Page 1

00809-0100-4853, Rev BA

Rosemount™ 3051SMV MultiVariable

Transmitter

with FOUNDATION™ Fieldbus Protocol

Reference Manual

January 2019

™

Page 2

Safety messages

NOTICE

Read this manual before working with the product. For personal and system safety, and for optimum product performance make

sure you thoroughly understand the contents before installing, using, or maintaining this product.

For technical assistance, contacts are listed below:

Customer Central

Technical support, quoting, and order-related questions. United States - 1-800-999-9307

(7:00 am to 7:00 pm CST) Asia Pacific- 65 777 8211Europe/Middle East/Africa - 49 (8153) 9390

North American Response Center

Equipment service needs.

1-800-654-7768 (24 hours—includes Canada)

Outside of these areas, contact your local Emerson™ representative.

CAUTION

The products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified

products in applications that require nuclear-qualified hardware or products may cause inaccurate readings.For information on

Rosemount nuclear-qualified products, contact your local Emerson Sales Representative.

WARNING

Explosions could result in death or serious injury.

Installation of this transmitter in an explosive environment must be in accordance with the appropriate local, national, and

international standards, codes, and practices. Review the approvals section of this manual for any restrictions associated with a

safe

• Before connecting a Field Communicator in an explosive atmosphere, ensure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• In an explosion-proof/flameproof installation, do not remove the transmitter covers when power is applied to the unit.

Process leaks may cause harm or result in death.

• Install and tighten process connectors before applying pressure.

• Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be present on leads can cause electrical shock.

WARNING

• Before connecting a HART® communicator in an explosive atmosphere, ensure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring practices.

• In an Explosion-Proof/Flameproof installation, do not remove the transmitter covers when power is applied to the unit.

Process leaks may cause harm or result in death.

• Install and tighten process connectors before applying pressure.

2

Page 3

WARNING

Replacement equipment or spare parts not approved by Emerson for use as spare parts could reduce the pressure retaining

capabilities of the transmitter and may render the instrument dangerous.

• Use only bolts supplied or sold by Emerson as spare parts.

• Refer to page 208 for a complete list of spare parts.

Improper assembly of manifolds to traditional flange can damage sensor module.

• For safe assembly of manifold to traditional flange, bolts must break back plane of flange web (i.e., bolt hole) but must not

contact sensor module housing.

3

Page 4

4

Page 5

Reference Manual Contents

00809-0100-4853 January 2019

Contents

Chapter 1 Introduction.................................................................................................................. 7

1.1 Using this manual.............................................................................................................................7

1.2 Product overview..............................................................................................................................7

1.3 Product recycling/disposal................................................................................................................8

Chapter 2 Configuration................................................................................................................ 9

2.1 Section overview.............................................................................................................................. 9

2.2 Safety messages...............................................................................................................................9

2.3 Flow configuration......................................................................................................................... 10

2.4 Variable configuration....................................................................................................................17

2.5 Device configuration...................................................................................................................... 20

2.6 Device capabilities..........................................................................................................................22

Chapter 3 Installation...................................................................................................................25

3.1 Section overview............................................................................................................................ 25

3.2 Safety messages.............................................................................................................................25

3.3 Considerations............................................................................................................................... 26

3.4 Steps required for quick installation................................................................................................27

3.5 Rosemount 305 and 304 Manifolds................................................................................................ 45

Chapter 4 Operation and Maintenance.........................................................................................57

4.1 Section overview............................................................................................................................ 57

4.2 Safety messages.............................................................................................................................57

4.3 Calibration......................................................................................................................................58

4.4 Field upgrades and replacements................................................................................................... 63

Chapter 5 Troubleshooting.......................................................................................................... 71

5.1 Section overview............................................................................................................................ 71

5.2 Safety messages.............................................................................................................................71

5.3 Measurement troubleshooting.......................................................................................................72

5.4 Communication troubleshooting................................................................................................... 73

5.5 Service support...............................................................................................................................77

Appendix A Reference Data.............................................................................................................79

A.1 Product Certifications.....................................................................................................................79

A.2 Ordering Information, Specifications, and Dimensional Drawings.................................................. 79

Reference Manual 5

Page 6

Contents Reference Manual

January 2019 00809-0100-4853

6 Reference Manual

Page 7

Reference Manual Introduction

00809-0100-4853 January 2019

1 Introduction

1.1 Using this manual

The sections in this manual provide information on installing, operating, and maintaining

the Rosemount™ 3051S MultiVariable™ FOUNDATION™ Fieldbus Transmitter (3051SMV). The

sections are organized as follows:

• Configuration provides instruction on commissioning and operating the Rosemount

3051SMV and information on flow configuration and device configuration.

• Installation contains mechanical and electrical installation instructions.

• Operation and Maintenance contains operation and maintenance techniques.

• Troubleshooting provides troubleshooting techniques for the most common operating

problems.

• Reference Data supplies reference and specification data, as well as ordering

information and contains intrinsic safety approval information, European ATEX

directive information, and approval drawings.

1.2 Product overview

This manual covers the Rosemount 3051SMV FOUNDATION Fieldbus Transmitter. The device

measures differential pressure, static pressure, and process temperature and has the

capability to calculate mass flow.

The following transmitters are covered in this manual:

Table 1-1: Rosemount 3051SMV Fully Compensated Mass Flow (M) Transmitter

Measurement type Description

1 Differential pressure, static pressure, temperature

2 Differential pressure and static pressure

Table 1-2: Rosemount 3051SMV Process Variables Only (P) Transmitter

Measurement type Description

1 Differential pressure, static pressure, temperature

2 Differential pressure and static pressure

Table 1-3: Device Driver Information

Release

date

NAMUR

Device identification Device driver

NAMUR

hardware

revision

(1)

software

revision

(1)

FOUNDATION

Fieldbus

software

revision

identification

FOUNDATION

Fieldbus

universal

revision

Device

revision

(3)

Review

instructions

Manual

(2)

document

number

Review

functionality

Change

description

Reference Manual 7

Page 8

Measured

process

inputs

DP

P

T

A/D

Micro

FF communications output

Introduction

January 2019 00809-0100-4853

Reference Manual

Table 1-3: Device Driver Information (continued)

Release

date

May-16 1.0.xx 1.0.xx 1.0.2 6.1.2 1 00809-0100-4853None: Initial

(1) NAMUR Revision is located on the hardware tag of the device. Differences in level 3 changes,

signified above by xx, represent minor product changes as defined per NE53. Compatibility and

functionality are preserved and product can be used interchangeably.

(2) Foundation Fieldbus device revision can be read using a Foundation Fieldbus capable

configuration tool. Value shown is minimum revision that could correspond to NAMUR

Revisions.

(3) Device driver file names use device and DD revision. To access new functionality, the new Device

Driver must be downloaded. It is recommended to download new Device Driver files to ensure

full functionality.

Device identification Device driver

identification

Figure 1-1: Transmitter Data Flow

1.3 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of

in accordance with local and national legislation/regulations.

Review

instructions

Review

functionality

Product Release

8 Reference Manual

Page 9

Reference Manual Configuration

00809-0100-4853 January 2019

2 Configuration

2.1 Section overview

This section contains information for the flow and device configuration of the Rosemount

3051S MultiVariable™ FOUNDATION™ Fieldbus Transmitter (3051SMV). Each FOUNDATION

Fieldbus host or configuration tool has different ways of displaying and performing

operations. Some hosts will use Device Descriptions (DD) and DD methods to complete

device configuration and will display data consistently across platforms.

The DD can be found on the FieldComm Group website at FieldCommGroup.org. There is

no requirement that a host or configuration tool support the features in the DD. For

DeltaV™ users, the DD can be found at EasyDeltaV.com. This section will describe how to

use the basic methods.

2.2 Safety messages

™

Instructions and procedures in this section may require special precautions to ensure the

safety of the personnel performing the operations. Information that raises potential safety

issues is indicated by a warning symbol ( ). Refer to the following safety messages before

performing an operation.

WARNING

Explosions could result in death or serious injury.

• Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

• Before connecting a handheld communicator in an explosive atmosphere, make sure

the instruments in the loop are installed in accordance with intrinsically safe or nonincendive field wiring practices.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

• Both housing covers must be fully engaged to meet flameproof/explosion-proof

requirements.

Failure to follow these installation guidelines could result in death or serious injury.

