flange and Flange Adapter Bolts

Bolt material Head markings Initial torque Final torque

Carbon Steel

(CS)

B7M

300 in-lb 650 in-lb

Stainless Steel

(SST)

316

316

316

SW

316

STM

316

R

B8M

150 in-lb 300 in-lb

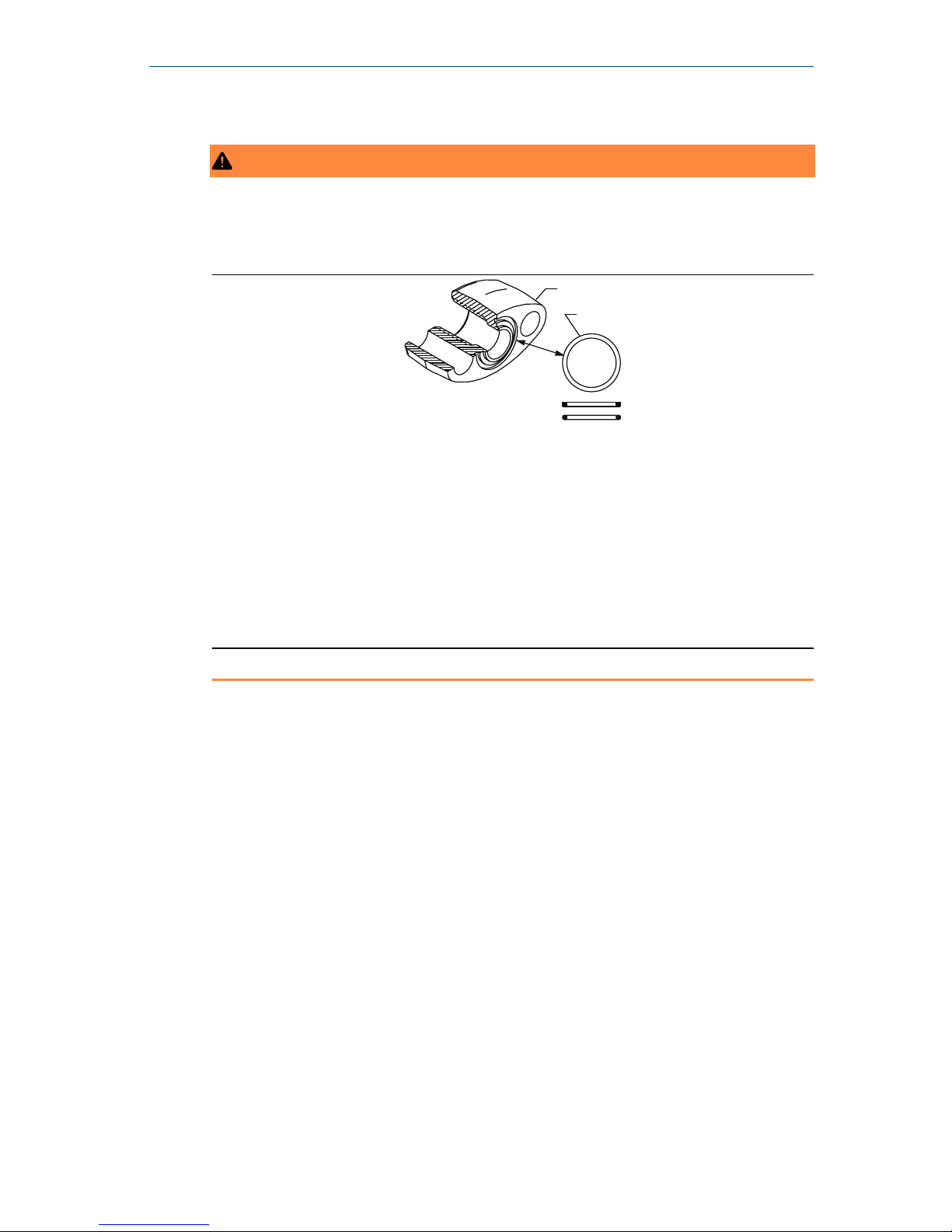

Figure 1-2: Proper Bolt Installation

A

B

A. Bolt

B. Sensor module

Quick Start Guide December 2018

8 Rosemount 3051S

1.6 O-rings with flange adapters

WARNING

Failure to install proper flange adapter O-rings may cause process leaks, which

can result in death or serious injury. Only use the O-ring that is designed for its

specific flange adapter.