• Make sure the device is installed by qualified personnel and in accordance with

applicable code of practice.

Electrical shock could cause death or serious injury.

• If the sensor is installed in a high-voltage environment and a fault or installation error

occurs, high voltage may be present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

Reference Manual 9

Page 10

Configuration Reference Manual

January 2019 00809-0100-4853

2.3 Flow configuration

2.3.1 Engineering Assistant 5.5.1 ver. 2

Engineering Assistant 5.5.1 ver. 2 is PC-based software that performs flow configuration

for the Rosemount 3051SMV with the fully compensated mass flow feature board. It is

available as a standalone application or as an AMS SNAP-ON™, and is required to complete

the flow configuration for the Rosemount 3051SMV Transmitter.

The following are the minimum system requirements to install the Engineering Assistant

5.5.1 ver. 2 software:

• Intel® Core™ Duo, 2.4 GHz

• 600 MB of available hard disk space

• 2GB RAM

• Microsoft® Windows™ 7 Operating System (32 or 64 bit)

• FOUNDATION Fieldbus interface Learn more about the Emerson USB Fieldbus Interface

device and its configuration here: Emerson.com/AMS/USB-Fieldbus-Interface.

2.3.2

Installing Engineering Assistant 5.5.1 ver. 2 Stand-Alone

About this task

Note

If using full AMS™ Device Manager, do not uninstall it. Obtain the SNAP-ON version of EA or

install Engineering Assistant 5.5.1 ver. 2 Stand-Alone on another PC.

Procedure

1. Insert Rosemount Engineering Assistant (EA) Software disk into the DVD-ROM.

2. Right-click Setup.exe, select Run as Administrator.

3. Reboot the PC when prompted.

Note

After the reboot installation will continue. The disk should remain in the drive.

4. If there are old versions of EA 5, uninstall them by selecting Remove when

prompted. Once uninstalled, right-click Setup.exe, then select Run as

Administrator.

Note

Do NOT uninstall Engineering Assistant 6. Engineering Assistant 5 is not a

replacement for Engineering Assistant 6.

10 Reference Manual

Page 11

A

A

Reference Manual Configuration

00809-0100-4853 January 2019

2.3.3 Launching Engineering Assistant 5.5.1 ver. 2 and

connecting to the transmitter

About this task

Connect the FOUNDATION Fieldbus interface from the PC to the Rosemount 3051SMV

Fieldbus Transmitter.

Procedure

1. Open the transmitter cover on the side marked “Field Terminals”.

2. Connect the communication wires to the terminals labeled “Fieldbus Wiring”.

3. If the device is at a non-commissioned address, use the Emerson USB Fieldbus

Interface’s Configuration Utility to “Commission” the Device.

Note

The Emerson USB Fieldbus Interface can be configured to power the connected

Fieldbus device. Never attempt to use two power sources at the same time. Doing

so can disrupt communications and may compromise automation safety. Refer to

the Emerson USB Fieldbus Interface User Manual (AW7060MNL) for further

information.

4. Connect the Rosemount 3051SMV Transmitter to a computer (see Figure 2-1).

Figure 2-1: Connecting a PC to the Rosemount 3051SMV Using the USB Fieldbus

Interface

Rosemount 3051SMV without optional

process temperature connection

Rosemount 3051SMV with optional

process temperature connection

A. USB Fieldbus Interface

5. Launch the Rosemount 3051SMV Engineering Assistant for FOUNDATION Fieldbus

program by selecting MV Engineering Assistant from the Start menu.

OR

6. Launch AMS Device Manager if using the SNAP-ON Engineering Assistant.

Reference Manual 11

Page 12

Configuration Reference Manual

January 2019 00809-0100-4853

a) Right click the device to be configured.

b) Select SNAP-ON/Linked Apps > MV Engineering Assistant 5.5.1 ver. 2.

7. Start a new configuration or load a saved configuration from a file.

8. Perform the steps outlined in the Creating a flow configuration section.

9. Once the configuration is complete, disconnect MV Engineering Assistant and the

USB Fieldbus Interface. Then, attach the housing cover and tighten so that metal

contacts metal to meet flame-proof/explosion-proof requirements.

12 Reference Manual

Page 13

Reference Manual Configuration

00809-0100-4853 January 2019

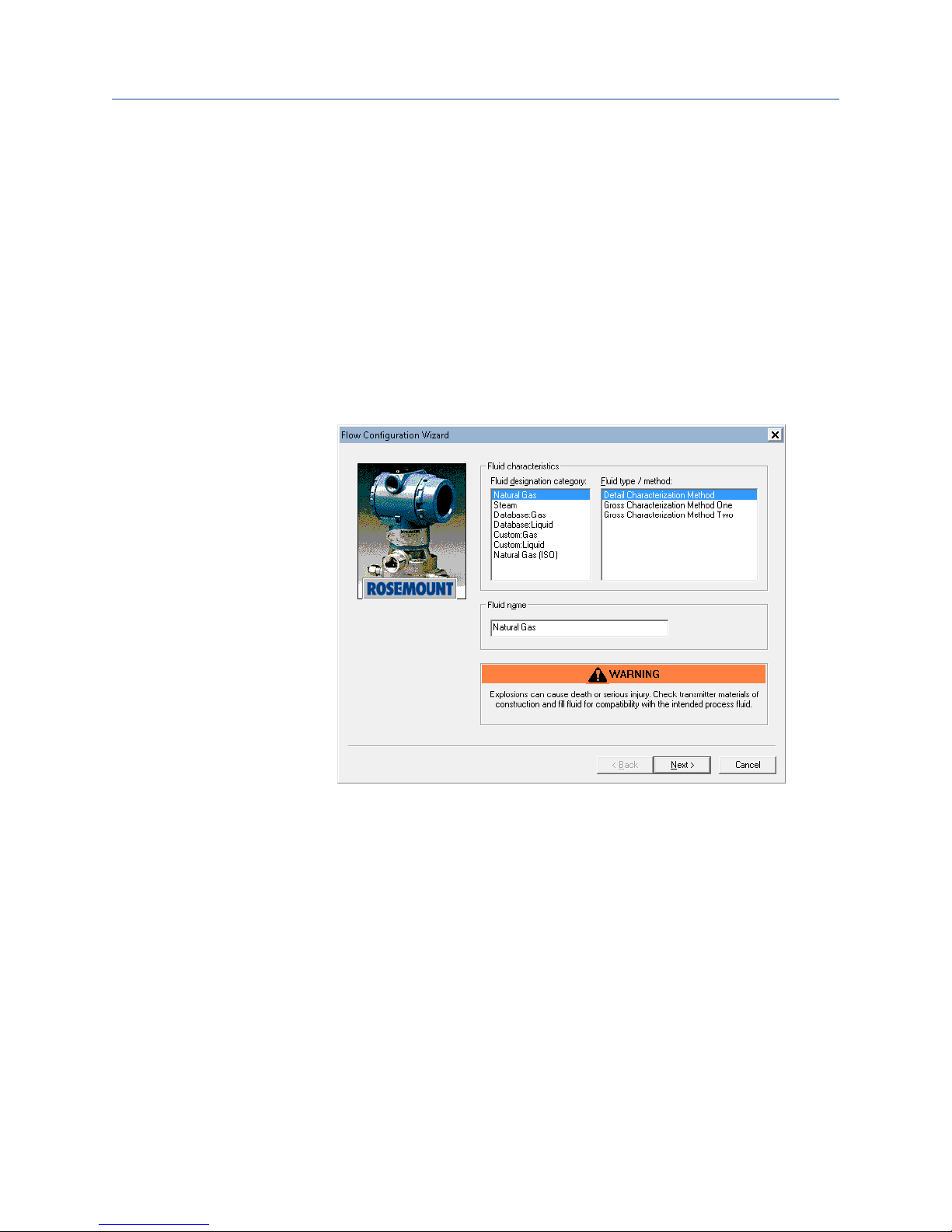

2.3.4 Creating a flow configuration

About this task

Engineering Assistant 5.5.1 ver. 2 is designed to guide the user through the setup of the

flow configuration for the Rosemount 3051SMV. This information will be used by the

Engineering Assistant to create the flow configuration parameters that can be sent to the

transmitter or saved for future use.

Procedure

1. Select the fluid designation category.

2. Select the fluid type.

3. Select Next.

Depending on the fluid selected, Engineering Assistant 5.5.1 ver. 2 may bring up a

screen for entering additional fluid information.

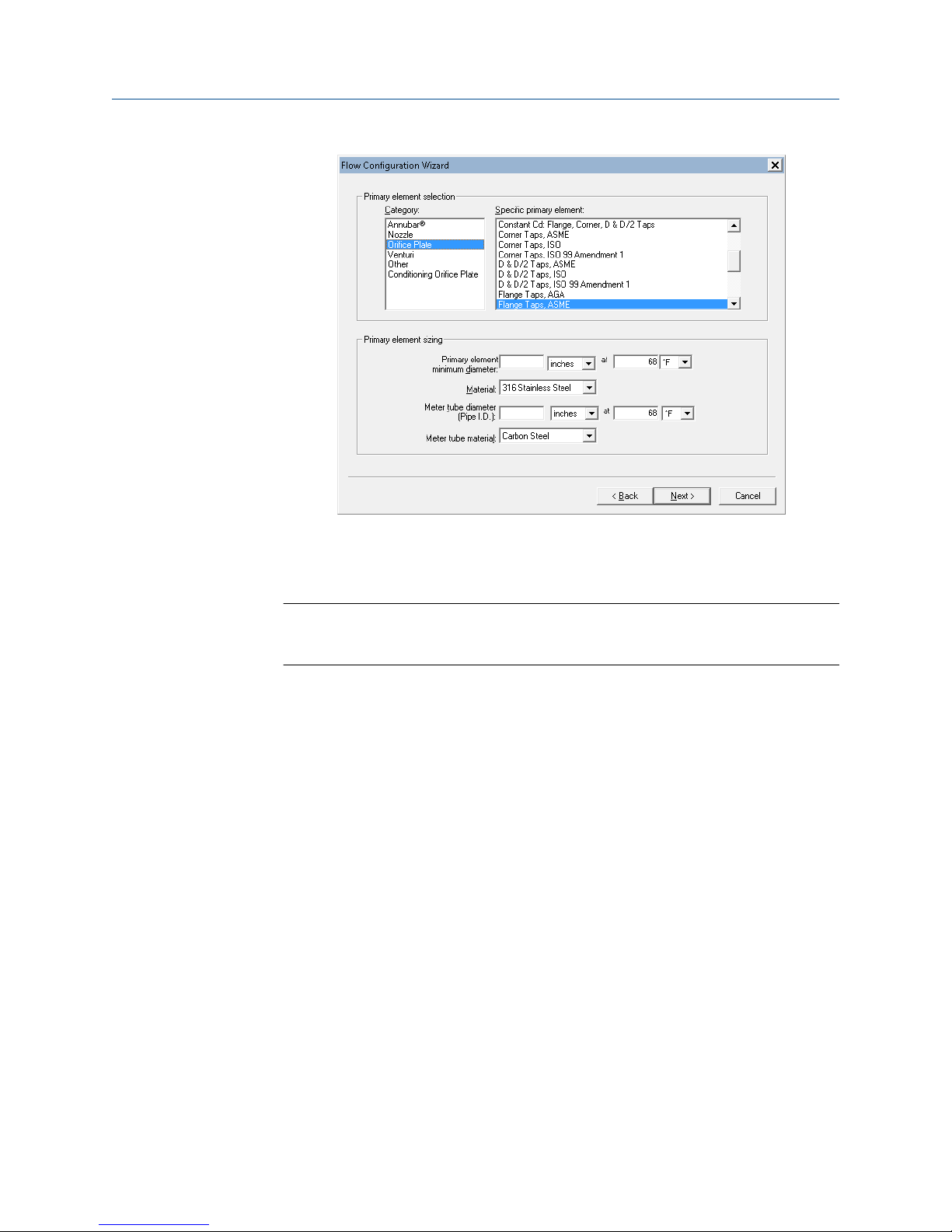

4. Select a primary element type, then enter the sizing information in the fields

provided.

5. Select Next.

Reference Manual 13

Page 14

Configuration Reference Manual

January 2019 00809-0100-4853

6. Enter the operating conditions for the fluid.

a) Select the pressure and temperature range based on the operating

conditions of the process, not the sensor range of the transmitter.

Note

An extremely large or small operating range may increase the uncertainty of the

flow calculation.

The units used for flow configuration are only used in the Engineering Assistant

software. For configuration of device variable units, see Units configuration.

7. Enter the atmospheric pressure.

The transmitter needs absolute pressure to calculate flow. If gage pressure is

measured, the transmitter will calculate absolute pressure based on the userdefined atmospheric pressure. Atmospheric pressure can be changed in the screen

below. This setting may also be configured per the atmospheric offset configuration

(see Static pressure on page 11) in the Sensor Transducer Block.

8. Select Next.

14 Reference Manual

Page 15

Reference Manual Configuration

00809-0100-4853 January 2019

9. Review fluid properties of the configuration.

10. Select Finish.

11. When prompted, save the flow configuration to the computer. The file must be

saved for review or to edit the mass flow configuration in the future.

Note

FOUNDATION Fieldbus mass flow configuration files cannot be uploaded from the

Rosemount 3051SMV. If the file is not saved, it cannot be retrieved.

Reference Manual 15

Page 16

Configuration Reference Manual

January 2019 00809-0100-4853

2.3.5 Sending a flow configuration to the transmitter

About this task

Select Send button to download the mass flow configuration file to the transmitter.

Sending the mass flow configuration file will overwrite the existing configuration in the

transmitter. Engineering Assistant will put the Mass Flow Transducer Block out of service

when sending the mass flow configuration.

Procedure

1. Select Send button. A confirmation message will display.

2. At the end of the download, choose which mode to put the Mass Flow Transducer

Block into, and then select Continue.

16 Reference Manual

Page 17

Reference Manual Configuration

00809-0100-4853 January 2019

2.3.6 Mass flow test calculation

The mass flow test calculation method allows the user to verify the flow configuration of

the Rosemount 3051SMV by entering expected values for the differential pressure,

absolute pressure, and process temperature variables. Test calculation units are always in

inH2O at 68 °F for differential pressure, psi for static pressure and °F for temperature.

To perform a test calculation, select Actions > Methods > Methods > Mass Flow Test

Calculation and follow the on-screen prompts.

Note

The device must be in Automatic Mode in order to successfully perform a mass flow test

calculation. If the resource block is not in automatic mode, the test calculation method

will still run, but the method will report the last live values, rather than the test calculation

outputs.

2.4 Variable configuration

2.4.1 Units configuration

Units for transmitter variables are configured in the XD Scale parameter in each AI Block.

Each AI Block is connected to a transmitter variable according to the Channel parameter in

the AI Block. When the units in an AI Block are changed, the units of the connected

channel variable will be changed in the Sensor Transducer Block or the Mass Flow

Transducer Block accordingly. If multiple AI Blocks are set to the same channel, the XD

Scale units must be manually synchronized to resolve configuration errors.

2.4.2

Mass flow

The following configuration items are found in the Mass Flow Transducer Block.

Note

These configuration items only apply to the Fully Compensated Mass Flow transmitter.

Reference Manual 17

Page 18

Configuration Reference Manual

January 2019 00809-0100-4853

Low flow cutoff

If the measured Differential Pressure value is less than the Low Flow Cutoff value, the

transmitter will calculate the Flow Rate value as zero.

The unit for this value is always inH2O at 68 °F.

Process temperature mode

The mass flow calculation can use a live process temperature reading or a fixed value

based on the selected Process Temperature Mode. To configure it, select Actions >

Methods > Methods > Mass Flow PT Mode Setup and follow the on-screen prompts.

Mode Description

Normal The transmitter will only use the actual measured process temperature value. If the

temperature sensor fails, the Flow output will go to Bad status.

Backup The transmitter will use the actual measured Process Temperature value. If the

temperature sensor fails, the transmitter will use the value shown in Fixed PT.

Fixed The transmitter will always use the temperature value shown in Fixed PT.

2.4.3

2.4.4

Note

The unit for the Fixed Process Temperature value always matches the Process

Temperature primary value unit. To change this unit setting, see Units configuration.

Differential pressure

The following configuration items are found in the Sensor Transducer Block.

Damping

The damping setting changes the response time of the transmitter; higher values can

smooth variations in output readings caused by rapid input changes. Determine the

appropriate damping setting based on the necessary response time, signal stability, and

other requirements.