A

B

C

D

A. Flange adapter

B. O-ring

C. PTFE-based profile (square)

D. Elastomer profile (round)

Whenever the flange or adapters are removed, visually inspect the O-rings.

Replace them if there are any signs of damage, such as nicks or cuts. If the Orings are replaced, re-torque the flange bolts and alignment screws after

installation to compensate for seating of the O-rings.

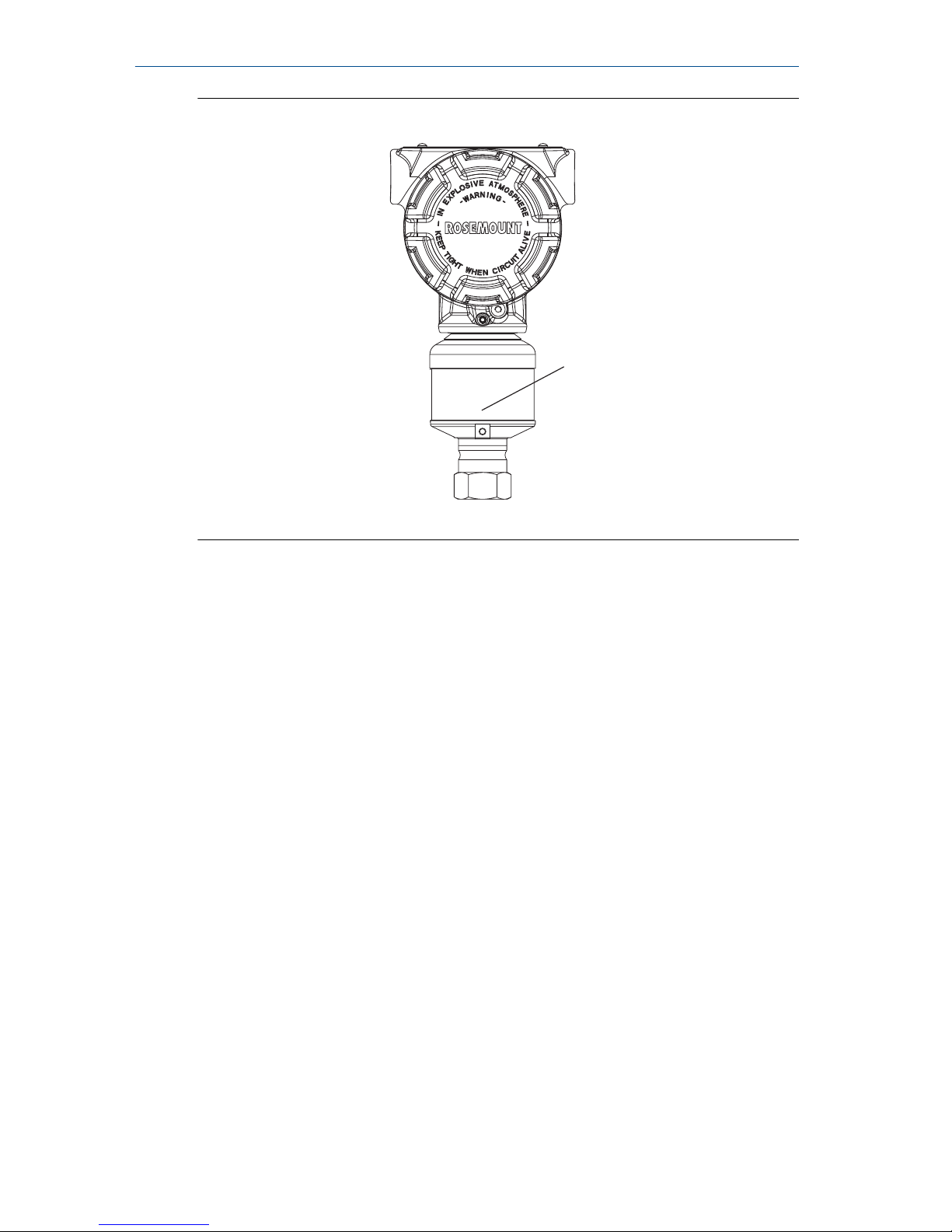

1.7

In-line gage transmitter orientation

The low side pressure port (atmospheric reference) on the in-line gage

transmitter is located under the sensor module neck label. (See Figure 1-3)

Keep the vent path free of any obstruction, including but not limited to paint,

dust, and lubrication by mounting the transmitter so that any contaminants

can drain away.