The setting for Differential Pressure Damping also affects the Mass Flow.

Static pressure

The following configuration items are found in the Sensor Transducer Block.

Damping

The damping setting changes the response time of the transmitter; higher values can

smooth variations in output readings caused by rapid input changes. Determine the

appropriate damping setting based on the necessary response time, signal stability, and

other requirements.

The setting for static pressure damping affects both absolute and gage pressure

measurements.

18 Reference Manual

Page 19

Reference Manual Configuration

00809-0100-4853 January 2019

Atmospheric offset

Both absolute and gage pressure are available as variables. The type of transmitter ordered

will determine which variable is measured. The transmitter will calculate either absolute or

gage pressure based on the user-defined atmospheric offset.

2.4.5 Process temperature

The following configuration items are found in the Sensor Transducer Block.

Damping

The damping setting changes the response time of the transmitter; higher values can

smooth variations in output readings caused by rapid input changes. Determine the

appropriate damping setting based on the necessary response time, signal stability, and

other requirements.

Callendar-Van Dusen Coefficients

The Rosemount 3051SMV accepts Callendar-Van Dusen constants from a calibrated RTD

schedule and generates a special custom curve to match that specific sensor Resistance

vs. Temperature performance. Matching the specific sensor curve with the transmitter

configuration enhances the temperature measurement accuracy. Under Actions > Methods

> Methods, the Callendar-Van Dusen constants R0, A, B, and C can be viewed. If the

Callendar-Van Dusen constants are known for the user’s specific Pt 100 RTD sensor, the

constants R0, A, B, and C may be edited by selecting the Callendar-Van Dusen Setup

method and following the on-screen prompts. The user may also view the α, β, and δ

coefficients by selecting the View Alpha, Beta, Delta button. The constants R0, α, β, and δ

may be edited by selecting the Callendar-Van Dusen Setup and following the on-screen

prompts. To reset the transmitter to the IEC 751 Defaults, select the Reset to IEC 751

Defaults method.

User-defined process temperature sensor limits

Process temperature sensor limits can be changed to allow early detection of RTD failures.

When the limits are exceeded, the transmitter will display a Process Temperature Out of

Limits alert in the transmitter status, set the PT measurement status to uncertain, and will

stop using the measured temperature value in the flow calculation. See Mass flow on page

10 for more information on configuring the process temperature mode for mass flow.

Enable/disable process temperature

Using the PT Measurement parameter, the Process Temperature measurement can be

disabled to prevent undesired diagnostic alarms and local display screens. This feature

may be useful if the Process Temperature option was ordered but will not be used or if the

RTD in use has failed and a replacement is not readily available.

When the Process Temperature measurement is disabled, the Process Temperature

measurement status will be “bad”. If using mass flow calculations, set the Mass Flow’s

Process Temperature Mode to Fixed to allow calculations to continue. Once an RTD is

available and wired, set the PT Measurement to Enabled and the Process Temperature

Mode to Normal to allow the live reading to be used for mass flow calculations.

Reference Manual 19

Page 20

Configuration Reference Manual

January 2019 00809-0100-4853

2.4.6 Variable simulation

The following configuration items are found in the AI Block.

Simulate replaces the channel value coming from the Sensor Transducer Block. For testing

purposes, it is possible to manually drive the output of the Analog Input Block to a desired

value. There are two ways to do this.

Manual mode

Complete the steps below to change only the OUT_VALUE and not the OUT_STATUS of

the AI Block.

Procedure

1. Set the block mode to Manual.

2. Change the Output Value to the desired value.

3. Restore the original block mode when finished.

Simulate

Procedure

1. If the simulate switch on the electronics board is in the Disabled position, move it to

the Enabled position. See Set the switches for more information.

2. Set the Simulate En/Disable parameter to Active.

3. Enter the desired Simulate Value and Status. Make sure the block mode is Auto to

see the value propagate through the block.

4. Set the Simulate En/Disable parameter back to Disabled when finished simulating.

2.5 Device configuration

2.5.1 Display configuration

The following configuration items are found in the LCD display Transducer Block.

The transmitter features a three-line display. The first line of five characters displays the

output description, the second line of seven digits displays the actual value, and the third

line of six characters displays engineering units. The LCD display meter can also display

diagnostic messages.

Each parameter configured for display will appear on the LCD display for a brief period

before the next parameter is displayed. Up to four different variables may be shown on the

display.

The LCD display meter is preconfigured to show the measured variables that correspond

to the transmitter configuration. It can be configured to display any measured or

calculated value that has a status parameter with it (i.e. FOUNDATION Fieldbus DS-65

parameter type). Configure each parameter for display as stated below.

20 Reference Manual

Page 21

Reference Manual Configuration

00809-0100-4853 January 2019

Display parameter select

The display of each configured parameter can be turned on or off by editing the Display

Parameter Select parameter.

Block type

Enter the Block Type for the block that contains the parameter to be displayed.

Block tag

Enter the Block Tag of the block that contains the parameter to be displayed.

Parameter index

Enter the Block Index of the parameter to be displayed.

Custom tag

Enter up to five characters to be displayed on the top line of the LCD display when this

parameter is displayed.

2.5.2

Units type

Select auto when the parameter to be displayed is pressure, temperature, mass flow, or

percent. The units of the parameter will be read and automatically displayed on the LCD

display.

Select custom to display up to six characters as configured in the Custom Units parameter.

Select none if the parameter is to be displayed without associated units.

Custom units

If the Units Type is set to custom specify up to six characters here to be displayed with the

configured parameter.

Write lock

The following configuration items are found in the Resource Block.

The Rosemount 3051SMV Transmitter supports both hardware and software write lock.

Locking the transmitter will prevent configuration changes until it is unlocked again.

Software write lock

To configure software write lock, select Actions > Methods > Methods > Write Lock

Setup and follow the on-screen prompts for Software Write Lock. The security switch on

the electronics board must be in the unlocked position to use software write lock.

To unlock the transmitter, run the Write Lock Setup method again and follow the onscreen prompts.

Reference Manual 21

Page 22

Configuration Reference Manual

January 2019 00809-0100-4853

Hardware write lock

To configure Hardware Write Lock, select Actions > Methods > Methods > Write Lock

Setup and follow the on-screen prompts for Hardware Write Lock. This method must be

run twice if software write lock is already configured, first to unlock the device, then to

switch to hardware write lock.

To lock or unlock the transmitter, set the security switch on the electronics board as

shown in Figure 3-9. Note that the hardware security switch is only followed if the

transmitter has been configured to use hardware write lock as described above.

The state of the security switch can be read in the Device Switches State parameter.

2.6 Device capabilities

2.6.1 General block information

Reference information on the process control function blocks can be found in the Function

Block Reference Manual.

2.6.2

2.6.3

Link active scheduler

The Rosemount 3051SMV can be designated to act as the backup Link Active Scheduler

(LAS) in the event that the LAS is disconnected from the segment. As the backup LAS, the

Rosemount 3051SMV will take over the management of communications until the host is

restored. The host system may provide a configuration tool specifically designed to

designate a particular device as a backup LAS.

Capabilities

There are a total of 20 Virtual Communication Relationships (VCRs). Two are permanent

and 18 are fully configurable by the host system. Twenty-five link objects are available.

Table 2-1: Network Parameters

Network parameter Value

Slot Time 6

Maximum Response Delay 4

Maximum Inactivity to Claim LAS Delay 5

Minimum Inter DLPDU Delay 7

Time Sync class 4 (1ms)

Maximum Scheduling Overhead 10

Per CLPDU PhL Overhead 4

Maximum Inter-channel Signal Skew 0

Required Number of Post-transmission-gap-ext Units 0

Required Number of Preamble-extension Units 1

22 Reference Manual

Page 23

Reference Manual Configuration

00809-0100-4853 January 2019

Host timer recommendations

T1 = 96000 T2 = 9600000 T3 = 480000

Table 2-2: Block Execution Times

Block Time (in ms)

Analog Input 20

PID 25

Arithmetic 20

Input Selection 20

Signal Characterizer 20

Integrator 20

Output Splitter 20

Control Selector 20

2.6.4 Node address

The transmitter is shipped at a temporary (248+) address. This enables FOUNDATION

Fieldbus host systems to automatically recognize the device and move it to a permanent

address.