December 2018 Quick Start Guide

Quick Start Guide 9

Figure 1-3: In-line Gage Transmitter

A

A. Low side pressure port (under neck label)

Quick Start Guide December 2018

10 Rosemount 3051S

2 Consider housing rotation

About this task

To improve field access to wiring or to better view the optional LCD display:

Procedure

1. Loosen the housing rotation set screw.

2. Turn the housing up to 180° left or right of its original (as shipped)

position.

3. Re-tighten the housing rotation set screw.

Figure 2-1: Transmitter Housing Set Screw

A. LCD display

B. Housing rotation set screw (3/32-in.)

CAUTION

Do not rotate the housing more than 180° without first performing a

disassembly procedure. Over-rotation may sever the electrical

connection between the sensor module and the electronics.

December 2018 Quick Start Guide

Quick Start Guide 11

3 Set switches and jumpers

About this task

If alarm and security adjustment option is not installed, the transmitter will

operate normally with the default alarm condition alarm “high” and the

security “off”.

Procedure

1. Do not remove the transmitter covers in explosive atmospheres when

the circuit is live. If the transmitters is live, set the loop to manual and

remove power.

2. Remove the electronics compartment cover. On the Plantweb housing

the cover is opposite the field terminals side, or on the junction box

housing remove the terminal block cover. Do not remove the housing

cover in explosive environments.

3. On the Plantweb housing, slide the security and alarm switches into

the preferred position by using a small screwdriver (An LCD display or

an adjustment module must be in place to activate the switches). On

the junction box housing pull the pins out and rotate 90° into desired

position to set the security and alarm.