2.6.5

Block instantiation

The Rosemount 3051SMV supports the use of function block instantiation. When a device

supports block instantiation, the number of blocks and block types can be defined to

match specific application needs. The number of blocks that can be instantiated is only

limited by the amount of memory within the device and the block types that are

supported by the device. Instantiation does not apply to standard device blocks like the

Resource or Transducer Blocks. Block instantiation is done by the host control system or

configuration tool, but not all hosts are required to implement this functionality. Refer to

the specific host or configuration tool manual for more information.

Reference Manual 23

Page 24

Configuration Reference Manual

January 2019 00809-0100-4853

24 Reference Manual

Page 25

Reference Manual Installation

00809-0100-4853 January 2019

3 Installation

3.1 Section overview

The information in this section covers installation considerations for the Rosemount

3051S MultiVariable™ FOUNDATION™ Fieldbus Transmitter (3051SMV). A Quick Start Guide is

shipped with every transmitter to describe basic installation, wiring, and startup

procedures. Dimensional drawings for each transmitter variation and mounting

configuration are included in Rosemount 3051SMV Product Data Sheet.

3.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

™

Reference Manual 25

Page 26

Installation

January 2019 00809-0100-4853

Reference Manual

WARNING

Explosions could result in death or serious injury.

• Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

• Fully engage both transmitter covers to meet explosion-proof requirements.

• Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the segment are installed in accordance with intrinsically safe or nonincendive field wiring practices.

• Verify the operating atmosphere of the transmitter is consistent with the appropriate

hazardous locations certifications.

Electrical shock could cause death or serious injury.

• Avoid contact with the leads and terminals.

Process leaks could result in death or serious injury.

• Install and tighten all four flange bolts before applying pressure.

• Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Use only bolts supplied or sold by Emerson as spare parts.

• Replacement equipment or spare parts not approved by Emerson™ for use as spare

parts could reduce the pressure retaining capabilities of the transmitter and may

render the instrument dangerous.

Improper assembly of manifolds to traditional flange can damage sensor module.

• For safe assembly of manifold to traditional flange, bolts must break back plane of

flange web (i.e., bolt hole) but must not contact sensor module housing.

Sensor module and electronics housing must have equivalent approval labeling in order to

maintain hazardous location approvals.

• When upgrading, verify sensor module and electronics housing certifications are

equivalent. Differences in temperature class ratings may exist, in which case the

complete assembly takes the lowest of the individual component temperature classes

(for example, a T4/T5 rated electronics housing assembled to a T4 rated sensor module

is a T4 rated transmitter.)

3.3 Considerations

3.3.1 General

Measurement performance depends upon proper installation of the transmitter and

impulse piping. Mount the transmitter close to the process and use minimum piping to

achieve best performance. Also, consider the need for easy access, personnel safety,

practical field calibration, and a suitable transmitter environment. Install the transmitter

to minimize vibration, shock, and temperature fluctuation.

Important

Install the enclosed pipe conduit plug (found in the box) in the unused conduit plug

opening. For straight threads, a minimum of seven threads must be engaged. For tapered

threads, a minimum of five threads must be engaged; install the plug wrench-tight. For

material compatibility considerations, see the Material Selection Technical Note.

26 Reference Manual

Page 27

Reference Manual

00809-0100-4853 January 2019

Installation

3.3.2 Mechanical

Steam service

For steam service or for applications with process temperatures greater than the limits of

the transmitter, do not blow down impulse piping through the transmitter. Flush lines

with the blocking valves closed and refill lines with water before resuming measurement.

Side mounting

When the transmitter is mounted on its side, position the coplanarflange to ensure proper

venting or draining. Mount the flange as shown in Mount the transmitter, keeping drain/

vent connections on the bottom for gas service and on the top for liquid service.

3.3.3

Environmental

Best practice is to mount the transmitter in an environment that has minimal ambient

temperature change. The transmitter electronics temperature operating limits are –40 to

185 °F (–40 to 85 °C). Rosemount 3051S Product Data Sheet lists the sensing element

operating limits. Mount the transmitter so it is not susceptible to vibration and mechanical

shock and does not have external contact with corrosive materials.

3.4 Steps required for quick installation

• Start >

• Mount the transmitter

• Commissioning (paper) tag

• Set the switches

• Wire, ground, and power

• > Finish

3.4.1

Mount the transmitter

Figure 3-1 illustrates a typical Rosemount 3051SMV installation site measuring dry gas

with an orifice plate.

Reference Manual 27

Page 28

Flow

A

B

C

D

Installation Reference Manual

January 2019 00809-0100-4853

Figure 3-1: Typical Rosemount 3051SMV Installation Site

A. Rosemount 3051SMV

B. RTD cable

C. Pt 100 RTD sensor

D. Process connections

Mounting brackets

The Rosemount 3051SMV can be mounted to a 2-in. (50.88 mm) pipe or to a panel using

an optional mounting bracket. The B4 Bracket (SST [Stainless steel]) option is for use with

the coplanar flange process connection. shows bracket dimensions and mounting

configurations for the B4 option. Other bracket options are listed in Table 3-1. When

installing the transmitter to one of the optional mounting brackets, torque the bolts to

125 in-lb (0,9 N-m).

Table 3-1: Mounting Brackets

Options Description Mounting type Bracket material Bolt material

B4 Coplanar flange

bracket

B1 Traditional flange

bracket

2-in. pipe/panel SST SST

2-in. pipe Painted CS (Carbon

steel)

CS

28 Reference Manual

Page 29

Reference Manual

00809-0100-4853 January 2019

Installation

Table 3-1: Mounting Brackets (continued)

Options Description Mounting type Bracket material Bolt material

B2 Traditional flange

bracket

B3 Traditional flange flat

bracket

B7 Traditional flange

bracket

B8 Traditional flange

bracket

B9 Traditional flange flat

bracket

BA Traditional flange

bracket

BC Traditional flange flat

bracket

Panel Painted CS CS

2-in. pipe Painted CS CS

2-in. pipe Painted CS SST

Panel Painted CS SST

2-in. pipe Painted CS SST

2-in. pipe SST SST

2-in. pipe SST SST

Flange bolts

The Rosemount 3051SMV can be shipped with a coplanar flange or a traditional flange

installed with four 1.75-in (44.4 mm). flange bolts. Mounting bolts and bolting

configurations for the coplanar and traditional flanges can be found in Cover installation.

SST bolts supplied by Emerson are coated with a lubricant to ease installation. CS bolts do

not require lubrication. No additional lubricant should be applied when installing either

type of bolt. Bolts supplied by Emerson are identified by their head markings:

A. Carbon Steel (CS) Head Markings

B. Stainless Steel (SST) Head Markings

C. Alloy K-500 Head Marking

Note

The last digit in the F593_ head marking may be any letter between A and M.

Reference Manual 29

Page 30

Installation

January 2019 00809-0100-4853

Reference Manual

Bolt installation

Only use bolts supplied with the 2051 or provided by Emerson Automation Solutions as

spare parts. When installing the transmitter to one of the optional mounting brackets,

torque the bolts to 125 in-lb. (0,9 N-m). Use the following bolt installation procedure:

Procedure

1. Finger-tighten the bolts.

2. Torque the bolts to the initial torque value using a crossing pattern.

3. Torque the bolts to the final torque value using the same crossing pattern.

Example

Torque values for the flange and manifold adapter bolts are as follows:

Table 3-2: Bolt Installation Torque Values

Bolt material Initial torque value Final torque value

CS-ASTM-A449 Standard 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

316 SST—Option L4 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

ASTM-A-193-B7M—Option L5 300 in.-lb (34 N-m) 650 in.-lb (73 N-m)

ASTM-A-193 Class 2, Grade B8M—Option L8 150 in.-lb (17 N-m) 300 in.-lb (34 N-m)

Figure 3-2: Traditional Flange Bolt Configurations

A. Drain/vent

B. Plug

Dimensions are in inches (millimeters).

30 Reference Manual

Page 31

Reference Manual

00809-0100-4853 January 2019

Installation

Figure 3-3: Mounting Bolts and Bolt Configurations for Coplanar Flange

Dimensions are in inches (millimeters).

Description Size in inches (mm)

Flange Bolts 1.75 (44)

Flange/Adapter Bolts 2.88 (73)

Manifold/Flange Bolts 2.25 (57)

Note

Rosemount 2051T transmitters are direct mount and do not require bolts for

process connection.