4. Reinstall the housing cover so metal contacts metal to meet explosionproof requirements.

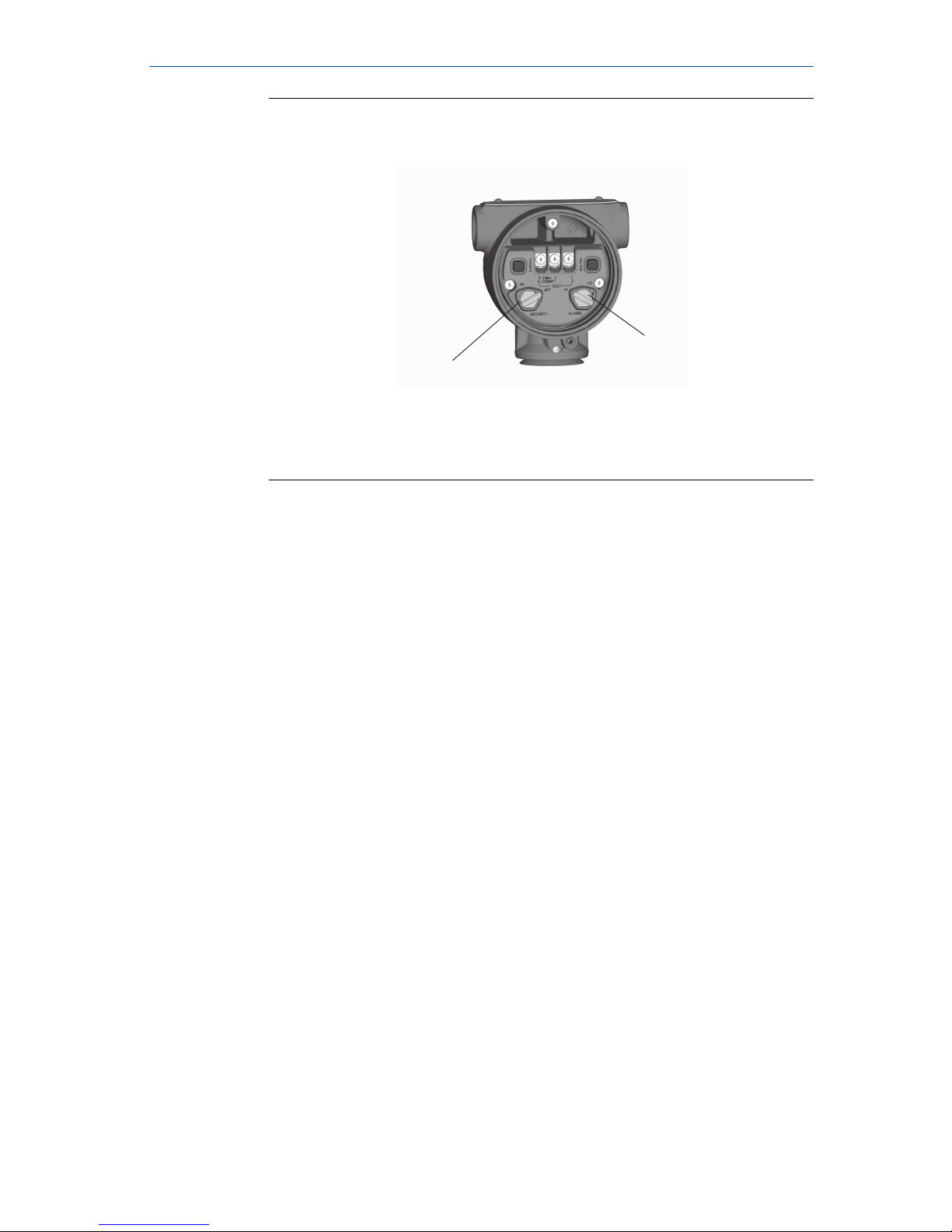

Figure 3-1: Transmitter Switch and Jumper Configuration

(Plantweb)

A

B

C

A. Meter/adjustment module

B. Security

C. Alarm

Quick Start Guide December 2018

12 Rosemount 3051S

Figure 3-2: Transmitter Switch and Jumper Configuration (Junction

Box)

B

C

A. Meter/adjustment module

B. Security

C. Alarm

December 2018 Quick Start Guide

Quick Start Guide 13

4 Connect wiring and power up

Procedure

1. Remove and discard orange conduit plugs.

2. Remove the housing cover labeled “Field Terminals.”

Note

Do not connect the power across the test terminals. Power could

damage the test diode in the test connection. Twisted pairs yield best

results. Use 24–14 AWG wire and do not exceed 5,000 ft. (1,500 m).

For single compartment housing (Junction Box housing), shielded

signal wiring should be used in high EMI/RFI environments.

3. Connect the positive lead to the “+” terminal, and the negative lead to

the “–” terminal.

4. CAUTION

When the enclosed threaded plug is utilized in the conduit opening, it

must be installed with a minimum thread engagement in order to

comply with explosion-proof requirements. For straight threads, a

minimum of seven threads must be engaged. For tapered threads, a

minimum of five threads must be engaged.

Plug and seal the unused conduit connection with the provided

conduit plug.

5. If applicable, install wiring with a drip loop. Arrange the drip loop

so the bottom is lower than the conduit connections and the

transmitter housing.

6. Reinstall the housing cover and tighten so the cover is fully seated with

metal to metal contact between the housing and cover in order to

meet explosion proof requirements.

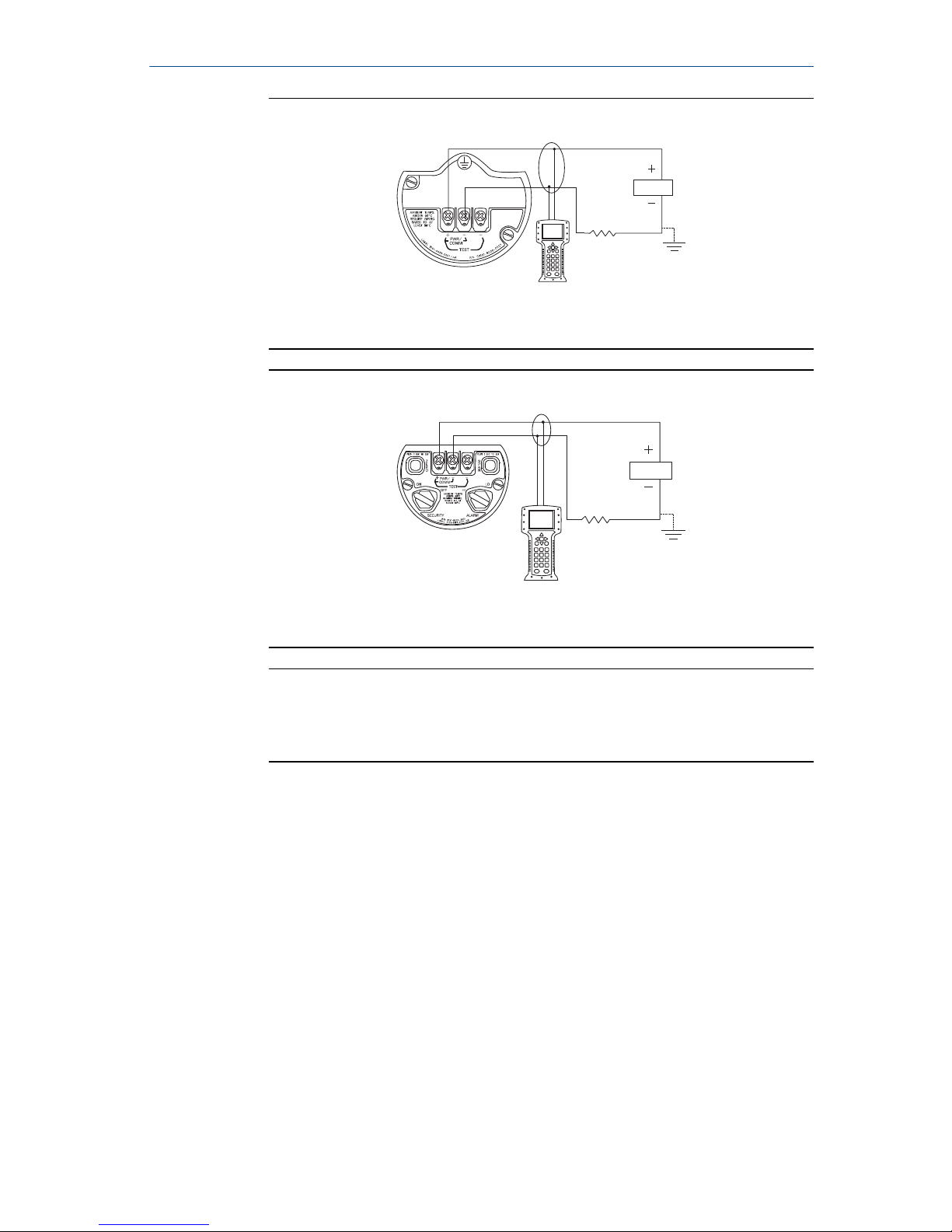

The figures below show the wiring connections necessary to power a

transmitter and enable communications with a hand-held Field

Communicator.

Quick Start Guide December 2018

14 Rosemount 3051S

Figure 4-1: Transmitter Wiring (Plantweb Housing)

A

B

A. RL ≥ 250 Ω

B. Power supply

Figure 4-2: Transmitter Wiring (Junction Box Housing)

A

B

A. RL ≥ 250 Ω

B. Power supply

Note

Installation of the transient protection terminal block does not provide

transient protection unless the Rosemount 3051S case is properly

grounded.

4.1

Ground signal wiring

About this task

Do not run signal wiring in conduit or open trays with power wiring, or near

heavy electrical equipment. Grounding terminations are provided on the

sensor module and inside the terminal compartment. These grounds are used

when transient protection terminal blocks are installed or to fulfill local

regulations.