Mounting requirements

Impulse piping configurations depend on specific measurement conditions. Refer to

Figure 3-4 for examples of the following mounting configurations:

Liquid flow measurement

• Place taps to the side of the line to prevent sediment deposits on the process isolators.

• Mount the transmitter beside or below the taps so gases vent into the process line.

• Mount drain/vent valve upward to allow gases to vent.

Gas flow measurement

• Place taps in the top or side of the line.

• Mount the transmitter beside or above the taps so to drain liquid into the process line.

Steam flow measurement

• Place taps to the side of the line.

• Mount the transmitter below the taps to ensure that impulse piping will remain filled

with condensate.

• In steam service above 250 °F (121 °C), fill impulse lines with water to prevent steam

from contacting the transmitter directly and to ensure accurate measurement start-up.

Reference Manual 31

Page 32

FLOW

Installation

January 2019 00809-0100-4853

Reference Manual

Note

For steam or other elevated temperature services, it is important that temperatures at the

transmitter process connection do not exceed the transmitter’s operating limits.

Figure 3-4: Installation Examples

Liquid service Gas service Steam service

3.4.2 O-rings

The two styles of Rosemount flange adapters (Rosemount 1151 and Rosemount

3051/2051/2024/3095) each require a unique O-ring (see Figure 3-5). Use only the O-ring

designed for the corresponding flange adapter.

WARNING

Failure to install proper flange adapter O-rings may cause process leaks, which can result in

death or serious injury. The two flange adapters are distinguished by unique O-ring

grooves. Only use the O-ring that is designed for its specific flange adapter, as shown

below. When compressed, PTFE O-rings tend to cold flow, which aids in their sealing

capabilities.

32 Reference Manual

Page 33

Reference Manual

00809-0100-4853 January 2019

Installation

Figure 3-5: O-rings

A. Flange adapter

B. O-ring

C. PFTE based

D. Elastomer

Note

You should replace PTFE O-rings if you remove the flange adapter.

Reference Manual 33

Page 34

Commissioning Tag

DEVICE ID:

001151AB00010001440-121698091 725

DEVICE REVISION: 1.0

PHYSICAL DEVICE TAG

DEVICE ID:

001151AB00010001440-121698091 725

DEVICE REVISION: 1.0

S / N :

PHYSICAL DEVICE TAG

Device Barcode

Installation

January 2019 00809-0100-4853

Reference Manual

3.4.3 Commissioning (paper) tag

To identify which device is at a particular location use the removable tag provided with the

transmitter. Ensure the physical device tag (PD tag field) is properly entered in both places

on the removable commissioning tag and tear off the bottom portion for each

transmitter.

Figure 3-6: Commissioning Tag

3.4.4 Rotate housing

34 Reference Manual

To improve field access to wiring or to better view the optional LCD display:

Procedure

1. Loosen the housing rotation set screw.

2. Rotate the housing clockwise to the desired location. If the desired location cannot

be achieved due to thread limit, rotate the housing counter clockwise to the desired

location (up to 360° from thread limit).

CAUTION

Do not rotate the housing more than 180° without first performing a disassembly

procedure. Over-rotation may sever the electrical connection between the sensor

module and the feature board electronics.

3. Retighten the housing rotation set screw up to 30 in-lb.

4. For wireless, consider access to the power module when selecting housing rotation.

Page 35

A

A

Reference Manual

00809-0100-4853 January 2019

Figure 3-7: Transmitter Housing Set Screw (Plantweb)

A. Housing rotation set screw (3/32-in.)

Figure 3-8: Transmitter Housing Set Screw (Junction Box)

Installation

A. Housing rotation set screw (3/32-in.)

3.4.5

Reference Manual 35

LCD display rotation

In addition to housing rotation, the optional LCD display can be rotated in 90° increments

by squeezing the two tabs, pulling out, rotating and snapping back into place.

Note

If LCD display pins are inadvertently removed from the feature board, re-insert the pins

before snapping the LCD display back into place.

Page 36

Installation

January 2019 00809-0100-4853

Reference Manual

3.4.6 Set the switches

About this task

Set Simulate and Security switch position before installation (location of switches shown in

Figure 3-9), as desired.

• The Simulate switch enables or disables the ability to set simulated alerts or simulated

measured value and status.

• The Security switch allows (unlocked symbol) or prevents (locked symbol) any

configuration of the transmitter.

Further security settings are available in the software, including settings which use a

software lock. Additionally, these settings can be used to disable both hardware and

software locks.

Use the following procedure to change the switch configuration:

Procedure

1. If the transmitter is installed, secure the segment, and remove power.

2. Remove the housing cover opposite the field terminal side. Do not remove the

instrument cover in explosive atmospheres when the circuit is live.

3. Slide the security and simulate switches into the preferred position.

4. Reinstall the housing cover and tighten so the cover is fully seated with metal to

metal contact between the housing and cover in order to meet explosion proof

requirements.

5. If the transmitter was installed, reapply power.

36 Reference Manual

Page 37

SECURITY

SIMULATE

ENABLE

DISABLE

C

D

E

F

B

A

Reference Manual

00809-0100-4853 January 2019

Installation

Example

Figure 3-9: Simulate and Security Switches

A. Security unlocked position

B. Security switch

C. Security locked position

D. Simulate disabled position

E. Simulate switch

F. Simulate enabled position

3.4.7

Wire, ground, and power

Use a copper wire of sufficient size to ensure the voltage across the transmitter power

terminals does not drop below 9 Vdc. Power supply voltage can be variable, especially

under abnormal conditions such as when operating on battery backup. A minimum of 12

Vdc under normal operating conditions is recommended. Shielded twisted pair Type A

cable is recommended.

Note

The power terminals are polarity insensitive, which means the electrical polarity of the

power leads does not matter when connecting to the power terminals. If polarity sensitive

devices are connected to the segment, terminal polarity should be followed.

3.4.8

Signal wiring and shield grounding

Do not run signal wiring in conduit or open trays with power wiring, or near heavy

electrical equipment. Grounding terminations are provided on the outside of the

electronics housing and inside the terminal compartment. These grounds are used when

transient protection terminal blocks are installed or to fulfill local regulations.

Reference Manual 37

Page 38

Installation

January 2019 00809-0100-4853

Reference Manual

Procedure

1. Remove the field terminals housing cover.

2. To power the transmitter, connect the power leads to the terminals indicated on

the terminal block label.

3. Tighten the terminal screws to ensure adequate contact.

4. Trim the cable shield as short as practical and insulate from touching the

transmitter housing as indicated in Figure 1 and Figure 2.

Note

Do NOT ground the cable shield at the transmitter; if the cable shield touches the

transmitter housing, it can create ground loops and interfere with communications.

To protect the fieldbus segment from noise, grounding techniques for shield wire

require a single grounding point for shield wire to avoid creating a ground loop.

a) Ensure the cable shield maintains a continuous connection to the power

supply ground.

b) Connect the cable shields for the entire segment to a single good earth

ground at the power supply.

Note

Improper grounding is the most frequent cause of poor segment

communications.

5. Reinstall the housing cover and tighten so the cover is fully seated with metal to

metal contact between the housing and cover in order to meet explosion proof

requirements.

6. Plug and seal unused conduit connections.

NOTICE

When the enclosed threaded plug is utilized in the conduit opening, it must be

installed with a minimum thread engagement in order to comply with explosionproof requirements. For straight threads, a minimum of seven threads must be

engaged. For tapered threads, a minimum of five threads must be engaged.

38 Reference Manual

Page 39

Reference Manual

00809-0100-4853 January 2019

Installation

3.4.9 Power supply

The transmitter requires between 9 and 32 Vdc (9 and 30 Vdc for intrinsic safety, and 9

and 17.5 Vdc for FISCO intrinsic safety) to operate and provide complete functionality.

3.4.10 Power conditioner

A Fieldbus segment requires a power conditioner to isolate the power supply, filter, and

decouple the segment from other segments attached to the same power supply.

3.4.11 Grounding

Signal wiring of the fieldbus segment can not be grounded. Grounding one of the signal

wires will shut down the entire fieldbus segment.

Transmitter case grounding

Always ground the transmitter case in accordance with national and local electrical codes.

The most effective transmitter case grounding method is a direct connection to earth

ground with minimal impedance. Methods for grounding the transmitter case are listed

below.

Internal ground connection

The internal ground connection screw is inside the FIELD TERMINALS side of the

electronics housing. This screw is identified by a ground symbol (

connection screw is standard on all Rosemount 3051SMV Transmitters.

). The ground

Reference Manual 39

Page 40

A

Installation

January 2019 00809-0100-4853

Reference Manual

A. Ground lug

External ground connection

The external ground connection is located on the exterior of the transmitter housing. This

connection is only available with option D4 and T1.

40 Reference Manual

Page 41

A

B

Reference Manual

00809-0100-4853 January 2019

Installation

A. External ground lug

B. External ground assembly (03151-9060-0001)

Note

Grounding the transmitter case via threaded conduit connection may not provide

sufficient ground continuity.

Transient protection terminal block grounding

The transmitter can withstand electrical transients of the energy level usually encountered

in static discharges or induced switching transients. However, high-energy transients,

such as those induced in wiring from nearby lightning strikes, can damage the transmitter.

The transient protection terminal block can be ordered as an installed option (option code

T1) or as a spare part to retrofit existing Rosemount 3051SMV Transmitters in the field.

The lightning bolt symbol shown in Figure 3-10 identifies the transient protection terminal

block.

Reference Manual 41

Page 42

A

A

Installation

January 2019 00809-0100-4853

Figure 3-10: Transient Protection Terminal Block with RTD

Reference Manual

A. Lightning bolt symbol location

Figure 3-11: Transient Protection Terminal Block without RTD

A. Lightning bolt symbol location

42 Reference Manual

Page 43

Reference Manual

00809-0100-4853 January 2019

Note

The transient protection terminal block does not provide transient protection unless the

transmitter case is properly grounded. Use the guidelines to ground the transmitter case

(see Grounding).

Installation

3.4.12 Signal termination

A terminator should be installed at the beginning and end of every fieldbus segment.

3.4.13 Install optional process temperature input (Pt 100 RTD

Sensor)

About this task

Note

To meet ATEX/IECEx Flameproof certification, only ATEX/IECEx Flameproof cables

(temperature input code C30, C32, C33, or C34) may be used.

Procedure

1. Mount the Pt 100 RTD Sensor in the appropriate location.

Use shielded four-wire cable for the process temperature connection.

2. Connect the RTD cable to the Rosemount 3051S MultiVariable Transmitter by

inserting the cable wires through the unused housing conduit and connect to the

four screws on the transmitter terminal block. An appropriate cable gland should be

used to seal the conduit opening around the cable.

3. Connect the RTD cable shield wire to the ground lug in the housing.

Reference Manual 43

Page 44

C

B

Red

Red

White

White

A

Installation

Reference Manual

January 2019 00809-0100-4853

Figure 3-12: Transmitter RTD Wiring Connection

A. Ground lug

B. RTD cable assembly wires

C. Pt 100 RTD sensor

Three-wire RTD

A four-wire Pt 100 RTD is required to maintain published performance specifications. A

three-wire Pt 100 RTD may be used with degraded performance. If connecting to a threewire RTD, use a four-wire cable to connect the Rosemount 3051SMV terminal block to the

RTD connection head. Within the RTD connection head, connect two of the same colored

wires from the Rosemount 3051SMV to the single colored wire of the RTD sensor.

44 Reference Manual

Page 45

Reference Manual Installation

00809-0100-4853 January 2019

3.5 Rosemount 305 and 304 Manifolds

The Rosemount 305 Integral Manifold is available in two designs: coplanar and traditional.

The traditional Rosemount 305 can be mounted to most primary elements with mounting

adapters.

Rosemount 305 Integral Coplanar Rosemount 305 Integral Traditional

The Rosemount 304 comes in two basic styles: traditional (flange X flange and flange X

pipe) and wafer. The Rosemount 304 Traditional Manifold comes in 2-, 3-, and 5-valve

configurations. The Rosemount 304 Wafer Manifold comes in 3- and 5-valve

configurations.

Rosemount 304 Traditional

Rosemount 304 Wafer

Reference Manual 45

Page 46

Installation

January 2019 00809-0100-4853

Reference Manual

3.5.1 Install Rosemount™ 305 Integral Manifold

Procedure

1. Inspect the PTFE sensor module O-rings.

You may reuse undamaged O-rings. If the O-rings are damaged (if they have nicks

or cuts, for example), replace with O-rings designed for Rosemount transmitters.

Important

If replacing the O-rings, take care not to scratch or deface the O-ring grooves or the

surface of the isolating diaphragm while you remove the damaged O-rings.

2. Install the Integral Manifold on the sensor module. Use the four 2.25-in (57.2 mm).

manifold bolts for alignment. Finger tighten the bolts; then tighten the bolts

incrementally in a cross pattern as seen in Figure 3-13 to final torque value.

See Flange bolts for complete bolt installation information and torque values. When

fully tightened, the bolts should extend through the top of the sensor

module housing.

Figure 3-13: Bolt Tightening Pattern

3. If you have replaced the PTFE sensor module O-rings, re-tighten the flange bolts

after installation to compensate for cold flow of the O-rings.

3.5.2

46 Reference Manual

Install Rosemount 304 Conventional Manifold

About this task

See Safety messages for complete warning information.

Procedure

1. Align the Conventional Manifold with the transmitter flange. Use the four manifold

bolts for alignment.

2. Finger tighten the bolts; then tighten the bolts incrementally in a cross pattern to

final torque value.

See Flange bolts for complete bolt installation information and torque values.When

fully tightened, the bolts should extend through the top of the sensor module

housing.

Page 47

Reference Manual

00809-0100-4853 January 2019

3. Leak-check assembly to maximum pressure range of transmitter.

Installation

3.5.3 Manifold operation

WARNING

Improper installation or operation of manifolds may result in process leaks, which may

cause death or serious injury.

Always perform a zero trim on the transmitter/manifold assembly after installation to

eliminate any shift due to mounting effects. See Sensor trim overview.

Coplanar transmitters

Operate three and five-valve manifolds

Performing zero trim at static line pressure

About this task

In normal operation, the two isolate (block) valves between the process ports and the

transmitter will be open, and the equalize valve will be closed.

A. Drain/vent valve

B. Isolate (open)

C. Equalize (closed)

D. Process

E. Isolate (open)

F. Drain/vent valve

Procedure

1. To zero trim the transmitter, close the isolate valve on the low side (downstream)

side of the transmitter.

Reference Manual 47

Page 48

Installation

January 2019 00809-0100-4853

Reference Manual

A. Drain/vent valve

B. Isolate (open)

C. Equalize (closed)

D. Process

E. Isolate (closed)

F. Drain/vent valve

2. Open the equalize valve to equalize the pressure on both sides of the transmitter.

The manifold is now in the proper configuration for performing a zero trim on the

transmitter.

A. Drain/vent valve

B. Isolate (open)

C. Equalize (open)

D. Process

E. Isolate (closed)

F. Drain/vent valve

3. After zeroing the transmitter, close the equalize valve.

A. Drain/vent valve

B. Isolate (open)

C. Equalize (closed)

D. Process

E. Isolate (closed)

F. Drain/vent valve

48 Reference Manual

Page 49

Reference Manual

00809-0100-4853 January 2019

Installation

4. Finally, to return the transmitter to service, open the low side isolate valve.

A. Drain/vent valve

B. Isolate (open)

C. Equalize (closed)

D. Process

E. Isolate (open)

F. Drain/vent valve

Operate five-valve natural gas manifold

Performing zero trim at static line pressure

About this task

Five-valve natural gas configurations shown:

In normal operation, the two isolate (block) valves between the process ports and the

transmitter will be open, and the equalize valves will be closed. Vent valves may be open

or closed.

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (closed)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (open)

I. (Plugged)

Procedure

1. To zero trim the transmitter, first close the isolate valve on the low pressure

(downstream) side of the transmitter and the vent valve.

Reference Manual 49

Page 50

Installation

January 2019 00809-0100-4853

Reference Manual

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (closed)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (closed)

I. (Plugged)

2. Open the equalize valve on the high pressure (upstream) side of the transmitter.

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (open)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (closed)

I. (Plugged)

3. Open the equalize valve on the low pressure (downstream) side of the transmitter.

The manifold is now in the proper configuration for zeroing the transmitter.

50 Reference Manual

Page 51

Reference Manual

00809-0100-4853 January 2019

Installation

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (open)

E. Equalize (open)

F. Drain vent (closed)

G. Process

H. Isolate (closed)

I. (Plugged)

4. After zeroing the transmitter, close the equalize valve on the low pressure

(downstream) side of the transmitter.