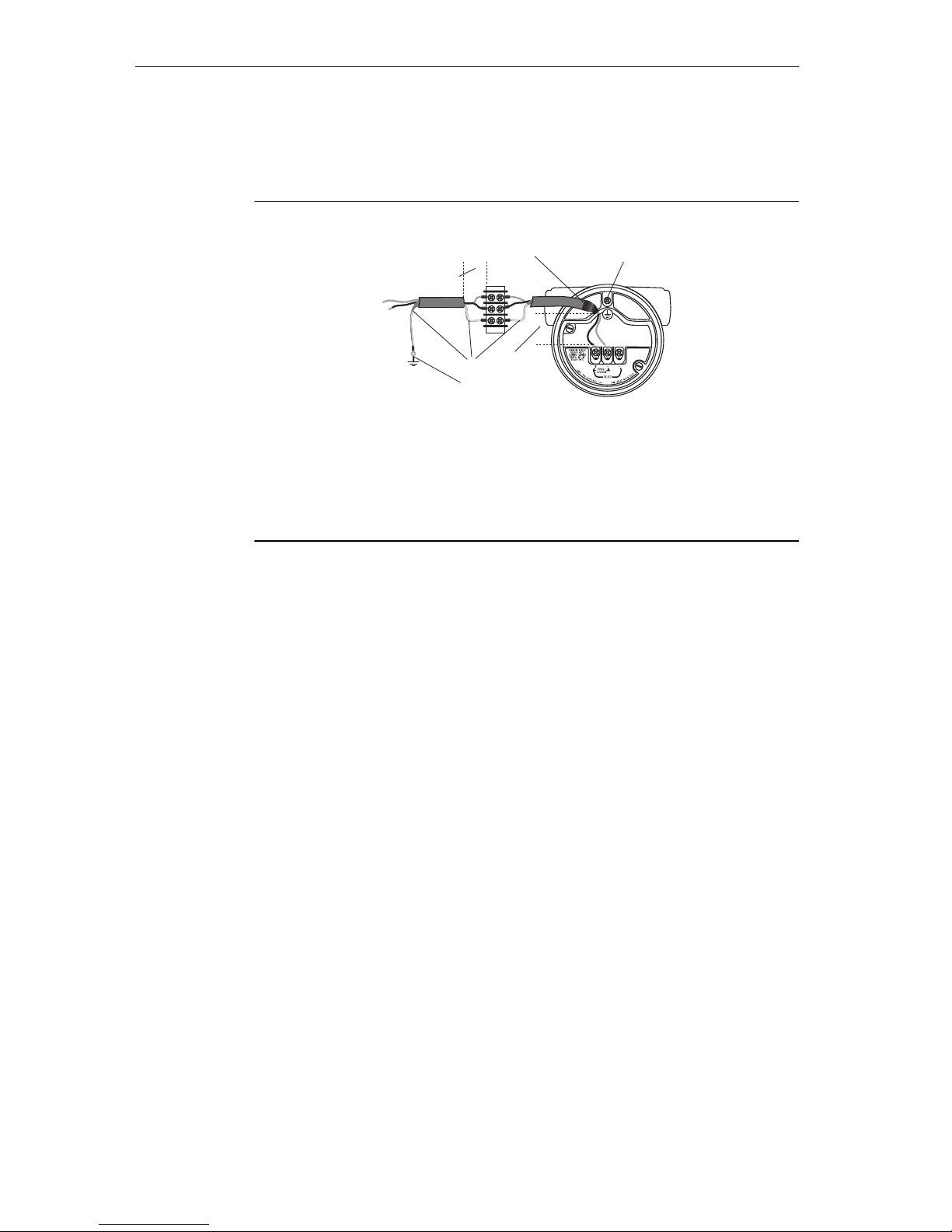

Procedure

1. Remove the Field Terminals housing cover.

2. Connect the wiring pair and ground as indicated in Figure 4-3.

The cable shield should:

December 2018 Quick Start Guide

Quick Start Guide 15

• Be trimmed close and insulated from touching the transmitter

housing

• Continuously connect to the termination point

• Be connected to a good earth ground at the power supply end

Figure 4-3: Wiring

DP

C

A

B

B

D

E

A. Insulate shield

B. Minimize distance

C. Connect shield back to the power supply ground

D. Trim shield and insulate

E. Safety ground

3. Replace the housing cover. It is recommended the cover be tightened

until there is no gap between the cover and the housing.

4. Plug and seal the unused conduit connection with the provided

conduit plug.

4.2

Remote display wiring and power up (if applicable)

The remote mount display and Interface system consists of a local transmitter

and a remote mount LCD display assembly. The local Rosemount 3051S

assembly includes a Junction Box housing with a three-position terminal block

integrally mounted to a sensor module. The remote mount LCD display

assembly consists of a dual compartment Plantweb housing with a seven

position terminal block. See Figure 4-4 for complete wiring instructions. The

following is a list of necessary information specific to the remote mount

display system:

• Each terminal block is unique for the remote display system.

• A 316 SST housing adaptor is permanently secured to the remote mount

LCD display Plantweb housing, providing an external ground and a means

for field mounting with the provided mounting bracket.

• A cable is required for wiring between the transmitter and remote mount

LCD display. The cable length is limited to 100 ft.

• 50 ft. (option M8) or 100 ft. (option M9) cable is provided for wiring

between the transmitter and remote mount LCD display. Option M7 does

not include cable; see recommended specifications below.

Quick Start Guide December 2018

16 Rosemount 3051S

Loading...

Loading...