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (open)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (closed)

I. (Plugged)

5. Close the equalize valve on the high pressure (upstream) side.

Reference Manual 51

Page 52

Installation

January 2019 00809-0100-4853

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (closed)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (closed)

I. (Plugged)

6. Finally, to return the transmitter to service, open the low side isolate valve and vent

valve.

The vent valve can remain open or closed during operation.

Reference Manual

A. (Plugged)

B. Isolate (open)

C. Process

D. Equalize (closed)

E. Equalize (closed)

F. Drain vent (closed)

G. Process

H. Isolate (open)

I. (Plugged)

In-line transmitters

2-valve and block and bleed style manifolds

Isolating the transmitter

About this task

In normal operation, the isolate (block) valve between the process port and transmitter

will be open and the test/vent valve will be closed. On a block and bleed style manifold, a

single block valve provides transmitter isolation, and a bleed screw provides drain/vent

capabilities.

52 Reference Manual

Page 53

Reference Manual

00809-0100-4853 January 2019

Installation

A. Transmitter

B. Vent (closed)

C. Isolate

D. Process (open)

Procedure

1. To isolate the transmitter, close the isolate valve.

A. Transmitter

B. Vent (closed)

C. Isolate

D. Process (closed)

2. To bring the transmitter to atmospheric pressure, open the vent valve or bleed

screw.

A. Transmitter

B. Vent (open)

C. Isolate

D. Process (closed)

Note

A ¼-in (6.35 mm). male NPT pipe plug may be installed in the test/vent port; you

will need to remove it with a wrench in order to vent the manifold properly.

Always use caution when venting directly to atmosphere.

Reference Manual 53

Page 54

Installation

January 2019 00809-0100-4853

3. After venting to atmosphere, perform any required calibration and then close the

test/vent valve or replace the bleed screw.

A. Transmitter

B. Vent (closed)

C. Isolate

D. Process (closed)

4. Open the isolate (block) valve to return the transmitter to service.

Reference Manual

A. Transmitter

B. Vent (closed)

C. Isolate

D. Process (open)

Adjust valve packing

Over time, the packing material inside a Rosemount manifold may require adjustment in

order to continue to provide proper pressure retention. Not all Rosemount manifolds have

this adjustment capability. The Rosemount manifold model number will indicate what

type of stem seal or packing material has been used.

About this task

The following steps are provided as a procedure to adjust valve packing:

Procedure

1. Remove all pressure from device.

2. Loosen manifold valve jam nut.

3. Tighten manifold valve packing adjuster nut ¼ turn.

4. Tighten manifold valve jam nut.

5. Re-apply pressure and check for leaks.

54 Reference Manual

Page 55

A

D

C

B

E

F

G

Reference Manual

00809-0100-4853 January 2019

Postrequisites

Repeat the above steps if necessary. If the above procedure does not result in proper

pressure retention, replace the complete manifold.

Figure 3-14: Valve Components

Installation

A. Bonnet

B. Stern

C. Packing

D. Ball seat

E. Packing adjuster

F. Jam nut

G. Packing follower

Reference Manual 55

Page 56

Installation Reference Manual

January 2019 00809-0100-4853

56 Reference Manual

Page 57

Reference Manual Operation and Maintenance

00809-0100-4853 January 2019

4 Operation and Maintenance

4.1 Section overview

This section contains information on operating and maintaining the Rosemount™ 3051S

MultiVariable™ FOUNDATION™ Fieldbus Transmitter (3051SMV). Each Foundation Fieldbus

host or configuration tool has different ways of displaying and performing operations.

Some hosts will use Device Descriptions (DD) and DD Methods to complete device

configuration and will display data consistently across platforms. The DD can be found on

the FieldComm Group website at FieldCommGroup.org. There is no requirement that a

host or configuration tool support the features in the DD. For DeltaV™ users, the DD can

be found at EasyDeltaV.com. The information in this section will describe how to use the

basic methods.

Based on the configuration ordered, some measurements (e.g. process temperature)

and/or calculation types (e.g. fully compensated mass flow, process variables only) may

not be available. Available measurements and/or calculation types are determined by the

multivariable type and measurement type codes ordered. See Rosemount 3051S Product

Data Sheet for more information.

4.2 Safety messages

Procedures and instructions in this section may require special precautions to ensure the

safety of the personnel performing the operation. Information that raises potential safety

issues is indicated with a warning symbol ( ). Refer to the following safety messages

before performing an operation preceded by this symbol.

Reference Manual 57

Page 58

Operation and Maintenance Reference Manual

January 2019 00809-0100-4853

WARNING

Failure to follow these installation guidelines could result in death or serious injury.

• Ensure only qualified personnel perform the installation.

Explosions could result in death or serious injury.

• Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

• Before connecting a communicator in an explosive atmosphere, make sure the

instruments in the segment are installed in accordance with intrinsically safe or nonincendive field wiring practices.

• Both housing covers must be fully engaged to meet flameproof/explosion-proof

requirements.

• Verify that the operating atmosphere of the transmitter is consistent with the

appropriate hazardous locations certifications.

Electrical shock could cause death or serious injury.

• If the sensor is installed in a high-voltage environment and a fault or installation error

occurs, high voltage may be present on transmitter leads and terminals.

• Use extreme caution when making contact with the leads and terminals.

Process leaks could result in death or serious injury.

• Install and tighten all four flange bolts before applying pressure.

• Do not attempt to loosen or remove flange bolts while the transmitter is in service.

Replacement equipment or spare parts not approved by Emerson™ for use as spare parts

could reduce the pressure retaining capabilities of the transmitter and may render the

instrument dangerous.

• Use only bolts supplied or sold by Emerson as spare parts.

Improper assembly of manifolds to traditional flange can damage the device.

• For safe assembly of manifold to traditional flange, bolts must break back plane of

flange web (i.e., bolt hole) but must not contact the sensor module.

Static electricity can damage sensitive components.

• Observe safe handling precautions for static-sensitive components.

4.3 Calibration

4.3.1 Calibration overview

Before calibrating the sensor complete configuration of the device in Configuration.

Calibration of the Rosemount 3051SMV involves the following tasks.

• Sensor trim

• Zero or lower sensor trim

58 Reference Manual

Page 59

Reference Manual Operation and Maintenance

00809-0100-4853 January 2019

4.3.2 Sensor trim overview

Trim the sensors using either upper or lower sensor or zero trim functions. Trim functions

vary in complexity and are application-dependent.

Note

When performing a sensor trim on a pressure sensor, it is possible to degrade the

performance of the sensor if inaccurate calibration equipment is used. Use calibration

equipment that is at least three times as accurate as the pressure sensor of the Rosemount

3051SMV Transmitter.

4.3.3 Determining necessary sensor trims

Bench calibration is not recommended for new instruments. The transmitter can be set

back to factory settings using the Restore Factory Calibration.

About this task

For transmitters that are field installed, the manifolds discussed in Manifold operation

allow the differential transmitter to be zeroed using the zero trim function. Both 3-valve

and 5-valve manifolds are discussed. This field calibration will eliminate any pressure

offsets caused by mounting effects and static pressure effects of the process. Determine

the necessary trims with the following steps.

4.3.4

Procedure

1. Complete a zero trim.

2. Apply pressure.

3. Check the pressure, if the pressure does not match the applied pressure, perform a

sensor trim (see Full trim).

Types of pressure trim

Zero trim

Zero trim is a single-point offset adjustment. It is useful for compensating for mounting

position effects and is most effective when performed with the transmitter installed in its

final mounting position. When performing a zero trim with a manifold, refer to Rosemount

305 and 304 Manifolds.

Note

To perform a zero trim function, the measured value of transmitter can be no larger than

five percent of the upper sensor limit from zero. The transmitter will not allow the user to

perform a zero trim on an absolute static pressure sensor. To correct mounting position

effects on the absolute static pressure sensor, perform a sensor trim. The lower sensor

trim function provides an offset correction similar to the zero trim function, but it does not

require zero-based input.

Reference Manual 59

Page 60

Operation and Maintenance Reference Manual

January 2019 00809-0100-4853

Full trim

Full sensor trim is a two-point sensor calibration where two end-point pressures are

applied, and all output is linearized between them. Always adjust the lower sensor trim